PRZEGL!D ELEKTROTECHNICZNY (Electrical Review), ISSN 0033-2097, R. 86 NR 10/2010 203

Lech GRODZKI

Bialystok Technical University - Faculty of Electrical Engineering

Constant-current driving of the LEDs' group

Abstract. Some LED applications need parallel driving of the groups of diodes. The article presents few selected chips designed to constant-current

LED driving. The paper contains the description of main properties of those integrated circuits and some results of realised research works on their

application features. Because the presented devices have SPI interface, they can be controlled by supervising microcontroller. The paper also

contains the proposal of automotive application, as the component of modern vehicle electrical system.

Streszczenie. Artyku! prezentuje kilka wybranych uk!adów scalonych przeznaczonych do sta!opr"dowego sterowania diodami LED. Obok

prezentacji cech u#ytkowych tych uk!adów, zawarto tak#e wybrane wyniki bada$ aplikacyjnych, zwi"zanych z wykorzystaniem interfejsu SPI do ich

sterowania przez mikrokontroler. Artyku! zawiera równie# propozycj% aplikacji uk!adów tego typu w nowoczesnej instalacji elektrycznej samochodu.

Ci!g"o-pr!dowe sterowanie grupowe diodami LED

Keywords: constant-current LED driving, LED group working, microcontrollers

S!owa kluczowe: sta!opr"dowe sterowanie LED, praca grupowa diod LED, mikrokontrolery

Group driving of LED diodes

Some LED applications are based on simultaneous

control of few or more devices. For example, they are used

for back-lighting other devices (like LCD displays,

illuminating advertising panels, etc.) or they perform

information functions directly, like traffic lights, road signs,

information panels, etc. In simplest case, LED driving

circuits in those applications have to switch on and off the

whole groups of LED devices. More advanced applications

need also the possibility of dimming the lighting sources.

That last feature allows to automatic control of emitting light

flux, according to external conditions, like external

illumination or the time of a day.

If group driving demands only simple switch on-off

features, without any brightness control, the driving circuits

can be reduced to bi-stable transistor valves. The

brightness control feature needs more complex circuits. To

achieve this feature, a PWM control of switching power

transistor has been applied, form many years [1, 2]. The

value of pulse width coefficient defines the switch-on and

switch-off periods of LED group. Increasing of that

coefficient causes the higher brightness of emitting light.

This dimming control idea is based on human eyesight

sense features: integrating light pulses and limited fast

event notification.

In last years some IC manufacturers started deliver the

integrated devices, which can control the constant current

supplying the LED. Such devices allow to more precise

control of LED brightness. Especially, integrated circuits

controlling few or more LED simultaneously are very

interesting for group LED driving.

Group driving ICs - general characteristics

Texas Instruments elaborated the series of integrated

circuits dedicated to the control of work of groups of LED

diodes. Among others, company offers either chips with 8

output channels - TLC5916/17 or 16 output channels -

TLC5926/27 [3, 4]. The characteristic feature of those ICs is

application of N controlled current sources, with commonly

adjusted current efficiency. Output current adjustment can

be realised in two ways:

1. By the change of the external resistor R

EXT

we can

define the maximum value of current source efficiency,

common for the all of outputs, according to formula:

(1)

EXT

OUTMAX

R

V

,

I

15

25

1

!

"

The internal construction and power dissipation

possibilities limit the range of output current I

OUTMAX

to

the range: 5 - 120 mA.

2. By sending via serial interface appropriate configuration

byte (Fig. 1). That byte determines the fraction of

maximum output current value I

OUTMAX

, defines by

formula 1, which states the present efficiency of current

sources. That fraction, called current gain (CG), can take

256 discrete values among the range: 1/12-127/128,

according to the following formulas.

(2)

#

$

%

&

'

(

)

)

"

64

1

4

1

CC

HC

VG

(3)

1

3

*

!

"

CM

VG

CG

where: CM, HC and 6-bit word CC are components of

the configuring byte.

After power-up devices work with default values:

CM

= 1, HC = 1, CC = 111111b. It means that CG equals

0,992 and causes maximum output current value

I

OUTMAX

, limited by external resistor R

EXT

. Figure 2 shows

the value of current gain CG depending on the value of

configuration byte with constant value of external

resistor R

EXT

.

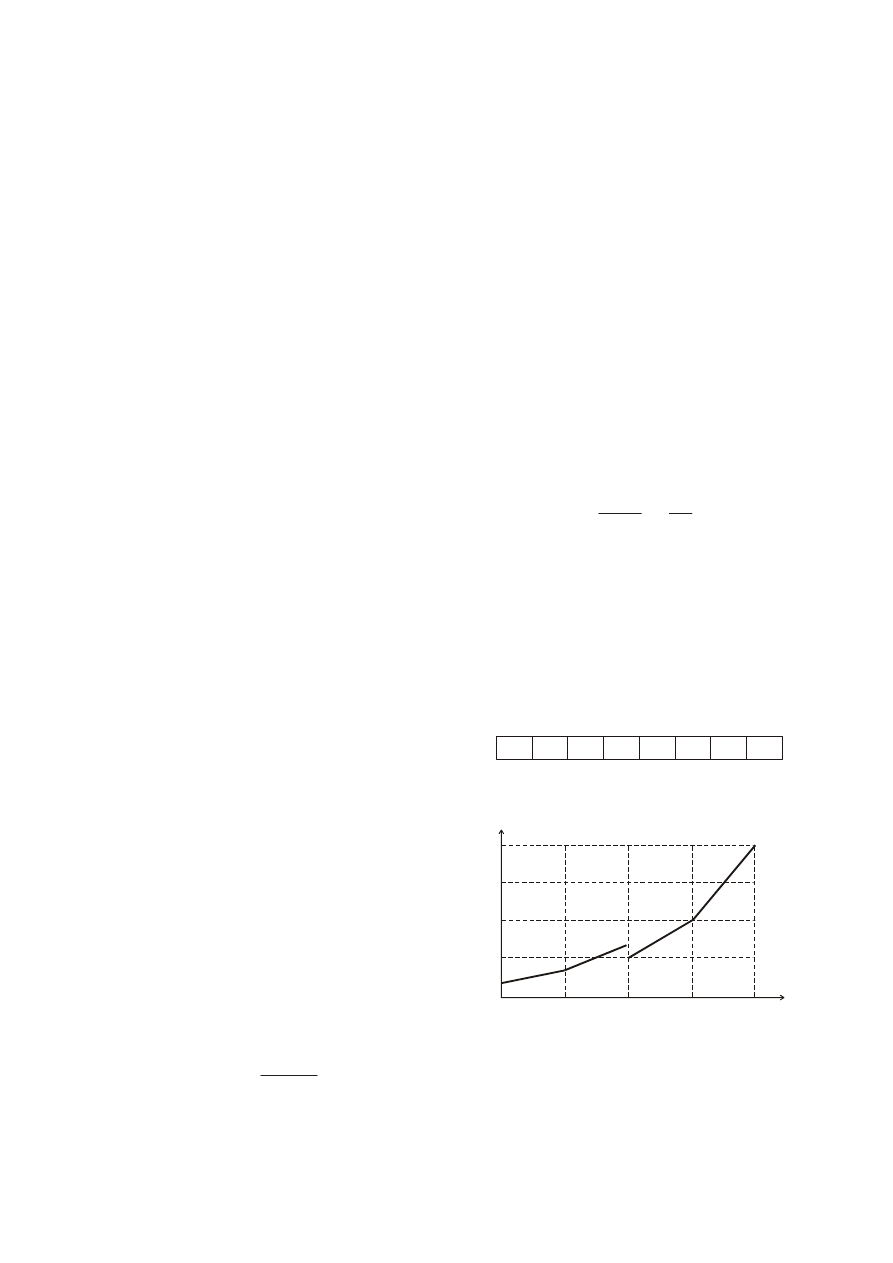

Fig.1. Configuration byte of TLC5916/17

Fig.2. Current gain (CG) versus value K of configuration byte

The utilization of the second method is possible only in

cooperation with supervising processor. Figure 3 shows the

testing circuit, used in described research works. It's a

typical application circuit for that family of integrated

devices. Microcontroller can manage the devices via serial

synchronous interface looking like SPI. This interface is

64

128

192

255

0,992

0,750

0,500

0,250

0,083

0

K

[-]

0

CG

[-]

CM

HC

CC

5

CC

4

CC

3

CC

2

CC

1

CC

0

204 PRZEGL!D ELEKTROTECHNICZNY (Electrical Review), ISSN 0033-2097, R. 86 NR 10/2010

used to transfer to IC driver on-off control word, switching

outputs OUT

X

, and configuration byte. The same interface

allows to read out the device status word, containing the

information about detected malfunctions of the output

channels. Control circuits of current sources can detect

following errors, separately for each channel:

+ open circuit - too low value of output voltage for

switched-on channel;

+ over-temperature shutdown in working output channel -

too high temperature of output circuit in given channel;

+ LED short-circuit - too high value of voltage for

switched-on output (only TLC5917 and TLC5927 ICs).

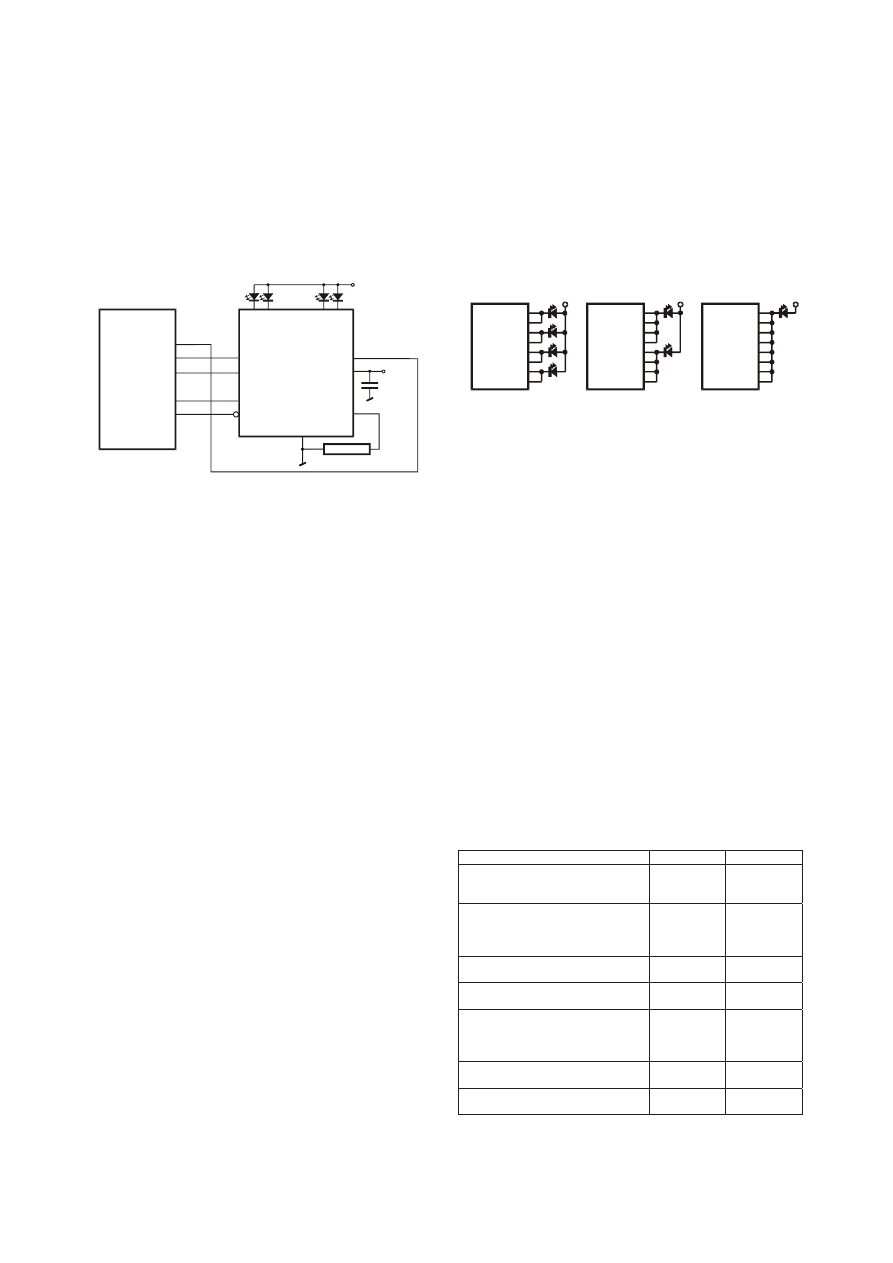

Fig.3. Testing circuit applied during research works

During simultaneous control of group of LED devices,

we try to achieve the same working points, as the condition

of steady brightness of several diodes. For presented IC

drivers manufacturer guarantees quite good output current

accuracy: ±3% between channels in the same chip and

±6% between different ICs. There are satisfied values,

looking at the typical divergence of LED working

characteristics.

Adjusting the LED forward current

In last capture two ways of output current adjustment

are pointed:

+

hardware method, by the changes of external resistor;

+

software method, utilizing the configuration byte

transferred to driver IC via serial interface.

The both methods allow to precise adjustment of LED

forward current. But the second of them is more suitable,

even though it needs the supervising microcontroller.

In practice, software method can realised in two ways:

1. External resistor R

EXT

is set to the value giving I

OUTMAX

current equal the needed LED forward current I

FLED

. It

causes that any configuration byte with value differ to

11111111b, written to IC driver will decrease the LED

current. We achieve the possibility of fluent control only

during dimming of LED group connected to the chip

output channels.

2. The value of the external resistor R

EXT

is set less then it's

described above. In such situation, the optimum LED

forward current I

FLED

we can achieve at current gain CG

less then 0,992 (I

FLED

< I

OUTMAX

). Then, before the

switching on the outputs OUT

X

, we should send to the IC

driver appropriate configuration byte, decreasing the

value of output currents I

OUT

. Presented solution results

in the less number of dimming steps, but also allows for

increasing the LED current over the chosen working

value. The possibility of occasional increasing the LED

luminance, can be very useful in some applications. For

example, if it is important to achieve the constant

luminance contrast between the vehicle signalling lamp

and the external lighting, it would be possible to

increase the luminous flux while the external luminance

flux reaches high values.

According to the application note [5], it’s possible to

point one another way of the output current adjustment,

especially useful for POWER LEDs. Even though the

maximum output current of each channel is equal 120 mA,

for driving of POWER LED devices it can be insufficient. In

such case, driver outputs can be connected in parallel, to

obtain controllable output current up to I

NOUTMAX

=

N

·120 mA. Using 8-channel TLC5916/17 ICs we can control

the 4, 2 or 1 POWER LED, up to 960 mA, according to their

forward currents - figure 4.

Fig.4. Possible POWER LED control configurations in order to their

forward current: a - up to 240 mA; b - up to 480 mA; c - up to

960 mA

In this way, we achieve additional method of POWER

LED current adjustment: simultaneous change the current

gain and the number of working paralleled channels. For

fluent dimming in wide range of LED forward current it's

sufficient to select the number of switched on channels and

the value of configuration byte. That additional POWER

LED current adjustment method widens the application

fields of presented IC drivers.

Selected results of tests

Data sheets of presented IC drivers states, that

maximum frequency of serial interface clocking signal is

equal 30 MHz. In practice, according to defined transfer

frame, does not matching fully to SPI standard, data

exchange between microcontroller and IC LED driver

should be realised under software control. The suitable

testing software, written in machine language, had been

prepared for testing circuit from figure 3. Programmes were

debugged and tested in IDE AVRStudio. The realised tests

with supervising microcontroller ATmega8515, clocked

frequency 10 MHz, allow to estimate software transfer

speed. Execution times of most important control operations

for TLC5916/17 and TLC5926/27 are presented in table 1.

Table 1. Execution time of selected software-implemented

operations for TLC5916/17 i TLC5926/27

Operation

TLC5916/17

TLC5926/27

control word transfer

(8b for TLC5916/17, 16b for

TLC5926/27)

11,1 #s

23,1 #s

configuring word (with current gain

coefficient) transfer

(8b for TLC5916/17, 16b for

TLC5926/27)

10,6 #s

16,3 #s

switching working mode from normal

to special

4,1 #s

4,1 #s

switching working mode from

special to normal

3,7 #s

3,7 #s

setting special working mode and

read out the error word

(8b for TLC5916/17, 16b for

TLC5926/27)

16,6 #s

26,2 #s

switching the LED group using /OE

signal

0,3 #s

0,3 #s

minimum period of SPI clocking

signal SCLK

0,4 #s

0,4 #s

SDI

CLK

LE

OE

SDO

VDD

REXT

O

U

T

0

O

U

T

1

:

:

:

O

U

T

6

O

U

T

7

G

N

D

PB6/MISO

PB5/MOSI

PB7/SCK

PB4

PB3

U

LED

R

EXT

U

CC

100nF

ATmega8515

TLC5916/17

U

LED

TLC5916/17

a)

U

LED

TLC5916/17

b)

U

LED

TLC5916/17

c)

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

PRZEGL!D ELEKTROTECHNICZNY (Electrical Review), ISSN 0033-2097, R. 86 NR 10/2010 205

The analysis of the table contents leads to a conclusion

that: for 8-channel driver switching word and configuration

byte can be updated about 90000 times per second. The IC

with 16 outputs is served slower.

Three of the mentioned in table 1 operations can be

supported by hardware SPI interface. It give us a shorter

execution times, as it is shown in table 2.

Table 2. Execution time of some operations using hardware SPI

interface for TLC5916/17 i TLC5926/27

Operation

TLC5916/17 TLC5926/27

control word transfer

(8b for TLC5916/17, 16b for

TLC5926/27)

5,7 #s

9,4#s

configuring word (with current

gain coefficient) transfer

(8b for TLC5916/17, 16b for

TLC5926/27)

6,6 #s

10,3 #s

setting special working mode and

read out the error word

(8b for TLC5916/17, 16b for

TLC5926/27)

14,0 #s

18,2#s

Application proposal

One of the possible applications of presented LED IC

drivers is their usage in vehicle signalling lamps. The aim is

designing, for instance, car STOP lights with ability of self-

adjusting their luminance, according to changing ambient

conditions, to guarantee the optimal luminance contrast

between activated signalling lamps and other vehicle lights

or ambient luminance. It should be noted, that adaptive

signalling vehicle lamps are already allowed by international

standards [6]. The concept of such car lamp was described

among other in [7]: proposed solution can be realised on

the base of local analog-digital circuit, adjusting the light

source supply voltage. The usage of local microcontroller

and IC LED driver really increases the construction

functionality.

TLC59xx

,C

SPI

CAN

12V

LS1

LS2

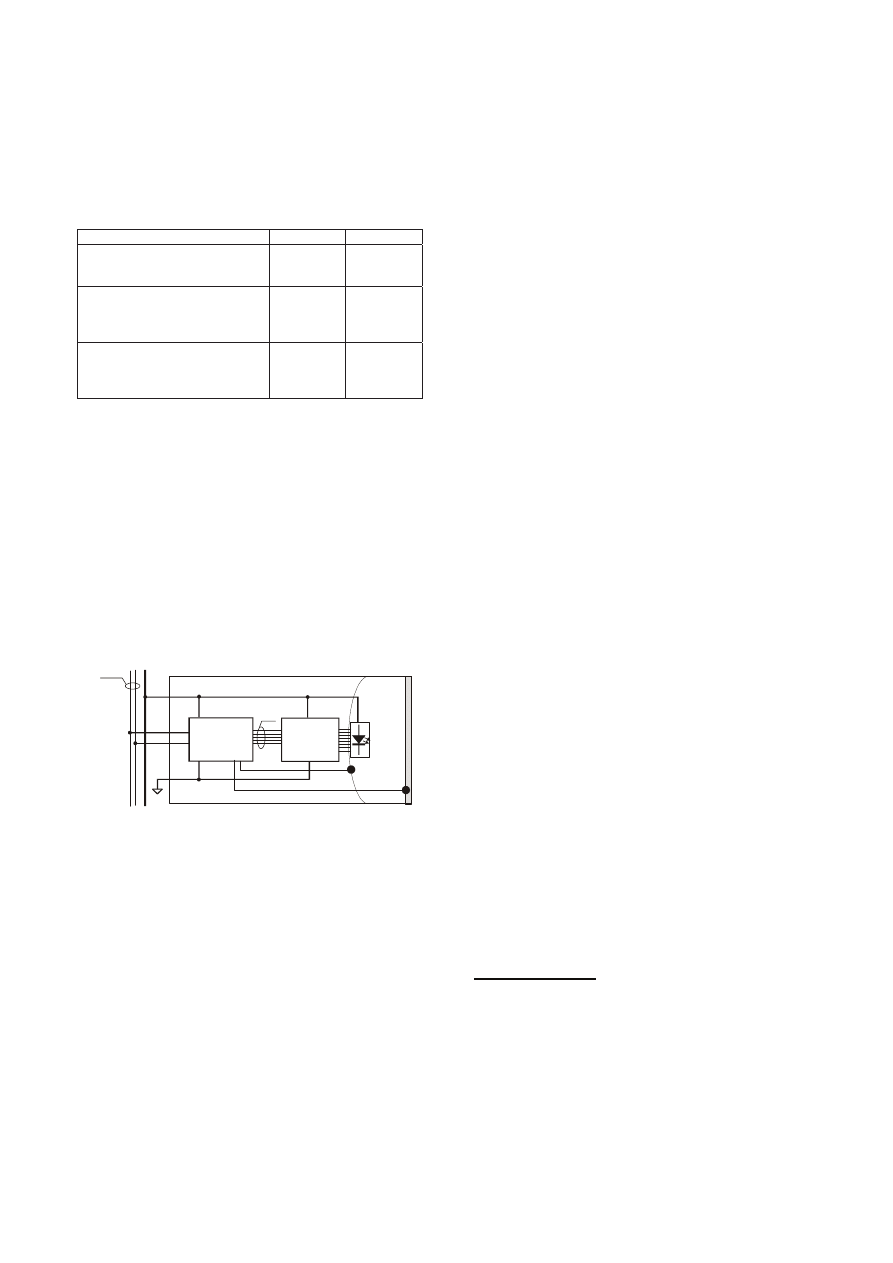

Fig.5. The proposal of intelligent vehicle signalling lamp

In proposed solution (Fig. 5) local microcontroller is

connected with LED driver by SPI interface. Using that

interface microcontroller sends to LED driver orders to

control the light source (switch on, switch off, brightness

adjustment), according to orders, received via CAN bus

from supervising computer.

Using the local light sensors LS1 and LS2 [7] and the

messages from CAN bus, microcontroller decides about

LED current adjustment. In addition, using the features of

TLC59xx chips, it can test the efficiency of group of LEDs.

As it was described earlier, troubles, like short break,

short-circuit, over-temperature shut down, in any output

channel are indicated in read out status word. This

information should be transfer to the vehicle central

computer. It can be also used locally to adjust the light

source, by increasing the currents in others active LED

supplying channels, to maintain the ordered luminance flux.

Suggested automotive application of TLC59xx family chips

can be applied also in classical electrical vehicle net. In that

case, local microcontroller of signal lamp should trace the

state of dedicated signal line instead the receiving

messages via CAN bus.

Conclusion

Integrated circuits providing constant current supplying

LEDs are offered by others manufactures, too. For

example, National Semiconductors offers several ICs, but

those chips have only single [8] or no more then few [9]

controlled outputs. In addition their applications need some

discrete external elements, like resistors, capacitors and

coils. Moreover, LED brightness adjustment is realised by

PWM signal provided to special terminal of ICs. Integrated

LED drivers with 8 or 16 output channels are also offered by

Allegro MicroSystems [10]. But embedded SPI interface

allows only for switching and checking LED diodes.

Dimming is possible only using additional PWM control

signal.

Watching the broadening offer of LED constant current

IC drivers, it is possible to suppose, that those chips will find

durable place for themselves in the wide range of LED

applications.

Presented results are the part of research work No S/WE/1/06.

REFERENCES

[1] Wojtkowski W.: Wielokana!owa regulacja jasno$ci $wiecenia

diod LED z wykorzystaniem uk!adów programowalnych FPGA.

Przegl"d Elektrotechniczny, 85 (2009), nr 11, 310-312.

[2] Wojtkowski W.: Wykorzystanie sprz%towych bloków PWM

mikrokontrolerów AVR do regulacji jasno$ci $wiecenia diod

LED du&ej mocy. Przegl"d Elektrotechniczny, 85 (2009), nr

11, 306-309.

[3] Texas Instruments: TLC5916, TLC5917 8-bit constant-current

LED sink drivers. Datasheets on www.ti.com. 2008.

[4] Texas Instruments: TLC5926, TLC5927 16-bit constant-

current LED sink drivers. Datasheets on www.ti.com. 2008.

[5] Day M.: LED driver - Paralleled Outputs Provide High-Current

Outputs. Application report on www.ti.com. 2006.

[6] Mo'ko W., Ka(mierczak P., )ukasik M.: Luminance contrast of

vehicle signalling lamps. Przegl"d Elektrotechniczny, 85

(2009), nr 11, 272-275.

[7] )ukasik M.: The concept of the wheeled vehicle's adaptive

stop lamps operation. Przegl"d Elektrotechniczny, 84 (2008),

nr 8, 186-189.

[8] National Semiconductors: LM3402/LM3402HV 0.5A constant

Current Buck Regulator for Driving High Power LEDs.

Datasheets on www.national.com. 2008.

[9] National

Semiconductors:

LM3432/LM3432B

6-Channel

Current Regulator for LED Backlight Application. Datasheets

on www.national.com. 2008.

[10] Allegro

MicroSystems:

Constant-Current

LED

Drivers.

Application Information AN29503 on www.allegromicro.com.

2007.

Author: dr in#. Lech Grodzki, Politechnika Bia!ostocka, Wydzia!

Elektryczny, ul. Wiejska 45D, 15-351 Bia!ystok, E-mail:

lgrodzki@we.pb.edu.pl

Wyszukiwarka

Podobne podstrony:

Constant current driving of the LEDs group

Constant current driving of the RGB LED

Constant current driving of the RGB LED

Edge of the Empire Group Sheet

fitopatologia, Microarrays are one of the new emerging methods in plant virology currently being dev

Consolidated Financial Statements of the Group & Bank Mellat

Legg Calve Perthes disease The prognostic significance of the subchondral fracture and a two group c

Melin E The Names of the Dnieper Rapids in Chapter 9 of Constantine Porphyrogenitus De administrando

Dan Mills Sniper One The Blistering True Story of a British Battle Group Under Siege (rtf)

Soliwoda, Katarzyna i inni The influence of the chain length and the functional group steric access

Pavsic Clifford Algebra of Spacetime & the Conformal Group (2002) [sharethefiles com]

Geoffrey de Villehardouin Memoirs or Chronicle of The Fourth Crusade and The Conquest of Constantin

THE GHOST SHIP Current state of research and project plan for maritime

Eringer Robert, The Global Manipulators, The Bilderberg Group Trilateral Commission Covert Power Gro

Measurements of the temperature dependent changes of the photometrical and electrical parameters of

Future Of The Dollar As World Reserve Currency Forbes

Aspden The Theory of the Proton Constants (1988)

więcej podobnych podstron