Biomaterials 23 (2002) 491–501

Characteristics of the surface oxides on turned and electrochemically

oxidized pure titanium implants up to dielectric breakdown:

the oxide thickness, micropore configurations, surface roughness,

crystal structure and chemical composition

Young-Taeg Sul

a,b,

*, Carina B. Johansson

a

, Sarunas Petronis

c

, Anatol Krozer

d

, Yongsoo

Jeong

e

, Ann Wennerberg

a

, Tomas Albrektsson

a

a

Department of Biomaterials/Handicap Research, Institute for Surgical Science, University of G

.ooteborg, Sweden

b

Osseointegration Research Institute, Seoul, South Korea

c

Department of Applied Physics, Chalmers University of Technology/GU, Sweden

d

Imego AB, Aschebergsgatan 46 build 11 411 33 G

.ooteborg, Sweden

e

Surface Engineering Department, Korea Institute of Machinery & Materials, 66 Sangnam-dong, Changwon, Kyungnam, South Korea 641 010

Received 16 November 2000; accepted 23 March 2001

Abstract

Titanium implants have been used widely and successfully for various types of bone-anchored reconstructions. It is believed that

properties of oxide films covering titanium implant surfaces are of crucial importance for a successful osseointegration, in particular

at compromized bone sites. The aim of the present study is to investigate the surface properties of anodic oxides formed on

commercially pure (c.p.) titanium screw implants as well as to study ‘native’ oxides on turned c.p. titanium implants. Anodic oxides

were prepared by galvanostatic mode in CH

3

COOH up to the high forming voltage of dielectric breakdown and spark formation.

The oxide thicknesses, measured with Auger electron spectroscopy (AES), were in the range of about 200–1000 nm. Barrier and

porous structures dominated the surface morphology of the anodic film. Quantitative morphometric analyses of the micropore

structures were performed using an image analysis system on scanning electron microscopy (SEM) negatives. The pore sizes were

p8 mm in diameter and had 1.27–2.1 mm

2

opening area. The porosity was in the range of 12.7–24.4%. The surface roughness was in

the range of 0.96–1.03 mm (S

a

), measured with TopScan 3D

s

. The crystal structures of the titanium oxide were amorphous, anatase,

and a mixtures of anatase and rutile type, as analyzed with thin-film X-ray diffractometry (TF-XRD) and Raman spectroscopy. The

chemical compositions

consisted mainly of TiO

2

, characterized with X-ray photoelectron spectroscopy (XPS). The native (thermal)

oxide on turned implants was 17.4 nm (

76.2) thick and amorphous. Its chemical composition was TiO

2

. The surface roughness had

an average height deviation of 0.83 mm (S

a

). The present results are needed to elucidate the influence of the oxide properties on the

biological reaction. The results of animal studies using the presently characterized surface oxides on titanium implants will be

published separately. r 2001 Elsevier Science Ltd. All rights reserved.

Keywords:

Titanium implants; Titanium oxides; Surface oxide properties; Oxide thickness; Micropore configurations

1. Introduction

Since the first scientific documentation of successfully

osseointegrated oral titanium implants based on the

clinical experience by Br

(aanemark et al. [1] in 1977, a

number of long term follow-up results over 10 years

have been documented [2–4]. However, in bone of poor

quantity and quality, inferior clinical results have been

reported by Albrektsson and Johansson [5]. It is possible

that a change in implant surface characteristics will

result in better clinical results. One way to change the

surface characteristics of implants is by varying proper-

ties of the oxide films always present on Ti surfaces.

Oxidized implants represent such a surface change. The

oxide properties of titanium implants probably do play

an important role during the dynamic build up of the

osseointegration process [6].

*Corresponding author. Department of Biomaterials/Handicap

Research, Institute for Surgical Science, G

.ooteborg University,

Medicinaregatan 8b, Box 412, S-405 30 G

.ooteborg, Sweden. Tel.:

+46-31-773-2950; fax: +46-31-773-2941.

E-mail addresses:

young-taeg.sul@hkf.gu.se (Y.-T. Sul).

0142-9612/02/$ - see front matter r 2001 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 0 1 ) 0 0 1 3 1 - 4

Titanium is normally covered with a thin protective

oxide film, which largely determines the surface proper-

ties of an implant. Regarding the surface oxide on

commercially available turned c.p. titanium implant

systems, previous spectroscopic studies have reported

that oxide thicknesses are in the range of 1.8–17 nm, and

that the chemical composition consisted mainly of TiO

2

[7–10]. The oxide structure was found to be non-

crystalline as surveyed by Raman spectroscopy [11].

Surface roughness varied from 0.53 to 0.67 mm in Ra

values as measured by TopScan 3D measuring system

[12]. This thin oxide film, naturally formed on a titanium

substrate, is presumably responsible for the excellent

biocompatibility of titanium implants due to a low level

of electronic conductivity [13], a high corrosion resis-

tance and a thermodynamically stable state at physio-

logical pH values [14–16]. In addition, titanium and its

oxide(s) have a low ion-formation tendency in aqueous

environments [17].

In the case of the anodic oxide film, surface properties

have been shown to be sensitive to oxide growth

conditions [18]. We have previously carried out inves-

tigations of electrochemical growth behavior of the

anodic oxide film on c.p. titanium metal in various

electrolytes. The growth behavior strongly depended on

a particular electrolyte used and, for a given electrolyte,

on the employed anodic process parameters such as the

applied current density, the electrolyte concentration,

the electrolyte temperature, agitation speed, and cath-

ode to anode surface area ratios [19]. In general, it has

been shown that various surface characteristics of

anodic films are accompanied with an increase of the

oxide thickness. Previous extensive studies have de-

scribed a variety of properties of anodic oxide films in

detail, e.g. surface morphology, chemical composition,

crystal structures and corrosion resistance [20–23].

Using the higher anodic forming voltage than break-

down voltage, corresponding to Group III–V in the

present study, have been prepared in the Ca- and P-

containing electrolytes [24–27].

The present study is focused on the oxide thickness

and morphology, especially pore configurations. The

crystal structure, chemical composition and surface

roughness are also presented. The biological results

from an animal model using the presently characterized

oxide films on commercially pure titanium implants will

be published separately [28,29].

2. Experimental

2.1. Sample preparation and anodizing apparatus

Screw shaped implants were turned from 5 mm rods

of c.p. titanium (ASTM Grade 1). They had an outer

diameter of 3 mm, a total length of 7 mm with a pitch-

height of 0.5 mm. The implants had a square shaped

head (4 mm 4 mm 2 mm) with an inner threaded

hole of 2 mm which was used as a sample holder during

anodizing. Additionally, a plate type of anode (ASTM

Grade 1) was used, being 30 mm 10 mm 1.0 mm with

a small handle of 30 mm 2.5 mm 1.0 mm. The plate

type was ground on both sides with SiC paper in

successive grades from 300 to 800 grit (Struers, Den-

mark). Each sample was separately put in glass tube and

degreased in trichlorethylene and cleaned in absolute

ethanol in an ultrasonic bath for 2 15 min, respec-

tively, dried in an oven at 501C for 24 h prior to further

surface oxide preparation. Details of the anodizing

apparatus and anodizing procedures employed in this

study have been described previously [19]. In brief, the

anodizing apparatus consisted of an electrolytic cell and

an IBM computer interfaced with a dc power supply. All

the surface oxides were prepared at galvanostatic mode

in 0.1 m acetic acid. Voltage to time characteristic curves

were recorded at intervals of 0.5 s by an IBM computer

interfaced with the power supply. Immediately after

anodic oxidation, all the specimens were thoroughly

rinsed with distilled water and absolute alcohol, again

dried in the same way as mentioned above, and finally

sterilized in a steam autoclaving machine at a maximum

of 1301C for 30 min. The samples were divided into five

groups in accordance with the conditions of the surface

oxide preparation employed.

Group I implants had turned surfaces.

Group II implants; turned and anodized surfaces up

to anodic forming voltage of 100 V with the anodic

oxide forming rate of 16.7 nm/s.

Group III implants; turned and anodized surfaces up

to anodic forming voltage of 200 V with the anodic

oxide forming rate of 15.2 nm/s.

Group IV implants; turned and anodized surfaces up

to anodic forming voltage of 280 V with the anodic

oxide forming rate of 8.9 nm/s.

Group V implants; turned and anodized surfaces up

to anodic forming voltage of 380 V with the anodic

oxide forming rate of 7.7 nm/s.

A total of 45 samples, 40 screw implants and five plate

samples, were investigated for surface analyses in the

present study.

2.2. Surface analysis

The oxide thickness and surface elements were

measured by continuous sputter etching with 4 KeV Ar

ion in Auger electron microscopy (AES, Physical

Electronics, model PHI 650). Measurements were

performed with a probing beam of 2.5 mm 4.0 mm at

four different locations; one thread-top, one thread-

valley, one thread-flank and in the bottom of the screw

implant. The determination of the oxide thickness was

calculated by the numerical formula d ¼ v

0

t

d

, where d is

Y.-T. Sul et al. / Biomaterials 23 (2002) 491–501

492

the film thickness, v

0

is the sputter rate, and t

d

is the

sputtering time to make the oxygen peak amplitude

decrease by 50% [30].

Overall surface morphology was characterized by

scanning electron microscopy (SEM, JEOL JSM-5800).

An image analysis system (Bildanalyssystem AB

s

) was

used to describe the pore configurations on SEM

negatives of 3000, e.g. the pore size distributions

(PSD), pore density and porosity, etc. These measure-

ments were obtained from three randomly selected

areas; two flanks and one bottom area of the screw

implant. Scanned areas were 26 mm 20 mm. Pore

characteristics in the present study were confined with

the ‘‘opened pores’’ on the surface (not including the

‘‘buried pores’’ in the anodic oxide film). The pore

density was presented as a total number of opening

pores/scanned area (3 26 mm 20 mm). The porosity

was presented as a total area of opening pores/scanned

area (3 26 mm 20 mm).

For the analyses of the crystal structure of the

titanium oxide, thin-film X-ray diffractometry (TF-

XRD, Rigaku Co.) with PW3020 goniometer was used

on the plate type of specimen, since the screw types

seldom permitted useful X-ray diffraction pattern due to

their geometry. The step size was 0.041 between 201 and

801 of measured scan. Spectra were recorded using Cu

K

a

radiation (1.54 (

A

A). Raman spectroscopy was used for

screw implants. Raman scattering experiments were

performed by using a DILOR LABRAM spectrometer

equipped with a 10 mW helium–neon laser (l¼ 6328 (

A

A)

and 1800 line/mm grating, giving spectral resolution of

about 1 1/cm. Spectra of frequency shifts of scattered

light were measured in 97–115 1/cm energy intervals

averaging three datasets, each accumulated in 100 s.

Probing spots were chosen on one thread-top, one

thread-valley, one thread-flank and one top area of the

screw implant. The probing spot was about 4 mm in

diameter. The spectrometer was calibrated by recording

the spectrum from Si sample with characteristic peak at

520 1/cm.

The chemical composition of titanium surfaces was

analyzed by X-ray photoelectron spectroscopy (XPS).

All the XPS (VG Scientific LTD, model ESCALAB

200R) spectra were recorded using normal Al K

a

radiation (1486.8 eV) with a resolution better than

0.7 eV. Ion gun energy was 5 KeV and ion beam current

was 0.3 mA. Two types of spectra were recorded: wide

energy survey scans and higher resolution narrow scans

of the dominant spectral peaks as detected in the survey

spectra. The latter included Ti 2p, O 1s and C 1s spectral

regions.

The surface roughness was measured with confocal

laser scanning profilometer (TopScan3D

s

) as described

by Wennerberg [31]. The confocal laser scanning (CLS)

method for the evaluation of implant surface roughness

has been compared to other techniques such as a contact

stylus profilometer and an AFM. The CLS equipment

was found to give very reliable data. Maximal vertical

and horizontal resolution of the CLS is 6 nm and 0.5 mm.

Three screws were selected and measured on the 3

thread-tops, 3 thread-valleys, and 3 thread-flanks each,

making 27 measurements for each Group. The measur-

ing area was 245 mm 245 mm for each group. A

Gaussian filter was used to separate roughness from

error of form and waveness. The filter type was set to

50 mm 50 mm.

3. Results and discussion

3.1. Thickness and growth of titanium oxide

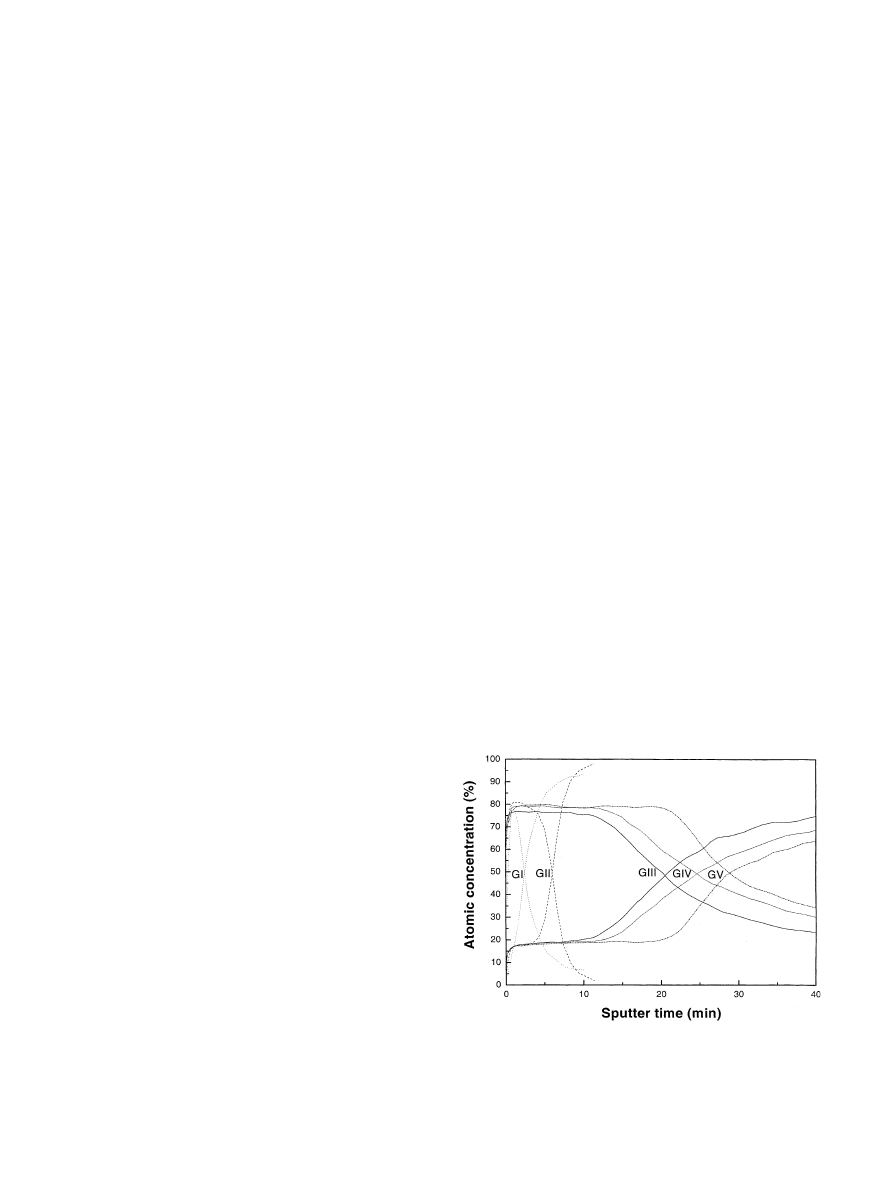

The general findings were a great variation in oxide

thickness (from 17 nm up to about 1000 nm) between the

five different groups. Fig. 1 shows the relative atomic

concentration distributions for Ti and O detected in

AES survey spectra from the turned and anodized

Groups. To translate ion sputter profiles into thickness a

calibration standard is needed. We used TiO

2

film

deposited on Si (1 0 0) by metal organic chemical vapor

deposition (MOCVD) as a reference for thickness ion

yield calibration. The film was 91.8 nm thick and had a

refractive index of 2.199 as evaluated by ellipsometry.

This value is about 2.0 for amorphous type and 2.5 for

anatase type. The sputtering rate was determined to be

about 7.1 nm/min. Group I implants had a mean oxide

thickness of 17.4 nm (

76.2), which is likely a thermal

oxide film developed mainly during implant manufac-

turing (machine-turning) and during implant steriliza-

tion up to 1341C. The turned implants in the present

study were prepared with no chemical coolants during

Fig. 1. AES depth profiles from thread-top of a screw implant

(GI=Group I) and anodized screw implants (GII–GV=Group II–

V). Thicker oxide films (Group III–V) showed relatively deeper O

diffusion near the interface zone in comparison to thinner oxide films

(Group I and II) (E

p

¼ 4:0 keV, I

p

¼ 300 nA).

Y.-T. Sul et al. / Biomaterials 23 (2002) 491–501

493

manufacturing. This together with the elevated tem-

peratures during sterilization are the probable reasons

for relatively thick ‘native’ oxide films of the Group I

implants. In previous studies the oxide thickness of

commercially available turned c.p. titanium implants

varied from 1.8 to 17 nm [8–10] and depended on the

preparation history of the implants, in particular the

ultimate temperatures the implants were exposed to, and

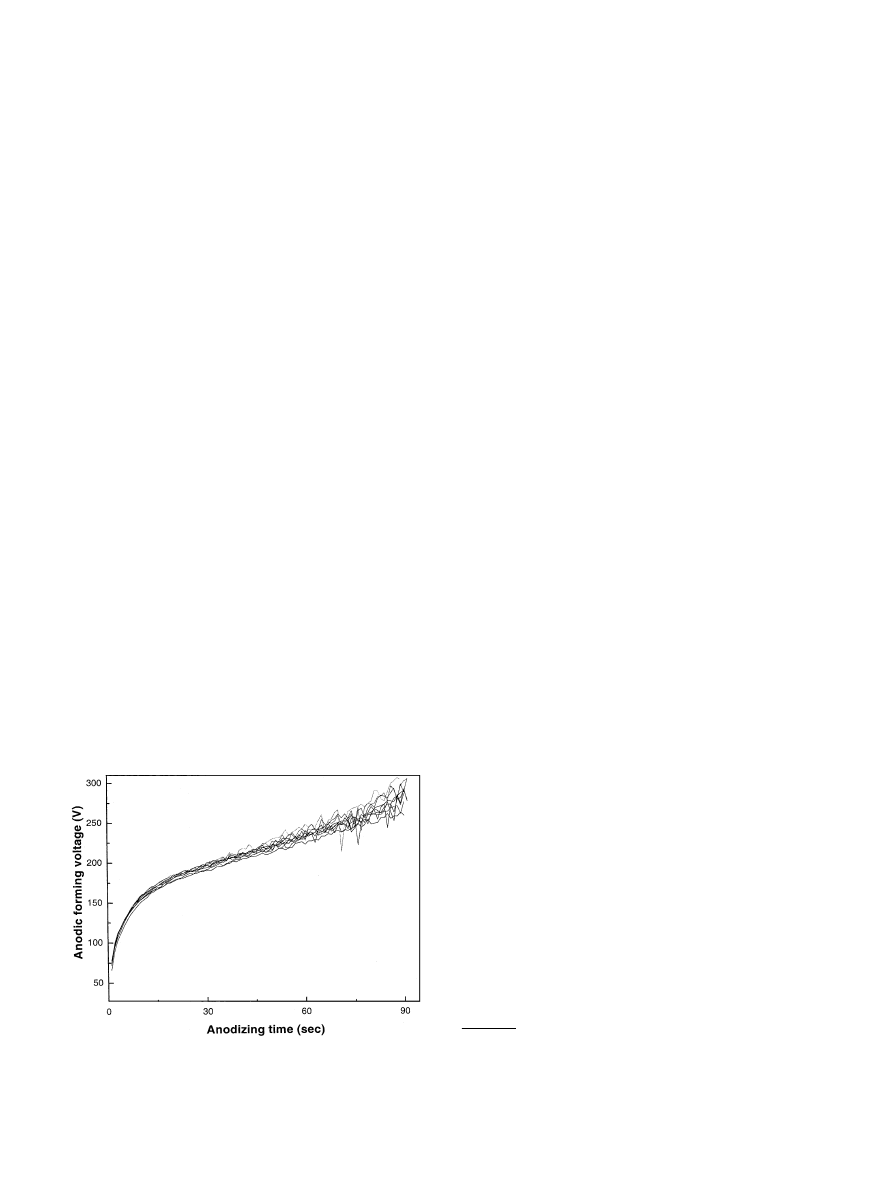

the duration of exposures [22]. Fig. 2 shows the anode-

to-cathode voltage drop (V) as a function of time during

galvanostatic anodization used in the present study.

Group II implants had an oxide thickness of 203 nm

(

753) formed up to 100 V of the anodic forming

voltage. The oxide film grew linearly with the anodic

oxide forming rate of 16.8 nm/s and the average growth

constant, a

E2:0 nm/V for Group II implants. This value

was consistent with 1.92 nm/V found in our previous

study [19]. Group III implants formed up to 200 V

(a

E3:0 nm/V, the anodic oxide forming rate of 15.2 nm/

s) had an oxide thickness of 608 nm (

7127). Group IV

implants formed up to 280 V (a

E2:9 nm/V, the anodic

oxide forming rate of 8.9 nm/s) had an oxide thickness

of 805 nm (

7112). Group V implants formed up to

380 V (a

E2:6 nm/V, the anodic oxide forming rate of

7.7 nm/s) had an oxide thickness of 998 nm (

7200). The

growth behaviors of the anodic films have been

described previously [19]. The anodic parameters

employed in the present study and corresponding oxide

thicknesses measured by AES at four different locations

of the screw implants; one thread-top, one thread-valley,

one thread-flank and on the head of the screw implant

are summarized in Table 1. The oxide thicknesses varied

slightly according to the measuring areas and were

thicker at thread-flanks than at the other measured areas

of the screw implants. The variations of the oxide

thickness are probably due to different geometry of the

measured areas in screw shaped implants, which made it

difficult to position the probing ion beam properly

during depth profiling. Another possible explanation for

these variations is related to the porous structures of the

anodic film (see Section 3.2), which essentially origi-

nated from the breakdown phenomenon of the anodic

oxide film. Fig. 2 shows the electrochemical growth

behavior of the oxide films during galvanostatic

anodizing employed in the present study. Below break-

down voltage involved in the preparation of Group II

implants, oxide growth behavior was very stable and

reproducible, and showed nearly linear relationship

between the anodic forming voltage and time. However,

beyond 200 V of the anodic forming voltage engaged in

the preparation of Group III, IV and V, there was

considerable voltage surge during breakdown (crater

formation) of the anodic oxide films. For instance, in the

case of Group V implants voltage surge was about

730 V. Subsequently during depth profile positioning of

the probing ion beam and the analyzing electron beam

into pores/craters on the oxide surface lead to shadow-

ing effects, which in turn may have resulted in the

observed variations of oxide thickness in Group III, IV

and V.

3.2. Morphology and micropore configuration

In general, with an increase of the anodic forming

voltage (increase of the oxide thickness) the micro arcing

on the screw shaped titanium anode surface (breakdown

phenomenon) became active and vigorous, resulting in

pores/craters

1

being irregular in shape. In addition, pore

size also became larger up to 8 mm in diameter. This is

most likely due to interconnection of some pores to one

another. The turned implants (Group I) were character-

ized by grooves and ridges of widths less than 10 mm and

pits (mechanically induced by machine-turning), and

oriented in the turning direction (Fig. 3a). In case of the

anodic films, morphologies critically depended on oxide

growth behaviors, especially the micro arcing phenom-

enon. Group II implants were anodized before the micro

arcing substantially began. Therefore, the surface oxide

was basically a non-porous barrier (compact and

uniform) film. As seen in Fig. 3b, Group II implants

appeared to have a similar morphology as Group I

implants. In contrast to Group I and II, the surface

morphologies in Group III–V implants had substan-

tially different porous film structures, characterized by

the appearance of craters on mountainous elevations

due to the dielectric breakdown (particularly the micro

Fig. 2. Voltage to time characteristic curves during galvanostatic

anodizing on screw shaped titanium anodes assessed with ten times-

repeated experiment. The range of voltage surge increases with the

anodizing time beyond breakdown voltage.

1

It should be noted that the term of pore and/or crater has been used

to describe the surface morphology with holes or cavities during

anodization. The concept of the pore/crater used in this paper also

involves the craters induced with the dielectric breakdown phenom-

enon.

Y.-T. Sul et al. / Biomaterials 23 (2002) 491–501

494

arcing) of the anodic films during oxide formation

(Fig. 2). As shown in SEM micrographs of Fig. 3c–e,

however, Group III, IV and V implants demonstrated

different surface topographies, especially when quanti-

fying the ‘‘opened pores’’ on the oxide surface (not

including the ‘‘buried pores’’ in the anodic oxide film).

The pores showed very irregular cauliflower-like ap-

pearance, formed on the relatively flat ground oxide

surface. The pore density (a total number of opening

pores/an entire scanning area

F3 mm 26 mm 20 mm)

was 0.1 in Group III implants, 0.16 in Group IV

implants, while it was 0.09 in Group V implants. The

pore size, measured by an opening area of each pore in a

given group, had a mean of 1.27 mm

2

in Group III

implants, 1.53 mm

2

in Group IV implants, and 2.1 mm

2

in

Group V implants, respectively. The pore size, measured

by long axis (diameter) in irregular shape of the opening

pores, was

p8 mm. The porosity (a total area of opening

pores/an entire scanning area

F3 mm 26 mm 20 mm)

was 12.7% in Group III implants, 24.4% in Group IV

implants and 18.7% in Group V implants. The decreases

of the pore density and porosity in Group V are

Table 1

The anodic parameters and oxide thickness of the turned (Group I) and anodized implants (Group II–V). The oxide thickness was measured by Ar

ion sputter etching in AES on four areas of each screw implant; one thread-top, one thread-flank, one thread-valley and one head area

Group I

Group II

Group III

Group IV

Group V

Anodic parameters

Anodic forming voltage (V)

F

100

200

280

380

Anodic oxide forming rate (nm/s)

F

16.8

15.2

8.9

7.7

Oxide growth constant (nm/V)

F

2

3

2.9

2.6

Oxide thickness (nm)

Thread-top

18.2

207.1

649

770.4

893.2

Thread-flank

27.4

274.6

743

898.4

1297.9

Thread-valley

12.8

174.7

436.8

674

893.2

Head of the screw

11.4

154.7

561.6

898.4

893.2

Mean values

17.4

202.7

608.4

805

998.4

Standard deviation

6.24

52.5

127.4

112.3

199.7

Fig. 3. SEM pictures show non-porous (Group I and II) and porous microstructure (Group III–V): a=turned surface

FGroup I; b=anodized

surface at 100 V

FGroup II; c=anodized surface at 200 VFGroup III; d=anodized surface at 280 VFGroup IV; e=anodized surface at

380 V

FGroup V.

Y.-T. Sul et al. / Biomaterials 23 (2002) 491–501

495

supported by the results of the roughness measurements

by TopScan3D

s

(see Section 3.3). One possible

explanation for the decreases of the pore density and

porosity in Group V may be due to interconnection of

some pores to each other, i.e. the pore size increased

while the number of pores decreased (Fig. 3). The

micropore configurations are summarized in Table 2.

3.3. Surface roughness

Average surface roughness (S

a

) was 0.83 mm for

turned implants (Group I), 0.96 mm for anodized

implants (Group II), 1.03 mm for anodized implants

(Group III), 1.02 mm for anodized implants (Group IV),

and 0.97 mm for anodized implants (Group V). The

values for the space descriptive parameter Scx and

hybrid parameter Sdr are summarized in Table 3. With

multiple comparisons of the Group I to test groups

using one-way ANOVA and Fisher’s PLSD method, S

a

value showed significant difference from Group III and

IV (p ¼ 0:018 and 0.029) and no significance from

Group II and V (p ¼ 0:373 and 0.098) of the present

study. This indicated that average surface roughness

(S

a

) significantly increased with increasing anodic

forming voltage up to 280 V (roughening effect), where-

after it decreased with anodic forming voltage up to

380 V. Eventually, changes of average surface roughness

(S

a

) were consistent with changes of the porosity in the

anodized implants (Group III–V).

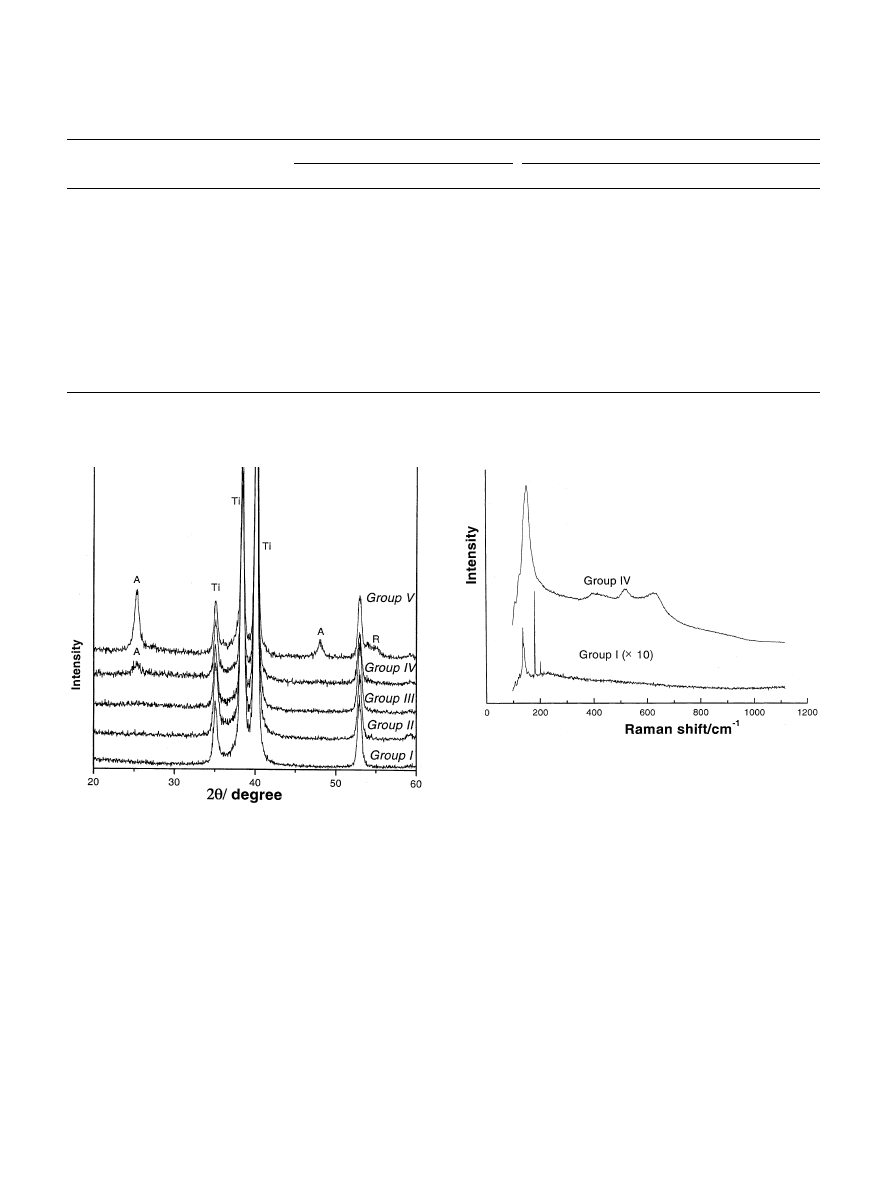

3.4. Crystal structure

TF-XRD diffraction patterns did not show features of

either anatase or rutile in Group I–III, but showed

anatase peaks in Group IV and a mixture of anatase and

rutile phase in Group V implants. In addition, Raman

spectra demonstrated a mixture of anatase and rutile

phase in Group IV implants. The results are summarized

in Table 4.

Group I implants were dominated by peaks of

titanium

substrate

on

X-ray

diffraction

patterns

(Fig. 4). Raman spectra in Group I demonstrated an

intensive double peak near 136–140 1/cm, a very sharp

and strong peak near 180 1/cm, a sharp and less

intensive peak near 201 1/cm, a very broad feature with

a maximum near 230 1/cm (probably due to fluores-

cence) and a weak peak near 285 1/cm. However, these

peak positions of Raman spectra have not been found as

any assignable characteristics of either anatase or rutile

in literature survey data (Table 4). One possible

explanation for the detected structures might be that

these arise from a non-continuous oxide network

formed at the Ti/TiO

2

interface. The thin oxide film is

thus neither amorphous nor cyrstalline but behaves

more like a molecular layer. This is consistent with the

appearance of the Ti1 and Ti

2+

related peaks in the XPS

spectra (see below) from group I implants.

The lack of X-ray diffraction patterns characteristic of

either anatase or rutile in Group II and III may indicate

Table 2

Pore characteristics of screw implants obtained using an image analysis of scanning electron microscopy (SEM) negatives of three randomly selected

areas with scanning area of 20 mm 26 mm

Sample

PSD

a

Porosity (%)

b

Pore density

c

Group I

F

F

F

Group II

Negligible

Negligible

Negligible

Group III

1.27

70.90 mm

2

,

p8 mm

12.7

73.6

0.1

70.01

Group IV

1.53

71.72 mm

2

,

p8 mm

24.4

73.7

0.16

70.03

Group V

2.10

71.96 mm

2

,

p8 mm

18.7

75.2

0.09

70.06

a

Pore size distribution (PSD) was presented by opening area and by diameter, (n ¼ 3, mean

7SD).

b

Porosity presented a total area of the opening pores/a total of the scanned area

F3 mm 20 mm 26 mm in %, (n ¼ 3, mean7SD).

c

The pore density was presented as a total number of opening pores/scanned area (3 mm 26 mm 20 mm), (n ¼ 3, mean

7SD).

Table 3

Three screw sides of each Group were measured, and each screw side was measured on 9 areas. The mean values and standard deviation in brackets

of 27 surface roughness measurements are summarized

a

Samples

S

a

(mm)

Scx (mm)

Sdr (mm)

Ssk (mm)

Group I

0.83 (0.32)

9.78 (1.40)

1.23 (0.11)

1.11 (0.92)

Group II

0.96 (0.34)

10.08 (1.46)

1.25 (0.11)

1.19 (1.0)

Group III

1.03 (0.33)

10.60 (1.02)

1.29 (0.11)

0.71 (0.96)

Group IV

1.02 (0.27)

11.11 (1.23)

1.26 (0.07)

0.54 (1.03)

Group V

0.97 (0.30)

11.16 (1.20)

1.22 (0.07)

0.11 (1.33)

a

S

a

presents the height deviation from the mean plane. Scx presents the average distance between the surface irregularities in spatial direction. Sdr

describes the surface developed ratio. 50 mm 50 mm Gaussian filter was used.

Y.-T. Sul et al. / Biomaterials 23 (2002) 491–501

496

either amorphous oxide or poorly crystallized anodic

oxides, consisting of ultrafine crystallites beyond the

sensitivity of the used equipment. Previous Raman

spectroscopy studies have reported non-crystalline oxide

[11]. TEM studies, however, showed the presence of

anatase [20]. This discrepancy may be due to differences

in the used electrolyte as previously described [19] or it

may be due to the history of the sample preparation.

Another explanation may be related to the higher

anodic oxide forming rates (nm/s) of the given anodic

films for Group II and III in comparison to Group IV

and V (Table 1). Leach and Pearson [32] have reported

that at higher growth, the appearance of crystalline

oxide was delayed to higher thicknesses.

X-ray diffraction patterns for group IV implants

showed a peak near 25.31, indicative of anatase

structure. In agreement with XRD results, Raman

spectra from Group IV exhibited a very strong peak

near 146 1/cm, and medium peaks near 397, 517 and

630 1/cm, which can be identified as the fingerprint

of anatase structure (Fig. 5). These data are in good

agreement with the reference spectra from anodic

oxide films [33,34]. The peaks at 146 1/cm and at

397 1/cm were accompanied by asymmetrical broad-

ening of the spectra towards higher frequencies while the

peak near 630 1/cm showed asymmetry towards lower

frequencies. These asymmetries are likely due to a

convolution of peaks due to anatase with those arising

from the rutile structure [34,35]. In addition, the peak

Table 4

Analysis of the crystal structures from TF-XRD and Raman spectroscopy

a

Sample

Structure

TF-XRD spectra (1)

Raman spectra (1/cm)

Present

Reference

Present

Reference

Group I

Amorphous

136m, 140m

Group II

Amorphous

201s, 230w

Group III

Amorphous

Group IV

Anatase

25.32

25.28

151s

145s, 440m, 515m, 640m (2)

397m

144s, 197w, 397m, 516m, 641m (4)

518m

144s, 197w, 399m, 516m, 639m (1)

630m

Rutile

143m, 236s, 447s, 612s (4)

143m, 447s, 612s, 826w (5)

Group V

Anatase

25.32s

25.28

48m

48.04

53.8 w

53.8

Rutile

54.4m

54.4

a

s=strong; m=medium; w=weak.

Group II, III and V were not measured by Raman spectroscopy.

Fig. 4. XRD spectra from all five Groups measured on plate types of

c.p. titanium samples.

Fig. 5. Raman spectra measured on the screw implant (Group I) and

anodized implant (Group IV).

Y.-T. Sul et al. / Biomaterials 23 (2002) 491–501

497

position and sharpness of Raman spectra measured on

top, flank and valley of the thread were similar. The

absence of rutile features in XRD spectra may be due to

the different sensitivities of Raman spectroscopy com-

pared to XRD, but may also be due to the difference

between sample types used for XRD and Raman

analysis, respectively, e.g. Ti plate and screw shaped

implants.

For Group V, X-ray diffraction patterns showed a

strong peak near 25.31 and a medium peak near 481,

indicating an anatase structure. In addition, there was

a broadening near 54.51, which suggested the presence

of rutile phase as well [36]. As a whole, the present

results indicate that the crystal structures of anodic

oxide films consist mainly of (small cyrstallites of)

anatase with some admixture of rutile. The rutile

admixture increases with increasing anodic forming

voltage up to 380 V.

3.5. Surface chemical composition and titanium oxide

stoichiometry

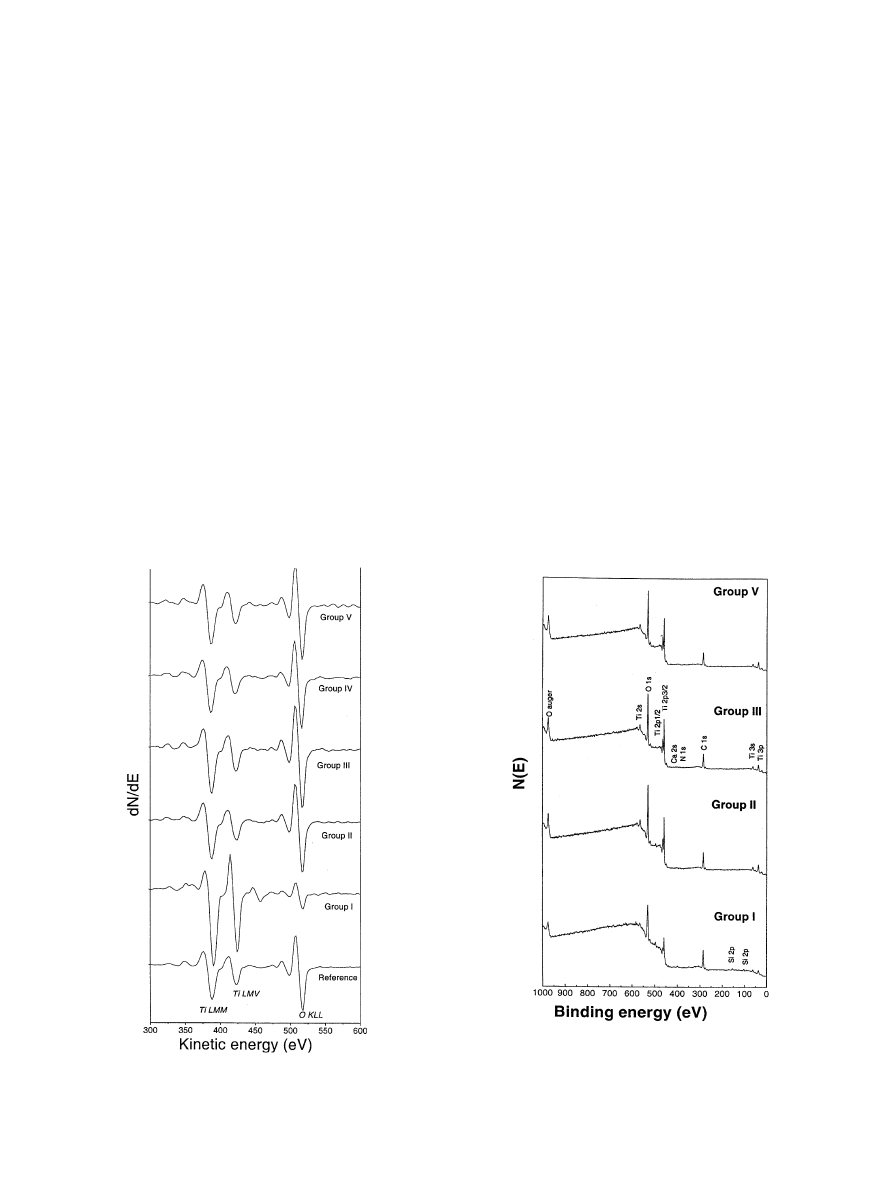

3.5.1. AES survey spectra

Fig. 6 shows typical AES survey spectra of turned

implants with native oxide (Group I), anodized implants

(Group II–V) and reference TiO

2

after sputter cleaning.

The survey spectra were dominated by strong signals of

Ti, O and C. Anodized implants (Group II–V) and

reference TiO

2

revealed similar shapes of the Auger

peaks. All the given oxide samples revealed Ti LMM

peaks at

E389 eV, Ti LMV at E422 eV and O KLL at

E517 eV. The relative intensity of the C signal and other

trace elements such as Na, Si, Ca, Al and Fe showed

some variation from group to group and from measur-

ing area to area. After argon sputter cleaning, corre-

sponding

approximately

to

1.4 nm

of

the

oxide

thickness, C, Na, Si and Ca almost disappeared.

This suggests that the trace elements are heterogeneous

and appear on the surfaces. In addition, disappearance

of the C signal implies the presence of carbon elements

on oxide surfaces only and the films of Group II–V did

not incorporate CH

3

COO– species into oxide film

during anodizing in CH

3

COOH, but rather from a

monomolecular layer of the contaminated surface

during sample transfer. It has been discussed that any

surface exposed to the ambient is always contaminated

by a chemically heterogeneous hydrocarbon film that

may be as thick as between 10% and 100% of a

monolayer [37].

Fig. 6. AES survey spectra of the surface oxides after sputter-cleaning

to a depth of about 1.4 nm from reference TiO

2

, turned screw implants,

Group I and anodized screw implants of Group II–V.

Fig. 7. Typical XPS spectra from as-received oxide surfaces at the

binding energy up to 1000 eV: turned screw implants, Group I and

anodized screw implants of Group II, Group III and Group V (Group

IV revealed a similar spectrum as the other anodized samples, thus not

shown here).

Y.-T. Sul et al. / Biomaterials 23 (2002) 491–501

498

3.5.2. XPS survey spectra

Fig. 7 shows a typical XPS survey spectra from as-

received oxide surface on turned and anodized screw

implants. The detected elements consisted primarily of

Ti, O and C. Traces of Ca, Si, Na and N were also

observed. The detected elements in anodized screw

implants (Group II–V) were nearly the same as those in

turned screw implant (Group I). Surface elements

detected by XPS spectra were generally similar to those

detected by AES, considering that XPS is relatively

more sensitive to elements with a higher atomic number

while AES is relatively more sensitive to elements with a

lower atomic number. Traces of Cr and Ni were detected

at only two implants sterilized using an autoclave

together with surgical instruments, but not for the

others sterilized in another autoclave without surgical

instruments.

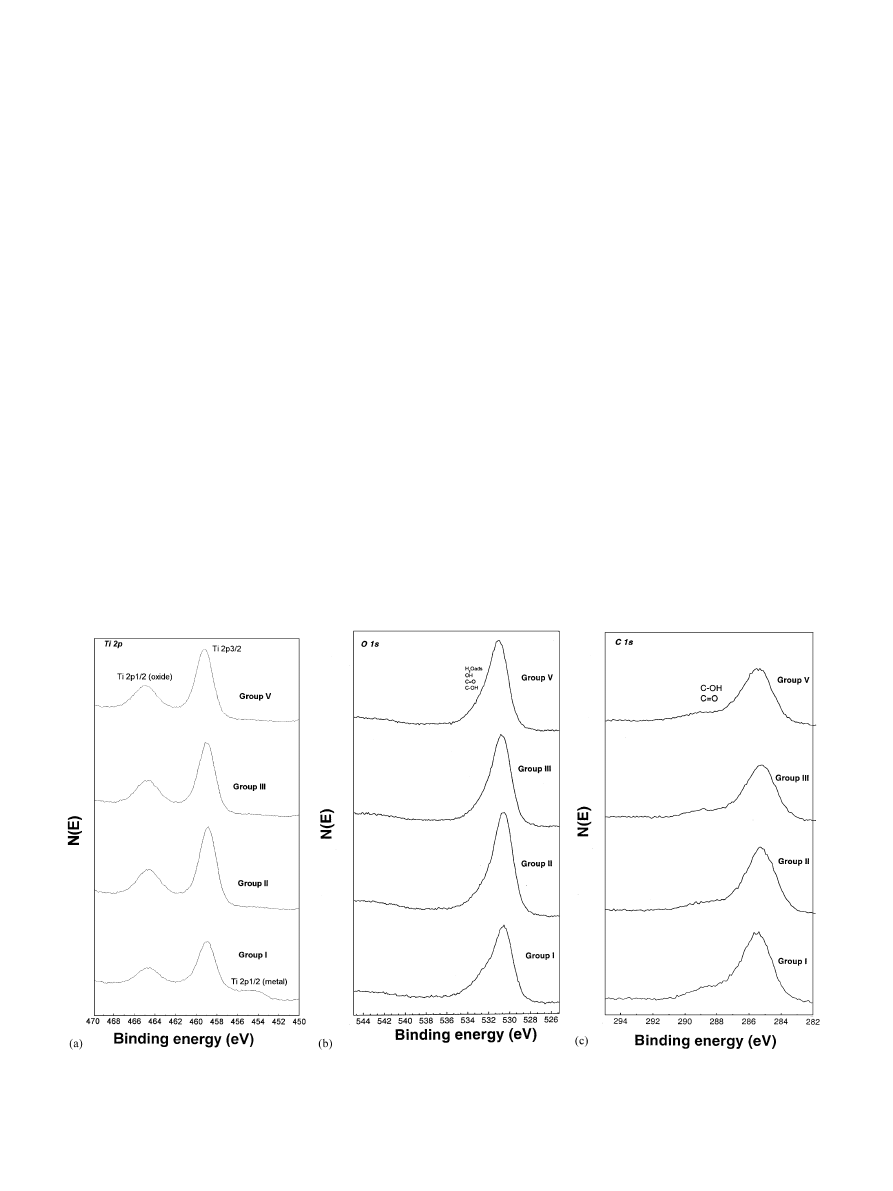

3.5.3. XPS line shapes of high resolution spectra

Fig. 8a–c shows typical XPS high resolution spectra

of Ti 2p, O 1s, and C 1s energy region from turned and

anodized implants. None of the Groups showed an

essential difference in terms of titanium oxide stoichio-

metry. Spectra of Ti 2p energy region consisted

dominantly of a doublet peak of at

E459 eV and

E464.8 eV (Fig. 8a). These two major peaks in each

sample were attributed to the tetravalent titanium form,

i.e., Ti

4+

2p3/2 and Ti

4+

2p1/2, respectively. Generally,

the present peak positions and line shapes are in good

agreement with those observed for TiO

2

reference

spectra [38]. Turned implants (Group I) showed a broad

shoulder of the spectrum at

E453.5 and E455.1 eV,

corresponding to Ti12p peak and Ti

2+

2p peak, respec-

tively. However, this broadening was not detected in all

the anodized implants (Group II–V). This may be due to

the relatively thin oxide thickness of 17 nm in Group I in

comparison to 200–1000 nm in Group II–V. In addition,

minor contributions between Ti

4+

2p3/2 peak and

Ti12p3/2 peak for turned implants may suggest the

presence of admixtures of other (hydro-) oxides.

Previous studies have reported non-stoichiometries of

titanium dioxide such as TiO and Ti

2

O

3

[39,40] and the

presence of carbide (TiC

x

) or nitride (TiN

x

) during

machining [7]. A three-layer model [41], i.e. an

intermediate suboxide TiO

2

@x

layer between a TiO

layer contacting with the titanium substrate and the

TiO

2

being in the outermost layer of the titanium oxide

has been proposed which is in rough agreement with our

results.

The typical high resolution XPS spectrum of the O 1s

peak shows a main peak at

E530.4 eV and asymmetrical

broadening in the range of 530.4–535.7 eV (Fig. 8b). The

O 1s peak at

E530.4 eV for both turned and anodized

implants is most certainly ascribed to oxygen in TiO

2

.

Fig. 8. Typical XPS high resolution spectra from as-received oxide surfaces of turned screw implants, Group I and anodized screw implants of

Group II, Group III and Group V (Group IV revealed similar spectra as the other anodized samples, thus not shown here) at: a=the Ti 2p region;

b

=the O 1s region; c=the C 1s region.

Y.-T. Sul et al. / Biomaterials 23 (2002) 491–501

499

However, asymmetrical broadening of the O 1s spectra

may be deconvoluted into a peak at

E533 eV for the

contaminated O

2

@

organic molecules such as C=O, O–

C=O, etc. [7,42] and a peak at

E532.4 eV related to OH

(for example from chemisorbed H

2

O or Ti–OH) [43–45].

Another explanation for the oxygen asymmetry in

anodized screw implants may be due to the appearance

of the patches of non-stoichiometric Ti oxides. It has

been reported that Ti–OH formation during anodic

oxidation [46] and defect concentration profile were

markedly dependent on the growth rate of the anodic

oxide film. Oxygen overstoichiometry in the presence of

hydrogen was also observed in the outer part of the

anodic oxide layer, using Rutherford back scattering

[47].

Fig. 8c shows high resolution spectra of the C 1s

region from turned implants and anodized implants.

The main peak of all Groups was dominated at 285 eV.

There was also an asymmetrical broadening of the

major peak toward the higher binding energy for all

group implants. This indicates that the presence of

various carbon species is essentially not a constituent of

the surface oxide layer but rather attributable to surface

contamination, by absorbed organic carbon-containing

molecules during sample handling.

4. Summary and conclusions

The thickness of the anodic oxide films prepared on

turned screw implants in CH

3

COOH at galvanostatic

mode was estimated to be 200 nm (

753) at 100 V,

600 nm (

7127) at 200 V, 800 nm (7112) at 280 V, and

1000 nm (

7200) at 380 V. With such an increase of the

oxide thickness, the microstructural properties and

crystallinity of the titanium oxide varied substantially

with the oxide thickness. In oxides thicker than 600 nm,

porous microstructures appeared due to voltage surge

and micro arcing (breakdown phenomenon). Quantita-

tive morphometric analysis of the micropore structures

for the anodized screw implants (Group III–IV) was

performed. The pore sizes were

p8 mm in diameter and

were about 1.27–2.1 mm

2

by opening area. The porosity

(a total area of opening pores/an entire scanning

area

F3 mm 26 mm 20 mm) ranged between 12.7%

and 24.4%. The crystal structures of the titanium oxide

revealed different oxide structures at different thick-

nesses: thermal oxide was amorphous (the films in

Group I and II may be too thin to be characterized by

XRD measurement) while anodic oxidation produced

mainly the anatase phase. Increasing oxide thickness

(voltage) resulted in the increase % of admixture of the

rutile into a main anatase phase. The chemical

compositions were essentially similar for all studied

implant Groups, consisting mainly of TiO

2

. The

contamination level of the surface elements was strongly

dependent on the handling procedures of the samples. In

conclusion, the present results describe native/anodic

oxide characteristics of titanium implants that may be

analyzed in future studies on how surface oxide

characteristics influence biological reactions.

Acknowledgements

This study was supported by grants from the Hjalmar

Svensson

Research

Foundation

and

the

Swedish

Medical Research Council.

References

[1] Br

(aanemark PI, Hansson BO, Adell R, Breine U, Lindstr.oom J,

Hall

!een O, .O

Ohman A. Osseointegrated implants in the treatment

of the edendulous jaw. Experience from a 10-year period. Scan

J Plast Reconstr Surg 1977;Suppl 16(1):7–127.

[2] Wyatt CCL, ZarbGA. Treatment outcomes of patients with

implant-supported fixed prostheses. Int J Oral Maxillofac

Implants 1998;13:204–11.

[3] Lekholm U, Gunne J, Henry P, Higuchi K, Lind

!een U, Bergstr.oom

C, Steenberghe DV. Survival of the Br

(aanemark implant in

partially edentulous jaws: a 10-year prospective multicenter study.

Int J Oral Maxillofac Implants 1999;14:639–45.

[4] Ivanoff CJ, Gr

.oodahl K, Bergstr.oom C, Lekholm U, Br(aanemark PI.

Influence

of

bicortical

or

monocortical

anchorage

on

maxillary implant stability: a 15-year retrospective study of

Br

(aanemark system implants. Int J Oral Maxillofac Implants

2000;15:103–10.

[5] Albrektsson T, Johansson CB. Experimental and clinical studies

of different ways to improve the outcome of implants placed in

bone of deficient quality and quality. J Parodontol a

D’Implantol Orale 2000;19:271–88.

[6] Albrektsson T, Br

(aanemark PI, Hansson HA, Kasemo B, Larsson

K, Lundstr

.oom I, McQueen D, Skalak R. The interface zone of

inorganic implants in vivo: titanium implants in bone. Ann

Biomed Eng 1983;11:1–27.

[7] Lausmaa J, Kasemo B. Surface spectroscopic characterization

of titanium implant materials. Appl Surf Sci 1990;44:133–46.

[8] Binon PP, Weir DJ, Marshall SJ. Surface analysis of an original

Br

(aanemark implant and three related clones. Int J Oral Maxillofac

Implants 1992;7:168–74.

[9] Olefjord I, Hansson S. Surface analysis of four dental implant

system. Int J Oral Maxillofac Implants 1993;8:32–40.

[10] Machnee CH, Wagner WC, Jaarda MJ, Lang BR. Identification

of oxide layers of commercially pure titanium in response to

cleaning procedures. Int J Oral Maxillofac Implants 1993;

8:529–33.

[11] W

.aalivaara B, Aronsson BO, Rodahl M, Lausmaa J, Tengvall P.

Titanium with different oxides: in vitro studies of protein

adsorption and contact activation. Biomaterials 1994;9:827–34.

[12] Wennerberg A, Albrektsson T, Andersson B. Design and surface

characteristics of 13 commercially available oral implant systems.

Int J Oral Maxillofac Implants 1993;8:622–33.

[13] Zitter H, Plenk HJ. The electrochemical behaviour of metallic

implant materials as indicator of their biocompatibility. J Biomed

Mater Res 1987;21:881–96.

[14] Jackson JD, Boyd WK. Stress corrosion cracking in titanium and

alloys. In: Jaffee RI, Promisel NE, editors. The science,

technology and application of titanium. Proceeding of an

Y.-T. Sul et al. / Biomaterials 23 (2002) 491–501

500

International

Conference.

Oxford:

Pergamon

Press,

1968.

p. 267–81.

[15] William DF. Corrosion of implant materials. Ann Rev Mater Sci

1976;6:237–65.

[16] Solar RJ, Pollack SR, Korostoff E. In vitro corrosion testing of

titanium surgical implant alloys: an approach to understanding

titanium release from implants. J Biomed Mater Res 1979;

13:217–50.

[17] Tengvall P, Lundstr

.oom I. Physico-chemical considerations of

titanium as a biomaterial. Clin Mater 1992;9:115–34.

[18] Blackwood DJ, Petter LM. The influence of growth rate on the

properties of anodic oxide films on titanium. Electrochim Acta

1989;34:1505–11.

[19] Sul YT, Johansson CB, Jeong Y, Albrektsson T. The electro-

chemical oxide growth behaviour on titanium in acid and alkaline

electrolytes. Medical Engineering and Physics 2001, accepted for

publication.

[20] Mattsson L, Rolander U. Structure and morphology of anodic

oxide films on titanium. G

.ooteborg Institute of Physics Report

GIPR-264, Chalmers University of Technology, G

.ooteborg,

Sweden, 1985.

[21] Tabrizi R. Surface treatments of titanium and its alloy. PhD

Thesis, University of Manchester, Institute of Science and

Technology, Corrosion and Protection Centre, UK, 1989.

[22] Lausmaa J. Surface oxides on titanium: preparation, character-

ization and biomaterial applications. PhD Thesis, Chalmers

University of Technology, G

.ooteborg, Sweden, 1991.

[23] Jeong Y. The structural chemistry of anodic alumina. PhD Thesis,

The University of Manchester Institute of Science and Technol-

ogy, Corrosion and Protection Centre, UK, 1993.

[24] Ishizawa H, Ogino M. Formation and characterization of anodic

titanium oxide films. J Biomed Mater Res 1995;29:65–72.

[25] Ishizawa H, Ogino M. Characterization of thin hydroxyapatite

layers formed on anodic titanium-oxide films containing C and

P by hydrothermal treatment. J Biomed Mater Res 1995;29:

1071–9.

[26] Ishizawa H, Ogino M. Thin hydroxyapatite layers formed

on porous titanium using electrochemical and hydrothermal

reaction. J Mater Sci 1996;31:6279–84.

[27] Schreckenbach J, Schlottig F, Textor M, Spencer ND, Marx G.

Characterization of anodic spark-converted titanium surfaces for

biomedical applications. J Mater Sci Med 1999;10:453–7.

[28] Sul YT, Johansson CB, Jeong Y, Wennerberg A, Albrektsson T.

Resonance frequency- and removal torque analysis of implants

with turned and anodized surface oxides. Clin Oral Impl Res

2001, accepted for publication.

[29] Sul YT, Johansson CB, R

.ooser K, Albrektsson T. Qualitative and

quantitative observations of bone tissue reactions to anodised

implants. A histologic, enzyme histochemical and histomorpho-

metric analysis. Biomaterials, submitted.

[30] Mathieu HJ, Mathieu JB, McClure DE, Landolt D. Beam effects

in Auger electron spectroscopy analysis of titanium oxide films.

J Vac Sci Technol 1977;14:1023–8.

[31] Wennerberg A. On surface roughness and implant incorporation.

PhD Thesis, University of G

.ooteborg, Sweden, 1966.

[32] Leach JSL, Pearson BR. Crystallization in anodic oxide films.

Corros Sci 1988;28:43–56.

[33] Ohtuka T, Guo J, Sato N. Raman spectra of the anodic oxide film

on titanium in acidic sulfate and neutral phosphate solutions.

J Electrochem Soc 1986;133:2473–6.

[34] Arsov LD, Kormann C, Plieth W. Electrochemical synthesis and

in situ Raman spectroscopy of thin films of titanium oxide.

J Raman Spectrosc 1991;22:573–5.

[35] Felske A, Plieth WJ. Raman spectroscopy of titanium dioxide

layers. Electrochim Acta 1988;34:75–7.

[36] JCPDS

FInternational Centre for Diffraction Data, 1994.

[37] Kasemo B, Lausmaa J. The biomaterial–tissue interface and its

analogues in surface science and technology. In: David JE, editor.

The bone–biomaterials interface. Toronto: University of Toronto

Press, 1991. p. 19–29.

[38] Chastain J, King RC. Handbook of X-ray photoelectron

spectroscopy. Eden Prairie, MN: Perkin-Elmer, 1992.

[39] Lewis G. X-ray photoelectron study of surface layers on

orthophedic alloy. J Vac Sci Technol A 1993;11:325–35.

[40] Pouilleau P, Devillier D, Garrido F, Durand-Vidal S, Mah

!ee E.

Structure and composition of passive titanium oxide films. Mater

Sci Eng 1997;B47:235–43.

[41] Blackwood DJ, Greef R, Peter LM. An ellipsometric study of the

growth and open-circuit dissolution of the anodic oxide film on

titanium. Electrochim Acta 1989;34:875–80.

[42] Briggs D. Applications of XPS in polymer technology. In: Briggs

D, Seah MP, editors. Practical surface analysis, vol. 1: auger and

X-ray photoelectron spectroscopy, 2nd ed. New York: Wiley,

1996. p. 437–83.

[43] Gopel W, Anderson JA, Frankel D, Jaehnig M, Phillips K,

Schafer JA, Rocker G. Surface defects of TiO

2

(1 1 0): a combined

XPS, XAES and ELS study. Surf Sci 1984;139:333–46.

[44] Shirkhanzadeh M. XRD and XPS characterization of super-

plastic TiO

2

coatings prepared on Ti6Al4 V surgical alloy by

an electrochemical method. J Mater Sci: Mater Med 1995;6:

206–10.

[45] Shibata T, Zhu YC. The effect of film formation conditions on the

structure and composition of anodic oxide films on titanium.

Corros Sci 1995;37:253–70.

[46] Ohtsuka T, Nomura N. The dependence of the optical property of

Ti anodic oxide film on its growth rate by ellipsometry. Corros Sci

1997;39:1253–63.

[47] Serruys Y, Sakout T, Gorse D. Anodic oxidation of titanium in

1M H

2

SO

4

, studied by Rutherford backscattering. Surf Sci

1993;282:279–87.

Y.-T. Sul et al. / Biomaterials 23 (2002) 491–501

501

Wyszukiwarka

Podobne podstrony:

In silico characterization of the family of PARP like

Fricke Visual assessments of the surface diusion properties of concert halls

Ultrastructural characterization of the implant

Characterization of titanium surfaces with calcium and phosp

analytical characterisation of the routes by thermolytic decarboxylation from tryptophan to tryptami

Crime and Punishment Analysis of the Character Raskol

Lord of the Flies Character Changes in the Story

65 935 946 Laser Surface Treatment of The High Nitrogen Steel X30CrMoN15 1

Empire of the Petal Throne Generating Pe Choi Characters in Gardasiyal

Death of a Salesman Analysis of the Character Willy

16 Changes in sea surface temperature of the South Baltic Sea (1854 2005)

Best Available Techniques for the Surface Treatment of metals and plastics

Crime and Punishment Analysis of the Character Raskolnikov

Detection and Molecular Characterization of 9000 Year Old Mycobacterium tuberculosis from a Neolithi

The characteristics of japanese tendai

Bondeson; Aristotle on Responsibility for Ones Character and the Possibility of Character Change

How to Have the Character of a Champion

0198752091 Oxford University Press USA The Character of Mind An Introduction to the Philosophy of Mi

Corrosion behavior and surface characterization of titanium

więcej podobnych podstron