Product Notes

What is the latest permanent

magnet technology development?

For high power permanent magnet (PM)

machines in the MW range the first wind

turbine applications have required

constructions with high pole numbers and

low speeds. With permanent magnet material

it is easy to design high pole number rotors.

In order to develop PM machines for higher

speeds, with 4 to 8 poles, the solutions and

constructions required are somewhat

different.

For higher speeds ABB has developed an

efficient rotor design that meets the

requirements of this application. It features

effective utilization of PM materials and

strong, robust and reliable construction. The

cooling arrangement has also been

developed to take advantage of the lower

losses, especially in the rotor.

In this solution the excitation is provided by

the permanent magnets. No windings are

therefore needed in the rotor, and excitation

losses in the rotor are also eliminated.

What are the main features?

frame size: 500 mm

nominal speed: 1500 rpm

typical speed range: 25...125 %

efficiency: > 98 %

power range: up to 3600 kW

What are the benefits for

customers?

The customer benefits are based on the

smaller size and higher efficiency of

permanent magnet generators. High

efficiency means better utilization of the wind

energy, i.e. more electrical power is produced

from the same amount of wind energy. The

compact size and reduced overall weight

provide benefits in the construction of the

nacelle.

There are also benefits in the machinery

design, as PM generators are easier to keep

cool. Low rotor losses with PM generators

mean the rotor can be kept at a lower

temperature, which in turn reduces the

bearing temperature.

What are permanent magnet

materials?

Ferromagnetic materials sustain their

magnetization after the external magnetic

field is removed. In commercial permanent

magnet materials this hysteresis effect

-which is controlled by the phase structure of

the material- is so strong that almost all of the

magnetic polarization generated by the

external field is retained after the field is

removed. When a piece of this material is

magnetized, it also generates a magnetic field

outside of itself. This property forms the basis

for the technical applications of permanent

magnets.

The most efficient materials available today

are so-called Neo or Nd-Fe-B magnets, these

are multiphase compounds, predominantly

manufactured using powder metallurgy. Their

main constituents are iron, neodymium and

boron. Some grades also contain dysprosium

and cobalt.

New Permanent Magnet Generator for

Wind Turbine Applications

PM304 RevA,Sep 03

Specifications subject to change without notice.

2.5 MW PM-generator

file oma.pmd

19.9.2003, 12:13

1

Product Notes

Are permanent magnet

generators

high or low speed machines?

The generators can be built for either high or

low speed depending on the requirements of

the wind turbine machinery. The generator

speed can be selected to match the choice of

gear ratio. The generator size is minimized in

high speed installations.

How are the high efficiency levels

achieved?

The high efficiency of permanent magnet

generators is mainly based on

their operating principle, with

excitation provided by the

permanent magnets. No

windings are therefore needed

in the rotor, and excitation

losses in the rotor are also

eliminated. This results in a

substantial increase in

efficiency, as excitation

losses typically represent 20

to 30 percent of overall

generator losses.

ABB Oy

Electrical Machines

Finland

Tel:

+358 10 22 11

Fax:

+358 10 22 22427

www.abb.com/motors&drives

Excitation losses are minimized in permanent

magnet generators, and this contributes to the

high efficiency of these generators over the whole

output range.

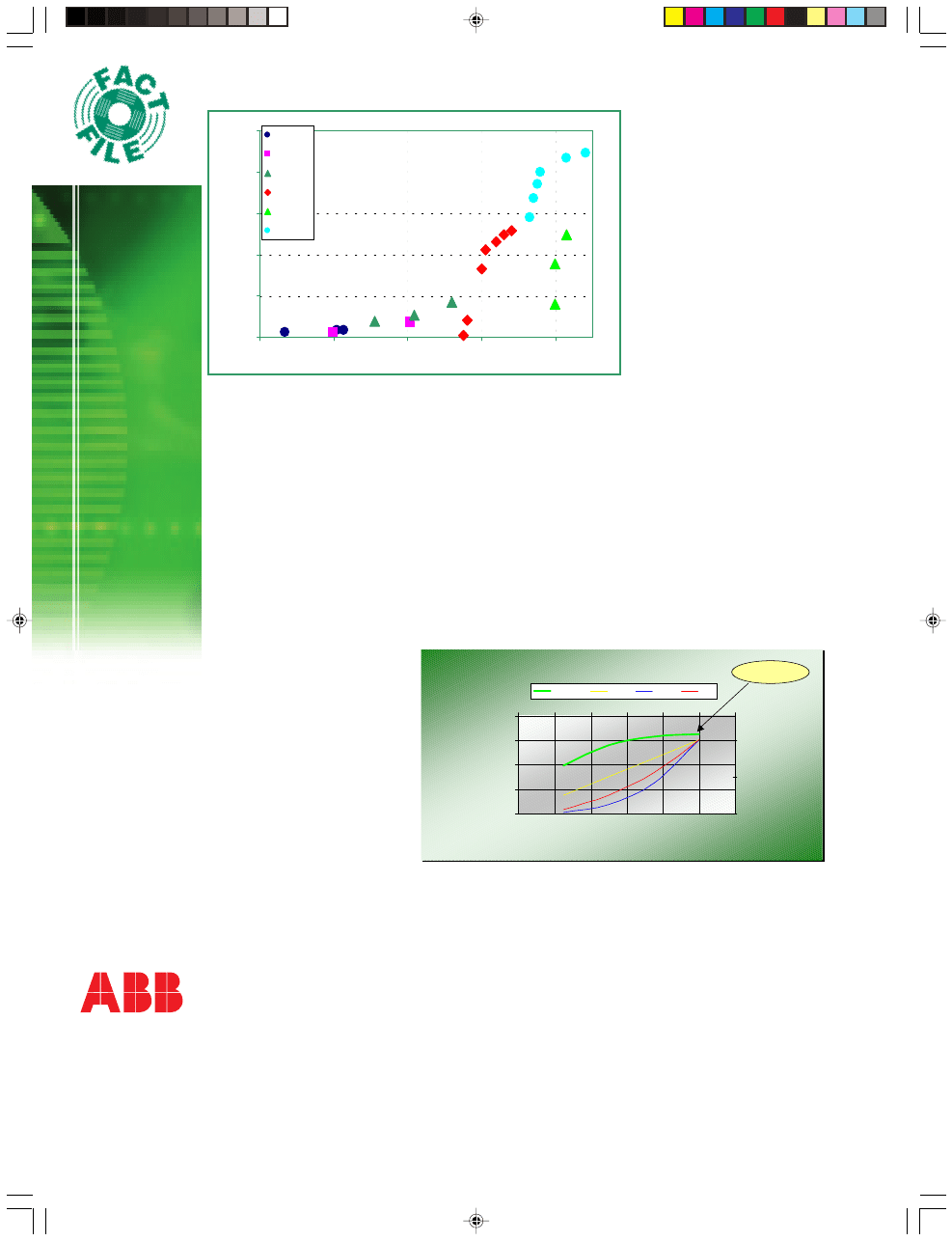

The development of magnetic

materials during the last

decade has led to significant

improvements in magnetic

properties. High remanence

(B) and high coersive force (H)

values have been achieved

with temperature ratings (up to

180 C) suitable for motor and

generator applications.

The graph shows how the

maximum magnetic energy of

permanent magnet materials

has developed.

0

100

200

300

400

500

1910

1930

1950

1970

1990

(BH)

ma

x

[k

J

m

³]

Steels

Ferrites

AlNiCo

SmCo

SmFeN

NdFeB

T ypical curves of a 2.5 M W PM G

0 ,9 8 2

0 ,9 5 9

0 ,9 2

0 ,9 4

0 ,9 6

0 ,9 8

1

0

0 ,2

0 ,4

0 ,6

0 ,8

1

1 ,2

sp eed (p u )

P, U, I

0

0,5

1

eff

e ta (p u)

U /un

P /p n

I/In

= 98,2 %

η

file oma.pmd

19.9.2003, 12:13

2

Wyszukiwarka

Podobne podstrony:

Control Issues Of A Permanent Magnet Generator Variable Speed Wind Turbine

A Low Speed, High Torque, Direct Drive Permanent Magnet Generator For Wind Turbines

Directly Driven Low speed Permanent Magnet Generators For Wind Power Application

(Wind) A Low Speed, High Torque, Direct Drive Permanent Magnet Generator For Wind Turbines

Design Of Direct Driven Permanent Magnet Generators For Wind Turbines

[2003] Constant Voltage Permanent Magnet Wind Generator

Development Of Wind Power Control System For Six Phase Permanent Magnet Synchronous Generators

Patent Of The Permanent Magnet Machine

permanent magnet motor controllers 1228

[2006] Application of Magnetic Energy Recovery Switch (MERS) to Improve Output Power of Wind Turbine

SMeyer EP0098897A2 Electrical Generator Utilizing Magnetized Particles

SMeyer EP0098897A3 Electrical Generator Utilizing Magnetized Particles

[2006] Application of Magnetic Energy Recovery Switch (MERS) to Improve Output Power of Wind Turbine

Dynamic Simulation Of Hybrid Wind Diesel Power Generation System With Superconducting Magnetic Energ

Metoda magnetyczna MT 14

MAGNETOTERAPIA PREZENTACJA

więcej podobnych podstron