STERILIZATION PROGRAMS,

AIR REMOVAL AND

STEAM PENETRATION

Peter Hooper

CEng MIMechE FIHEEM, United Kingdom

WFHSS Conference, Crete, October 2009

Sterilization Programs, Air Removal and Steam Penetration

Agenda:

How steam sterilization works

Why air is a problem

How is air removed

What are the effects of poor air removal

Different cycle types

Monitoring air removal

Steam sterilization works by:

Using steam to transfer energy from the boiler/generator to

the load in the sterilizer

The steam contains two packets of energy

1.

that to raise its temperature from cold to boiling point

2.

t

hat to turn boiling water into steam at the same

temperature

For each kilogram of steam energy 2 is approximately 4-5

times that of energy 1

When steam condenses energy 2 is given to the surface it

condenses on

– this condensation is vital

Sterilization Programs, Air Removal and Steam

Penetration

Why is air a problem?

It inhibits the access of steam (and hence energy transfer) to

ALL surfaces –

ie inhibits steam penetration

It acts as an insulator to inhibit energy transfer

It mixes with the steam to destroy the fixed

pressure/temperature relationship used to control the

sterilizer

It is non-condensible and contains little energy to transfer

Thus AIR MUST BE REMOVED FROM THE ENTIRE CHAMBER

Sterilization Programs, Air Removal and Steam Penetration

A steam sterilizer cycle consists of:

Air removal –

the stage without which sterilization will not occur

Heat-up

Sterilization –

the central 3 minutes of a 45-minute cycle

Steam removal

Drying

Air inlet

Sterilization Programs, Air Removal and Steam Penetration

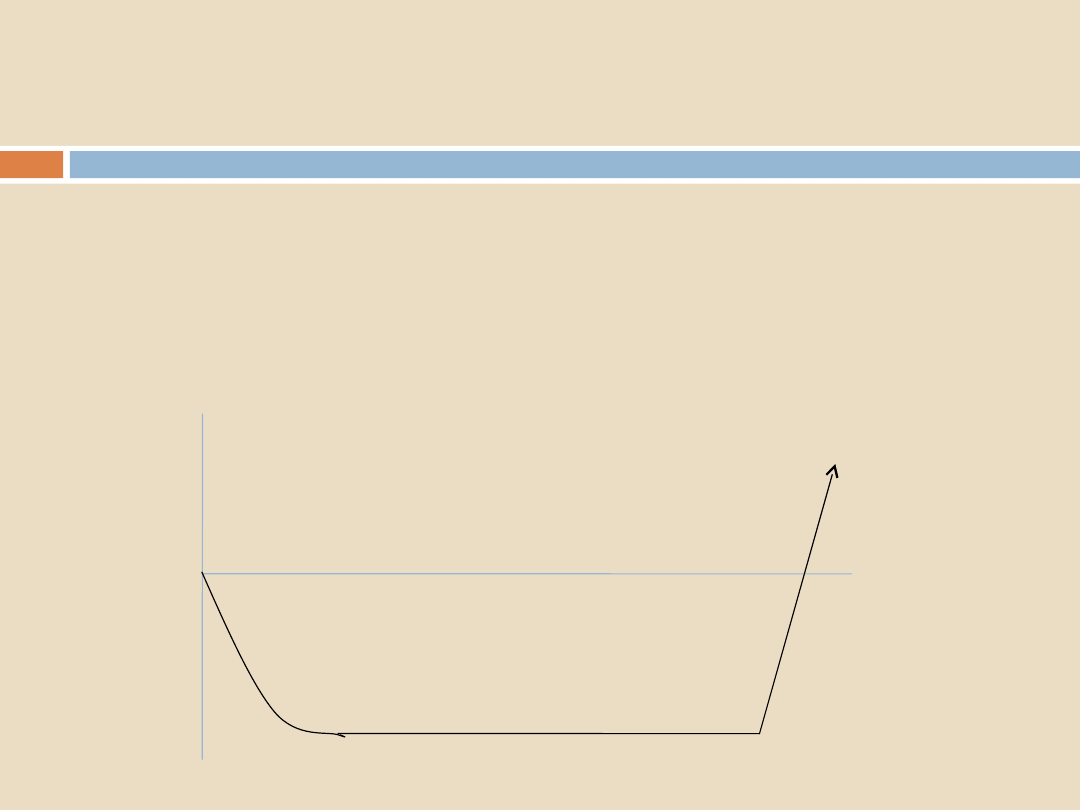

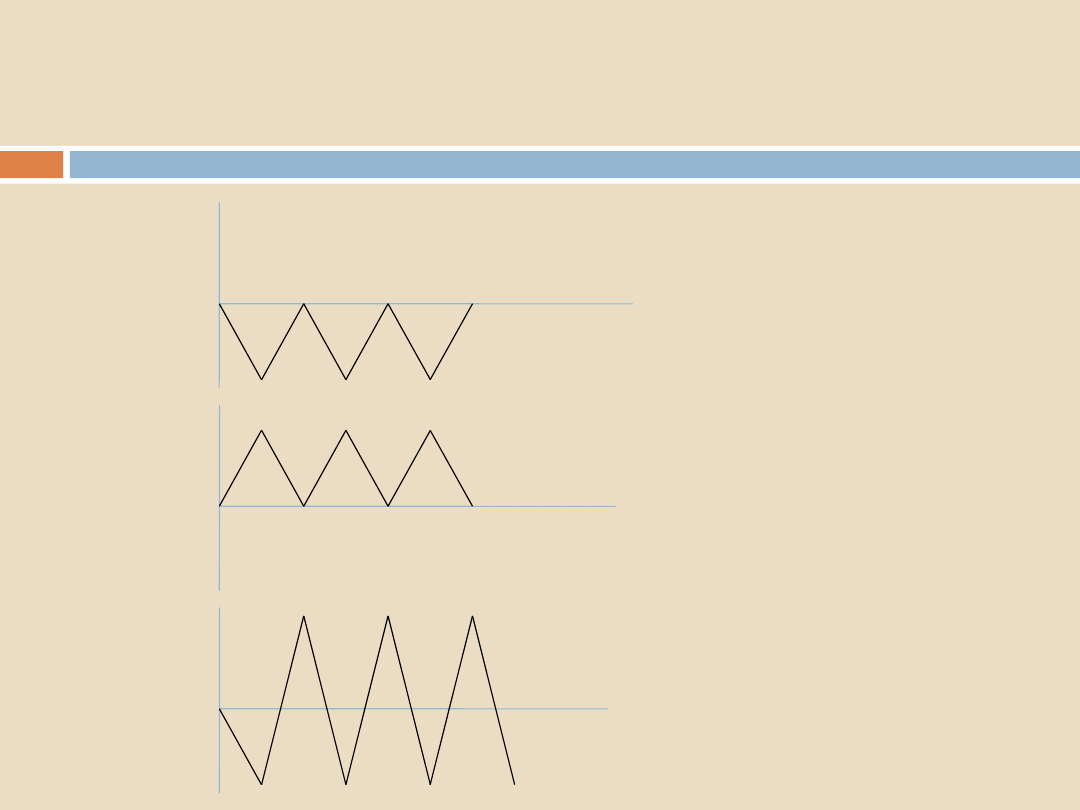

How is air removed?

1.

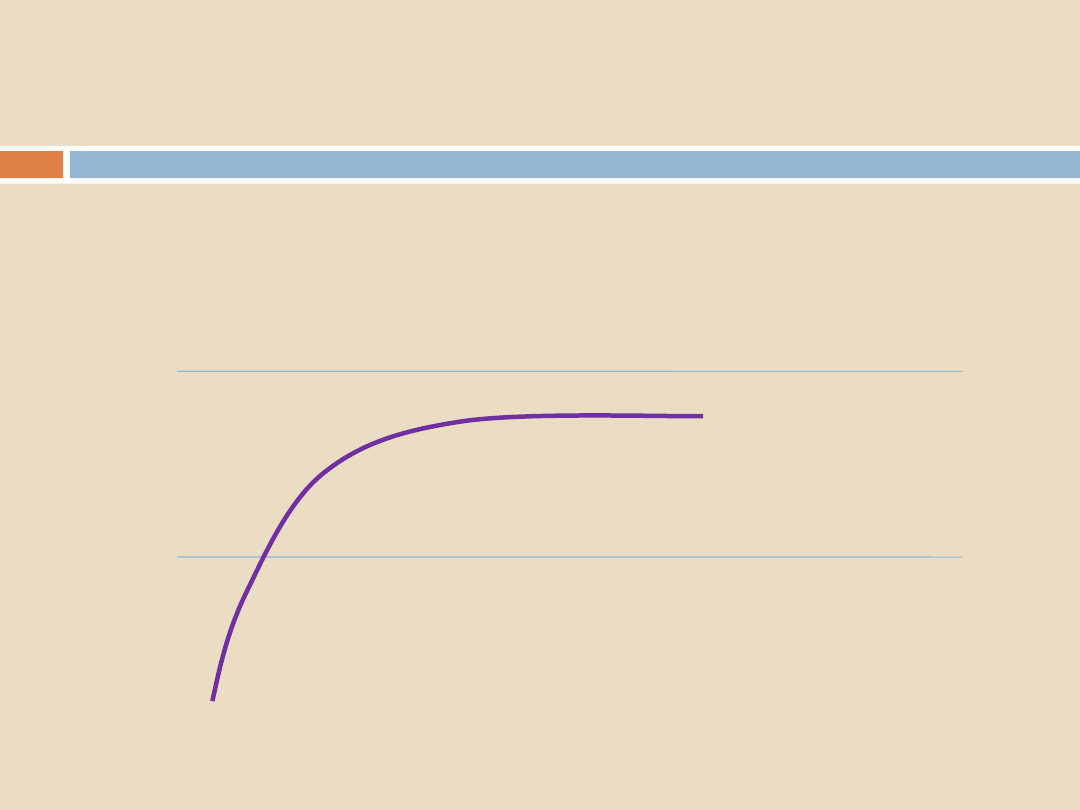

A long, deep vacuum at the start of the cycle?

Sterilization Programs, Air Removal and Steam Penetration

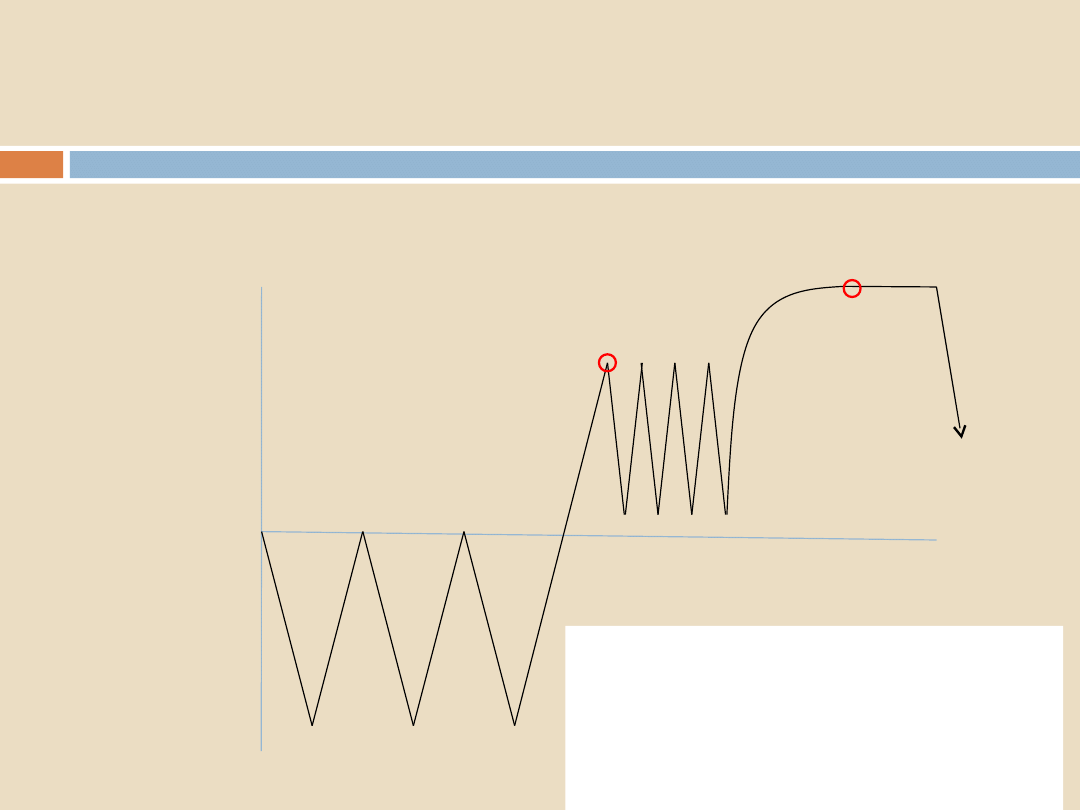

TIME

PRESSUR

E

VACUU

M

ATMOSPH

ERIC

PRESSURE

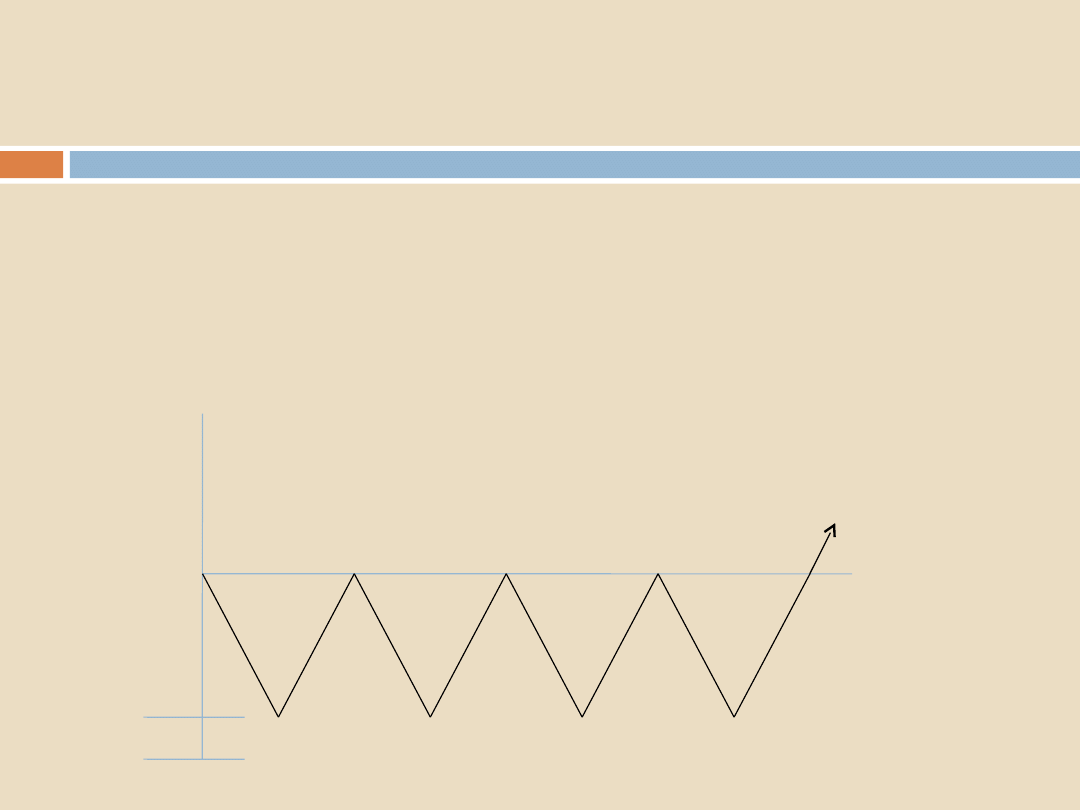

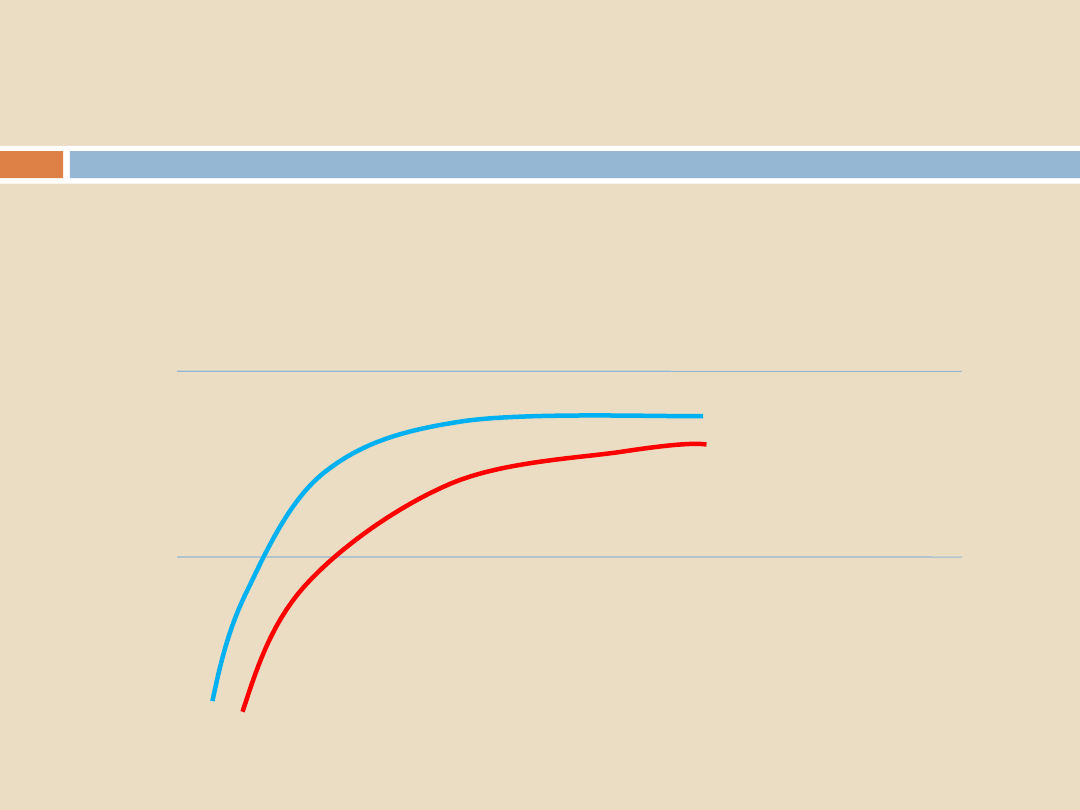

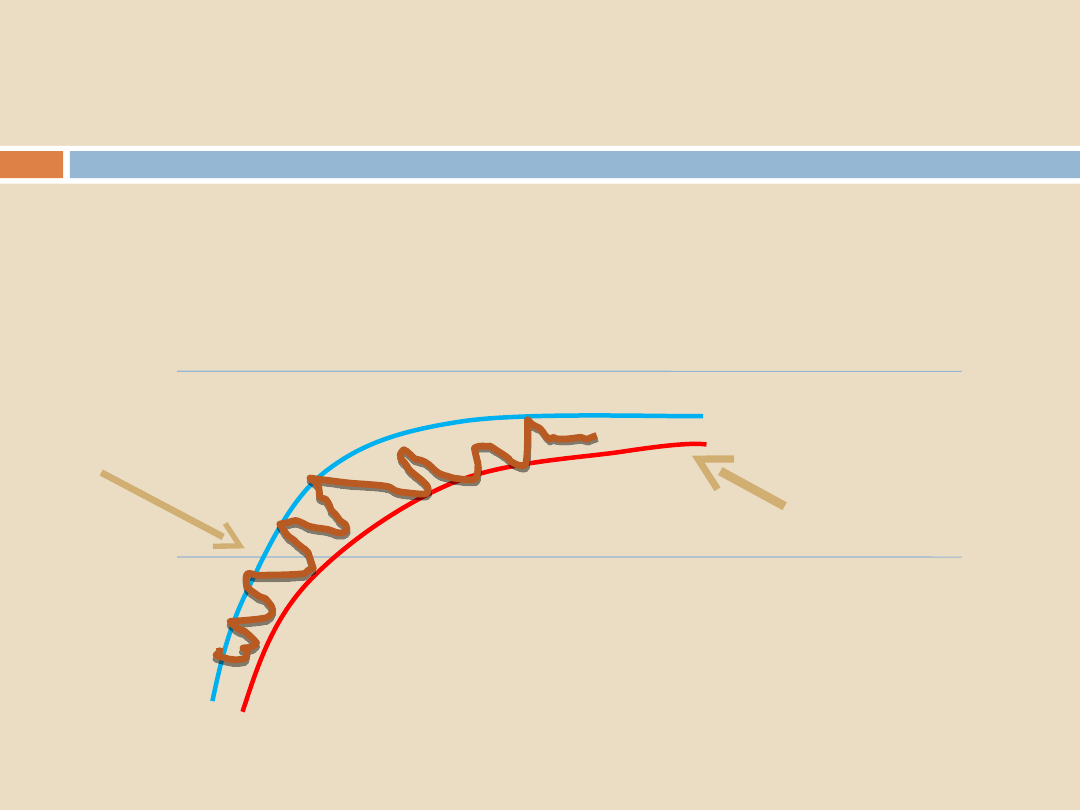

How is air removed?

2.

Pulsing

Sterilization Programs, Air Removal and Steam Penetration

TIME

100% 10% 1% 0.1% 0.01%

AIR

0% 90% 99% 99.9%

99.99%

STEAM

10% 1% 0.1% 0.01%

AIR

0% 9% 9.9% 9.99%

STEAM

0 mbar

-900 mbar

-1000

mbar

Conclusion:

Pulsing is the most efficient method

The efficiency depends upon:

1.

The number of pulses

2.

The depth of each pulse

So which is the best pulsing system design?

Sterilization Programs, Air Removal and Steam Penetration

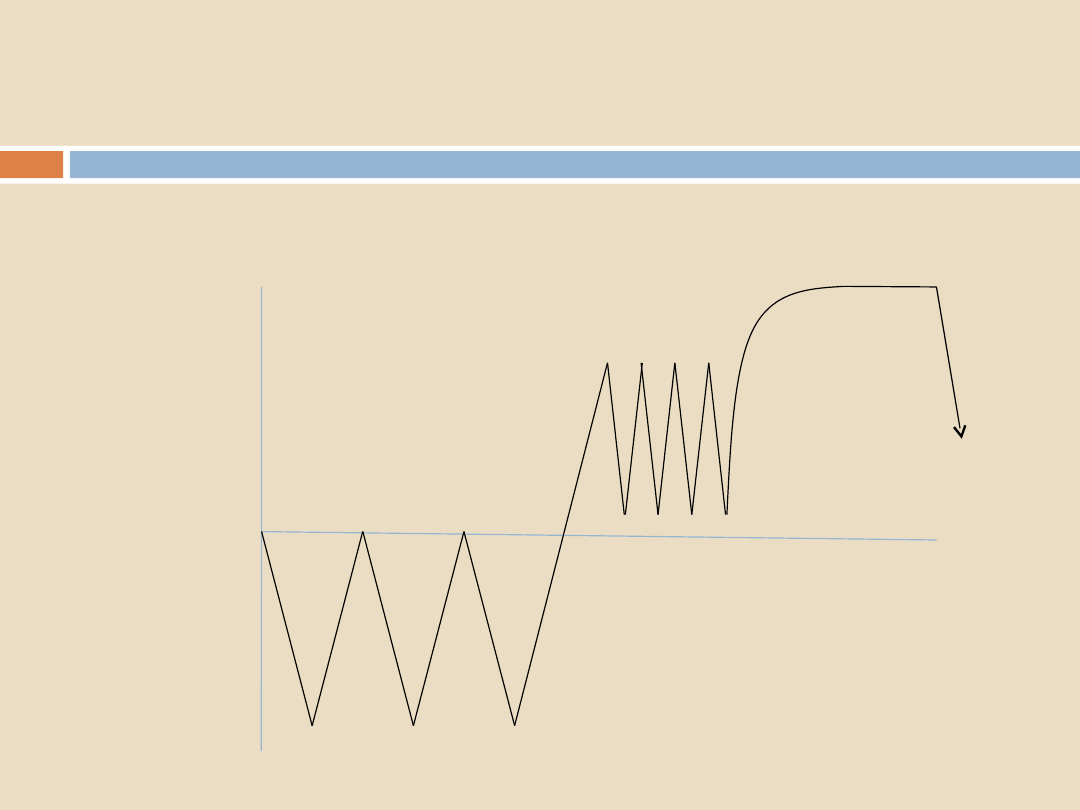

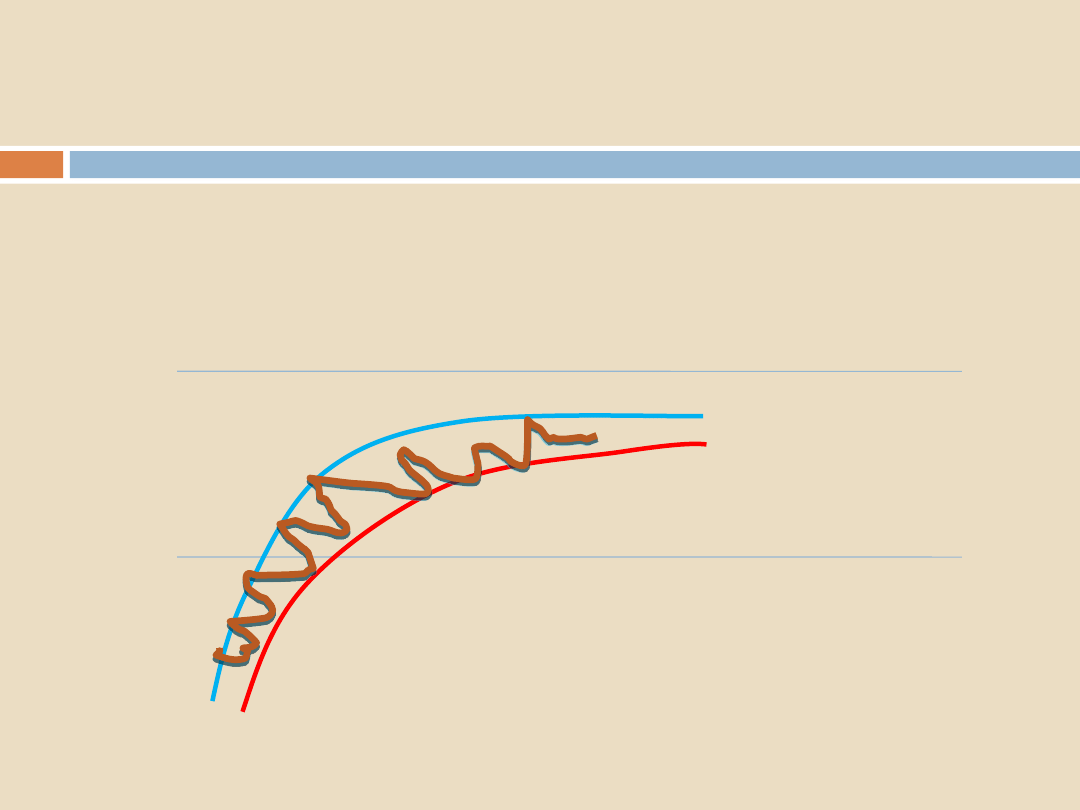

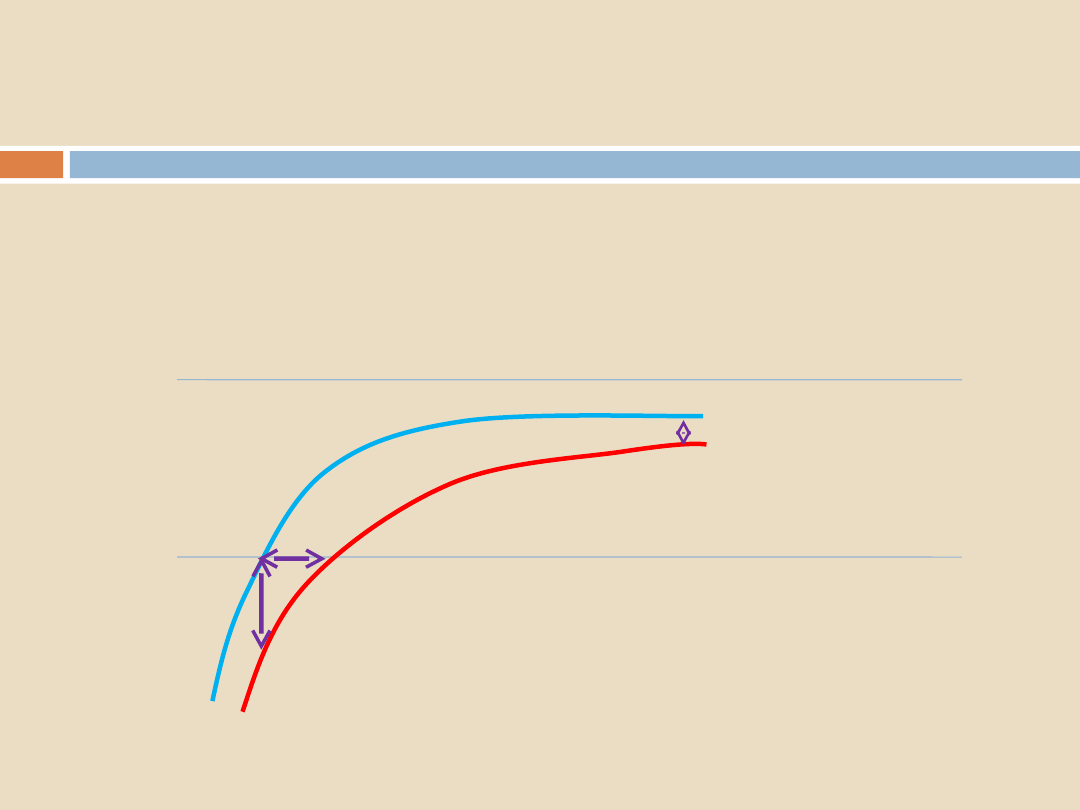

Sterilization Programs, Air Removal and Steam Penetration

NEGATIVE

POSITIVE

TRANS_ATMOSPH

ERIC

1

2

3

Advantages & disadvantages:

Negative pulses

Can induce air through leaks

Positive pulses

Less efficient but no air ingress

Trans-atmospheric pulses

Most efficient but has negative sections

Sterilization Programs, Air Removal and Steam Penetration

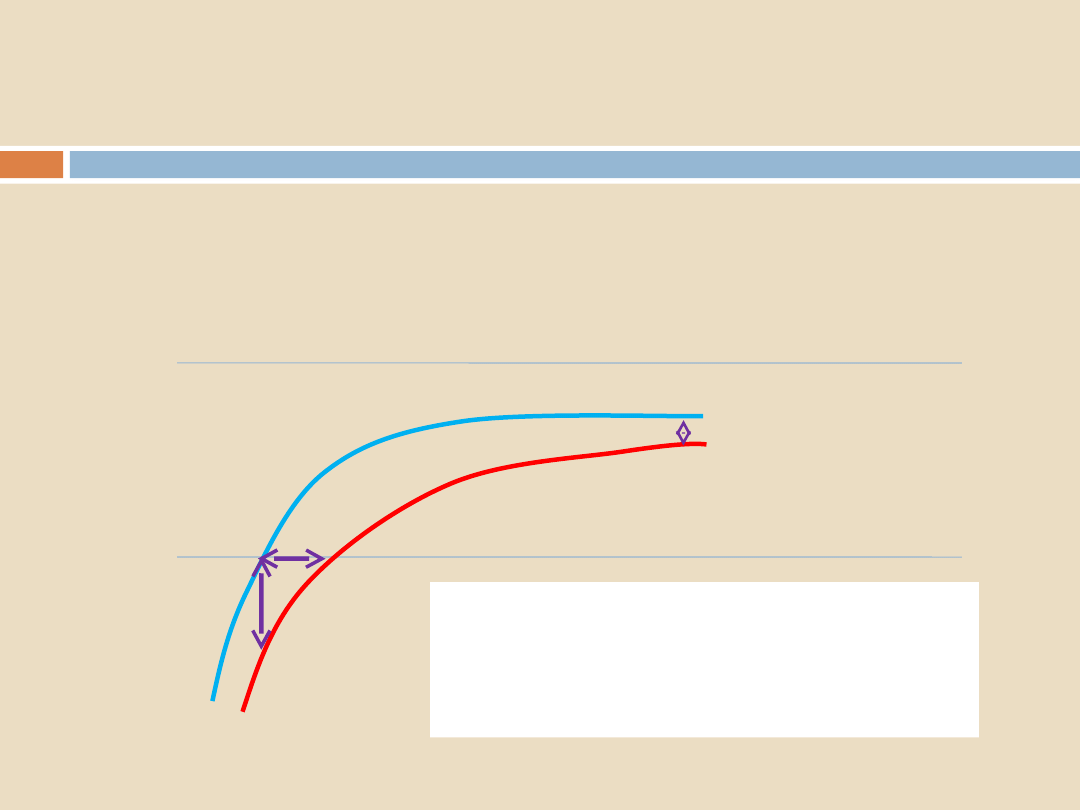

Sterilization Programs, Air Removal and Steam Penetration

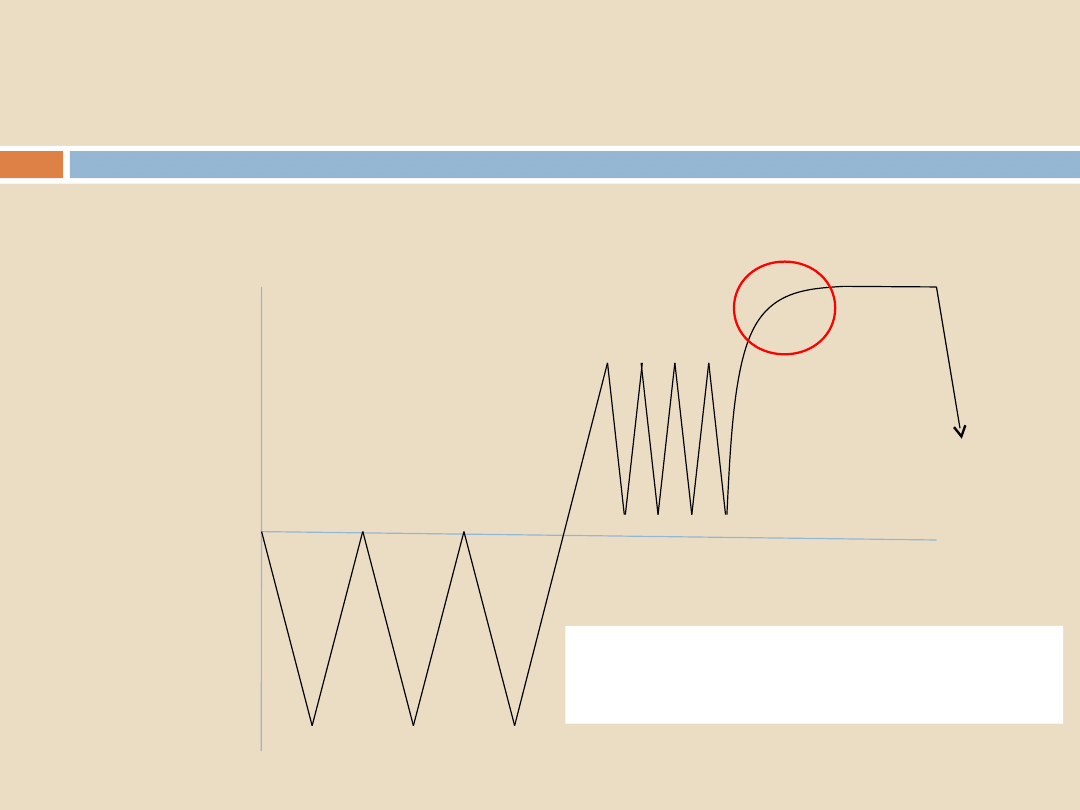

A possible final cycle – a compromise:

Sterilization Programs, Air Removal and Steam Penetration

Important points for air removal:

1

1. Poor air-removal can be

identified here

Measuring air-removal:

Sterilization Programs, Air Removal and Steam Penetration

LOAD

CENTRE

DRAIN/

REFERE

NCE

Thermocouple traces: perfection

Sterilization Programs, Air Removal and Steam Penetration

137 C

134 C

LOAD CENTRE

DRAIN/REFERENC

E

Thermocouple traces: reality

Sterilization Programs, Air Removal and Steam Penetration

137 C

134 C

LOAD CENTRE

DRAIN/REFERENC

E

Thermocouple traces:

Sterilization Programs, Air Removal and Steam Penetration

137 C

134 C

INDICATION OF POOR

AIR REMOVAL – the

greater the area the worse

the air removal

Thermocouple traces:

Sterilization Programs, Air Removal and Steam Penetration

137 C

134 C

*

= points at which

measurement can be done

*

*

Quantification of thermocouple traces:

Sterilization Programs, Air Removal and Steam Penetration

137 C

134 C

1: EQUILIBRATION

2: DEPRESSION

3: DIFFERENCE IN LAST 2 MINUTES

2

1

3

Quantification of thermocouple traces:

Sterilization Programs, Air Removal and Steam Penetration

137 C

134 C

AIR REMOVAL CAN NOW BE

QUANTIFIED BY PUTTING VALUES

TO THESE THREE PARAMETERS

2

1

3

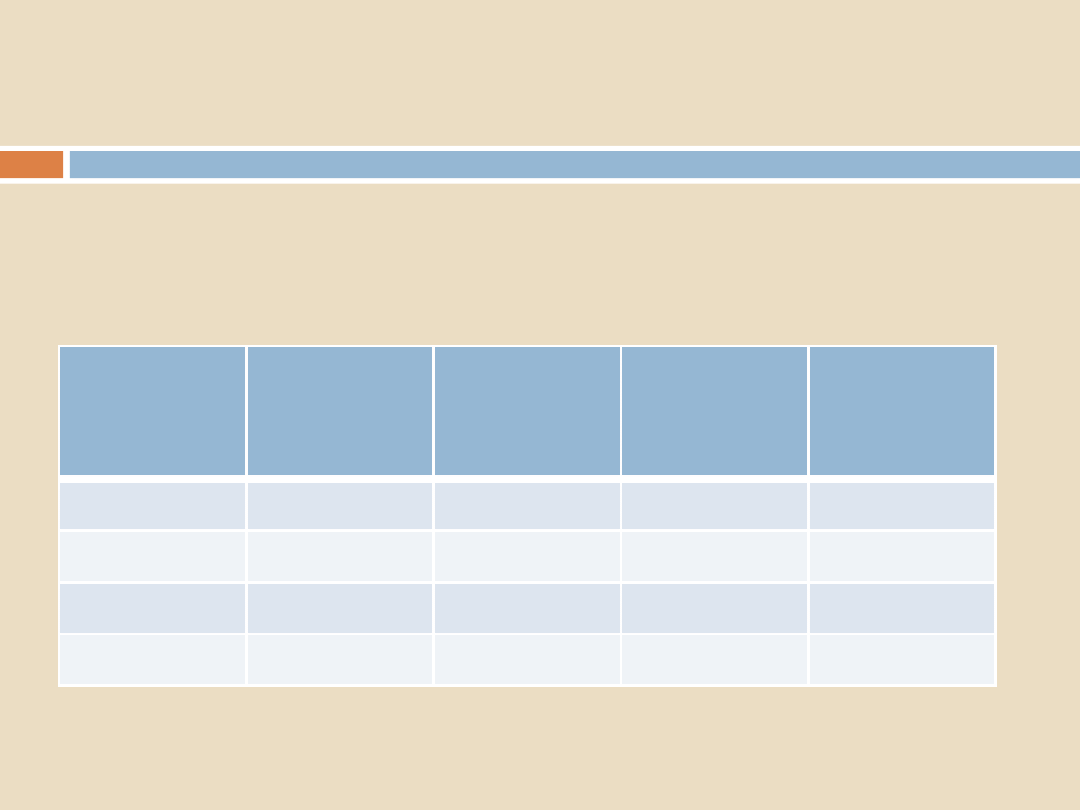

Comparison of parameter values in the UK:

Sterilization Programs, Air Removal and Steam Penetration

DOCUME

NT

YEAR

1

equilibratio

n

2

depression

3

difference

HTM 10

1968

-

-

-

HTM 10

1980

-

-

0

HTM 2010

1994

15

2*

2

EN 285 >>

1994 >>

15

2*

2

* = for air detectors

Air removal monitoring:

Internal sensors and timers (control)

Bowie & Dick test (daily test

Process Challenge devices (in-chamber in-cycle

when used)

Air detector (external in-cycle every cycle)

Sterilization Programs, Air Removal and Steam Penetration

Bowie & Dick test:

Initially defined with Standard Test Pack (textile)

Later quantified via Standards

Parameter definitions used to define failure chemistry

NOTE: parameter values and test pack details may

differ in different parts of the World

Sterilization Programs, Air Removal and Steam Penetration

Air detector:

A device to automatically monitor the efficacy of the

air-removal process – it can automatically fail the cycle

if it measures unacceptable air removal

It can function each cycle

It is part of the control system, not an accessory

It can abort cycles at an early stage of air-removal

– ie it can be predictive

It must be validated and periodically tested with care

and skill

It is extremely accurate and precise

Sterilization Programs, Air Removal and Steam Penetration

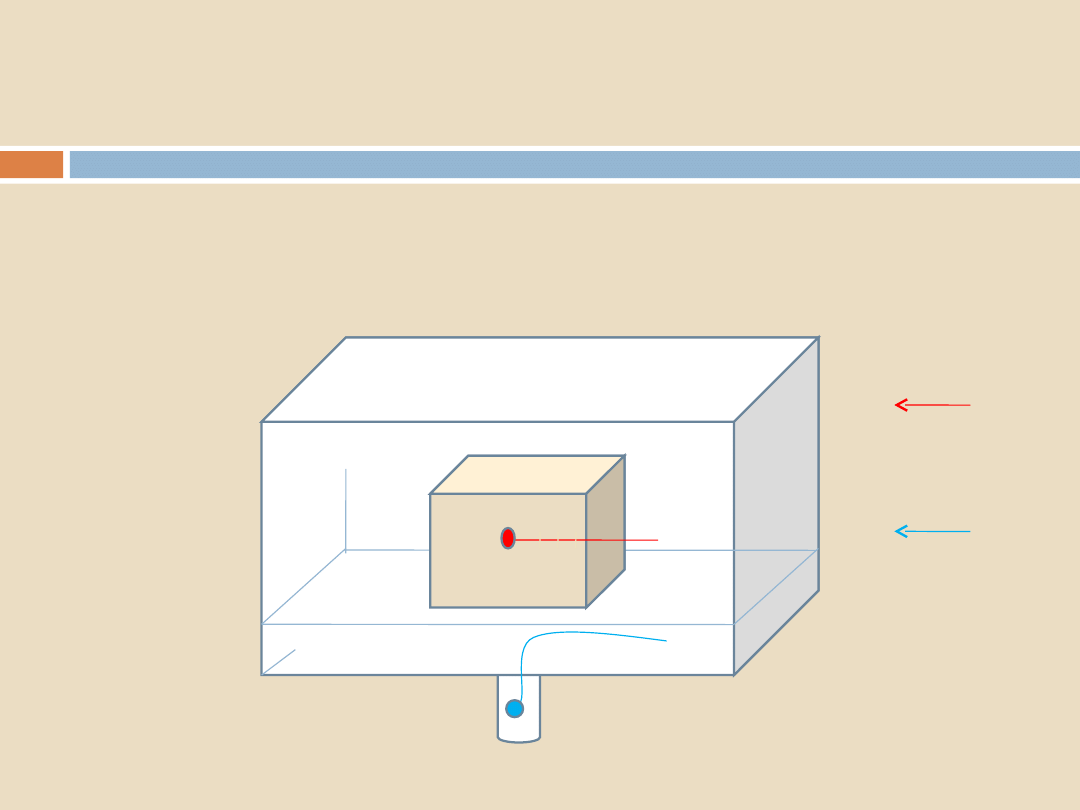

Air detector:

It works by sealing a sample of chamber contents and, by

condensation caused by heat loss, separates residual

air

The amount of air can be measured by either its partial

pressure or temperature depression

It is part of the chamber but external to it to enable the

heat loss to occur

A temperature-operated air detector can be predictive

and can be used to monitor hold-time conditions

Sterilization Programs, Air Removal and Steam Penetration

Sterilization Programs, Air Removal and Steam Penetration

Important points for air detector:

1

1. A decision can be made here

to minimise lost productivity

2. It can also monitor NCG

levels

2

Summary:

Complete air-removal is essential to good sterilization

Pulsing is the most efficient method of air removal

A variety of pulsing systems may be used – they each have

benefits and disadvantages

Poor air-removal can be shown by thermometric testing

Thermometric data can be used to quantify air-removal and

thus define performance of air-removal monitors

Bowie & Dick test parameters can be thus defined but may

differ from place to place

An air-detector is an accurate and repeatable method of

monitoring every process cycle

Sterilization Programs, Air Removal and Steam Penetration

Thank you

σε ευχαριστώ

Document Outline

- Sterilization Programs, Air Removal AND Steam Penetration

- Sterilization Programs, Air Removal and Steam Penetration

- Slide 3

- Slide 4

- Slide 5

- Slide 6

- Slide 7

- Slide 8

- Slide 9

- Slide 10

- Slide 11

- Slide 12

- Slide 13

- Slide 14

- Slide 15

- Slide 16

- Slide 17

- Slide 18

- Slide 19

- Slide 20

- Slide 21

- Slide 22

- Slide 23

- Slide 24

- Slide 25

- Slide 26

- Slide 27

Wyszukiwarka

Podobne podstrony:

wfhss conf20091007 lecture sp op03 en

wfhss conf20091007 lecture sp s401 en

wfhss conf20100730 lecture sp s502 en

wfhss conf20091007 lecture sp s501 en

wfhss conf20091007 lecture sp s301 en

wfhss conf20091007 lecture sp s401 training programme en

wfhss conf20100730 lecture sp oc01 pt

wfhss conf20100730 lecture sp s901 pt

wfhss conf20100730 lecture sp s303 pt

wfhss conf20070503 lecture10 en

wfhss conf20070503 lecture03 en

wfhss conf20070503 lecture09 en

wfhss conf20070503 lecture05 en

wfhss conf20070503 lecture15 en

wfhss conf20080604 lecture1 02 it

wfhss conf20080604 lecture4 03 it

co acpce conf20070927 lecture c04 en

fr cefh conf20080409 lecture00 en

więcej podobnych podstron