Ž

.

Fitoterapia 71 2000 501

᎐506

Factors affecting volatile terpene and

non-terpene biotransformation products in

plant cell cultures

W. Zhu, G. Asghari, G.B. Lockwood

U

School of Pharmacy & Pharmaceutical Scienes, Uni

¨

ersity of Manchester, Manchester M13 9PL,

UK

Received 7 January 2000; accepted in revised form 16 February 2000

Abstract

Suspension cultures from Peganum harmala were shown to carry out biotransformations

of a number of terpenes and non-terpenes. The rate of biotransformation was dependant

upon substrate concentration, density of cell suspensions, and the structure and isomeric

form of the substrates.

䊚 2000 Elsevier Science B.V. All rights reserved.

Keywords: Peganum harmala; Biotransformation; Essential oil constituents

1. Introduction

The production and accumulation of volatile essential oil constituents in plant

w x

cell cultures has been reviewed 1,2 . Although plant cells cultured in vitro are

considered to be totipotent, i.e. contain all necessary genetic material to carry out

any or all of the functions shown by the intact plant, in practice many either fail to

produce essential oil constituents or produce a few in only very low levels. It is

often accepted that as undifferentiated cultures contain no structures such as

w x

trichomes or vittae for storage of these constituents 3 none will accumulate. In

U

Corresponding author. Tel.:

q44-161-275-2334; fax: q44-161-275-2396.

Ž

.

E-mail address: lockwood@fsl.pa.man.ac.uk G.B. Lockwood .

0367-326X

r00r$ - see front matter 䊚 2000 Elsevier Science B.V. All rights reserved.

Ž

.

PII: S 0 3 6 7 - 3 2 6 X 0 0 0 0 1 6 0 - X

(

)

W. Zhu et al.

rFitoterapia 71 2000 501᎐506

502

many systems particular enzyme systems needed for a biosynthetic step have been

w x

shown to be present 1 , but inoperative, and this inhibits production of the end

Ž .

product s . A number of workers have attempted to improve production and

w x

accumulation of these compounds by feeding precursors 1,2 , but levels are still

well below those of intact plants. We decided to use a range of techniques to

investigate if levels of biotransformation products could be increased. Biotransform-

ation of geraniol acetate to geraniol by plant cell cultures has not previously been

Table 1

Volatile substrates and their major biotransformation products produced by P. harmala suspension

cultures

Substrate

Product

Substrate

Products

Benzyl acetate

Benzyl alcohol

Bornyl acetate

Borneol

Cinnamyl acetate

Cinnamyl alcohol

Dihydrocarvyl

Dihydrocarveol

acetate

Farnesyl acetate

Farnesol

Fenchyl acetate

Fenchol

Geranyl acetate

Geraniol

Linalyl acetate

Linalool

␣-Terpineol

Geranyl acetate

Menthyl acetate

Menthol

Neryl acetate

Nerol

Geraniol

Phenethyl acetate

Phenethyl alcohol

5-Acetoxymethyl-2-

5-Acetoxymethyl-2-

furaldehyde

furfuryl alcohol

m, p and o-

m, p & o-Anisyl

Benzaldehyde

Benzyl alcohol

Anisaldehyde

alcohol

Cinnamaldehyde

Cinnamyl alcohol

Citral

Geraniol

Hydrocinnamyl

Nerol

alcohol

Citronellal

Citronellol

Cumic aldehyde

Cumic alcohol

3,5-Dimethoxy-

3,5-Dimethoxy-

benzaldehyde

benzyl alcohol

Ethylvanillin

Ethylvanillyl

Furfural

Furfuryl alcohol

alcohol

Hydrocinnamal-

Hydrocinnamyl

Isovanillin

Isovanillyl alcohol

dehyde

alcohol

Myristicin aldehyde

Myristicin alcohol

Myrtenal

Myrtenol

Myrtanol

Perillaldehyde

Perilla alcohol

Phenethylaldehyde

Phenethyl alcohol

Piperonal

Piperonol

Salicylaldehyde

Salicyl alcohol

-Ionone

-Ionol

Menthone

Menthol

7-Hydro-

-ionone

Piperitol

Geraniol

Nerol

Verbenol

Verbenone

d-Limonene

Limonene epoxide

␣-Pinene

Verbenol

p-2,8-Menthadien-1-

Verbenone

ol

Carveol

-Pinene

Myrtenol

␥-Terpinene

p-Cymene

Myrtenal

p-Cymen-8-ol

(

)

W. Zhu et al.

rFitoterapia 71 2000 501᎐506

503

reported, although there is one report of the reverse reaction occurring, in a study

w x

of the biogenesis of monoterpenes using cultures derived from Muscat grapes 4 .

However, a few reports have described the biotransformation of other terpene

w x

acetates into their parent alcohols by plant cell cultures 5,6 , but in both instances

the parent alcohol was only the major product, not the sole product. In an attempt

to show variation in levels of biotransformation of volatile terpenoids and non-

Ž

.

terpenoids, we chose suspension cultures of Peganum harmala L. Zygophyllaceae

for the feeding experiments.

2. Experimental

2.1. Cell culture

Seeds of P. harmala from Esfahan Botanical Research Centre, Iran, were

surface-sterilised with 30% w

rv hydrogen peroxide containing one drop of Triton,

Ž

.

w x

and a primary callus was maintained in Murashige & Skoog media MS

7

containing 3% sucrose, 5 mg

rl ascorbic acid, 1.0 mgrl 2,4-dichlorophenoxyacetic

Ž

.

acid

2,4-D , and 0.1 mg

rl kinetin. The suspension culture from the fourth

Ž

generation of callus culture was maintained in the same media as callus except

.

without the agar in 24-h continuous light at 25

" 2⬚C and subcultured every 3

weeks. Subcultures were done by transferring 10 ml of the old suspension to 90 ml

of the new media.

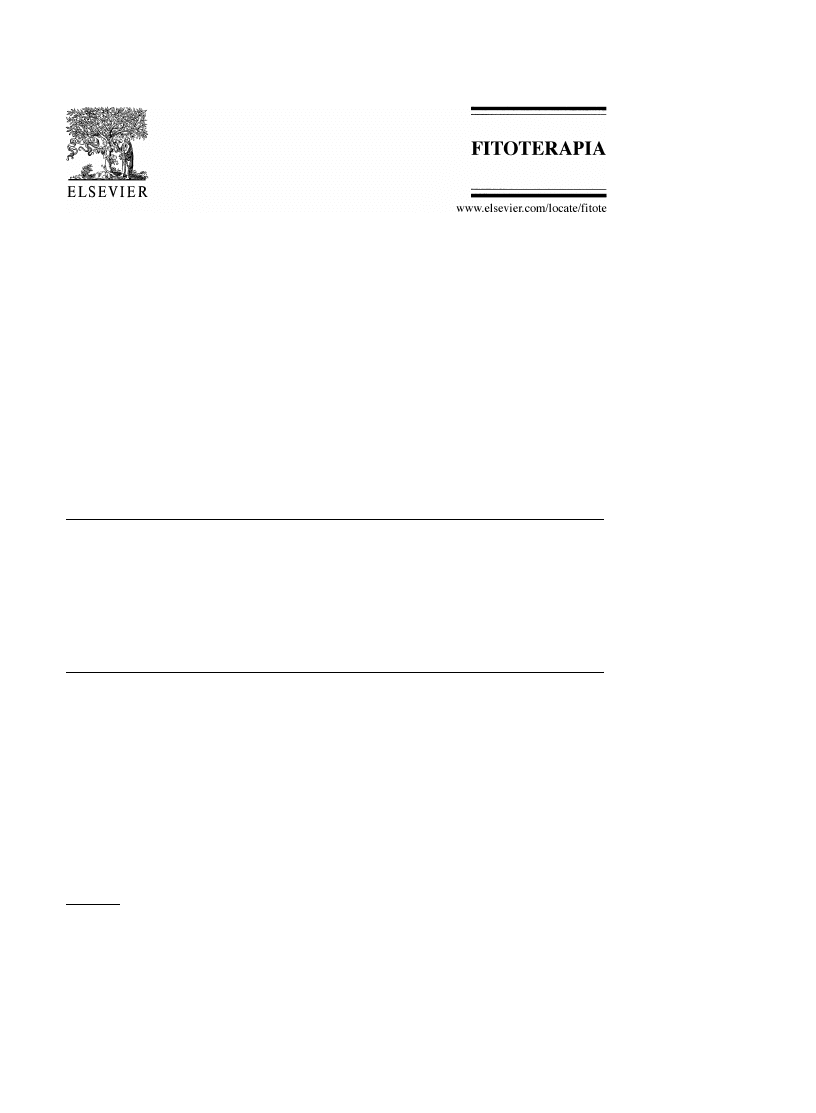

Fig. 1.

Effect of geranyl acetate substrate concentration on product levels in P. harmala suspension

cultures.

(

)

W. Zhu et al.

rFitoterapia 71 2000 501᎐506

504

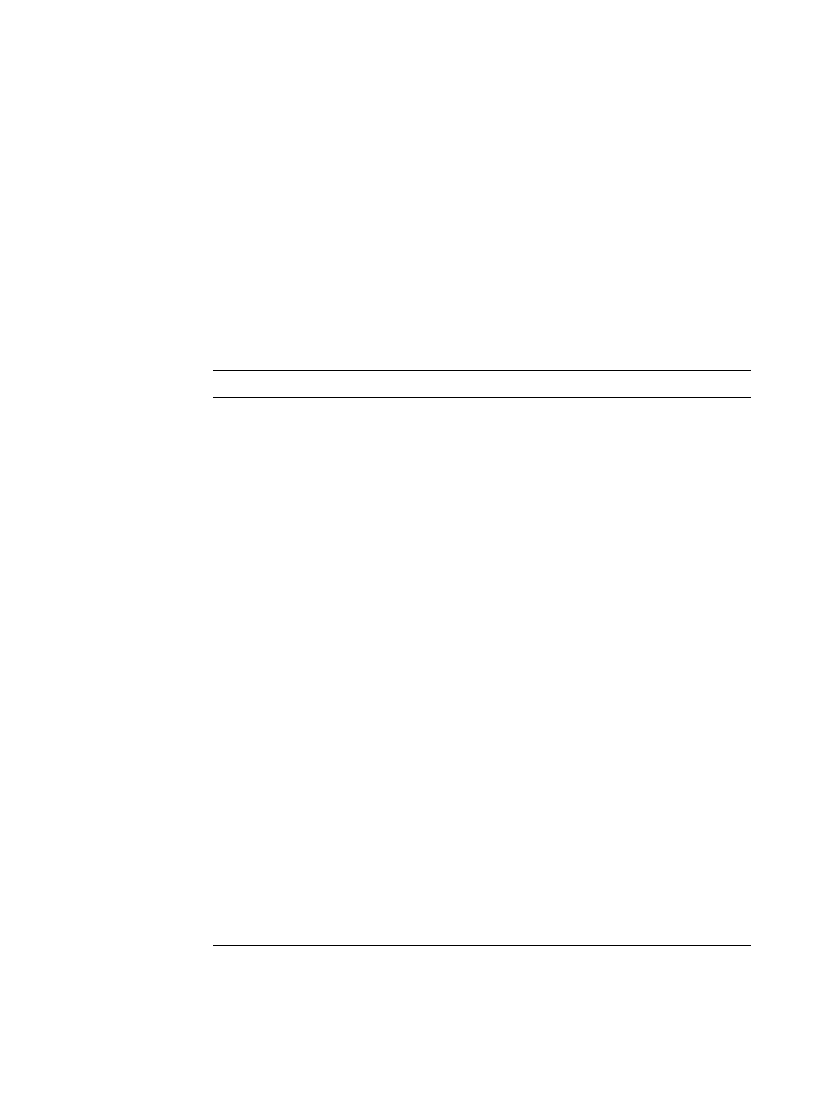

Fig. 2.

Effect of cell density on levels of product after feeding bornyl acetate to P. harmala suspension

cultures.

2.2. Biotransformation

Ž

.

Substrates Fluka and Aldrich were mixed with 70% EtOH and injected through

Ž

.

a preautoclaved Mobile Phase Filter 0.45-mM pore size, Whatman to the suspen-

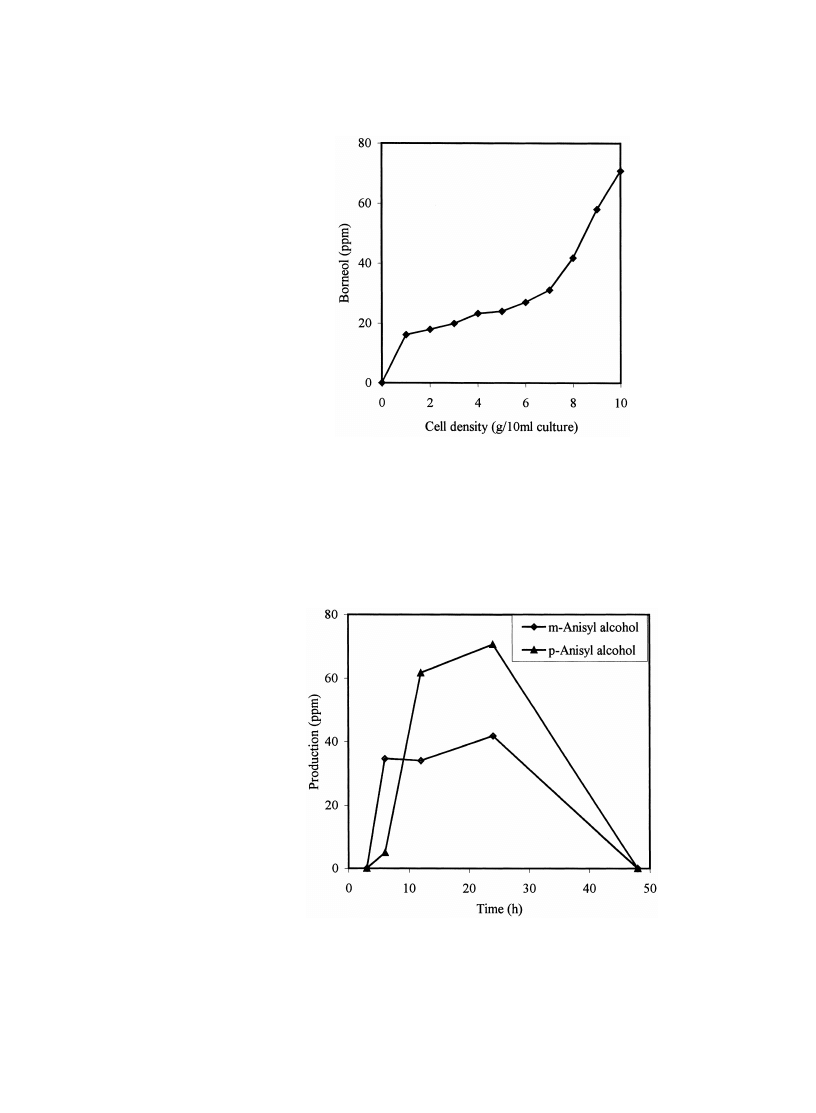

Fig. 3.

Levels of products after feeding structural isomers of anisaldehyde to P. harmala suspension

cultures.

(

)

W. Zhu et al.

rFitoterapia 71 2000 501᎐506

505

sion, 5 days after subculture. Feeding concentration was 100 ppm unless otherwise

Ž

.

stated. Samples 5 ml were removed from the suspensions after 24 h inoculation,

and analysed.

2.3. Analysis

Ž

.

Aliquots 5 ml were extracted with 5 ml CH Cl and pentadecane as an internal

2

2

standard was added prior to extraction. The CH Cl

layer was passed through

2

2

Whatman No.1 filter paper, and dried with anhydrous sodium sulfate. The organic

layer was evaporated under nitrogen to reduce the volume to 100

l, and subjected

to analysis by gas chromatography. Gas chromatography analysis used a HP 5890A

Ž

with an FID detector. The column was BP1 fused-silica column 25 m

= 0.32 mm,

.

film thickness 0.25 mm . Oven temperature programming was 50

᎐280⬚C, at

10

⬚Crmin, and held isothermal for 5 min. The injector and detector temperatures

were 250 and 280

⬚C, respectively. Identification of components was checked using

standards where available, and GC-MS using the same column.

3. Results and discussion

Table 1 shows substrates and the major biotransformation products produced by

freely suspended cells of P. harmala. Many of these biotransformations have been

w

x

reported for other suspension cultures 1,2,8 , but the biotransformations of

-

ionone to

-ionol and 7-hydro--ionone, and neryl acetate to nerol and geraniol

were previously unreported in plant cell cultures. The effects of substrate concen-

tration upon biotransformation levels can be seen in Fig. 1. Optimum turnover

occurs at a substrate concentration of 100 ppm. Previous reports showed that this

w x

optimum level varied from 80 to 200 ppm in Catharanthus roseus cultures 9 , while

Brown and co-workers showed that feeding from 250 to 420 ppm limonene to

w x

cultures of Pelargonium fragrans reduced viability to zero 10 . Fig. 2 shows the

effect of increasing suspension cell density on levels of biotransformation product

after feeding with bornyl acetate. Levels continue increasing up to cell densities of

10 g

r10 ml. Structural isomers have been reported to be metabolised regioselec-

w x

tively 11 , and this was also noted here with isomers of anisaldehyde. In addition,

Fig. 3 shows distinct differences in the levels of m- and p-anisaldehyde metabolites,

the anisyl alcohol isomers, over the 50 h since substrate feeding.

References

w x

1

Mulder-Krieger TH, Verpoorte R, Svendsen AB, Scheffer JJC. Plant Cell Tissue Organ Cult

1988;13:85.

w x

2

Shin S. Kor J Pharmacogn 1995;26:227.

w x

3

Everitt Z, Lockwood GB. Plant Physiol Life Sci Adv 1989;8:75.

w x

4

Ambid C, Moisseeff M, Fallot J. Plant Cell Rep 1982;1:91.

w x

5

Hirata T, Aoki T, Hiranno Y, Ito T, Suga T. Bull Chem Soc Jpn 1981;54:3527.

(

)

W. Zhu et al.

rFitoterapia 71 2000 501᎐506

506

w x

6

Hook I, Lecky R, Mckenna B, Sheridan H. Phytochemistry 1990;29:2143.

w x

7

Murashige T, Skoog F. Physiol Plant 1962;15:473.

w x

8

Suga T, Hirata T. Phytochemistry 1990;29:2393.

w x

9

Balsevich J. Planta Med 1985;49:128.

w x

10

Brown JT, Hegarty PK, Charlwood BV. Plant Sci 1987;48:195.

w x

11

Hirata T, Koya K, Sarfo KJ et al. J Mol Catal B Enzymatic 1999;6:67.

Wyszukiwarka

Podobne podstrony:

Cadmium and Other Metal Levels in Autopsy Samplesfrom a Cadmium Polluted Area and Non polluted Contr

Ziyaeemehr, Kumar, Abdullah Use and Non use of Humor in Academic ESL Classrooms

Microwaves in organic synthesis Thermal and non thermal microwave

127729 5 4a Factors affecting economic growth16 01 03

blocking and non blocking

Factors affecting

Microwaves in organic synthesis Thermal and non thermal microwave

Linear and non Linear SR 2012

part 2 7 Information Structure and Non canonical Syntax

Do Big Five personality Factors aFFect inDiviDual

ImplicituresCancelability and Non detachability

0739116452 10 17 African American Slave Medicine Herbal and non Herbal Treatments

Co existence of GM and non GM arable crops the non GM and organic context in the EU1

Performance Parameters of Explosives Equilibrium and Non Equilibrium Reactions

2005 Diet and Age Affect Intestinal Morphology and Large Bowel Fermentative End Product Concentratio

The role of child sexual abuse in the etiology of suicide and non suicidal self injury

meaning H P Grice natural and non natural meaning

A Comparison of Linear Vs Non Linear Models of Aversive Self Awareness, Dissociation, and Non Suicid

Kant and Non Euclidean Geometry

więcej podobnych podstron