Photon recycling across a ultraviolet-blocking layer by luminescence

in polymer solar cells

Sebastian Engmann, Marie Machalett, Vida Turkovic, Roland R€

osch, Edda R€

adlein,

Gerhard Gobsch, and Harald Hoppe

Institute of Physics, Ilmenau University of Technology, Weimarer Str. 32, D-98693 Ilmenau, Germany

(Received 23 April 2012; accepted 11 July 2012; published online 15 August 2012)

UV-blocking layers can increase the long term stability of organic solar cell devices; however, they

limit the amount of light that can be utilized for energy conversion. We present photon recycling

and down-conversion via a luminescent layer across a UV-blocking TiO

2

layer. Our results show

that the use of an additional UV-blocking layer does not necessarily reduce the overall efficiency

of organic solar cells, since the loss in photocurrent due to the UV-absorption loss can be partially

compensated using high energy photon down-conversion via luminescence layers.

V

C

2012

American Institute of Physics. [

http://dx.doi.org/10.1063/1.4745016

I. INTRODUCTION

Organic photovoltaic currently receives great attention

from a large community, spanning from natural sciences to

engineering. Impressive progress in the development of bet-

ter materials and advanced cell architectures over the last

few years resulted in continuous efficiency increase to over

9%.

This efficiency boost promotes organic photovoltaics

to become more competitive with other thin film technolo-

gies and increases market opportunities. First products are

launched into the market,

although the durability still needs

to be improved further for long term applications.

One of

the major driving factors for degradation is the interaction of

UV-light with the organic semiconductors. In combination

with the ingress of oxygen and water into the solar cell

devices, photoinduced oxidation severely limits the lifetime

in organic photovoltaics (OPV).

One way to reduce deg-

radation is to prevent water and oxygen diffusion into the

device by encapsulation. In addition, getter materials can be

introduced to further reduce the influence of radicals within

the encapsulated device.

Finally, a good amount of photo-

chemistry can be effectively hindered by introducing UV-

blocking layers within the sealing of the device. However,

cutting out the UV-part of the electromagnetic spectrum also

leads to a loss in energy conversion due to the missing pho-

tocurrent generation. To avoid the problem of decreasing

device performance by stabilization with UV-blocking

layers, down-conversion of a part of the blocked UV-light

enables recycling of the photons otherwise dismissed.

For an efficient recycling of the down-converted photons

on the one hand, to achieve an efficient down-converted pho-

tons recycling, the absorption region of the conversion layer

should be well matched with the range of the blocked UV light.

On the other hand, a proper overlap between the emission of

the conversion layer and the absorption of the photoactive layer

should be achieved as well. We have verified this beneficial

photon recycling process by stacking a luminescent layer on

top of a UV-blocking layer at the outer side of a thin film poly-

mer solar cell. An increase of the external quantum efficiency

in the UV region <380 nm is demonstrated.

II. EXPERIMENTAL

We employed a combination of titanium and silicon ox-

ide to form a UV-blocking layer on top of the transparent

side of the solar cell. This UV-blocking layer was built up in

three steps. First, a TiO

2

sol-gel based on titanethoxid and

acetylacetone was deposited on top of the glass, in order to

promote better adhesion. The second layer was a thick po-

rous TiO

2

layer, formed from a colloidal solution purchased

by Evonik Degussa (Aerodisp

V

R

W 740X). To stabilize the

TiO

2

layer, the film was topped by a SiOx sol-gel. In order

to form a rigid network, the layer stack was thermally con-

verted at 250

C.

Organic solar cells were prepared using poly(3-hexylth-

iophene) (P3HT) and [6,6]-phenyl-C

61

-butyric acid methyl

ester (PCBM) bulk-hetero junction devices. An approxi-

mately 100 nm thick polymer/fullerene active layer was spin

coated from a 2 wt. % chlorobenzene solution on top of a

PEDOT:PSS (Clevios PH) covered ITO substrates. The alu-

minium cathode was evaporated in high vacuum at 2

10

6

mbar base pressure. All solar cell devices were annealed at

elevated temperature for 5 min prior to the glass encapsula-

tion. Absorption and photoluminescence measurements were

carried out in the spectral range between 300 and 800 nm.

Solar cells were characterized using a class A solar simulator

with an illumination intensity of 100 mW/cm

2

. Quantum ef-

ficiency (IPCE) measurements were performed in the range

between 300 and 800 nm. The material used as the lumines-

cent layer is a UV-curing epoxy glue, containing an anthra-

cene derivative used as the photo initiator enabling UV

curing of the epoxy matrix.

III. RESULTS AND DISCUSSION

Solar cells with an active area of 0.5 cm

2

were prepared

in conventional geometry

on ITO coated glass. On a part of

the samples, a TiO

2

-SiO

X

UV-blocking layer was coated on

the outer side of the glass substrates. Figure

shows the

transmission spectra obtained prior to the solar cell prepara-

tion. The transmission of high energy photons through the

0021-8979/2012/112(3)/034517/4/$30.00

V

C

2012 American Institute of Physics

112, 034517-1

JOURNAL OF APPLIED PHYSICS 112, 034517 (2012)

substrate with UV-blocking layer is drastically reduced com-

pared to the reference substrate. Since UV-radiation was

identified as a source of degradation of organic solar cells,

the introduction of an UV-blocking layer should result in an

increased life-time of the photovoltaic device, which was

suggested by Jïrgensen

and recently shown by Ryu

et al.

The drawback of the UV-filter is that the current output of

the solar cell, and thus the efficiency, gets reduced, as the

additional absorption of the UV-blocking layer limits charge

generation in the photoactive layer. However, a better spec-

trally adapted UV-blocking layer will reduce these losses.

Here, we discuss how the loss of UV-photons for current

generation can be in part recovered by addition of a lumines-

cent layer as the outermost layer towards the light source. It

is to mention that since this luminescence layer absorbs a

part of the UV light itself, a sufficiently thick film could

replace the UV-blocking layer. However, in this study we

use an additional UV-blocking layer to ensure zero transmis-

sion of the UV light into the solar cell, in order to investigate

the effect of the fluorescence from the luminescence layer on

the photocurrent. By doing so, we do not have to distinguish

between the effect of fluorescence and residual light trans-

mission through the luminescence layer.

While the introduction of such a luminescence layer by

physical vapor deposition was recently reported by Wang

et al.,

our goal was to implement a roll-to-roll compatible

process. On the other hand, the photo down-conversion layer

used in the mentioned reference was N,N

0

-bis(3-methyl-

phenyl)-N,N

0

-bis(phenyl)-benzidine

(TPD)

exhibiting

a

strong luminescence in the wavelength range between

375 nm and 450 nm far below the absorption maximum of

P3HT/PCBM solar cell devices. The reported efficiency

enhancement was mainly due to the deposition of an anti-

reflection coating on top of the solar cell devices and the pos-

itive effect of the luminescence layer could in our opinion

not be proven by corresponding IPCE measurements.

Two sets of devices were prepared: both of them contained

the UV-blocking layer and additionally one of them was coated

with an approximately 50 lm thick luminescence layer on top

of the blocking layer facing towards the illumination source.

The luminescence layer was deposited by doctor blading and

cured by UV-irradiation, both of the processes easily done in a

roll-to-roll process. After production, the solar cells were meas-

ured under AM1.5 solar irradiation, as described in the experi-

mental section. Because of the comparably large thickness, no

interference effects have to be considered when evaluating the

transmission through this layer.

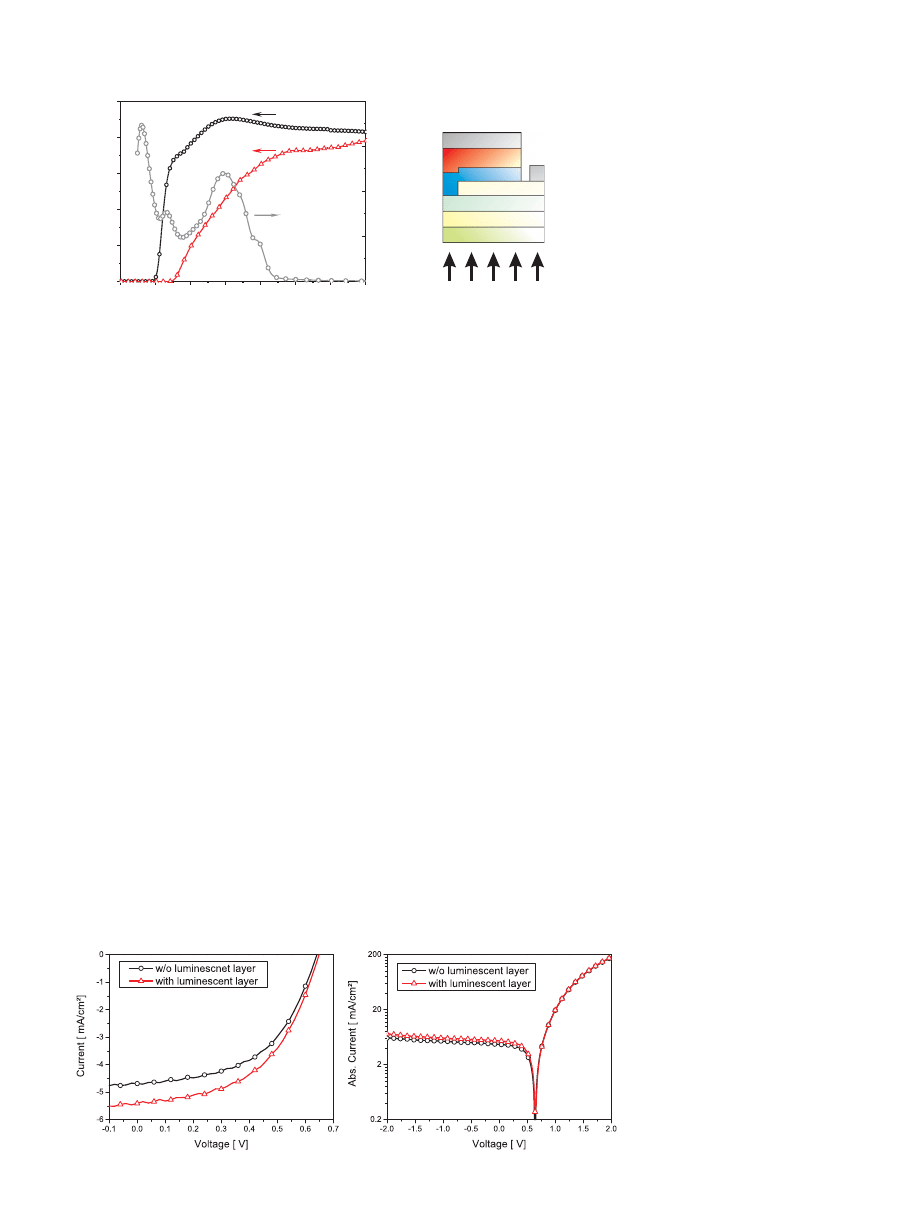

Figure

shows the IV-characteristics of the best devices

with and without luminescence layer. The comparably small

short circuit current

J

sc

is due to the strong absorbance of the

TiO

2

-SiO

X

layer in the UV-vis region, compare with Figure

Table

shows the device parameters of the best performing so-

lar cell. While the fill factor

FF, as well as the open circuit volt-

age

V

oc

, are very comparable in both devices, the generated

photo current is about 15% higher in the device with the lumi-

nescence layer compared to the device without.

The relative efficiency increase of the device containing

the luminescent layer is caused by two effects. First, since the

refractive index of the TiOx layer is comparably high and the

surface is rough due to the use of colloidal nano-particles, the

luminescence layer, based on a low refractive index material,

acts as an anti-reflection coating. This effect is especially bene-

ficial in the visible wavelength region near the emission maxi-

mum of the sun, and therefore this effect results in the biggest

ITO

Glass

Clevios PH

P3HT/[60]PCBM

Aluminium

TiOx-SiOx

Luminescent layer

b)

200

300

400

500

600

700

800

900

0

20

40

60

80

100

0.0

5.0x10

4

1.0x10

5

1.5x10

5

2.0x10

5

Transmission

[%

]

Wavelength [ nm]

ITO/glass

ITO/glass/TiOx

P3HT : PCBM

1wt.% : 1wt.%

Absorption

coeff.

P3HT:PCBM

[1/cm]

a)

FIG. 1. Transmission spectra of ITO coated glass with

and without UV-blocking layer. Additionally, the

absorption

coefficient

of

P3HT:PCBM

is

shown

(a). The layer stack including the cathode layers to com-

plete a solar cell device is shown in (b).

FIG. 2. Device characteristics of the de-

vice with and without luminescent layer.

The device structure is (luminescence

layer)/UV-blocking

layer/glass/ITO/

PEDOT:PSS/P3HT:PCBM/Al.

034517-2

Engmann et al.

J. Appl. Phys. 112, 034517 (2012)

efficiency increase between the two devices. Nevertheless, the

second effect is due to the increase in photocurrent based on

the re-emission of photons by luminescence into the absorption

maximum of the device. UV light which would be lost either

by absorption of the UV-blocking layer or simply by the glass

substrate is absorbed by the anthracene derivative inside the

nearly transparent epoxy matrix and emitted near the absorption

maximum of the photoactive layer.

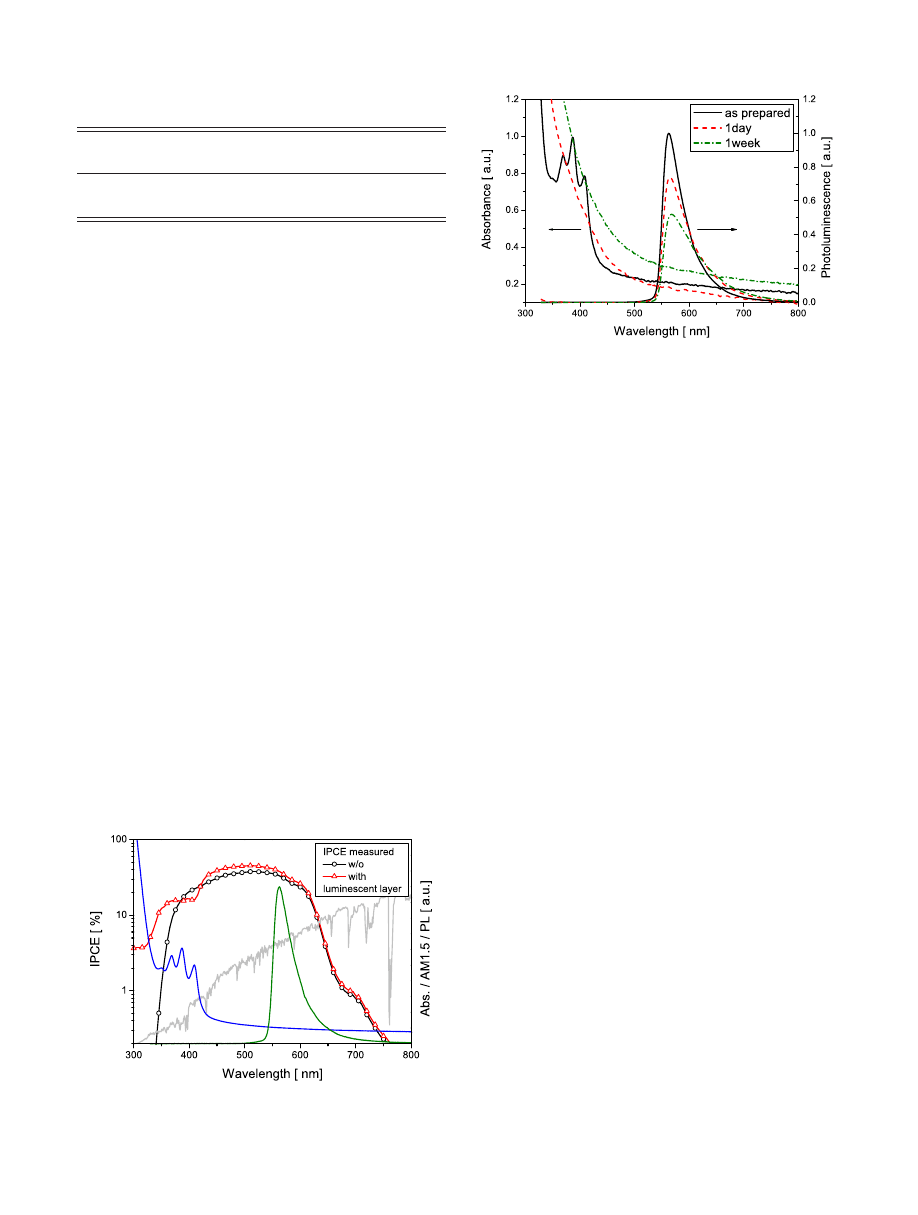

In order to quantify the increase in photocurrent over the

relevant spectral region, we conducted external quantum effi-

ciency (incident photon to charge carrier efficiency/IPCE)

measurements showing the spectral response of the device.

Figure

shows the photocurrent response of a device with

and without luminescence layer, as well as the absorbance and

the photoluminescence of this layer. With the luminescent

layer, the current generation is extended far into the UV

region. Due to the large film thickness and strong lumines-

cence near the overall IPCE maximum, a considerable

increase in the current generation can be observed. Due to the

non-ideal spectral overlap between the luminescent and the

UV-blocking layer a part of the absorption is still lost around

400 nm as compared to the control device. However, this can

be overcome in the future by maximizing the corresponding

spectral overlap.

Another topic which has to be addressed in the future is

the long-term stability of the organic luminescence layer.

Due to the organic nature of this layer, photo-induced degra-

dation may occur. In order to investigate the stability under

illumination, transmission and photoluminescence spectra of

the luminescence layer deposited on glass were measured.

Figure

shows the initial photoluminescence spectra to-

gether with those after exposure to light from a metal halide

lamp (intensity 1000 W/m

2

) under ambient conditions for

1 day and for 1 week. Due to photoreactions, the luminescence

layer slowly degrades which manifests in polymer yellowing.

Furthermore, the peak photoluminescence signal gets reduced

to about 50% of its initial value within 1 week of continuous

illumination. However, we are convinced that degradation

effects can be overcome in the future. First, the polymer ma-

trix for the fluorophore, in this study an epoxy material, could

be exchanged with a carrier matrix exhibiting lower yellowing

during UV illumination. Second, sol-gel or conventionally

processed oxygen and water barrier layers can be applied, in

order to prevent photo-oxidation of the fluorophore. These

barrier layers will become necessary in flexible organic elec-

tronics, in order to prevent water and oxygen permeation

through the substrate, which may cause oxidation or photo-

oxidative processes. Once these ultra-barrier layers allow a

sufficient UV-light transmission, the concept of energy trans-

fer (and thus photon recycling) over a UV-barrier becomes a

viable option in the future OPV production.

IV. CONCLUSIONS

We have shown that the overall device performance of

polymer solar cells can be increased by photon recycling via

introduction of a luminescent layer on top of a UV-blocking

layer. Thus the absorption and the corresponding photocur-

rent loss due to a UV-blocking layer, can in part be compen-

sated by application of an anti-reflection and luminescent

layer, if the luminescence is efficiently matched to the

absorption of the photo active layer. Using this approach, we

demonstrate the current output of the solar device to be

increased by more than 10%. Luminescent layers based on a

fluorophore inside a transparent matrix, as described here,

can easily be produced by roll-to-roll techniques. In the

future, such fluorophore could be incorporated as additives

into luminescence substrates. Since photon recycling by

luminescence shows typically higher efficiencies than photon

down-conversion of one high energy photon into two lower

energy photons, this seems to be an appropriate way to

increase the overall device performance of flexible solar

cells.

TABLE I. Solar cell parameters derived from IV measurements under

AM1.5.

J

sc

(mA/cm

2

)

V

oc

(mV)

FF

(%)

Efficiency

(%)

Without luminescent layer

4.69

639

52.4

1.57

With luminescent layer

5.40

647

51.4

1.79

FIG. 3. IPCE of P3HT:PCBM solar cells with and without luminescence

layer for photon recycling. For comparison, the absorbance (blue) and pho-

toluminescence (green) of the luminescent layer on glass, as well as the

AM1.5 solar spectrum (grey), are shown in the same spectral region.

FIG. 4. Absorbance and photoluminescence spectra of the organic lumines-

cence layer deposited on glass. The luminescence layer was exposed to light

from a metal halide lamp (intensity 1000 W/m

2

) under ambient conditions.

034517-3

Engmann et al.

J. Appl. Phys. 112, 034517 (2012)

ACKNOWLEDGMENTS

Financial support of the author by the "Bundesministe-

rium f€

ur Bildung und Forschung," Germany within the proj-

ects “SonnTex” (BMBF 03X3518G) and “EOS” (BMBF

03X3516F) are gratefully acknowledged. We also thank the

“Center for Micro- and Nanotechnologies” (ZMN) for pro-

viding the facilities needed in sample preparation.

1

R. F. Service, “Outlook brightens for plastic solar cells,”

332,

293–293 (2011).

2

See

for Konarka Power Plastics.

3

M. Jïrgensen, K. Norrman, and F. C. Krebs, “Stability/degradation of

polymer solar cells,”

92, 686–714 (2008).

4

S. Chambon, A. Rivaton, J.-L. Gardette, and M. Firon, “Durability of

MDMO-PPV and MDMO-PPV: PCBM blends under illumination in the

absence of oxygen,”

92, 785–792 (2008).

5

Y.-M. Chang, W.-F. Su, and L. Wang, “Influence of photo-induced degra-

dation

on

the

optoelectronic

properties

of

regioregular

poly(3-

hexylthiophene),”

92, 761–765 (2008).

6

F. C. Krebs, J. E. Carl

e, N. Cruys-Bagger, M. Andersen, M. R. Lilliedal,

M. A. Hammond, and S. Hvidt, “Lifetimes of organic photovoltaics: Pho-

tochemistry,

atmosphere

effects

and

barrier

layers

in

ITO-

MEHPPV:PCBM-aluminium devices,”

, 86,

499–516 (2005).

7

T. Kuwabara, T. Nakayama, K. Uozumi, T. Yamaguchi, and K. Taka-

hashi, “Highly durable inverted-type organic solar cell using amor-

phous titanium oxide as electron collection electrode inserted between

ITO and organic layer,”

92, 1476–1482

(2008).

8

F. Wang, Z. J. Chen, L. X. Xiao, B. Qu, and Q. H. Gong, “Enhancement of

the power conversion efficiency by expanding the absorption spectrum

with fluorescence layers,”

19, A361–A368 (2011).

9

J. A. Renz, T. Keller, M. Schneider, S. Shokhovets, K. D. Jandt, G.

Gobsch, and H. Hoppe, “Multiparametric optimization of polymer solar

cells: A route to reproducible high efficiency,”

93, 508–513 (2009).

10

M. S. Ryu, H. J. Cha, and J. Jang, “Improvement of operation life-

time for conjugated polymer: Fullerene organic solar cells by intro-

ducing a UV absorbing film,”

94,

152–156 (2010).

034517-4

Engmann et al.

J. Appl. Phys. 112, 034517 (2012)

Journal of Applied Physics is copyrighted by the American Institute of Physics (AIP). Redistribution of journal

material is subject to the AIP online journal license and/or AIP copyright. For more information, see

http://ojps.aip.org/japo/japcr/jsp

Wyszukiwarka

Podobne podstrony:

D19240360 Obwieszczenie Ministra Skarbu z dnia 15 kwietnia 1924 r w przedmiocie rozpoczęcia czynnoś

15 Formowanie cienkich warstw metodą chemicznej?pozycji par CVD

przez 15 KWASY KARBOKSYLOWE2

Zmiany w używaniu substancji psychoaktywnych przez młodzież w wieku 11 15 lat w Polsce w latach 2002

15 W rok przez Biblię Pieśń nad pieśniamiid 16061

8x02 (93) Az do 15 pazdziernika, Książka pisana przez Asię (14 lat)

15, zamiawiane przez chomików

15. W rok przez Biblię, Pieśń nad pieśniami

Ciecz przepływająca przez przewody przylega do ścian przewodu tworząc nieruchomą warstwę

NERW UDOWY , NERW UDOWY - powstaje między powierzchowną a głęboką warstwą mięśnia lędźwiowego większ

15-06, W postępowaniu administracyjnym rozumianym jako ciąg czynności procesowych podejmowanych prze

15 - arkusz analizy formalnej (2) , Załącznik do protokołu z posiedzenia Komisji Egzaminacyjnej powo

15 Formowanie cienkich warstw metodą chemicznej?pozycji par CVD

przez 15 KWASY KARBOKSYLOWE2

2018 03 15 Brigitte Macron obrażona przez uczniów Kobieta

OMIAR NAPRĘŻEŃ WŁASNYCH METODĄ USUWANIA WARSTW PRZEZ DOCIERANIE PO OBRÓBCE EDM I KULOWANIU STRUMIENI

D19250704 Rozporządzenie Prezydenta Rzeczypospolitej z dnia 15 września 1925 r o sposobie odbywania

więcej podobnych podstron