Modeling and tool wear in drilling of CFRP

D. Iliescu

a

, D. Gehin

a

, M.E. Gutierrez

b

, F. Girot

a,b,c,n

a

Arts et Me´tiers ParisTech—LAMEFIP, Esplanade des Arts et Me´tiers, 33405 Talence cedex, France

b

ETSIB - Universidad del Paı´s Vasco, Alameda de Urquijo s/n, 48013 Bilbao, Spain

c

IKERBASQUE, Basque Foundation for Science, 48011, Bilbao, Spain

a r t i c l e

i n f o

Article history:

Received 29 July 2009

Received in revised form

14 October 2009

Accepted 16 October 2009

Available online 5 November 2009

Keywords:

Tool wear

Modeling

Carbon fiber

Carbide tool

Diamond coating

Drilling

a b s t r a c t

This paper presents the prediction and evaluation of thrust force in drilling of carbon composite

material. In order to extend tool life and improve quality of hole drilling, a better understanding of

uncoated and coated tool behaviors is required. This paper describes the development of a

phenomenological model between the thrust force, the drilling parameters and the tool wear. The

experimental results indicate that the feed rate, the cutting speed and the tool wear are the most

significant factors affecting the thrust force. The model can then be used for tool-wear monitoring. The

model presented here is verified by experimental tests.

&

2009 Elsevier Ltd. All rights reserved.

1. Introduction

Carbon fiber-reinforced polymer composites materials (CFRP)

are characterized by a combination of high properties (specific

strength and stiffness, light weight, etc.), which make their use

especially attractive for aircraft and aerospace applications

However, these materials are extremely abrasive during the

machining operations. Machining of CFRP is difficult due to their

material discontinuity, inhomogenity and anisotropic nature.

Thus, the choice of the cutting tool and the optimal cutting

parameters is very important when cutting this kind of materials.

The machining process affects significantly these materials

leading to various modes of damages. This damage consists of

various fiber breakage, matrix cracking, fiber–matrix debonding

and plies delamination. To improve the quality of the machined

surface, some problems such as surface delamination and fiber/

resin pull-out have to be overcome. To achieve the desired surface

quality, it is necessary to understand the physical mechanisms of

the material removal and the kinetics of the machining process

affecting the performance of the cutting tools. Compared to the

machining of metals, studies on machining of composites are few

and limited in number.

Koplev

was the first in 1980 to conduct a series of

experiments under orthogonal cutting of carbon fiber-reinforced

polymer composites (CFRP). The author concluded that the chip

formation is strongly influenced by the fiber orientation and

occurs through a series of successive ruptures. The surface quality

and the delamination factor are strongly dependent on the cutting

parameters such as the tool geometry and cutting forces. Crack

propagation ahead of the tool tip (Mode I) was observed during

machining of laminates with 01 fiber orientation and compres-

sion-induced rupture was noticed during machining of laminates

with 901 fiber orientation. The cutting of negative fiber orienta-

tion graphite/epoxy composites was attributed to compression-

induced shear failure by Arola et al.

. For the same range of

fiber orientations Bhatnagar et al.

ascribed fiber breakage due

to axial tension as the cutting mechanism. Pwu and Hocheng

suggested that the fibers break when the bending stresses

exceeded the ultimate material strength. Arola and Ramulu

described the chip formation mechanisms during machining with

a diamond-tipped tool. The authors explained that the chip

formation is due to a brittle fracture independent of the fiber

orientation. Arola and Ramulu observed from experiments that

both cutting and thrust force registered a minimum in the 15–301

fiber orientation range and increased up to 901.

Among the several machining processes, drilling is one of the

most frequently used for the production of holes for screws, rivets

and bolts. Delamination and surface finish in drilling composite

materials have been found to be influenced by a number of factors

such as feed rate, cutting speed, drill geometry, tool wear and tool

ARTICLE IN PRESS

Contents lists available at

journal homepage:

www.elsevier.com/locate/ijmactool

International Journal of Machine Tools & Manufacture

0890-6955/$ - see front matter & 2009 Elsevier Ltd. All rights reserved.

doi:10.1016/j.ijmachtools.2009.10.004

n

Corresponding author at: Arts et Me´tiers ParisTech—LAMEFIP, Esplanade des Arts

et Me´tiers, 33405 Talence cedex, France. Tel.: +33 556 845 348/+34 946 017 394;

fax: +33 556 845 366/+34 946 014 215.

E-mail addresses: franck.girot@ensam.eu, franck_girot@ehu.es (F. Girot).

International Journal of Machine Tools & Manufacture 50 (2010) 204–213

ARTICLE IN PRESS

material. Delamination remains the most serious damage mode as

it reduces severely the load carrying capacity of laminated

composite structures and, therefore, must be avoided (Abrate

, Persson et al.

). The importance of tool geometry in

delamination reduction is evidenced by several authors. Piquet

et al.

suggested the use of a great number of cutting edges, in

order to increase the contact length between tool and part, a point

angle of 1181 and a small rake angle.

In addition to experimental methods, an analytical way is also

possible to predict the thrust force and delamination. Studies

based on linear elastic fracture mechanics theory have proposed

values for the critical cutting forces at the onset of delamination

during composite drilling. If the thrust force is exceeded,

delamination will occur. It is the uncut thickness that has to

withstand the indentation force induced by the drill. This

thickness tends towards zero as the drilling progresses, causing

the critical thrust force to be lower when the drill bit approaches

the exit side of the laminate. The first model was presented by

Hocheng and Dharan

. The authors studied the onset of

delamination in two different situations: push-out at exit and

peel-up at entrance. Based on the energy balance equation, the

expression for critical thrust force was modeled. Piquet et al.

considered the existence of a normal stress perpendicular to the

ply surface. To obtain the final result, the part of the plate located

beneath the drill has been modeled in terms of a thin circular

orthotropic plate. This representation does not take into account

the global deflection of the plate. It is only valid for a small

number of plies under the drill. Zhang et al.

considered a

different approach. In their model, the shape of the delamination

is elliptical even when multidirectional composites are drilled.

The ellipse has two principal directions aligned with the fiber

direction and the transverse direction of the uncut ply below the

drill tip. Jain and Yang

developed a model starting from

Hocheng and Dharan

, considering an elliptical shape of the

delamination area.

Tsao and Hocheng

analyzed the effect of a backup plate on

delamination. Results show that the use of a backup plate causes

an increase in the critical thrust force, allowing for higher feed

rates. In another work

, Tsao and Hocheng conducted several

experiences to prove the benefit of using special drill when

compared to commercially available tools, like twist drill. In this

study, it was possible to conclude that thrust force varies with

drill geometry and with feed rate. More recently, Tsao and

Hocheng

have presented the advantages of a core drill. The

influence of spindle speed was relatively insignificant. Fernandes

and Cook

investigated the thrust force during drilling with

‘‘one shot’’ drill bit. Their objective was to extend tool life and

improve hole quality. For that, a mathematical model leading to

the calculation of feed in order to keep thrust force under a critical

threshold was developed. Finally, Tsao

evaluated the

importance of pilot hole on delamination reduction when using

core and saw drills. Pilot hole eliminates the chisel edge effect,

reducing delamination hazard. The ratio of pre-drilled hole to drill

diameter must be controlled in order to drill with higher feed rate

without delamination. Recently, statistical tools had been used in

the search for optimal cutting conditions or tool design. Tsao

applied the Taguchi method and analysis of variance.

The wear is often defined as the amount of matter lost by the

tool. When wear is characterized by the appearance of ribbed

bands formed by abrasion on the clearance face, the life criteria

can be established from direct observations on the tool. The

friction of the workpiece against the clearance face shows a

frontal area of wear, whose height VB is more or less regularly.

One can quantify the lifetime of tools by simply measuring the

average width of wear VB. It is also possible to assess the damage

of a cutting tool from indirect criteria based on performance or

quality of machining. Thus, the surface condition and geometrical

tolerances of the parts can be used as indicators of the level of

wear. In drilling, for example, we can define the life of a drill by

the number of holes drilled meeting certain quality criteria. From

the wear criteria are established the lifetime models. The oldest

and most used is the Taylor’s model or modified Taylor’s model.

These models describe the relation between lifetime and the

cutting parameters such as cutting speed, feed rate, and cutting

depth. In the literature very few authors have introduced the wear

in their model.

The model of Tsao et al.

takes into account the tool wear

but does not include important machining parameters such as the

feed rate and the cutting speed. It correlates the feed load to the

tool wear and the damage of the material. Therefore, a machining

quality criterion is used (maximum load allowed to ensure a

certain quality). Lin and Ting

have proposed a model for

monitoring the wear. The feed load F and the torque M are fitted

as a function of the cutting parameters (cutting speed V

c

, feed rate

f (mm/rev) or feed speed V

f

(mm/min), tool diameter d and wear

W). The authors noted that the influence of wear on the feed load

F is more important than the influence of the wear on the torque

M. In other words, the recorded signal of the feed load is more

sensitive to changes in the tool wear than the torque signal.

In this paper, a phenomenological model based on the

evolution of the feed load (thrust force) with tool wear and

composite damage is developed. The model takes into account the

evolution of the feed load F with the feed rate f, the cutting speed

V

c

and the tool wear W. The cutting length L

c

is the length of the

path travelled by the tool tip when in contact with the composite

material, so different from the machined length. Experimental

work was also performed in order to validate the mathematical

model. Experimental and model results are compared.

2. Experimental approach

2.1. Procedures and experiments performed

In order to establish the model, only parameters with

significant effects on thrust force are included. In order to study

the effects of cutting parameters and tool wear on cutting force

signals, a series of experiments are conducted. Tests are carried

out on a rigid instrumented drilling bench, with a power of 14 kW

and a maximum rotation speed of 42,000 rpm, and a 5-axis

FATRONIK-HERA machine with a power of 40 kW and a maximum

rotation speed of 40,000 rpm.

The drilling bench is equipped with a high-speed spindle

FISHER-MFW 1230/42. A HEIDENHAIN TNC 124 system control

allows regulating the spindle rotation and the axial displacement

of the bench. The experimental data were collected with a data

acquisition system composed of a 9272 Kistler drilling dynam-

ometer and a 5019 A Kistler amplifier, which allow to measure

thrust forces. Average thrust forces for each test is estimated with

Table 1

. Drilling conditions and drilling sequence for tests on the drilling bench.

Test

conditions

Feed rate f

(mm/rev)

Spindle speed N

(rpm)

Cutting speed

V

c

(m/min)

A

0.05

3000

56.55

B

0.05

6000

113.10

C

0.05

9000

169.65

D

0.05

12000

226.19

E

0.1

3000

56.55

F

0.15

3000

56.55

Drilling sequence : A B C D A E F A E F A E F A E F A E F A B C D

D. Iliescu et al. / International Journal of Machine Tools & Manufacture 50 (2010) 204–213

205

ARTICLE IN PRESS

the Labview software. The procedure on the drilling bench

consists of 4 tests with constant feed rate and variable spindle

speed; then 15 tests (3 tests repeated 5 times) with a variable feed

rate and a constant cutting speed and finally 4 tests with constant

feed rate and variable cutting speed (

). The drillings have

been performed under dry conditions.

The FATRONIK -HERA 5-axis machine is equipped with

horizontal spindle, a vertical fixation table and a composite dust

aspiration system. Data acquisition system on 5-axis machine is

composed of a 9257B Kistler dynamometer and a 5019 A Kistler

amplifier. The procedure on the 5-axis machine is as follows: all

10 holes, the thrust forces are recorded. The following cutting

parameters have been used: f= 0.05 mm/rev and N =9000 rpm and

dry drilling.

With these cutting parameters the cutting length for

each hole is the same, which allows us to compare the tools

more easily. To study the influence of tool wear on the thrust

force, we took into account the contact length achieved by

each drill (Eq. 1).

L

c

¼

h

f

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

f

2

þ ð

p

dÞ

2

q

ð

1Þ

Table 2

. Mechanical properties of T800/914 composite material.

E

11

(GPa)

E

22

(GPa)

G

12

(GPa)

n

159

8.4

4.1

0.33

Table 3

. Tool geometries and coatings used in the study.

Tool

manufacturer

Reference

Point

angle

Helix

angle

Clearance

angle

Coating

DIAGER

22,690

1251

351

111 +271

-

SOFIMAG

Proto 2

1301

401

111 +251

-

SOFIMAG

Proto 4

1251 +901

351

101+ 251

-

DIAGER

22,691

1251

351

111 + 271

diamond

SOFIMAG

Proto 6

1301

401

111 +251

diamond BS

diamond CN

SOFIMAG

Proto 8

1251 +901

351

101+ 251

diamond BS

diamond CN

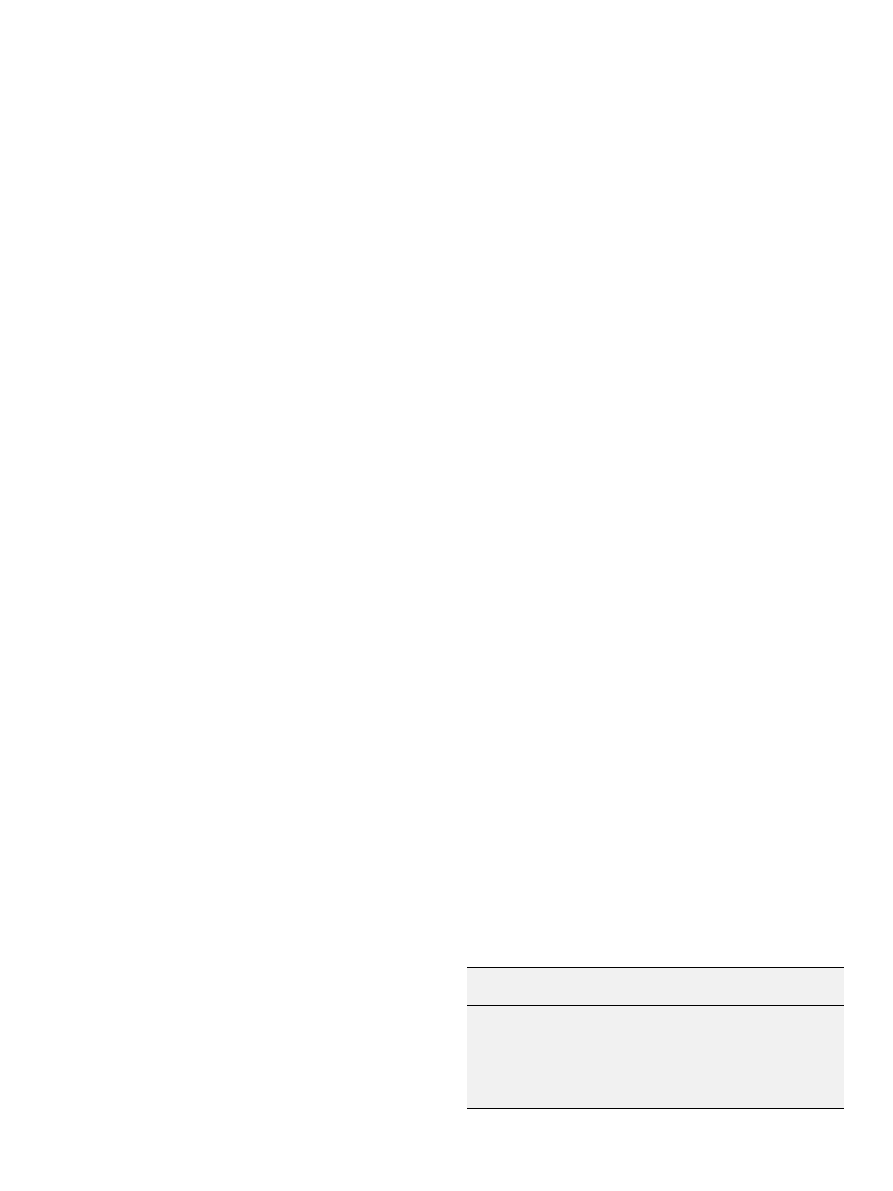

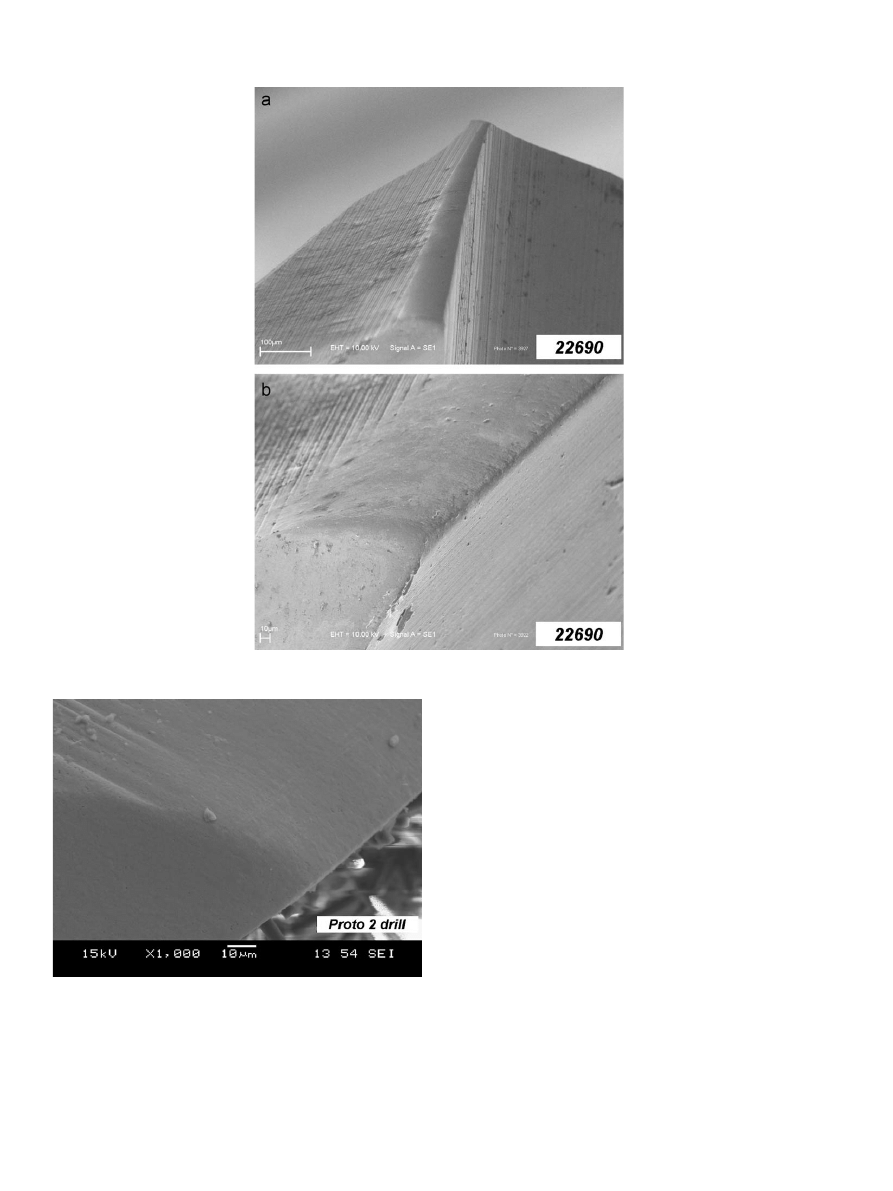

Fig. 1. Pictures of the 22,690 Diager drill, prototypes 2 and 4 and schematic details of prototype 4 geometry .

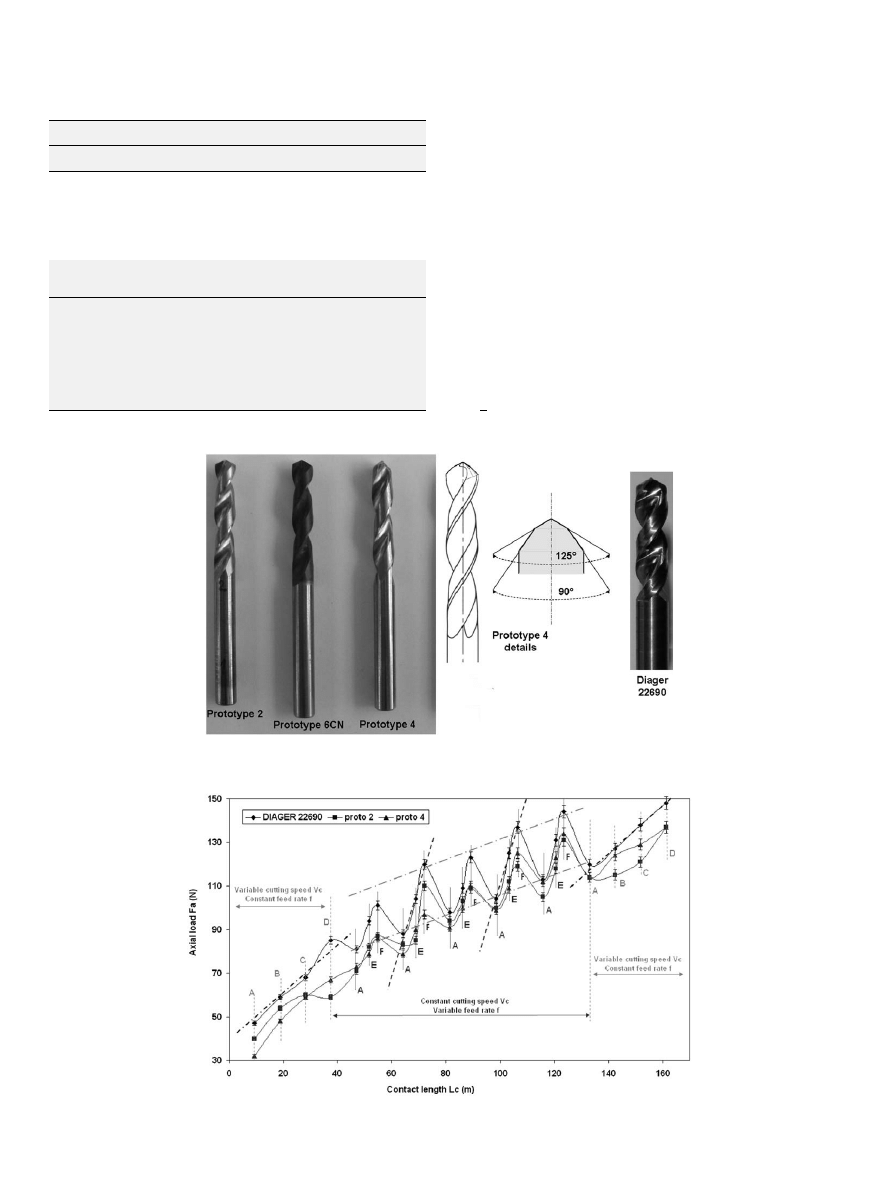

Fig. 2. Axial load during drilling for the uncoated prototypes and the 22,690 Diager reference drill. Conditions A–F are given in

.

D. Iliescu et al. / International Journal of Machine Tools & Manufacture 50 (2010) 204–213

206

ARTICLE IN PRESS

where h is the thickness of the material drilled (25 mm), f is the

feed rate and d is the tool diameter (6 mm).

The composite material employed consists of carbon fiber

T800 (

s

= 5589 MPa, E= 280 GPa, density

r

= 1,76 g/cm

3

and fiber

diameter of 7

m

m), and a 914 epoxy matrix (

). Each layer

(ply) has a width of 255

m

m with an average fiber rate of 60%. The

laminate material is highly oriented.

2.2. Tools and coatings used

To carry out various tests, uncoated (22,690) and diamond-

coated (22,691) twist drills from Diager have been used as

reference tools. Based on previous results, prototype drills were

developed and manufactured by Sofimag (France). The geome-

trical characteristics of Diager and prototype drills are given in

and

. The coatings used on prototypes are: Balzers

diamond plus

coating (nanocrystalline

structure, 6–12

m

m

thickness) noted BS, and Cemecon fiber speed coating (6–10

m

m

thickness) noted CN.

2.3. Results obtained

summarizes the tests performed on the drilling bench

for uncoated carbide prototypes. They are compared with

DIAGER 22690 drill, which is the uncoated carbide reference

tool. The results are reported for the drilling sequence defined in

(ABCD AEF AEF AEF AEF AEF ABCD). The waviness of the

graph is representative of the dependence of the axial or thrust

load F

a

with the cutting speed V

c

, the feed rate f and the tool

wear w. Prototype 2 and 4 drills have a thrust force lower than

22,690 Diager tool during the same tests. The geometry of

prototypes 2 and 4 is better suited to the machining of this type

of material. The points corresponding to a same tool and similar

drilling conditions point out an increase in evolution of the

thrust load due to tool wear (grey mixed dotted lines for

example). This evolution is independent of the cutting speed and

the feed rate (grey mixed dotted lines are parallel), which means

a linear tool wear. This linear wear is also pointed out when

comparing the tests under variable cutting speeds (parallel black

mixed dotted lines) or under variable feed rates (parrallel black

dotted lines).

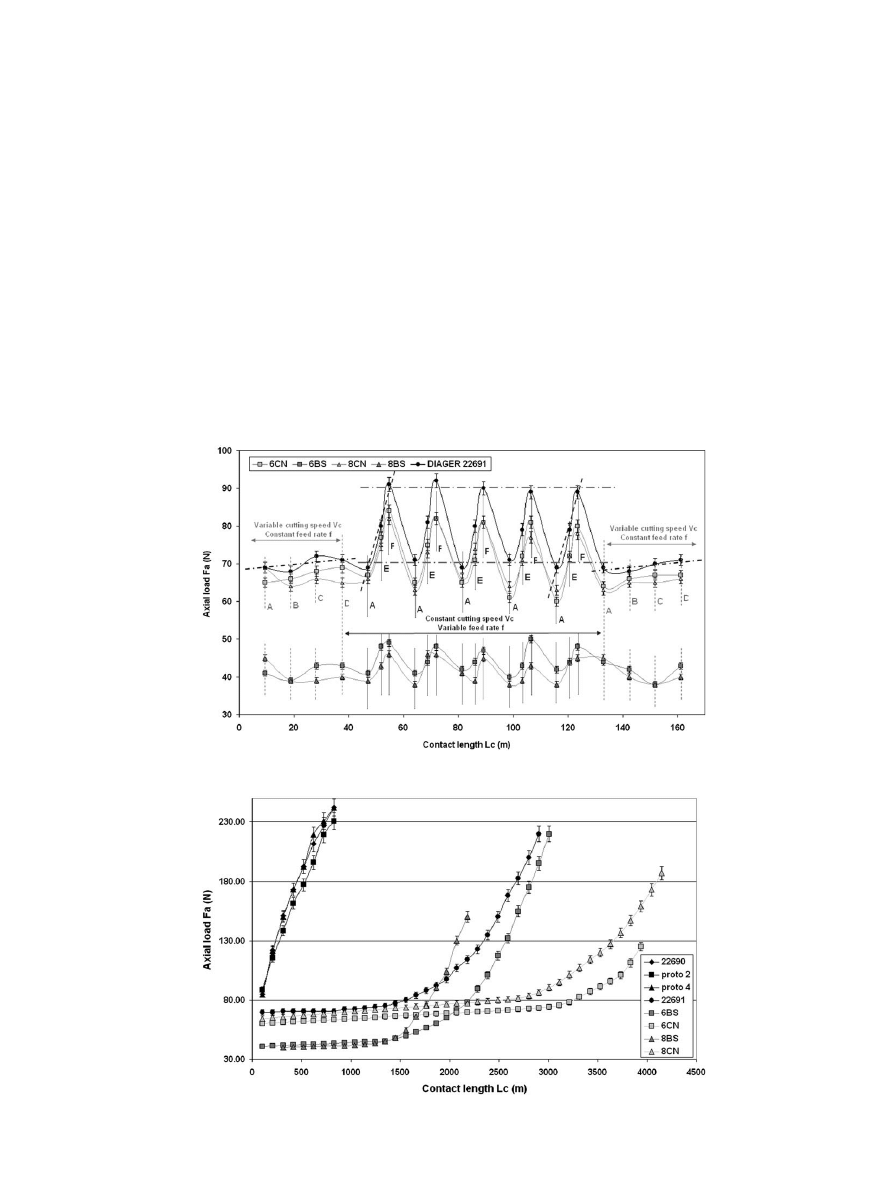

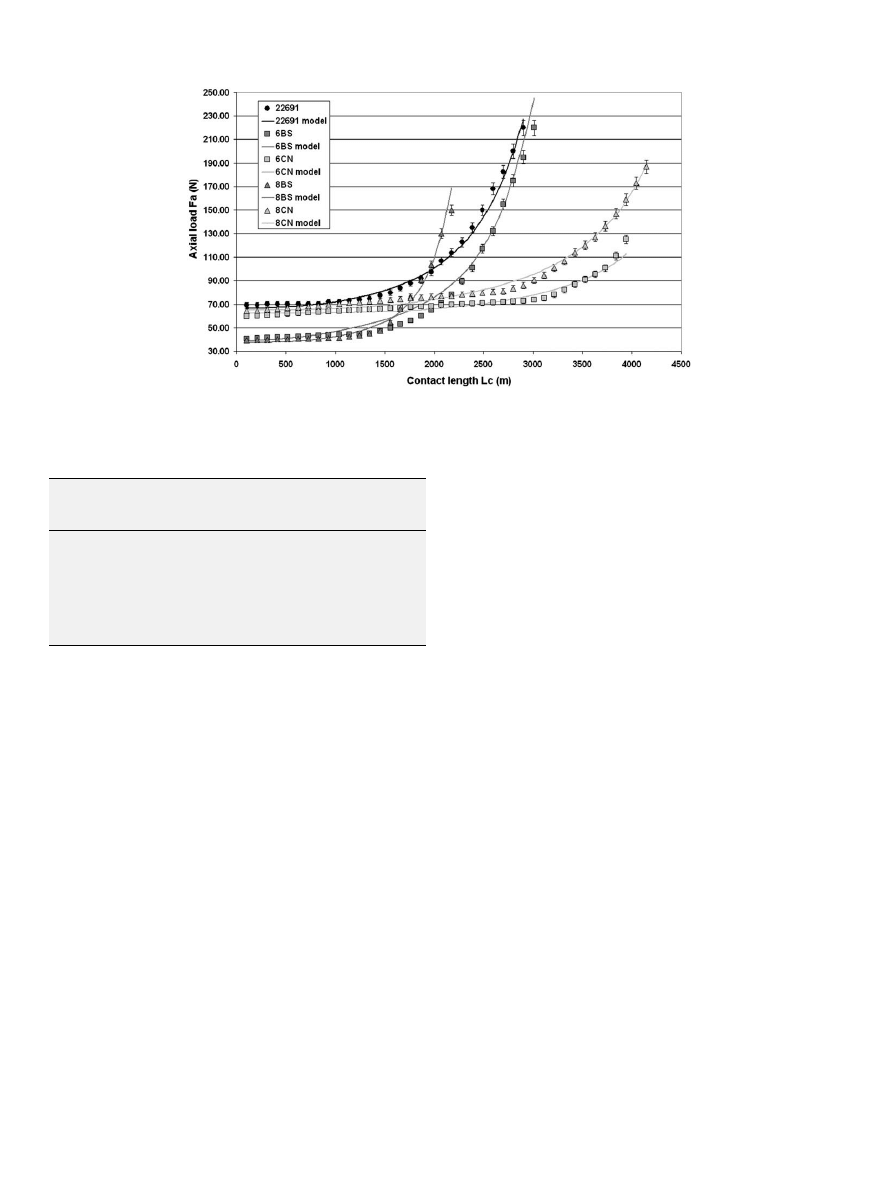

Fig. 3. Axial load during drilling for the coated prototypes and the 22691 Diager reference drill. Conditions A–F are given in

.

Fig. 4. Comparison of uncoated prototypes with the 22,690 Diager reference drill and coated prototypes with the 22,691 Diager reference drill.

D. Iliescu et al. / International Journal of Machine Tools & Manufacture 50 (2010) 204–213

207

ARTICLE IN PRESS

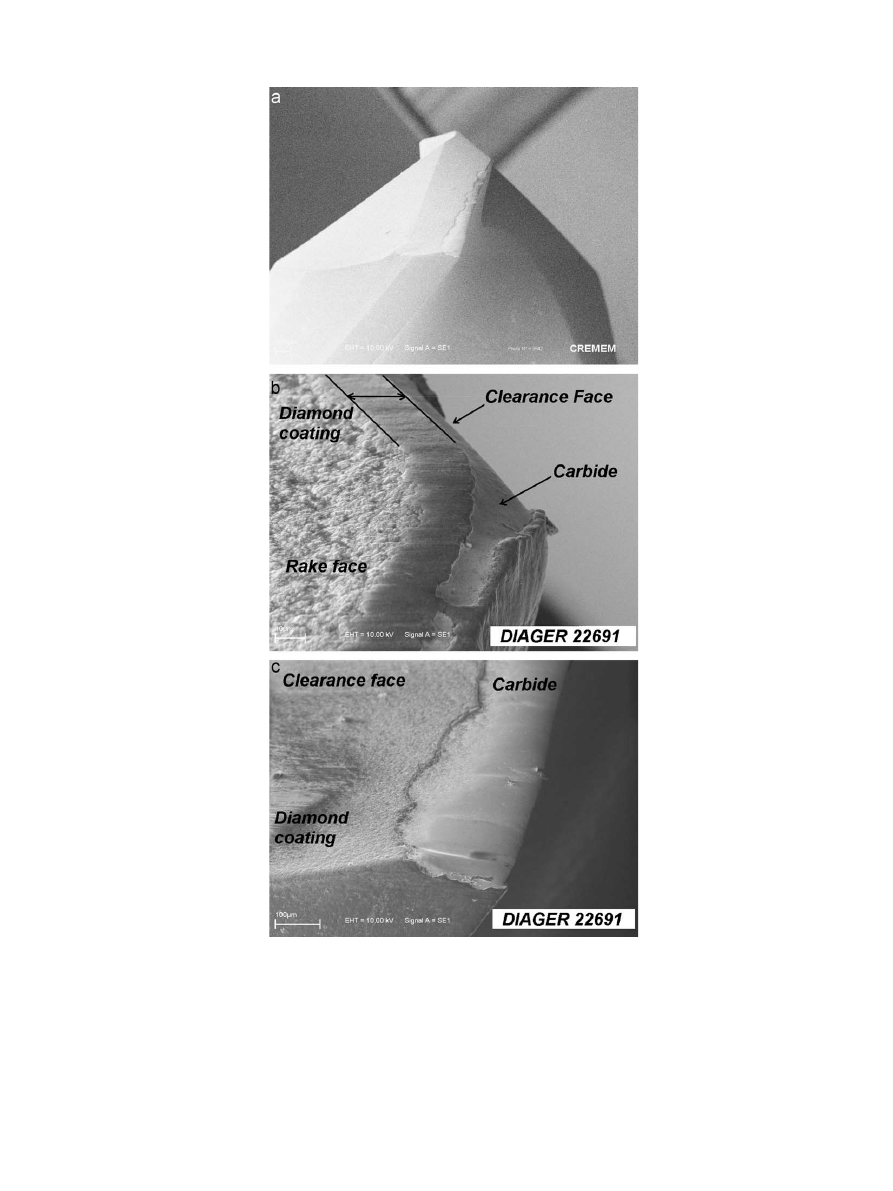

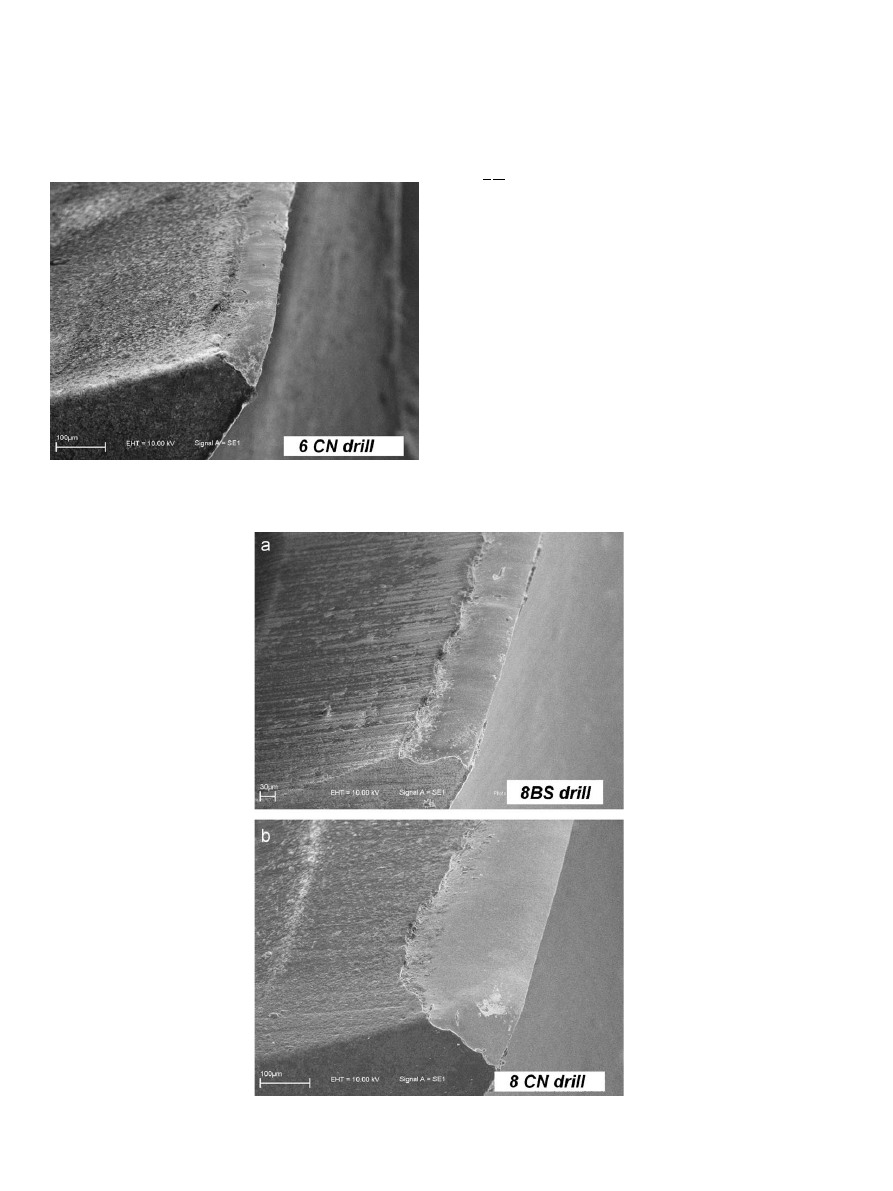

Tests performed on the drilling bench with diamond-coated

prototypes are compared with 22,691 Diager drill, which is the

diamond-coated reference tool (

). The good adhesion of

diamond on the carbide substrate is verified. Prototype 6 and 8

drills coated with Balzers (BS) and Cemecon (CN) diamond (6CN,

6BS, 8CN and 8BS) have lower thrust force than the 22,691 Diager

reference. All BS-coated prototypes exhibit significantly lower

thrust force than the CN-coated prototypes. All tools are not really

influenced by the spindle rotational speed. The influence of the

feed rate is more pronounced for CN- than for BS-coated

prototypes. Although the wear is also linear, its evolution is

very low compared to uncoated tools.

In order to highlight the geometries that are more resistant to

wear, endurance tests have been performed on a 5-axis FATRONIK

machine for uncoated and coated tools. In regard to uncoated carbide

tools, all geometries have spent wear tests under the same cutting

conditions as the reference drill (f=0.05 mm/rev and N=3000 rpm).

The prototype drills 2 and 4 seem to behave better when compared

with the reference tool (

). These wear tests confirmed the good

results of these two tools obtained on the bench drill.

The SEM analysis of the worn tools, after 88 drillings, have

confirmed the abrasive nature of the wear, and the better

behavior of prototype 2 drill (

) with respect to reference

) and prototype 4 drills. The roundness of the cutting edge is

lower for the prototype 2 drill than for the other two drills.

In regard to diamond-coated carbide tools, endurance tests

have been performed on the same 5-axis FATRONIK. All geo-

metries have spent wear tests under the same cutting conditions

as the reference drill (f= 0.05 mm/rev and N =9000 rpm). Two

areas of the evolution curves (

) are well-defined: a first

linear zone where the diamond coating wears very slowly and a

second area corresponding to a local vanishing of the coating. In

second area the wear is more rapid because the carbide is no

Fig. 5. Carbide wear of 22690 Diager tool after 88 drillings.

Fig. 6. Carbide wear of prototype 2 after 88 drillings.

D. Iliescu et al. / International Journal of Machine Tools & Manufacture 50 (2010) 204–213

208

ARTICLE IN PRESS

longer protected by the coating and it will disappear in small

fragments, leaving even more unprotected carbide (

allows to point out the behavior of the tools and shows that

the tools coating have a good quality if they have a good adhesion

to the carbide and a regular wear.

The behavior of 22,691 Diager drill is comparable to

that of BS diamond-coated prototypes, which makes to think

that the type of coating are similar (nanocrystalline structure).

The difference that can be pointed out (lower thrust force for

low values of contact length) can be attributed to the tool

geometry.

CN diamond-coated drills have a greater life expectancy than

the other drills. The wear first area ends at L

c

=2800 m for CN

coating, and around 1500 m for BS or Diager coating. For CN

coating, this first area translates into greater hole numbers. The

prototype 6CN and 8CN drills have the best tool life.

Fig. 7. Diamond coating wear of 22691 Diager tool after 309 drillings.

D. Iliescu et al. / International Journal of Machine Tools & Manufacture 50 (2010) 204–213

209

ARTICLE IN PRESS

3. Phenomenological model for abrasive wear

The experimental results have confirmed that the thrust force

is influenced by feed rate, cutting speed and tool wear.

A major contribution in wear modeling was made by Archard

(Eq. 2). The worn volume (detached from the materials rubbing

together) is proportional to the force applied to the contact and

the contact length.

W ¼

K

3

FL

H

ð

2Þ

where W is the volumetric wear of the material, K the Archard

wear coefficient, F the contact force, L the cutting length and H the

hardness of the softest material, in this case the tool. So, the wear

is a function of the product of the axial force F

a

applied to the

cutting edge by the contact length between the cutting edge and

the composite material L

c

.

As it has been pointed out by different tests performed with

uncoated and diamond-coated tools (

), the abrasive

wear can be considered as quasi-linear with the contact length L

c

(or the cutting time t

c

). When considering the F

a

L

c

factor, this

dependence is of power law type for uncoated tools, and quasi-

constant on a large range and then of power type for the

diamond-coated tools.

Considering that the thrust force depends also on the feed rate

and the cutting speed, the following phenomenological model is

proposed:

F

a

¼

Kf

a

V

b

c

gðWÞ

ð

3Þ

Fig. 9. Diamond coating wear of 8BS and 8CN prototype tools after 243 and 440 drillings, respectively.

Fig. 8. Diamond coating wear of 6CN prototype tool after 410 drillings.

D. Iliescu et al. / International Journal of Machine Tools & Manufacture 50 (2010) 204–213

210

ARTICLE IN PRESS

where g(W) is a function of the tool wear and is defined as

follows:

gðWÞ ¼ ðW

0

þ

A

0

WÞ

d

for uncoated tools

gðWÞ ¼ W

0

þ

A

0

W

d

for diamond coated tools

ð

4Þ

During a test i, all the wear mechanisms related to the

machining sequences from i =1 to i 1 is taken into consideration.

The thrust force F

i

for the ith machining sequence depends on the

value of the tool wear reached after i 1 machining trials (Eq. 5).

F

ai

¼

K

c

f

a

i

V

b

ci

gðW

i1

Þ

ð

5Þ

gðW

i

Þ ¼ ð

W

0

þ

A

0

g

i1

Þ

d

for uncoated tools

gðW

i

Þ ¼

W

0

þ

A

0

g

i1

d

for diamond coated tools

ð

6Þ

g

i1

¼

X

i1

j ¼ 1

F

aj

L

cj

ð

7Þ

where W

0

is the initial value of cutting edge acuity, A

0

is the tool

abrasion rate, g(W

i

) is the tool wear after test i and K

c

is a constant

depending on the geometry of the tool and the properties of the

material being machined.

4. Results and analysis

4.1. Determination of the model constants for each tool

The constants of Eq. 5 (K

c

, W

0

, A

0

,

a

,

b

and

d

) are obtained from

the experimental data (

, after a multiple non-linear

regression and minimizing the residues. Then the values of the

models are compared with experimental ones (

).

4.2. Tool behavior comparison

4.2.1. Influence of tool geometry on axial load

K

c

is the coefficient that takes into account the tool geometry

as well as the material characteristics. But, since the material has

been the same for all experimental trials, this parameter is

representative of the influence of the tool geometry.

For the uncoated tools, the double point angle geometry leads

to the lowest K

c

. For the diamond-coated tools, the influence of

the diamond structure seems to be more important than the effect

of the tool geometry. The lowest value of K

c

is obtained for a

double point angle geometry associated with a Balzers coating.

But for the same geometry and the Cemecon coating the highest

value of K

c

is obtained. The geometry of Diager drill and prototype

2 tool are quite similar and the K

c

values obtained for 22,690 and

prototype 2 drills or 22,691 and Cemecon diamond-coated

prototype 2 drills are quite closed (14.9 and 16.5; 215 and 225).

But for Balzers diamond-coated prototype 2, the K

c

value is quite

different (1 3 0). This is probably due to the nanostructure of the

Balzers coating.

4.2.2. Influence of feed rate and cutting speed on axial load

a

and

b

are the coefficients that take into account the influence

of the feed rate and the cutting speed, respectively.

The values of

a

and

b

are the lowest for the prototype tool 4,

then for the prototype tool 2 and finally for the 22,690 Diager

reference drill. This classification is not affected by the presence of

a diamond coating.

Moreover, in the case of

b

coefficient, the use of a diamond

coating leads to a decrease in the obtained values pointing out

the low dependence of different tools with cutting speed

(a variation of the cutting speed does not affect significantly the

axial load).

The values of

a

and

b

are again lower for the Balzers diamond-

coated tools than for the Cemecon or Diager diamond-coated

drills certainly due to its nanocrystalline structure.

4.2.3. Influence of tool wear on axial load

The coefficients

d

, W

0

and A

0

describe the influence of tool

wear on the variation of the axial load. The coefficient

d

is the

dependence of axial load with tool wear, W

0

is representative of

the initial tool edge acuity and A

0

is the tool wear rate.

The coefficient

d

is mostly constant for all the uncoated tools

since the carbide material is quite similar (submicron grains; 94%

CW and 6% Co).

For coated tools, this coefficient

d

is lower for the Diager- and

the Balzers-coated drill (2359 and 2355, respectively), and higher

for the Cemecon-coated drill (

E2,947).

Table 4

. Values of the parameters of the model and regression coefficients.

Tool

K

c

a

b

d

W

0

A

0

Regression Coefficient r

DIAGER 22690

14.90

0.17

0.102

0.363

2.58

0.0199

0.999

Proto 2

16.50

0.102

0.02

0.363

17.31

0.0193

0.999

Proto 4

11.80

0.094

0.067

0.385

31.51

0.0196

0.998

DIAGER 22691

225

0.226

0.0102

2.359

0.55

1.68 10

-13

0.997

Proto 6 CN

215

0.2236

0.0485

3.227

0.44

8.67 10

-19

0.979

Proto 6 BS

130

0.1371

0.0089

1.931

0.43

1.02 10

-10

0.995

Proto 8 CN

288

0.2011

0.0194

2.666

0.37

9.80 10

-16

0.995

Proto 8 BS

92

0.1079

0.0069

2.779

0.54

1.20 10

-14

0.991

Fig. 10. Comparison of measured and estimated thrust force for uncoated tools.

D. Iliescu et al. / International Journal of Machine Tools & Manufacture 50 (2010) 204–213

211

ARTICLE IN PRESS

The initial tool edge acuity W

0

is lower for uncoated Diager

tool (2.58) than for prototype drills 2 and 4 (17.31 and 31.51,

respectively). These differences are due to the geometry of the

cutting edge that influence on their sharpness. However, the

lowest values of W

0

are reached with the coated tools (

E0.46).

The edge finishing techniques used before the coating of the drill

allow to improve the edge acuity although a 6–12

m

m thickness

coating is present.

The wear rate coefficient A

0

is similar for all the uncoated drills

since the carbide grade is the same (

E0.0196), while for the

coated tools this coefficient depends strongly on the microstruc-

ture of the diamond coating. The lowest wear rates are obtained

for the Cemecon coatings in concordance with the experimental

results. The highest wear rates for the Balzers coatings, which

means that the nanocrystalline structure of the coating wears

more quickly. The behavior of the Diager coatings is slightly better

than the Balzers coating.

4.3. Tool behavior optimization

The performance of the drill is limited by the damage induced

during the process on the composite material surface: plies

delamination during the exit of the drill, pull-out of fiber bundles

on the hole surface, and burning of the material. Usually, the first

damage type controls the drilling and determines when the tool

wear is sufficiently high to change the tool. The delamination

phenomenon has been extensively described in the literature

and depends significantly on the axial load

applied to the material and the mechanical characteristics of the

remaining material to drill (the final plies of the laminate)

. For the material used, the critical axial load

leading to delamination of the last and two last plies has been

evaluated to 120 and 280 N, respectively . Since the values of the

axial load have been recorded lower than 280 N, only the last ply

of the composite is able to delaminate. This behavior has been

confirmed experimentally for the range of drilling conditions.

The use of previous model allows to predict the number of

holes, which is possible to drill before delamination occurs

(

The predicted results are in good agreement with the

experimental values. In the case of uncoated tools, the experi-

mental values correspond to a tolerable delamination damage of

0.1 mm, which means that the experimental values are over-

estimated. In the case of coated tools, the predicted values are

overestimating the experimental results, which means that the

critical axial load leading to delamination of the last ply of the

laminate is lower than 120 N.

5. Conclusions

The wear of uncoated and diamond-coated carbide tools when

drilling CFRP is strongly dependent on the product of the axial

force F

a

applied to the cutting edge by the contact length between

the cutting edge and the composite material L

c

. It has been shown

that for uncoated carbide tools, this dependence is a power law

function, when for diamond-coated carbide tools the dependence

is linear and quasi-constant at the beginning and is power law

function at the end.

A phenomenological model of axial load taking into account

the tool wear has been proposed and is in good agreement with

experimental results.

To determine the model coefficients, a trial of limited

experiments (23 in this case) is large enough for uncoated drills.

For diamond-coated tools, an endurance test has to be added to

determine the dependence of axial load with long-term wear.

This procedure is well-adapted to abrasion damage modes

(machining of the CFRP, ceramic materials, etc.) where the wear

evolves linearly with time. In the case of metallic materials, a

procedure very similar is being evaluated. It consists in repeating

5 times randomly 9 lines of a factorial design in which 5 holes

were made (125 tests). The trial is completed if necessary by

Table 5

. Predicted and realized numbers of drillings before delamination of the last ply of

the composite laminate.

Tool reference

Numbers of holes

predicted before

delamination

Numbers of holes

realized before

delamination

Real

delamination

value (mm)

22690

22

33

0.1

Prototype 2

25

44

0.1

Prototype 4

22

33

0.1

22691

242

246

0

Prototype 6BS

265

255

0

Prototype 6CN

374

354

0

Prototype 8BS

214

205

0

Prototype 8CN

415

400

0

Fig. 11. Comparison of measured and estimated thrust force for diamond-coated tools.

D. Iliescu et al. / International Journal of Machine Tools & Manufacture 50 (2010) 204–213

212

ARTICLE IN PRESS

an endurance test to determine more accurately the dependence

of wear.

The model allows to predict the parallel evolution of axial load

and wear with different drilling sequences that a tool will face

during its life. The predictions made are in good agreement with

experimental data and allow to optimize the drilling sequence of

the CFRP. The differences between the model and experiments

can be attributed to a temperature deviation of the drill during

the tests, vibrations in the drilling of plates used for testing and

the choice of the mathematical function that describes the wear.

Concerning the prediction of the number of holes, the thrust

load leading to delamination of the last ply has been estimated

using the Piquet’s model

. Tests at different feed rates starting

from very low values would probably allow to determine more

accurately this critical axial load.

Moreover, the study has also pointed out the beneficial

effect of the presence of a diamond coating on the carbide drill

leading to tool life 10 to 12 times the tool life of the uncoated

carbide drill for cutting speeds 3 times higher (170 m/min instead

of 56 m/min).

Finally, the drill allowing to achieve the greatest number of

holes in the CFRP without delamination must follow the following

specifications:

a point angle ensuring a proper balance of the dril (near

125–1301) and allowing if compatible with a very progressive

output, which minimizes the thrust load (near 901),

an helix angle acting like a corkscrew (near 35–401),

a clearance angle between 101 and 251 with a preference for

the double slope flank geometry (101/111+ 251),

a Cemecon type diamond coating,

a cutting speed and a feed rate of 170 m/min and 0.05 mm/rev,

respectively.

These specifications correspond to the prototype 8, which gave

the best results and to a lesser extent the prototype 6.

Acknowledgements

The authors wish to thank J. BEGA for his help in the present

work and for conducting part of the experiments. Research

support was provided by the French Department of Education

and Science trough the contract n102K0538 (MEDOC project).

References

[1] WF. Smith, in: Principles of Materials Science and Engineering, McGraw-Hill,

New York, 1990 699–724.

[2] A. Koplev, Cutting of CFRP with single edge tools, in: Proceedings of the

Third International Conference on Composite Materials, Paris, (2), 1980,

pp. 1597–1605.

[3] A. Koplev, A. Lystrup, T. Vorm, The cutting process, chips and cutting forces in

machining CFRP, Composites 14 (4) (1983) 371–376.

[4] D. Arola, M. Ramulu, D.H. Wang, Chip formation in orthogonal trimming of

graphite/epoxy composite, Composites A 27 (1996) 121–133.

[5] N. Bhatnagar, N. Ramakrishana, N.K. Nail, R. Komanduri, On the machining of

fibre reinforced plastic (FRP) composite laminates, Int J. Mach. Tools Manuf.

35 (5) (1995) 701–716.

[6] H.Y. Pwu, H. Hocheng, Chip formation model of cutting fibre-reinforced

plastics perpendicular to fibre axis, Trans ASME 120 (1998) 192–196.

[7] D. Arola, M. Ramulu, Orthogonal cutting of fibre-reinforced composites:

a finite element analysis, Int J Mach Tool Manuf. 39 (5) (1997) 597–613.

[8] S. Abrate, Machining of composite materials, in: P.K. Mallick (Ed.), Composites

Engineering handbook, Marcel Dekker, New York, 1997, pp. 777–809.

[9] E. Persson, I. Eriksson, L. Zackrisson, Effects of hole machining defects on strength

and fatigue life of composite laminates, Composites A 28 (1997) 141–151.

[10] E. Persson, I. Eriksson, P. Hammersberg, Propagation of hole machining defects

in pin-loaded composite laminates, J Compos. Mater 31 (1997) 383–408.

[11] R. Piquet, B. Ferret, F. Lachaud, P. Swider, Experimental analysis of drilling

damage in thin carbon/epoxy plate using special drills, Composites A 31

(2000) 1107–1115.

[12] H. Hocheng, C.K.H. Dharan, Delamination during drilling in composite

laminates, J Eng Ind. 112 (1990) 236–239.

[13] L.B. Zhang, L.J. Wang, X.Y. Liu, A mechanical model for predicting critical

thrust forces in drilling composite laminates, Proc. Inst. Mech. Eng. B 215

(2001) 135–146.

[14] S. Jain, D.C.H. Yang, Effects of feed rate and chisel edge on delamination in

composites drilling, J. Eng. Ind. 115 (1993) 398–405.

[15] C.C. Tsao, H. Hocheng, Effects of exit back-up on delamination in drilling

composite materials using a saw drill and a core drill, Int. J. Mach. Tools

Manuf. 45 (2005) 1261–1270.

[16] H. Hocheng, C.C. Tsao, Effects of special drill bits on drilling-induced

delamination of composite materials, Int. J. Mach. Tools Manuf. 46 (2006)

1403–1416.

[17] C.C. Tsao, H. Hocheng, Parametric study on thrust force of core drill, J Mater

Proc. Technol. 192–193 (2007) 37–40.

[18] M. Fernandes, C. Cook, Drilling of carbon composites using a one shot drill bit.

Part II: empirical modelling of maximum thrust force, Int. J. Mach. Tools

Manuf. 46 (2006) 76–79.

[19] C.C. Tsao, The effect of pilot hole on delamination when core drilling

composite materials, Int. J. Mach. Tools Manuf. 46 (2006) 1653–1661.

[20] C.C. Tsao, Effect of pilot hole on thrust force by saw drill, Int. J. Mach. Tools

Manuf. 47 (2007) 2172–2176.

[21] C.C. Tsao, Prediction of thrust force of step drill in drilling composite material

by Taguchi method and radial basis function network, Int. J. Adv. Manuf.

Technol. 36 (2008) 11–18.

[22] C.C. Tsao, H. Hocheng, Effect of tool wear on delamination in drilling

composite materials, Int. J. Mech. Sci. 49 (8) (2007) 983–988.

[23] S.C. Lin, C.J. Ting, Tool wear monitoring in drilling using force signals, Wear

180 (1-2) (1995) 53–60.

[24] H. Hocheng, C.C Tsao, Comprehensive analysis of delamination in drilling of

composite materials with various drill bits, J. Mater. Proc. Technol. 140 (1–3)

(2003) 335–339.

[25] F. Lachaud, R. Piquet, F. Collombet, L. Surcin, Drilling of composite structures,

Compos. Struct. 52 (3–4) (2001) 511–516.

D. Iliescu et al. / International Journal of Machine Tools & Manufacture 50 (2010) 204–213

213

Document Outline

- Modeling and tool wear in drilling of CFRP

Wyszukiwarka

Podobne podstrony:

87 1237 1248 Machinability and Tool Wear During the High Speed Milling of Some Hardened

Interaction between ascorbic acid and gallic acid in a model of

Rodrigues & Vaz SUBLUMINAL AND SUPERLUMINAL SOLUTIONS IN VACUUM OF THE MAXWELL EQUATIONS AND THE MA

Cadmium, chromium, lead, manganese and nickel concentrations in blood of women in non polluted areas

Mathematical and technical optima in design of weld steel shell structures

PROPAGATION MODELING AND ANALYSIS OF VIRUSES IN P2P NETWORKS

Minimum Quantity Lubrication Drilling of Lightweight Aluminum and Magnesium Alloys Used in A

Functional Origins of Religious Concepts Ontological and Strategic Selection in Evolved Minds

16 197 208 Material Behaviour of Powder Metall Tool Steels in Tensile

Civil Society and Political Theory in the Work of Luhmann

79 1111 1124 The Performance of Spray Formed Tool Steels in Comparison to Conventional

02 Modeling and Design of a Micromechanical Phase Shifting Gate Optical ModulatorW42 03

54 767 780 Numerical Models and Their Validity in the Prediction of Heat Checking in Die

No Man's land Gender bias and social constructivism in the diagnosis of borderline personality disor

Adorno [on] 'Immanent Critique' and 'Dialetical Mimesis' in Adorno & Horkheimer's Dialectic of Enli

15 Multi annual variability of cloudiness and sunshine duration in Cracow between 1826 and 2005

więcej podobnych podstron