Using ultrasonic vacuum spray dryer to produce highly viable dry probiotics

David Semyonov, Ory Ramon, Eyal Shimoni

Faculty of Biotechnology and Food Engineering, Technion - Israel Institute of Technology, Haifa 32000, Israel

a r t i c l e i n f o

Article history:

Received 25 October 2009

Received in revised form

17 March 2011

Accepted 18 March 2011

Keywords:

Spray dryer

Probiotic

Microencapsulation

Storage

a b s t r a c t

Ultrasonic vacuum spray dryer was used to produce a dry powder of highly viable probiotic cells. The

drying was performed through two stages: Vacuum spray drying of the solution followed by

fluidized-

bed drying of the powder. The embedding matrix was a combination of trehalose and maltodextrin. The

effects of external and internal variables on cell survival during the drying process and storage were

investigated. The hypothesis was that by minimizing the oxidative and thermal stresses in the drying

stages, in addition to adequate formulation choice, the cell viability during the drying and storage will

increase. It was concluded that during the drying process the faster the embedding matrix reaches

a glassy state the higher was the probiotic survival. Evaluating water activity and moisture limit of the

glassy matrix concluded that maltodextrin DE5 is a better encapsulating matrix than maltodextrin DE19.

Combining trehalose to maltodextrin in the encapsulating matrix resulted in a signi

ficant increase in the

survival up to 70.6

6.2%.

Ó 2011 Elsevier Ltd. All rights reserved.

1. Introduction

Probiotics are described as

“live micro-organisms which when

administered in adequate numbers confer a health bene

fit on the

host

” (

). They are commonly included in fermented

milks, yoghurts and cheese, but are also available in the form of

dietary supplements where the probiotic is in the form of a dried

product. Probiotic-containing foods can be categorized as functional

foods, and along with prebiotics represent the largest segment of

the functional foods market in Europe, Japan and Australia. The

market for this food category continues to expand, in parallel with

growing consumer awareness of the role of diet in health mainte-

nance (

’Donnell, 1998; Stanton et al., 2001

).

Probiotics such as Lactobacillus and Bi

fidobacteria species are

added to foods mainly to improve intestinal microbial balance.

Lactobacillus, a genus of Gram-positive facultative anaerobic

bacteria, are a major part of the Lactic Acid Bacteria group. Such

probiotics are common and usually benign, even essential, inhabi-

tants of humans and other animals. Lactobacillus and Bi

fidobacte-

rium species are the most commonly used probiotics in foods for

human consumption given the signi

ficant health benefits associated

with ingestion of these micro-organisms. These micro-organisms

share a number of common traits, such as generally regarded as safe

(GRAS) status, acid and bile tolerance, and ability to adhere to

intestinal cells (

). It is recommended that the

probiotic culture must be present in the product at minimum

numbers of 10

7

CFU/ml and even higher numbers have been rec-

ommended (

Ishibashi & Shimamura, 1993; Lee & Salminen, 1995

).

Probiotic cultures for food applications are frequently supplied in

frozen or dried form, either as freeze-dried or spray-dried powders

(

’t Riet,1993; Holzapfel, Haberer, Geisen, Bjorkroth, &

). Relatively successful drying of lactobacilli and

bi

fidobacteria has previously been reported for a number of

different strains (

), including Lactoba-

cillus paracasei (

). An adequate solution to

improve probiotic survival during their processing is their micro-

encapsulation (

). In order to extend the pro-

biotic storage stability, techniques such as spray drying, freeze

drying and

fluidized bed spray coating were employed resulting in

a dry powder. However, most probiotic lactobacilli do not survive

well during the temperature and osmotic extremes to which they

are exposed during the conventional drying and encapsulation

processes (

Goderska & Czarnecki, 2008; Ross, Desmond, Fitzgerald,

).

The energy consumption of spray drying is 6

e10 times lower

compared to freeze drying, since both mass and energy are fast

transferred in a very short time without using an exchange surface

(

). Spray drying technique was applied mostly in dairy

industry and in food products where original properties can be

preserved. However the use of spray drying to produce dry pro-

biotics is questionable because of high bacterial mortality due to

simultaneous dehydration, thermal and oxygen stresses imposed

* Corresponding author. Tel.: þ972 4 8292484; fax: þ972 4 8293399.

E-mail address:

(E. Shimoni).

Contents lists available at

LWT - Food Science and Technology

j o u r n a l h o m e p a g e : w w w . e l s e v i e r . c o m / l o c a t e / l w t

0023-6438/$

e see front matter Ó 2011 Elsevier Ltd. All rights reserved.

during the spray drying process (

Anal & Singh, 2007; Ross et al.,

). A technique based on spray drying incorporation of

L. paracasei NFBC 338 in a carrier, by a combination of protein and

carbohydrate, contributed to retain a high viability after spray

drying and to extend survival rates during storage (

’Callaghan, Fitzgerald, & Stanton, 2002

).

Our basic hypothesis is that by minimizing the thermal and

oxidative stresses during the drying process the cell viability at the

end of the drying and/or storage stages will increase signi

ficantly.

In the present study we evaluate a new spray drying technique and

process using a newly developed ultrasonic vacuum spray drier. In

order to obtain high survival rates of Lactobacillus casei subsp.

paracasei LMG P-21380 were embedded in a maltodextrin-treha-

lose matrix (

). We expect that it can be ach-

ieved due to the short residence time of the uniform droplets

generated by the ultrasonic nozzle, as well due the low tempera-

ture and vacuum atmosphere in the drier chamber space (

Merkle, & Gander, 2004; Sadykhov & Kish, 1997

). The role of the

maltodextrin-trehalose embedding matrix was to increase the

survival by maintaining the probiotic cells membrane integrity

during the drying process and storage of the dried probiotics as

well as to promote the stabilizing effect of the bacteria

’s proteins

Crowe, Crowe, Rudolph, Womersley, & Appel, 1985; Leslie, Israeli,

Lighthart, Crowe, & Crowe, 1995; Castro, Teixeira, & Kirby, 1997

The main objective of this study was therefore to explore the

application of ultrasonic vacuum spray drying process in the

formation of dried probiotic powder (Lactobacillus casei subsp.

paracasei LMG P-21380) with high survival rate and extended shelf

life. We studied the effect of the drying temperature, matrix

composition, solids and probiotics concentrations, and dextrose

equivalent on their survival. The effect of storage temperature and

oxygen level on the physical state and viability in the dried pro-

biotic powder of various matrix formulations was also measured.

2. Materials and methods

2.1. Materials

2.1.1. Bacterial culture

The bacterial strain used in this study was pure freeze dried

culture of Lactobacillus casei subsp. paracasei LMG P-21380 provided

by Probiotical s.r.l, Novara, Italy.

The following compounds were tested for their protecting

effect: Trehalose (Cargill, Minneapolis, USA) and Maltodextrins DE5

(Mw

w150000) and DE19 (Mw w13000) (Galam, Kibbutz Maanit,

Israel).

2.2. Methods

2.2.1. Preparation of the probiotic solutions

Solutions of maltodextrin (MD) and trehalose formulation of

various ratios were prepared as follows: distilled water was heated

to at least 93

C prior to addition of maltodextrins and trehalose in

order to obtain complete dissolution of the maltodextrin. The

solutions were then cooled to room temperature. The dry probiotic

cultures were dissolved in the formulation solution for at least one

hour before their drying by the ultrasonic vacuum spray drying

process. Oxidative stress was minimized by storing the solutions in

closed vials. Several different solutions of Lactobacillus paracasei

were prepared for the examination.

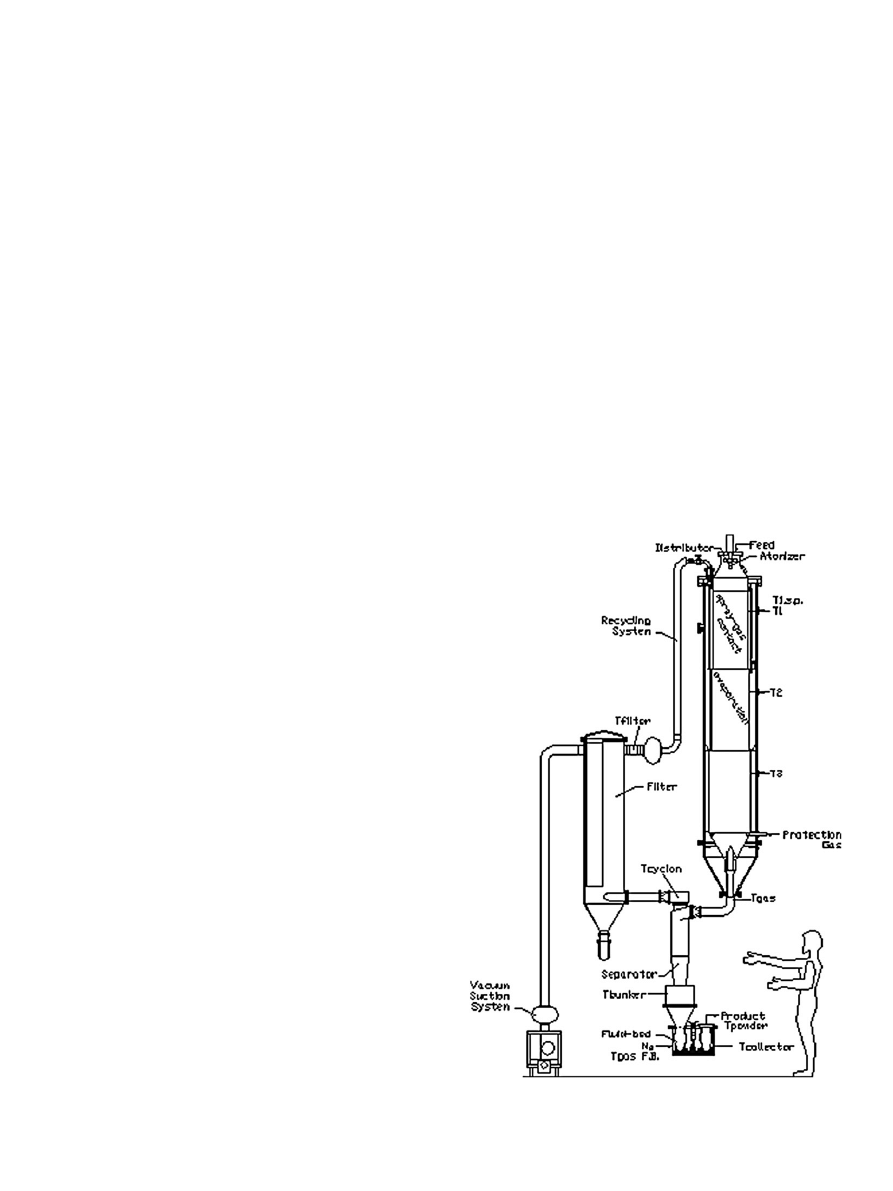

2.2.2. The drying setup

Ultrasonic Vacuum Spray Dryer (UVSD) (Nanosol, Israel) is

a spray dryer that operates under vacuum conditions. The system

includes a special designed ultrasonic atomizer which can operate

in a vacuum environment, dispersing the product solution evenly,

to the vacuum drying zone. The particle size distribution of the

drops is signi

ficantly narrower than in conventional spraying

systems, and can be controlled within certain limits. UVSD includes

a vacuum chamber with three adjustable heating zones (

). The

atomized drops are directed into a vacuum chamber. The internal

temperature in the drying chamber is adjusted by several heating

coils according to the speci

fic task. The heating of the falling drops

inside the drying chamber occurs though the convection of heat

from the chamber wall towards the atomized drops.

The drying was performed through two stages. In the

first stage,

the narrow size distribution of the drops (from 10

m

m to 50

m

m

depending on solution viscosity) fall free with low velocities within

3

e4 s and evaporate the majority of the free water. The solution

feeding and the vacuum in the drying chamber were maintained at

9 ml/min and 2.27 or 3.33 kPa. In that pressure conditions the drops

temperature does not exceed 20

e30

C. Using this technique the

heating is gentle and the vacuum in the drier space signi

ficantly

reduces the temperature of the product, the oxidative stress, as well

as the residence time of the particles in the drying camber.

The remaining water was evaporated during the second drying

stage that was performed in a cooled (10

e15

C) vacuum and

Nitrogen environment

fluidized-bed, for 20e60 min. After this

stage the product with the required water activity was removed

from the collector without stopping the process.

Fig. 1. Schematic representation of Ultrasonic Vacuum Spray Dryer (UVSD). Presented

with permission of Dr. Sadykhov (Nanosol, Israel).

D. Semyonov et al. / LWT - Food Science and Technology 44 (2011) 1844

e1852

1845

The internal parameters of the feed solutions were: cell

concentration (0.75, 2.5, 5 and 10 g/100 g), solids concentration

(10

e30 g/100 g), MD dextrose equivalent (DE5 and DE19), and

maltodextrin - trehalose ratios (1:0, 2:1, 1:1 respectively).

External variables that were investigated were: vacuum pres-

sure in the drying chamber that effect directly the temperature of

the product and the heat pro

file in the dryer, and the water activity

of the dry product after a known residence time in the UVSD second

stage, i.e. the

fluidized-bed vacuum chamber.

The

first variable investigated was the vacuum magnitude in the

drying chamber (2.27 and/or 3.33 kPa). Two solutions containing

(20 g/100g maltodextrin DE19) 0.75 g/100g Lactobacillus paracasei

were dried under vacuum pressures of 2.27 or 3.33 kPa, which

represents pure water boiling temperatures of 19.3 and 25.7

C

respectively. The dry probiotic powder was retrieved from the

powder collection site and then dissolved to determine cells

survival. In order to determine the effect of solids concentration in

the feed solution on probiotics survival during the drying stage of

the UVSD process (at 2.27 kPa vacuum), Lactobacillus paracasei

0.25 g/100g cells were embedded in a matrix of four different

maltodextrin DE19 concentrations: 10, 15, 20 and 25 g/100g. In

order to determine effect of trehalose on the survival Lactobacillus

paracasei 0.75 g/100g was embedded and microencapsulated by

the UVSD process in various matrixes: maltodextrin DE5/DE19-

trehalose [1:1] (20 and 30 g/100g) and maltodextrin DE5/DE19-

trehalose [2:1] (30 g/100g). To examine the in

fluence of probiotic

concentration in the formulation on their survival, four solutions

were prepared: maltodextrin DE5-trehalose (1:1) with 0.75, 2, 5

and 10 g/100g of Lactobacillus paracasei (all at 20 g/100g total

solids). All four were microencapsulated using the UVSD process

and the vacuum in the drying chamber was 3.33 kPa.

2.2.3. Shelf life evaluation

The in

fluence of three storage temperatures and two types of

storage atmospheres (air and N

2

) on the dried encapsulated pro-

biotics stability was studied. For standard atmosphere storage, 5 g of

dried granules were placed in glass containers in dark rooms at 4

C

(typical refrigerating temperature), 25

C (proper room temperature

storage), and 37

C (simulation temperature abuse conditions). For N

2

atmosphere storage, 2 g of dry probiotic microcapsules were placed

in glass containers and compressed N

2

gas was allowed to purge the

container for 3 min. The top was quickly closed after the tube was

withdrawn. The containers were placed in a dark room at 25

C.

Samples were taken on a weekly basis to determine the concentra-

tion of L. paracasei survival.

2.2.4. Survival determination of Lactobacillus paracasei

2.2.4.1. Viable cell counts in the probiotic solutions. The viable pro-

biotic cells counts in the feed solutions were determined as follows:

probiotic samples were spread plated on MRS agar plates (DifcoTM

Lactobacilli MRS agar, BD, Sparks, MD, USA), after appropriate 10-

fold serial dilutions in saline solution. Viable cells counts were

determined after 48 h incubation under anaerobic conditions at

37

C. Anaerobic jars and gas generating kits (Oxoid Ltd.) were used

for creating anaerobic conditions. Plates containing 20350 colonies

were measured and recorded as colony forming units (CFU) per g of

the product or ml of solution (N

B

).

2.2.4.2. Viable cell counts in dry samples. Dry samples in four

replicates (100

e300 mg) were rehydrated at ambient temperature

and dissolved in 4.5 ml saline (NaCl 0.85 g/100g water). Dissolved

samples were spread plated on MRS agar as described above. The %

survival of the samples tested was calculated as follows:

Survival percentage

¼ ð100 N=N

0

Þ;

(1)

Where N

0

is the number of bacteria per g of dry matter before

drying and N is the number of bacteria per g of dry matter in the

capsules.

2.2.5. Water activity

Water activity of the dry probiotic microcapsules at the end of

the second stage of the UVSD process was measured by using an

“Hygropalm Aw1” water activity indicator (Rotronic Instrument

corp., Basserdorf, Germany).

2.2.6. Scanning electron microscopy

Encapsulated and coated probiotic capsules were stored in

desiccators (silica gel), and goldcoated by Polaron SC515 (Fisons

Instruments, UK) prior the observation by JSM-5400 SEM (Jeol,

Japan). Digital images were obtained using an EDS-unit with

Voyager II software (Moran, Netherlands).

2.2.7. Data collection and statistical analysis

All the experiments were performed with at least three repli-

cates. The results hereto are expressed as their means

the stan-

dard deviation (SD). Where necessary, the number of repetition is

noted in the text. The signi

ficance of the differences between

groups was tested using t-test analysis. A probability level (p value)

of

<0.05 was considered to be statistically significant unless stated

otherwise. Statistical analysis was performed by the data analysis

tool pack of Microsoft Excel 2003 software.

3. Results and discussion

The aim of this investigation was to evaluate a new method for

producing dry microcapsules (MC), containing high concentration

of viable Lactobacillus paracasei cells by an ultrasonic vacuum spray

drier (UVSD). Our hypothesis was that since UVSD process operates

under vacuum and low temperature, along with a gentle heating

mode by radiation, thus product temperature, oxidative stress, and

the residence time of the drying drop/microcapsule in the drying

chamber would be reduced signi

ficantly.

In the UVSD setup, an ultrasonic atomizer creates droplets with

low velocities that drift under the in

fluence of gravity down the

drying chamber. The height and diameter of the chamber and

the heating system are designed to ensure that the droplets reach the

powder collection site in a dry state. The droplet size (10

e50

m

m) is

a function of several factors, primarily the nozzle vibration frequency

but also on the liquid solution viscosity. The liquid outlet is large

compared with that of a pressure nozzle without moving parts pre-

venting clogging, and it enables creating drops from high viscosity

solutions. The UVSD drying chamber is built of three heat controlled

zones that can be adjusted to produce an appropriate heat pro

file,

and a vacuum system that can operate under several vacuum pres-

sures keeping the temperature as low as possible.

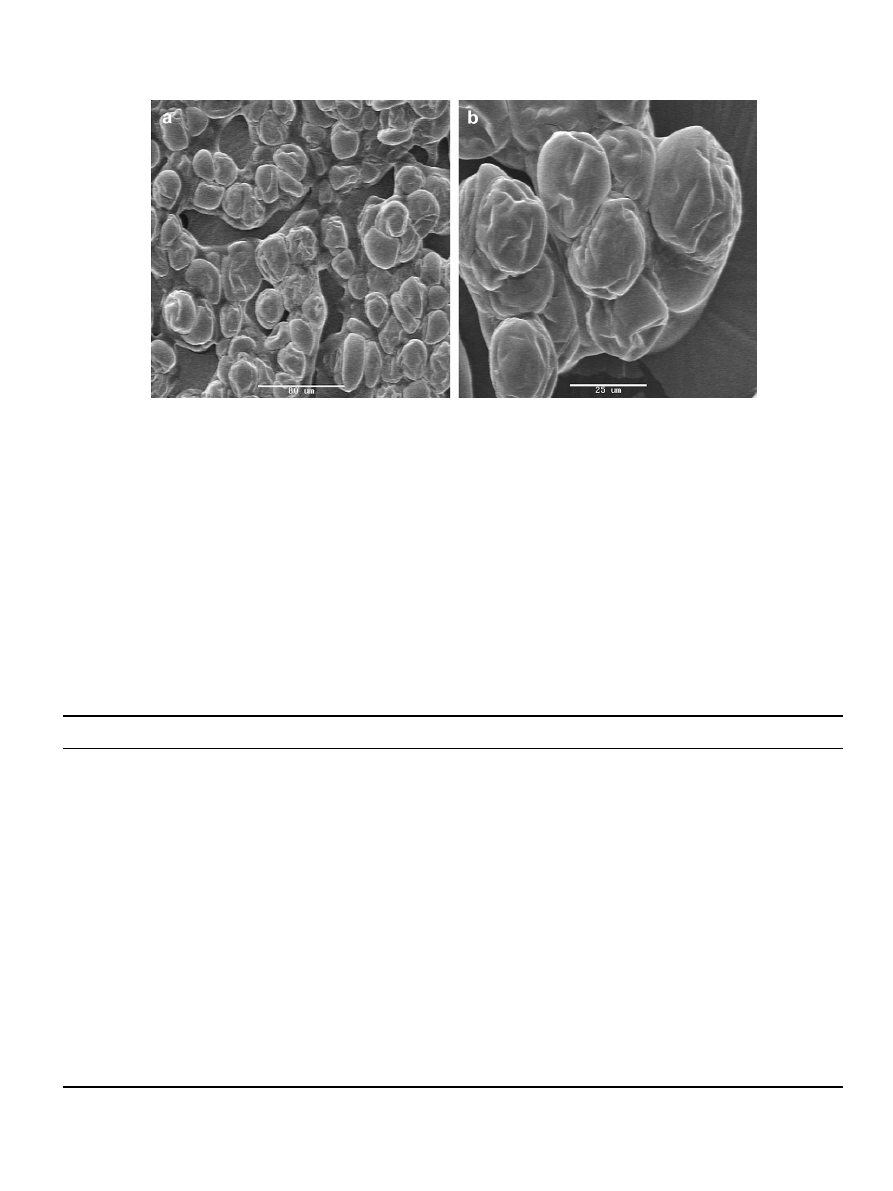

The dried Lactobacillus paracasei powder had features like high

flow ability, mono-dispersive, and immediate solubility. The

microcapsules were rod shaped particles with particle size ranging

from 20 to 50

m

m depend on solids concentration in the sprayed

solution (

).

3.1. Effects of matrix composition

To protect the probiotic cells from dehydration induced damage,

such as disruption of cells membranes due to irreversible phase

transitions, and in order to enhance the probiotic stability during

storage of the dried powder, we encapsulated the Lactobacillus par-

acasei cells in a matrix of maltodextrin and/or in a mixture of the later

with trehalose. Polysaccharides such as maltodextrin are used as

matrix wall materials due to their ability to form glasses of a very high

D. Semyonov et al. / LWT - Food Science and Technology 44 (2011) 1844

e1852

1846

viscosity (10

7

e10

11

kPa s

1

). It is known that in the glassy state

chemical reactions that require diffusion are practically stopped

(

Oldenhof, Wolkers, Fonseca, Passot, & Marin, 2005

), thus increasing

the stability of the dried cells during drying and storage. Large poly-

mers cannot act as osmotic and volumetric spacers preventing

fluid

-gel phase transition temperature (Tm) of cells membranes (

). Thus, high M

w

maltodextrins such as

MD DE19 and MD DE5 are excluded from the intra-membrane space

(intra lamellar region) and their main role is by causing spacing

between the cells and increasing the strength of the glassy matrix

that embed them (

Koster et al., 2003; Oldenhof et al., 2005

The effect of the drying temperature (vacuum) on L. paracasei

survival is shown in

A. From this table one can note that

there was no signi

ficant difference in probiotic survival after drying

in vacuum of 2.27 or 3.33 kPa, as in both matrix formulations of

Maltodextrin DE19 the survival was 29.2

4.9 and 30.8 3.1%

respectively. Thus it can be concluded that the difference in drying

survival between vacuum pressures of 2.27 or 3.33 kPa which affect

the temperature of the product during the drying process, in the

UVSD system, is not signi

ficant.

3.2. Effect of solids concentration

The effect of the maltodextrin concentration on L. paracasei

survival is presented in

A, showing that the survival of the

probiotic was signi

ficantly high solids concentration of maltodextrin

Fig. 2. SEM images of microcapsules produced by UVSD process. L. paracasei (0.75 g/100g) encapsulated in maltodextrin DE5-trehalose (1:1) matrix.

Table 1

Survival of Lactobacillus casei subsp. paracasei LMG P-21380 after the encapsulation process using the UVSD process. (A) Encapsulation in maltodextrin; (B) Effect of trehalose;

(C) Effect of L. paracasei concentration; and (D) Effect of high

final water activity of the powder.

Matrix composition

Solids

concent. [g/100g]

Drying

vacuum [KPa]

Initial cell

concent. [CFU/g d m]

Final water

activity

Survival [%]

Signi

ficance

of differences

b

A

MD DE19

10

2.27

1.4

10

8

0.11

20.4

0.8

a

A

MD DE19

15

2.27

2.6

10

8

0.04

18.2

3.0

A

MD DE19

20

2.27

2.7

10

8

0.12

29.2

4.9

B

MD DE19

25

2.27

2.6

10

8

0.25

33.8

3.9

B

MD DE19

20

3.33

2.6

10

8

0.16

30.8

3.1

B

MD DE5

20

3.33

2.4

10

8

0.13

51.6

8.9

C

B

MD DE19 : Trehalose (2:1)

30

2.27

3.2

10

8

0.19

49.8

7.3

C

MD DE19 : Trehalose (2:1)

30

3.33

5.5

10

8

0.19

48.3

5.3

C

MD DE19 : Trehalose (1:1)

20

2.27

5.0

10

8

0.11

29.6

4.0

B

MD DE19 : Trehalose (1:1)

20

3.33

3.3

10

8

0.20

39.8

8.1

B,C

MD DE19 : Trehalose (1:1)

30

2.27

2.4

10

8

0.21

47.5

6.9

C

MD DE19 : Trehalose (1:1)

30

3.33

3.1

10

8

0.31

49.9

7.0

C

MD DE5 : Trehalose (2:1)

30

3.33

5.3

10

8

0.25

62.8

7.9

C,D

MD DE5 : Trehalose (1:1)

20

3.33

3.4

10

8

0.21

70.6

6.2

D

MD DE5 : Trehalose (1:1)

30

3.33

5.2

10

8

0.28

64.3

4.1

D

C

MD DE19 : Trehalose (1:1)

20

3.33

1.6

10

9

0.17

56.0

8.3

C,D

MD DE19 : Trehalose (1:1)

20

3.33

3.3

10

9

0.13

50.8

8.0

C

MD DE19 : Trehalose (1:1)

20

3.33

7.0

10

9

0.20

47.2

10.0

B,C

D

MD DE19

25

2.27

2.6

10

8

0.42

28.4

4.6

B

MD DE19 : Trehalose (2:1)

30

2.27

3.2

10

8

0.44

17.1

2.8

A

MD DE19 : Trehalose (2:1)

30

3.33

6.4

10

8

0.33

45.9

5.6

C

MD DE19 : Trehalose (1:1)

30

2.27

2.4

10

8

0.49

27.5

4.4

A,B

MD DE19 : Trehalose (1:1)

30

3.33

3.0

10

9

0.40

27.4

4.5

A,B

a

The error represent standard deviation of means (n

3).

b

p

< 0.05.

D. Semyonov et al. / LWT - Food Science and Technology 44 (2011) 1844

e1852

1847

DE19 (20

e30 g/100g), than at lower solids concentration (10e15 g/

100g). Since the size of the droplets created by the ultrasonic nozzle

are in the range 10

e50

m

m, and the inlet

flow rate and the nozzle

vibration frequency were kept constant during the drying experi-

ments, the main factor that affect the droplets size was the viscosity

of the inlet solution. The solution viscosity at 25

C (room temper-

ature) increases with solid concentration, therefore increasing the

droplets size. We may therefore suggest that the larger the droplets

are the more protection can be provided.

3.3. The role of trehalose

In order to form a glassy matrix and provide optimal protection

to probiotic cells during dehydration, we combined the maltodex-

trins with trehalose. The effect of the maltodextrin DE and treha-

lose concentrations on L. paracasei survival is shown in

B.

Apparently, trehalose presence in the matrix with maltodextrin

DE5 increased signi

ficantly (p < 0.05) the probiotic survival during

drying (

A and B). However, increase of trehalose concen-

tration from 33% to 50% g/100g did not increase the L. paracasei

survival.

It was suggested that damage to probiotic cells following drying

can be related to: 1) Changes in physical state of membrane lipids;

2) Changes in structure of sensitive proteins (

).

Preservation of the structure and functionality of lipid membranes

and proteins during drying may be achieved by several mecha-

nisms (

Carpenter, Martin, Crowe, & Crowe, 1987; Crowe, Crowe,

). One mechanism is the disaccharide

ability to form a glass of a very high viscosity and low mobility.

Trehalose posses a high Tg in dry state (much higher than other

disaccharides) and has the capacity to form a dehydrate that enable

trehalose to remain in glassy state at a higher moisture content

(

Crowe, Reid, & Crowe, 1996; Patist & Zoerb, 2005

). During the

preparation of the matrix solution the low molecular weight

trehalose (Mw

¼ 342.3) can penetrate into the cells inter-

membrane space prior to drying, turning into a glassy state during

the dehydration process. This glassy state provides mechanical

resistance to the membrane bilayer (

).

During the dehydration process, trehalose vitri

fies, at a tempera-

ture lower than Tm

e the fluid membrane, and the vitrified sugar in

the inter-membrane space acts as a volumetric spacer. Reduction of

T

m

by trehalose glassy state prevents packing defects and phase

transitions accompanied by cytoplasm leakage upon rehydration.

In addition, the glassy trehalose restricts the mobility of cytoplasm

proteins, as well as the protein unfolding (

Trehalose interaction with the polar groups of the lipid

membrane, may replace the hydration water at the membrane

interface, thus lowering the phase transition temperature T

m

during drying processes (

Crowe et al., 1988; Crowe, Carpenter, &

). This stabilizing effect of trehalose is related to its

structure, providing the most favorable

fit with the polar head

groups of the phospholipids membrane (

), thus maintaining the polar groups at

their hydrated position. Besides lowering T

m

of membranes,

trehalose has the ability to preserve the structure and functionality

of cell proteins during drying. This ability is associated to formation

of the hydrogen bonds between the hydroxyl groups and polar

residues of the protein (

The results (

B) indicate that the survival at 1:1 and 2:1

maltodextrin-trehalose ratio is similar. At higher amounts of

trehalose, the plasticizing effect of the added sugar is more

accentuated, the glass transition temperature of the mixture is

lower as well the a

wg

limit (water activity at glass transition) for

stabilization while the moisture stabilization limit m

g

(moisture

content at glass transition) is lower too (

). On the other hand the water replacement

capability of trehalose due hydrogen bonding will be more signif-

icant at higher trehalose fractions. Therefore we suggest that the

latter effect compensates for the lower glass transition temperature

and different moisture stability limit.

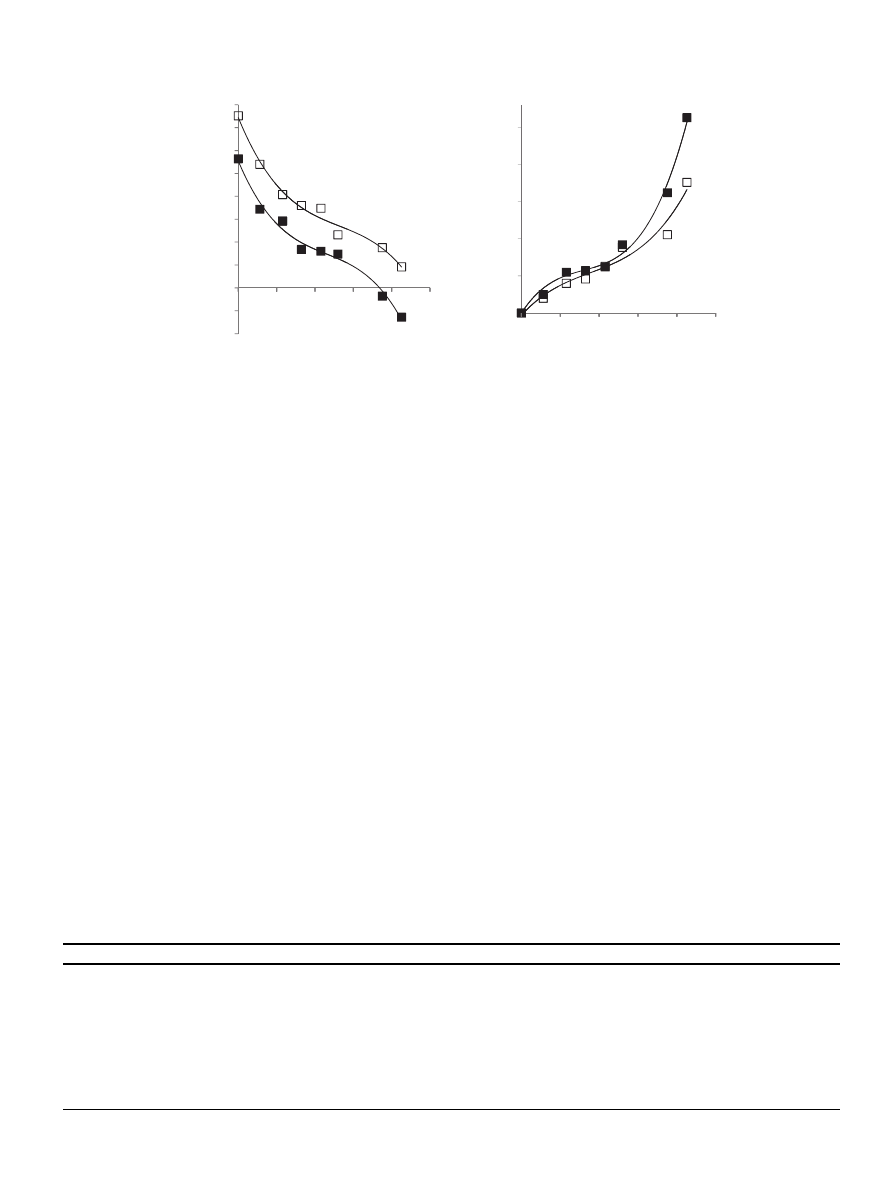

3.4. Effect of water activity on microcapsule stability

The effect of water activity and moisture content on the stability

of the microcapsule was tested in formulations composed of mal-

todextrins DE5 and DE19, both as mixed maltodextrin-trehalose

matrixes. Increase in

final water activity (a

w

>0.4) in maltodextrin-

trehalose matrix lead to a decrease in probiotic survival (p

< 0.05)

D). The effect of water activity on the glass transition of MD

DE19 was previously evaluated by determining the moisture

sorption isotherm (at 25

C) and DSC determination of the glass

transition, T

g

for maltodextrin DE20 (

A) (

). This

use of existing data on maltodextrin DE20 for calculations related to

DE19 was carried out assuming that for the purpose of this

discussion, the difference is insigni

ficant. Bouquerand (

) also determined the limit of maltodextrin DE20

moisture stability as an encapsulation carrier. They demonstrated

that as long as the Tg is higher than the storage temperature, it

remains in a glassy state, and the molecular mobility is restricted at

that water activity limit a

wg

. Using this concept we evaluated the

moisture content corresponding to 25

C as the glass transition

temperature, Tg vs. the moisture content (m) curve of MD DE20

(

). Once determining the moisture content at

glass transition (m

g

), the stability limit value of the water activity

(a

wg

) is evaluated from the sorption isotherms curve of maltodex-

trin DE20 at 25

C presented in the form of moisture content m

(g water/g solids) as function of the water activity a

w

(

B).

Bellow this m

g

maltodextrin DE20 remains in a glassy state. This

way we calculated the estimated stability limits of maltodextrin

DE20 as m

g

(DE20)

¼ 0.11 (g water/g solids), and a

wg

(DE20)

¼ 0.59.

Based on polymer physics principles, we used an additional

method to determine a

wg

and m

g

. The water sorption isotherms

data can be transformed using the equations below into a new

form, representing the osmotic pressure

P

osm

(MPa) of the polymer

(MD DE 20) as a function of solids concentration C

* (g/ml solution)

The relationship between polysaccharide concentration and

moisture content m can be expressed as follow (

SilberbergBouhnik, Eichler, & Cohen, 1997

).

C

* ¼

1

m

y

w

þ

y

s

(2)

m

¼

1

C*

y

s

C

*

y

w

(3)

Where: C

* is the solids concentration in g solids/ml solution;

m is the moisture content in g

water

/g

solids

n

s,

n

w

, are the speci

fic volume of the solids and of the water in

ml/g

solids

.

The osmotic pressure is calculated from the water activity data

according to the following expression:

p

osm

¼

RT

V

w

lna

w

(4)

Where

T is the temperature in K,

R is the gas constant,

V

w

is molar volume of liquid water 18 ml/mol.

D. Semyonov et al. / LWT - Food Science and Technology 44 (2011) 1844

e1852

1848

The values of C

* can be evaluated from the sorption isotherm

data and from Eq.

.

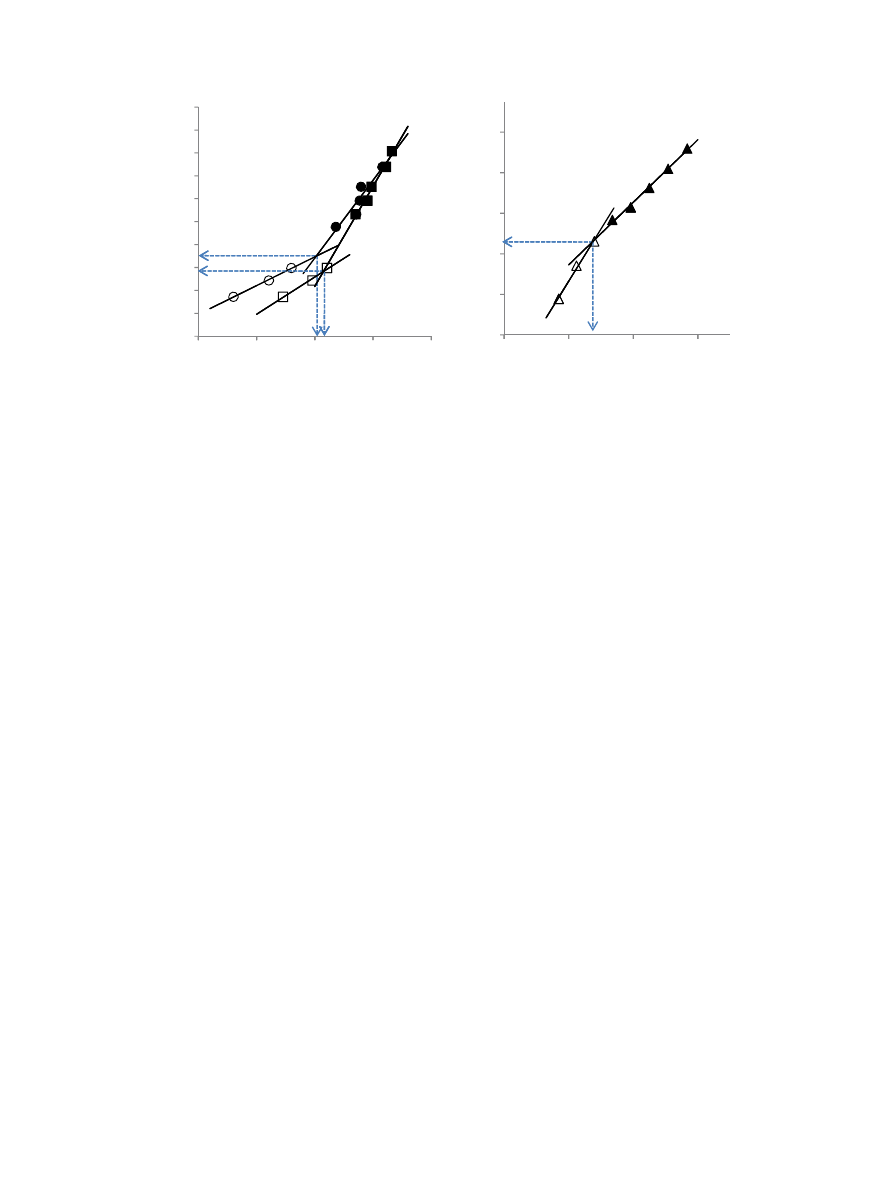

By plotting the sorption isotherm data in the form of log (

P

osm

)

versus log(C

*) one can see two distinct straight lines. One, repre-

senting the rubbery region of the water sorption isotherm and the

second representing its glassy region. The obtained straight lines

intersect each other (

), and from that intersection one can

evaluate the concentration C

g

* and osmotic pressure

P

osm

magni-

tudes at the onset glassi

fication. From C*

g

and Eq.

the moisture

limit value, m

g

the moisture content at the glassy onset is evalu-

ated, assuming that in the limit of the rubbery region

y

w

y1.

From the magnitude of log(

P

osm

) at the intersection of the

straight lines (see the horizontal line in

) it is possible to

estimate a

wg

. The stability limits of maltodextrin DE 20 were

calculated from (

A) are: m

g

(DE20)

¼ 0.108 (g water/g solids),

and a

wg

(DE20)

¼ 0.63. Thus, by employing this method we

obtained very similar stability limits, m

g

and a

wg

for MD DE20, as

those found by

.

In maltodextrin-trehalose mixtures, trehalose crystallization

may be inhibited due the presence of the polysaccharide malto-

dextrin, as suggested for amorphous sucrose (

and lactose (

Labrousse, Roos, & Karel, 1992

). By adding high Mw

maltodextrin DE5 (Mw 150000) or DE20 (Mw 9000), we expected

the anhydrous Tg of the mixture maltodextrin-trehalose to

increase. We assumed that trehalose acts as a plasticizer for the

large maltodextrin molecule, thus lowering the Tg as function of

moisture content. This would lead to a decrease in the stability limit

of the water activity, a

wg

and the moisture content needed for the

matrix to be in glassy state (m

g

).

Plotting the water sorption isotherm of maltodextrin-trehalose

mixture 1:1 one can estimate the moisture and water activity limit

as previously described. We therefore transformed the sorption

isotherm of maltodextrin-trehalose 1:1 data, determined at 25

C

by Iglesias (

Iglesias, Chirife, & Buera, 1997

), to osmotic pressure vs

water activity (

) and plot it in the form log(

P

osm

) vs. log(C

*)

(

B). The calculated moisture and water activity limits, m

g

and

a

wg

for the 1:1 maltodextrin

etrehalose mixture were a

wg

¼ 0.59

and m

g

¼ 0.11(g water/g solids) respectively. It can be therefore

seen that the a

wg

limit (0.59) is lower than for MD alone

(DE5

¼ 0.77 and DE20 ¼ 0.63). However the trehalose presence and

its additional protection lead to an overall higher survival in the

trehalose-maltodextrin mixture than for MD alone.

3.5. The effect of the dextrose equivalent

The survival of the probiotic cells was signi

ficantly higher when

the encapsulation matrix was based on maltodextrin with low DE

rather than high DE (p

< 0.05 maltodextrin and maltodextrin-

trehalose formulations) (

A and B). The viability difference

between DE5 and DE19 was up to 20%. In addition, we have found

that while at similar solids concentration (30 g/100g) the survival at

maltodextrin DE5-tehalose 2:1 ratio was similar to 1:1 ratio

(

B), both were higher than in the mixtures of maltodextrin

DE19-trehalose 2:1 and 1:1. The reason to the 20% increase in cell

survival is probably the higher glass transition temperature of DE5

(anhydrous Tg is 188

C versus 141

C for DE20). This effect was

even more prominent at 20 g/100g solids concentration. Here the

survival was almost doubled for the high MW maltodextrin (DE5).

Table 2

The osmotic pressure

P

osm

(MPa) of the formulation as function of solids concentration C

* (g/ml solution) (based on

Maltodextrin DE5

Maltodextrin DE20

Maltodextrin-Trehalose

Concentration C

*

(g solids/ml solution)

Osmotic pressure

(MPa)

Concentration C

*

(g solids/ml solution)

Osmotic pressure

(MPa)

Concentration C

*

(g solids/ml solution)

Osmotic pressure (MPa)

0

0

0

0

0

0

1.18

22.1

1.07

22.1

1.25

37.8

1.25

30.7

1.15

30.7

1.27

55.2

1.29

39.4

1.20

39.4

1.28

72.7

1.32

90.2

1.31

90.2

1.30

92.7

1.36

115.9

1.37

115.9

1.32

106.9

1.40

152.9

1.38

152.9

1.33

133.3

1.41

201.8

1.38

201.8

1.35

165.8

1.45

301.0

1.44

301.0

1.37

208.5

Tg (°C)

A

B

200

175

150

125

100

75

50

25

0

0

0.2

0.4

0.6

0.8

1

0

0.2

0.4

0.6

0.8

1

0.25

0.20

0.15

0.10

0.05

0.00

25-

50-

Water activity

m (gr water / gr d.m.)

Water activity

Fig. 3. (A) The dependency of glass transition (Tg) on the water activity (a

w

) (based on

). The curves were

fitted to a third degree polynom (R

2

0.987). (B) Sorption

isotherms at 25

C of maltodextrins DE5 and DE20. Both curves were

fitted to a third degree polynom (R

2

(DE5)

¼ 0.963, R

2

(DE20)

¼ 0.991). , Maltodextrin DE5,

-

maltodextrin

DE20. From these graphs we estimated the water activity and moisture content limit (aw

g

and m

g

) for both polymers: m

g

(DE20)

¼ 0.108 (g water/g solids), a

wg

(DE20)

¼ 0.63;

m

g

(DE5)

¼ 0.17 (g water/g solids), a

wg

(DE5)

¼ 0.80.

D. Semyonov et al. / LWT - Food Science and Technology 44 (2011) 1844

e1852

1849

In order to determine the water activity and moisture content

stability limit for maltodextrin DE5 we employed again the two

methods used for determining the a

wg

and m

g

for DE 20. The

evaluated stability limits of maltodextrin DE5 m

g

and a

wg

:

m

g

(DE5)

¼ 0.17 (g water/g solids), a

wg

(DE5)

¼ 0.80. The sorption

isotherm of maltodextrin DE5 was plotted in the same manner in

the form of

P

osm

vs C

* (

) and (

). Here too, we observed

two distinct straight lines, and at their intersection we evaluated

the concentration C

*

g

and osmotic pressure

P

osm

at the glassy state

onset, and then calculated a

wg

. The stability limits of the malto-

dextrins were therefore m

g

(DE5)

¼ 0.11 (g water/g solids),

a

wg

(DE5)

¼ 0.77 for DE5 and m

g

(DE20)

¼ 0.11 (g water/g solids),

a

wg

(DE20)

¼ 0.63 for DE20.

Two different methods thus, showed very close stability limits,

m

g

and a

wg

were obtained for MD DE20 and DE5. These results

indicate that MD DE5 is in a glassy state at a higher water activity

than MD DE20. This implies that during the moisture removal the

MD DE5 falling drops will reach faster the glassy state due the

vitri

fication mechanism. This in turn may lead to better protection

of the probiotic cells than with MD DE19. This observation may

therefore explain the increase in the survival percentage when the

probiotics were embedded in a maltodextrin DE5 matrix.

3.6. The effect of the probiotic concentration

The survival of L. paracasei in relation to its concentration in the

matrix is shown in

C. There was a decrease in the survival

with the increase in cell concentration. Hence, part of the cells can

be located at the drop surface; therefore, the matrix formulation

cannot protect them during the drying stages. At low probiotic

concentrations, fewer cells are at the droops surface and the

survival in both methods is similar. Despite the decreased viability,

UVSD process provided an opportunity to encapsulate more than

3

10

9

CFU/g L. paracasei with near 50% survival.

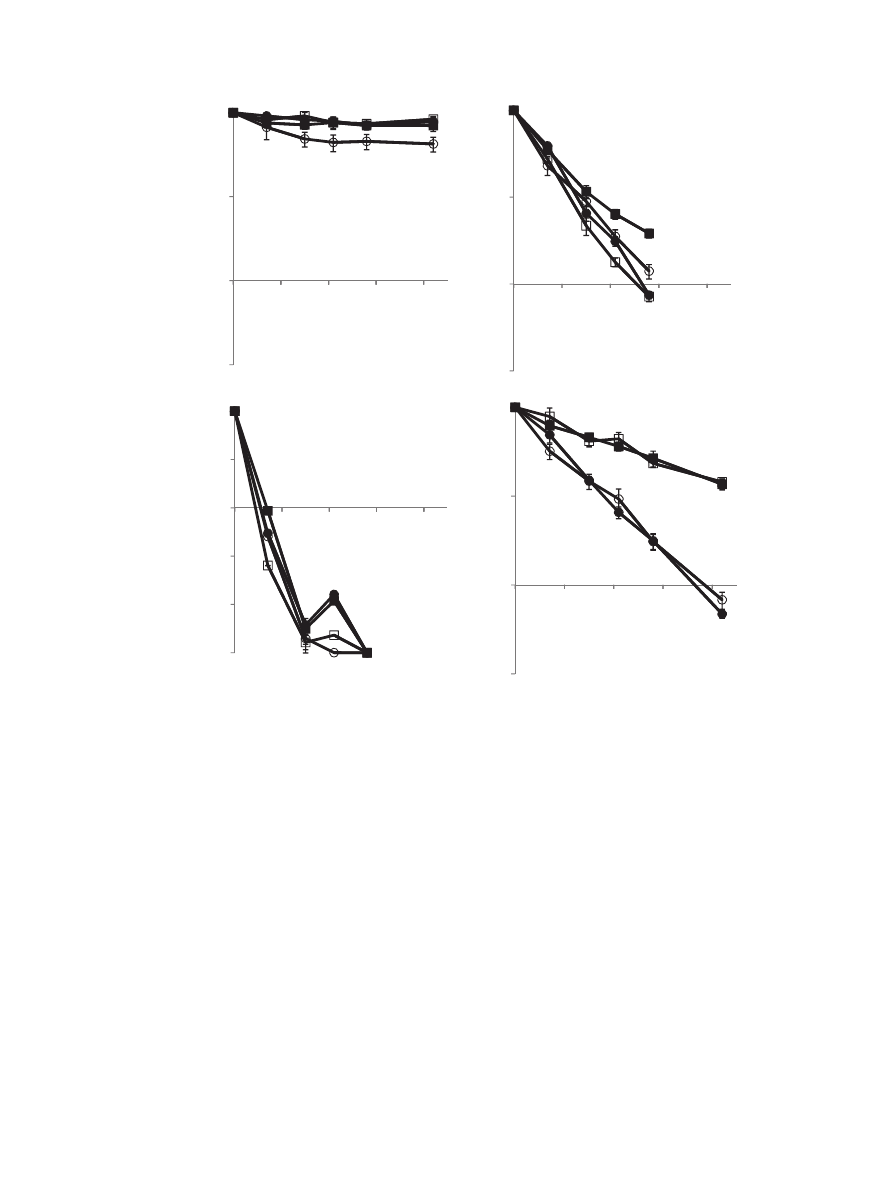

3.7. Stability of the encapsulated probiotics

Probiotic bacteria integrated in food products should retain

their viability during storage, thus ensuring adequate number of

cells in the consumed product. We therefore examined changes in

the probiotic survival during storage. The effect of storage

temperature on L. paracasei stability in matrixes composed of

maltodextrins and various dextrose equivalent (DE) and malto-

dextrin-trehalose ratio is shown in

. Indeed, storage temper-

ature affects probiotic survival in a very signi

ficant manner. Similar

results were reported by other researchers (

Tailliez, 1993; Gardiner et al., 2000; Teixeira, Castro, Malcata, &

Kirby, 1995

). In addition, the survival was considerably lost after 7

days and 28 days of storage at 37 and 25

C respectively. The results

also indicate that in most compositions the probiotic survival was

above 70% for at least 42 days when stored at 4

C.

The presence of trehalose in the matrix increased viability,

especially in combination with low oxygen level (N

2

). At low

oxygen level, using trehalose as part of the encapsulation matrix

provided better protection than encapsulation in a maltodextrin

matrix alone (p

< 0.01) (

). Interestingly, dextrose equivalent,

DE, did not have signi

ficant effect on probiotic survival during

storage at 25 and 37

C. However in combination with trehalose the

best results were obtained with lower DE, probably because the

higher T

g

of the mixture. This would increase the difference

between the T

g

and the storage temperature T, (T - T

g

) that is known

to control the rate of physical, chemical and biological changes

(

As noted brie

fly before, we also explored the effect of oxygen

level as an external factor affecting probiotic survival. Samples that

were stored in vessels

flushed with nitrogen and stored under

nitrogen at 25

C maintained higher viability for longer time than

samples stored at 25

C in air (p

< 0.01) as described in

B and D.

Several studies claimed that reduction of cell viability during

storage can be related to oxidation of membrane lipids that initiate

the production of hydroperoxides which have been shown to

induce also DNA damage (

Akasaka, 1986; Inouye, 1984; Marnett

). Thus chemical stability is also an important factor to

be considered to increase preservation of the dried probiotic cells

during storage. From this point of view the glassy state of the

encapsulating matrix reduce the rate of chemical reactions and

decrease the molecular mobility in the cytoplasm (

). In light of this study, the fast decay of viability at

37

C is likely due to the fact that the carrier matrix is not in a glassy

state.

1.

1.

1.

1.

2.

2.

2.

2.

log(Osm. Pres.)

A

B

1

.2

.4

.6

.8

2

.2

.4

.6

.8

3

0

0..05

0.1

log(

0.15

C*)

0.2

1.

1.

1.

2.

2.

log(Osm. Pres.)

.4

.6

.8

2

.2

.4

0.08

0.1

0.1

log(C*)

12

0.14

)

Fig. 4. Evaluation of moisture content and water activity limit (aw

g

and m

g

) from curves of osmotic pressure as function of the concentration. (A) Maltodextrin DE5:

, rubbery,

-

glassy; and maltodextrin DE20:

B rubbery, C glassy. From these graphs we estimated the water activity and moisture content limit (aw

g

and m

g

) for both polymers:

m

g

(DE5)

¼ 0.11 (g water/g solids), a

wg

(DE5)

¼ 0.77; and m

g

(DE20)

¼ 0.11 (g water/g solids), a

wg

(DE20)

¼ 0.63 (based on

). (B) Evaluation of moisture content and

water activity limit (aw

g

and m

g

) from curves of osmotic pressure as function of the concentration of maltodextrin-trehalose mixture (based on

):

6

rubbery,

: glassy. From these graphs we estimated the water activity and moisture content limit: a

wg

¼ 0.59 and m

g

¼ 0.11 (g water/g solids).

D. Semyonov et al. / LWT - Food Science and Technology 44 (2011) 1844

e1852

1850

4. Conclusions

The aim of this investigation was to study a process for the

formation of dry-encapsulated probiotics, using ultrasonic vacuum

spray drying (UVSD), and microcapsule matrix composed of mal-

todextrin and trehalose. The results of this study demonstrate that

using UVSD brought the matrix rapidly to a glassy state and

provided high survival of the probiotic cells - 3.3

10

9

CFU/g d m,

that was achieved with maltodextrin DE19-trehalose (1:1) 20%

g/100g matrix and 7.0

10

9

CFU/g d.m. initial L. paracasei

concentration. It was found that MD DE5 was a better encapsula-

tion matrix than MD DE19, probably due to the fact that DE5 matrix

maintained its glassy state at a higher a

w

. The addition of trehalose

increased the viability signi

ficantly during the drying and during

storage of the dried powder. MD DE5-trehalose combination (1:1)

resulted with the highest survival (70.6

6.2%). Evidently, further

protection should be provided to the cells against oxidation, as

storage in nitrogen was essential in order to gain storage stability.

Further studies should be conducted to provide further protection

to the probiotics by better control of (T - T

g

), and enhancement of

the chemical stability during storage by employing additional

compatible solutes and coatings.

Acknowledgment

The research was supported by the Israeli Ministry of Industry

Commerce and Trade.

References

Akasaka, S. (1986). Inactivation of transforming activity of plasmid DNA by lipid-

peroxidation. Biochimica and Biophysica Acta, 867(4), 201

e208.

Anal, A. K., & Singh, H. (2007). Recent advances in microencapsulation of probiotics

for industrial applications and targeted delivery. Trends in Food Science &

Technology, 18(5), 240

e251.

Berner, L. A., & O

’Donnell, J. A. (1998). Functional foods and health claims legisla-

tion: applications to dairy foods. International Dairy Journal, 8(5

e6), 355e362.

Bouquerand, P.-E., Maio, S., Meyer, F., & Normand, V. (2008). Moisture stability of

maltodextrin-based delivery systems. Food Biophysics, 3(2), 182

e185.

Buitink, J., & Leprince, O. (2004). Glass formation in plant anhydrobiotes: survival in

the dry state. Cryobiology, 48(3), 215

e228.

Carpenter, J. F., & Crowe, J. H. (1989). An Infrared spectroscopic study of the inter-

actions of carbohydrates with dried proteins. Biochemistry, 28(9), 3916

e3922.

Carpenter, J. F., Martin, B., Crowe, L. M., & Crowe, J. H. (1987). Stabilization of

phosphofructokinase during air-drying with sugars and sugar transition-metal

mixtures. Cryobiology, 24(5), 455

e464.

Castro, H. P., Teixeira, P. M., & Kirby, R. (1997). Evidence of membrane damage in

Lactobacillus bulgaricus following freeze drying. Journal of Applied Microbiology,

82(1), 87

e94.

0

1

Viabil

ity [

%

]

A

B

D

C

0.0

0

0

Viability [%]

0.1

1

10

00

0

1

01

.01

.1

1

10

0

1

10

20

Time (days)

0

20

Time (days)

30

4

30

4

40

0

0.

1

10

Viability [

%

]

0

1

100

Viab

ility [%]

.1

1

10

0

0

10

.1

1

0

0

10

0

20

Time (days)

0

20

Time (days)

30

40

30

4

0

40

Fig. 5. Effect of the storage temperature and oxygen level on L. paracasei survival. (A) microcapsules stored in air at 4

C; (B) microcapsules stored in air at 25

C; (C) microcapsules

stored in air at 37

C; and (D) microcapsules stored in vessels

flashed with nitrogen at 25

C

B maltodextrin DE5, , maltodextrin DE5 [1:1] trehalose, C maltodextrin DE19, and

-

maltodextrin DE19 [1:1] trehalose. The error bars represent standard deviation of means (n

3).

D. Semyonov et al. / LWT - Food Science and Technology 44 (2011) 1844

e1852

1851

Crowe, J. H., Carpenter, J. F., & Crowe, L. M. (1998). The role of vitri

fication in

anhydrobiosis. Annual Review of Physiology, 60, 73

e103.

Crowe, J. H., Crowe, L. M., Carpenter, J. F., Rudolph, A. S., Wistrom, C. A., Spargo, B. J.,

et al. (1988). Interactions of sugars with membranes. Biochimica and Biophysica

Acta (BBA) - Reviews on Biomembranes, 947(2), 367

e384.

Crowe, J. H., Crowe, L. M., Carpenter, J. F., & Wistrom, C. A. (1987). Stabilization of dry

phospholipid-bilayers and proteins by sugars. Biochemical Journal, 242(1), 1

e10.

Crowe, L. M., Crowe, J. H., Rudolph, A., Womersley, C., & Appel, L. (1985). Preser-

vation of freeze-dried liposomes by trehalose. Archives of Biochemistry and

Biophysics, 242(1), 240

e247.

Crowe, L. M., Reid, D. S., & Crowe, J. H. (1996). Is trehalose special for preserving dry

biomaterials? Biophysical Journal, 71(4), 2087

e2093.

Desmond, C., Ross, R. P., O

’Callaghan, E., Fitzgerald, G., & Stanton, C. (2002).

Improved survival of Lactobacillus paracasei NFBC 338 in spray-dried powders

containing gum acacia. Journal of Applied Microbiology, 93(6), 1003

e1011.

Dunne, C., O

’Mahony, L., Murphy, L., Thornton, G., Morrissey, D., O’Halloran, S., et al.

(2001). In vitro selection criteria for probiotic bacteria of human origin:

correlation with in vivo

findings. American Journal of Clinical Nutrition, 73(2),

386S

e392S.

FAO/WHO. (2001). Evaluation of health and nutritional properties of powder milk with

live lactic acid bacteria. Report from FAO/WHO Expert Consultation.

Freitas, S., Merkle, H. P., & Gander, B. (2004). Ultrasonic atomisation into reduced

pressure atmosphere

eenvisaging aseptic spray-drying for microencapsulation.

Journal of Controlled Release, 95(2), 185

e195.

Gardiner, G. E., O

’Sullivan, E., Kelly, J., Auty, M. A. E., Fitzgerald, G. F., Collins, J. K.,

et al. (2000). Comparative survival rates of human-derived probiotic Lactoba-

cillus paracasei and L-salivarius strains during heat treatment and spray drying.

Applied and Environmental Microbiology, 66(6), 2605

e2612.

Goderska, K., & Czarnecki, Z. (2008). In

fluence of microencapsulation and spray

drying on the viability of Lactobacillus and Bi

fidobacterium strains. Polish

Journal of Microbiology, 57(2), 135

e140.

Hector, A.,I., & Jorge, C. (1978). Delayed crystallization of amorphous sucrose in

humidi

fied freeze dried model systems. International Journal of Food Science and

Technology, 13(2), 137

e144.

Holzapfel, W. H., Haberer, P., Geisen, R., Bjorkroth, J., & Schillinger, U. (2001).

Taxonomy and important features of probiotic microorganisms in food and

nutrition. American Journal of Clinical Nutrition, 73(2), 365S

e373S.

Iglesias, H. A., Chirife, J., & Buera, M. P. (1997). Adsorption isotherm of amorphous

trehalose. Journal of the Science of Food and Agriculture, 75(2), 183

e186.

Inouye, S. (1984). Site-speci

fic cleavage of double-strand DNA by hydroperoxide of

linoleic acid. FEBS Letters, 172(2), 231

e234.

Ishibashi, N., & Shimamura, S. (1993). Bi

fidobacteria - research-and-development in

Japan. Food Technology, 47(6), 126

e134.

Knorr, D. (1998). Technology aspects related to microorganisms in functional foods.

Trends in Food Science & Technology, 9(8

e9), 295e306.

Koster, K. L., Maddocks, K. J., & Bryant, G. (2003). Exclusion of maltodextrins from

phosphatidylcholine multilayers during dehydration: effects on membrane

phase behaviour. European Biophysics Journal with Biophysics Letters, 32(2),

96

e105.

Labrousse, S., Roos, Y. H., & Karel, M. (1992). Collapse and crystallization in amor-

phous matrices with encapsulated compounds. Sciences Des Aliments, 12(4),

757

e769.

Lee, Y. K., & Salminen, S. (1995). The coming of age of probiotics. Trends in Food

Science & Technology, 6(7), 241

e245.

Leslie, S. B., Israeli, E., Lighthart, B., Crowe, J. H., & Crowe, L. M. (1995). Trehalose and

sucrose protect both membranes and proteins in intact bacteria during drying.

Applied and Environmental Microbiology, 61(10), 3592

e3597.

Lievense, L. C., & Van

’t Riet, K. (1993). Convective drying of bacteria. I: the drying

processes. Advances in Biochemical Engineering/ Biotechnology, vol. 50(82 ref.), 45

e63.

Marnett, L. J., Hurd, H. K., Hollstein, M. C., Levin, D. E., Esterbauer, H., & Ames, B. N.

(1985). Naturally-occurring carbonyl-compounds are mutagens in Salmonella

tester strain Ta104. Mutation Research, 148(1

e2), 25e34.

Mary, P., Moschetto, N., & Tailliez, R. (1993). Production and survival during storage

of spray-dried Bradyrhizobium japonicum cell concentrates. Journal of Applied

Microbiology, 74(3), 340

e344.

Menashe, E. (1995). Physical models to invistigate water sorption isotherms and their

relation to the glass transition temperature, mobility and stabality of food systems.

Biotechnology and Food Engineering. Haifa, Technion - Israel Institute of

Technology. B.Sc.

Mizrahi, S., Ramon, O., SilberbergBouhnik, M., Eichler, S., & Cohen, Y. (1997). Scaling

approach to water sorption isotherms of hydrogels and foods. International

Journal of Food Science and Technology, 32(2), 95

e105.

Oldenhof, H., Wolkers, W. F., Fonseca, F., Passot, S. P., & Marin, M. (2005). Effect of

sucrose and maltodextrin on the physical properties and survival of air-dried

Lactobacillus bulgaricus: an in situ Fourier transform infrared spectroscopy

study. Biotechnology Progress, 21(3), 885

e892.

Patist, A., & Zoerb, H. (2005). Preservation mechanisms of trehalose in food and

biosystems. Colloids Surf B Biointerfaces, 40(2), 107

e113.

Roos, Y., & Karel, M. (1991). Phase transitions of mixtures of amorphous poly-

saccharides and sugars. Biotechnology Progress, 7, 49

e53.

Ross, R. P., Desmond, C., Fitzgerald, G. F., & Stanton, C. (2005). Overcoming the

technological hurdles in the development of probiotic foods. Journal of Applied

Microbiology, 98(6), 1410

e1417.

Rudolph, B. R., Chandrasekhar, I., Gaber, B. P., & Nagumo, M. (1990). Molecular

modelling of saccharide-lipid interactions. Chemistry and Physics of Lipids,

53(2

e3), 243e261.

Sadykhov, A., & Kish, S. (1997). Unique ultrasonic vacuum spray dryer

e a new spray

drying concept for high quality powder. The second Israel Conference for

Conveying and Handling of Particulate Solids, Jerusalem, Isreal.

Semyonov, D., Ramon, O., Kaplun, Z., Levin-Brener, L., Gurevich, N., & Shimoni, E.

(2010). Microencapsulation of Lactobacillus paracasei by spray freeze drying.

Food Research International, 43(1), 193

e202.

Shah, N. P., & Ravula, R. R. (2000). Microencapsulation of probiotic bacteria and their

survival in frozen fermented dairy desserts. Australian Journal of Dairy Tech-

nology, 55(3), 139

e144.

Stanton, C., Gardiner, G., Meehan, H., Collins, K., Fitzgerald, G., Lynch, P. B., et al.

(2001). Market potential for probiotics. American Journal of Clinical Nutrition,

73(2), 476S

e483S.

Teixeira, P. C., Castro, M. H., Malcata, F. X., & Kirby, R. M. (1995). Survival of Lacto-

bacillus-delbrueckii ssp bulgaricus following spray-drying. Journal of Dairy

Science, 78(5), 1025

e1031.

Zhang, J., & Steponkus, P. L. (1996). Proposed mechanism for depression of the

liquid-crystalline-to-gel phase transition temperature of phospholipids in

dehydrated sugar-phospholipid mixtures. Cryobiology, 33, 21A.

D. Semyonov et al. / LWT - Food Science and Technology 44 (2011) 1844

e1852

1852

Document Outline

- Using ultrasonic vacuum spray dryer to produce highly viable dry probiotics

- 1 Introduction

- 2 Materials and methods

- 3 Results and discussion

- 4 Conclusions

- Acknowledgment

- References

Wyszukiwarka

Podobne podstrony:

Encapsulating probiotic bacteria by ultrasonic vacuum spray drying (D Semyonov, O Ramon and E Shimon

2003 12 Docbook Using Openoffice Org to Produce Docbook Files

Improving Grape Quality Using Microwave Vacuum Drying Associated with Temperature Control (Clary)

Experimental vacuum spray dryin Nieznany

Improving Grape Quality Using Microwave Vacuum Drying Associated with Temperature Control (Clary)

Kher, Neelam, Molstad Using humor in the classroom to enhance teaching effectiveness in dread cours

Terrorism And Development Using Social and Economic Development to Prevent a Resurgence of Terroris

Wiktorek Smagur, Aneta i inni Green Way of Biomedicine – How to Force Plants to Produce New Importa

Barnett C Helzberg, Jr What I Learned Before I Sold to Warren Buffett [An Entrepreneur’s Guide to D

Using Probabilistic Knowledge And Simulation To Play Poker (Darse Billings)

Ten Secrets to Becoming a Highly Profitable Residential Developer Real Estate Investing Day Trading

Using an open source framework to catch the bad guy

Co to znaczy być biednym, Rok szkolny 2011-2012

NATO to nie tylko USA Nasz Dziennik, 2011 03 18

Odejście tupolewem na drugi krąg to naprawdę nic trudnego Nasz Dziennik, 2011 01 24

więcej podobnych podstron