LWT 38 (2005) 549–553

Drying of carrots in microwave and halogen lamp–microwave

combination ovens

Gulum Sumnu

, Elif Turabi, Mecit Oztop

Department of Food Engineering, Middle East Technical University, 06531 Ankara, Turkey

Received 16 September 2003; received in revised form 20 July 2004; accepted 22 July 2004

Abstract

Carrot slices were dried by using microwave, halogen lamp–microwave combination and hot-air drying. Microwave and halogen

lamp–microwave combination drying were applied after carrots were dried to 0.47 kg moisture/kg dry solid by hot-air drying.

Drying time, rehydration capacity and colour of the carrots dried by different methods were compared. The increase in microwave

oven power level decreased the drying time. Microwave drying at the highest power and halogen lamp–microwave combination

drying reduced the drying time to an extend of 98% in comparison to conventionalhot-air drying and a high-quality dried product

was obtained. Moreover, in the case of halogen lamp–microwave combination drying, moisture level was reduced to a level, which is

lower than the one achieved by other methods. Less colour change occurred when microwave and halogen lamp–microwave

combination drying were applied. Carrots dried in microwave and halogen lamp–microwave combination oven had lower L*, higher

a* and b* values and had higher rehydration capacity as compared to hot-air drying.

r

2004 Swiss Society of Food Science and Technology. Published by Elsevier Ltd. All rights reserved.

Keywords: Microwave; Halogen lamp; Drying; Carrot; Colour

1. Introduction

Carrot (Daucus carota L.) is one of the important

vegetables grown throughout the world containing high

amounts of sugar. Carrot is cooked, dried to be used in

instant soups or meals or consumed as raw. Carrots are

the highest carotene containing foods which makes dried

carrot slices an excellent candidate for developing an oil

free snack food if the nutritionalval

ue and a puffed

texture can be preserved (

).

Hot-air drying is commonly used to dry carrots. The

properties of dried vegetables are affected by chemical

and physicalchanges. Chemicalchanges mainly affect

sensory characteristics such as colour, taste and aroma

where as physicalchanges affect handl

ing properties

such as swelling capacity and cooking time (

). The disadvantages of hot-air drying is that it

takes a long time even at high temperatures which

results in degradation of the dried product quality

(

). Microwave drying offers an

alternative way to improve the quality of dried products.

Microwave drying has the advantages of selective

heating, energy efficiency, speed and requirement of less

floor space (

). The drawbacks of

microwave drying are uneven heating, damage of food

texture in case of very rapid mass transfer and high

start-up costs (

). Therefore, combined

convection-microwave drying is more common as

compared to sole microwave drying. The usual means

of applying microwaves to a drying process is at the end

of falling rate period. Enhanced moisture loss due to the

pressure driven flow is seen in microwave drying. In the

later stages of a conventional drying process internal

thermal penetration is slow thus slowing down the

drying process. Microwaves that are applied during later

ARTICLE IN PRESS

0023-6438/$30.00 r 2004 Swiss Society of Food Science and Technology. Published by Elsevier Ltd. All rights reserved.

doi:10.1016/j.lwt.2004.07.006

Corresponding author. Tel.: +90-312-2105628; fax: +90-312-

2101270.

E-mail address: gulum@metu.edu.tr (G. Sumnu).

stages of conventionaldrying penetrate easily and are

absorbed selectively in wet layers. Thus, much higher

penetration rates can be maintained toward the later

part of a drying process (

Microwave drying is used for drying of pasta and

post-baking of biscuits. Microwave drying of some

vegetables like onion and potato slices in combination

with hot air is carried out in industrialscale (

). There are various studies at the research

level about drying of vegetables (

Riva, Schiraldi, & Di Ceseare, 1991

). Microwave drying of mushrooms in

combination of hot air resulted in improved moisture

diffusivity, better rehydration properties and improved

flavour retention (

). Vacuum microwave

dried carrot slices were shown to have higher rehydra-

tion capacity, higher nutritive value, lighter colour

and softer texture than air dried carrots (

). Combined microwave hot-air drying resulted

in a reduction in the drying time of garlic cloves

to an extend of 80–90% in comparison to conventional

hot-air drying and the garlic cloves were lighter in

colour (

). In addition, the

retention of volatile components responsible for flavour

strength

was

more

in

microwave

hot-air

drying

than hot-air drying. When the effects of different

drying methods (tray, spouted bed, combined micro-

wave and spouted bed, refractance window drying on

asparagus quality was compared, microwave-spouted

bed drying resulted in highest retention of total

antioxidant activity (

Pretreatment methods were found to be effective in

quality of microwave dried vegetables. Pretreatment

with fructose corn syrup was shown to retard enzymatic

browning and reduce the tartness of microwave vacuum

dried cranberrires (

).

Halogen lamp–microwave combination drying com-

bines the time saving advantages of microwaves with

surface

moisture

removaladvantages

of

hal

ogen

lamp heating. Halogen lamp heating provides near

infrared radiation (wavelength 0.7–5 mm) with deeper

penetration depth than typicalinfrared sources that emit

in the mid-infrared. In halogen lamp heating inside oven

is heated and radiation is focused at the surface of the

food which can help to remove moisture from the

surface and to prevent sogginess of the dried product.

There is no information in scientific literature about

drying of fruits and vegetables by using this method.

Therefore, the objective of this study is to compare the

effects of microwave drying, halogen lamp–microwave

combination drying and hot-air drying on the drying

rate and on the quality of carrots. The effects of

different microwave powers on the quality of carrots

were also studied.

2. Materials and methods

2.1. Material

Fresh carrots with initialmoisture content of 90%

were obtained from a local market. Prior to drying,

samples were washed, peeled and sliced having a

thickness of 6 mm.

2.2. Drying

The hot-air drying experiments were performed in a

pilot plant tray dryer (Armfield Limited, D 27412,

England) Drying was performed at 60 1C with an air

velocity of 1.7

70.1 m/s untila moisture content of

0.12 kg moisture/kg dry solid was reached. Four

hundred grams of fresh carrots were used in each run.

Microwave drying experiments were performed in a

domestic microwave oven (Vestel, Turkey). Power levels

were determined by IMPI 2-L test (

). High

power level was calculated as 560 W, medium power as

397 W and low power as 286 W. Microwave drying was

performed after carrots were dried to a moisture content

of 0.47 kg moisture/kg dry solid (dry basis) by hot-air

drying. The reason for using such a combination was to

prevent cooking of carrots in microwave oven. Twenty

grams of samples were placed in the oven and in every

15 s, weight loss was recorded by a digital balance.

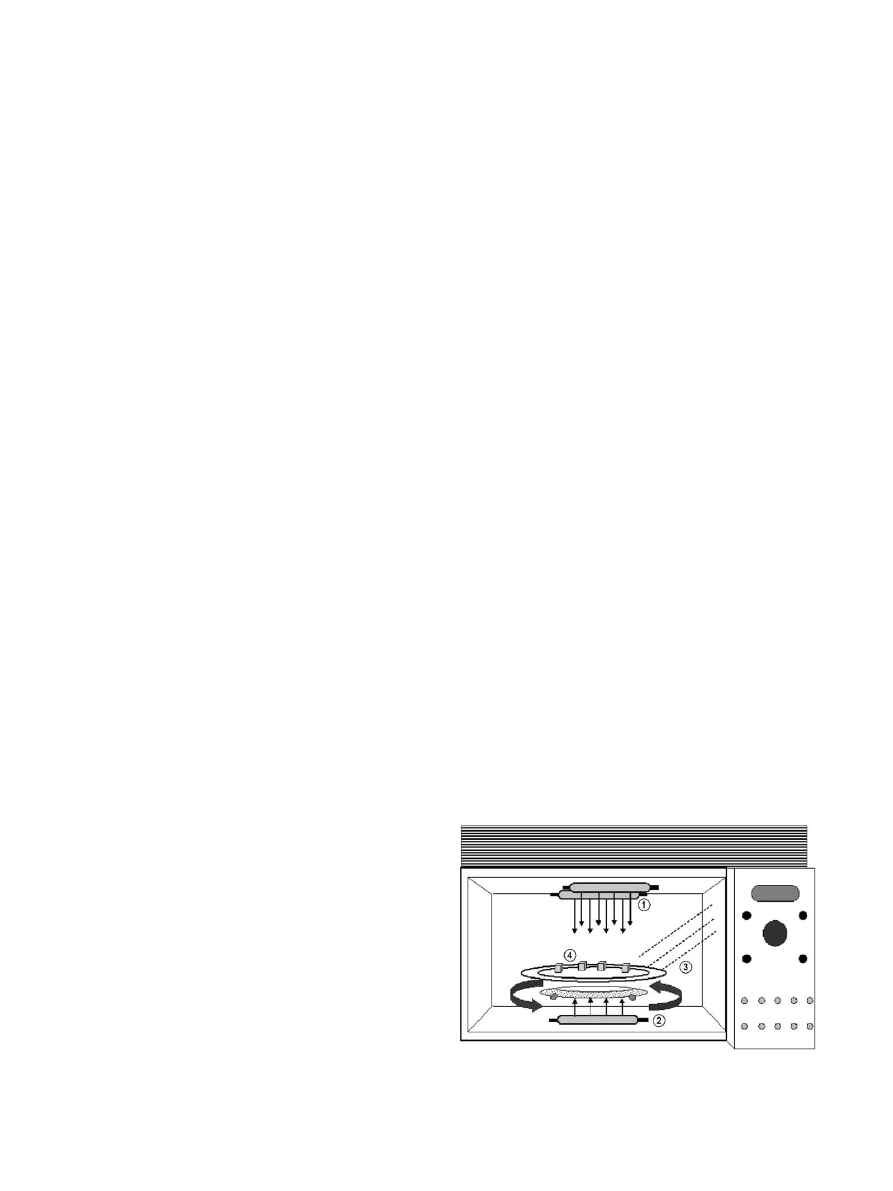

Halogen lamp–microwave combination oven (Advan-

tium ovent, General Electric Company, Louisville, KY,

USA) was used in halogen lamp–microwave combina-

tion drying (

). Halogen lamp at the top was

located 15 cm above the food surface while the halogen

lamp at the bottom was just under the rotary table.

Halogen lamps at the top and bottom were operated at

50% power and microwaves were operated at 50%

power. The power of the oven was determined as 706 W

by using IMPI 2-liter test (

). Halogen

ARTICLE IN PRESS

Fig. 1. Illustration of halogen lamp–microwave combination oven:

(1) upper halogen lamps, (2) lower halogen lamp, (3) microwaves,

(4) turntable.

G. Sumnu et al. / LWT 38 (2005) 549–553

550

lamp–microwave combination drying was also per-

formed after carrots were dried to a moisture content

of 0.47 kg moisture/kg dry solid (dry basis) by hot-air

drying.

2.3. Quality evaluation

Colour: Colour of the samples was measured using a

Minolta colour reader (CR-10, Japan). The colour

readings were expressed by ICI coordinates (L*a*b*)

system. L*, a* and b* indicates whiteness/darkness,

redness/greenness, blueness/yellowness values, respec-

tively. A standard white colour was used as a reference.

Eight replicate readings were carried out.

Rehydration ratio: Rehydration ratio was determined

by using the method of

. The rehydration

capacity of dried carrot slices was evaluated by

immersing 10 g of dried samples in water at 50 1C for

50 min. In every 10 min, sample was taken out, blotted

with paper towelto eliminate surface water and then

reweighed. The rehydration ratio described as percen-

tage water gain was calculated from sample weight

difference before and after rehydration using Eq. (1):

Rehydration ratio ¼

W

t

W

d

W

d

;

(1)

where W

t

is the weight of rehydrated sample (g) at any

time and W

d

is the weight of the dried sample.

2.4. Statistical analysis

Analysis of variance (ANOVA) was performed to

determine significant differences between different dry-

ing methods (p

p0.05). Variable means were compared

by Duncan’s Multiple Range test. Standard errors were

calculated and added to the bar graphs. Drying

experiments were repeated twice.

3. Results and discussion

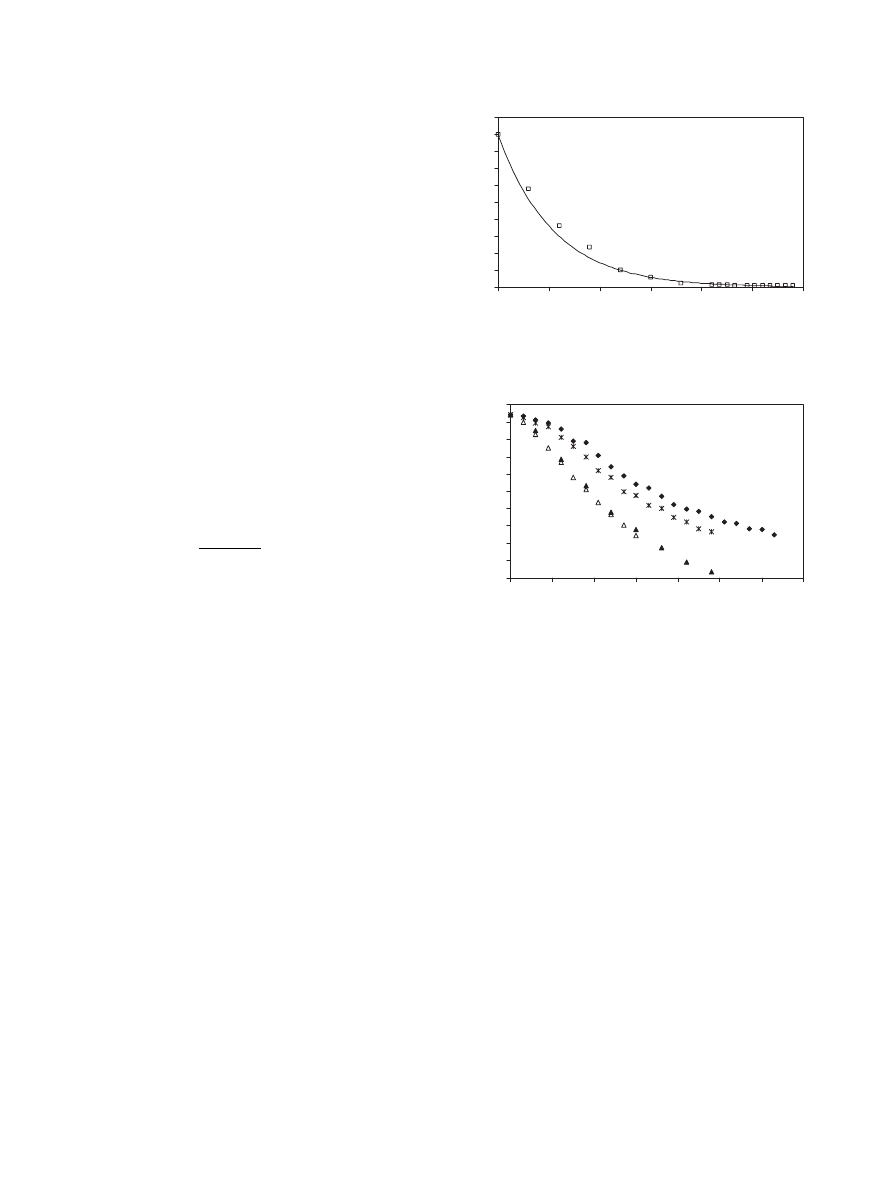

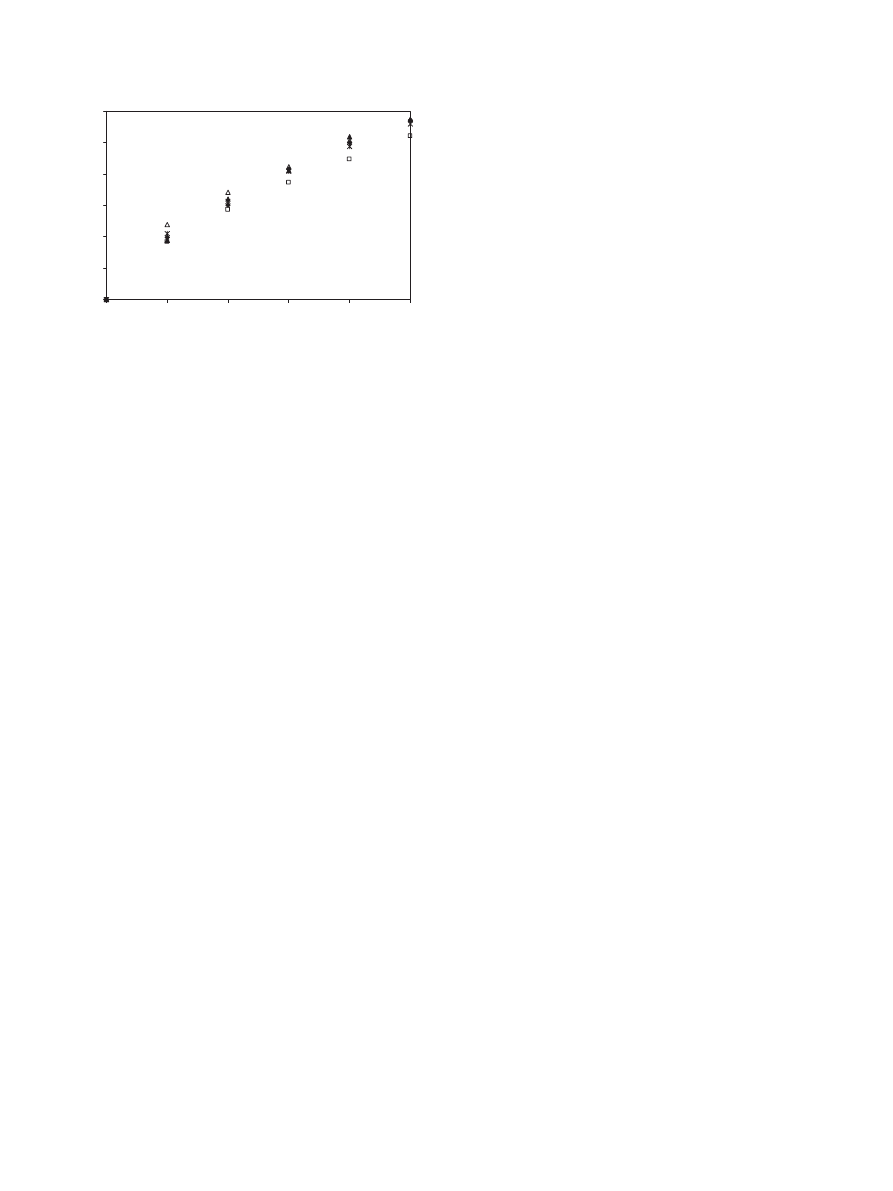

shows the change in moisture content of carrots

with time by hot-air drying. The moisture content

decreased exponentially with drying time with a

coefficient of determination of 0.97. When microwave

or halogen lamp–microwave combination drying was

applied to fresh carrots, carrots were cooked instead of

being dried. Therefore, microwave was applied after

moisture content of carrots was reduced to 0.47 kg

moisture/kg dry solid by hot-air drying. The drying

curves of carrots for microwave drying and halogen–

microwave combination drying after hot-air drying can

be seen in

. As expected higher absorbed

microwave power led to increased rates of evaporation

and moisture loss. When microwave drying continued

after 0.12 kg moisture/dry solid was reached, charring

and arcing occurred.

When microwave heating was combined with halogen

lamp heating, it was possible to dry carrots faster as

compared to microwave drying only. Drying time in

halogen lamp–microwave combination oven was almost

the same as compared to drying time in microwave oven

at the highest power. The near infrared radiation from

the halogen lamp was combined by the effects of

microwaves which caused higher rates of moisture loss

from the product. Moreover, in combination oven it was

possible to dry carrots to a moisture content of 0.018 kg

moisture/kg dry solid without charring and arcing

taking place.

Time required to reduce moisture content of carrots

from 0.47 to 0.12 kg moisture/kg dry solid with

microwave drying at the highest power was 2.5 min

while it was 2.6 min in halogen lamp–microwave

combination drying. The respective drying times were

128 min under hot-air drying. Thus, the drying times

were about 98% shorter in microwave drying at the

ARTICLE IN PRESS

y = 8.9239e

-0.0091x

R

2

= 0.9713

0

1

2

3

4

5

6

7

8

9

10

0

100

200

300

400

500

600

Time (min)

Moisture content (kg water/kg dry solid)

Fig. 2. Drying curve of carrots in hot-air drying.

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0

50

100

150

200

250

300

350

Time (s)

Moisture content (kg water/kg dry solid)

Fig. 3. Drying curves of carrots in microwave and halogen lamp–

microwave combination drying: (~), microwave (low power);

(*), microwave (medium power); (D), microwave (high power); (m),

halogen lamp–microwave combination.

G. Sumnu et al. / LWT 38 (2005) 549–553

551

highest power and in halogen lamp–microwave combi-

nation drying than that of corresponding hot-air drying.

Shorter drying time in microwave oven can be explained

by high internalpressure and concentration gradients

which increased the flow of liquid through the food to

the boundary. Similar results were obtained by different

studies in which hot-air microwave finish drying was

found to reduce convection drying time of fruits and

vegetables significantly (

;

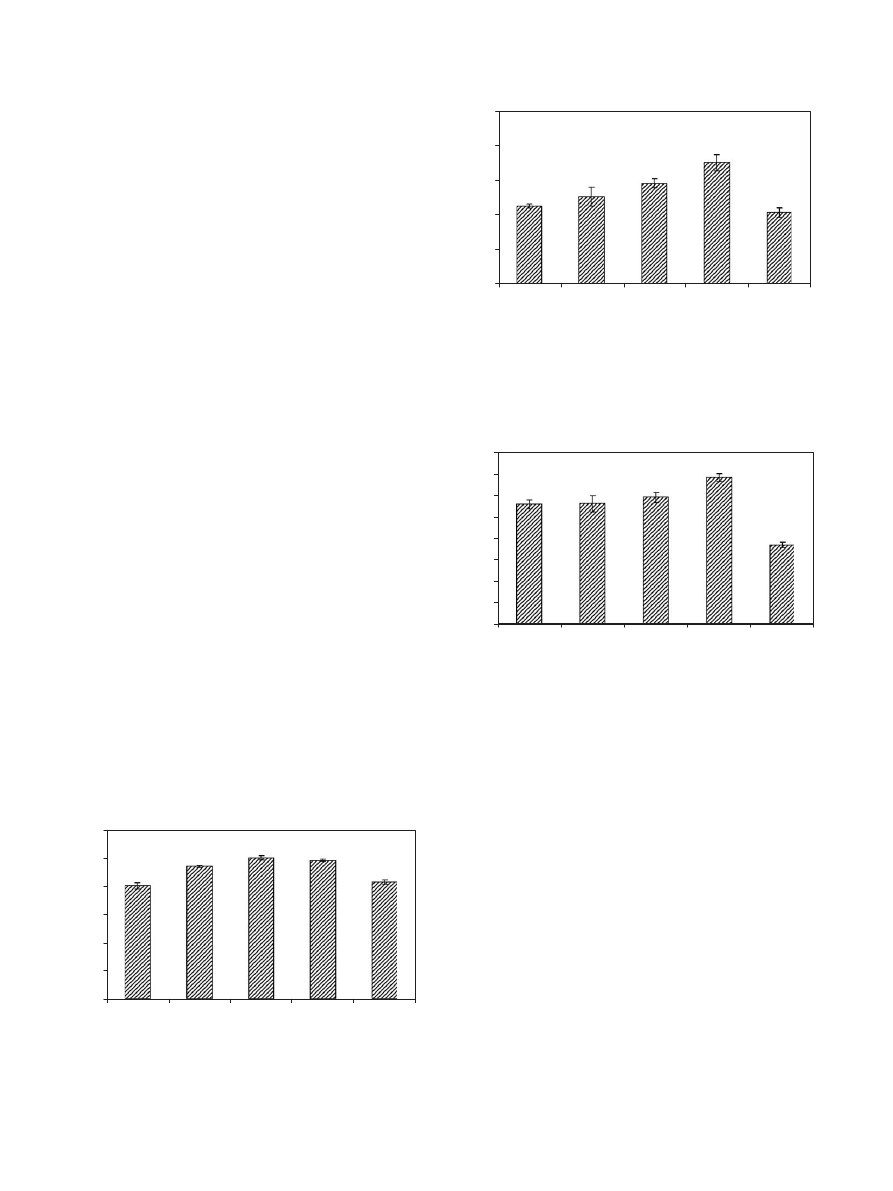

As microwave power increased L* values of carrots

increased meaning that carrots having a lighter colour

was obtained (

). When high powers were used,

drying was performed in a shorter time so that colour

was much more preserved.

also showed that microwave drying and microwave-

vacuum drying prevented colour damages during dry-

ing. Hot-air dried carrots were significantly darker in

colour as compared to carrots dried by high and

medium powers of microwave heating or halogen–mi-

crowave combination drying. This was due to the high

temperature reached during long time of drying. No

significant difference was found between L* values of

carrots dried in microwave or combination oven.

According to

Howard, Barswell, and Aselage (1996)

the lightness of carrot was affected by processing

temperatures with higher temperatures causing darker

colour.

The a* and b* values of carrots dried in microwave at

high powers and halogen lamp–microwave combination

oven were found to be significantly the same (

and

). Air dried carrot slices were found to be darker with

less yellow and red hues as compared to microwave

dried ones (

). The yellow and red colour

of carrot slices is attributed to the presence of carotenes

(

). Due to the short period of

drying in microwave and halogen lamp–microwave

combination oven carotenes might be less destroyed

and colour is more preserved.

Rehydration ratio is widely used as a quality

evaluation method after drying. In fact, it is a complex

process and indicates the chemicaland physicalchanges

caused by drying procedures (

). The rehydration ratio of carrots dried by

microwave or halogen lamp–microwave combination

oven was found to be significantly different from that of

hot-air dried carrots (p

p0.05) (

). This can be

explained by the high internal pressure produced by

microwave heating which can cause structure of carrot

slices to expand and puff. It was previously shown that

microwave dried carrot slices exhibited higher rehydra-

tion ratio than air dried ones (

). A less

dense structure had higher capacity to absorb water

reconstituted. Lower rehydration values of hot-air dried

carrots can be an evidence for product shrinkage caused

by severe heating and for prolonged drying resulting in

irreversible physical and chemical changes.

ARTICLE IN PRESS

c

b

a

ba

c

10

20

30

40

50

60

70

1

2

3

4

5

Drying method

L*

Fig. 4. Effects of different drying methods on L* values of carrots: (1)

microwave (low power), (2) microwave (medium power), (3) micro-

wave (high power), (4) halogen lamp–microwave combination, (5) hot

air. Bars having different letters are significantly different (p

p0.05).

bc

c

a

ab

bc

10

15

20

25

30

35

1

2

3

4

5

Drying method

a* val

u

e

Fig. 5. Effects of different drying methods on a* values of carrots: (1)

microwave (low power), (2) microwave (medium power), (3) micro-

wave (high power), (4) halogen lamp–microwave combination, (5) hot

air. Bars having different letters are significantly different (p

p0.05).

b

b

ab

a

c

10

15

20

25

30

35

40

45

50

1

2

3

4

5

Drying method

b* val

ue

Fig. 6. Effects of different drying methods on b* values of carrots: (1)

microwave (low power), (2) microwave (medium power), (3) micro-

wave (high power), (4) halogen lamp–microwave combination, (5) hot

air. Bars having different letters are significantly different (p

p0.05).

G. Sumnu et al. / LWT 38 (2005) 549–553

552

4. Conclusions

In this paper the effects of different drying methods

on quality of carrots were compared. Microwave drying

at the highest power and halogen lamp–microwave

combination drying shortened the drying time of carrots

significantly. Carrots dried in microwave and halogen

lamp–microwave combination oven had significantly

higher rehydration ratio and less colour deterioration.

Therefore, these methods can be advised for drying of

carrots which can be used in the industry of instant

soups and snack foods. In addition, halogen lamp–mi-

crowave combination oven can be recommended to be

used if the moisture content of the product is required to

be reduced to very low values.

Acknowledgements

General Electrics Company is greatly acknowledged

for donation of the halogen lamp–microwave combina-

tion oven (Advantiumt oven).

References

Buffler, C. (1993). Microwave Cooking and Processing: Engineering

Fundamentals for the Food Scientist, New York: Avi Book.

Datta, A. K. (2001). Fundamentals of heat and moisture transport for

microwaveable food product and process development. In A. K.

Datta, & R. C. Anantheswaran (Eds.), Handbook of Microwave

Technology for Food Applications (pp. 115–172). New York: Marcel

Dekker.

Feng, H., & Tang, J. (1998). Microwave finish drying of diced apples in

a spouted bed. Journal of Food Science, 63, 679–683.

Funeba, T., & Ohlson, T. (1998). Microwave assisted air dehydration

of apple and mushroom. Journal of Food Engineering, 38, 353–367.

Howard, L. R., Barswell, D. D., & Aselage, J. (1996). Chemical

composition and color of stained carrots as affected by processing.

Journal of Food Science, 61, 327–330.

Krokida, M. K., & Maroulis, Z. B. (1999). Effect of microwave drying

on some quality properties of dehydrated prodcuts. Drying

Technology, 17, 449–466.

Lewicki, P. P. (1998). Some remarks on rehydration of dried foods.

Journal of Food Engineering, 36, 81–87.

Lin, T. M., Durance, T. D., & Scaman, C. H. (1998). Characterization

of vacuum microwave, air and freeze dried carrot slices. Food

Research International, 31, 111–117.

Maskan, M. (2000). Microwave/air and microwave finish drying of

banana. Journal of Food Engineering, 44, 71–78.

Maskan, M. (2001). Kinetic of colour change of kiwifruits during hot

air and microwave drying. Journal of Food Engineering, 48,

169–175.

Nijhuis, H. H., Torringa, H. M., Muresan, S., Yuksel, D., Leguijt, C.,

& Kloek, W. (1998). Approaches to improving the quality of dried

fruits and vegetables. Trends in Food Science and Technology, 9,

13–20.

Nindo, C. I., Sun, T., Wang, S. W., Tang, J., & Powers, J. R. (2003).

Evaluation of drying technologies for retention of physical quality

and antioxidants in asparagus (Asparagus officinalis, L.). Lebens-

mittel Wissenschaft und Technologie, 36, 507–516.

Riva, M., Schiraldi, A., & Di Ceseare, L. F. (1991). Drying of Agaricus

Biosporus mushrooms by microwave hot-air combination. Lebens-

mittel Wissenschaft und Technologie, 24, 479–483.

Schiffmann, R. F. (2001). Microwave Processes for the Food Industry.

In A. K. Datta, & R. C. Anantheswaran (Eds.), Handbook of

Microwave Technology for Food Applications (pp. 299–338). New

York: MarcelDekker.

Sharma, G. P., & Prasad, S. (2001). Drying of garlic (Allium sativum)

cloves by microwave-hot air combination. Journal of Food

Engineering, 50, 99–105.

Yongsawatdigul, J., & Gunasekaran, S. (1996). Microwave-vacuum

drying of cranberries: Part II. Quality Evaluation. Journal of Food

Processing and Preservation, 20, 145–156.

Wagner, L. A., & Warthesen, J. J. (1995). Stability of spray dried

encapsulated carrot carotenes. Journal of Food Science, 60,

1048–1053.

ARTICLE IN PRESS

0

0.5

1

1.5

2

2.5

3

0

10

20

30

40

50

Time (min)

Rehydration ratio

Fig. 7. Effects of different drying methods on rehydration ratio of

carrots: (~), microwave (low power)

b*

; (*), microwave (medium

power)

b

; (D), microwave (high power)

a

; (m), halogen lamp–microwave

combination

ba

; (&), hot air

c

. *Treatments having different letters are

significantly different (p

p0.05).

G. Sumnu et al. / LWT 38 (2005) 549–553

553

Document Outline

Wyszukiwarka

Podobne podstrony:

Continuous Drying of Lumber in a Microwave Vacuum Kiln

Microwave Drying of Parsley Modelling, Kinetics, and Energy Aspects

Experimental study on drying of chilli in a combined Microwave vacuum rotary drum dryer (Weerachai K

Guide to the properties and uses of detergents in biology and biochemistry

Modeling with shrinkage during the vacuum drying of carrot (daucus carota) (Arévalo Pinedo, Xidieh M

Tenets of Wordsworth in Resolution and Independence

Guide to the properties and uses of detergents in biology and biochemistry

Views of love in romeo and juliet doc

The Role of Vitamin A in Prevention and Corrective Treatments

The Structure of DP in English and Polish (MA)

The Problem Of Order In Society, And The Program Of An Analytical Sociology Talcott Parsons,

REPRESENTATION OF NATURE IN buddhist and western art

Problem of Substance in Spinoza and Whitehead

Balme; Development of biology in Aristotle and Theophrastus theory of spontaneous generation

Views of love in romeo and juliet

The Spectre of Shakespeare in Rosencrantz and Guildenstern are Dead

027 Drying of Potato, Sweet Potato and Other Roots

KOLE The arrow of time in cosmology and statistical physics (termodynamics, reductionism)

więcej podobnych podstron