SPME App Note 13 Page 1

Screening Packaging

Materials with

Automated SPME

and GC/MS

Varian Application Note

Number 13

Zelda Penton

Varian Chromatography Systems

Key Words:

SPME, 8200CX, Polymers, Saturn

Solid phase microextraction (SPME) was used to compare various packaging materials to assess their suitability

for storing and shipping analytical materials. In a previous publication (SPME Application Note #7), polymeric

beads that had been subjected to various heat treatments were compared; in this note, finished sheets were

examined. The various materials showed specific repeatable contamination patterns. The technique was very

simple—approximately 1-cm

2

of the various samples were placed into 2-mL screw cap vials and the air in the

vials was sampled at ambient temperature.

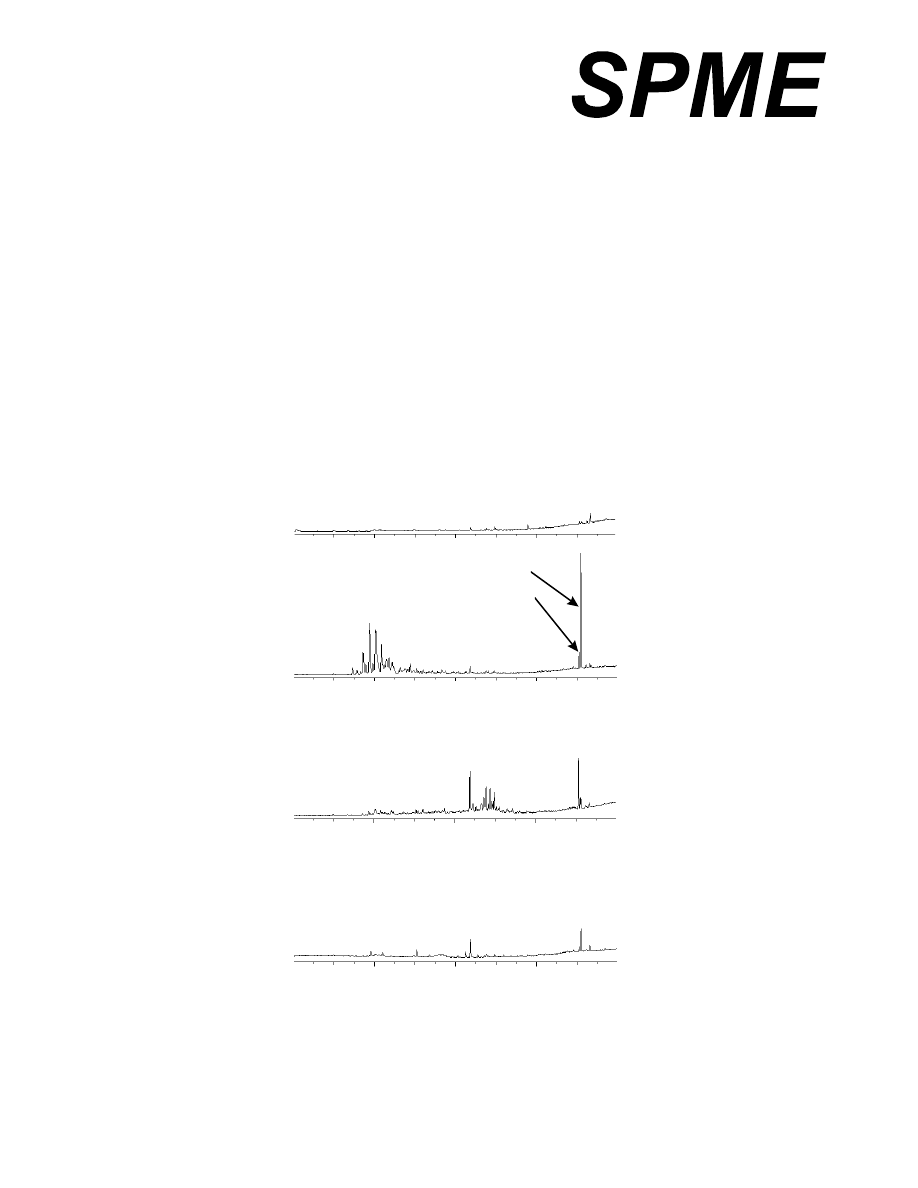

0 5 10 15 20

Retention time (min)

C

B

A

Empty vial

2

1

Figure 1: Total ion chromatograms of air sampled with a SPME fiber from a blank vial and vials

containing three different packaging materials. Peaks 1 and 2 were tentatively identified as butylated

hydroxytoluene and 2,6-bis (1,1-dimethylethyl)-4-ethylphenol.

varian

SPME App Note 13 Page 2

Instrumentation and Conditions

Instrument:

Varian Saturn 2000 GCMS equipped with an automated SPME III system.

Column:

30 m x 0.25 mm coated with 0.50-µm Supelcowax 10

TM

, 50°C, 1 minute, 10°C/min to 210°, hold 8 min.

Carrier gas: helium, 41 cm/s at 60°C.

Injector:

SPI with SPME insert at 210°C, isothermal.

Ion trap:

Electron impact ionization mode, mass range 50-250 m/z, ion trap temperature, 200°C.

Automated

SPME

Conditions:

Fibers (Supelco, Inc.) were coated with 100-µm Polydimethylsiloxane.

Headspace sampling without agitation in 2-mL vials, 30 minutes absorption, 2 minutes desorption, one

sampling per vial.

Samples:

Three different packaging materials.

Results and Discussion

The samples were cut into one-cm squares and placed in the vials (one piece per vial). Samples were run in

duplicate, with an empty vial at the beginning and end of the series. The total ion chromatograms were inspected

at comparable attenuation. Figure 1 clearly shows the differences in the packaging materials. Note that

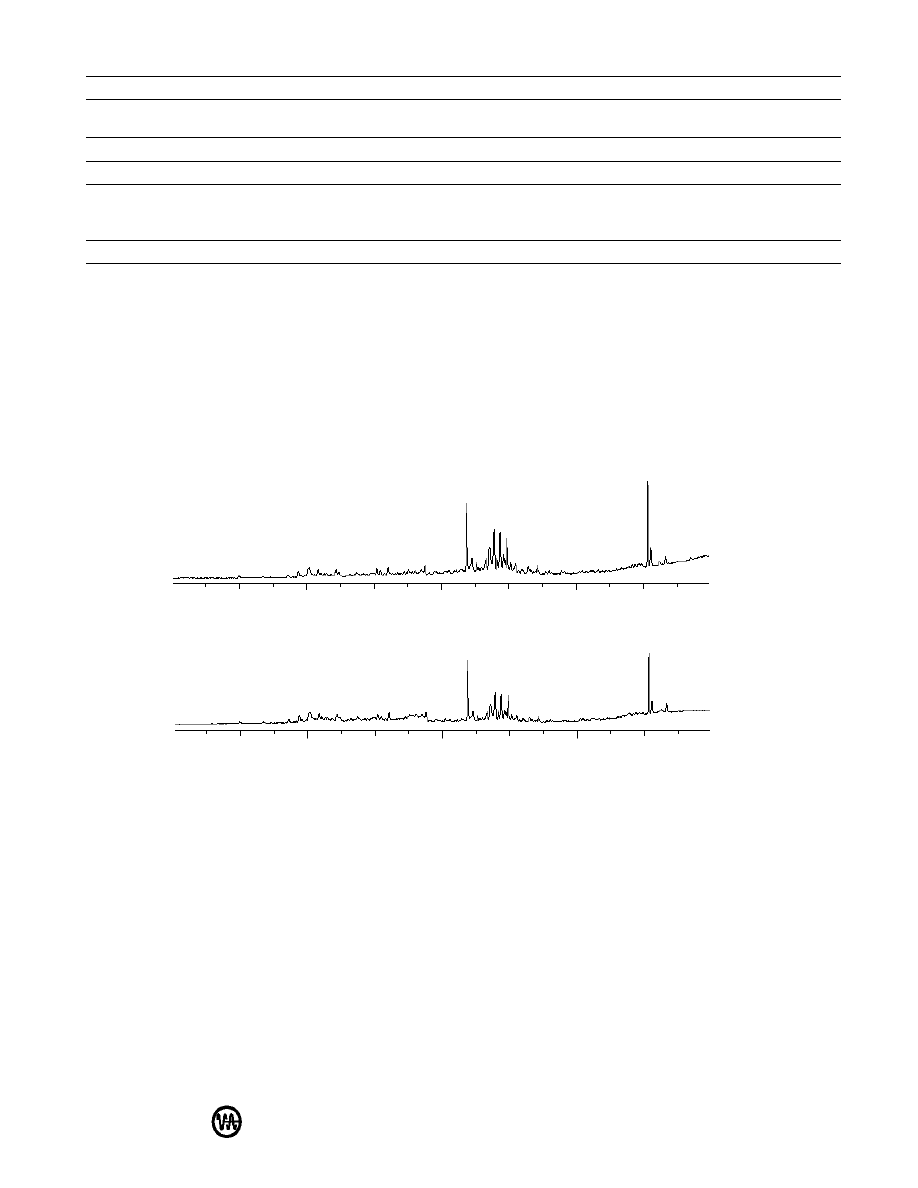

duplicates of the same sample were virtually identical (Figure 2). The method is not quantitative, as one would

expect the quantities of the various compounds released from the packaging material to be proportional to the

surface area, but if similar-sized pieces of the materials are placed in the sampling vials, the relative cleanliness

of the different samples becomes obvious.

Figure 2: Total ion chromatograms of two samples of packaging material “B”.

Conclusions

SPME is a very simple and effective technique for rapidly evaluating the cleanliness of packaging materials.

A simple GC-FID system may be used for fingerprinting, or if identification of the contaminants is required,

GC/MS should be utilized.

Document Outline

- I

- Instrumentation and Conditions

- Conclusions

- SPME is a very simple and effective technique for rapidly evaluating the cleanliness of packaging materials.

- A simple GC-FID system may be used for fingerprinting, or if identification of the contaminants is required, GC/MS should be utilized.

Wyszukiwarka

Podobne podstrony:

HS SPME in packaging materials

in vitro, materiały

Food analysis Packaging Materials

Barczyk i in Mikroekonomia Materiały do ćwiczeń (2)

Kultury in vitro materiał

zestawienie materiału do matury, in italiano, LICEUM

16 197 208 Material Behaviour of Powder Metall Tool Steels in Tensile

A picnic table is a project you?n buy all the material for and build in a?y

Wytrzymałość materiałów, Zginanie proste -wyznaczanie granicznej nośności belki zginanej, Wy?sza Szk

Pytania na zasady, POLITECHNIKA ŚLĄSKA Wydział Mechaniczny-Technologiczny - MiBM POLSL, Semestr 5, S

Legg Calvé Perthes Disease in Czech Archaeological Material

ca a chemia, Mol jest jednostk? liczno?ci substancji (materii), kt?ra zawiera tyle samo atom?w; jon?

materiały z niedzielnych wykładów i in, Terapia Pedagogiczna

rozmnazanie in vitro roslin, ogrodnictwo VII semestr, Od Mateusza S, materiały sggw, SGGW materiały

Wyklady In, Studia, I o, rok II, semestr III, inżynieria materiałowa, od Pauliny

lab, MATER1 C, Krzysztof Bry˙a Sprawozdanie z In˙.

więcej podobnych podstron