Applied Engineering in Agriculture

Vol. 22(3): 421-426

E 2006 American Society of Agricultural and Biological Engineers ISSN 0883−8542

421

E

CONOMICS

OF

P

RODUCING

F

UEL

P

ELLETS

FROM

B

IOMASS

S. Mani, S. Sokhansanj, X. Bi, A. Turhollow

A

BSTRACT.

An engineering economic analysis of a biomass pelleting process was performed for conditions in North America.

The pelletization of biomass consists of a series of unit operations: drying, size reduction, densifying, cooling, screening, and

warehousing. Capital and operating cost of the pelleting plant was estimated at several plant capacities. Pellet production

cost for a base case plant capacity of 6 t/h was about $51/t of pellets. Raw material cost was the largest cost element of the

total pellet production cost followed by personnel cost, drying cost, and pelleting mill cost. An increase in raw material cost

substantially increased the pellet production cost. Pellet plants with a capacity of more than 10 t/h decreased the costs to

roughly $40/t of pellets. Five different burner fuels – wet sawdust, dry sawdust, biomass pellets, natural gas, and coal were

tested for their effect on the cost of pellet production. Wet sawdust and coal, the cheapest burner fuels, produced the lowest

pellet production cost. The environmental impacts due to the potential emissions of these fuels during the combustion process

require further investigation.

Keywords. Pelletization costs, Cost analysis, Wood pellets, Solid fuels.

ignocellulosic biomass (biomass from plants), in its

original form usually have a low bulk density of

30 kg/m

3

and a moisture content ranging from 10%

to 70% (wb). Pelleting increases the specific densi-

ty (gravity) of biomass to more than 1000 kg/m

3

(Lehtikan-

gas, 2001; Mani et al., 2004). Pelleted biomass is low and

uniform in moisture content. It can be handled and stored

cheaply and safely using well developed handling systems

for grains (Fasina and Sokhansanj, 1996).

Forest and sawmill residues, agricultural crop residues,

and energy crops can be densified into pellets. Pellets are

cylindrical, 6 to 8 mm in diameter and 10 to 12 mm long.

Melin (2005) reports that in North America, more than

1.2 million t (In this article, t indicates tonne in SI Units) of

fuel pellets are produced annually. Most of the U.S. pellets

are bagged and marketed for domestic pellet stoves. In

Canada, pellets produced from sawdust and wood shavings

are exported to European countries – Sweden and Denmark.

The recent increases in oil and gas prices and climate

change have boosted the demand for biomass. In spite of their

many desirable attributes, biomass pellets cannot compete

with fossil fuel sources because it is still expensive to densify

biomass. Samson et al. (2000) reported that depending upon

the raw material cost, switchgrass pellets range from $72 to

$102/t. Drying costs are not included in this price. Thek and

Submitted for review in September 2005 as manuscript number FPE

6086; approved for publication by the Food & Process Engineering

Institute Division of ASABE in March 2006.

The authors are Sudhagar Mani, ASABE Student Member, Graduate

Student, Xiaotao Bi, Associate Professor, Department of Chemical and

Biological Engineering, University of British Columbia, Vancouver, BC

Canada; Shahab Sokhansanj, ASABE Member Engineer, Distinguished

Research Scientist, and Anthony Turhollow, ASABE Member Engineer,

Research Scientist, Oak Ridge National Laboratory, Environmental

Sciences Division, Oak Ridge, Tennessee. Corresponding author:

Sudhagar Mani, Dept. of Chemical and Biological Engineering, University

of British Columbia, 2360 East Mall, Vancouver, BC Canada V6T 1Z3;

phone: 604-827-3413; fax: 604-822-6003; e-mail:

msudhagar@chml.ubc.ca.

Obernberger (2004) reported the pellet production cost in

Sweden and Austria between $78 and $113/t. The main cost

difference was due to the larger plant capacity and the lower

electricity price in Sweden. Raw material is a major

contributor to the cost of pellets produced (Mani, 2005). To

produce biomass pellets economically, a detailed economic

analysis for the North American condition is required taking

into consideration plant capacity, feedstock cost, drying cost,

and plant utilization time. The objectives of this work were

to develop the cost of producing biomass pellets and to

investigate the effect of feedstock cost, plant capacity, and

dryer fuel options on pellet production cost.

D

ESCRIPTION

OF

A

T

YPICAL

B

IOMASS

P

ELLETING

O

PERATION

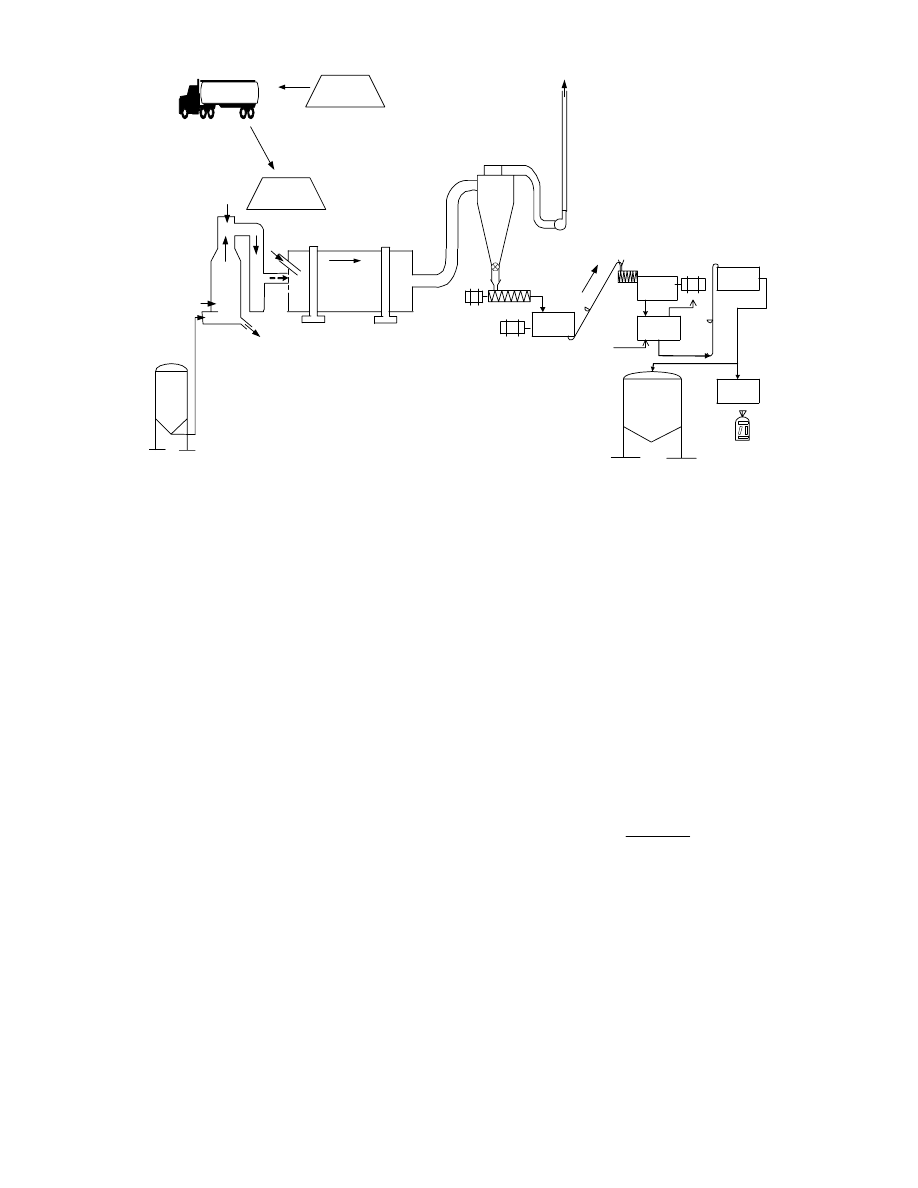

Apart from animal feed, alfalfa and sawmill residues are

the other two biomass that are pelletized extensively in

Canada. Figure 1 shows the unit operations and the flow of

biomass in a typical biomass pelleting operation that consists

of three major unit operations, drying, size reduction

(grinding), and densification (pelleting). The biomass is

dried to about 10% (wb) in the rotary drum dryer. Super-

heated steam dryers, flash dryers, spouted bed dryers, and

belt dryers are also common in European countries (Stahl

et al., 2004; Thek and Obernberger, 2004) but they are not

used in North America (to the knowledge of the authors). The

drying medium is the flue gas from the direct combustion of

natural gas. Solid fuels, especially biomass fuels, are

gradually replacing natural gas because of recent price

increases in fossil fuels.

After drying, a hammer mill equipped with a screen size

of 3.2 to 6.4 mm reduces the dried biomass to a particle size

suitable for pelleting. The ground biomass is compacted in

the press mill to form pellets. The individual pellet density

ranges from 1000 to 1200 kg/m

3

. The bulk density of pellets

ranges from 550 to 700 kg/m

3

depending on size of pellets.

Pellet density and durability are influenced by physical and

chemical properties of the feedstock, temperature and

L

422

A

PPLIED

E

NGINEERING

IN

A

GRICULTURE

Truck transport

Biomass

storage

Raw

material

Feed in

Cyclone

Rotary dryer

(single/triple)

Fan

Hammer

mill

Solid

fuel

burner

Ash

Dilution Air

Air

Fuel

tank

Fuel

Motor

Conveyor

Pellet

mill

Screening

Cooler

Packing

bags

Pellet

storage

Cool

air

Pellet

Figure 1. Schematic layout of a typical biomass pelleting plant.

applied pressure during the pelleting process (Mani et al.,

2003). In some operations, the ground material is treated with

super-heated steam at temperatures above 100

°C before

compaction. The superheated steam increases moisture and

temperature of the mash causing the release and activation of

the natural binders present in the biomass. Moisture also acts

as a binder and lubricator (Robinson, 1984).

In some operations, binders or stabilizing agents are used

to reduce the pellet springiness and to increase the pellet

density and durability. Most widely used binders for pelleting

of animal feeds are calcium lignosulfonate, colloids, benton-

ite, starches, proteins and calcium hydroxide (Pfost, 1964;

Tabil and Sokhansanj, 1996). Pfost and Young (1974)

reported that there was a significant increase in pellet

durability when using colloids and calcium lingo-sulphonate

as additives in the range of 2.6% by weight. Biomass from

woody plants contains higher percentages of resins and lignin

compared to agricultural crop residues (straw and stover).

When lignin-rich biomass is compacted under high pressure

and temperature, lignin becomes soft exhibiting thermoset-

ting properties (van Dam et al., 2004). The softened lignin

acts as glue.

The temperature of pellets coming out of the pellet mill

ranges from 70

°C to 90°C. The elevated temperature is due

to the frictional heat generated during extrusion and material

pre-heating. Pellets are cooled to within 5

°C of the ambient

temperature in a cooler. The hardened cooled pellets are

conveyed from the cooler to storage areas using mechanical

or pneumatic conveying systems. Pellets may be passed over

a screen to have fines removed and were weighed before

being stored in enclosed storage areas.

P

ELLET

P

RODUCTION

C

OSTS

The cost of pelleting includes fixed (capital) and operating

costs. The purchase cost of different equipment was collected

from the manufacturers and published literature sources. All

capital cost components follow the economy of scale, i.e.

expansion of the unit size with respect to its characteristics

dimensions will reduce the capital cost, non-proportional to

the actual size of expansion (Krokida et al., 2002). For

notations used in this article, see the List of Nomenclatures

at the end of the text.

The total capital cost, C

c

($/y) was calculated by:

eq

c

eC

C

=

(1)

where e is the capital recovery factor and C

eq

is the cost of the

equipment ($).

The capital recovery factor was calculated using equa-

tion 2:

( )

( )

1

1

1

−

+

+

=

N

N

i

i

i

e

(2)

where i is the interest rate (decimal) and N is the lifetime of

the equipment (years).

The equipment cost, C

eq

, was found from the general

relationship.

eq

n

eq

eq

P

C

α

=

(3)

where

a

eq

is the unit cost of the equipment ($), n

eq

is the

scaling factor of the equipment, and P is the characteristic

parameter of the equipment.

423

Vol. 22(3): 421-426

The following cost versus capacity relationship was used

(Ulrich, 1984) wherever the specific equipment cost for a

particular capacity was not available,

g

eq

eq

C

C

C

C

=

2

1

2

1

(4)

C

1

and C

2

are the capacity of equipment 1 and 2; g is the

exponent. The exponent value for process equipment ranges

from 0.4 to 0.8. We used the exponent value of 0.6 in this

study.

The total cost, C

T

, was calculated by:

op

c

T

C

C

C

+

=

(5)

where C

op

is the operating cost ($/y).

The production cost, C

P

($/kg), for any product was

estimated from equation 6:

P

op

T

p

G

t

C

C

=

(6)

where t

op

is the total operating hours of the plant per year (h/y)

and G

p

is the production rate (kg/h).

Equipment price relationships quoted in different years

are adjusted to 2004 U.S. dollar values by taking into account

for inflation factors (Consumer Price Index) published by

National Aeronautics and Space Administration (NASA)

cost estimating web site (NASA, 2004). Installation cost of

the equipment was in the range of 40% to 75% of the purchase

cost. The purchase and installation cost of various equipment

were taken from Perry and Green (1999) and Walas (1990).

The capital cost of hammer and pellet mills were received

from equipment manufacturers. The capital cost includes the

land cost, purchase, installation and maintenance, office

building construction cost, and costs of dump trucks, forklifts

and front-end loaders. Cost analysis of dump trucks,

front-end loaders, and forklifts was based on the ASAE

standard EP496.2 (ASAE Standards, 2003).

We assumed a 6% interest rate. The maintenance of

equipment and building was assumed to be 2% of the capital

cost except for the pellet and hammer mills. Pellet and

hammer mills have high repair and maintenance cost (10%

of the purchase cost) due to the wear and tear of the

equipment. The operating cost includes the cost of the raw

material, heat energy cost for drying, electricity cost, and

personnel costs. The heat energy cost for the dryer depends

on the type of fuel used and the fuel cost. Costs for five

different dryer fuels (wet biomass, dry biomass, fuel pellets,

natural gas, and coal) were calculated. Personnel costs were

included in pellet production, marketing, and administration.

In order to produce wood pellets, no steam conditioning or

external binders were used. Because lignin in the sawdust

acts as a natural binder during pelletization, the cost of steam

or binders was not included in the cost analysis. The pellet

production cost was calculated for the base case scenario of

6 t/h wood pellet plant. The base case pellet cost estimation

was used to investigate the effect of plant capacity, raw

material cost, and dryer fuel options on the pellet production

cost.

R

ESULTS

AND

D

ISCUSSIONS

The base case pellet plant has a production capacity of 6 t

of pellets/h with the annual production of 45,000 t. The plant

operates 24 h for 310 days annually (annual utilization period

85%). Table 1 lists the cost of the equipment purchase,

installation, annualized cost, and the cost in $/t of pellets

produced for each equipment. In this analysis, the transporta-

tion cost of raw material to the pellet operation facility was

included. We also assumed that the plant was located within

5 to 10 km of the biomass source. The costs of the dryer and

the pellet mill were the largest among the annual capital

costs. The capital cost of the pellet production plant was

about $6/t of pellet production. The capital cost may be

further reduced if the plant capacity is increased from the

current production rate (45,000 t/y).

Table 2 shows the cost of pellet production including

variable costs. The transportation of raw material to the pellet

plant was included in the cost estimation. For the base case,

Table 1. Summary of initial capital cost of the equipment for the pellet production plant (base case – 6 t/h production rate).

Equipment

Purchase Cost

(1000 $)

Installation Cost

(1000 $)

Expected Life

(y)

Capital Recovery

Factor

Annual Capital Cost

(1000 $)

Specific Capital Cost

($/t)

Solid fuel burner

143

71

10

0.1359

29

0.65

Rotary drum dryer

350

210

15

0.1030

58

1.28

Hammer mill

60

24

10

0.1359

11

0.25

Pellet mill

315

160

10

0.1359

64

1.43

Pellet cooler

32

24

15

0.1030

6

0.13

Screen shaker

24

14

10

0.1359

5

0.11

Packaging unit

80

15

10

0.1359

13

0.29

Storage bin

24

14

20

0.0872

3

0.07

Miscellaneous equipment

168

68

10

0.1359

31

0.68

Front end loader

100

−

10

0.1359

14

0.30

Fork lifter

82

−

10

0.1359

11

0.25

Dump truck

100

−

15

0.1030

15

0.34

Office building

72

−

20

0.0872

6

0.14

Land use

40

−

25

0.0782

3

0.07

Total

1590

600

269

6.00

424

A

PPLIED

E

NGINEERING

IN

A

GRICULTURE

Table 2. Cost of biomass pellet production

for the base case (2004 US $).

Pellet Process Operations

Capital

Cost

($/t)

Operating

Cost

($/t)

Total

Cost

($/t)

Percent

Cost

Distribution

Raw material

[a]

0.34

19.39

19.73

39.02

Drying operation

2.46

7.84

10.30

20.37

Hammer mill

0.25

0.70

0.95

1.88

Pellet mill

1.43

1.88

3.31

6.55

Pellet cooler

0.13

0.21

0.34

0.67

Screening

0.11

0.05

0.16

0.32

Packing

0.56

1.37

1.93

3.82

Pellet Storage

0.07

0.01

0.08

0.16

Miscellaneous equipment

0.42

0.33

0.76

1.50

Personnel cost

0.00

12.74

12.74

25.19

Land use and building

0.21

0.05

0.26

0.51

Total cost

5.99

44.58

50.57

100

[a]

Raw material cost includes both the biomass and transportation cost.

wood shavings at 10% (wb) moisture content was considered

as a burner fuel with a fuel cost of $40/t of fuel delivered. Cost

of wood shavings is considerably higher due to the high

demand for animal bedding materials and as a fuel for the

pulp mills. The capital and operating cost of producing

biomass pellets are $6 and $45 per t of pellet production,

respectively. The cost of producing pellets ($51/t) may be

further reduced if the plant capacity is increased.

Pellets produced in North America are cheaper compared

to that produced in European countries. In Austria and

Sweden, the cost of production of fuel pellets was $113 and

$78/t of pellets, respectively. The difference in pellet cost

from the two countries was mainly due to the larger plant

capacity and the lower price for electricity in Sweden (Thek

and Obernberger, 2004).

Figure 2 shows the effect of pellet production rate on the

total cost of pellet production. We assumed that the plant

operates 7500 h annually, which is about 85% of the year. If

the plant operates 6000 h annually then the pellet cost

increased by $4.50/t. An increase in pellet production rate

(plant capacity) substantially decreased the pellet production

cost mainly due to the economics of scale for larger pellet

plants. For example, the personnel cost for the pellet plant

with 10 t/h production rate is about $4/t compared to $16/t for

the pellet plant with 2 t/h production rate. For a production

rate of 10 t/h, the cost of pellet produced decreased to about

0

20

40

60

80

100

120

0

2

4

6

8

10

12

14

16

Pellet production rate (t/h)

Pellet production cost ($/t)

Total cost

Capital cost

Operating cost

Figure 2. Pellet production cost vs. production rate.

$41/t with the annual production rate of 75,000 t/y. At $41/t

with the annual production rate of 75,000 t/y. At higher plant

capacity, the capital cost of the plant did not increase

substantially due to the plant scaling factor of 0.6. The

operating cost decreased considerably more than the capital

cost of the plant due to the increase in annual pellet

production rate.

Table 2 shows the distribution of pellet production cost

with various process operations and cost components. Cost of

raw material has the highest contribution to pellet production

cost, with a share of about 40%. The raw material considered

in this study was wet sawdust with 40% (wb) moisture

content. The cost of raw material at the sawmill plant was

about $10/t. If the transportation cost of the raw material was

included, the cost of raw material at the pellet plant site was

increased to about $19.73/t for an average transportation

distance of 7.5 km.

The cost of raw material increases to more than $32/t

(Sokhansanj and Turhollow, 2004) when the raw material

requires collection, baling, transportation and storage. Fig-

ure 3 shows that an increase in raw material cost substantially

increased the pellet production cost. If the raw material cost

is about $50/t, this would increase the pellet production cost

to about $110/t. If profit margin is assumed to be 20% of

production cost, the sale price of pellets would increase to

about $132/t ($8/GJ), which is almost equal to the current

natural gas price. Therefore, the raw material cost plays a

major role in the cost of pellet production.

Other major cost components are personnel and drying

costs with shares of 25% and 20%, respectively. Personnel

cost includes costs for personnel in the production, market-

ing, and administration. In the production, two people are

required for the entire production plant. The process requires

additional three people for the shift for bagging pellets into

18-kg (40-lb) bags.. We assumed that one third of the pellets

produced in the plants are packed. Personnel cost may be

considerably reduced when the packaging of pellets is

eliminated in the production operation. Personnel cost again

depends on the pellet production and administration strate-

gies set by the pellet plant operators.

Cost of operating a dryer in the pelleting plant is also a

major cost component compared to pellet and hammer mills.

To investigate the effect of burner fuel options on the pellet

production cost, five different fuel sources- wet sawdust, dry

sawdust, fuel pellets, natural gas, and coal were considered.

It was assumed that one solid fuel burner would handle all the

0

20

40

60

80

100

120

140

160

0

10

20

30

40

50

60

70

80

Raw material cost (US$)

Pellet production cost

(US$/t )

Figure 3. Effect of raw material cost on pellet production cost.

425

Vol. 22(3): 421-426

Table 3. Effect of various burner fuel options

on the cost of pellet production.

Burner Fuel Options

Fuel Cost ($/t)

Pellet Cost ($/t)

Wet biomass

10

48.53

Dry biomass

32

50.57

Fuel pellets

52

52.31

Natural gas

10/GJ

64.48

Coal

40

49.75

fuel options except natural gas. Table 3 shows the types of

burner fuel options used in the pellet production. The pellet

cost was based on a pellet production rate of 6 t/h (base case).

Wet sawdust produced the lowest pellet production cost of

$48.50/t followed by coal with a pellet production cost of

$50/t. Although wet sawdust and coal promise the lowest

pellet production cost, potential emissions during the com-

bustion of these fuels require further investigation. Mani

et al. (2005) explain the environmental impacts of using

these fuels for the production of pellets.

Use of emission control devices for various fuels may

further increase pellet production cost. As expected, the

pellet production cost increased to $64/t when natural gas

was the burner fuel. Environment impact of using natural gas

is considerably less compared to other fuel options (Mani

et al., 2005). Thek and Obernberger (2004) reported that a

superheated steam dryer may significantly reduce drying

cost. The main advantage of a superheated steam dryer is the

high potential of heat recovery from the exhaust steam, which

increases the dryer efficiency to about 90%. The capital cost

of superheated steam dryers is relatively high compared to

rotary drum dryers. Raw materials such as wood shavings and

other low moisture biomass sources may not require further

drying in the pellet plant. If the drying is eliminated from the

plant, the cost of pellet production would drop down to about

$39 from $51/t of pellets.

The pelletization operation is also one of the main cost

factors in the pellet production cost followed by hammer

milling. In this study, no additional binders are used for

producing pellets. If the raw material does not contain natural

binders (lignin), additional binders or stabilizing agents may

be required. This would further increase the pellet production

cost. Pellet and hammer mills have high repair and mainte-

nance costs (10% of the purchase cost) due to the wear and

tear of the equipment and also consume large amounts of

electricity in the whole pellet production process. Power

consumption of the pelleting process may be reduced, if the

current ring die pellet mills are replaced with a new mill

design. Additional information on energy consumption of

biomass pelleting process and production of binderless

pellets can be obtained from Mani et al. (2006) and

Sokhansanj et al. (2005).

C

ONCLUSIONS

Biomass pellets can be economically produced with a

production cost of $51/t, assuming a raw materials cost of

$10/t and drying biomass from 40% to 10% moisture using

dry shavings as fuel. Raw material and personnel costs are the

major cost factors on the pellet production cost followed by

dryer and pellet mill costs. An increase in raw material cost

substantially increases the pellet production cost. Scale of the

plant, burner fuel options, and the fuel cost had a significant

influence on the pellet production cost. Small-scale pellet

plants are more expensive to operate, which eventually

increases the pellet production cost. A larger scale pellet

plant with a production capacity (>10 t/h) would produce less

expensive pellets. Among the five burner fuel options tested,

coal or wet biomass may considerably reduce the pellet

production cost. However, environmental impacts due to the

combustion of these fuels require further investigation to

control potential emissions.

A

CKNOWLEDGEMENTS

Authors acknowledge funding sources for this project

from the following organizations: Office of Biomass Pro-

grams through Oak Ridge National Laboratory, the Natural

Sciences and Engineering Research Council of Canada

(NSERC), and the University of British Columbia Graduate

Fellowship (UGF) and Jack Davis Scholarship for Energy

Studies.

R

EFERENCES

ASAE Standards, 49

th

Ed. 2003. EP496.2. Agricultural machinery

management. St. Joseph, Mich.: ASAE.

Fasina, O. O., and S. Sokhansanj. 1996. Storage and handling

characteristics of alfalfa pellets. Powder Handling and

Processing 8(4): 361-365.

Krokida, M. K., Z. B. Maroulis, and C. Kremalis. 2002. Process

design of rotary dryers for olive cake. Drying Technology

20(4&5): 771-788.

Lehtikangas, P. 2001. Quality properties of pelletised sawdust,

logging residues and bark. Biomass and Bioenergy 20(5):

351-360.

Mani, S., L. G. Tabil, and S. Sokhansanj. 2003. An overview of

compaction of biomass grinds. Powder Handling and

Processing 15(3): 160-168.

Mani, S., L. G. Tabil, and S. Sokhansanj. 2004. Evaluation of

compaction equations applied to four biomass species.

Canadian Biosystems Engineering 46(1): 3.55-3.61.

Mani, S. 2005. A systems analysis of biomass densification process.

Ph.D. dissertation. Vancouver, Canada: University of British

Columbia, Chemical and Biological Engineering.

Mani, S., X. Bi, and S. Sokhansanj. 2005. Environmental systems

assessment of biomass densification process. CSAE Paper No.

05081. Winnipeg, MB: CSAE/SCGR.

Mani, S., L. G. Tabil, and S. Sokhansanj. 2006. Specific energy

requirement for compacting corn stover. Bioresource Technology

97(12): 1420-1426.

Melin, S. 2005. Personal Communications. drc@dccnet.com. Delta,

BC: Delta Research Center.

NASA. 2004. Cost estimating web site – Consumer Price Index

(CPI) inflation calculator. Washington, D.C.: National

Aeronautics and Space Administration. Available at

http://www1.jsc.nasa.gov/bu2/inflateCPI.html. Accessed on 15

March 2004.

Perry, R. H., and D. W. Green. 1999. Perry’s Chemical Engineers’

Handbook. New York: McGraw Hill Inc.

Pfost, H. B. 1964. The effect of lignin binders, die thickness and

temperature on the pelleting process. Feedstuffs 36(22): 20, 54.

Pfost, H. B., and L. R. Young. 1974. Effect of colloidal binder and

other factors on pelleting. Feedstuffs 45(49): 22.

Robinson, R. 1984. Pelleting. In Manufacture of Animal Feed, ed.

D. A. Beaven, 50-53. Herts, England: Turrent-Wheatland Ltd.

426

A

PPLIED

E

NGINEERING

IN

A

GRICULTURE

Sokhansanj, S., S. Mani, and P. Zaini. 2005. Binderless pelletization

of biomass. ASAE Paper No. 056061. St. Joseph., Mich.:

ASAE.

Sokhansanj, S., and A. F. Turhollow. 2004. Biomass densification –

cubing operations and costs for corn stover. Applied

Engineering in Agriculture 20(4): 495-499.

Samson, P., P. Duxbury, M. Drisdelle, C. Lapointe. 2000.

Assessment of pelletized biofuels. Available at

http://www.reap-canada.com/online_library/Reports%20and%2

0Newsletters/Bioenergy/ 15%20Assessment%20of. Accessed on

2 January 2006.

Stahl, M., K. Granstrom, J. Berghel, and R. Renstrom. 2004.

Industrial processes for biomass drying and their effects on the

quality properties of wood pellets. Biomass and Bioenergy

27(6): 621-628.

Tabil, L., and S. Sokhansanj. 1996. Process conditions affecting the

physical quality of alfalfa pellets. Applied Engineering in

Agriculture 12(3): 345-350.

Thek, G., and I. Obernberger. 2004. Wood pellet production costs

under Austrian and in comparison to Swedish framework

conditions. Biomass and Bioenergy 27(6): 671-693.

Ulrich, G. D. 1984. A Guide to Chemical Engineering Process

Design and Economics. New York: John Wiley & Sons.

van Dam, J. E. G., M. J. A. van den Oever, W. Teunissen, E. R. P.

Keijsers, and A. G. Peralta. 2004. Process for production of high

density/high performance binderless boards from whole coconut

husk - Part 1: Lignin as intrinsic thermosetting binder resin.

Industrial Crops and Products 19(3): 207-216.

Walas, S. M. 1990. Chemical Process Equipment – Selection and

Design. New York: Elsevier.

N

OMENCLATURE

C

c

= total capital cost ($/y)

C

E

= cost of electricity ($/kWh)

C

eq

= equipment cost ($)

C

P

= production cost ($/kg)

C

op

= operating cost ($/y)

C

T

= total annual cost ($/y)

e

= capital recovery factor

g

= exponent for the capacity of equipment

G

P

= production rate of the product (kg/h)

i

= annual interest rate (%)

N

= life time of the equipment (y)

n

eq

= scaling factors for equipment

P

= characteristic parameter for any equipment

(eg. heat transfer area, length, flow rate etc.)

t

op

= operation hours per year (h/y)

a

eq

= unit cost of equipment ($)

C

eq1

= equipment cost ($) for the capacity, C

1

C

eq2

= equipment cost ($) for the capacity, C

2

Wyszukiwarka

Podobne podstrony:

Fuel and chemical products from biomass syngas A comparison of gas fermentation to thermochemical co

Production of Energy from Biomass Residues 020bm 496 1993

Energetic and economic evaluation of a poplar cultivation for the biomass production in Italy Włochy

Economics of poplar short rotation coppice plantations on marginal land in Germany 2013 Biomass and

the illict preparation of morphine and heroin from pharmaceutical products containing codeine homeba

Production of xylan degrading enzymes from Amazon forest fungal

Organic pollutants profiling of wood ashes from biomass power plants

An%20Analysis%20of%20the%20Data%20Obtained%20from%20Ventilat

Blacksmith The Origins Of Metallurgy Distinguishing Stone From Metal(1)

Economic?velopment of Hawaii

A Political Economy of Formatted Pleasures

pobłocki the economics of nostalgia

Good Capitalism, Bad Capitalism, and the Economics of Growth and Prosperity

This is a copy of a install sheet provided from TRD USA

An%20Analysis%20of%20the%20Data%20Obtained%20from%20Ventilat

From Bosnia to Baghdad The Evolution of U S Army Special Forces from 1995 2004

0262033291 The MIT Press Paths to a Green World The Political Economy of the Global Environment Apr

Mechanics of a Diesel Fuel Injection System

więcej podobnych podstron