Easy-to-make

Timber Bookcase

Other easy-to-make projects

from Pine Solutions Australia

ask for them at your local Stylewood distributor

Another do-it-yourself idea from Pine Solutions Australia

www.pinesolutions.com.au

Distributor

Easy-to-make Timber Bookcase

PROJECT MATERIALS LIST

Component

Material

Quantity

Purchase Size & Finished Size

Sides

Stylewood DAR

2 lengths

240mm x 19mm x 2400mm

CUT TO 2000mm long

5 shelves + top

Stylewood DAR

7 lengths

240mm x 19mm x 900mm

and bottom

CUT TO 862mm long

Back

Stylewood

7 lengths

140mm x 12mm x 2400mm

T&G Vee Jointed

CUT TO 2000mm long

Screws

Countersunk Rib

34 pieces

Head Chipboard

of 50x8g

Nails

-

as required

PVA Adhesive

-

as required

Sandpaper

Fine

as required

TOOLS YOU WILL NEED FOR THE JOB

Electric hand saw • Drill and bits • Square • Plane • Steps

STEP-BY-STEP INSTRUCTIONS

STEP 1.

Cut all the timber pieces to length, making sure all cuts are square. (See Finished Size

in Materials List.)

STEP 2.

Mark out the desired shelf spacing (optional) and pre-drill both side panels for the

screws. 2 screws per shelf will be adequate.

STEP 3.

Glue and screw each shelf. Start with the base and work up to the top on one side,

and then add the other side. Check regularly to ensure it is square and make sure

that the shelves are level with the sides.

STEP 4.

Once the shelves are in position, check again that the whole bookcase is square in all

directions.

STEP 5.

Now the 140 x12 T&G Vee Jointed boards can be fixed to the back of the unit.

STEP 6.

With the unit lying on its face, set out the Vee Jointed boards to cover the

back. Allow sufficient overhang on each side to permit

trimming. Glue and nail the

back in place on top, centre

and bottom shelves and sides.

Ensure the back is well nailed

to the sides.

STEP 7.

Trim off the overhang with the

saw, then plane to a smooth

finish.

STEP 8.

Sand the completed bookcase

all over, and apply your choice

of timber finish.

Safety warning: Inhalation of dust generated from processing Stylewood may cause irritation and sensitisation by inhalation (asth-

ma) and by skin contact (dermatitis). Repeated inhalation of wood dust increases the risk of nasal cavity cancer and of lung fibrosis

(scarring). Do not breathe dust, wear a respirator if using power tools. Phone 132 321 for a Material Safety Data Sheet.

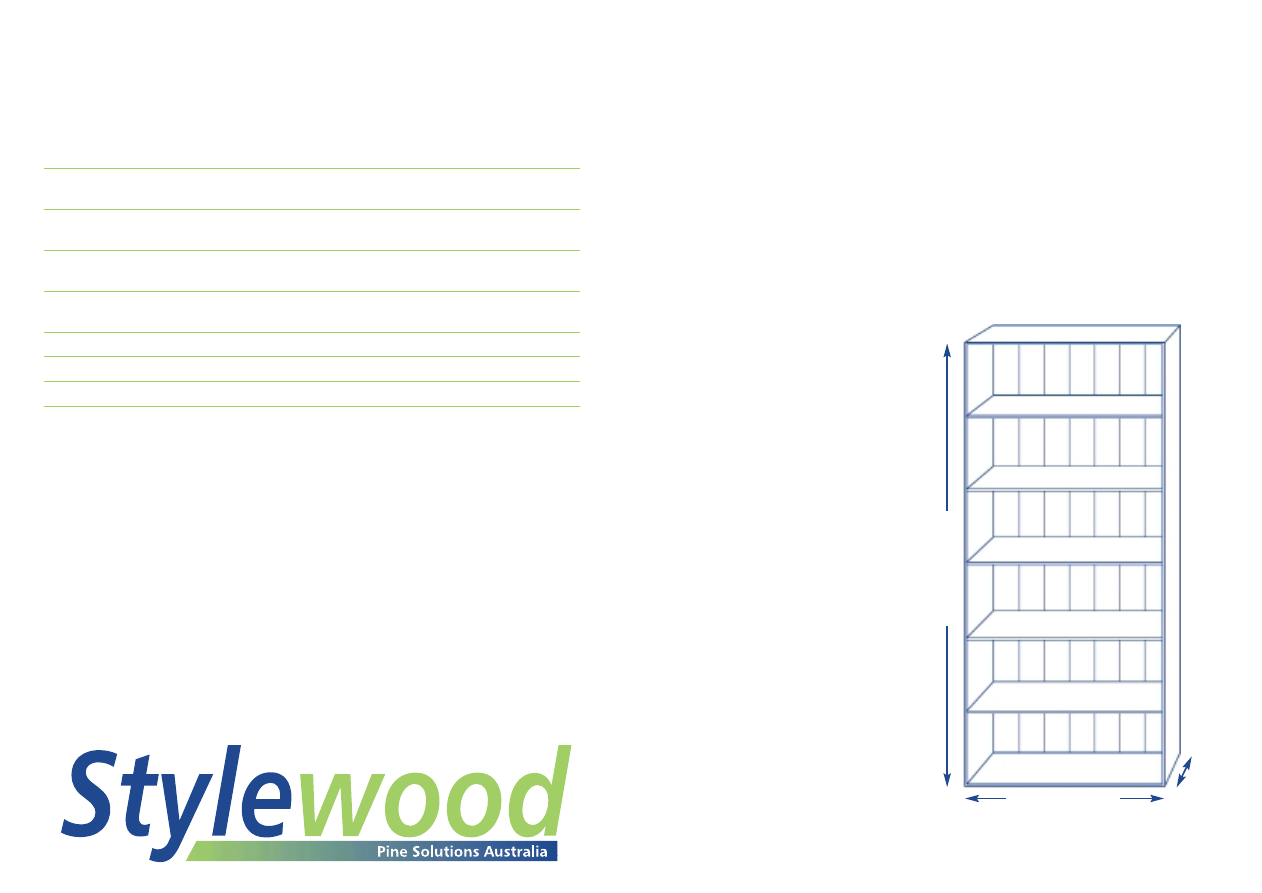

252mm

deep

900mm wide

2000mm

high

Wyszukiwarka

Podobne podstrony:

Woodworking Plans Timber Garden Shed Part I

(Ebooks) Diy Woodwork Plans Timber Garden Shed Part Ii

American Woodworker Two Part Bookcase id 58984 (2)

(madera) Woodworking plans Workbench Popular Mechanics Hard Maple

eBook DIY Woodworking Plans Guide To Wood Finishing

2 Woodworking plans settletable

(EBooks) DIY Woodwork Plans 10 Workbench Accessories

Woodworking Plans Garden Bench(1)

2 Woodworking Plans Standing Router Table

2 woodworking plans trestletable

Diy Workshop Woodwork Plans Drawings For Homemade Wood Lathe

Woodwork Plans Workbench

WoodWorking Plans Roll out Shelves

(Ebooks) DIY Woodwork Plans Drill Press Table

(Ebooks) Diy Woodwork Plans Kitchen Cabinets

2 Woodworking Plans Oakplate

Crafts Woodworking Plans (ebook) candle holder

więcej podobnych podstron