Biomaterials 19 (1998) 1621 — 1639

Review

Titanium alloys in total joint replacement—a materials

science perspective

Marc Long, H.J. Rack*

School of Chemical and Materials Engineering, Clemson University, Clemson, SC 29634, USA

Received 26 May 1996; accepted 6 July 1997

Abstract

Increased use of titanium alloys as biomaterials is occurring due to their lower modulus, superior biocompatibility and enhanced

corrosion resistance when compared to more conventional stainless steels and cobalt-based alloys. These attractive properties were

a driving force for the early introduction of

a (cpTi) and a#b (Ti—6Al—4V) alloys as well as for the more recent development of new

Ti-alloy compositions and orthopaedic metastable

b titanium alloys. The later possess enhanced biocompatibility, reduced elastic

modulus, and superior strain-controlled and notch fatigue resistance. However, the poor shear strength and wear resistance of

titanium alloys have nevertheless limited their biomedical use. Although the wear resistance of

b-Ti alloys has shown some

improvement when compared to

a#b alloys, the ultimate utility of orthopaedic titanium alloys as wear components will require

a more complete fundamental understanding of the wear mechanisms involved. This review examines current information on the

physical and mechanical characteristics of titanium alloys used in artifical joint replacement prostheses, with a special focus on those

issues associated with the long-term prosthetic requirements, e.g., fatigue and wear.

( 1998 Published by Elsevier Science Ltd.

All rights reserved

Keywords: Titanium; Titanium alloys; Total joint replacement; Orthopaedics; Fatigue; Wear; Biocompatibility

1. Introduction

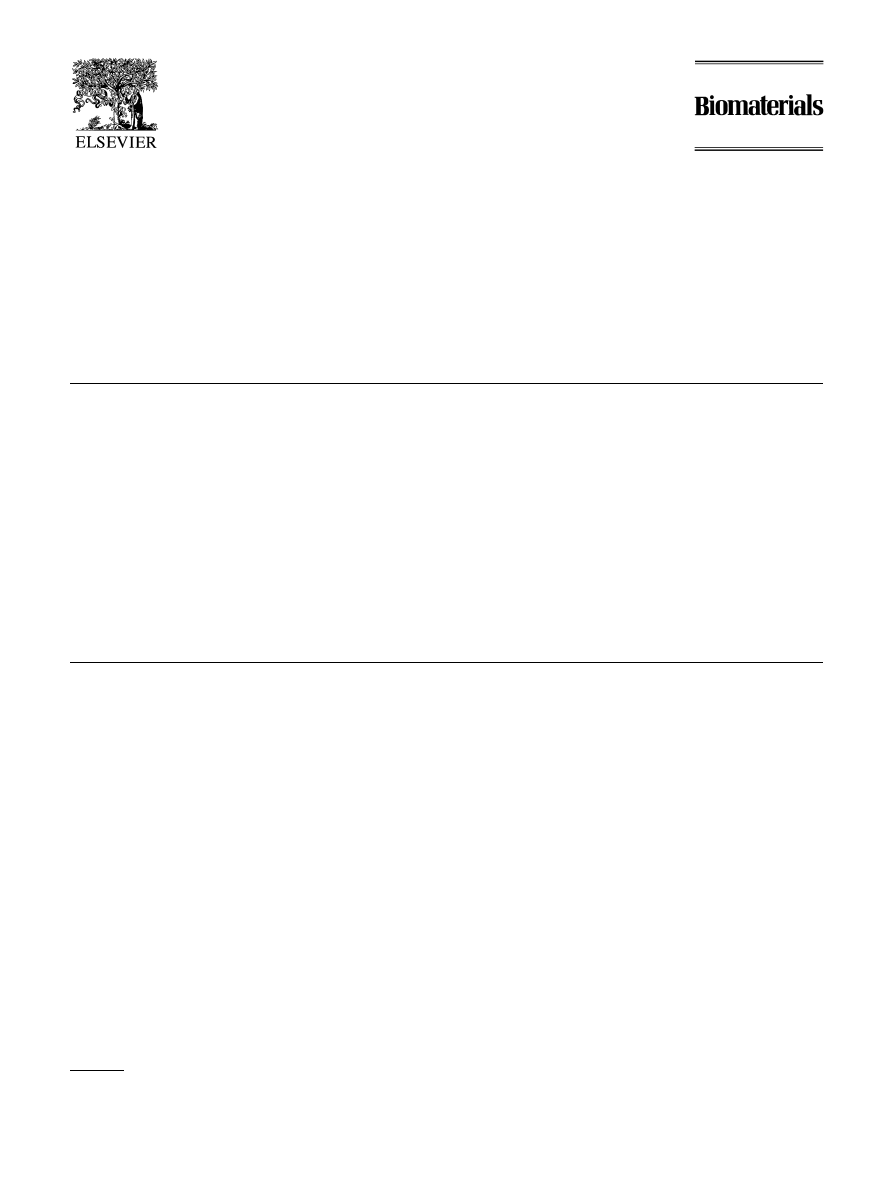

Natural synovial joints, e.g., hip, knee or shoulder

joints, are complex and delicate structures capable of

functioning under critical conditions. Their performance

is due to the optimized combination of articular carti-

lage, a load-bearing connective tissue covering the bones

involved in the joint, and synovial fluid, a nutrient fluid

secreted within the joint area [1, 2] (Fig. 1). Unfortunate-

ly, human joints are prone to degenerative and inflam-

matory diseases that result in pain and joint stiffness.

Primary or secondary osteoarthritis (osteoarthrosis), and

to a lesser extent rheumatoid arthritis (inflammation of

the synovial membrane) and chondromalacia (softening

of cartilage), are, apart from normal ageing of articular

cartilage, the most common degenerative processes af-

fecting synovial joints [3, 4]. In fact, 90% of the popula-

tion over the age of 40 suffers from some degree of

* Corresponding author.

degenerative joint disease [5]. Premature joint degener-

ation may arise from deficiencies in joint biomaterial

properties, from excessive loading conditions, or from

failure of normal repair processes, the explicit degen-

erative processes not yet being completely understood.

Degeneration of weight bearing joints often requires

surgery to relieve pain and increase mobility. Through

minimum invasive damage, arthroscopic surgery, most

frequently performed on knee joints, provides an efficient

surgical method for diagnosis and symptomatic relief of

painful joints. Ultimately replacement of diseased joint

surfaces by metal, plastic, or ceramic artificial materials is

accomplished through arthroplastic surgery when the

natural joint can no longer adequately perform.

Total joint replacement (TJR) arthroplasty is recog-

nized as a major achievement in orthopaedic surgery.

Successful replacement of the natural joints through ar-

throplastic surgery has been the long-time objective of

orthopaedic surgeons. Arthroplasty (Dorland’s Medical

Dictionary definition ‘plastic repair of a joint’) is a surgi-

cal technique which replaces all articulating degenerated

natural surfaces with artificial materials, hence achieving

0142-9612/98/$ — See front matter

( 1998 Published by Elsevier Science Ltd. All rights reserved.

PII S 0 1 4 2 - 9 6 1 2 ( 9 7 ) 0 0 1 4 6 - 4

Fig. 1. Representation of human knee and hip joints during loading

[44].

relief of pain and improved joint mobility by creation of

a new prosthetic joint. From early excision through inter-

position to replacement arthroplasty, great progress has

been achieved over 170 years of orthopaedic surgery and

joint prostheses are now being considered for many

joints in the human body [6]. Total hip (THR) and total

knee (TKR) joint replacements, due to population needs

and their complex behavior, have nevertheless been the

principal focus of artificial joint studies. TJR is now

a fairly well established orthopaedic technique involving

the replacement of a growing number of hip and knee

joints, 275 000 hip and knee joints having been replaced

during 1995 in the United States [7]. Unfortunately

in vivo degradation, primarily as a result of the higher

wear rates associated with artificial implant materials,

and the consequent adverse biological effect of the gener-

ated wear debris on bone mass/density and implant fix-

ation, typically, however, results in a shorter lifetime for

these artificial joints when compared with natural

synovial joints. Further, when compared to the initial

TJR surgery, revision surgery of an implant is more

difficult, has a lower success rate, may induce additional

damage to the surrounding tissues and increases health

care costs by one third [7].

Replacement arthroplasty made important advance-

ments during the 1950s and 1960s, through the out-

standing contributions of G.K. McKee and Sir John

Charnley. McKee introduced metal-on-metal hip pros-

thesis in which components were originally made of

stainless steel which rapidly changed to a cobalt—chro-

mium—molybdenum alloy (Vitallium

TM) to mitigate the

excessive friction and rapid loosening of the stainless steel

pair [8, 9]. Moreover, the substitution of methyl-methac-

rylate cement for fixation screws increased the short-term

implantation success rate to'90%. It was further recog-

nized that the use of identical metals in the tribological

pair, though necessary to avoid galvanic corrosion, was

not an optimized tribology design. A high rate of loosen-

ing was encountered with early metal-on-metal artificial

joints due to non-optimum fit between the articulating

surfaces which produced high frictional moments and

excessive wear of the bearing surfaces [8—10]. These early

concerns limited the application of metal-on-metal ar-

ticulating devices, although follow-up examinations of

metal-on-metal hip protheses have shown very low wear

rates (a few

lm per year per component) for protheses

implanted for up to 20 years [11].

Sir John Charnley in the 1960s developed the concept

of low-friction arthroplasty by introducing a new design

consisting of a small-diameter metallic femoral head ar-

ticulating with a polymeric (originally PTFE to be later

replaced by ultra-high-molecular-weight polyethylene

(UHMWPE)) acetabular cup [12, 13]. The initial success

of UHMWPE as the cup material [14] has prevailed for

30 yrs, UHMWPE being the dominant orthopaedic ma-

terial in TJRs [6]. Wear of UHMWPE has, however,

been invariably observed when rubbing against metal

femoral heads or femoral condylar components of TJRs

[15].

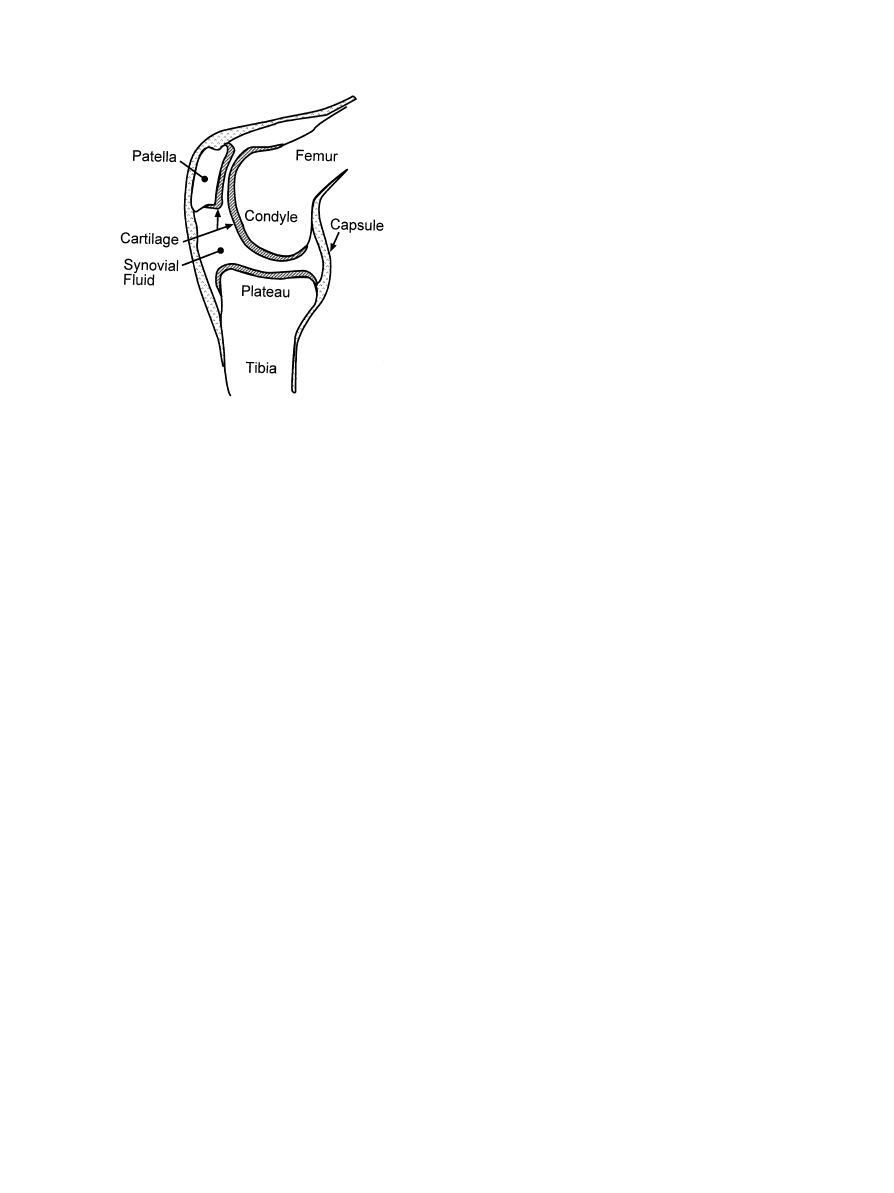

Beside clinical factors and design considerations, the

latter to minimize contact stresses, choice of counterpart

material has been shown to be a critical factor in

UHMWPE wear behavior. Ti—6Al—4V has generally

been found to have a more detrimental impact on

UHMWPE wear than Co—Cr—Mo alloys [14, 15]. In

order to achieve minimum wear and maximum success

rate, subsequent studies have considered alternative ma-

terials combinations [16—23], Table 1, e.g., ceramic/

UHMWPE prostheses where the ceramic component

creates minimum damage to the UHMWPE counterpart

when compared to Co—Cr—Mo or Ti—6Al—4V. Wear of

joint prostheses materials unavoidably represents a long-

term limitation to the lifetime of a total joint replacement

as accumulation of UHMWPE, and to a lesser extent

metal or ceramic wear debris has been associated with

incidence of non-specific pain and prosthesis loosening.

The former is a result of adverse tissue reaction, while the

latter is a result of adverse reaction to wear debris of the

implant/bone fixation [24—36]. There is therefore an in-

creasing concern about the long-term use of UHMWPE,

underscored by recent recognition of the non-specificity

(variable MW and MW distribution, processing and fab-

rication history) of the material, reports on the possible

harmful effects of UHMWPE sterilization, and the inter-

action of UHMWPE debris with the body fluids and

tissues [37—41].

Simultaneously development in metal-on-metal tech-

nology [10], through optimization of CoCrMo alloys,

prosthesis geometry, and manufacturing practices, has

created a renaissance of metal-on-metal prostheses in

1622

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

Table 1

Materials combinations used in TJR prostheses

Femoral component

Hip/tibial component

Results

Co—Cr—Mo

Co—Cr—Mo

Early high loosening rate and limited use. New developments show lowest

wear rate (THR only — in clinical use in Europe)

Co—Cr—Mo

UHMWPE

Widely employed; low wear

Alumina/zirconia

UHMWPE

Very low wear rate. Zirconia more impact resistant (not used in TKR but in

clinical evaluation in Japan)

Alumina

Alumina

Minimum wear rate (components matched) Pain—Not in clinical use in the US

Ti—6Al—4V

UHMWPE

Reports of high UHMW-PE wear due to breakdown of titanium surface

Surface coated Ti—6Al—4V

UHMWPE

Enhanced wear resistance to abrasion. Only thin treated layer achieved

Fig. 2. Comparison of wear behavior of different material combina-

tions (adapted from Ref. [10]).

Europe [6, 42, 43]. Metal-on-metal combinations may

now provide wear rates lower than metal-or ceramic-

on-UHMWPE combinations (Fig. 2), eliminating the

high-wear debris generation and long-term degradation

associated with UHMWPE.

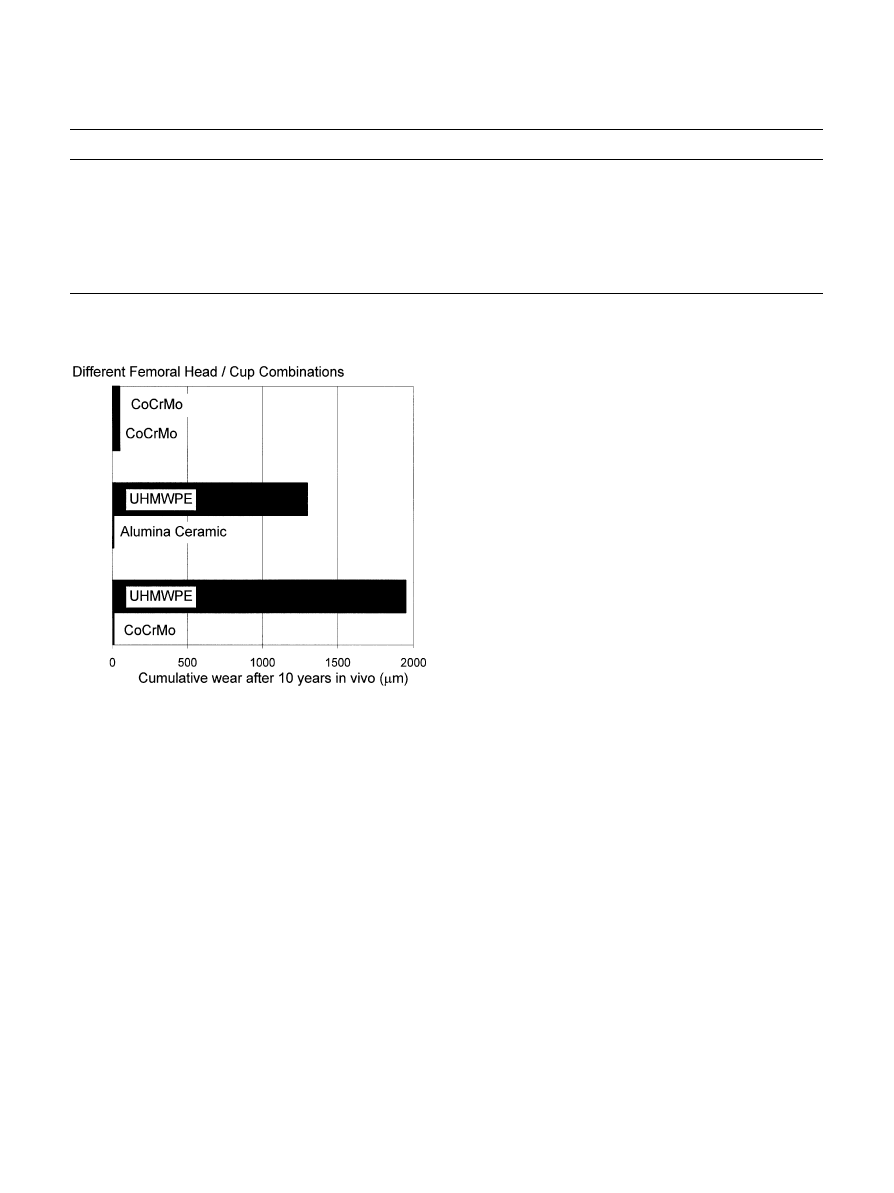

While continued development of TJR materials has

increased the success of total joint replacements (with

success rates of 95% and higher at 10 years and 85—90%

at 15 years), longer human life expectancy and implanta-

tion in younger patients has driven bioengineers from

original implant concerns, e.g., materials strength, infec-

tion and short-term rejection, to consideration of long-

term materials limitations, e.g., wear, fatigue strength,

and long-term biocompatibility, Fig. 3. The ‘ideal’ mate-

rial or material combination for TJR prostheses should

therefore exhibit the following properties: a ‘biocompat-

ible’ chemical composition to avoid adverse tissue reac-

tions, an excellent resistance to degradation (corrosion)

in the human body environment, acceptable strength to

sustain the cyclic loading endured by the joint, a low

modulus to minimize bone resorption, and a high-wear

resistance to minimize debris generation.

Until recently, the mainstream approach taken for the

introduction of orthopaedic materials has involved ad-

aptation of existing materials, as exemplified by the use of

Ti—6Al—4V ELI, an alloy originally designed for aero-

space applications. Standard metallic orthopaedic mate-

rials include stainless steels, cobalt-base alloys, and

titanium-base alloys [44—46] (Table 2), with an increas-

ing number of devices being made of titanium and tita-

nium alloys. The latter alloys are generally preferred to

stainless steel and Co-alloys because of their lower

modulus, superior biocompatibility and corrosion resist-

ance [6, 44]. Recently, new titanium alloy compositions,

specifically tailored for biomedical applications, have

been developed. These first generation orthopaedic alloys

included Ti—6Al—7Nb [47] and Ti—5Al—2.5Fe [48, 49],

two alloys with properties similar to Ti—6Al—4V that

were developed in response to concerns relating V to

potential cytotoxicity [50, 51] and adverse reaction with

body tissues [52]. Further, biocompatibility enhance-

ment and lower modulus has been achieved through the

introduction of second generation titanium orthopaedic

alloys including Ti—12Mo—6Zr—2Fe ‘TMZF’ [53, 54]

Ti—15Mo—5Zr—3Al [55], Ti—15Mo—3Nb—3O (21SRx)

[56],

Ti—15Zr—4Nb—2Ta—0.2Pd

and

Ti—15Sn—4Nb—

2Ta—0.2Pd alloys [57], as well as the ‘completely biocom-

patible’ Ti—13Nb—13Zr alloy [58, 59]. Finally, minimum

elastic moduli have been achieved by ‘TNZT’ alloys

based on the Ti—Nb—Ta—Zr system [60], specifically by

the development of the ‘biocompatible’ Ti—35Nb—5Ta—

7Zr alloy.

This review presents the advances in the development

of orthopaedic titanium alloys. After a brief summary of

the physical metallurgy of titanium and titanium alloys,

their biocompatibility, corrosion behavior, and mechan-

ical properties will be discussed. Finally, their wear be-

havior will be examined.

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

1623

Fig. 3. Implant materials requirements in orthopaedic applications (adapted from Ref. [126]).

Table 2

Some characteristics of orthopaedic metallic implant materials

Stainless steels

Cobalt-base alloys

Ti & Ti-base alloys

Designation

ASTM F-138

ASTM F-75

ASTM F-67 (ISO 5832/II)

(‘316 LDVM’)

ASTM F-799

ASTM F-136 (ISO 5832/II)

ASTM F-1537

ASTM F-1295

(Cast and wrought)

(Cast and wrought)

Principal alloying

Fe(bal.)

Co(bal.)

Ti(bal.)

elements (wt%)

Cr(17—20)

Cr(19—30)

Al(6)

Ni(12—14)

Mo(0—10)

V(4)

Mo(2—4)

Ni(0—37)

Nb(7)

Advantages

f

cost, availability

f

wear resistance

f

biocompatibility

f

processing

f

corrosion resistance

f

corrosion

f

fatigue strength

f

minimum modulus

f

fatigue strength

Disadvantages

f

long term behavior

f

high modulus

f

power wear resistance

f

high modulus

f

biocompatibility

f

low shear strength

Primary utilisations

Temporary devices

Dentistry castings

Used in THRs with modular

(fracture plates, screws, hip nails)

Prostheses stems

(CoCrMo or ceramic) femoral heads

Used for THRs stems

Load-bearing components

Long-term, permanent

in UK (high Nitrogen)

in TJR (wrought alloys)

devices (nails, pacemakers)

2. Physical metallurgy of titanium alloys—a brief

overview

Titanium is a transition metal with an incomplete shell

in its electronic structure enables it to form solid solu-

tions with most substitutional elements having a size

factor within $20%. In its elemental form titanium has

a high melting point (1678°C), exhibiting an hexagonal

close packed crystal structure (hcp)

a up to the beta

transus (882.5°C), transforming to a body centered cubic

structure (bcc)

b above this temperature [61].

Titanium alloys may be classified as either

a, near-a,

a#b, metastable b or stable b depending upon their

room temperature microstructure [61, 62]. In this regard

alloying elements for titanium fall into three categories:

a-stabilizers, such as Al, O, N, C, b-stabilizers, such as

Mo, V, Nb, Ta, (isomorphous), Fe, W, Cr, Si, Ni, Co, Mn,

H (eutectoid), and neutral, such as Zr.

a and near-a

titanium alloys exhibit superior corrosion resistance with

their utility as biomedical materials being principally

limited by their low ambient temperature strength. In

contrast,

a#b alloys exhibit higher strength due to the

presence of both

a and b phases. Their properties depend

upon composition, the relative proportions of the

a/b

phases, and the alloy’s prior thermal treatment and

thermo-mechanical processing conditions.

b alloys (meta-

stable or stable) are titanium alloys with high strength,

good formability and high hardenability.

b alloys also

1624

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

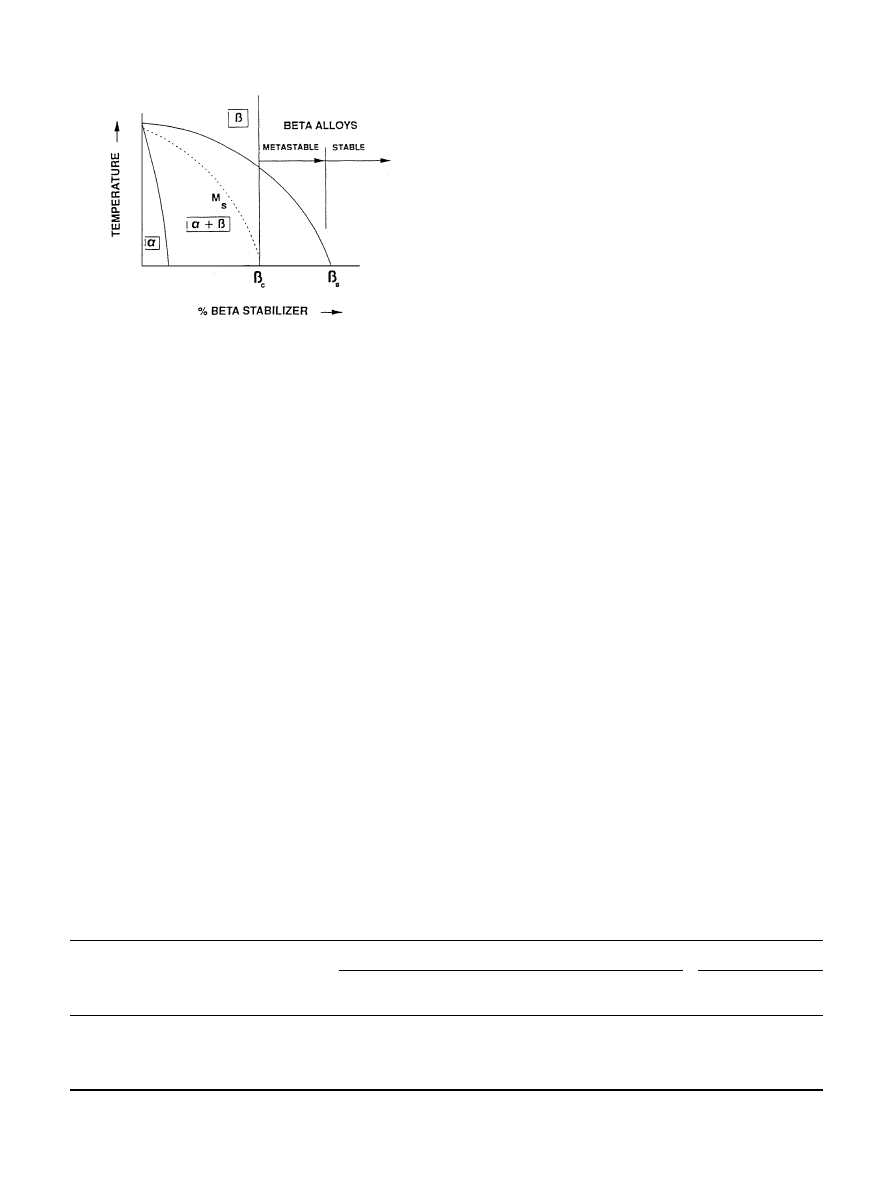

Fig. 4. Pseudo-binary phase diagram of Ti-

b stabilizer [63].

Table 3

Tissue reaction around metallic implants (adapted from [50, 51])

Classification by thicknesses of

Minor reaction

Severe reaction

pseudomembrane around implant

Titanium alloys

Fe, Co, Cr,Ni,

Stainless steels, CoCr alloys

Mo, V, Mn, Incoloy

Classification by type of reaction

‘Vital’

‘Capsule’

‘Toxic’

(cellular inflammatory, fibrous)

Ti, Zr, Nb, Ta,

Al, Fe, Mo, Ag, Au,

Co, Ni, Cu, V

Pt, Ti alloys

Stainless steels,

CoCr alloys

offer the unique possibility of combined low elastic

modulus and superior corrosion resistance [63, 64].

A

b-alloy is operationally defined as an alloy whose

chemical composition lies above

b#, (Fig. 4) that is, it

contains sufficient total

b stabilizer content to retain

100%

b upon quenching from above the b transus [63].

Alloys lying above this critical minimum level of

b-stabi-

lizer content may still lie within a two-phase region, with

the resulting as-quenched

b-phase being metastable with

the potential of precipitating a second phase upon aging.

Alloys with increasing alloying content ultimately ex-

ceeding a critical

b4 value are considered stable b alloys,

in which no precipitation takes place during practical

long-time thermal exposure.

Process variations are traditionally used to control the

alloy microstructure and therefore to optimize titanium

alloys properties, i.e. ductility, strength, fatigue resistance

or fracture toughness. The effects of various microstruc-

tures are then correlated with engineering properties,

with the most common microstructural features studied

in metastable

b alloys being b grain size and the size and

distribution of aged

a [65]. Apart from a phase, precipi-

tation of transient

b@ or u phases and/or intermetallic

compounds may be observed in metastable

b alloys de-

pending upon alloy composition, heat treatment, pro-

cessing history and service conditions [65, 66].

3. Biocompatibility and corrosion behavior of orthopaedic

titanium alloys

Studies of the biological behavior of metallic elements

have shown that the composition of biomaterials should

be carefully tailored to minimize adverse body reactions

[50, 51]. Local adverse tissue reactions or elicit allergy

reactions caused by metallic implants originate from the

release of metal ions from the implant. This release of

ions depends upon the corrosion rate of the alloy and on

the solubility of the first formed corrosion products. In

an in vivo corrosion study, Steinemann [51] concluded

that V, Ni, and Co were toxic elements while Ti and its

alloys, stainless steels and CoCrMoNi alloys, and Ta, Zr,

Nb, and Pt composed the class of ‘resistant metallic

biomaterials’ based on corrosion rates. Consideration of

corrosion product stability in tissue further limits this

choice [79, 84], Ti and some of its alloys, Ta, Nb, and Zr,

producing essentially insoluble oxides, Table 3.

Response to these observations initially resulted in the

development of two alloys, Ti—6Al—7Nb [47] and

Ti—5Al—2.5Fe [67], where Nb and Fe were substituted for

V in Ti—6Al—4V, V having been reported to be toxic

[50, 51] and to show adverse tissue effects [52]. These

alloys still, however, contained Al which has been sugges-

ted to be causal in osteolysis and neural disorders

[68, 69]. Subsequent

b-titanium alloys based on the

Ti—Mo system were then developed: ‘TMZF’ Ti—12Mo—

6Zr—2Fe [53, 54], Ti—15Mo—5Zr—3Al [55], and Ti—

15Mo—3Nb—3O (21SRx) [56], although the large per-

centage of Mo may still be potentially detrimental, Mo

having been associated with severe tissue reactions in

animal studies [52]. Elimination of Mo was preferred in

Ti—15Zr—4Nb—2Ta—0.2Pd

and

Ti—15Sh—4Nb—2Ta—

0.2Pd alloys [57], although here again elemental Sn and

Pd do not show complete biocompatibility. Ultimately,

development of Ti—13Nb—13Zr [58, 59] may have an-

swered the issue of biocompatibility with the exclusive

addition of biocompatible elements, i.e. Zr and Nb. An-

other group [70] has investigated the possible use of

titanium—zirconium binary alloys. Finally, recently

synthesized Ti—Nb—Zr—Ta ‘TNZT’ alloys [60] offer

the opportunity of minimizing potentially adverse tissue

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

1625

Table 4

Nature of oxides formed on titanium and its alloys (adapted from [71])

Material

Oxide

TiO2 Al2O3 Nb2O5 MoO3/MoO2 ZrO2

cp Ti

x

Ti—6Al—4V

x

x

Ti—5Al—2.5Fe

x

x

Ti—6Al—7Nb

x

x

x

Ti—15Mo—5Zr—3Al

x

x

x

x

Table 5

Orthopaedic alloys developed and/or utilized as orthopaedic implants and their mechanical properties (E"elastic modulus, YS"yield strength,

UTS"ultimate strength)

Alloy designation

Microstructure

E (GPa)

YS (MPa)

UTS (MPa)

cpTi

MaN

105

692

785

Ti—6Al—4V

Ma/bN

110

850—900

960—970

Ti—6Al—7Nb (protasul-100)

Ma/bN

105

921

1024

Ti—5Al—2.5Fe

Ma/bN

110

914

1033

Ti—12Mo—6Zr—2Fe (TMZF)

MMetastable bN

74—85

1000—1060

1060—1100

Ti—15Mo—5Zr—3Al

MMetastable bN

75

870—968

882—975

MAged b#aN

88—113

1087—1284

1099—1312

Ti—15Mo—2.8Nb—3Al

MMetastable bN

82

771

812

MAged b#aN

100

1215

1310

Ti—0/20Zr—0/20Sn-4/8Nb-2/4Ta#(Pd, N, O)

Ma/bN

N/A

726—990

750—1200

Ti—Zr

Cast

Ma@/bN

N/A

N/A

900

Ti—13Nb—13Zr

Ma@/bN

79

900

1030

Ti—15Mo—3Nb—0.3O (21SRx)

MMetastable bN#silicides

82

1020

1020

Ti—35Nb—5Ta—7Zr (TNZT)

MMetastable bN

55

530

590

Ti—35Nb—5Ta—7Zr—0.4O (TNZTO)

MMetastable bN

66

976

1010

CoCrMo

MAustenite(fcc)#hcpN

200—230

275—1585

600—1795

Stainless Steel 316 L

MAusteniteN

200

170—750

465—950

Bone

Viscoelastic composite

10—40

—

90—140

MOHAp#collagenN

150—400

!

! Compressive strength.

reaction through the restricted use of ‘biocompatible’ Nb,

Ta, and Zr.

As previously mentioned, the biocompatibility perfor-

mance of a metallic alloy is closely associated with

its corrosion resistance and the biocompatibility of its

corrosion products. Corrosion data show excellent resis-

tance

for

titanium

and

its

alloys

though

some

precautions should be taken in order to optimize their

composition [50, 51].

b-titanium alloys generally show

attractive corrosion behavior, their corrosion resistance

again depending on alloy composition and environment

[64]. For example, anodic polarization tests [53] in-

dicated that Ti—12Mo—6Zr—2Fe (TMZF)’s protective ox-

ide has a breakdown resistance equal to Ti—6Al—4V,

while corrosion current densities lower than that of cp

titanium were found for Ti—5Mo—5Zr—3Al alloy [55].

Electrochemical

measurements

of

Ti—13Nb—13Zr

[58, 59] also confirmed the potency of Ti, Nb, and Zr to

develop highly protective passive layers, resulting in

a much lower potential electrochemical interaction than

Ti—6Al—4V. Finally, Nb and Zr exhibit ideal passivity

and are not prone to chemical breakdown of the passive

layer, exhibiting minimum passive dissolution rates. In

fact, Nb and Zr contribute to the formation of a spontan-

eous highly protective passive film on titanium alloys and

are not, as are Al and V, released into the environment as

dissolved metal ions, but are rather incorporated into the

passive layer [58]. The latter report again emphasizes the

relationship between bulk alloy composition and the

nature of the surface oxides. Electropolishing studies

confirm this suggestion, Table 4, the authors noting that

when the alloying elements (except V and Fe) form an

oxide, those oxides occur as discrete clusters embedded in

a titanium oxide matrix [71]. Surface oxides composition

and/or distribution should be expected to affect the cor-

rosion behavior of orthopaedic alloys and detailed char-

acterizations of these surfaces are required in order to

adequately interpret and understand corrosion data to

optimize the ‘biocompatibility’ of titanium alloys.

4. Mechanical properties of orthopaedic titanium alloys

Alloy design and thermo-mechanical processing con-

trol of titanium alloys has allowed the production of

implant materials with enhanced properties. As shown in

Table 5, strength levels for orthopaedic alloys are gener-

ally acceptable with adequate ductility, as defined by

either the percent elongation or the percent reduction of

1626

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

Table 6

Typical modulus of elasticity of joints materials is use (adapted from

[2])

Joint material

Elastic modulus (GPa)

Articular cartilage

0.001—0.17

Natural rubber

0.0025—0.1

Silicone rubber

0.01

PTFE

0.5

UHMW-PE

0.5

Bone cement (PMMA)

3.0

Bone

10—30

TNZT alloys

55—66

‘New generation’ Ti-alloys

74—85

Ti—6Al—4V alloy

110

Zirconia

200

Stainless steel

205

Co—Cr—Mo alloy

230

Alumina

350

area in a standard tensile test, being retained at room

temperature. However there has been, and is still, con-

cern about the high elastic modulus of the alloys as

compared to bone, and the variable fatigue resistance of

the metallic implant. Both properties, if not optimized,

may eventually lead to prosthesis failure through loosen-

ing or fracture.

Long-term experience indicates that insufficient load

transfer from the artificial implant to the adjacent re-

modeling bone may result in bone resorption and event-

ual loosening of the prosthetic device [72, 73]. ‘¼olff ’s

¸

aw (‘The form being given, tissue adapts to best fulfill its

mechanical function’) suggests that the coupling of an

implant with a previously load bearing natural structure

may result in tissue loss. Indeed, it has been shown that

when the tension/compression load or bending moment

to which living bone is exposed is reduced, decreased

bone thickness, bone mass loss, and increased osteoporo-

sis ensue [74—76]. This phenomenon, termed ‘stress

shielding’, has been related to the difference in flexibility

or stiffness, dependent in part on elastic moduli, between

natural bone and the implant material [77]. Dowson [2]

appropriately pointed out that, as improvements in the

combinations of TJR sliding material pairs have been

recorded, the elastic modulus of the prosthetic materials

has been moving further away from those of the natural

joint they were intended to replace (Table 6). Any reduc-

tion in the stiffness of the implant, for example, through

substitution of present orthopaedic alloys with newer,

lower modulus materials, is expected to enhance stress

redistribution to the adjacent bone tissues, therefore min-

imizing stress shielding and eventually prolonging device

lifetime.

The problems related to implant stiffness-related-stress

shielding of bone have resulted in a number of proposed

solutions for more flexible designs and low modulus

materials. For example, carbon—carbon and carbon—

polymer composites, because of the ability to tailor their

elastic modulus closer to bone than metals [44, 47], have

been investigated as candidates for a new generation of

implants. However, they are far from being totally effec-

tive due to potential environmental degradation and

poor tribological behavior.

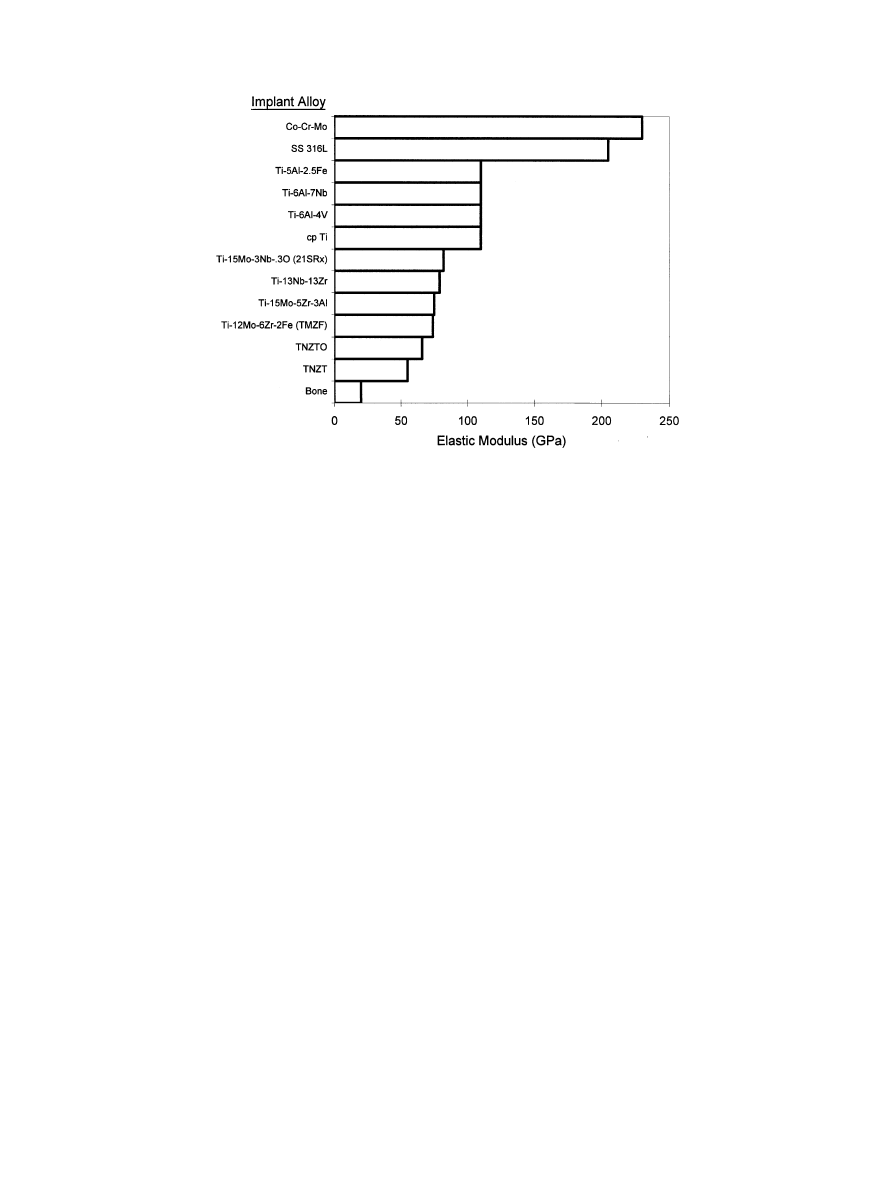

Alternatively, a first attempt at reducing the elastic

modulus of orthopaedic alloys was made by the intro-

duction of

a/b titanium alloys having elastic modulus

values approximately half that of stainless steels or

CoCrMo alloys (Fig. 5). However, the modulus of

Ti—6Al—4V and related

a/b alloys is still high (110 GPa),

approximately 4—10 times that of bone. Recent attempts

at further minimizing orthopaedic alloys moduli have led

to the introduction of metastable

b-titanium alloys,

Ti—15Mo—5Zr—3Al,

Ti—12Mo—6Zr—2Fe

(TMZF),

Ti—15Mo—3Nb—0.3O (21SRx) and Ti—13Nb—13Zr, hav-

ing minimum elastic modulus values ranging from 74 to

88 GPa (Fig. 5 and Table 5). The elastic modulus values

of these second generation

b-alloys are still 2—7 times

higher than E"0/%. Continued synthesis of minimum

modulus Ti—Nb—Zr—Ta alloys (TNZT) intended for or-

thopaedic applications has recently been demonstrated

[60], these alloys exhibiting moduli 20—25% lower than

other available alloys (Fig. 5).

Cyclic loading is applied to orthopaedic implants

during body motion, resulting in alternating plastic de-

formation of microscopically small zones of stress con-

centration produced by notches or microstructural

inhomogeneities. The interdependency between factors

such as implant shape, material, processing and type of

cyclic loading, makes the determination of the fatigue

resistance of a component an intricate, but critical, task.

Since testing an actual implant under simulated im-

plantation and load conditions is a difficult and expen-

sive process, standardized fatigue tests have been selected

for initial screening of orthopaedic material candidates,

joint simulator trials being generally reserved for a later

stage in the implant development process. ‘Standard’

fatigue tests include tension/compression, bending, tor-

sion, and rotating bending fatigue (RBF) testing, the

latter, a relatively simple test, being widely used to evalu-

ate orthopaedic metallic materials. Unfortunately, no

standard for fatigue evaluation of biomaterials testing

has yet been established, a variety of testing conditions

being encountered in reported fatigue studies of ortho-

paedic materials.

Nonetheless, Ti—6Al—4V is generally considered as

a ‘standard material’ when evaluating the fatigue resis-

tance of new orthopaedic titanium alloys. The mechan-

ical response of Ti—6Al—4V alloy is, however, extremely

sensitive to prior thermo-mechanical processing history,

e.g., prior

b grain size, the ratio of primary a to trans-

formed

b, the a grain size and the a/b morphologies, all

impacting performance, particularly high-cycle fatigue

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

1627

Fig. 5. Elastic modulus values of orthopaedic alloys.

lifetime (HCF) [78—80]. For example, maximum fracture

toughness and fatigue crack growth resistance is achieved

with Widmansta¨tten microstructures resulting from a

b

recrystallization anneal. However, this microstructure

results in inferior HCF performance, the development of

a bi-modal primary

a plus transformed b microstructure

being preferred [81] to prevent fatigue crack initiation.

Indeed, the transition to fine equiaxed, fine lamellar,

coarse equiaxed, and coarse lamellar leads to progressive

reductions in lifetime [82].

Further enhancement of the HCF resistance of

Ti—6Al—4V may be achieved, under careful control, by

shot peening. Shot peening is a cold working process in

which the surface is bombarded with small, typically

spherical media plastically deforming the surface. The

resulting compressive residual stresses may provide in-

creased part life when surface-related failure mechanisms,

such as fatigue or corrosion, are involved. While shot

peening may increase the fatigue limit, a balance between

the high compressive surface residual stresses and the

increased surface roughness produced during shot peen-

ing is required for optimal fatigue performance. Wagner

et al. [83—85], have suggested that since the high-cycle

fatigue strength for a smooth surface is determined by the

resistance to fatigue crack nucleation, shot-peening im-

proves HCF mainly though the beneficial influence of

residual compressive stresses on microcrack initiation

and propagation in the surface region. For instance,

shot-peening prior to grit blasting can increase by 10%

the fatigue strength of Ti—6Al—4V over grit blasting alone

[86]. In contrast, the increase of surface damage and

surface roughness due to shot peening (as well as poor

polishing or surface preparation) may induce early crack

initiation causing a reduction in the fatigue limit. Indeed,

electropolishing after shot-peening results in the highest

fatigue limit achievable (30% higher than unshot-peened)

[85].

The sensitivity of Ti-alloy fatigue properties to surface

condition is associated with their high notch sensitivity,

as exemplified by Ti—6Al—4V whose smooth RBF

strength is reduced by 40% with notched samples [87].

Various surface preparation techniques and treatments

may result in even larger reductions (up to 80%) in

fatigue strength [88]. This is illustrated by the effect of

surface finishing techniques on the fatigue strength of

a and a/b titanium alloys, where a reduction in fatigue

limit of as much as 80% may be observed (Table 7). For

biomedical applications the notch sensitivity of

a/b tita-

nium alloys is a critical factor in the performance of

porous-coated implant for cementless prostheses, where

the application of a bead- or wire-coating produces pref-

erential crack initiation sites at the porous-coating/sub-

strate interface. Porous-coated Ti—5Al—2.5Fe [89] and

Ti—6Al—4V [90] hip stems both show a large reduction in

the fatigue limit as compared to the smooth condition,

resulting in an unacceptable low fatigue resistance, i.e.,

below the suggested 425 MPa minimum required for

prostheses [91]. An FEM model of Ti—6Al—4V implants,

correlating with actual results, showed that the porous-

coated condition exhibits a HCF strength approximately

one-third the strength of the uncoated condition [92] due

to the poor fatigue crack initiation resistance of the

Ti—6Al—4V substrate. The latter substrate has, because of

the coating sintering treatment, been transformed to

1628

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

Table 7

Effect of surface preparation on the fatigue properties of

a and a/b titanium alloys

Titanium alloy

Test conditions

Fatigue limit

K

`

& "

(MPa)

!

cpTi

Mechanically polished [88]

234

—

Electrolytically polished

200

0.9

Ti—6Al—4V

Gentle surface grinding [88]

427

—

Gentle chemical machining

90

0.8

Abusive chemical machining

352

0.8

Abusive surface grinding

310

0.2

Polished (320—600 alumina grit) [86]

596

—

Belted and glass bead blasted

610

1.0

Belted, beaded, shot-peened, and grit blasted

505

0.9

Belted, beaded, and grit blasted

555

0.8

Ti—5Al—2.5Sn

Ultrasonic machined [88]

676

—

Shot peened

531

0.8

Ground

359

0.5

Electrical-discharge machined

145

0.2

! At 107 cycles.

" K& is a fatigue strength reduction factor defined as fatigue limit (surface treatment)/fatigue limit (smooth-control) under same test conditions.

Table 8

Smooth fatigue strength of orthopaedic titanium alloys

Alloy designation

Test conditions

Fatigue limit

!

Fatigue limit/

(MPa)

yield strength

cpTi

RBF(R"!1/100 Hz) [55]

430

0.6

Ti—6Al—4V

axial (R"!1/292 Hz) [87]

500

0.6

axial (R"0.1/292 Hz) [87]

330

0.4

RBF(R"!1/60 Hz)

610

0.7

Ti—6Al—7Nb

RBF(R"!1) [47]

500—600

0.7

Ti—5Al—2.5Fe

RBF(R"!1) [48]

580

0.8

Ti—15Mo—5Zr—3Al

RBF(R"!1/100 Hz) [55]

560—640

0.5

(aged

b#a condition)

Ti—13Nb—13Zr

axial (R"0.1/60 Hz) [59]

500

0.6

Ti—12Mo—6Zr—2Fe (TMZF)

RBF(R"!1/167 Hz) [53]

525

0.5

Ti—15Mo—3Nb—0.3O (21SRx)

RBF(R"!1/60 Hz)

490

0.5

TNZT

RBF(R"!1/60 Hz)

265

0.5

TNZTO

RBF(R"!1/60 Hz)

450

0.5

SS 316L

RBF(R"!1/100 Hz)

440

0.6

CoCrMo

RBF(R"!1) [91]

400—500

0.4—0.5

RBF(R"!1/100 Hz) [55]

500—580

—

! Fatigue limit at 107 cycles.

a low-crack-initiation-resistance

b-transformed coarse

lamellar microstructure, with associated high surface

stress concentrations at the coating/substrate interface

[92].

The introduction of new low modulus orthopaedic

titanium alloys has been accompanied with renewed real-

ization that the smooth fatigue resistance of

b-titanium

alloys is generally low [93, 94] when compared to

a/b

titanium alloys on an equivalent yield strength basis

(Table 8). Aging the SHT (Solution Heat Treated: heated

above

b-transus followed by rapid cooling) alloy below

the

b-transus will increase the fatigue resistance of meta-

stable

b-alloys by the transformation of the b-phase to

two-phase

a/b microstructures. For instance, the fatigue

limit of beta-C may be increased from 390 MPa in the

SHT condition to 650 MPa after a 16 h/530°C aging

treatment [94]. However, aging increases the elastic

modulus, therefore eliminating the benefit of modulus

reduction associated with

b-alloys. For instance, the elas-

tic modulus of Ti—15Mo—5Zr—3Al increases from 75 GPa

in SHT condition to 88—113 GPa after various aging

treatments [55].

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

1629

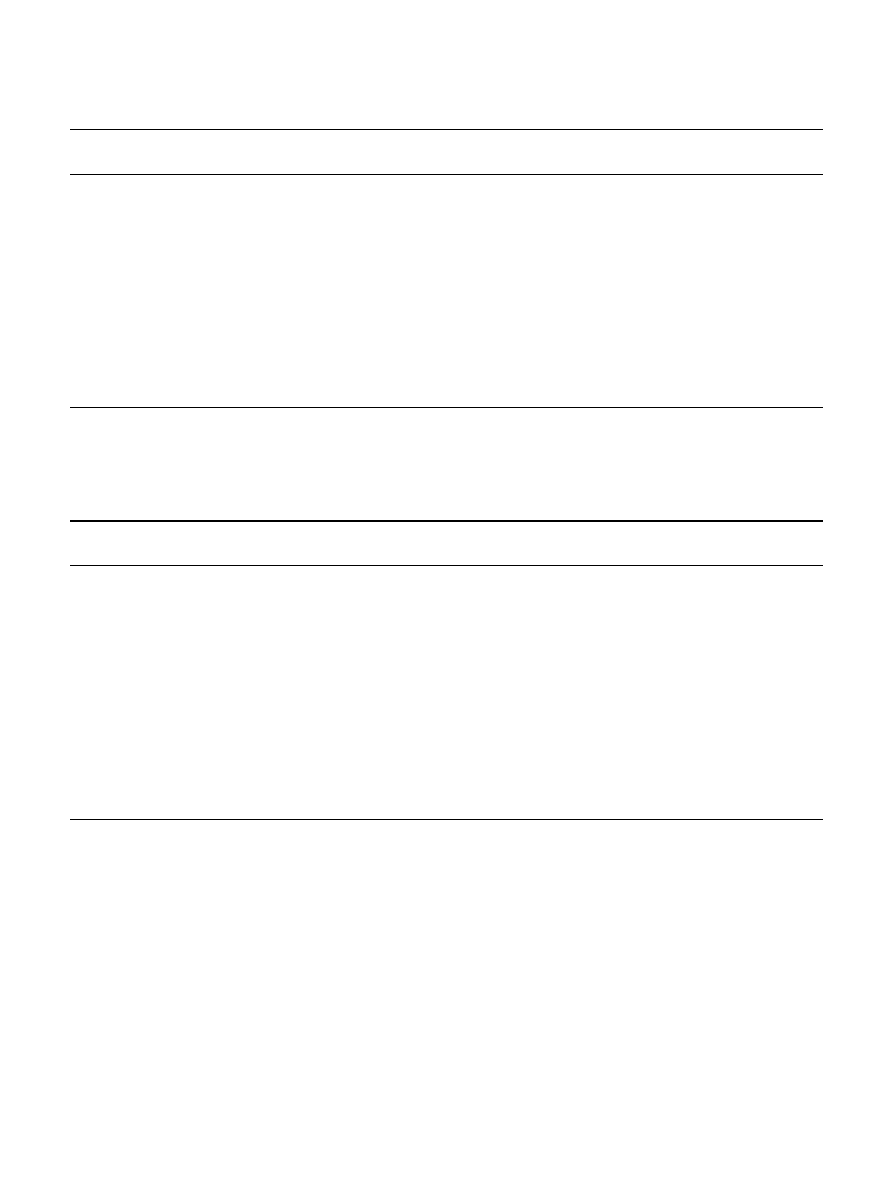

Fig. 6. Stress-controlled (RBF, R"!1, 60 Hz) fatigue response of new

metastable-

b Ti-alloys as compared to a#b Ti—6Al—4V.

Fig. 7. Total strain-controlled (RBF, R"!1, 60 Hz) fatigue response

of TNZT alloys and 21SRx as compared to Ti—6Al—4V.

Table 9

Notch fatigue strength of orthopaedic titanium alloys

Alloy designation

Smooth fatigue limit

Notch fatigue limit

K&"

K

Ti6Al4V

#

(MPa)

!

(MPa)

!

a/b alloys

Ti—6Al—4V

500

290 (K5"3.3)

0.6

—

290 (K5"3.3)

Ti—5Al—2.5Fe

580

300 (K5"3.6)

0.5

—

Ti—15Mo—5Zr—3Al

560—640

190 (K5"2.8)

0.3

1.0

(aged)

Martensitic

a@/b alloy

Ti—13Nb—13Zr

500

335 (K5"1.6)

0.7

1.0

215 (K5"3.0)

0.4

1.3

Metastable-

b alloy

Ti—12Mo—6Zr—2Fe

525

410 (K5"1.6)

0.8

1.4

! At 107 cycles.

" K& is a fatigue strength reduction factor defined as fatigue limit (notch)/fatigue limit (smooth control) under same test conditions.

# K

Ti6Al4V

is a fatigue strength factor relative to Ti—6Al—4V defined as fatigue limit (alloy)/fatigue limit (Ti6Al4V) under same test conditions.

Fatigue properties may also be improved by altering

the interstitial content (O, C, N, H) as illustrated by the

TNZT alloys (Fig. 6) [60]. Increasing the oxygen level in

TNZT resulted in an increase in strength and fatigue

limit for TNZTO, with some increase in modulus, the

latter value still, however, remaining below the presently

available orthopaedic alloys. A similar approach has

been undertaken in the development of TIMETAL

'

21SRx (21SRx), an orthopaedic grade of the TIME-

TAL

'

21S commercial alloy, where ‘toxic’ Al present in

the latter was eliminated in the former and compensated

by an increase in O content to 0.3 wt % in order to confer

additional strength to the Rx grade [56]. SHT-21SRx

show typical strength values for

b-titanium alloys with

a good fatigue behavior (only 15% lower than

Ti—6Al—4V) (Fig. 6).

Finally, the lower stress-controlled smooth fatigue

limit of

b-alloys may not be an appropriate characteriza-

tion for orthopaedic applications, where notch fatigue

behavior, more closely associated with strain-controlled

fatigue, may be more representative of in vivo conditions.

For example, hip stems rarely have a smooth surface but

are typically structured with wedges and coatings cre-

ating stress concentration sites. When considering fatigue

strain, i.e., the ratio between fatigue stress and elastic

modulus (Fig. 7), the strain-controlled fatigue behavior of

TNZT alloys is comparable to that of

a/b Ti—6Al—4V

alloy. Indeed a smaller reduction in fatigue limit occa-

sioned by the introduction of notches is typically ob-

served in

b-alloys when compared to Ti—6Al—4V, the

former exhibiting a comparable or higher notch fatigue

resistance than Ti—6Al—4V in all cases (Table 9).

5. Wear behavior of orthopaedic titanium alloys

Tribology, defined as the science and technology of

interacting surfaces in relative motion, and embracing

1630

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

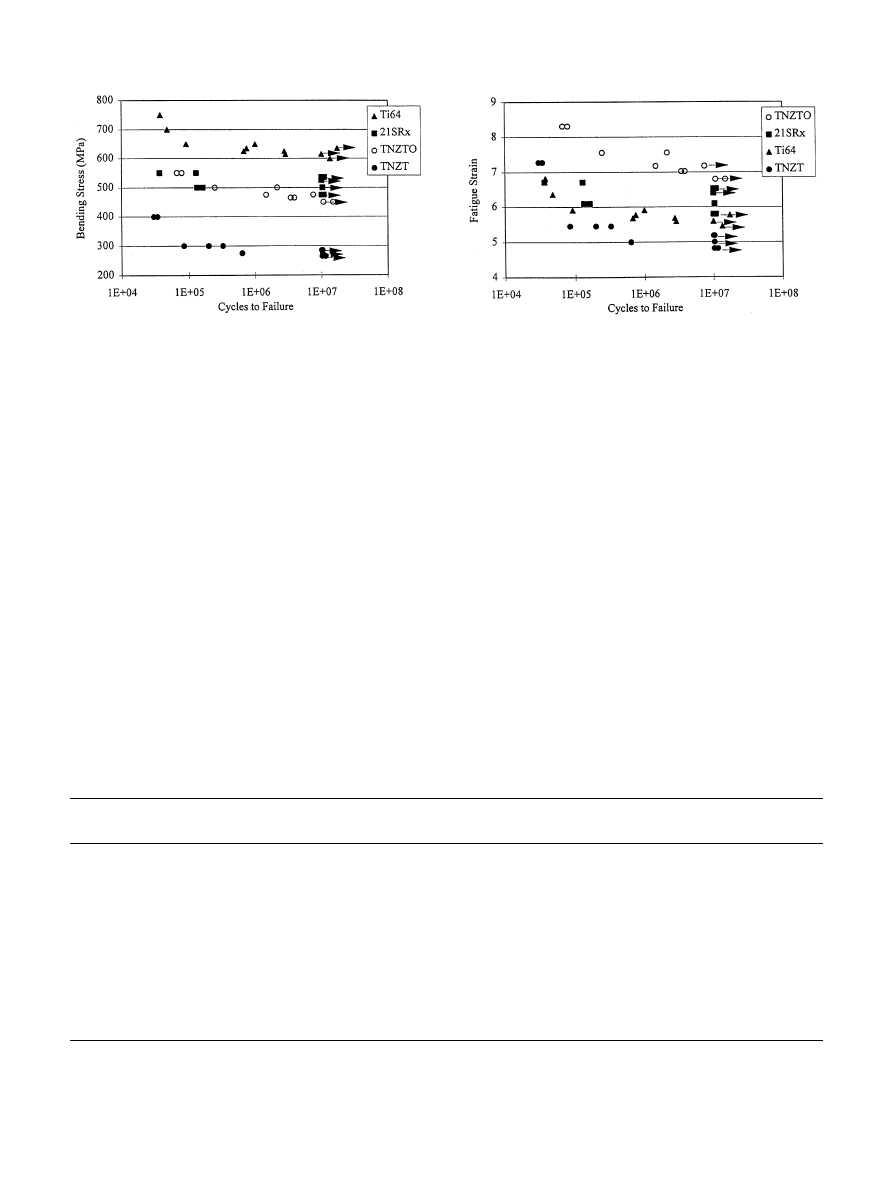

Fig. 8. Diagram illustrating the sequence of events during oxidative/abrasive/adhesive wear of the Ti—6Al—4V/UHMW-PE tribological pair (adapted

from [16]).

the study of friction, wear and lubrication [95, 96], has

emerged as a primary field in bioengineering. While

healthy natural joints exhibit remarkable tribological

characteristics, the latter being attributed to the intrinsic

properties of articular cartilage (high compliance) and

synovial fluid and the subsequent optimized lubrication

modes [1, 2, 97, 98], total replacement joints based upon

current available materials experience mixed/boundary

lubrication [6, 97]. This lower lubrication performance is

generally attributed to the high rigidity (low compliance)

of artificial materials. As some surface contact takes

place, friction between artificial materials is much higher

than in natural joints (

k"0.005—0.02) and non-recover-

able wear of the artificial joint materials takes place.

Clinical studies and retrieval examinations have shown

evidence that excessive wear of UHMWPE and/or metal

appears to be the principal mode of failure for the long

term use of TJRs [24—29, 30, 33]. Failure generally oc-

curs due to excessive wear of the components [99], wear

debris accumulation producing an adverse cellular re-

sponse leading to inflammation, release of damaging

enzymes, bone cell lysis, osteolysis, infection and pain,

implant loosening eventually ensuing [44, 45].

Early studies of Ti—6Al—4V wear performance in labo-

ratory tests has resulted in contradictory conclusions

[100]. Although the Ti—6Al—4V/UHMWPE combina-

tion seemed acceptable for use in total joint replacement

prosthesis, care should be taken as UHMWPE wear

rates for Ti—6Al—4V have been reported to 35% greater

than that for Co—Cr—Mo in hip simulator testing. Re-

trieval of implanted Ti—6Al—4V femoral components

have generally shown directional scratching and pitting/

delamination of bearing surfaces, those features being

non-uniformly distributed over the femoral head area

[27, 101, 102]. The high UHMWPE wear rates asso-

ciated with titanium alloy counterparts has been related

to the mechanical instability of the metal oxide layer

[16, 22, 103] (Fig. 8). It has been proposed that when

normal or shear stresses are high enough to induce

breakdown of the surface passive layer, the oxide will be

disrupted. The exposed metal surface may then either

reform a passive layer or adhesively bond to the polymer

surface. The latter situation leads to continuous removal

(material disruption) and reformation (oxidation) of the

passivating layer and results in gradual consumption of

alloy material. Concurrently, the surface roughness of the

metal surface will increase which results in yet higher

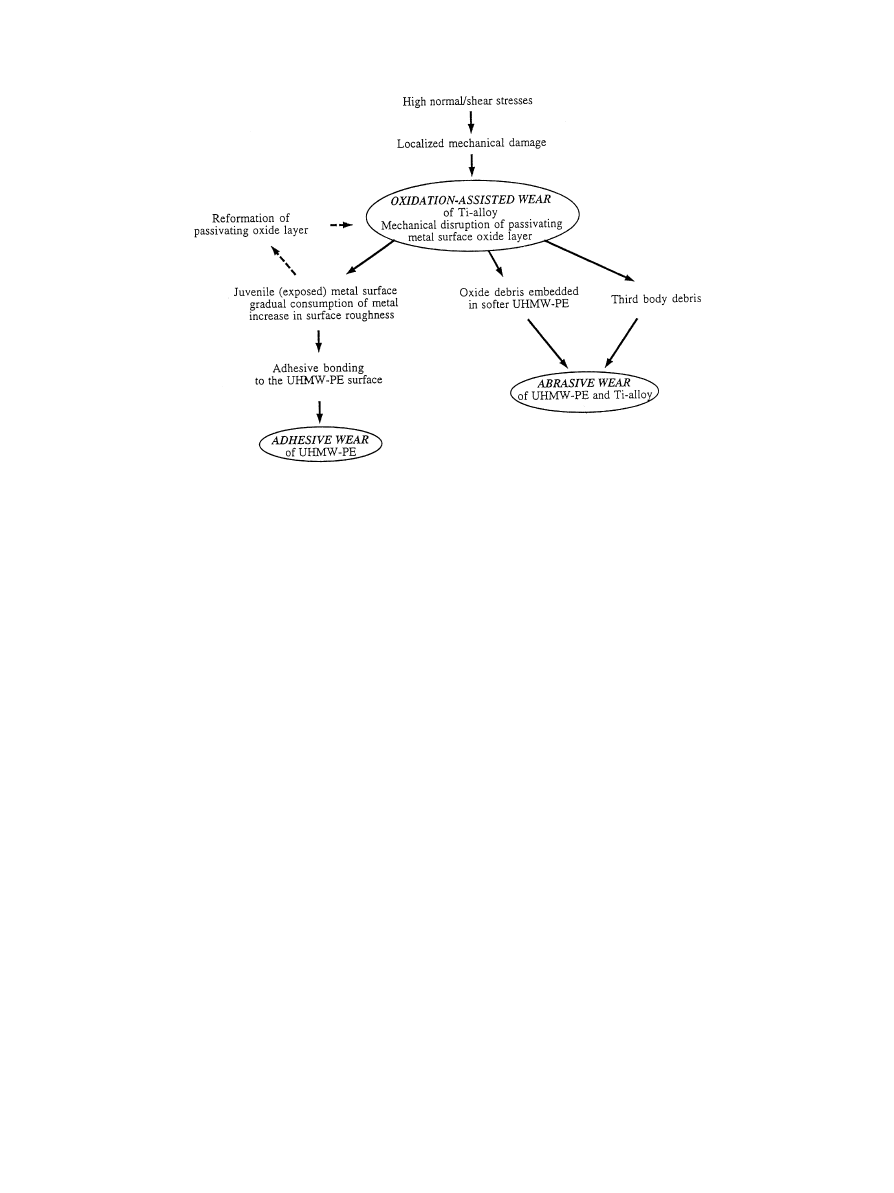

UHMWPE wear [104, 105]. Ultimately, the breakdown

of the oxide layer creates the potential for abrasive wear,

where the hard oxide debris act as third body abrasive

components (Fig. 9). Finally, it has also been observed

that excessive Ti—6Al—4V wear may be caused by the

presence of foreign bodies in the UHMWPE counterpart

component leading to severe abrasive wear of the

Ti—6Al—4V femoral head [27].

While wrought Co—Cr—Mo and ceramic (alumina and

zirconia) have been preferred to titanium alloys for bear-

ing surface UHMWPE counterpart implant materials,

UHMWPE wear and long-term degradation have gener-

ated renewed interest in metal-on-metal prostheses. In-

deed optimum friction and wear conditions can be

achieved and retained with metal-on-metal Co—Cr—Mo

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

1631

Fig. 9. Schematic illustration of the suggested oxidative/abrasive wear

process during articulation of metal on UHMWPE (adapted from Ref.

[16]).

Table 10

Oxides (dominant species) to be considered in aqueous solutions [113]

Alloying element

Oxide(s)

Ti

TiO, TiO2, Ti2O3, TiO3, Ti3O5

Nb

NbO, NbO2, Nb2O5

Ta

Ta2O5

Zr

ZrO2

pairs [10]. Notwithstanding this behavior the superior

biocompatibility and mechanical properties of titanium

alloys make them superior candidates for joint implants

should a better understanding of their tribological behav-

ior and an enhancement in their wear resistance be

achieved.

Detailed studies of titanium alloys friction and wear

performance are however sparse [106]. An original study

on friction and wear properties of

a-titanium has shown

poor wear characteristics for unalloyed Ti as well as

common titanium alloys [107]. This performance was

related to the properties of the oxide layer and the defor-

mation behavior of the subsurface regions.

a-titanium,

a relatively low shear strength hcp material, exhibited

higher

k values, but also greater material transfer, due to

its high reactivity, to non-metallic counterfaces, than

higher strength materials. Hence, titanium and titanium

alloys were considered to have poor oxidative wear res-

istance when ‘tribo-chemical’ reactions occur at the con-

tact area. In a fundamental tribological study of titanium

sliding against Al2O3 [108], the static formation of TiO2

was reported to decrease the wear and friction coefficient

of titanium. However, relatively high friction coefficients

(0.4—0.75) were observed at room temperature, these

values being in contradiction with the reported low fric-

tion coefficient of TiO2 (0.1—0.15) [109]. XRD analysis of

wear debris showed that TiO was a dominant oxide,

suggesting that the formation of TiO during tribo-oxida-

tion destroys the protective oxide layer and therefore

increases friction. It was proposed that the scaling layer

due to tribo-oxidation is composed, from surface to bulk

material, of a thin TiO2 layer, a thicker TiO layer, and

the Ti matrix. These findings were confirmed in another

study by analysis of wear debris revealing the cubic TiO

structure [110], this debris originating from regions

where critical wear was observed (‘smeared’ regions).

A non-continuous discrete layer of compacted wear frag-

ment was revealed, suggesting that the mechanical insta-

bility of this layer was responsible for the erratic and

high-friction behavior. Sufficient resistance of the under-

lying base material to plastic deformation is required for

mechanical integrity of the surface layer during rubbing

contact.

As the surface features of titanium alloys are of prime

importance of friction and wear resistance, the nature

and properties of the oxides present in the near-surface

region deserve special attention. Tribo-chemical reac-

tions during use, or even detailed surface treatments

before implantation, modify the surface characteristics of

the alloy [111, 112]. Further, bulk composition has been

shown to alter the composition of surface oxide layer, as

illustrated in Table 4, suggesting it may be possible to

optimize the mechanical response of this outermost layer

and improve its properties and integrity to the bulk

material through bulk chemical modification. For

example, the various ‘biocompatible’ oxides which could

possibly exist in a stable state in aqueous solution are

listed in Table 10 [113], where bold formulas correspond

to the surface oxide stable in potential-pH conditions

similar to human body fluids surrounding orthopaedic

implants [45].

However, care must be taken regarding the presence of

oxides at the surface and compositional effects cannot be

regarded as the only factor influencing the surface prop-

erties of oxides. The kinetics of repassivation (material-

electrolyte property) and the shear resistance of the oxide

layer (material property only) are two important para-

meters that will influence the behavior of the oxide layer

[114]. For instance, Ta tends to repassivate more rapidly

(96 ms) than Ti (172 ms) but more slowly than CoCrMo

(77 ms); Ta’s shear resistance (1.09 N mm

~2) is weaker

than Ti (3.7 N mm

~2) and CoCrMo (4.9 N mm~2), but

higher than Ti—6Al—4V (0.67 N mm

~2). Another study

[115] demonstrated that the presence of Ta and Nb

layers at the interface between Ti—30Ta and Al2O3 before

diffusion welding resulted in a reduction of the brittleness

of the interface and a decrease in the O and Al uptake of

the metal, and consequently a decrease in the brittleness

of the coupling. Oxide reaction at the interface might be

the cause of better bonding, reflecting the effect of com-

position on surface/interface properties.

In addition to the surface characteristics of titanium

alloys, a basic understanding of the mechanisms involved

in the friction and wear of titanium alloys is required with

particular attention on the subsurface deformation in-

duced during wear. High-strain deformation occurring in

the near-surface zone of a material undergoing wear is

1632

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

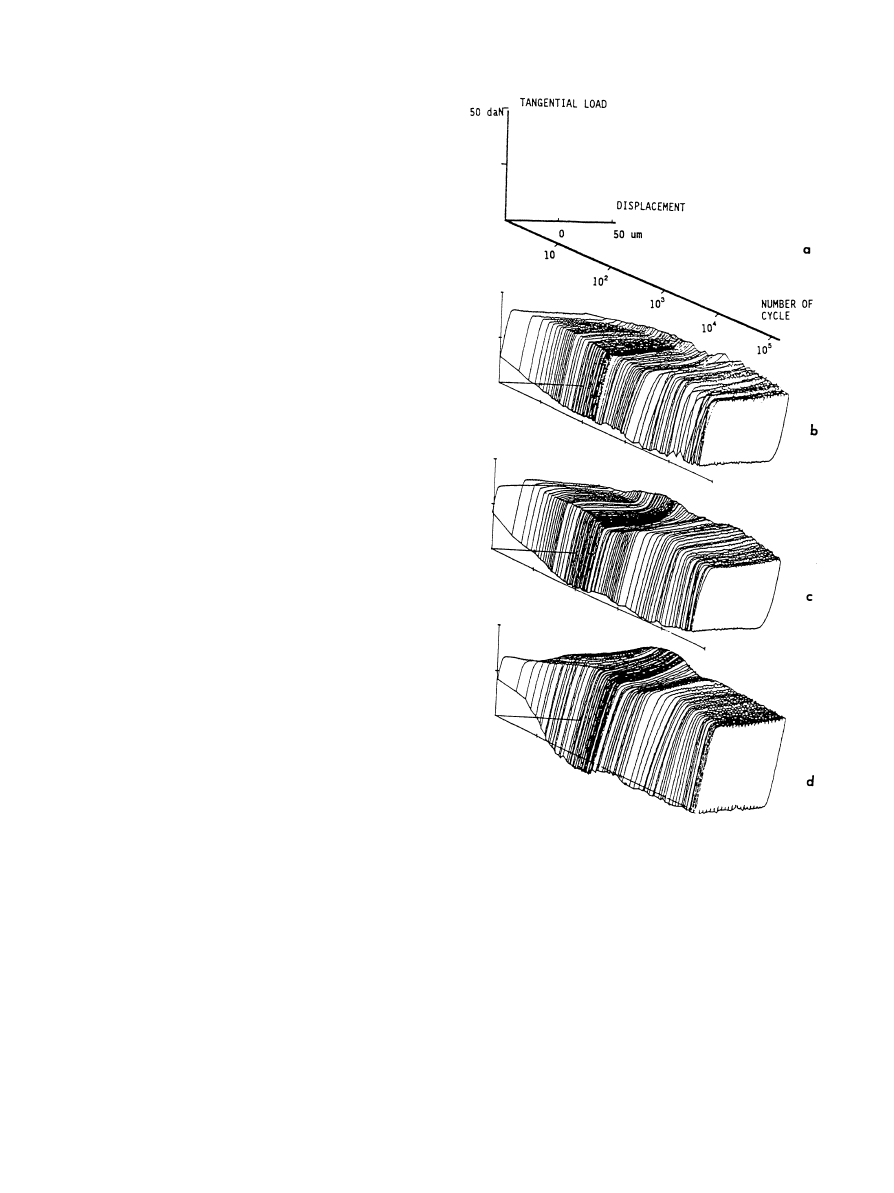

Fig. 10. ‘Friction log’ curves of titanium alloys: (a) definition of the

three axes, (b) aged ‘

a’-Ti—15V—3Cr—3Sn, (c) a#b-Ti—6Al—4V, (d) solu-

tion treated

b-Ti—15V—3Al—3Cr—3Sn [134].

a fundamental part of the wear process [116, 117] and

has been studied extensively in high stacking fault energy

materials such as copper alloys and aluminium [116—

119], but to a very limited extent in titanium alloys.

Sub-surface wear damage of cp-Ti has been investigated,

cross sections of wear samples revealing a layer of com-

pacted debris at the worn surface, with plastic flow be-

neath. Subsurface plastic flow was characterized by

a highly deformed cellular microstructure with a prefer-

red crystallographic orientation, validating dislocation

theories of friction and wear [120, 121]. While limited

data is available for

a-Ti, none exists for b-Ti, as typified

by the new orthopaedic alloys. However, if the low strain

hardening characteristics of

a/b titanium alloys [122] are

responsible for their low resistance to deformation within

the subsurface were region, then

b-titanium alloys, which

exhibit some strain hardening [123], may offer the poten-

tial for enhanced wear resistance [124].

Cyclic deformation behavior, due to the reciprocating

motion/loading of implants, is a critical element of ortho-

paedic alloys. While in-depth reciprocating-sliding stud-

ies of titanium and titanium alloys are not available,

fretting wear [131—137], resulting from low amplitude

((:300

lm)-reciprocating sliding motion between two

materials, has been studied in titanium and titanium

alloys [137—138]. As the displacement amplitude in-

creases, reciprocating sliding must be considered, that is

when wear mechanisms and wear rates may be related to

those in unidirectional sliding [96]. An important dis-

tinction between fretting and reciprocating-sliding wear

rises from the ease with which the wear debris can escape

from the contact region. After only a few strokes or

passes, the contact situation changes from a two to

a three-body contact formed by the two rubbing speci-

mens and the interface [135]. The wear process, resulting

from velocity accommodation both in the bulk and at the

interface, may be divided into three steps, i.e., (i) particle

detachment (by adhesion, abrasion, corrosion, fatigue,

etc.), (ii) third body behavior (trapped particle in the

interface region, changing in both morphology and com-

position), and (ii) particle ejection.

Waterhouse and Taylor [125] concluded from a fret-

ting study on pure titanium that fretting debris were

produced by the spreading of sub-surface cracks leading

to the detachment of phatelike particles of oxide coated

metal, this observation being consistent with the de-

lamination theory of wear during sliding. Further studies

of fretting behavior in titanium alloys have focused on

defining the particle detachment process and the evolu-

tion of the superficial layers during wear (gross slip con-

dition) [133, 134]. Fretting maps or friction logs were

obtained (Fig. 10) in titanium—titanium friction condi-

tions such that gross slip at the interface was achieved.

These curves were divided into two parts: (1) tangential

load linearly increasing with the displacement, corres-

ponding to the elastic response of the system and the

elastic deformation of the samples and the device, (2)

tangential load nearly constant with increasing displace-

ment, actual sliding taking place at the interface. Particle

detachment was observed in every case, and compacted

debris particle were observed on the wear track. The

friction coefficient was very high ('1) and slightly higher

for the

b alloy (1.2) than for the other a/a#b alloys (1.1).

In all alloys, a superficial layer with a tribologically

transformed structure, named ‘TTS’ by the authors,

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

1633

was observed. This TTS layer was formed of ultra fine

non-oriented grains of

a-titanium with no b-phase. The

thickness of this layer decreased with increasing

b con-

tent, from 100

lm (aged-Ti—15V—3Al—3Cr—3Sn) to 40 lm

(

a#b-Ti—6Al—4V) to 15 lm (b-Ti—15V—3Al—3Cr—3Sn).

Continuity between the TTS layer and the bulk alloy was

also reported, with cracks being observed in the TTS

region. The authors concluded that the thickness of the

debris layer, and thus that of the TTS, is a very critical

parameter, directly controlling the stress transmitted to

the surface and near-surface layers. The detachment of

wear particles was then associated with propagation of

the cracks in the TTS or at the interface between the TTS

and the bulk material. Here intense plastic deformation

occurred, wear debris particles, characterized as TiO and

TiO2 oxides, originating from the TTS layer. Formation

of this TTS was ascribed to deformation-induced trans-

formation, the transformation of the near-surface zones

leading to the formation of the more stable phase, with

the major controlling parameters being strains ampli-

tudes and rates. Two types of microstructural changes

were observed in the superficial layers of the titanium

alloys after friction: (i) transformation of

b-phase, and (ii)

formation of the ultra-fine grained

a-phase. While the

authors concluded through limited evidence that the

metastable

b-phase transformed to a, their X-ray data

can also be interpreted as the formation of stress-induced

orthorhombic martensite,

aA [66, 138]. Stress-induced

martensite and twinning around wear scratches were also

observed in Ti—6Al—4V. It was finally suggested that the

mechanisms of particle detachment are related to plastic

deformation of the superficial and subsurface layers, but

correlations with reciprocating/fretting sliding or con-

tinuous sliding observations were not fully established.

However, it can be agreed that the mechanisms of par-

ticle detachment during fretting wear are closely related

to those observed in continuous/reciprocating sliding,

i.e., formation of a highly deformed layer, transfer layer,

particle detachment/delamination, and third body (de-

bris, lubricant) contact. Introduction of the influence of

cyclic loading and consequent fatigue behavior still need

to be addressed.

The poor tribological properties of Ti—6Al—4V for im-

plant articulation surfaces has resulted in the develop-

ment of surface treatments to enhance the hardness and

the abrasive wear resistance of the alloy and thereby to

minimize UHMWPE wear debris generation [23, 103,

139, 140]. Various procedures including PVD coating

(TiN, TiC), ion implantation (N

`), thermal treatments

(nitriding, diffusion hardening) [141], or laser alloying

with TiC [142] have been examined. Ion-implantation

has been the most common treatment employed

[22, 140, 143], resulting in either little or substantial im-

provement in the sliding wear resistance of Ti—6Al—4V,

though there has been reported consistent improvement

in wear resistance to abrasion [139]. While surface treat-

ments producing a harder layer composed of various

oxides improve lubrication, no long term data are yet

available and the limitation of such surface treatments to

the modification of only a thin layer ((10

lm in best

cases) may promote catastrophic wear as the treated

surface wears away or become discontinuous.

Surface modification by oxygen diffusion hardening

(ODH) has been considered to enhance the wear resis-

tance of Ti—6Al—7Nb [144]. This treatment provides

a gradual increase in hardness through a relatively thick

50

lm transformed layer and a friction coefficient for

ODH—Ti—6Al—7Nb against UHMWPE lower than other

low wear materials (Table 11). A similar approach was

taken by Zwicker et al. [67] for enhanced friction behav-

ior of Ti—5Al—2.5Fe against UHMWPE (Table 11), using

oxide films formation by thermal oxidation. Properly

oxidized and oil quenched Ti—5Al—2.5Fe balls displayed

friction properties comparable to alumina balls based

on topography measurements made before and after

testing.

Sliding wear tests have also been conducted in order to

assess the wear properties of the newer titanium alloys

(Table 11). In general, improved friction and wear behav-

ior has been observed, with or without surface treatment,

relative to Ti—6Al—4V. In a pin-on-disk study against

PMMA cement in deionized water, the friction coeffic-

ient of TMZF was found to be less than half that of

Ti—6Al—4V [53, 54]. At low load and after 10

5 cycles,

TMZF exhibited no change in surface roughness and no

surface scratching. The ‘self-perpetuating’ wear asso-

ciated with Ti—6Al—4V, where the formation of third

body metallic and bone cement particles results in high

weight loss of both parts and black debris from the

titanium alloy, was not observed with the TMZF alloy.

When tested against UHMWPE, the friction coefficient

of the TMZF alloy was again half the value of Ti—6Al—4V

against UHMWPE.

Diffusion/oxidation surface hardening (DH) was very

beneficial in improving the abrasive wear of TI—13Nb—

13Zr to levels comparable to Co—Cr—Mo alloy and much

superior to TiN-coated Ti—6Al—4V [59] (Table 11). This

diffusion hardening process produced a hardened surface

by diffusion of oxygen into the substrate, and not by

deposition of an overlay coating on the substrate, as in

the case of N-implantation. A blue ceramic surface layer,

0.2

lm thick, composed of TiO2, TiO, and ZrO2, was

formed on the alloy, the depth of the diffusion hardened

layer being 2—3

lm. The presence of ZrO2 oxides in the

‘ceramic’ surface of diffusion hardened Ti—13Nb—13Zr

resulted in improved wear resistance to abrasion sugges-

ting again that the composition of the oxide layer can be

tailored through composition control of bulk composi-

tions in order to optimize the surface properties of ortho-

paedic alloys and improve their wear resistance.

Future improvements in the wear resistance of ortho-

paedic titanium alloys will eventually develop from a

1634

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

Table 11

Summarized tribological studies of orthopaedic titanium alloys

Titanium alloy

Tribo-test conditins

!

Friction/wear data

[‘Reference’ material]

[load-stress/sliding velocity]

(same conditions)

Ti—6Al—7Nb [47, 48]

Pin-on-disk, Ringer’s#30% serum

k

k-value (

]10~7)

k

k-value

Abrasive PMMA pin [3.45 MPa/25 mm s

~1]

0.100

3.32 (N

`)

(

]10~7)

0.078

2.11 (TiN)

0.094

2.72 [CoCrMo]

0.051

1.35 (ODH

")

0.079

2.13 [Al2O3]

Ti—5Al—2.5Fe [67]

Pin-on-disk, 0.9% NaCl-solution

Depth (

km) of wear track on disk

UHMWPE disk [50N]

18—44 (polished)

N/A

#

12—24 (oxidized)

Ball-in-socket, 0.9% NaCl-solution

Friction moment (Nm)

Friction moment (Nm)

UHMWPE socket [100—2500 N]

0.5—1 (oxidized, induction hardened)

1.5 [Al2O3]

Ti—15Mo—5Zr—3Al [55]

NaCl-solution

k

wear

k

wear

Other parameters N/A

#

0.82(SHT

b) (SHTb)"3](SS316L)

0.43—0.53

cpTi"2

]SS

0.43—0.53

(

b#a)$"3](SS316L)

[SS, cpTi]

(

b#a)$

Ti—12Mo—6Zr—2Fe [53]

Pin-on-disk, deionized water

k

k

abrasive PMMA pin [100 g/74 mm s

~1]

0.30—0.44

:

0.80 [Ti—6Al—4V]

UHMWPE pin [500 g/73 mm s

~1]

0.04

0.08 [Ti—6Al—4V]

Ti—13Nb—13Zr [59]

Reciprocating pin-on-disk, Ringer’s

Depth (

km) of metal wear track

Depth (

km)

PMMA pin [107 MPa/74 mm s

~1

(2.5 Hz/15 mm)]

Ti—13Nb—13Zr

Ti—13Nb—13Zr(ODH

")

0.21

21 [Ti—6Al—4V]

0.15

7.8 [Ti—6Al—4V/TiN coated]

! Tribo-part in italics is titanium alloy.

" ODH: Oxygen Diffusion Hardening.

# Not Available.

$ Aged condition.

systematic approach based on achieving a basic under-

standing of their tribological properties. Though suc-

cessful in many cases, the ‘trial and comparison’ ap-

proach exemplified in Table 11 by the inconsistent proto-

cols followed, has limited progress in improving bi-

omaterials properties [145]. Because of the complexity of

tribology and wear problems, a systematic approach

aiming at understanding basic mechanisms, suitable to

a large number of non-specific applications, should

be implemented. More specifically, the separate invest-

igation of surface, subsurface, and third body (debris)

behaviors, the three wear ‘precursors’ as described

by Sannino and Rack [146] could ultimately identify

basic wear mechanisms while avoiding misleading extra-

polation when different experimental parameters are se-

lected.

6. Conclusions

1. Titanium alloys are generally preferred mateials for

orthopaedic applications due to their relatively low

modulus vis-a`-vis Co—Cr—Mo alloys, superior biocom-

patibility and corrosion resistance.

2. Enhanced biocompatibility and reduced elastic

modulus in titanium alloys have been achieved by the

recent development of biomedical alloys baed on

b-solu-

tion treatment (metastable

b or martensite a@#b) micro-

structures.

3. The wear resistance of

b-Ti alloys show some im-

provement when compared to

a#b alloys.

4. Overall alloy composition, which controls surface

oxide composition and subsurface deformation behavior,

is a critical factor in the wear behavior of

b-alloys.

5. Ultimately the use of orthopaedic titanium alloys as

wear components will require a more detailed under-

standing of the basic wear mechanisms involved.

Acknowledgements

The authors would like to acknowledge the partial

support of Osteonics, Inc. (Allendale, NJ), Teledyne-AL-

LVAC (Monro´e, NC), and TIMET (Henderson, NV).

The authors wish to thank Jonathan Black, Ph.D., FBSE,

for his review of this manuscript and his valuable com-

ments. Special thanks are due to Martine LaBerge,

Ph.D., for numerous beneficial discussions.

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

1635

References

[1] Mow VC, Soslowsky LJ. Friction, lubrication, and wear of

dirthridial joints. In: Basic orthopaedic biomechanics. New

York: Raven Press Ltd., 1991:245—92.

[2] Dowson D. Bio-tribology of natural and replacement synovial

joints. In: Mow VC, Ratcliffe A, Woo SL-Y, editors. Bio-

mechanics of diarthrodial joints, vol. II. Chap. 29. New York:

Springer, 1992:305—45.

[3] Ardill J. What is orthopaedics? PhD Thesis. The Department of

Orthopaedic Surgery, The Queen’s University of Belfast, 1995.

[4] Schumacher HR. In: Schumacher HR, Klippel JH, Robinson

DR, editors. Primer on the Rheumatic Diseases, 9th edn. At-

lanta, GA: The Arthritis Foundation, 1988.

[5] Lowman EW. Osteoarthritis. J Amer Med Acad 1955;157:487.

[6] Dowson D. Friction and wear of medical implants and pros-

thetic devices. ASM Handbook, vol. 18. Gereland: Materials

Park, OH: ASM International, 1992:656—64.

[7] American Academy of Orthopaedic Surgeons. Survey Presented

at the Orthopaedic Research Society Annual Meeting. Orlando,

FL, February 1995.

[8] McKee GK, Watson-Farrar J. Replacement of arthritic hips by

the McKee-Farrar prosthesis. J Bone J Surg 1996;48-B(2):

245—59.

[9] Walker PS, Gold BL. The tribology (friction lubrication and

wear) of all-metal artificial hip joints. Wear 1971;17:285—99.

[10] Protek AG. METASUL

TM metal-on metal articulation. Tech-

nical brochure, Protek AG, Switzerland, Edition 2/94, 1994.

[11] Streicher RM, Scho¨n R, Semlitsch M. Investigation of the

tribological behavior of metal-on-metal combinations for artifi-

cial hip joints. Biomedizinische Technik 1990;35(5):3—7.

[12] Charnley J. Arthroplasty of the hip. Lancet 27 May 1961:1129—32.

[13] Charnley J. Total hip replacement by low-friction arthroplasty.

Clin Orthop Relat Res 1970;72:7—21.

[14] Galante JO, Rostoker W. Wear in total hip protheses. Acta

Orthp Scand Suppl 1973;145:1—46.

[15] Dumbleton JH. Wear and prosthetic joints. In: Morrey BF,

editor. Joint replacement arthroplasty, Chap 6. New York:

Churchill Livingstone, 1991:47—9.

[16] Poggie RA, Wert JJ, Mishra AK, Davidson JA. Friction and

wear characterization of UHMWPE in reciprocating sliding

contact with Co—Cr, Ti—6Al—4V, and zirconia implant bearing

surfaces In: Denton R, Keshavan MK, editors. In: Wear and

friction of elastomers. ASTM STP 1145, Philadelphia, PA:

American Society for Testing and Materials, 1992:65—81.

[17] McKellop H, Clarke IC, Markolf KL, Amstutz HC, Friction and

wear characteristics of polymer, metal, and ceramic prosthetic

joint materials evaluated on a multichannel screening device.

J Biomed Res 1981;15:619—53.

[18] Oonishi H, Tsuji E, Mizukoshi T, Fujisawa A, Murata N,

Kushitani S, Aono M, Meguro Y. Wear of polyethylene and

alumina in clinical cases of alumina total knee prosthesis. In:

Hulbert J, Hulbert SF, editors. Bioceramics 3. Terra Haute, IN:

Rose-Hulman Institute of Technology, 1992:137—45.

[19] Oonishi H, Aono M. Clinical results of total knee arthroplasty in

combination with alumina against polyethylene—a five to eight

year follow up study. In: Hulbert J, Hulbert SF, editors. Bio-

ceramics 3. Terra Haute, IN: Rose-Hulman Institute of Techno-

logy, 1992:147—56.

[20] Saikko V. Wear and friction properties of prosthetic joint mate-

rials evaluated on a reciprocating pin-on-flat apparatus. Wear

1993;166:169—78.

[21] Saikko V. Wear of polyethylene acetabular cups against zirconia

femoral heads studied with a hip joint simulator. Wear

1994;176:207—12.

[22] Buchanan RA, Rigney ED Jr, Williams JM. Wear-accelerated

corrosion of Ti—6Al—4V and nitrogen-ion-implanted Ti—6Al—4V:

mechanisms and influence of fixed-stress magnitude. J Biomed

Mater Res 1987;21:367—77.

[23] Peterson CD, Hillberry BM, Heck DA. Component wear of total

knee prostheses using Ti—6Al—4V, titanium nitride coated

Ti—6Al—4V, and cobalt-chromium-molybdenum femoral com-

ponents. J Biomed Mater Res 1988:22.

[24] Agins HJ, Alcock NC, Bansal M, Salvati EA, Wilson PD, Pel-

licci PM, Bullough PG. Metallic wear in failed titanium-alloy

total hip replacements. J Bone J Surg 1988;70-A(3):347—56.

[25] Argenson J-N, O’Connor JJ. Polyethylene wear in meniscal knee

replacement. J Bone J Surg 1992;74-B(2):228—32.

[26] Berry DJ, Wold LE, Rand JA. Extensive osteolysis around an

aseptic, stable, uncemented total knee replacement. Clin Orthop

Relat Res 1993;293:204—7.

[27] Black J, Sherk H, Bonini J, Rostoker WR, Schajowicz F, Galante

JO. Metallosis associated with a stable titanium-alloy femoral

component in total hip replacement. J Bone J Surg 1990;72-A(1):

126—30.

[28] Cates HE, Faris PM, Keating EM, Ritter MA. Polyethylene

wear in cemented metal-backed acetabular cups. J Bone J Surg

1993;75-B(2):249—53.

[29] Engh GA, Dwyer KA, Hanes CK. Polyethylene wear of metal-

backed tibial components in total and uncompartimental knee

prostheses. J Bone J Surg 1992;74-B(1):9—17.

[30] Winter M, Griss P, Scheller G, Moser T. 10—14 years results of

ceramic-metal-composite hip prostheses with a cementless

socket. In: Heimke G, editor. Bioceramics, vol. 2. Cologne,

Germany:

Deutsche

Keramische

Gesellschaft

eV,

1990:

436—44.

[31] Jones SMG, Pinder IM, Moran CG, Malcom AJ. Polyethylene

wear in uncemented knee replacements. J Bone J Surg 1992:

74-B:18—22.

[32] Kabo JM, Gebhard JS, Loren G, Amstutz HC. In vivo wear of

polyethylene acetabular components. J Bone J Surg 1993;75-B:

254—58.

[33] Nolan JF, Bucknill TM. Aggressive granulomatosis from poly-

ethylene failure in an uncemented knee replacement. J Bone

J Surg 1992;74-B(1):23—4.

[34] Santavirta S, Nordstro¨m D, Metsa¨rinne K, Kontinnen YT. Bio-

compatibility of polyethylene and host response to loosening of

cementless total hip replacement. Clin Orthop Relat Res 1993;

297:100—10.

[35] Shanbhag AS, Jacobs JJ, Glant TT, Gilbert JL, Black J, Galante

JO. Composition and morphology of wear debris in failed un-

cemented total hip replacement. J Bone J Surg 1994;76-B(1):

60—7.

[36] Jacobs JJ, Shanbag A, Glant TT, Black J, Galante JO. Wear

debris in total joint replacements. J Amer Acad Orthop Surg

1994;2(4):212—20.

[37] Dumbleton JH. The clinical significance of wear in total hip anf

knee prostheses. J Biomater Appl 1988;3:3—32.

[38] Ries MD, Rose RM, Greer J, Weaver KD, Sauer WL. Steriliza-

tion-induced effects on UHMWPE performance properties. Sci-

entific Exhibition Presented at the 62nd Annual Meeting of the

American Academy of Orthopaedic Surgeons. Orlando, FL,

16—21 February 1995.

[39] Sutula LC, Sperling DK, Collier JP, Saum KA, Williams IR.

Clinical wear of UHMWPE acetabular and tibial compo-

nents—impact of gamma sterilization in air and material con-

solidation. Scientific exhibition Presented at the 62nd Annual

Meeting of the American Academy of Orthopaedic Surgeons.

Orlando, FL, 16—21 Februay 1995.

[40] White SE, Whiteside LA, Poggie RA, Farrar D, Tanner MG.

In-vivo wear and material properties of UHMWPE tribial com-

ponents. Scientific Exhibition Presented at the 62nd Annual

Meeting of the American Academy of Orthopaedic Surgeons.

Orlando, FL, 16—21 February 1995.

1636

M. Long, H.J. Rack / Biomaterials 19 (1998) 1621—1639

[41] Wright Medical Technology Inc. Effects of sterilization methods

on UHMWPE. Technical Monograph Presented at the 62nd

Annual Meeting of the American Academy of Orthopaedic

Surgeon. Orlando, FL, 16—21 February 1995.

[42] Streicher RM, Semlitsch MF, Weber H, Schon R. Metal-on-

metal articulation: a new generation of wear resistant implants.

Transactions of the 20th Annual Meeting of the Society for

Biomaterials. Boston, MA, April 1994:323.

[43] Medley JB, Krygier JJ, Bobyn JD, Chan FW, Tanzer M.

Metal—metal bearing surfaces in the hip: early wear results from a

simulator apparatus. Transactions of the 21st Annual Meeting of

the Society for Biomaterials. San Francisco, CA, April 1995:47.

[44] Park JB, Lakes RS. Biomaterials—An introduction, 2nd edn.

New York, London: Plenum Press, 1992.

[45] Black J. Biological performance of materials—fundamentals of

biocompatibility, 2nd edn. New York: Marcel Dekker Inc., 1992.

[46] Freese H, Teledyne-Allvac, Monroe NC. Private communica-