Form No. F –K400037/8B

CATALOGUE CARD

K4-15-082

ISSUE 3

DFME

DAMEL S.A.

MINING INDUCTION MOTORS

SP3(2) 315M-4, SP3(2) 315L-4

PAGE

1/4

File No: 132, 160 kW SP3(2) 315M-4, SP3(2) 315L-4.doc/2005

Translated by: PTU -DAMAR- Sosnowiec

APPLICATION.

One-speed motors of type SP3(2) with mechanical value of 315 are intended for driving mining

machines and equipment , especially for driving belt conveyors and scraper belt conveyors.

The motors can be used in underground parts of mines and surface installations of the mines, where

there are possible explosion conditions for methane and/ or coal dust.

There is also possible to operate the motors in the surroundings where the explosion-proof equipment

is not required.

CHARACTERISTIC FEATURES OF MOTORS

•

Induction 3-phase motors with welded squirrel-cage rotor,

•

Explosion-proof construction with flame-proof casing of motor „d” - mark

I M2 EExd I or

II

2G EExd IIAT4, equipment ranked as group I of category M2 or group II category 2G according

to Directive 94/9/EC,

•

The degree of protection IP 55 acc. to PN-EN 60034-5:2002U,

•

The motors are cooled by air – own fan – IC 411,

•

Form of execution:

− flanged execution – IM 3001(B5) – designation of type SP3…., flange FF600(500),

− arm - flanged execution – IM 2001(B3/B5) – designation of type SP2 …. flange FF600(500),

• Voltage execution:

– one voltage 380∆, 500Y, 660Y; 1000Y; 1140V Y – 50Hz,

– two voltage switch able in terminal box:

∆/Y: 380/660V; 660/1140V – 50Hz,

YY/Y: 500/1000V – 50Hz,

After settlement it is possible to execute the motors for other voltage in the range 380 to 1140V

and frequency of 60Hz.

•

Class of insulation: class H – primary execution, class H + reinforced wound insulation –

execution against order,

•

Thermal protection of motors: bimetal sensors NC or posistor PTC sensors in winding and

bearing nodes – two identical circuits basic and stand-by .

•

Temperature control: thermometric resistors Pt 100 in winding and bearing nodes (execution

against order).

•

Three – inlet terminal box, equipped with one or two cable inlets with rubber gaskets selected to

the outer diameters of conductors, type Wk3u/d100… or Wk2u/d80… and inlet Wk2u/d47…

produced by DAMEL (Catalogue Card K4-15-136),

•

The motor is equipped with the final link of protection conductor continuity control circuit,

mounted in the terminal box – primary execution: final unit CK-0A

After settlement the assembly of final unit CK of other type is possible (e.g. diode+resistor,

reverse polarity, etc.) produced by DAMEL (Catalogue Card K4-15-121).

• Feeding and start-up: the motors are intended for feeding from power network – start-up by direct

switching on the voltage,

• The motors adapted for work in temperate climate; after settlement the adaptation for work in

tropical climate TA or TH is possible.

COMPATIBILITY WITH REQUIREMENTS OF STANDARDS

The motors meet requirements of Directive 94/9/EC (ATEX), European harmonized standards and

domestic norms:

- norms for electrical equipment in areas of explosion hazard:

-

EN 50014:1997+A1:1999+A2:1999 – Polish equivalent PN-EN 50014:2002U,

-

EN 50018:2000+A1:2002 – Polish equivalent PN-EN 50018:2002U,

-

EN 50019:2000 – Polish equivalent PN-EN 50019:2002U,

- norms for rotational electric machines:

-

EN 60034-1:1998+A1:1998+A2:1999+AC:2000 – Polish equivalent PN-EN 60034-1:2001

- domestic norms for induction motors for mining machines:

- PN G-38010:1997 (domestic norm).

Form No. F –K400037/8B

CATALOGUE CARD

K4-15-082

ISSUE 3

DFME

DAMEL S.A.

MINING INDUCTION MOTORS

SP3(2) 315M-4, SP3(2) 315L-4

PAGE

2/4

File No: 132, 160 kW SP3(2) 315M-4, SP3(2) 315L-4.doc/2005

Translated by: PTU -DAMAR- Sosnowiec

CERTIFICATES

The motors have certificates:

− certificate EC (ATEX) issued by notified Testing Station GIG KD “BARBARA”, valid on the

area of European Union.

TECHNICAL DATA

Table 1

Parameters

SP3(2) 315M-4

SP3(2) 315L-4

Rated power P

N

[kW]

132

160

Current at rated voltage

I

N

[A] 660V

I

N

[A] 1000V

I

N

[A] 1140V

138

91

80

167

110

96,5

Power coefficient

cos

φ

0,89 0,89

Efficiency

η

[%] 94

94,3

Rotational speed n

[1/min]

1476

1476

Rated moment M

N

[Nm]

854

1035

Multiplicity of start-up current

I

K

/I

N

6,0

6,6

Multiplicity of start-up moment

M

K

/M

N

2,2

2,2

Multiplicity of critical moment

M

max

/M

N

2,0

2,0

Mode of operation

S1;

S4-60%, 40c/h, J

ext

/J

M

=1

Rotor moment of inertia J

M

[kgm

2

] 4,5

5,0

Mass of motor: flanged execution

arm-flanged execution

kg

1260

1330

1320

1390

1. The parameters of motor: rated current, efficiency, power factor, rotational speed and rated

moment relate to rated load at rated feeding conditions – 50Hz.

2. Multiplicities of start-up current , start-up moment and critical moment refer to direct

connection of the motor to the supply network (mains).

3. J

ext

– inertia moment of motor load referred to the shaft of motor.

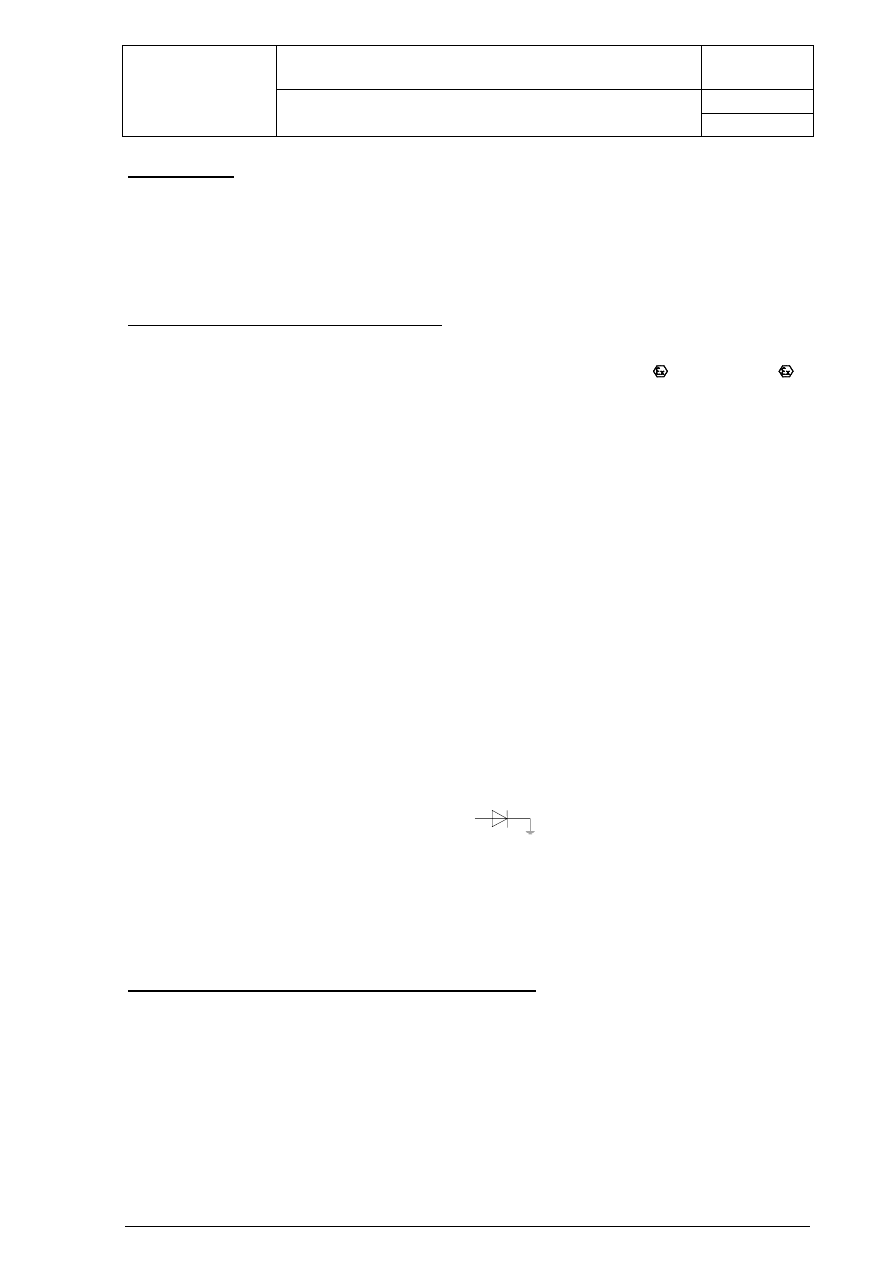

Fig.1 Diagram of motor connections – winding, final unit and protective terminals

Fig.2 Diagram of connections of temperature sensors

one voltage motors

switchable two voltage motors ∆/Y switchable two voltage motors YY/Y

winding bearing

winding

bearing

bimetal sensors NC or posistor sensors PTC

winding

bearing

bimetal sensors NC or posistor sensors PTC and resistors Pt 100

Form No. F –K400037/8B

CATALOGUE CARD

K4-15-082

ISSUE 3

DFME

DAMEL S.A.

MINING INDUCTION MOTORS

SP3(2) 315M-4, SP3(2) 315L-4

PAGE

3/4

File No: 132, 160 kW SP3(2) 315M-4, SP3(2) 315L-4.doc/2005

Translated by: PTU -DAMAR- Sosnowiec

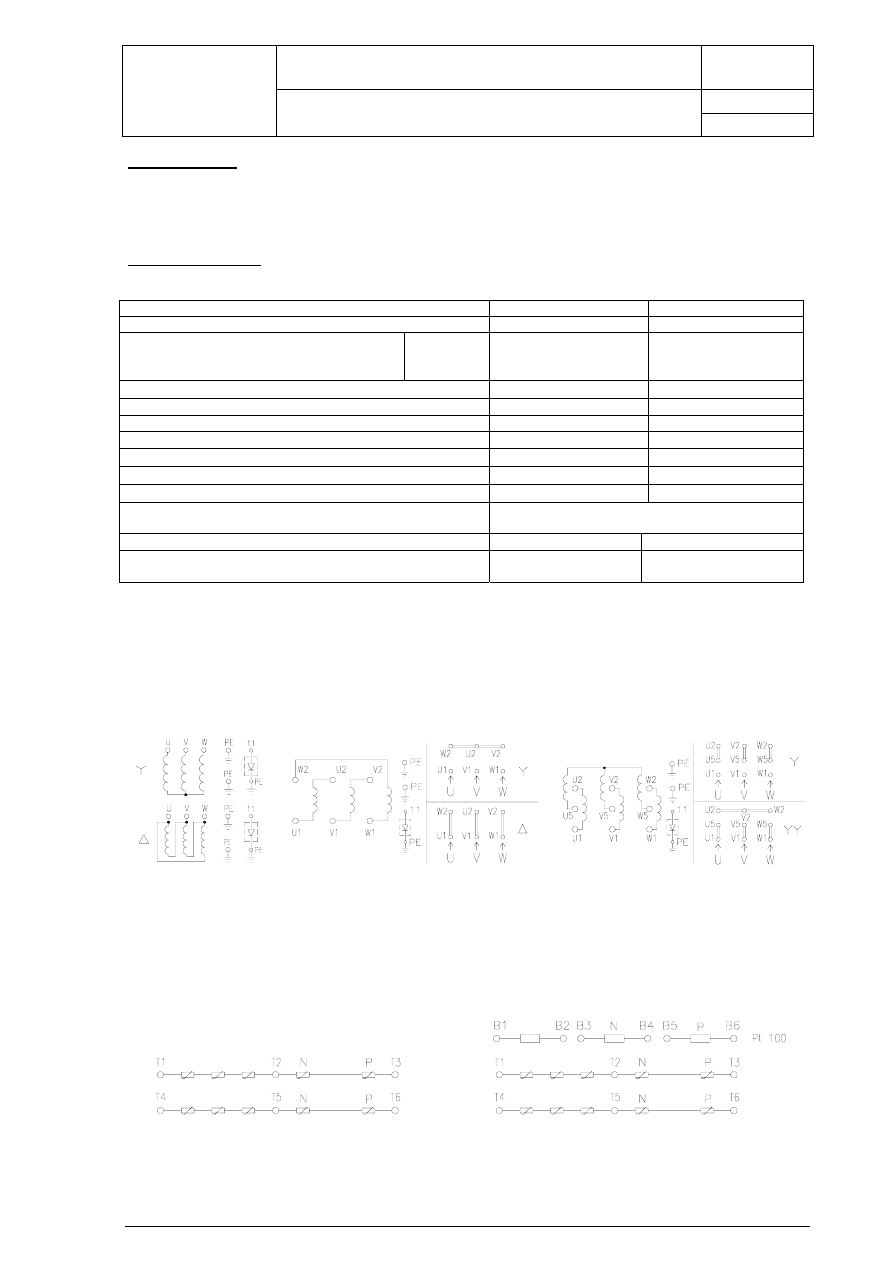

Fig. 3 Overall and assembly dimensions

CONDITIONS OF OPERATION AND APPLICATION

• Ambient temperature

0

0

÷40

o

C

• Relative humidity at temperature of 35

o

97÷100%

• Height above the sea level

≤ 1000m

• Degree of corrosive aggressiveness C acc. to PN-71/H-04651

• Admissible inclination of the shaft axis to level

< 30

o

• Supply voltage

(0,95÷1,05)U

N

Power supply connection – mining armor conductor with rubber armor and insulation, multicore,

screened for the voltage of 0.6/1kV with section area of cores selected to operating conditions.

Connection of circuits of temperature sensors and temperature control thermometric elements –

auxiliary cores of feeder armor flexible cable or multicore (control) armored conductor with

section area of conductors up to 4mm

2

.

When connecting the motor with one conductor the other inlet of terminal box is FLP stopped by

stopper Zk3u, Zk2u.

• Leading the armor conductors to terminal box through cable inlets selected according to the outer

diameter of conductors acc. to table 2.

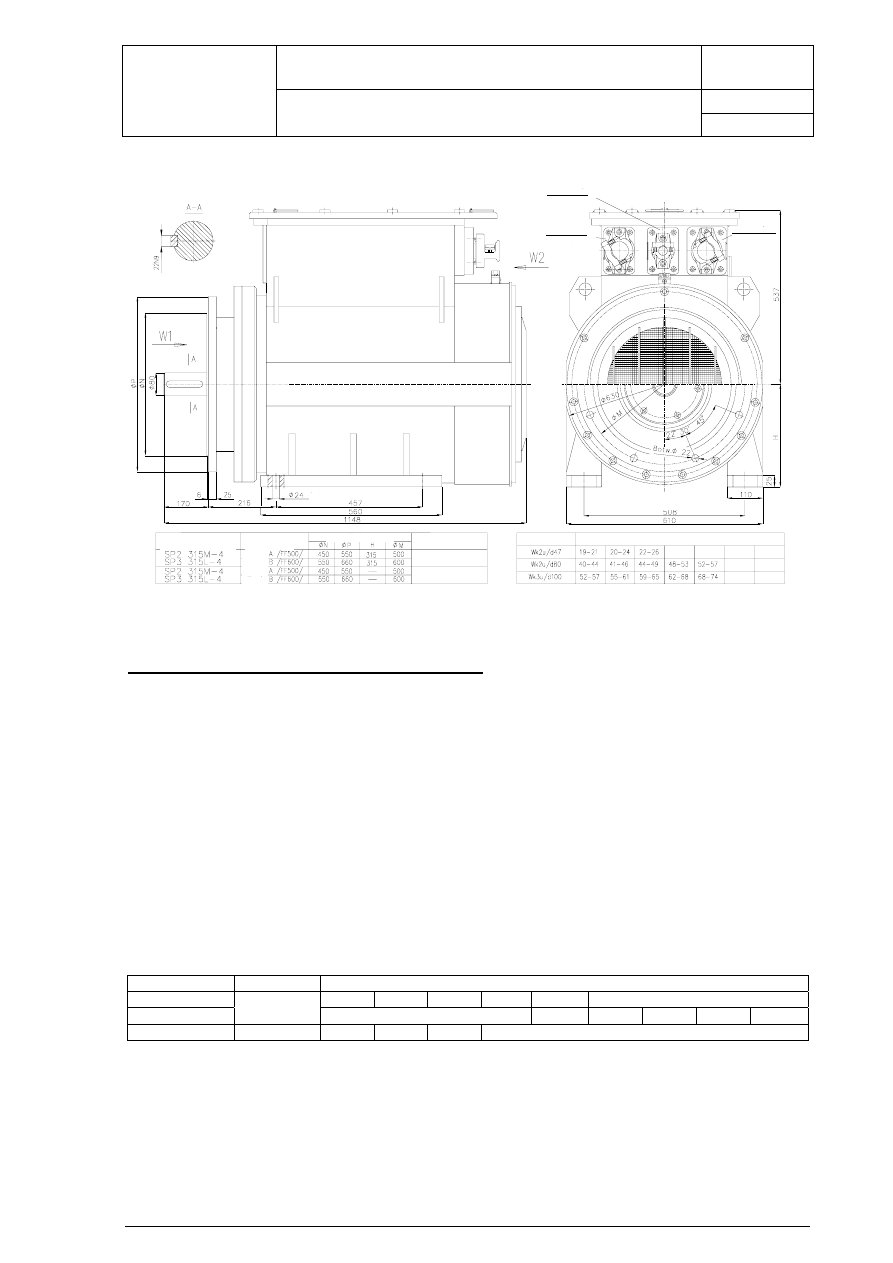

Table 2

Type of inlet

Conductor

The range of diameters of conductors for cable inlets

Wk2u/d80

40÷44 41÷46 44÷49 48÷53 52÷57

Wk3u/d100

Feeder

cable

52÷57 55÷61 59÷65 62÷68 68÷74

Wk3u/d47

Pilot

wire

19÷21

20÷24

22÷26

In case the Orderer does not state the type of cable inlet (outer diameter of conductor) the motor is

delivered with cable inlet and stopper acc. to table 3.

4 holes

View W2

Inlet Wk2u/d47

or stopper Zk2u

Inlet Wk2u/d80

or stopper Zk2u

Inlet Wk3u/d100

or stopper Zk3u

View W1

Type of motor

Execution

Version

Version

Version

Version

Dimensions

Modification

Arm – flanged

Flanged

Type of inlet

The range of diameters of gaskets of cable inlets

Form No. F –K400037/8B

CATALOGUE CARD

K4-15-082

ISSUE 3

DFME

DAMEL S.A.

MINING INDUCTION MOTORS

SP3(2) 315M-4, SP3(2) 315L-4

PAGE

4/4

File No: 132, 160 kW SP3(2) 315M-4, SP3(2) 315L-4.doc/2005

Translated by: PTU -DAMAR- Sosnowiec

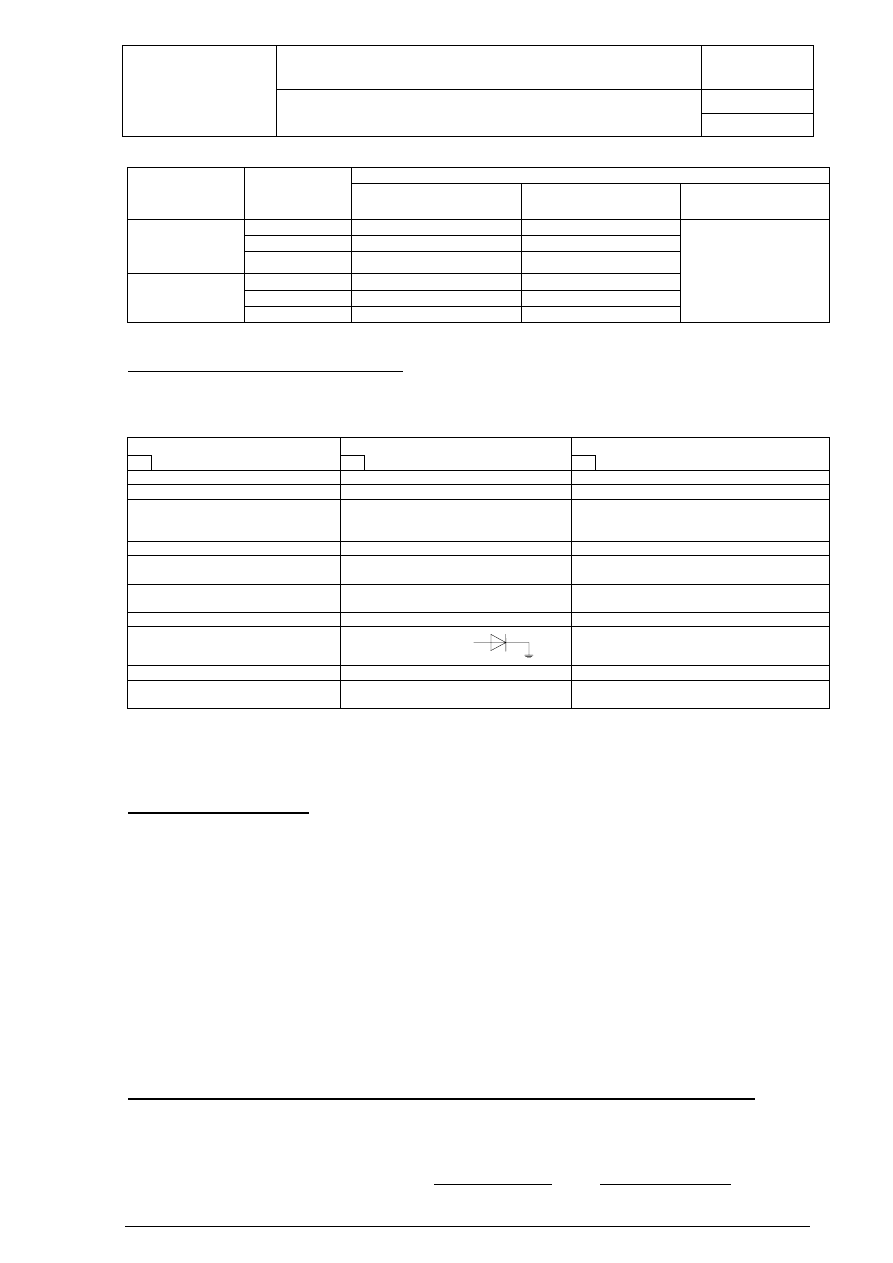

Table 3

Primary execution

Type of motor

Power

Supply voltage

Inlet Wk3u/d100…

or stopper Zk3u

Wk2u/d80…

or stopper Zk2u

Wk2u/d47…(control)

or stopper Zk2u

500V Wk3u/d100-52-57

Zk2u

660V Zk3u

Wk2u/d80-41-46

SP3(2) 315M-4

132kW

1000V, 1140V

Zk3u

Wk2u/d80-40-44

500V Wk3u/d100-59-65

Zk2u

660V Zk3u

Wk2u/d80-48-53

SP3(2) 315L-4

160kW

1000V, 1140V

Zk3u

Wk2u/d80-41-46

Zk2u

OFFER FOR DELIVERIES OF MOTORS

The producer offers motors in primary execution and in options executed against the customer order (additional,

diversified equipment).

Table 4

1

Constructional characteristic

of motor

2

Primary execution

3

Execution against order

rated voltage

500; 660; 1000; 1140V

500/100V; 660/1140V and other up to 1140V

frequency 50Hz

50/60Hz

form of execution

Version B - FF600

flanged IM 3001(B5)

Version A or B – FF500 or FF600

flanged IM 3001(B5)

arm - flanged IM 2001 (B3/B5)

class of insulation

H

H + reinforced wound insulation

thermal

protection – type of sensors

bimetal NC

posistor PTC

temperature control

– thermometric elements

–

thermometric resistors Pt100

cable inlets

see table 3

see table 2

final link

of control circuit

CK-0A

CK … appointed by Orderer

(acc. to catalogue card K4-15-121)

climatic execution

for mild climate

for tropical climate TH or TA

constructional characteristic other

than above mentioned

–

acc. to settlements, it can require acceptance

of the unit certifying the product

The following items are included to the delivered motor by producer:

- Technical & Operational Documentation (Service Manual of the motor).

- declaration of conformity EC.

ORDERING PROCEDURE

The following data should be stated in the order directed to the address of manufacturer given below:

-

type of motor, power

-

rated voltage and frequency

-

motor execution: preliminary – see table 4 column 2 or execution against order, for which

required equipment and constructional characteristic should be determined acc. to table 4

column 3.

When ordering we recommend to fill up the questionnaire „Statement of technical data of the motor...”

– accessible at internet (web) sites and in Marketing Department of DFME DAMEL.

The producer offers additionally:

- guarantee and after guarantee service,

- delivery of spare parts,

- training of employees in the range of correct maintenance and operating the motor.

Producer reserves the right to implement to the motor changes resulting from technical progress.

Dąbrowska Fabryka Maszyn Elektrycznych DAMEL S. A.

Aleja Józefa Piłsudskiego 2, 41-300 Dąbrowa Górnicza, POLSKA, tel: (32) 262-32-30 do 39

Faks (32) 264-34-26, 264-10-12, http: www.damel.com.pl, email: office@damel.com.pl

Elaboration: „DAMEL” – TK/LP/05/2005

Wyszukiwarka

Podobne podstrony:

132 kW, 3SG4 315M 4

132, 150 kW, SG6 570M 4, SG6 570M 4A

How to install HD Audio driver?ter installation of slipstreamed XP SP3

VESPEL SP3

Integracja dodatku SP3 z obrazem płyty instalacyjnej Windows XP

Audio Research SP3 riaa sch

pracekontrolne sp3 2009

Windows XP Professional SP3 (32bit) VLK CD [PL] [. iso], Windows - Systemy

Wytrzymalosc-sp3, Studia, Materiałoznastwo, Metaloznastwo i Podstawy Obrobki Cieplnej, Meteloznastwo

Piknik Sp3

klucz do xp sp3

Instalacja i aktywacja Pervasive 11 SP3

cd key ( windows xp home SP3)

Win XP SP3 PL styczeń 10 działa OK

Metylowanie i arylowanie wiązań C H sp2 i sp3 prostych kwasów karboksylowych z zastosowaniem katali

więcej podobnych podstron