Section I

Introduction

Rizvi / Handbook of Photomask Manufacturing Technology DK2192_c001 Final Proof page 1 7.3.2005 6:12pm

© 2005 by Taylor & Francis Group.

1

Introduction to Mask Making

Andrew G. Zanzal

CONTENTS

1.1 Introduction

1.2 How Masks are Fabricated

Data Preparation

1.2.1.1 Transformation

1.2.1.2 Augmentation

1.2.1.3 Verification

Front End of Line

1.2.2.1 Mask Writing

1.2.2.2 Process

Back End of Line

1.2.3.1 Defect Inspection

1.2.3.2 Defect Repair

1.2.3.3 Pellicle Application

1.3 The Technology History of Masks

1.1

Introduction

A mask can be defined in simplest terms as a pattern transfer artifact, wherein exists a

patterned surface on a substrate material. The patterned surface is transferred to form an

image of the pattern on a receiving substrate, which is subsequently fabricated into

electronic, electromechanical, or mechanical devices. In most cases, the transfer artifact

substrate is highly transparent to the change agent of the pattern transfer (usually light),

while the patterned media on the mask substrate is less transparent or opaque to the

change agent. The transmitted image may pass through a lens, with either demagnifica-

tion or 1:1, or it may be contact printed directly to the receiving substrate (

Typical masks used by the semiconductor industry over the past 25—30 years have been

comprised of a thin (80–100 nm) layer of chrome on a glass or fused silica substrate. The

chrome is patterned using a coating of photosensitive material, known as photoresist,

which is resistant to chrome etching. After selective exposure with energy, the photoresist

Rizvi / Handbook of Photomask Manufacturing Technology DK2192_c001 Final Proof page 3 7.3.2005 6:12pm

© 2005 by Taylor & Francis Group.

is chemically developed, leaving voids where an etching chemical may be applied to

remove unwanted chrome.

Masks, as used in the semiconductor and related industries that have adopted semi-

conductor fabrication methods, have their origin in traditional printing and lithography.

For the purpose of this publication, mask refers to the pattern transfer artifact as described

above when used in the fabrication of microelectronic or similar micro devices. In this

genre, masks have also become commonly referred to as photomasks or reticles, almost

interchangeably. Traditionally, a mask or photomask was a pattern transfer artifact that

contained the complete pattern content of a single layer of a full semiconductor wafer,

which could be printed in a single exposure without any optical demagnification. A reticle

also contains a single layer of pattern data but only for a small part of the wafer. The

reticle image could be projected, with or without demagnification, onto the small part of

the wafer (

After the formation of this single image by exposure, the wafer

would move on a stage, and then a second image would be printed, until several

subsequent areas of the wafer were printed with the pattern content from the reticle.

Semiconductor and related industries have migrated over the years to using mostly

reticles, but the interchangeable use of the terms reticle, photomask, and mask has blurred

the traditional distinction.

As a class of pattern transfer artifacts masks can be used in multiple ways. They can be

used with broadband or single wavelength light (radiation) sources. They can have

transmitting or reflecting substrates. The pattern media can be fully opaque or par-

tially transmitting for transmission masks, or absorptive for reflective masks. The sub-

strate and media can be engineered and processed in such a way as to change the phase

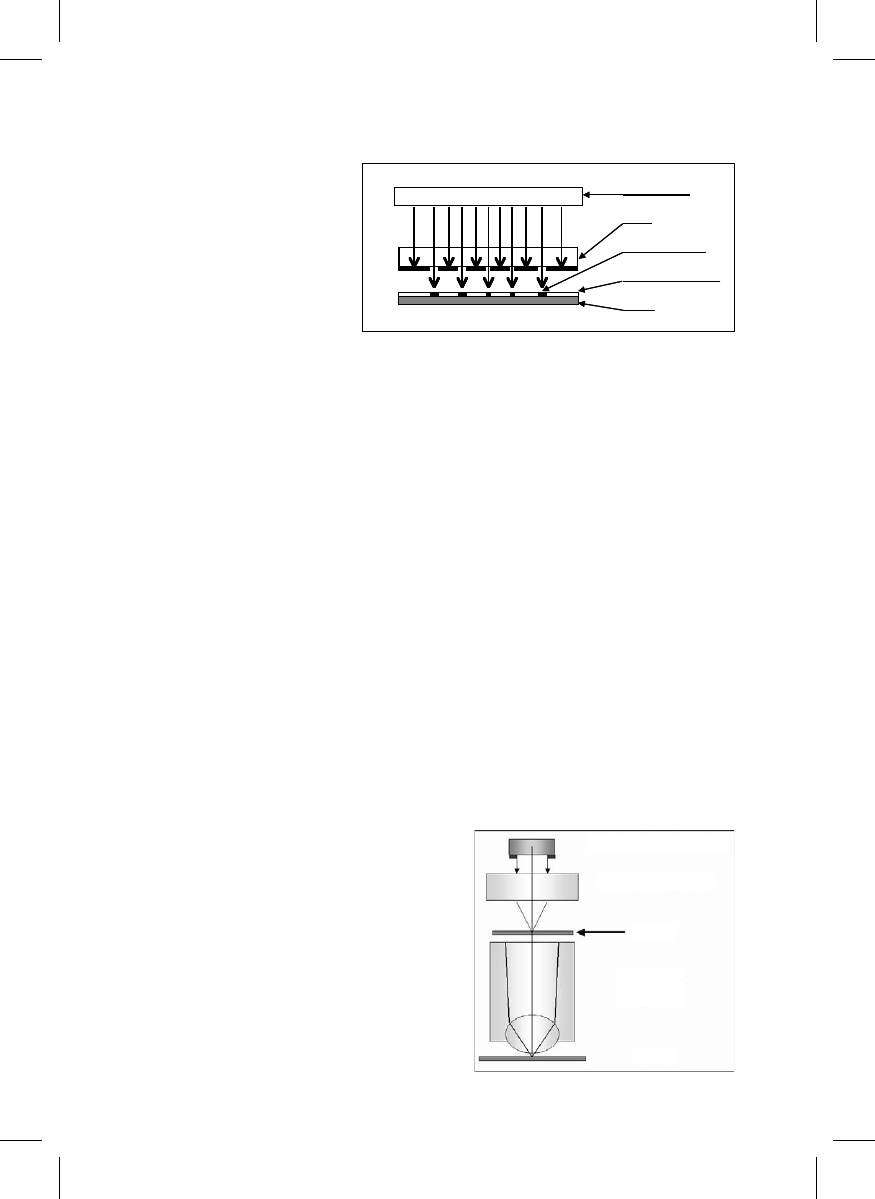

FIGURE 1.1

Schematic of wafer exposure using a

mask.

Light source

Mask

Exposed resist

Unexposed resist

Wafer

FIGURE 1.2

Mask in a typical projection/reduction lithography system.

Illumination aperture

Condenser lens

Mask

Projection

optics

Wafer

© 2005 by Taylor & Francis Group.

of the radiating wavelength. The substrates can be of rigid contiguous media or thin

membranes with discontinuities. Masks can be used in direct hard contact or in projection

with a particle-free ‘‘mini-environment’’ known as a pellicle. These and other options will

be highlighted in the subsequent chapters.

The most common masks in use today are those with an image media of chromium that

is sputtered on a fused silica substrate. The chromium is highly opaque to the radiating

wavelength (usually 248 or 193 nm), while fused silica is highly transparent. The masks

will most likely be used on a tool that prints multiple fields in an expose-and-repeat

fashion. The mask will have a pellicle attached to the media coated surface. A pellicle is a

transparent membrane that is stretched across a metal frame and subsequently attached

to the mask using an adhesive. The pellicle keeps any particles from contaminating the

patterned surface and provides a suitable distance to keep away such particles out of the

printing focal plane. A mask as described in this paragraph is alternatively referred to as a

binary intensity mask (BIM) or chrome-on-glass (COG) mask.

1.2

How Masks are Fabricated

Masks have been made by a variety of means since the 1960s, some of which will be

described from a historical perspective later in this chapter. For the purposes of this

section, however, the flow described is typical of processes used in producing BIMs

today. The details of the process are often proprietary to the practitioner, and, as such,

intimate details are omitted from this chapter. More complex flows that are required to

produce more exotic masks either in use today or contemplated for the future, are

described in subsequent chapters.

Today’s mask patterns are defined using electronic design automation (EDA) software

tools on computer automated design (CAD) systems. This operation is most often per-

formed outside the mask arena, so the output from the design activity is the starting point

of mask fabrication. The fabrication process can be subdivided into three broad categories

of manufacturing activities: data preparation, front end of line (FEOL), and back end of

line (BEOL).

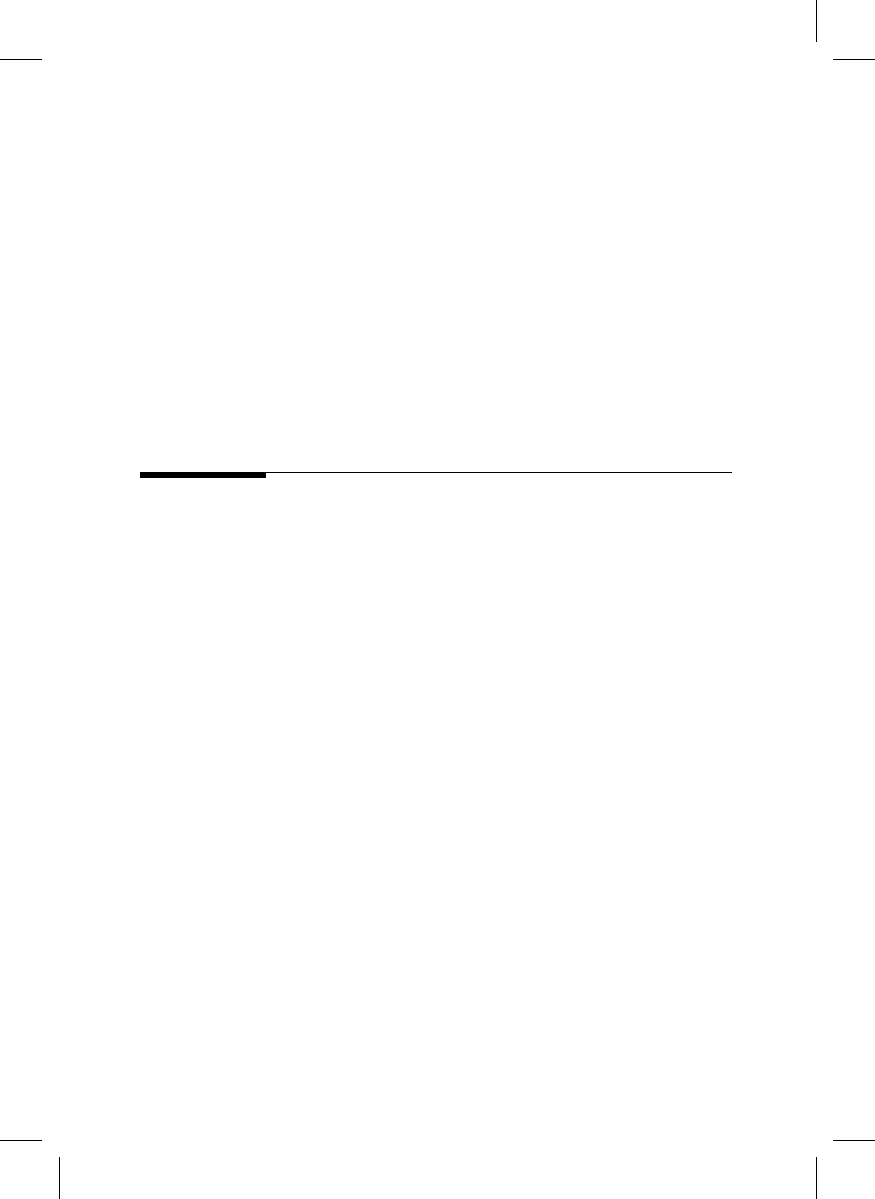

is a highly simplified diagram of the process flow and is meant to

broadly convey the general steps employed. The reader should be aware that the actual

processes can include loops or repetitions of many of the steps in the diagram

1.2.1 Data Preparation

The data preparation process is comprised of three broad process steps performed once

the mask data files are received from the circuit designer. These process steps can be

broadly categorized as transformation, augmentation, and verification.

1.2.1.1 Transformation

Incoming mask data from circuit designers can be either passed directly to the FEOL step or

any number of data file manipulation steps can be performed. These include transforming

the data from the input format to a format compatible with the mask writing tool used in

FEOL processes. This transformation process is commonly referred to as fracturing and

may or may not include the addition of process bias to compensate for linear differences in

feature sizes between the mask process and the desired final wafer result. Advanced masks

© 2005 by Taylor & Francis Group.

may also require differential biasing where compensations are made based on local pat-

terning attributes. In addition to preparing data files for mask writing, data files used to

inspect the finished mask are also included in the transformation process.

1.2.1.2 Augmentation

Other functions that may occur in the data preparation stage include the addition of optical

proximity correction (OPC) features and the addition of standard mask patterns, such as

machine-readable barcodes, human-readable labels, alignment marks, and metrology cells.

Additionally, this step often includes composing a set of instructions, known as a job deck,

that tell the mask writer where to put the content from multiple mask files onto the mask.

1.2.1.3 Verification

To varying degrees, based on project complexity and customer requirements, automated

and manual verifications are performed. These steps are performed to minimize the

number of masks that must be remanufactured and to cycle through more costly pro-

cesses in FEOL and BEOL. Some of these processes include automatic comparison of the

fractured data to the input file and may also include local or remote on-screen viewing by

customers of the mask fabrication facility. A trend towards automating many of the

verification processes has been apparent over the last several years

1.2.2 Front End of Line

The FEOL processes include the mask writing step, chemical processing, and metrology.

Metrology, or measurement, may be inserted many times in the flow to ensure the final

outcome and detect failures in the flow as early as possible to avoid adding unnecessary

cost by performing operations on a mask that will subsequently be rejected.

Transformation

Verification

Writing

Process

Augmentation

Metrology

Pellicle

Defect repair

Defect inspection

Data preparation

Back end of line

Front end of line

Design data

Finished Mask

FIGURE 1.3

Simplified mask-making flow.

© 2005 by Taylor & Francis Group.

1.2.2.1 Mask Writing

Today’s masks are generally written on either of the two classes of write tools. Electron

beam (e-beam) writers precisely direct a focused stream of electrons onto the mask

substrate while controlling the position of those electrons through the use of an interfer-

ometer controlled stage. Laser writers essentially perform in the same fashion but use

laser generated photon energy rather than negatively charged electrons. The optics and

mechanics of how these electrons or photons are delivered to the substrate surface are

distinctly different for virtually every writer employed in the industry. These differences

will be discussed in later chapters.

1.2.2.2 Process

The energy delivered by the mask writer to the substrate surface is intended to react with

a coating on the chromium. The coating, generically referred to as resist, is engineered to

be sensitive to either e-beam or laser exposure. Resist is a chemical polymer that is usually

cross-linked at the molecular level when exposed to the radiation wavelength for which it

is designed.

1.2.2.2.1 Develop

The locally cross-linked molecules become either sensitive or insensitive to chemical

developers used in post-write processing steps. When the develop step removes exposed

resist, the process is referred to as positive-working, and when leaving behind exposed

resist, negative-working.

1.2.2.2.2 Etch

After development the mask moves on to the etch step. In this part of the process, the

surface of the mask that has been left uncovered by resist becomes exposed to the etching

chemistry. The resists are engineered to withstand the etching process and at the very

least stand up to the etch chemistry with a removal rate that is slower than the removal

rate of the underlying chromium. Etching can be accomplished by using liquid (wet) or

plasma (dry) etch chemistry. After complete removal of unwanted chromium by etching,

the mask is stripped of all remaining resists.

1.2.2.2.3 Metrology

Masks are subjected to metrology throughout the manufacturing process, but most

rigorously at the postdevelop and postetch stages. Postdevelop measurements of critical

dimensions (CDs) are taken to ensure that the develop process has not over or under shot

the final desired CD. Often an iterative develop process can ensure the likelihood of final

CDs’ meeting the specification. Iterative etching processes are also used but are less

common. Once a sample of CDs is found to be within the desired final outcome after

etching, customer specific sampling plans are generally employed to assure compliance

with specifications. Another form of metrology that is often employed is registration or

position metrology. This metrology is used to ascertain that elements of the mask are at

intended locations relative to other customer-identified features.

1.2.3 Back End of Line

BEOL process is generally performed to ensure quality of the outgoing mask and to

protect the mask from particles in transit to the user, and through its useful life. These

© 2005 by Taylor & Francis Group.

steps include defect inspection, defect repair, and pellicle application. The impact of

cleaning processes should not be ignored or understated as the mask may go through

cleaning cycles before and after each inspection and repair, and a rigorous final cleaning

process just prior to pellicle application.

1.2.3.1 Defect Inspection

Masks are inspected for defects on automated tools that scan the mask surface and con-

stantly compare the physical mask to a reference image. Any anomaly detected that shows a

difference within preset limits between the mask and the reference image is flagged as a

potential defect, and its location is recorded for later review and classification by an

inspection operator. The reference image can either be an intended identical pattern from

another area of the mask, known as die-to-die inspection, or a digital representation on the

intended mask image that was prepared in the transformation phase of data preparation.

1.2.3.2 Defect Repair

Once found, defects that are large enough to print need to be repaired. Printability

assessment through lithography simulation has not become a universally accepted prac-

tice, resulting in an industry that tends to repair every defect it detects. Repair is

accomplished on advanced masks using both focused ion beams and nano-machining

with atomic force microscope (AFM) tipped repair tools. More mature masks are still

repaired using laser tools.

1.2.3.3 Pellicle Application

After rigorous final cleaning and assessment to ensure that there are no particulate

contaminants or chemical stains, a pellicle is attached to protect the mask surface from

subsequent contamination in shipment and through the masks’ useful life. The mask is

inspected with both reflected and transmitted light after the pellicle is attached to ensure

that the area under the pellicle has remained defect- and contaminant-free throughout the

pellicle application process.

1.3

The Technology History of Masks

The use of masks to print semiconductor wafers goes back to the very early days of the

formation of the industry. In the intervening decades, the mask industry has continually

adapted its product offering to meet the needs of its semiconductor-producing customers.

The changes in mask product offerings were usually driven by the development in wafer

lithography. The industry has progressed from 1 contact print lithography through 1

projection to reduction lithography. In the most recent era beginning 1999, masks, and the

lithography processes that support masks, have entered the subwavelength era where the

line widths printed are often far smaller than the wavelength of light used to print them.

1.3.1 The Contact Print Era

In the early days of the semiconductor industry, masks were almost exclusively used in

contact print applications. Masks used in this fashion were placed in intimate contact with

© 2005 by Taylor & Francis Group.

the wafer, which was subsequently exposed with ultraviolet light. In the process of

making intimate contact, difficulties arose in the area of creation of defects on the mask,

which printed on subsequent wafers. Alignment with previous layers was also a problem,

caused by thermal stability of mask materials and lack of other than visual or manual

alignment.

The first masks in this era were actually not on the rigid glass substrates we know of

today, but were actually made from either a material called rubylith or photographic film.

Rubylith is a two-layer polymer-based material comprised of light-blocking red film

laminated to a clear polymer base. In the contact print era, rubylith material was widely

used in the graphic arts and adapted easily to the fledgling semiconductor industry. The

softer red layer could be cut with a knife without damaging the tougher clear layer. After

cutting, the unwanted red areas could be peeled away and a mask comprised of clear and

opaque areas was created. The rubylith material could be printed directly on the wafer or

copied onto a film, with or without reduction, and then printed. Obviously, this technique

had little merit for any level of production volume, but in early R&D stages it was

adequate for proof of concept demonstrations.

To enhance mask precision and manufacturing volume, the industry evolved to one

where rubylith continued to be used but the circuits were cut into the material at high

magnifications (often 200). The resultant representation of the circuit was called ‘‘art-

work.’’ The artwork was photo reduced (often 20:1) onto emulsion glass substrates

usually resulting in a 10 reticle. Metrology in those days consisted of checking the

rubylith feature sizes with a steel scale and an eye loupe. Through this era, the precision

and error rate of rubylith cutting were greatly enhanced by the development of a tool

called a coordinatograph, which has an effective light table to which the rubylith was

affixed

This tool had mechanical stops in the X and Y directions to which

coordinates could be applied to precisely guide the length and direction of the cut. Some

coordinatographs also had rotating light tables so that even angled features could be cut.

Later versions of coordinatographs used primitive computer numerical control to make

the precise cuts required to generate even more complex artwork.

The 10 reticle produced from the photo-reduced artwork was used in a tool called a

photorepeater, which reduced the mask image to the final desired size while simultan-

eously printing it on a photographic emulsion coated glass substrate. This ‘‘camera’’

would expose, step to the next location, and then repeat the process until the mask was

completed. The photorepeater also became known as a step and repeat camera and was a

precursor to the wafer stepper that is used in most semiconductor fabrication methods

today. The resultant mask from the photorepeater became a master mask from which

many copies were made.

In this era, mask materials moved from the initial mylar-based films with rubylith or

photographic emulsion to soda-lime glass substrates with photographic emulsion. Ini-

tially used in wafer contact printing, masks had a finite life, and many copies were made

to support production lines making large volumes of devices. Emulsion photomasks first

supported the industry; however, the emulsion coating was relatively soft and did not

stand up long to contact printing. Each print added additional defects to the mask, in

some cases rendering it useless after printing just a few wafers.

To mitigate these defect issues, the industry migrated over time to so-called hard

surface materials that consisted of sputtered or evaporated metal films that had appro-

priate optical properties and could be cleaned repeatedly. Although not totally impervi-

ous to added defects over time, hard surface photomasks were far less susceptible to

damage as compared to emulsion masks during the contact printing process, and they

could be cleaned of particles. The two films the industry settled upon were iron oxide and

chromium. Iron oxide provided the benefit of being transparent in the visible wavelength

© 2005 by Taylor & Francis Group.

while being opaque at the exposure wavelength, allowing the user to see through the

mask when aligning to a previous layer. The drawbacks of iron oxide were that the

material processed poorly, was prone to excessive defects, and provided such non-

uniform results, and that the semiconductor device specifications quickly outpaced its

usefulness as a viable material. Chromium provided a much more uniform result and to

this day remains the dominant material for mask making.

The key technology breakthroughs in this era from the 1960s to the early 1970s were the

eventual development and migration to hard surface photomasks. More significant

though, was the development of a tool called an optical pattern generator (

This class of tools, developed by companies like David Mann Company and Electromask,

effectively replaced rubylith as a means of creating artwork by allowing the production of

10 reticles directly on emulsion glass substrates. The tool had a computer-controlled

stage that allowed for the movement of the substrate in the X or Y direction. An aperture

in the optical path allowed for a variable shaped slit from a wide range of height and

width values. The optics and aperture were mounted on a turret that could be rotated in

0.18 increments, allowing for angled features as well. These tools appeared on the scene in

the late 1960s and reached their full popularity in the mid-1970s, at a time when the

complexity of leading edge devices had gone beyond the ability of operators to cut them

in rubylith. These tools allowed the industry to move beyond the physical mask content

and subsequent verification limitations that had been imposed by using rubylith.

1.3.2 The 1 Projection Era

In the mid-1970s, the need for masks with longer lifetimes became apparent to the

industry. Using large quantities of contact print masks was difficult to manage in

a production line, but more significant were the yield losses associated with contact

FIGURE 1.4

Operators cutting rubylith artwork. (Photo cour-

tesy of Intel Corp.)

© 2005 by Taylor & Francis Group.

printing due to defects on masks printing on wafers and contact with wafers damaging

the masks. In this era, Perkin-Elmer Corporation developed the Micralign projection

aligner and through its deployment precipitated several profound changes to the business

of making masks that have continued forward to this day, many of which are discussed in

later chapters.

The Micralign eliminated contact printing by using a system of mirrors and lenses to

project the mask image onto the wafer. The mask never came in contact with the wafer,

thereby eliminating the defect issues associated with contact printing. Another feature of

the Micralign was the ability of the tool to automatically align to a previously printed

layer through the use of specially designed and located alignment marks.

In this era, several changes in substrate materials were ushered into the industry. Since

masks did not have to be cleaned as often, they were used for many more wafer exposures

leading to increases in temperature at the mask plane. Over time, the thermal properties

of soda-lime glass led to wafer alignment issues, which forced the industry to migrate to

glass substrate materials that had a lower thermal coefficient of expansion. The industry

settled on borosilicate glass materials, which had thermal properties similar to those of

silicon wafers. Towards the end of the 1 projection era, wafer exposure wavelengths

migrated to near 365 nm, creating the need for a substrate with higher transmission

properties than borosilicate. The industry turned to synthetic quartz, or fused silica,

which had very high transmission properties all the way through 193 nm, and remarkable

thermal stability. Fused silica remains, to this day the substrate of choice for leading-edge

mask techonology.

Some of the breakthrough technology advancements that occurred in this era included

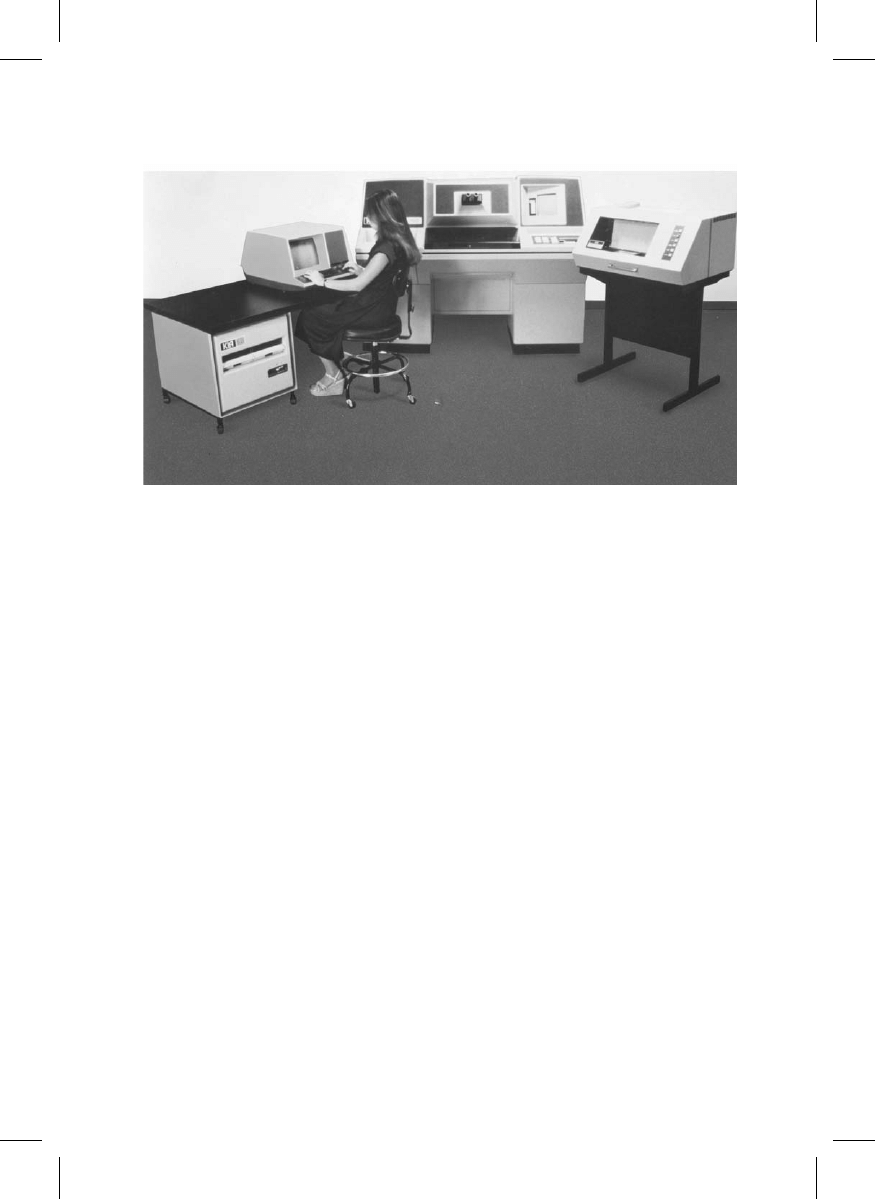

automated defect inspection, laser repair, and pellicle protection. The first automated

defect inspection machine appeared on the scene in early 1978. Developed by KLA

Instruments, the KLA 100 tool (

performed defect inspection by scanning and

comparing adjacent fields on the photomask intended to be identical. When an anomaly

FIGURE 1.5

Mann3000 Pattern Generator. (Photo courtesy of the Uni-

versity of Notre Dame.)

© 2005 by Taylor & Francis Group.

between the two inspected fields was detected, the location was recorded and stored for

later review and classification by a machine operator. This automation replaced the

tedious visual inspection method whereby an operator would spend his or her day

scanning masks through a microscope and counting defects. Other benefits, in addition

to the reduction of tedium, was the ability to replace sampling plans with 100% inspection

and the ability to use the tool for process improvement through rapid collection of results

in defect reduction experiments.

Of course, finding defects was only half of the story. The desire to achieve defect-free

masks could only be accomplished with reasonable yield through the use of repair tools.

The first laser repair tools from companies like Quantronix and Florod appeared in the

late 1970s. These systems used laser pulses to remove unwanted chrome spots from the

mask. Later versions included the ability to repair voids in the chrome through laser-

assisted chemical vapor deposition. Although primitive by today’s standards, these tools

proliferated rapidly through the industry and continue to be used for trailing edge mask

products even today.

Once defects were found and repaired, maintaining their low-to-zero defect condition

became the next focus area. Again the industry responded by developing a hardware

addition to the mask called a pellicle. A pellicle is essentially a thin transparent membrane

that is stretched over a metal frame. The purpose was to effectively seal the surface of the

mask to keep out particles. The height of the frame was designed specifically to keep any

particles that landed on the membrane surface out of the focal plane of the exposure

system, thereby keeping the particles from printing on the wafer. Companies like Ad-

vanced Semiconductor Products (ASP), Mitsui, and Micro Lithography Incorporated

(MLI) introduced pellicles commercially in the early 1980s. Pellicles have become an

integral part of photomasks and today’s masks are rarely used without them.

Through this era, device complexity continued to increase to the point where the optical

pattern generators that were used to create the 10 reticles, from which 1 projection

masks were made, were unable to keep up with the increasing density. Pattern generation

FIGURE 1.6

KLA 101 Die-to-die automated defect inspection system. (Photo courtesy of KLA-Tencor.)

© 2005 by Taylor & Francis Group.

files soon eclipsed several hundred thousand exposures, and reticles could take as long as

48 h to expose. To mitigate this development, a faster method of writing these reticles was

required. The answer was the development of the e-beam writer, which came out of Bell

Laboratories to be commercialized in the late 1970s by ETEC Corporation (Figure 1.7).

Dubbed the Manufacturing Electron Beam Exposure System (MEBES), this tool provided

the ability to write reticles for use on photorepeaters at much faster throughput rates than

possible with optical pattern generators. The added benefit of this tool was that it was

significantly over-engineered for the task of making photorepeater reticles and could be

used to make 1 masks directly from a data file. This led to the ability to create masks

with die sizes that were not constrained by the photorepeater lens field, as well as having

masks without repeating features, if desired. The resolution and flexibility of the early

MEBES and its successors served the industry as the platform of choice well into the mid-

1990s. Since these tools were capable of manufacturing 1 masks for leading edge

devices, their inherent abilities precipitated an era that later came to be referred to by

the industry insiders alternatively as ‘‘the mask maker’s holiday’’ or the ‘‘5 holiday.’’

1.3.3 The Wafer Stepper Era

Through the later stages of the 1 projection era, the semiconductor industry migrated

rapidly to wafer steppers as the lithography process of choice, from companies like GCA,

Nikon, and Canon. Much of the reason for the adoption of wafer steppers was due to

difficulties in printing in the 1 mm and below regime with 1 projection aligners. With

reduction steppers these dimensions could be achieved with wide process windows and

robust manufacturing yields. Another benefit was that defect-free masks could be easily

achieved from within the existing mask infrastructure, which at the time was geared to

FIGURE 1.7

Operator at MEBES-III console. (Photo courtesy of Photronics, Inc.)

© 2005 by Taylor & Francis Group.

produce 1 masks. The earliest wafer steppers were 10 tools, so the reticles needed to

support lithography were effectively 10 times easier to make from a resolution and CD

control standpoint. Later, even as wafer steppers migrated to 5, the relaxation of

specification criteria brought on by the magnification change from 1 was still profound.

Given an infrastructure of tools capable of much finer precision than that needed by its

customers, the mask industry focused on the service aspects of the business, including

reducing cycle time, reducing defects, improving mask data handling and transfer, and

implementing quality improvement systems.

Through this so-called holiday there was considerable consolidation in the merchant

mask industry and divestiture of captive facilities. Cycle times, often 2 weeks in the 1

optical mask making days, were reduced to 3–4 days in routine cases and less than 24 h on

a rush basis. Mask orders no longer required the magnetic tapes be shipped to the mask

provider but, instead, the use of dedicated dial up lines, later to be supplanted by Internet

transfer, flourished. Encouraged by their customers, mask makers embraced statistical

process control and quality systems, such as ISO 9000.

The industry also implemented new innovations from its supplier base, many of which

are covered in detail in later chapters. High throughput laser mask writers from com-

panies like Ateq and later Mirconic Laser Systems supplanted many MEBES tools for all

but the most technically challenging requirements. KLA introduced inspection systems

that compared the mask to the data file from which it was produced allowing for defect

inspection on masks without repeating patterns. Interferometer-based metrology tools

from Nikon and Leica were developed to measure position accuracy and led to the ability

of mask makers to match masks successfully from different mask writers. Focused ion

beam repair tools, from companies like Seiko Instruments and Micrion, augmented laser

repair systems. These tools did far less surface damage to the mask and allowed for repair

of smaller defects with greater precision.

As mentioned in the previous paragraphs, the 5 holiday was not a holiday at all but

an era that provided the opportunity for the industry to focus on time-to-market issues,

BEOL inspection and metrology, implementation of quality systems, and consolidation.

By the end of this era (ca 1994) the number of merchant mask suppliers in the world was

reduced through consolidation to four major and about half dozen lesser players. The

growth of these leading players towards achieving critical mass for attracting adequate

capital investment proved to be of major consequence as the industry entered the sub-

wavelength era in the late 1990s.

1.3.4 The Subwavelength Era

The mask industry is currently in the subwavelength era and will remain firmly therein

through at least the rest of the first decade of the 21st century. This era is defined by the

relative wavelength used by customers on their wafer exposure systems compared to the

feature sizes being printed on the wafer. Over the years, since the first wafer steppers were

introduced, stepper exposure wavelengths have continued to migrate downward from

their initial state at 436 nm, through 365 and 248 nm, to today’s state-of-the-art 193-nm

exposure systems. Once feature sizes migrate below wavelength, lithographers need to

apply techniques to enhance the imaging to achieve the wafer features. Some of these

techniques can be applied at the wafer end of the stepper, such as special photoresists and

antireflection coatings, while some might be applied to the illumination end of the stepper,

such as off-axis or dipole illumination. At the reticle plane, enhancements can be made to

the mask to improve the printed wafer results. These reticle treatments, collectively known

as resolution enhancement techniques (RET), include a variety of techniques [phase shift

© 2005 by Taylor & Francis Group.

masks (PSM) and OPC, discussed in greater detail in later chapters] to shift the phase of

light and number of methods to correct feature shape loss during reduction.

There was little need to use RET at 436 nm as the transition to 365-nm steppers was

relatively painless for the semiconductor industry. RET, as a means of advancing leading

edge semiconductors, was implemented briefly in North America at 365 nm before giving

way to the 248-nm wavelength. In Japan, however, RET at 365 nm was used in production

for a longer period as a means of extending the useable life of wafer steppers. With the

introduction of 248-nm exposure systems and the subsequent delay in availability of

193-nm systems, RET has quickly become a requirement for virtually all critical layers

in a set of masks for advanced semiconductor devices.

With the near-term roadmap for the semiconductor industry indicating 193 nm, and

possibly 157 nm, as the wavelengths of choice at least through the current decade, reticles

have become and will remain a key enabling part of the lithography process. Feature sizes

are expected to be nearly a one third of the wavelength by the year 2007, driving up the

content and complexity of masks. Creating reliable and cost-effective methods for manu-

facturing the challenging masks of today and those contemplated in the future require

significant investment in R&D and capital equipment costing hundreds of millions of

dollars. Clearly, the industry will benefit from the visionary management at companies

like Photronics and Dupont Photomask, and to a lesser extent at Dai Nippon and Toppan,

that brought about the global consolidation of many small independent and captive

mask-manufacturing organizations*. These larger organizations tend to have greater

access to the capital resources required to extend mask technology.

Mask making in the subwavelength era requires the mask maker to possess a broader

product offering to address the wide variety of RET, and one can infer that a broader set

of core skills and new tools are required as well. Writers for advanced critical layer masks

are now mostly high voltage e-beam systems with variable shaped beams and vector

scanning positioning systems. Unlike earlier raster scan systems, which scanned the

entire mask, these systems address and write only parts of the mask that need to be

exposed. Complex software and algorithms control the size, shape, and energy of each

exposure. Shape control is critical in providing the high fidelity OPC needed to provide

adequate masks. To enhance the speed of these tools, both positive and negative chem-

ically amplified resists are widely used. These new high voltage vector scan variable

shaped e-beams are discussed in greater detail in later chapters. Mask makers also have

moved into an era where new materials with precise optical properties for phase shifting

require multilevel exposure, as well as different etch techniques, than those used in

previous eras. In addition to new materials, tools and processes, knowledge and compe-

tence in lithography, simulation is also becoming more recognized in mask development

organizations as critical to the rapid and robust implementation of ever more complex

RET. In today’s semiconductor economy, masks are no longer viewed as a commodity but

as an integral part of a complete system.

1.4

The Future of Masks

The direction that mask making may take in the future beyond the year 2010 is unclear, as

approaches to lithography after the 193-nm wavelength or perhaps 157-nm wavelength

* Editor’s Note: Since the time the chapter was written, Dupout Photomask has announced plan to be acquired

by Toppan.

© 2005 by Taylor & Francis Group.

are yet to be proven production worthy. Certainly, significant effort in developing

lithography systems for the postoptical era has narrowed down the choices from among

many candidates, but as often those that were thought to be dead are revived for

another round of consideration. These postoptical or next generation lithography (NGL)

approaches include extreme UV (EUV), electron projection lithography (EPL), ion projec-

tion lithography (IPL), proximity x-ray lithography (PXL), nano-imprint, and one might

also argue direct write. With the exception of the latter, all of the choices require masks

that are radically different in many ways from those that are used today and all except

nano-imprint (a recently added option) are discussed in greater detail in later chapters.

There are pockets of support around the globe for each of these technologies, though

considerable effort continues to be invested in EUV and EPL. Although it is too soon to

predict if any of these technologies will become as dominant as optical lithography has

been, it is not difficult to envision that they will be used at least in a mix-and-match mode

for applications for which they are best suited, such as PXL or EPL for contact holes.

Direct write maskless lithography looms on the horizon as a potential contender, but

throughput and uniformity issues may relegate this technology to low volume applica-

tions, such as ASIC devices. The inherent benefit that has been embedded in masks since

they were first used, through to the present day, is their ability to allow parallel exposure

of massive amounts of content and to do so repeatedly wafer after wafer. I believe that the

semiconductor industry will continue to leverage this attribute as long as there is no

economically attractive alternative.

© 2005 by Taylor & Francis Group.

Document Outline

- Contents

- Section I Introduction

Wyszukiwarka

Podobne podstrony:

Elektroforeza DNA komórkowego BioAut1, BioAut2 i Ch1

ch1-pobieranie probek, weterynaria, Analityka, Próbówki

WYKLAD z fizyki atomowej i mol w3-4 2008, Fizyka, 13.Fizyka jądrowa, mat ch1

ch1

Ch1 Q1

Cw ch1, Akademia Morska Szczecin Nawigacja, uczelnia, Tomek, FIZYKA- SPRAWOZDANIA, FIZYKA- SPRAWOZDA

ch1 010902

Ch1 FundamentalOfPowerPlant 1 17 1 24

KIMMEL genderedsociety ch1

Ch0 Ch1 RationaleForForestEnergyProduction

CH1

ch1 revised id 110456 Nieznany

przykladowe zadania z fizyki jadrowej, Fizyka, 13.Fizyka jądrowa, mat ch1

cisco2 ch1 focus VRLS2G3H5FTBZYQ74NPB5LY5G4YM4HEVHUCF6TY

Ch1 Q3

Chromatografia cieczowa-CH1-CH2(1), NAUKA, chemia, lab

cisco2 ch1 concept T4CVTHOOK2UP7DYCEZ3YSGBWW62BKATM2APLUMY

cisco2 ch1 vocab HKRKBHHHSRQGUVIAIJ5YHAFAYK6FWYQNS7A2ILA

CH1

więcej podobnych podstron