PCBA Debug Guide

Página 1 de 10

Rev. 2.8

PCIE Faults

Debug Guide

Rev 2.8

PCBA Debug Guide

Página 2 de 10

Rev. 2.8

1. Revision History

Revision

Description

Author/Revised

By

Date

1.0

Draft release

Luis Rodríguez

14 0ct 2005

2.0

Category C added

Luis Rodríguez

24 Jan 2006

2.1

Updated category B

(Refer to the table)

(Modified the components to replace with

the CPUs bits 00010101: U4D1 instead of

U2E1 for the 1

st

repair, U7D1 instead of

U2C1 in the 2

nd

repair and there are no 3

rd

repair)

Luis Rodríguez

José C. Bravo

06 Mar 2006

2.2

Updated category B

(Refer to the table)

(Added 2

nd

and 3

rd

repair in failures with

CPUs bits 01000100)

Luis Rodriguez

José C. Bravo

08 Mar 2006

2.3

Updated category B

(Refer to the table)

(Added repair action for CPU bits

00000000)

Luis Rodriguez

José C. Bravo

09 Mar 2006

2.4

Updated category B

(Refer to the table)

(Added repair action for CPU bits

10101111)

Luis Rodriguez

José C. Bravo

22 Mar 2006

2.5

Updated category B

(Refer to the table)

(Added repair action for CPU bits 01010001

& 10110011)

Luis Rodriguez

José C. Bravo

04 April 2006

2.6

Updated category B

(Refer to the table)

(Added repair action for CPU bits

10010110)

Luis Rodriguez

José C. Bravo

09 May 2006

2.7

Updated category A & C

(Added replacement of component in first

repair U2C1 & in second repair U4D1 in

category A )

(Added replacement of component in first

repair: U4D1 in category C)

Luis Rodriguez

José C. Bravo

14 July 2006

2.8

Updated category B & C

(Refer to the table)

(Added repair action for CPU bits

00100000, 01000101, 01001111,

10010100,

01011000, 10101101 &

10100010)

(Added replacement of component in first

repair: Fault Infineon R3G6 & R3G7)

Moisés Anzaldo

28 July 2006

PCBA Debug Guide

Página 3 de 10

Rev. 2.8

2. Table of Contents

1. Revision History ......................................................................................................................... 2

2. Table of Contents........................................................................................................................ 3

3. Introduction................................................................................................................................. 3

4. Scope.......................................................................................................................................... 3

5. Audience ..................................................................................................................................... 3

6. Process ........................................................................................................................................ 4

7. Category Grouping...................................................................................................................... 4

7.2 Category A Error Code 0x09................................................................................................ 4

7.2 Category B Error Code 0x0A ............................................................................................... 6

7.3 Category C Error Code 0x08................................................................................................ 9

3. Introduction

This document describes a process for diagnosing and repairing NO PCIE failures from

the PCBA tester. The process and groupings below outlines possible measurements to

determine the appropriate component, for repair or replacement. Core digital errors can

also be identified by 3 of the 4 LEDs on the “ring of light” flashing.

4. Scope

This document has been developed from experience gained on X803158-001 Xenon

XDK motherboards. The failure analysis process outlined in this document should be

used in conjunction with the “Motherboard Debug Guide Development Process”

document.

5. Audience

This document is aimed at Engineers and Technicians who are performing first pass

debug of core digital failures from the XBOX360 motherboard PCBA tester.

PCBA Debug Guide

Página 4 de 10

Rev. 2.8

6. Process

7. Category Grouping

Note: Error Codes on front panel are in hexadecimal: 0x

FF

Error Codes in the Functional Test are shown with 8 digits: 0x

12345678

Bits get on the PCBA test points are 8 digits:

01010101

7.2 Category A Error Code 0x09

The PCI-E link failed to enter L0 in time during seqUnReset

Test Name: PowerGroupPowerUp, Variation: PCBA-TighterLimits

Error Code: 0x81600868

Error Facility: TESTER (FACILITY_MTE_POWER)

Error Description: Measured value lower than limit V12_CURRENT: 5.963584 less than

6.500000

Test Name: PowerGroupPowerUp, Variation: PCBA-TighterLimits

Error Code: 0x81600BE5

Error Facility: TESTER (FACILITY_MTE_POWER)

Error Description: The PCI-E link failed to enter L0 in time during seqUnReset. SMC

ErrorCode: 9

Replace U2C1 as a first repair

Replace U4D1 as a second repair

If the failure is still present, continue next repairs

•

Check for proper voltage on V_GPUPCIE (U5C1 pin2), target is 1.25v, if

not present change U5U1

•

Check for proper voltage on V_SBPCIE (U3P1 pin 2), target is 1.87v, if not

present change U3P1

•

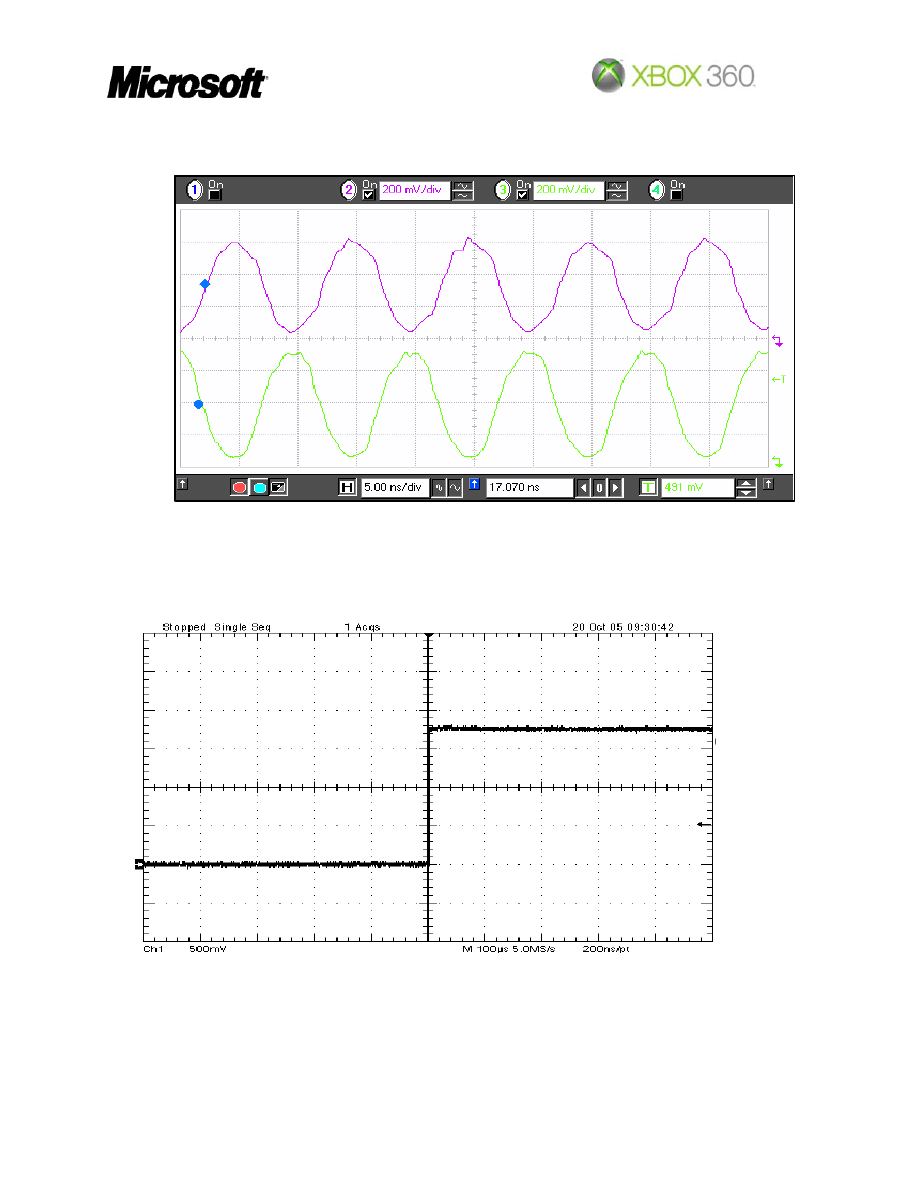

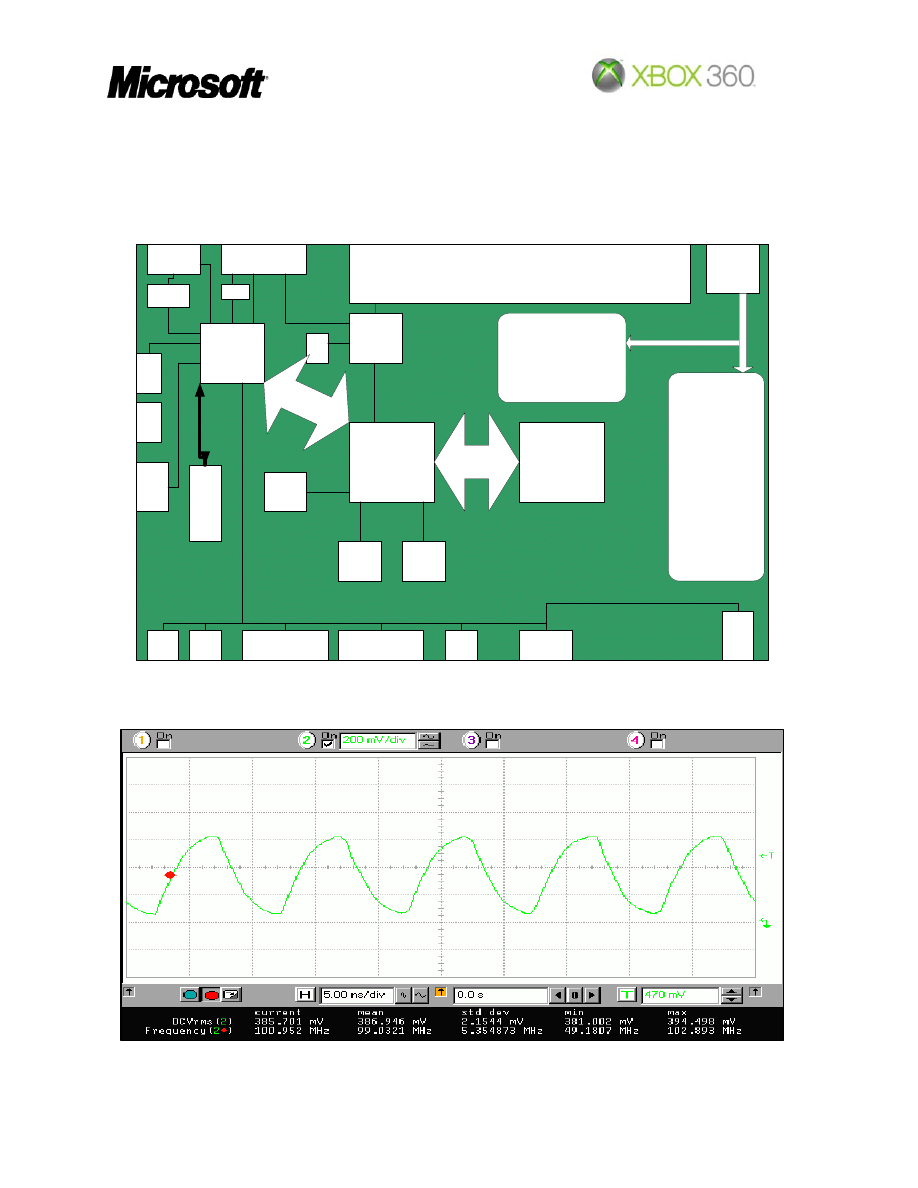

Check for PCIE CLK

•

PCIE_CLK_DP on FT3P2, frequency of 100MHz

•

PCIE_CLK_DN on FT3P1, frequency of 100MHz, as shown below

•

Check C2C1, C2C2, C2C3, C2C4, C4D1, C4D2, C4D3 & C5D1

•

Check GPU_CLK_DP/DN, frequency of 100MHz (junction between

R3C16 & R3C15)

PCBA Debug Guide

Página 5 de 10

Rev. 2.8

PCIEX_CLK_DP

PCIEX_CLK_DN

If frequencies are not present then change U3B4

•

Check CPU_RST_N (R7R4 pin 2) target is 1.24v, if not voltage change

U2C1

CPU_RST_N

PCBA Debug Guide

Página 6 de 10

Rev. 2.8

CPU_RST_N (via

near U2C1)

7.2 Category B Error Code 0x0A

Test Name: TcsBootStrappingDuration, Variation: PCBA

Error Code: 0x81510027

At this point of failure the V_CPUCORE is good, the PCI-E link has entered into a

known good state, and the SMC releases the CPU reset line CPU_RST_N.

CPU_RST_N is expected to go high. The SMC monitors the CPU initialization process

as it comes out of reset and begins to execute code. If the CPU fails to initialize properly

the SMC will enter the error state ERROR_NO_HANDSHAKE.

A typical problem found with this failure is that CPU programming code in flash is

corrupted. The CPU initializes and begins executing code from flash and falls on its

face. Change the Flash as a first repair.

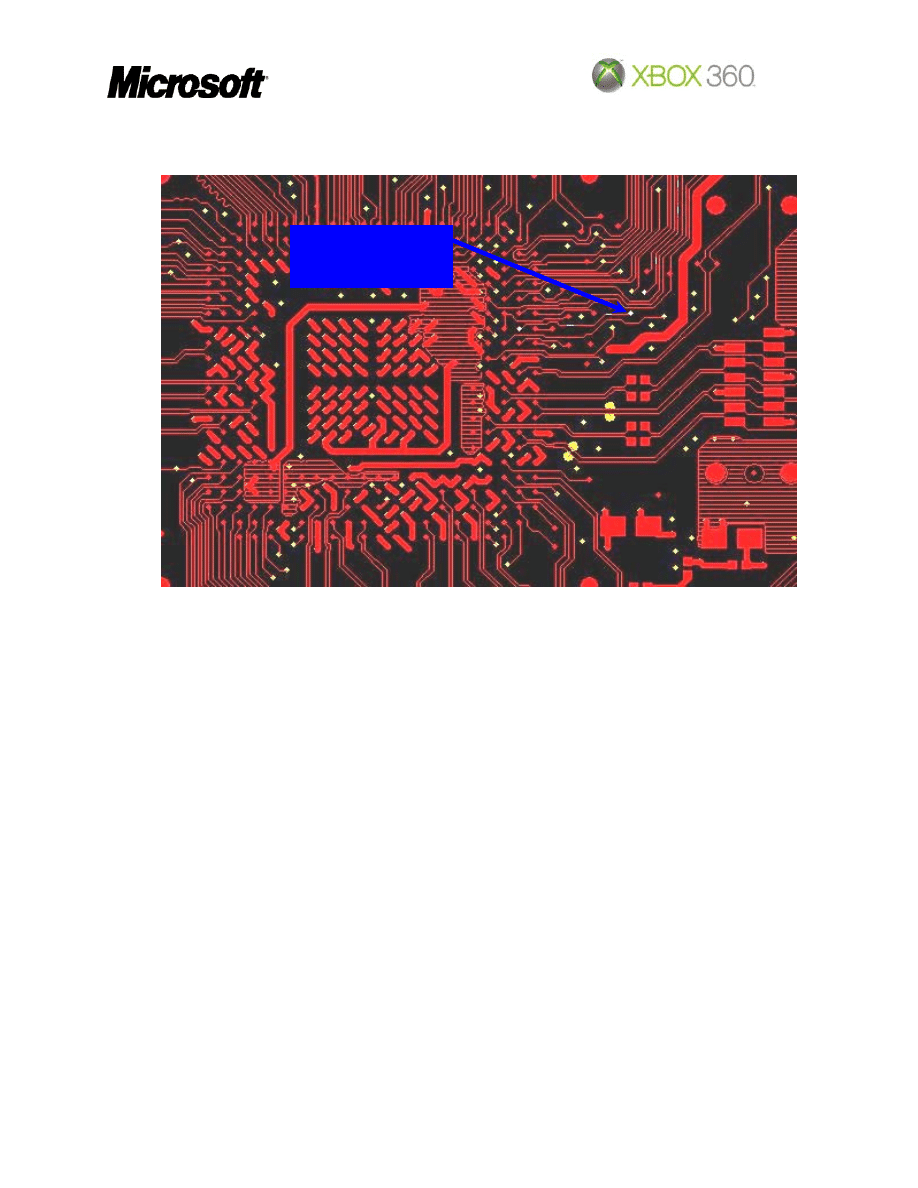

The CPU accesses flash through the path of CPU Chip ↔ Front Side Bus ↔ North

Bridge chip ↔ Back Side Bus ↔ South Bridge chip ↔ Flash chip. See picture below.

Failure along any segment of this path will cause ERROR_NO_HANDSHAKE as the

CPU cannot execute code from flash.

PCBA Debug Guide

Página 7 de 10

Rev. 2.8

Note

: At this early time the SMC does not double check the status of the Back Side Bus (BSB)

after a failure of the CPU to handshake. (A failure of the BSB is indicated with the previous error

code ERROR_NO_PCIE). It is possible that the BSB has failed after initial good status.

CPU

GPU

North

Bridge

RAM

RAM

RAM

South

Bridge

SMC

ANA

LAN/USB

Connector

LAN

AV Connector

Audio

DAC

Clock

Gen

FLA

S

H

HDD

SATA

ODD

Pwr

ODD

SAT

A

Eject

Switch

IR

Rx

USB Memory

Connector

USB Memory

Connector

Binding

Button

Argon

Connector

USB

Game

Pad

Power

Supply

Connector

FAN ASSEMBLY

Front

Side Bus

Bac

k S

ide

Bus

GPU

Voltage Regulators

CPU

Voltage

Regulators

SPDIF

• Check for proper control and power good signals.

CPU Clock Signal

PCBA Debug Guide

Página 8 de 10

Rev. 2.8

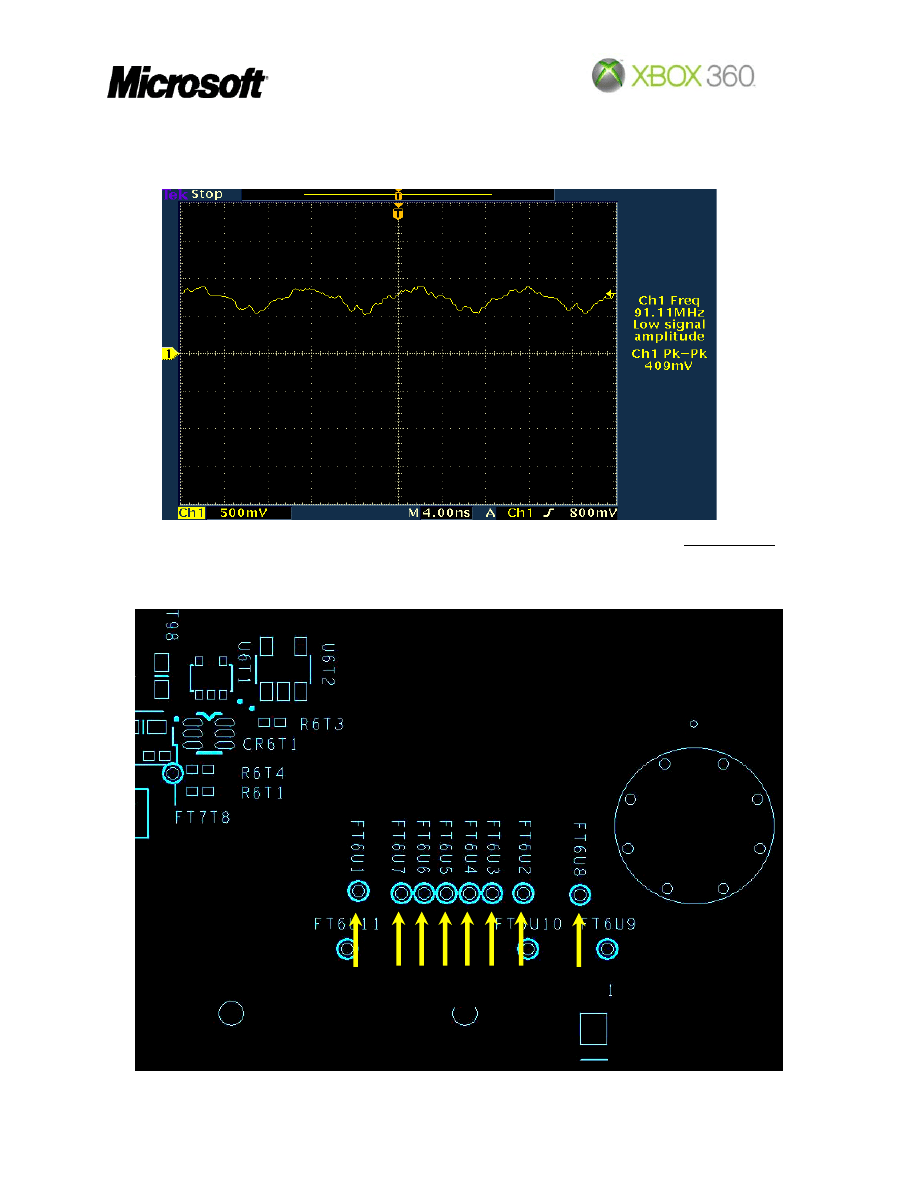

If CPU CLK (junction between R3C12 & R3C18) is not present or the signal is bad (e.g.

picture below), replace U3B4 as a first repair.

• If ENET_RST_N (boards with U1B2) & AUD_RST_N signals are not present and

the others are normal, change U7D1.

Bad CPU Clock Signal

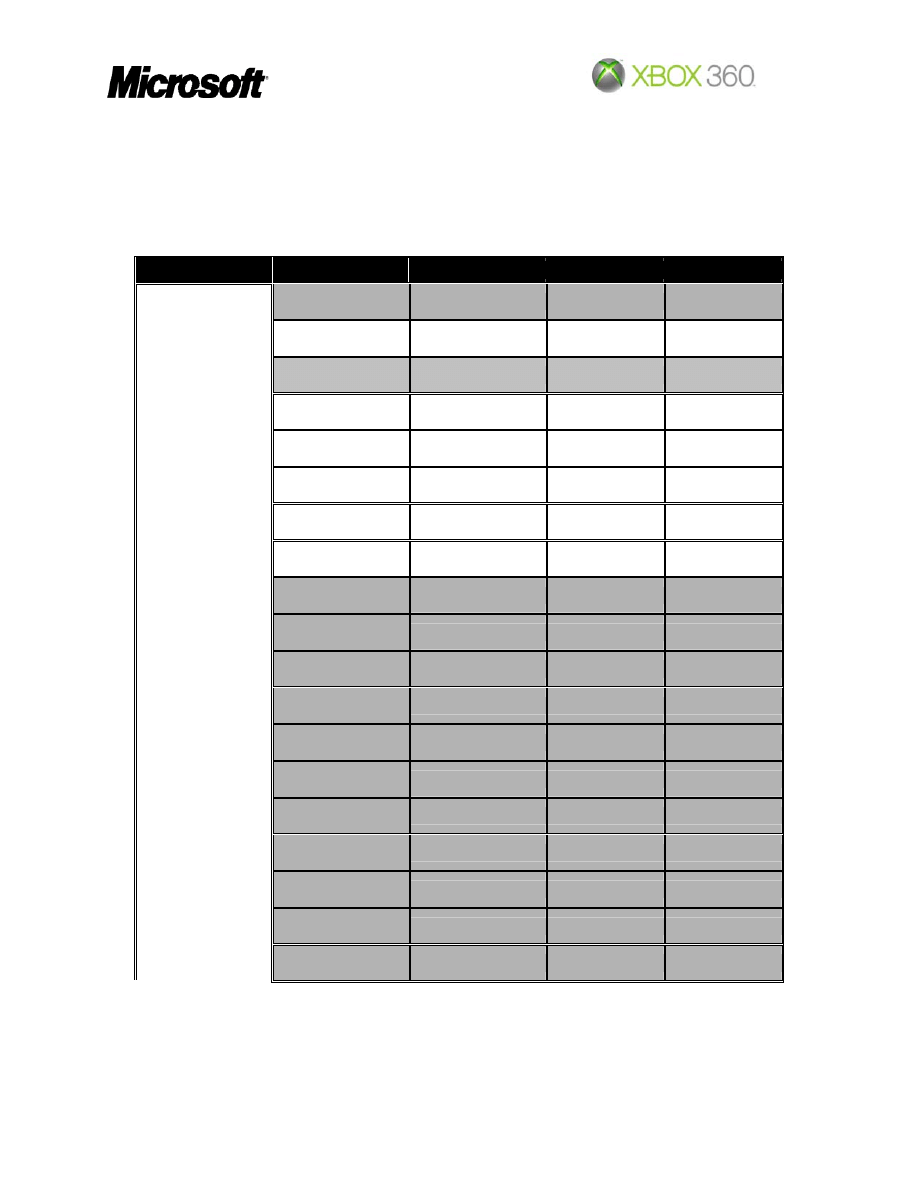

CPU Bits:

Bit: 0 1 2 3 4 5 6 7

PCBA Debug Guide

Página 9 de 10

Rev. 2.8

Do measures on the test points behind U7D1 (bottom side)

e.g.

Bits order: 76543210

Value 64: 01000000

Value 175:10101111

Front panel Code

CPU bits

1

st

repair

2

nd

repair

3

rd

repair

00000000

(0)

U7D1

00010100

(20)

U4D1 U7D1

00010101

(21)

U4D1

U7D1

00010110

(22)

U4D1 U7D1

00011000

(24)

U4D1 U7D1

00100000

(32)

U7D1

00101110

(46)

U4D1 U7D1

01000000

(64)

U3E1 U3D1

U4D1

01000100

(68)

U5F1/U5U1

U3E1/U3T1

U3D1/U3R1

01000101

(69)

U3D1/U3R1

U3E1/U3T1

U5F1/U5U1

01001111

(79)

U2E1

U7D1

01010001

(81)

U2E1

01011000

(88)

U2E1

10010100

(148)

U4D1

10010110

(150)

U2E1

U4D1

10101101

(153)

U2E1

10100010

(162)

U2E1

10101111

(175)

U4D1

U4F1/U4U1

0x0A

10110011

(179)

U2E1

7.3 Category C Error Code 0x08

Replace U4D1 as a first repair

PCBA Debug Guide

Página 10 de 10

Rev. 2.8

If the failure is still present, continue next repairs

•

Check for proper voltage on V_GPUPCIE (U5C1 pin2), target is 1.25v, if

not present change U5U1 (first check V_3P3 on U1F1 pin 4 replace as

necessary)

•

Check for proper voltage on V_SBPCIE (U3P1 pin 2), target is 1.87v, if not

present change U3P1

•

Check voltage V_MEM on DB3F1, expected value 1.8v, if the voltage is

not present: Measure resistance to GND, the expected value is 63Ω, if the

resistance is ok then check the signal VREG_1P8_EN on junction

between R3G5 & R3G1, in STBY mode is high, when the console is

turned on the signal goes low, this signal comes from the South Bridge if

is not present replace U2C1, if is present replace U4V1

•

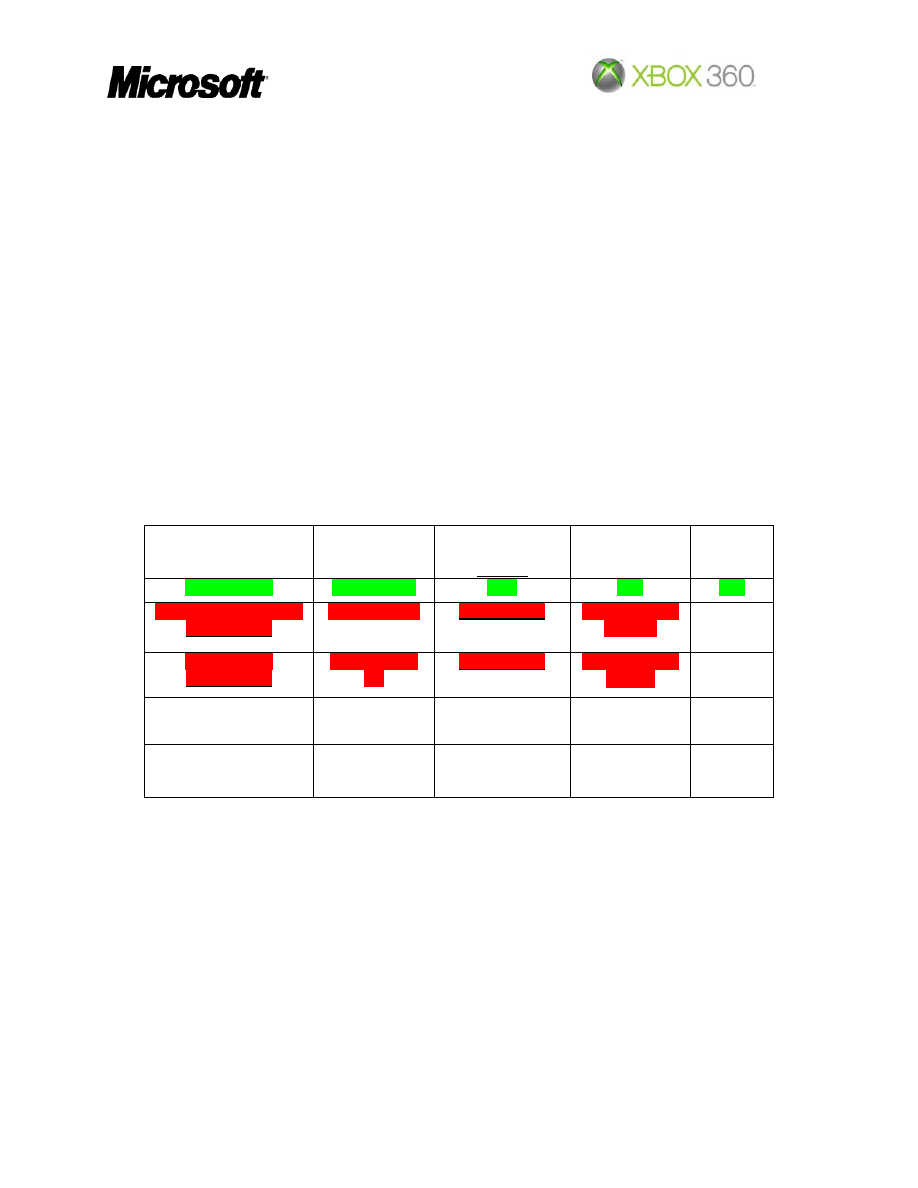

Fault because of the voltage V_MEM altered in units with memories

Infineon

Impedance

between R3G6&

R3G7 a GND

Voltage in DB3F1

For memory

Infineon

Repair without

short in

DB3F1&GND

front panel

code

Normal value

600Ω a 800Ω

2.1V

N/A

N/A

Elevates R3G6& R3G7

No connected

Bigger a 5K Ω

No connected

Replace R3G6

& R3G7

Elevate R3G6

No connected

1.17kΩ a 1.49

kΩ

No connected

Replace R3G6

y R3G7

Elevate R3G7

2.20 kΩ a 2.40

kΩ

0.7V

Replace R3G6

y R3G7

0X08

Inverted

R3G6& R3G7

908Ω a 912 Ω 1.30V

Replace R3G6

y R3G7

0X08

Any another value of impedance between R3G6 & R3G7 a GND replace

R3G6 & R3G7

Note

: Units with memories Infineon first check R3G6 & R3G7 for a possible

bad repair, if the impedance on nodes V_MEM to GND is less than 5Ω (with

front panel code 0X08 or 0X14) replace memories and the GPU

•

If the impedance on these nodes (V_MEM & GND) is less than 50Ω

replace memories

•

If the impedance on these nodes (V_MEM & GND) is less than 0.3Ω

check in X- ray test memory and GPU possible short, change integrated in

short.

Document Outline

- 1. Revision History

- 2. Table of Contents

- 3. Introduction

- 4. Scope

- 5. Audience

- 6. Process

- 7. Category Grouping

Wyszukiwarka

Podobne podstrony:

Zamówienia publiczne, 104PROTOKÓŁ pow. prog. NO v2, oznaczenie sprawy

64GB ALL KILLER NO FILLER EDITION V2

DTC v2

No Home, No Homeland raport

NO 04 A004 4 2010

Elektro (v2) poprawka

l1213 r iMiBM lakei v2

logika rozw zadan v2

poprawkowe, MAD ep 13 02 2002 v2

Chopin Bourrée No 2, Op D2 No 2

DSC PC5010 v2 0 obs lcd

87 Dz U 08 25 150 Prawo ochrony środowiska v2

DSC PC5010 v2 0 ark

No Longer White

więcej podobnych podstron