26

Drying of Herbal Medicines

and Tea

Guohua Chen and Arun S. Mujumdar

CONTENTS

Acknowledgment ............................................................................................................................................ 645

References ...................................................................................................................................................... 646

26.1 INTRODUCTION

Herbal medicine is part of human civilization. It has

been used in China for nearly 5000 y. One of the oldest

and most important documents is the Egyptian Ebers

papyrus (ca. 1550

BC

), which includes more than 700

prescriptions using natural products such as caraway,

coriander, garlic, linseed, peppermint, figs, fennel, anise,

poppy, and castor oil [1]. Shen Nong’s Materia Medica

was compiled by ancient Chinese in about 200

BC

, which

described the properties and usages of 365 types of

Chinese medicines in three categories. In ancient Greece

there was a guild of rhizomatists or root collectors, who

gathered, prepared, and sold medicinal plants. The

Greek botanist and physician, Dioscorides (

AD

40–90),

compiled the first systematic description of 579 plants

and their 4700 medicinal uses and modes of action. His

work titled De Materia Medica was of central import-

ance to European medicine until the 17th century [1].

Ayurveda is the principal traditional medical system of

India, Pakistan, Nepal, and Sri Lanka, which has also

influenced medicine in Tibet, Burma, and Malaysia.

No doubt that synthetic drugs have played a vital

role in the enhancement of human living standards

during the past century; herbal medicine has regained

its momentum once again in recent years. Long-term

ailments cannot typically be cured by injection or

consumption of a single medicine. Instead of focusing

only on curing an illness, people are paying more

attention nowadays to improve the whole body im-

mune system so as to prevent the attack of diseases.

Besides their traditional pharmaceutical usage, herbs

have also become one of the important sources for

drug discovery and production. Herbal medicine

plays an important role in healthcare in many regions

of the world. The combined sales of herbal medicine

products in major markets around the world exceeded

US$12 bill ion in 1994,

the report from Herbal Medical Database Ltd., the

US market for herbal medicines has been estimated to

ß

2006 by Taylor & Francis Group, LLC.

be worth US$ 58 billion in 1999 with an annu al

growth rate of 25%.

Ther e are more than 1000 types of herbs in use

around the world as medic ines, spices, flavors, etc. On

the basis of their biologi cal complex ity, they can be

classified as algae, fun gi, liverw orts and mosses, ferns

and fern allies, seed -bearing plants , and higher flower -

ing plan ts [3]. Dep ending on their physica l prop erties,

one can further classif y them as follows: sticky, aro-

matic, powder y, oily, and lust rous. This latter classi-

ficatio n determines the way the herb s are hand led.

The stick y he rbs usu ally contai n significa nt amou nt

of suga r, e.g., Radix Asparagi , Rhizoma Polygonati .

The a romatic herbs are known by their sp ecial scents .

Typical aromat ic herbs are: Herba Schizonepetae ,

Herba Menthae (also known as mint), Herba Elsholt-

ziae , and Rosae banksiae , etc. The powder y herbs

contai n large amo unts of star ch such as Rhizoma

Dioscoreae or rhizom e of c ommon yam. Radix Angel-

icae sinensis and Rhizoma Ligustici chuanxiong are two

oily herbs. For lust rous herbs, such as Radix Platycodi ,

Rhizoma Alismatis , and Astragalus membranaceus the

brightn ess of their surfaces is quite impor tant [4].

The quality of the he rbs depe nds very much on the

content s of active ingredi ents. It is known that heat-

ing or thermal drying, if not carried out prop erly, can

cause a signifi cant loss of the acti ve ingredi ents. The

drying methods describ ed below theref ore should be

adopted with care. For a specific herb sp ecies, its

traditi onal way of dr ying shou ld be analyze d caref ully

before any alternati ve methods are employ ed. The

compari son of diffe rent dr ying methods on the qual-

ity of herbs has to be carri ed out ba sed on physica l

and chemica l analyses. Var ious cou ntries hav e estab-

lished standar d testing methods for herb examin ation

with known indica tors for given specie s, for exampl e,

Species Systematization and Quality Evaluation of

Commonly Used Chinese Traditional Drugs [5] and

Handbook of Composition and Pharmacological Ac-

tion of Commonly Used Traditional Chinese Medicine

[6] are available in Chi na.

A large assort ment of drye rs can be used for dry-

ing herbs and medicinal plants. The reader is referred

to

of this handb ook for infor mation on

selection criteria for dryers.

26.2 DRYING OF HERBS AFTER

HARVESTING

26.2.1 H

ERBS IN

S

MALL

Q

UANTITY

Herbs are very delicate plants. Their efficacy depends

on species, parts, planting location, harvest time, dry-

ing method, and storage. For a specific species, the

medicinal effect may derive from seeds, flowers, leaves,

stems, or roots, or all of these. Herbs were traditionally

harvested in small quantities from the mountains or

fields by individuals. Besides the active ingredients,

fresh plant material contains a high portion of water.

Leaves and flowers usually lose up to 85% of their

weight on drying. The fresh plant material is spread

out in thin layers (or in certain cases hung up in

bunches) and kept in a dry, well-ventilated place.

Tubers and roots take longer to dry than flowers

and leaves even though the former are often cut

up into pieces. The selection of proper drying tempera-

ture is vital. Too high a temperature may cause loss of

active ingredients. On the other hand, too low a tem-

perature may actually accelerate decomposition by

promoting enzyme activity within the plant itself

or even microbial attack, particularly for sugar-con-

taining substances.

Herbs are usually harvested when the flowers are

just coming into bloom, as they are then richest in

aromatic oils. As a guideline, one should pick herbs

just after the dew has gone and discard any yellow or

damaged herbs. Herbs should be handled with care

and only rinsed to remove obvious dust or soil. Herbs

may be dried in a ventilated room or in a barely warm

oven, leaving the oven door open. The temperature

should not exceed 348C. The following procedure is

suggested: lay the herbs on wire cooling racks covered

with muslin, cheesecloth, or nylon net. When dry, the

herbs are brittle and crumbly. Put the dried herbs

into storage jars, preferably of tinted glass, and

cover with a plastic screw cap. Appearance of signs

of condensation inside the jar, which implies that the

herbs are incompletely dried and hence should be

returned to the drying cupboard or oven. Long-

stemmed herbs may be dried by hanging them in a

warm, dry, airy place for a few days. They may be tied

in small bunches in a loose fashion. Cover the

bunches with dark paper if direct exposure to sunlight

may occur [3]. It should be pointed out that some

herbs are dried under direct sunshine, for example,

TABLE 26.1

Global Market for Herbal Medicine Products in 1994

Region

Annual Herbal Product Sales,

in Millions US$

European Union

6000

Rest of Europe

500

Asia

2300

Japan

2100

N. America

1500

ß

2006 by Taylor & Francis Group, LLC.

Caulis Ephedrae, Radix Polygalae, Radix Astragali,

Radix Glycyrrhizae, Shiitake mushrooms, etc. Micro-

wave oven has been used recently for drying garden

herbs. For microwave drying, place a single layer of

herb leaves between double thickness of paper towels.

Dry them for 1–2 min on a medium to high setting (or

half of the power), depending on the thickness of the

leaves. Flip over and repeat for one more minute [7].

Pretests with grass are suggested if one is not familiar

with the microwave oven drying practice.

Catalytic Drying Technologies has introduced a

technology capable of significantly reducing the mois-

ture content of a wide range of agricultural products,

quickly and without causing product damage or gen-

erating regulated emissions. Tests have proven this

technology capable of reducing moisture content

from as high as 60% to levels between 3.4 and 4.4%.

The catalytic infrared system (burning gas without

flame) dries rice quickly and uniformly in a continu-

ous 3-h cycle. Low operating temperatures minimize

energy consumption; patented material handling and

agitation technology maximize efficient and uniform

drying [8]. The heat pump dryer has been investigated

and found to be useful in herb drying. It dehumidifies

the drying air, heats it, and leads it back for recir-

culation. This type of dryer can work at low air

temperature; thus color and active substances remain

intact. Another feature of the heat pump dryer is

its characteristic low energy consumption [9,10]. Sil-

ica sand drying can be used when the herbs are not

used as cooking recipes. Freeze drying can also

be used if it is important to retain the color of the

herbs and the active ingredients are highly heat-sen-

sitive. For a small quantity, simply place the fresh

herbs inside the freezer, which allows dehydration to

take place via sublimation. Freeze drying is an ex-

pensive process recommended only for high-value,

low-volume products.

26.2.2 D

RYING OF

T

EA

L

EAVES

Tea is an ancient crop that has been cultivated for

thousands of years. Its exact origins have not been

confirmed by historians. There are many theories

about the discovery of tea. According to tradition,

tea was discovered by the Chinese Emperor, Shen

Nong in 3000

BC

. The first records of tea date from

the 4th century

AD

in China. Tea leaves are probably

one of the earliest and most consumed herbs. They

were initially found to have the property to counter-

act the poisonous effects derived from other herbs.

Nowadays, tea has become one of the everyday

drinks next to coffee and cocoa. The main tea produ-

cers are India, China, Sri Lanka, Kenya, Malawi, and

Indonesia. There are more than 1500 teas to choose

from, originating from more than 29 different coun-

tries [11]. The majority of the teas can be classified as

green tea, oolong tea, and black tea. Each requires

a different process and hence a different drying sys-

tem is required. The quality of dried tea depends to

a great extent on the drying system and operating

conditions used.

26.2.2.1 Green Tea

Green tea is drunk mainly in China, Japan, and some

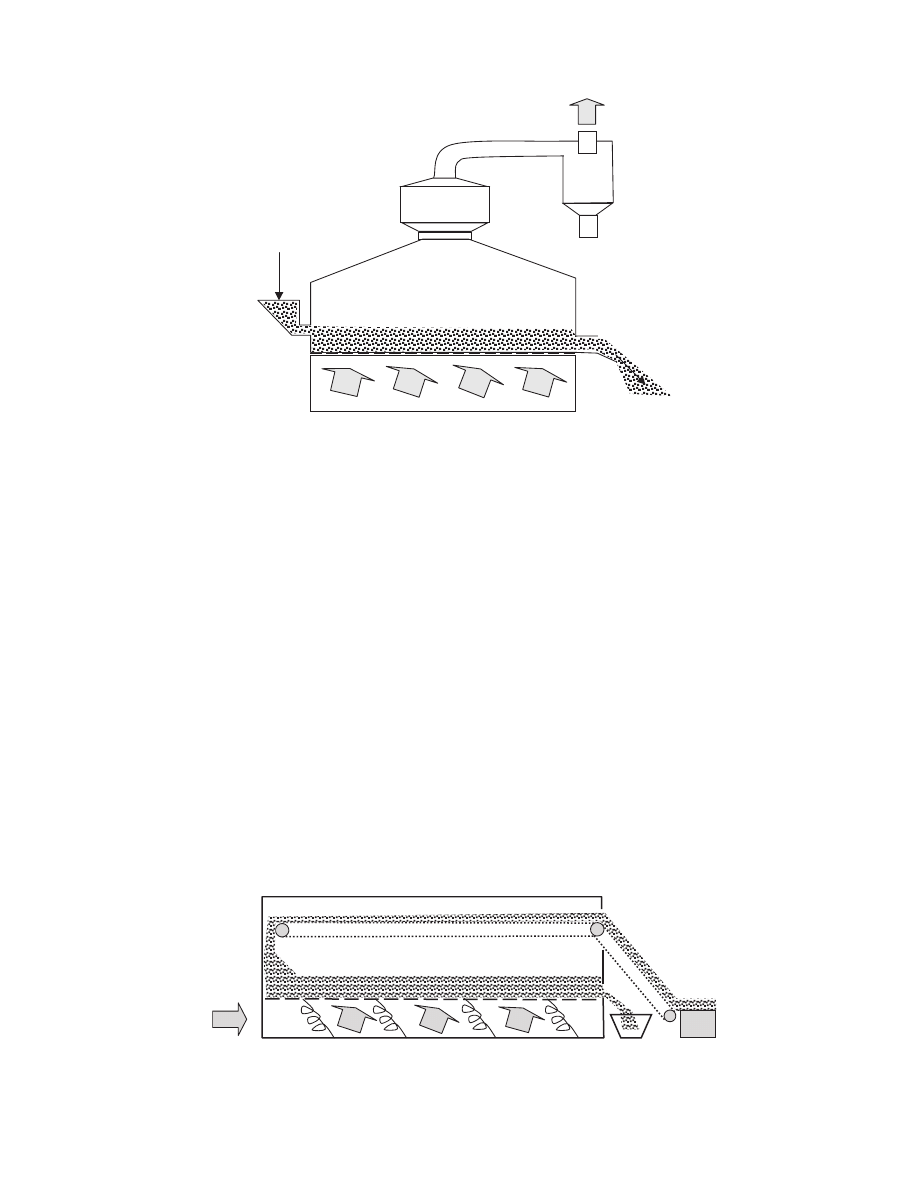

parts of South America. Figure 26.1 shows the pro-

cess of a typical green tea production before final

sorting and packaging [12]. The initial water content

of fresh tea leaves after plucking is around 75–78%

(wet basis) in spring and 65–70% (wet basis) in au-

tumn [13]. The withering process is accomplished by

laying the tea leaves on trays or racks in the shade at

25–308C for a few hours depending on how wet the

leaf is. This process prepares the tea leaves for rolling

without losing juice. Meanwhile, the water content

falls to about 50% (wet basis). The kill out process

can be achieved by pan frying, steaming, or baking.

This process is designed to arrest the enzymatic reac-

tion, oxidation in particular. Pan drying usually em-

ploys a wok at a surface temperature of 400–4708C

(preferably 430–4608C) to reduce the leaves’ moisture

content to 10–15%. The drying step starts with using

hot air at 110–1208C to evaporate water in a layer of

tea leaves about 20-mm thick. In practice, air tem-

perature up to 1508C can be used. It is recommended

to have the dried tea leaves tempered to prevent the

edges of leaves from ‘‘crisping.’’ Then the next drying

starts with the wok temperature at 150–1608C and

drying time of 30–40 min until moisture content

reaches about 20%. Afterwards, the wok surface tem-

perature is reduced to 80–1008C and drying continues

for 60–90 min to have the moisture content of 9–10%.

Finally, the wok surface temperature is dropped to

Plucking

Sorting and

cleaning

Killing-out

Withering

Rolling

Drying

FIGURE 26.1 Production of green tea.

ß

2006 by Taylor & Francis Group, LLC.

608C and drying carried out for 60–90 min until the

final moisture content of 4–5% is reached [13].

26.2.2.2 Oolong Tea

The process of oolong tea production is shown in

Figure 26.2. The freshly plucked shoots from Cam-

ellia sinensis are spread out thinly over a cleared area

of flat ground, which is usually covered with a mat or

a towel to keep leaves from contact with the earth.

The shoots are wilted in air under the sun for 30–60

min, depending on the temperature. The leaves are

then taken indoors to wither further at ambient tem-

perature for a few hours. This withering process can

also be assisted by heated air at <408C to shorten the

process time. During this process, the leaves are gen-

tly agitated by hand every hour. This process causes

the edges of the leaves to turn red [14]. During this

process, there is about 20% decrease in moisture con-

tent of the tea leaves. This step is accompanied by

‘‘fermentation’’ or curing to produce the unique

aroma and color found in oolong teas. To arrest

the enzymatic reaction so as to stop the leaves from

getting dark, the leaves are dried for 5–7 min at a

temperature slightly lower than that required for

‘‘killing-out’’ in green tea production. Afterwards,

the tea leaves are dried in a few steps in heated air

with rolling in between the drying steps. The first hot

air drying in conveyer belt or an oven is usually

achieved at a temperature around 1258C with the

depth of leaves 10–20 mm for 7–10 min. At the end

of this step the moisture content is about 40–45% (wet

basis). The second drying step is completed with air

temperature of 90–1008C for another 7–10 min until

the moisture content nearly reaches its equilibrium

level. A third drying step may be used at air tempera-

ture of 80–908C and a bed depth of 20–30 mm for 20

min. The second and third drying steps may be com-

bined using air temperature of 80–908C. The depth of

leaves can be a bit higher depending on the location of

the tea plants [13].

26.2.2.3 Black Tea

The process of black tea production is shown in

Figure 26.3. Tender young growth is picked by hand

from Camellia sinensis. Any surface water on

the leaves and shoots is allowed to dry on racks for

10–20 h to bring down the internal moisture content

so as to make the leaf more pliable for the next step.

The light, medium, and heavy withering can be

adopted with the moisture content decreases in 10,

15, 20% (wet basis), respectively. The selection of

degree of withering depends on the downstream

processes and the final product specification [13]. The

leaves are bruised to allow the fermentation process to

begin. Cutting is done at this point if necessary. The

rolling process will last until the leaves turn shining

dark red like a bright copper penny. The leaves are

allowed to ferment by placing thin layers on a tray in

a shady location for 2–3 days before drying [14]. If a

fermenter is used for the cut leaves, the temperature

should be controlled around 328C and time within 90

min. When moist air of 20–268C is blown through the

leaves, the fermentation time should be below 60 min

[13]. The drying can be accomplished in an oven set at

110–1208C for 12–16 min to obtain 18–25% water

content in the leaves of depth 15–20 mm. Further

drying is achieved by having oven temperature of

90–958C for another 12–16 min to the final moisture

content of 5–6% (wet basis). The higher temperature

step is necessary to stop the enzymatic fermentation

reaction and seal the flavors inside the leaves.

26.2.3 S

OME

T

YPICAL

D

RYERS FOR

T

EA

L

EAVES

26.2.3.1 Multitray Oven

This type of dryer is usually designed for specialty tea

processing. It is an oven with about four layers of

trays. The drying surface area is 1–2 m

2

. Electrical

heating or heated air can be the source of drying

energy. The wet tea leaves are placed on the top layer

tray. The product is obtained in the bottom layer tray.

The moving of the trays is accomplished manually

Plucking

Sorting and

cleaning

Rolling or

shaking

Withering

Fermen-

tation

Frying and

drying

FIGURE 26.2 Production of oolong tea.

Plucking

Sorting and

cleaning

Rolling or

cutting

Withering

Fermen-

tation

Firing and

drying

FIGURE 26.3 Production of black tea.

ß

2006 by Taylor & Francis Group, LLC.

usually from top to bot tom as drying pro ceeds. To

arrest the ferm entation quickly , he ated air can be

blown individu ally into each layer [13] .

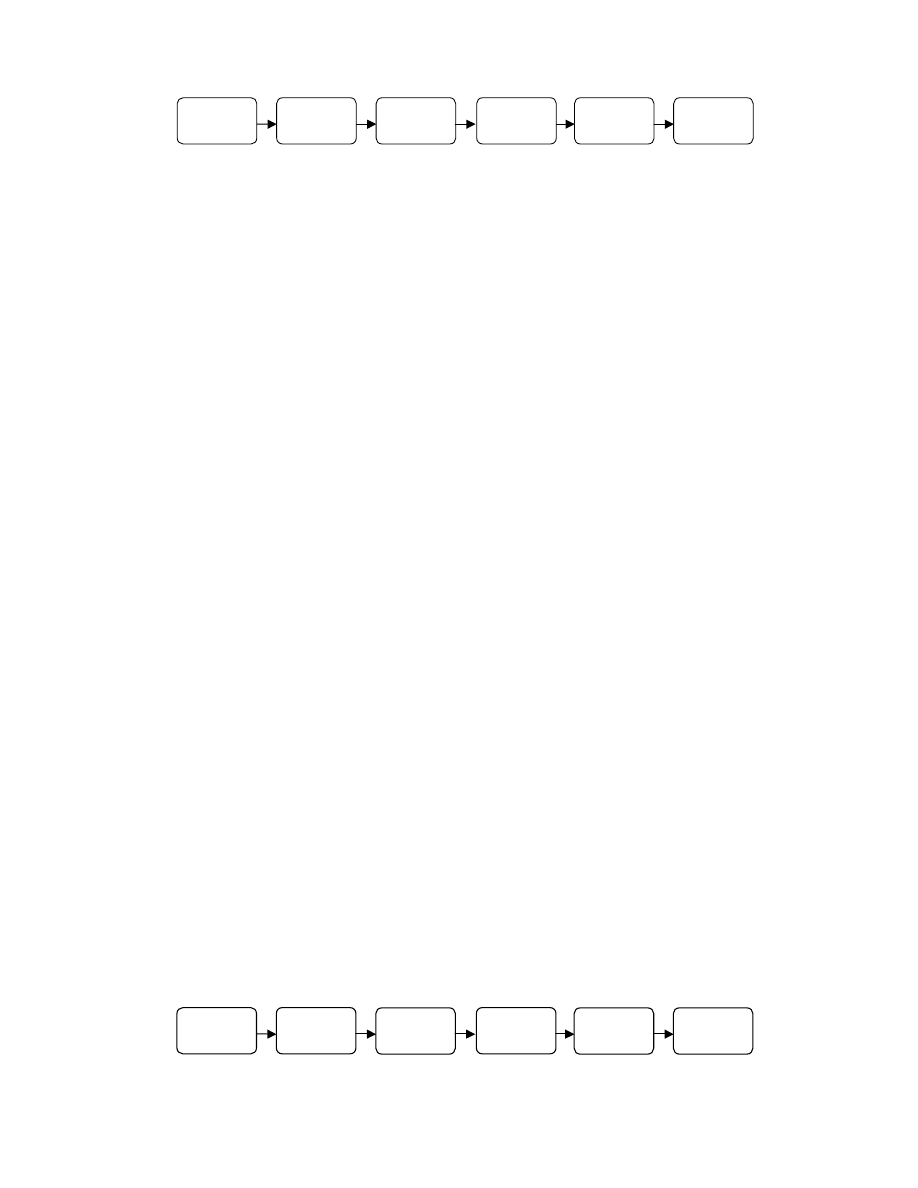

26.2.3 .2 L ouver-Ty pe Oven

This dryer is similar to that of multit ray oven. The

main difference is that there are us ually six layers of

louver plates. The size of this dryer can v ary acco rd-

ing to the capacity req uirement. Again the wet leaves

are loaded at the top. As dry ing proceeds, the louvers

are flipped manual ly to turn the leaves to the ne xt

layer below . The flipping is done in alte rnative direc-

tions so a s to accomp lish a more uni form drying.

Heated air is blown from one side of the dryer. The

dried prod uct is colle cted at the bottom of the ov en.

This dr yer can also operate in the co ntinuous mo de.

The wet tea leaves are fed onto the continuous

moving louver plates. The louver plates make five

turns insi de the drying ch amber before sending out

the dried produ ct to the bottom . While moving , the

louvers are flipp ed accordi ng to the sch edule to ha ve a

more unifor m drying. This type of dryer c an have

a drying area of 50 m

2

. A schema tic diagra m of this

type of oven is shown in Figure 26.4 [13] .

26.2.3 .3 Conve yer Belt Dry er

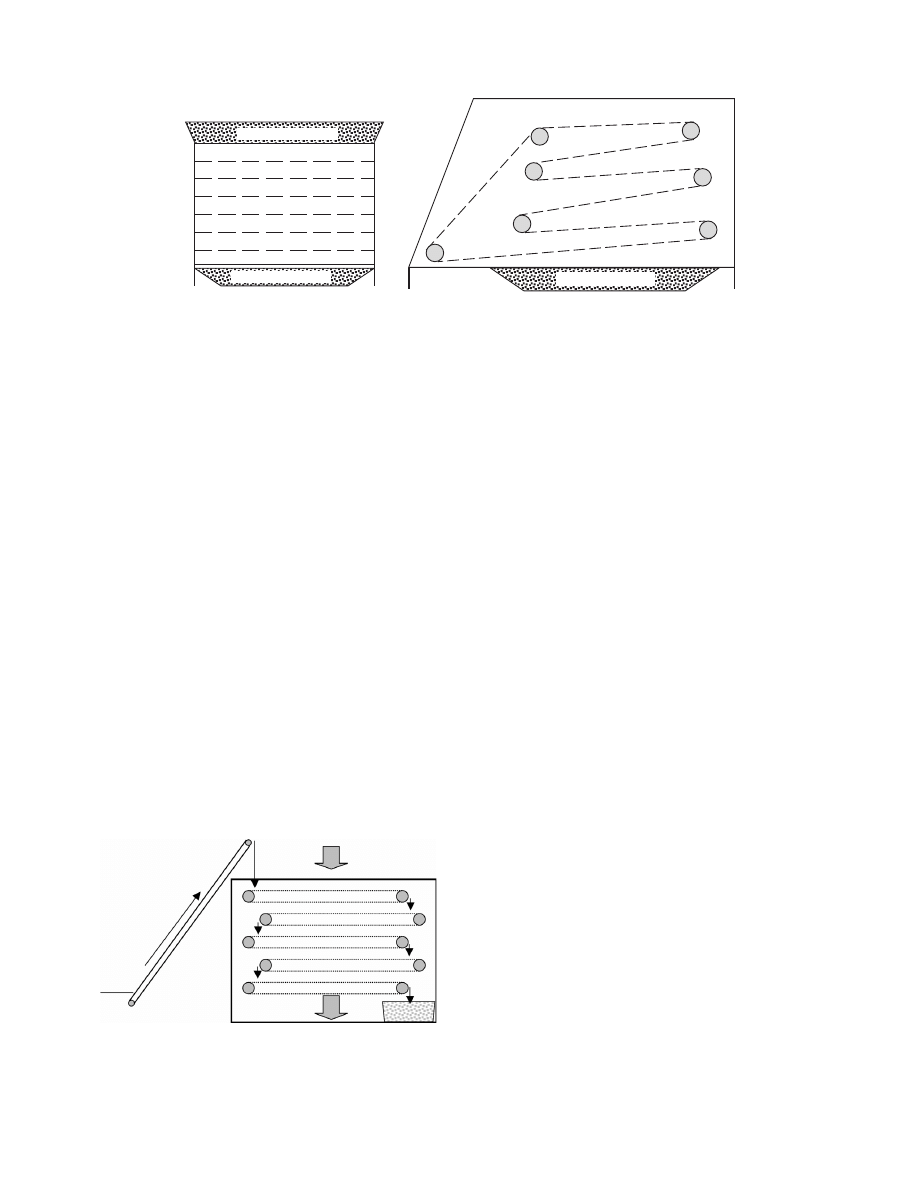

Figure 26 .5 sho ws how a co nveyer dryer operate s.

Instead of louver plate s, a net belt is used in this

dryer. Supe rheate d steam is used as the drying med-

ium. The drying area can be 20 m

2

. It is go od for

drying small pieces of herbs and vegeta bles. Electr ical

heatin g can also be us ed as an auxiliary source of

thermal energy.

26.2.3 .4 Flui dized Be d Dryer

sho ws the schema tic layout of a fluidized

bed dryer [13]. This type of dryer is go od for drying

cut leaves in black tea produ ction. It can give a

unifor m drying in a relative ly sho rt period of tim e.

Mobile bed in co mbination wi th vibrating fluidized

bed may also be used for this purpo se. A fluid bed

dryer co nsists of a grid through whi ch hot a ir is

forced out. Fermen ted leaf wi th not too high mois -

ture content is suspe nded by the air stre ams, resul ting

in flui dization. The air also acts as a carrier of the

particles through the dryer, making the bed of leaves

move forward until the dried leaves are discharged .

To faci litate fluidiza tion of wet ferm ented leaf par-

ticles, the grid can be vibrat ed with half-ampl itude of

severa l millimete rs an d frequenci es in the range of 10–

20 Hz using metal spring s to make a v ibro-flu idized

bed dryer,

[15] . Thi s type of dryer for tea

leaves has be come very popular ov er the pa st three

decades. It is claimed to produce less fines and result

in gentler handling of the fragile leaves resulting in a

better quality product.

The fluidized bed dryer essentially consists of a

drying chamber, plenum chamber, dust collectors,

and flow control dampers. The drying chamber

normally consists of three drying zones and one cool-

ing zone. Fermented leaf is loaded on the grid plate of

the drying chamber. The top of the drying chamber

is closed and two sets of centrifugal exhaust fans

Wet tea leaves

Dried tea leaves

Dried tea leaves

Wet tea leaves

(a)

(b)

FIGURE 26.4 Louver-type oven: (a) manual operation; (b) continuous.

Wet tea leaves

FIGURE 26.5 Conveyer belt dryer. (From Hu, J., Drying of

tea, in Modern Drying Technology, Eds. Y.K. Pan and X.Z.

Wang, Chemical Industry Press, Beijing, 1998, pp. 788–809.)

ß

2006 by Taylor & Francis Group, LLC.

provided with cyclones—one for refiring and the other

for dust extraction. In the first zone of the dryer, the air

flowrate is the maximum to remove the very high mois-

ture content of the fermented leaf rapidly. As the

moisture content is reduced, the density of the particles

is also decreased. These lower moisture content leaves

tend to move away from the feed end and are replaced

by a new load of fermented leaf particles. When the tea

leaves are fully dried, they are expelled into a cooling

chamber where ambient air is introduced [15]. The

hybrid dryer consisting of tray dryer and fluidized

bed dryer may also be used to reduce the temperature

of the hot air in the fluidized bed and also to save on

energy consumption.

26.2.4 D

RYING OF

G

INSENG

R

OOTS

Ginseng is the most commonly used medicinal plant

in Asia. Recently, this ancient, cultivated plant has

been rediscovered in the Western world as a remedy

with numerous and diverse benefits. Traditionally,

ginseng was dug from the forest in the mountains. It

is a very delicate herb that usually takes 6 y or much

longer time to grow. In fact, high-quality roots should

be around 15 y or older. The harvested ginseng roots

are usually sun-dried [16].

Because of its economic values, ginseng roots are

now cultivated in China, Korea, North America, and

even Australia. The majority of ginseng root con-

sumed in the world today first needs to be dried.

The fresh root moisture content is around 72% (wet

basis). The dried ginseng has a moisture content of

approximately 8–12% (wet basis) [17]. Good quality

dried roots should have final moisture content

from 5.5 to 7.5% depending on the size of the roots

[18]. Drying is critical for quality ginseng root. Heat

damage or fungal development can occur from too

short or too long a drying process. Roots should be

sized and similar sizes dried together. The drying of

ginseng root can be achieved by placing them on wire

racks or bamboo baskets and leaving them under the

sun as done traditionally. It will take a few weeks for

the roots to dry. They are more often dried inside by

stacking the wire racks in a room with temperature

FIGURE 26.6 Fluidized bed dryer. (From Hu, J., Drying of tea, in Modern Drying Technology, Eds. Y.K. Pan and X.Z.

Wang, Chemical Industry Press, Beijing, 1998, pp. 788–809.)

FIGURE 26.7 Vibro-fluidized bed dryer. (From Hu, J., Drying of tea, in Modern Drying Technology, Eds. Y.K. Pan and

X.Z. Wang, Chemical Industry Press, Beijing, 1998, pp. 788–809.)

ß

2006 by Taylor & Francis Group, LLC.

maintained around 388C. This drying process will

take about 2–3 weeks to complete. The dried product

will have a brittle exterior and creamy-white interior

[17]. The rough quality control is carried out by snap-

ping tests. A modified tobacco kiln dryer can be

used for large volumes of ginseng. Drying cabinets

can also be employed with the air circulation and

dehumidification systems equipped.

Temperature management is important in ginseng

drying. Too low a temperature will result in the green

coloring or molding, whereas too high a temperature

will give a product that is too hard (not easy to snap)

and of a brown color indicating the formation of

caramelized sugars. The danger of brown roots devel-

oping is greater toward the end of drying. It is not

recommended to accelerate the drying by increasing

the drying temperature at the last stage of drying.

Generally, drying is begun with temperatures at least

above 308C and temperatures below 388C are used

after root wilt. Using higher temperatures at the

beginning of the cycle will reduce the drying time

but it has to be ensured that the root temperatures

throughout the dryer are always within the safe limit.

Three or four thermometers should be placed inside

the drying shed to monitor the temperatures. The floor

temperature should also be monitored where the

value is the lowest. Heating of the shed can

be achieved by natural gas or electricity. Electric

heated walls have the advantage of not introducing

any odor from burning of natural gas.

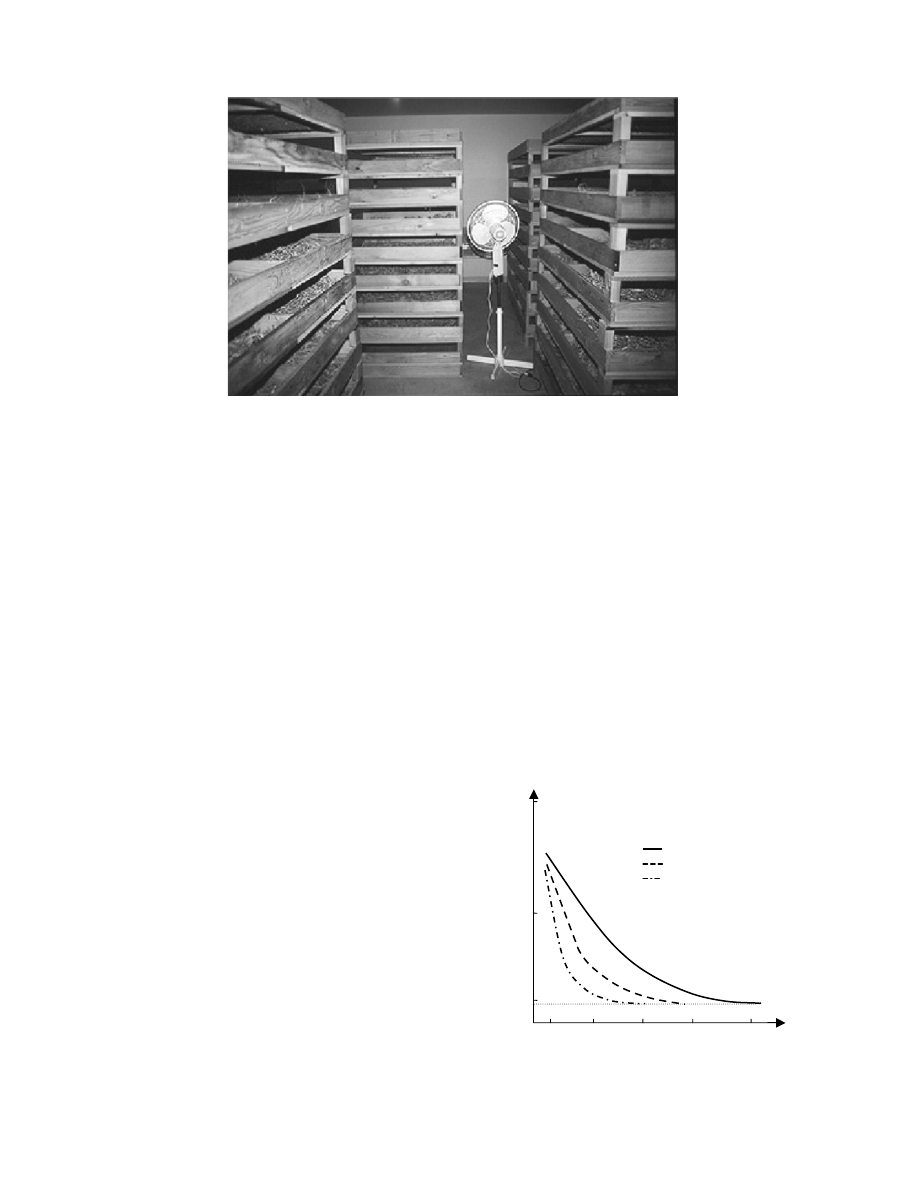

Figure 26.8 shows a photo of a shed dryer for

ginseng roots. The drying history of different

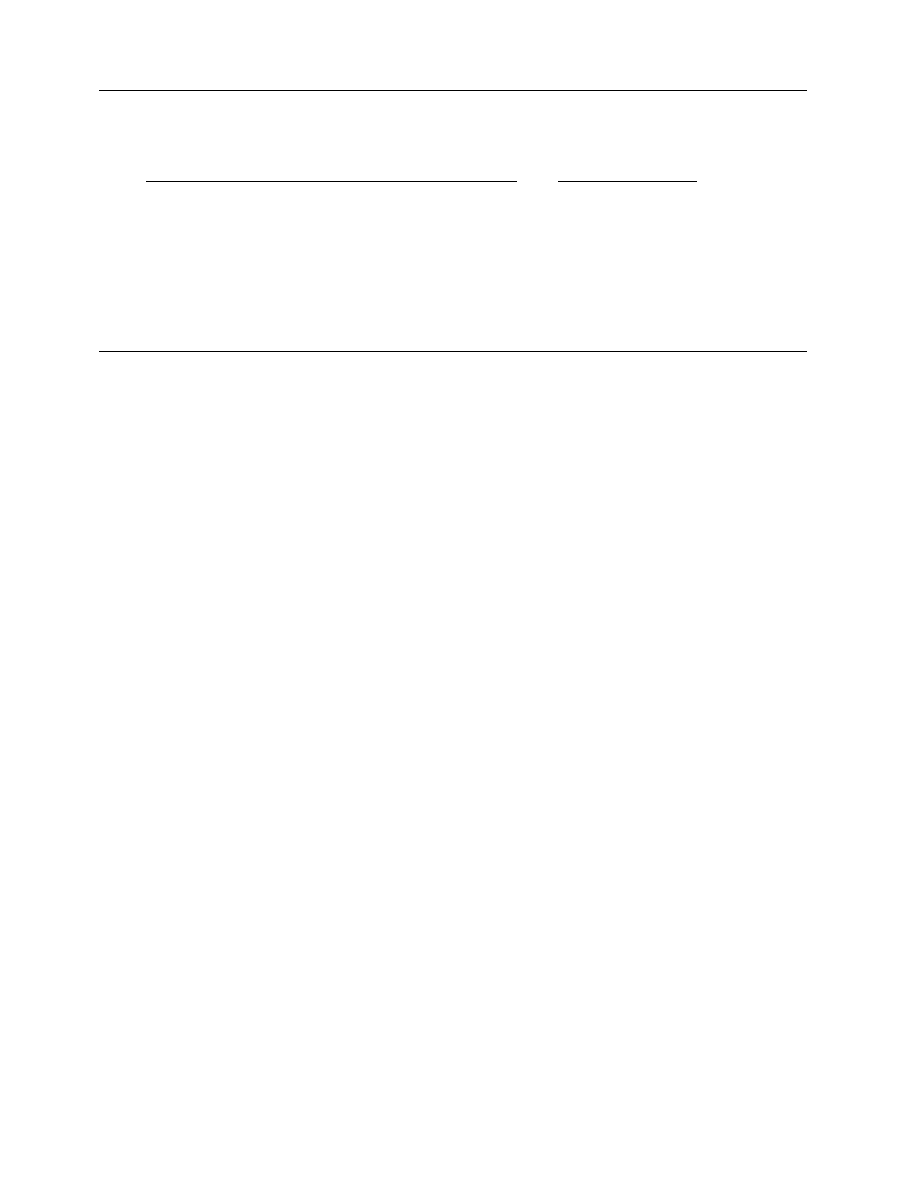

sized ginseng roots is illustrated in Figure 26.9.

Large root refers usually to those of larger than

17 mm in diameter. The diameters of medium-sized

roots are from 12 to 17 mm. The small roots are those

of 7–12 mm in diameter. Any root with diameter

below 7 mm is classified as a fiber [18].

In a shed-type dryer the moisture laden, cooler air

will sink to the lower levels of the room. Thus, the

upper trays will tend to dry faster. To maintain a

uniform drying, either the upper trays are loaded

with large roots or the trays are rebuilt during the

course of drying to move the upper trays down and

lower trays up. During the first week of drying, the air

inside the room should be refreshed every 10–15 min

using an exhaust fan. The capacity of a shed dryer can

vary from 125 to 200 kg fresh root per sq. m. If higher

FIGURE 26.8 A shed dryer for ginseng roots. (From Brun, C.A., Ginseng, Cooperative Extension Program, Washington

State University, 2004.)

1

7

10

14

10

50

100

Moisture content, %(WB)

Days of drying

Value for long-term storage

Large

Medium

Small

4

FIGURE 26.9 Hypothetical drying curves of ginseng roots.

ß

2006 by Taylor & Francis Group, LLC.

TABLE 26.2

List of Experimental Data of Some Herbs Dried by Convective Flow Heated Air

Name

Allowed

T, 8C

Actual

Maximum T, 8C

Ingredient

Loss, %

Maximum DT,

8

C

Air

Velocity, m=s

T

air

, 8C

Initial Moisture

Content,

kg Water=kg

Solids

Mean Drying

Rate,

g=kgmin

1

Cortex Mori Raicis

70–80

79

14.9

20

1.1

70

! 80

0.773

9.9

2

Fructus Aurantii seu Ponciri

50–60

63

1.4

11

0.7

20

! 75 ! 84 ! 68 ! 47

0.75

7.77

3

Herba Caricis phacotae

70–80

67

100

20

1.0

70

1.00

7.70

4

Herba Menthae

Ambient

68.5

100

35

1.3

70

0.80

6.8

5

Polyporus umbellatus

70–80

69.6

16

7

0.9

20

! 70 ! 54

0.88

6.76

6

Radix Trichosanthis

70–80

71.2

66.7

28

0.9

70

0.87

6.7

7

Cortex Moutan Radicis

50–60

68

2.7

20

1.0

70

0.60

6.5

8

Radix Paeoniae alba

70–80

69

60

16

1.1

70

0.70

6.5

9

Citrus reticulata

50–60

66

0

10

0.5

20

! 74 ! 26

0.28

6.1

10

Curcumae aromaticae

70–80

68

61.8

14

0.9

70

0.90

5.42

11

Astragalus membranaceus

70–80

68

0

15

0.8

50

! 70 ! 30

0.53

5.36

12

Cortex Magnoliae Officinalis

70–80

72

2.8

20

0.5

50

! 76 ! 70

1.03

5.22

13

Atractylodes macrocephala

70–80

72

2.8

20

0.5

50

! 70 ! 88

0.74

4.77

14

Cortex Phellodendri

70–80

49.1

17.4

16

1.2

50

0.40

4.6

15

Radix Platycodi

70–80

68

33.6

18

0.8

40

! 74 ! 68

0.29

4.5

16

Rhizoma Ligustici chuanxiong

50–60

48

22

6

0.8

57

! 50

0.923

4.5

17

Semen Arecae

70–80

69

0.5

28

1.3

50

! 70 ! 68

0.80

4.4

18

Radix Saposhnikoviae divaricatae

70–80

69

41.3

20

0.8

52

! 72 ! 66 ! 69 ! 50

0.34

4.3

19

Radix Glycyrrhizae

50–60

49

24.2

14

1.0

54

! 50 ! 45

0.44

4.09

20

Rhizoma Dioscoreae

70–80

69.8

16.6

21

0.7

70

0.81

4.14

21

Rheum Officiale

70–80

70.2

43

19

0.95

50

! 80 ! 53 ! 62

1.12

3.86

22

Radix Salviae

70–80

73.4

33.7

20

0.8

60

! 67 ! 62 ! 40

0.64

3.78

23

Radix Angelicae sinensis

50–60

59

29.1

15

1.0

50

! 59.8

0.75

3.77

24

Caulis Lonicerae

71

28.6

36

1.2

70

0.72

3.72

25

Atractylodes chinensis

50–60

49.9

0

12

0.8

50

0.356

3.69

26

Radix Isatidis

70–80

43.9

59.2

8

0.8

55

! 59 ! 56

0.29

3.1

27

Rehmannia glutinosa

50–60

62

11.4

20

0.92

50

! 71 ! 50 ! 60

1.08

2.74

ß

2006

by

Taylor

&

Francis

Group,

LLC.

loading rates are req uired, a better-cont rolled dry ing

room should be used.

Ele ctrohydr odynami c (EHD ) drying has been

report ed to work well for drying of root or sliced

root material s [19]. This techni que employ s high volt-

age DC and sharp cathode to generat e a corona to

accele rate the air movem ent close to the surfa ce of the

wet mate rial [20]. Bec ause this drying techni que re-

quires only slightly heated a ir for drying, it g ives very

high qua lity of dried mate rial. It is claimed as high

quality as freez e dried mate rials are obtaine d [21,22].

The econ omics of this novel drying process are not

clear as yet. For add itional detai ls, the reader may

refer other sections of this handb ook.

26.3 DRYING OF HERBAL MEDICINES

IN SMALL PIECES

Before the herbs can be used as herbal medic ines, fur-

ther treat ment is necessa ry. The dried herbs are usually

collected by a herbal pha rmace utical compan y where

they are was hed or rewett ed, cut, dried, and packaged

for sale. The rewett ing step is necessa ry to prepa re the

herbs for the cutting pro cess. Dryi ng is obv iously very

impor tant in smal l pieces herbal medicine process ing.

lis ts the effe ct of convecti ve air drying on 27

types of herbs in smal l pieces , whi ch were placed on a

screen as heated air was blow n throu gh [23] . The dry ing

chamber used in these tests was 1.03 m

0.85 m

0.85 m in cross-sect ion. The weight loss of the material

was obtaine d from the reading s of an elect ronic bal-

ance. The dep ths of the beds of herbs were abo ut 30

mm. Nine tempe ratur es wer e mon itored in the fixed

bed of the herb pieces located at the center planes of the

rectan gular box . The maximum tempe ratur e in the

material and also the maxi mum tempe ratur e difference

in the mate rials are lis ted. Most of the drying was

condu cted over 90 min with the final mois ture

content of 0.08 kg water =kg solid s. The initial load of

the wet mate rial was about 400 g. The loss of active

ingredie nts can be quite high even though the

operatio n was co nducted at a temperatur e supposed

to be safe for these herbs [23] . More experi ments

by these au thors show that neithe r the air flowra te

nor the initial mois ture co ntent affect the quality

of dried he rb pieces . The qua lity of the dried herbs

depend s on the drying technol ogy and dry ing con -

ditions with tempe rature being a key parame ter to

control . It is antic ipated that for some herbs the cur-

rently listed values of a llowed tempe ratur e are simp ly

too high.

In order to maint ain a high drying rate an d a

low temperatur e of herb pieces , it is suggeste d to use

staged drying with variation of tempe ratur es of

heated air. For exampl e, in drying of 400 g of Radix

Glycyrrhizae from 0 .44 to 0.08 kg water =kg soli ds,

it took 70, 61, 48, and 55 min, respect ively, at tem-

peratur es of 40, 50, 70, an d (30

! 77 ! 60) 8C. For the

staged drying, the he ating from 30 to 77 8 C takes 28

min a nd the cooling to 60 8C takes about 27 min.

Table 26.3 g ives the temperatur e varia tion within

the materials. The depth of the fixed bed is also a

parameter to consider as demonstrated in the drying

of Cortex Mori Raicis. When the bed depth is in-

creased from 25 to 50 mm, the drying time is 2.7 times

longer and within the material, the maximum temp-

erature differences increased from 10 to 188C at a

drying temperature of 668C [23]. The optimal depth

for the experimental facilities described previously is

about 30 mm.

When infrared drying is used, the loss of active

ingredients is even higher for some herbs as shown

in

[23]. In this drying experi ment, the

IR radiates sideways toward the fixed bed of herb

pieces. The depth of the bed is 30 mm. The initial

TABLE 26.3

The Experimental Data of Drying of Radix Glycyrrhizae

Temperature, 8C

Drying Rate, g=kgmin

Drying Time,

min

Heated

Air

Maximum at the

Bottom Surface

Maximum Difference

between Top and Bottom

Maximum

Average

1

40

33.5

7.8

10.5

5.6

70

2

50

46

15

11.5

6.2

61

3

70

63

28

12.4

8.6

48

4

30

! 77 ! 60

49

7.6

10.0

6.9

55

Air flow velocity

¼ 1 m=s, initial moisture content ¼ 0.44, final moisture content ¼ 0.08, depth of bed ¼ 30 mm, convective flow of heated

air drying.

ß

2006 by Taylor & Francis Group, LLC.

mass of the wet mate rial is about 400 g. It is interest ing

to find also that some herbs remai n acti ve even though

drying was carri ed out a tempe rature exceed ing the

allowed values such as Polyporus umbellatus , Radix

Trichosanthis , Radix Glycyrrhizae , Rhizoma Ligustici

chuanxiong , etc. A compari son of the ingredi ent losse s

of the herbs dried by he ated air an d IR is given in

. Bes ides the mate rial tempe ratur e, the way in

which the heat is supplied an d the mois ture is taken

away from the drying ch amber definite ly plays a role in

the quality of the dried he rbs. W hen infr ared drying is

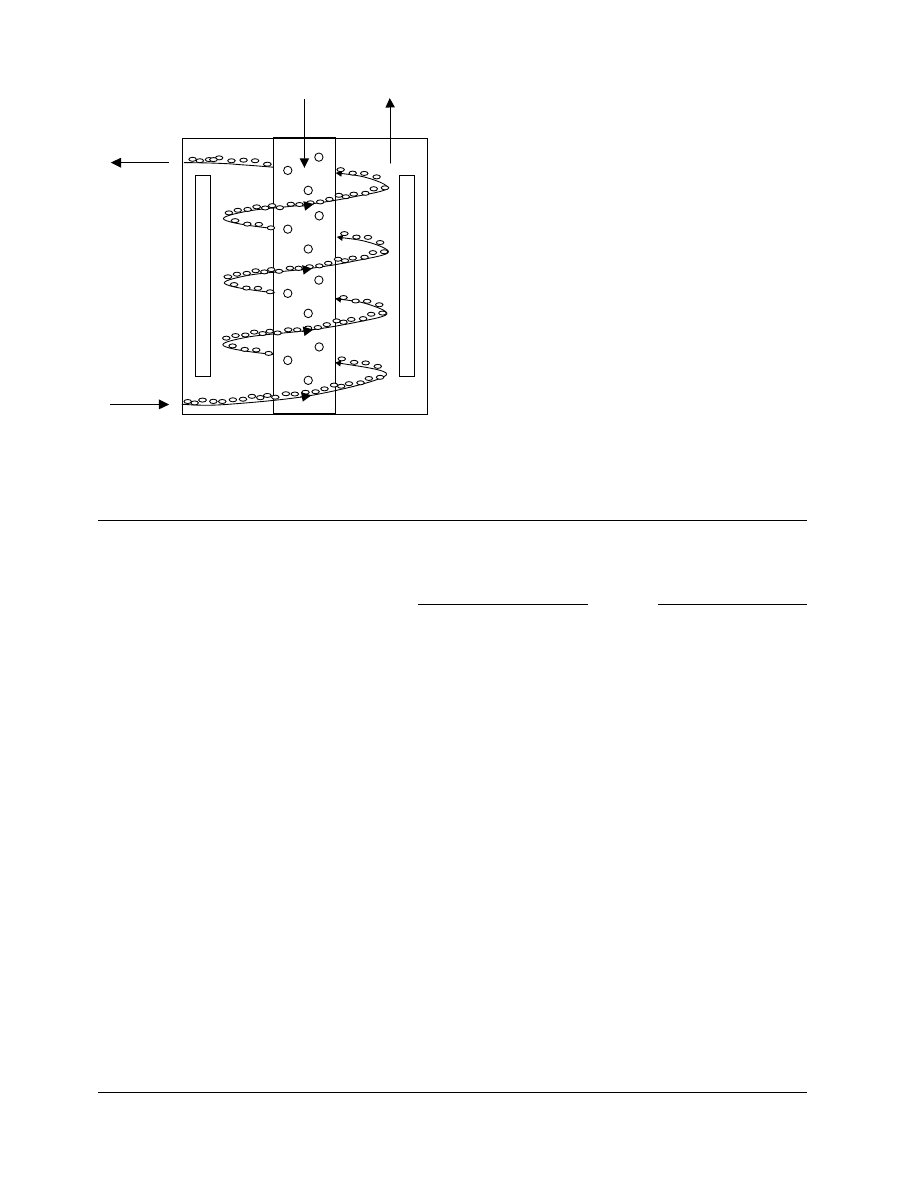

combined with vibro-flu idized bed, Figure 26 .10, the

drying rate as well as the quality of the dried pro duct is

impro ved signi ficantl y [23]. Tabl e 26.5 lists 27 herbs.

For infor mation of herbs and their active ingredi ents,

readers are refer red to an on-lin e reference [24] .

The typical dryers found in drying of he rbs in

small pieces are oven , drying house, tunnel dryer,

vacuum dryer, and fluidized bed dryer. The descrip -

tions of these dryers can be found in the other chap -

ters of this handb ook [23,25].

26.4 CONCLUSIONS

Herb drying includes drying after harvest and drying

before processing. The drying after harvest usually

involves small volumes, thus the household equipment

can also be used. Either heated air or ambient drying

TABLE 26.4

The Experimental Data of Infrared Drying of Herbs

Name

Temperature, 8C

Active Ingredients

Tested=Method

Loss, %

Allowed

Actual

Heating Plate

1

Cortex Mori Raicis

80

78

292

Water extracts=standard

12.3

2

Fructus Aurantii seu Ponciri

60

62

279

! 212, K

1

¼ 0.76

Synephrine=HPLC

9.5

3

Herba Caricis phacotae

80

82

300

Phenylethyl alcohol=HPLC

100

4

Herba Menthae

Ambient

75

200

! 150, K

1

¼ 0.28

Menthol=GC

100

5

Polyporus umbellatus

60

70

293

! 229, K

1

¼ 0.13

Polyporus umbellatus

polysaccharides=UV

6.0

6

Radix Trichosanthis

80

84

386

Trichosanthin=UV

27.8

7

Cortex Moutan Radicis

60

68

282

! 175, K

1

¼ 0.74

Paeonol=HPLC

0

8

Radix Paeoniae alba

80

79

289

! 250, K

1

¼ 0.31

Albiflorin=HPLC

65

9

Citrus reticulata

60

62

275

! 130 ! 62,

K

1

¼ K

2

¼ 0.05

Hesperidin=HPLC

40.0

10

Curcumae aromaticae

80

88.9

280

Camphor=GC

39.3

11

Astragalus membranaceus

80

85

278

Water extracts=standard

17.6

12

Cortex Magnoliae Officinalis

80

72.6

295

Magnolol=GC

12.4

13

Atractylodes macrocephala

80

88.9

360

Water solubles=UV

11.7

14

Cortex Phellodendri

80

67

360

Berberine=HPLC

17.8

15

Radix Platycodi

80

75

387

Platycodoside=standard

28.6

16

Rhizoma Ligustici chuanxiong

60

70

374

! 219, K

1

¼ 0.81

Water extracts=standard

3.8

17

Semen Arecae

60

78

351

! 220 ! 170,

K

1

¼ K

2

¼ 0.23

Arecolime=standard

22.7

18

Radix Saposhnikoviae divaricatae

80

79.4

377

Mannitol=GC

65.9

19

Radix Glycyrrhizae

60

62

386

Glycyrrhizic acid=HPLC

17.9

20

Rhizoma Dioscoreae

80

78

296

! 241, K

1

¼ 0.33

Allantion=UV

10.25

21

Rheum Officiale

80

98

278

! 248 ! 217,

K

1

¼ K

2

¼ 0.22

Rhammoside=HPLC

64

22

Radix Salviae

80

75

281

! 264, K

1

¼ 0.71

Water extracts=standard

11.9

23

Radix Angelicae sinensis

60

64

338

! 286 ! 243,

K

1

¼ K

2

¼ 0.13

Ferulic acid=HPLC

55.6

24

Caulis Lonicerae

79.5

360

Chlorogenic acid=HPLC

0

25

Atractylodes chinensis

60

71

388

! 275, K

1

¼ 0.55

Alcohol extracts=GC

0

26

Radix Isatidis

80

77.7

360

Indirubin=UV

38.3

27

Rehmannia glutinosa

60

81

370

! 300, K

1

¼ 0.89

Water extracts=standard

0.08

K

¼ heating time at T=total drying time.

ß

2006 by Taylor & Francis Group, LLC.

can be used. Freeze drying, microwave drying, or silica

sand drying can be used depending on the value and

sensitivity of the herb. For large quantity of herbs,

such as tea leaves or ginseng, drying requires indus-

trial-scale operation. The quality of the dried products

is important to control and thus governs the drying

conditions. For the drying of small pieces of herb

medicines, temperature control is important in retain-

ing the active ingredients. The selection of drying tech-

niques is also important in affecting the quality of the

dried herbs. Uniform drying of the small herb pieces

can give better quality of the products. The reader

may refer to other chapters of this handbook for an

in-depth discussion of industrial-scale drying e.g.,

fluidized bed, freeze drying, microwave drying, etc.

ACKNOWLEDGMENT

The authors are grateful for the financial support

of HK SAR Government from RGC600704 and

HKUST6038=00P.

TABLE 26.5

Comparison of Ingredient Loss between Heated Air and IR Drying

Name

Actual Maximum T, 8C

Ingredient Loss, %

Heated Air

IR

Heated

IR

1

Cortex Mori Raicis

79

78

14.9

12.3

2

Fructus Aurantii seu Ponciri

63

62

1.4

9.5

3

Herba Caricis phacotae

67

82

100

100

4

Herba Menthae

68.5

75

100

100

5

Polyporus umbellatus

69.6

70

16

6.0

6

Radix Trichosanthis

71.2

84

66.7

27.8

7

Cortex Moutan Radicis

68

68

2.7

0

8

Radix Paeoniae alba

69

79

60

65

9

Citrus reticulata

66

62

0

40.0

10

Curcumae aromaticae

68

88.9

61.8

39.3

11

Astragalus membranaceus

68

85

0

17.6

12

Cortex Magnoliae Officinalis

72

72.6

2.8

12.4

13

Atractylodes macrocephala

72

88.9

2.8

11.7

14

Cortex Phellodendri

49.1

67

17.4

17.8

15

Radix Platycodi

68

75

33.6

28.6

16

Rhizoma Ligustici chuanxiong

48

70

22

3.8

17

Semen Arecae

69

78

0.5

22.7

18

Radix Saposhnikoviae divaricatae

69

79.4

41.3

65.9

19

Radix Glycyrrhizae

49

62

24.2

17.9

20

Rhizoma Dioscoreae

69.8

78

16.6

10.25

21

Rheum Officiale

70.2

98

43

64

22

Radix Salviae

73.4

75

33.7

11.9

23

Radix Angelicae sinensis

59

64

29.1

55.6

24

Caulis Lonicerae

71

79.5

28.6

0

25

Atractylodes chinensis

49.9

71

0

0

26

Radix Isatidis

43.9

77.7

59.2

38.3

27

Rehmannia glutinosa

62

81

11.4

0.08

Wet

pieces

Dried

pieces

Heated air

Exit air

Infrared source

Infrared source

FIGURE 26.10 Vibro-fluidized bed dryer with IR heating.

(From Chu, Z.D., Drying of small pieces of Chinese medi-

cine, in Modern Drying Technology, Eds. Y.K. Pan and X.Z.

Wang, Chemical Industry Press, Beijing, 1998, pp. 810–841.)

ß

2006 by Taylor & Francis Group, LLC.

REFERENCES

1. Lipp, F.J., Herbalism—the heeling power of plant:

regional translations, in Remedies & Recipes , Duncan

Baird Publishers, London, 1996.

2. Wang, D.I.C., Leung, J.C., Wu, I.-C., and Cao, N.,

Biotechnology and Hong Kong, in Made by Hong

Kong , S. Berger & R.K. Lester, Oxford University

Press, 1997.

3. Stuart, M., The Encyclopedia of Herbs and Herbalism ,

Orbis Publishing, London, 1979.

4. Ye, D.J., Zhang, S.C., and Chen, Q., Chinese Medicine

Preparation, Shanghai Science & Technology Publish-

ing, 2000 (in Chinese).

5. Lou, Z.-C. and Qin, B., Species Systematization and Qual-

ity Evaluation of Commonly Used Chinese Traditional

Drugs , Beijing Medical University & China Xiehe Med-

i c a l U n iv e r si ty J o in t P ub li sh in g, 1 9 94 ( i n C hi ne s e) .

6. Huang, T.K., Handbook of Composition and Pharmaco-

logical Action of Commonly Used Traditional Chinese

Medicine , China Medico-Pharmaceutical Science and

Technology Publishing House, 1994 (in Chinese).

7. Blose, N. Herb Drying Handbook: Includes Complete

Microwave Drying Instructions , Sterling Publishing

Co. Inc., New York, 2001.

8. Catalytic Drying Technologies, 20th and Sycamore,

drying.com =company_profile.htm

9 . Universal Drying Locker T D-60, ThermoDynamic ,

http: == ww w. t hermo -dm. si=en =dryi ng_of_fruits.php

, 2004.

10. Chua, K.J., Chou, S.K., Ho, J.C., and Hawlader

M.N.A., Heat pump drying: recent developments and

future trends, Drying Techn ., 20(8): 1579–1610, 2002.

11. Crawford, H., The Chemistry of Tea, University of Bristol,

200 3.

http: == www.chem.bris.ac. u k=webprojects2 001=

12. Tillberg, M., The Way of Tea, Tea Processing,

http: == tea.hypermart.net =teapage.html

, 2004.

13. Hu, J., Drying of tea, in Modern Drying Technology ,

Eds. Y.K. Pan and X.Z. Wang, Chemical Industry

Press, Beijing, 1998, pp. 788–809.

14. Live Herb Nursery, The Tea Plant Place, Processing

http: == liveherbnursery.com =index.htm

, 2004.

15. Tea Research Association, Tocklai Experimental

Station, Tea Manufacture—Drying,

lai.org=manufacture =drying.htm

, 2004.

16. Prinzenberg, E.D., Ginseng—Stay Young & Vital ,

Sterling Publishing Co., Inc., New York, 1999.

17. Brun, C.A., Ginseng, Cooperative Extension Program,

Washington State University, 2004.

18. Van Dalfsen, B., 1998, Ginseng Dryer Operation, Farm

Mechanization Fact Sheet, Ministry of Agriculture,

Food and Fisheries, British Columbia, Canada, Order

No. 280.380–1, 1998.

19. Hashinaga, F., Bajgai, T.R., Isobe, S., and Barthakur

N.N., Electrohydrodynamic (EHD) drying of apple

slices, Drying Techn ., 17(3): 479–496, 1999.

20. Lai, F.C. and Lai, K.-W., EHD—Enhanced drying

with wire electrode, Drying Techn ., 20(7): 1393–1405,

2002.

21. Chen, G . a nd Mujumdar , A. S., Appl icat ion of e lec-

trical fiel ds i n de watering an d drying. Dev. Chem. Eng.

Miner. Process.—Australas. Res. J., 1 0( 3 =4 ) : 4 29 – 44 2 ,

20 0 2.

22. Liang, Y.Z., Study of the Technologies of Electrostatics

Drying, Proceedings of the 7th National Drying Sympo-

sium , Jinan, China, 1999, pp. 343–348.

23. Chu, Z.D., Drying of small pieces of Chinese medicine,

in Modern Drying Technology , Eds. Y.K. Pan and

X.Z. Wang, Chemical Industry Press, Beijing, 1998,

pp. 810–841.

24. Chu, H.K., Traditional Chinese Medicine, 2004, in

Complementary and Alternative Healing University,

http: == alternativehealing.org

.

25. Zheng, P.Q., Formulation of Chinese Medicines, China

Pharmaceutical Technology Press, Beijing, 1998.

ß

2006 by Taylor & Francis Group, LLC.

Document Outline

- Table of Contents

- Chapter 026: Drying of Herbal Medicines and Tea

Wyszukiwarka

Podobne podstrony:

Dr Gary L Glum Calling Of An Angel The True Story Of Rene Caisse And An Indian Herbal Medicine Cal

DISTILLING KNOWLEDGE new histories of science, technology, and medicine

Far infrared and microwave drying of peach (Jun Wang, Kuichuan Sheng)

Herbs Of The Field And Herbs Of The Garden In Byzantine Medicinal Pharmacy

Advantages and disadvantages of alternative medicine

Modeling and minimizing process time of combined convective and vacuum drying of mushrooms and parsl

022 Drying of Fish and Seafood

Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opi

The Medicines and Dilutions of them habitually used by Hahnemann po angielsku

medicine and surgery of unusual pets 2008

Effect of vacuum microwave drying on selected mechanical and rheological properties of carrot

Microwave Drying of Parsley Modelling, Kinetics, and Energy Aspects

Effect of cocoa and tea intake on blood pressure

Drying kinetics and rehydration characteristics of microwave vacuum and convective hot air dried mus

Use of exponential, Page’s and diffusional models to simulate the drying kinetics of kiwi fruit

Thin layer modelling of the convective, microwave, microwave convective and microwave vacuum drying

DISTILLING KNOWLEDGE new histories of science, technology, and medicine

A comparative study on heat pump, microwave and freeze drying of fresh fruits

więcej podobnych podstron