* Corresponding author. Tel.: #81-88-633-7333; fax: #81-88-633-

9125.

E-mail address: asaoka@dent.tokushima-u.ac.jp (K. Asaoka).

Biomaterials 22 (2001) 2257}2262

Degradation and fracture of Ni}Ti superelastic wire in an oral cavity

Ken'ichi Yokoyama , Kenichi Hamada , Keiji Moriyama

, Kenzo Asaoka *

Department of Dental Engineering, School of Dentistry, Tokushima University, 3-18-15 Kuramoto-cho, Tokushima 770-8504, Japan

Department of Orthodontics, School of Dentistry, Tokushima University, 3-18-15 Kuramoto-cho, Tokushima 770-8504, Japan

Received 21 June 2000; accepted 25 November 2000

Abstract

Superelastic Ni}Ti wire is widely used in orthodontic clinics, but delayed fracture in the oral cavity has been observed. Because

hydrogen embrittlement is known to cause damage to Ti alloy systems, orthodontic wires were charged with hydrogen using an

electro-chemical system in saline. Tensile tests were carried out, and fracture surfaces were observed after hydrogen charging. The

strength of the Co}Cr alloy and stainless steel used in orthodontic treatment, was not a!ected by the hydrogen charging. However,

Ni}Ti wire showed signi"cant decreases in strength. The critical stress of martensite transformation was increased with increasing

hydrogen charging, and the alloy was embrittled. The fractured surface of the alloys with severe hydrogen charging exhibited dimple

patterns similar to those in the alloys from patients. In view of the galvanic current in the mouth, the fracture of the Ni}Ti alloys might

be attributed to the degradation of the mechanical properties due to hydrogen absorption.

2001 Elsevier Science Ltd. All rights

reserved.

Keywords: Hydrogen; Ni}Ti alloy; Superelasticity; Orthodontic wire; Tensile strength

1. Introduction

Many alloy systems show shape memory and/or

superelastic behavior but a few of themhave been de-

veloped on a commercial scale for industrial and medical

use. In these alloys, recent innovations in the processing

of Ni}Ti alloy systems have improved both mechanical

properties and formability [1]. The alloy has shown

excellent ductility and fatigue life, and typical ductile

features such as reduction in the area at fracture and

dimple patterns in its fracture pattern [2]. Because of

their good corrosion resistance and biocompatibility,

Ni}Ti alloys as well as titanium, titanium alloys, Co}Cr-

based alloys and stainless steels have been successfully

used as biomaterials [3}8]. Ni}Ti arch wire is widely

used in orthodontic clinics because it allows the teeth to

move under almost constant force over a long treatment

time, and a much larger displacement of the teeth can be

achieved before the dentist has to retighten the wire.

However, it is known that some wires may break in the

oral cavity after a few months from setting. Some dentists

have recognized that the alloy is pliable during setting

but that the broken wire had lost its deformability [9].

Research on hydrogen fuel as a substitute for fossil fuel

lead to the development of hydrogen storage alloys. In

such research, alloy systems such as titanium, zirconium,

nickel and palladiumalloys were identi"ed as materials

having the ability to absorb hydrogen. Furthermore,

hydrogen absorption was shown to degrade the mechan-

ical properties of those alloys [10]. For example, the

delayed fracture of high-strength steel was attributed to

hydrogen absorption in ambient air [11]. Mechanisms of

hydrogen embrittlement of the alloy are not clearly

understood [12,13]. The absorption of hydrogen easily

occurs in a bioenvironment compared with the ambient

air because hydrogen ions exist in saliva and galvanic

currents may accelerate absorption. Fretting corrosion

might be a contributing factor because hydrogen ions

generally are associated with repassivation of the alloys

with an oxide "lm. The alloys under the same chemical

concentration of hydrogen do not always show brittle-

ness, because hydrogen susceptibility is a unique prop-

erty of the individual alloy.

The e!ect of hydrogen uptake on functions of shape

memory and/or superelasticity for Ni}Ti alloys was

studied [14}16]. However, delayed fracture due to hy-

drogen embrittlement has not been studied in the dental

0142-9612/01/$ - see front matter

2001 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 0 0 ) 0 0 4 1 4 - 2

Table 1

Compositions and lot numbers of the commercial orthodontic wires

used

Wire alloy

Brand name

General compositions

(wt%)

Lot number

Ni}Ti

Sentalloy light

55.8% Ni, 44.2% Ti

D4043

Co}Cr

Elgiloy blue

40% Co, 20% Cr,

15% Ni, 15.8% Fe,

7% Mo, 2% Mn,

0.15% C, 0.04% Be

19990614

Stainless

steel

Tomy staineless-

steel red

17}20% Cr, 8}12%

Ni, 0.15% C maxi-

mum, balance

principally Fe

A399

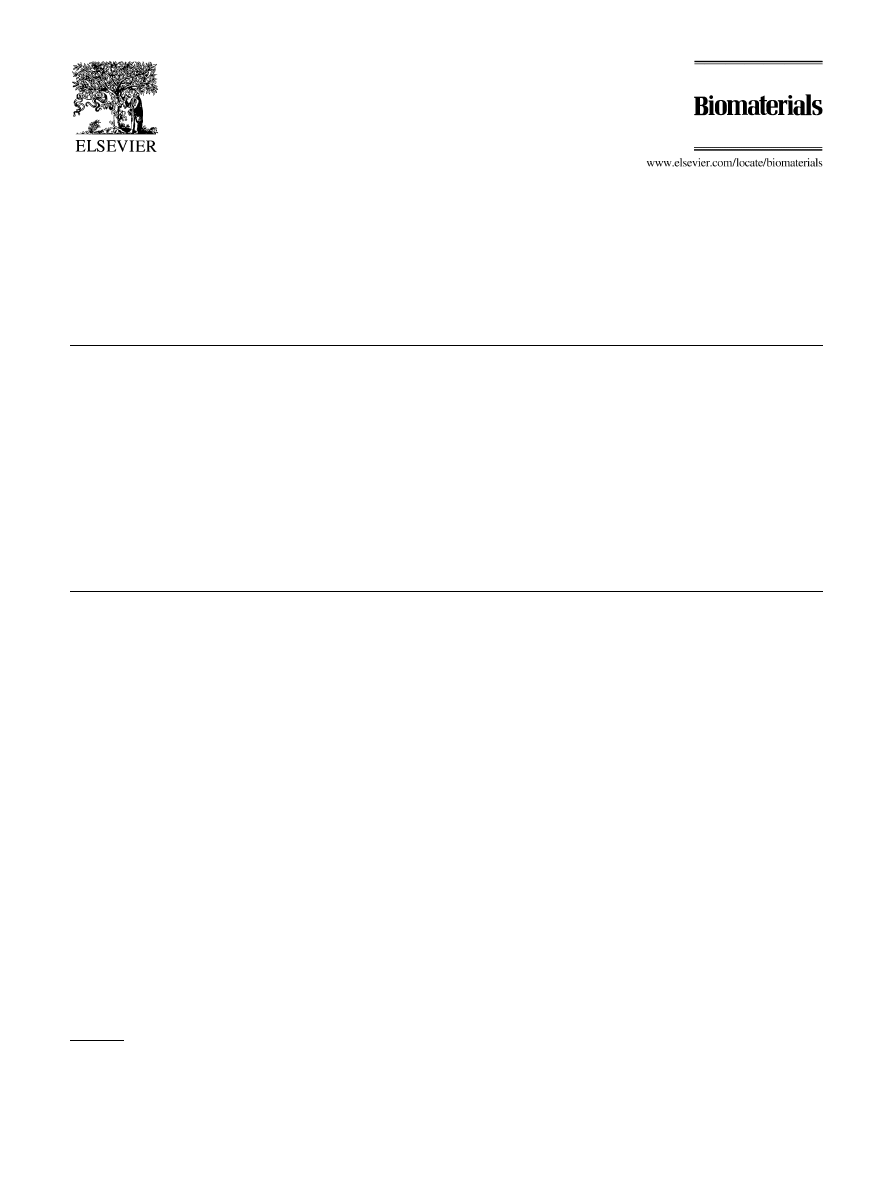

Fig. 1. Scheme of hydrogen charging system by electrolysis.

or medical "eld. Corrosion, fatigue and abrasive wear of

medical/dental devices are reported, but degradation of

its mechanical properties due to microstructural change

has not been touched upon [4,17]. In general, the e!ect of

hydrogen on the mechanical properties of the alloys is

tested using exposure or immersion tests. However, these

tests are not practical because the alloys must be kept in

a speci"c environment for long periods. Hydrogen em-

brittlement of Ni}Ti wires could occur in service. The

aimof this work is to evaluate the conditions of its

occurrence, its extent, and its e!ects on the mechanical

properties of the wires. For this purpose, accelerated

hydrogen embrittlement tests using an electro-chemical

reaction in saline solution were carried out. Stress}strain

curves of the alloys charged with hydrogen were mea-

sured and related to the current density as an indication

of the hydrogen concentration. The fracture surfaces of

the samples were observed.

2. Materials and methods

Three kinds of commercial orthodontic wires with

a diameter of 0.56 mm are used, i.e., Ni}Ti alloy (Sental-

loy Light, Tomy International Inc., Tokyo, Japan),

Co}Cr alloy (Elgiloy Blue, Rocky Mountain Morita Cor-

poration, Tokyo, Japan) and stainless-steel (Tomy Stain-

less-Steel Red, Tomy International Inc., Tokyo, Japan).

Compositions and lot numbers are listed in Table 1.

A direct-current generator (7011DC Signal Source,

Hioki, Ueda, Japan) was used for the charging of hydro-

gen, as shown in Fig. 1. Platinumand the specimen alloy

were based in 0.9% NaCl solution as the anode and

cathode, respectively. Gaseous hydrogen, which was gen-

erated on the surface of the sample, was controlled by the

current density. The alloys were charged with hydrogen

at roomtemperature for 24 h with di!erent current dens-

ities of 100, 200 and 300 A/m

. For Ni

}Ti alloys, speci-

mens with current densities of 1, 2, 5, 7, 10, 15 and

20 A/m

were arranged. The e

!ect of charging time on

the mechanical properties of the alloys was measured

under constant current densities of 1, 2, 5 and 10 A/m

,

up to 144 h. Tensile tests of the charged alloys were

carried out at roomtem

perature on an Instron-type

machine (Autograph AG-100A, Shimadzu, Kyoto, Ja-

pan) at a strain rate of 8.33

;10\/s within a few minutes

after removal from the electrolytic bath. Here, the total

length of the specimen was 50 mm and a gage length of

10 mm was used. Apparent strain was calculated from the

displacement of the cross-head position and initial gage

length. To assure quality of the as-received Ni}Ti wires,

stress}strain curves were measured and statistical analy-

sis was carried out. The fractured surface after rupture

test of each specimen was observed by scanning micros-

copy.

3. Results

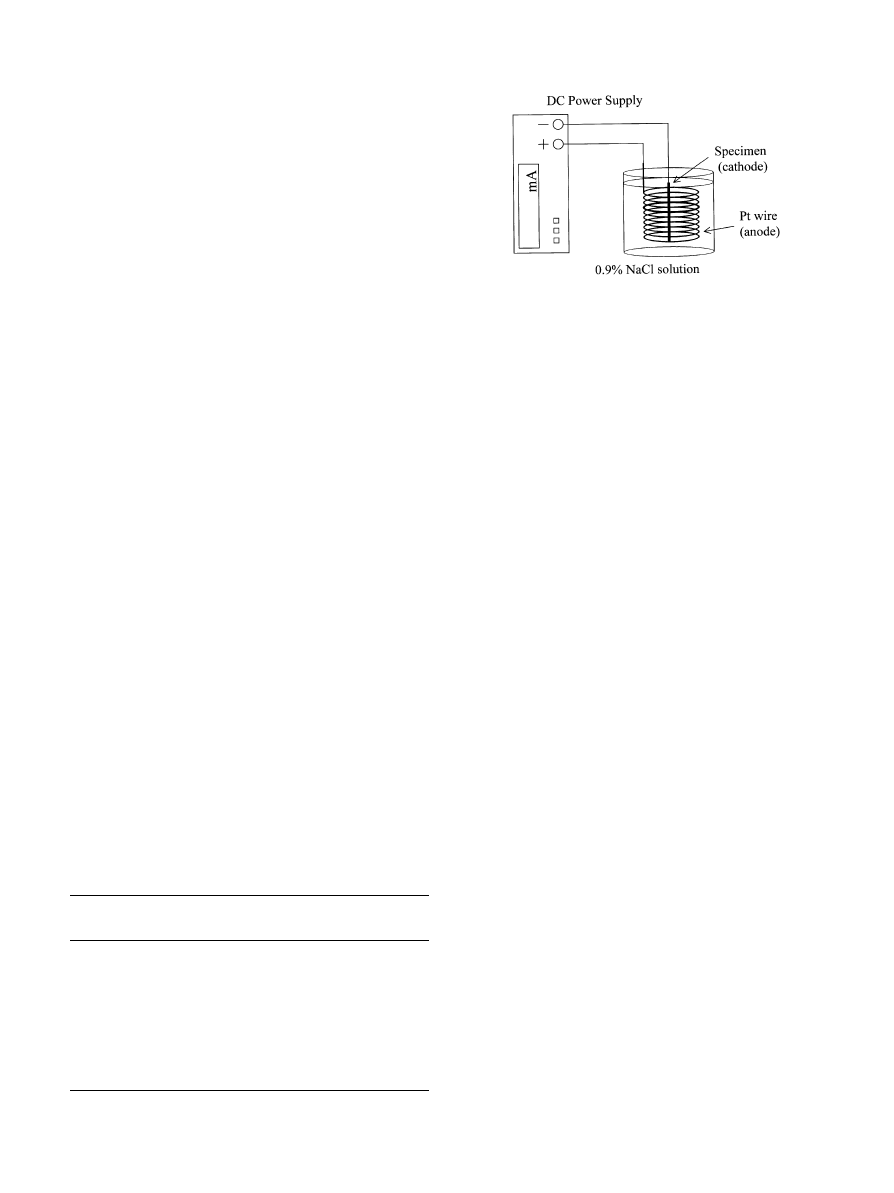

Tensile strength of the Co}Cr and stainless-steel alloys

charged with hydrogen for 24 h, was not a!ected by the

charged hydrogen, as shown in Fig. 2. However, the

Ni}Ti superelastic alloys exhibited typical hydrogen em-

brittlement (decrease of strength). Typical superelastic

strain was observed for the as-received Ni}Ti alloys; that

is, after reaching a critical transformation stress

(240 MPa), the alloy starts to transform(fromaustenite

to martensite). During further straining, the stress at

which the transformation occurs is almost constant until

the material is fully transformed. Further straining leads

to elastic loading of the martensite, followed by plastic

deformation and fracture (1164 MPa). Tensile strength

and transformation stress of the as-received wires were

1164$6 MPa and 240$5 MPa, respectively, for seven

samples. Here, the standard deviation was calculated

(p(0.05). This result indicated that the wires used were

high-quality products. Thus, the roles of impurities and

scratches were negligible factors in fracture mechanics.

Because measurement of the exact amount of hydrogen

absorbed in the alloy after charging is di$cult, the

stress}strain curves were measured for the alloys with di!er-

ent experimental conditions of charging and compared.

2258

K. Yokoyama et al. / Biomaterials 22 (2001) 2257}2262

Fig. 2. Each symbol represents the strength of the sample with the

charged hydrogen which was controlled by the current density. Charg-

ing time of 24 h is measured.

Fig. 3. Stress}strain curves of the Ni}Ti superelastic alloy charged with

hydrogen and as-received alloy. Current densities of 1, 2, 5, 7, and

10 A/m

are charged for 24 h. Strain is calculated fromelongation

(displacement of cross-head) and the initial gauge length.

Fig. 4. Each symbol represents the critical stress due to stress-induced

transformation (from austenite to martensite) and tensile strength of the

Ni}Ti superelastic alloy which had been charged with hydrogen with

controlled current density. Charging time of 24 h is used.

Fig. 5. Each symbol represents the tensile strength of Ni}Ti alloys

which had been charged at di!erent current densities and charging

times.

The strength of the superelastic alloys decreased from

1200 to 400 MPa after the absorption of hydrogen. The

stress}strain curves of the Ni}Ti alloys charged with

hydrogen for 24 h are shown in Fig. 3. The lower limit of

the strength was about 400 MPa less when restricted to

current density higher than 7 A/m

, as shown in Fig. 4. At

the higher current density of 10 A/m

, the alloy was

fractured under the critical stress of martensitic trans-

formation. Critical stress for martensitic transformation

increased with from200 to 400 MPa when a high current

density was supplied.

Fig. 5 shows the e!ect of charging time on the strength

of the Ni}Ti alloys. Here, the densities of direct current 1,

2, 5 and 10 A/m

are plotted. In these results, only the

data of 1 A/m

indicated a large spread of values in

tensile strength. The critical stress does not increase with

the charging time for 1 A/m

, and the sample breaks after

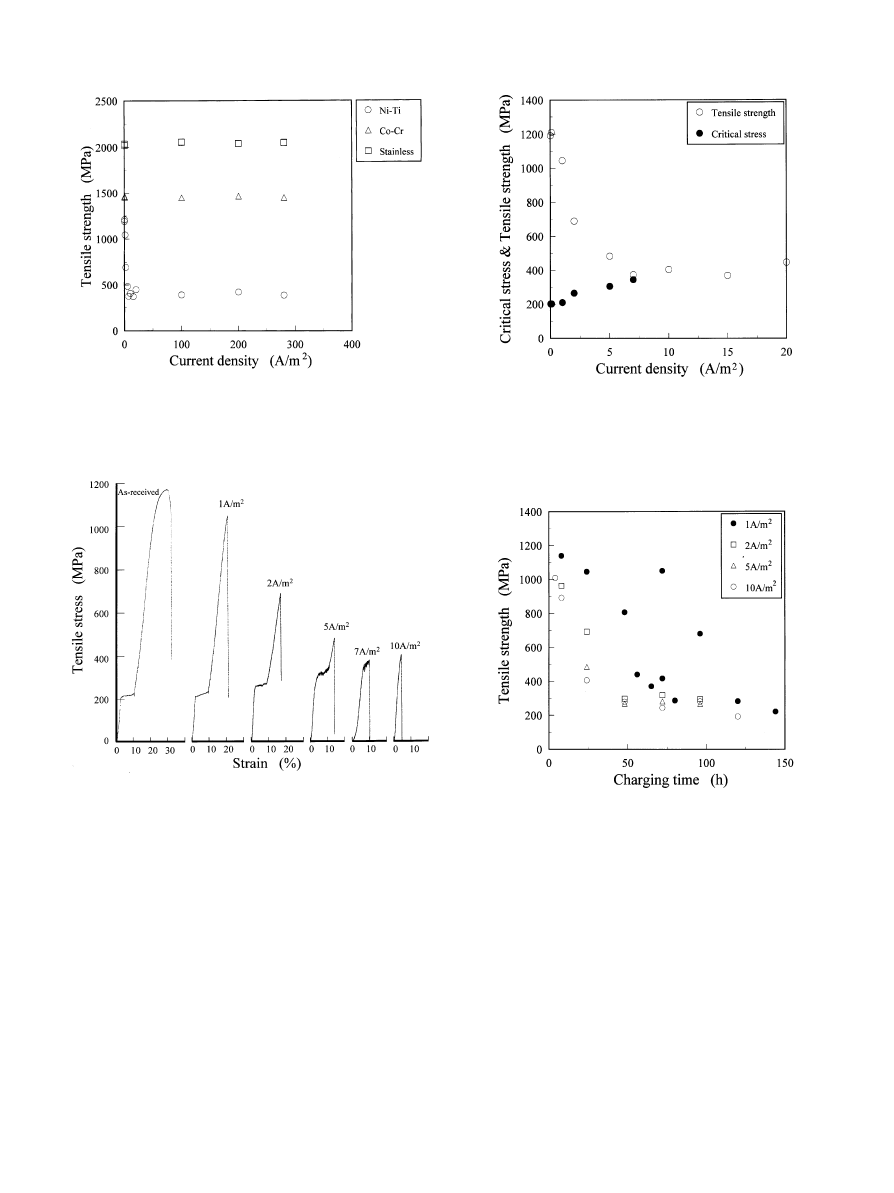

stress-induced transformation. Stress-strain curves of the

alloys, which had been charged with 1 and 10 A/m

are

shown in Fig. 6.

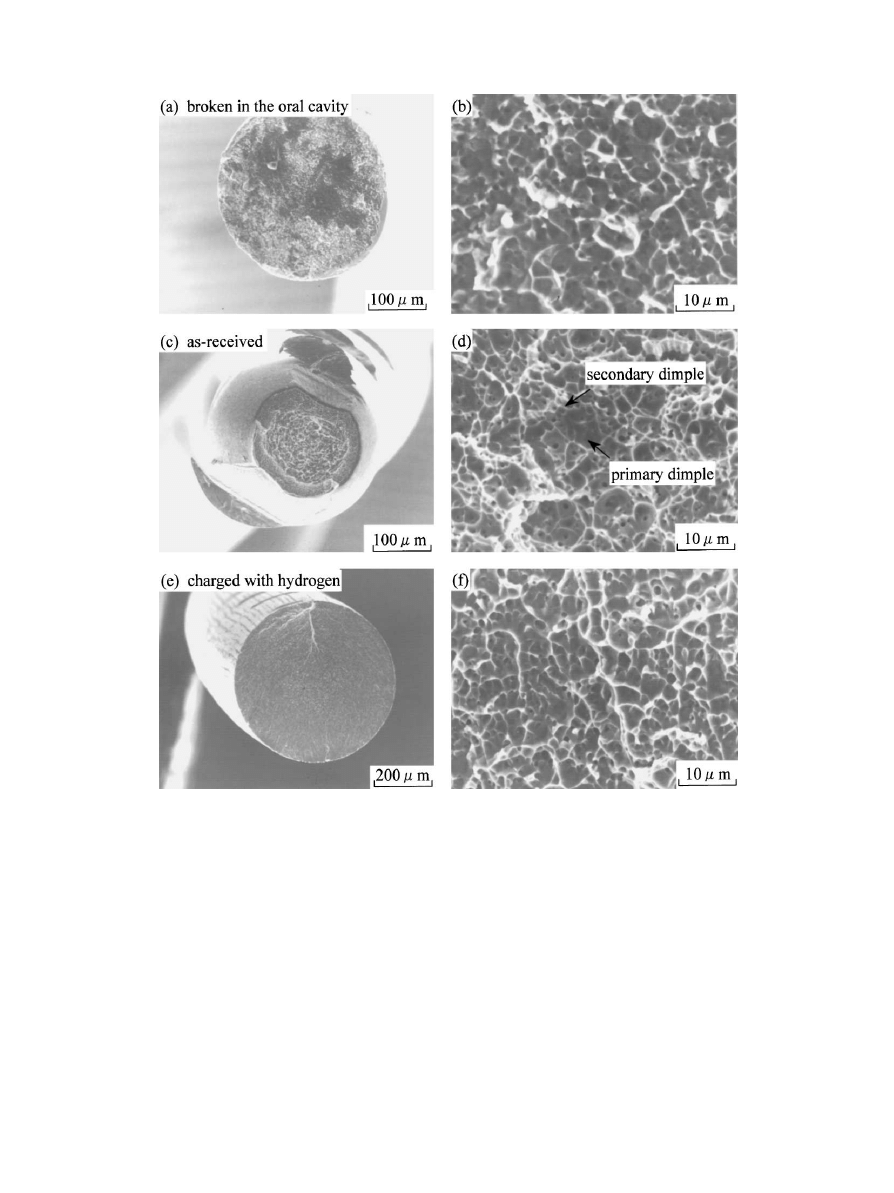

Fig. 7(a) and (b) show the fracture surface of a super-

elastic arch wire, which broke in an oral cavity. The wire,

K. Yokoyama et al. / Biomaterials 22 (2001) 2257}2262

2259

Fig. 6. Typical stress-strain curves of the Ni}Ti superelastic alloy with

hydrogen charging. Current densities of 1 or 10 A/m

in given periods

of time were charged for each alloy.

which had been suspended for about one month by the

orthodontic brackets, was taken o! when the patient

returned for follow-up treatment. The typical reduction

in the area at fracture could not be con"rmed from Fig.

7(a). The alloy was washed in acetone using ultrasonic

cleaning equipment, but accretions were still observed.

The fracture surfaces of the as-received and hydrogen-

charged wires tested are shown in Fig. 7(c), (d) and (e), (f),

respectively. The reduction in the area is observed in

Fig. 7(c) for the as-received alloy. Ductile surfaces are

characterized by dimple morphology, which indicates

local strain. For as-received alloy, small dimples (second-

ary dimples) were observed in the areas between large

dimples (primary dimples), as shown in Fig. 7(d). How-

ever, dimples in Fig. 7(b) and (f ) are only primary and

shallow. These fracture micrographs indicated that the

as-received alloy had ductility but the alloys fractured in

an oral cavity and hydrogen severely charged were frac-

tured without plastic deformation. Dimples that are

hemispherical or equiaxial may form from the in#uence

of uniformplastic strain in the direction of applied stress.

The size of the dimple is determined by factors such as

the size of the inclusions, precipitate particles, and their

densities as well as the amount of plastic growth that

takes place. Secondary dimples may form in association

with the development of primary dimples. A high density

of inclusions (hydrides) may lead to low ductility and no

secondary dimpling.

4. Discussion

4.1. Hydrogen embrittlement of Ni}Ti alloy

Degradation by hydrogen absorption was only ob-

served for Ni}Ti in orthodontic wires (Fig. 2). The prom-

inent features of hydrogen embrittlement [10,12,18,19]

are as follows. (1) Small reduction of the area is exhibited

at fracture. (2) Surface and internal layers have di!erent

patterns of fractography, i.e., the surface layer exhibits

brittle fracture due to hydrogen absorption. (3) For cer-

tain alloys, a high degree of grain re"nement is observed.

Hydrogen absorption of the Ni}Ti alloys tested was

con"rmed from the degradation of mechanical proper-

ties, small reduction of the area and the typical fracture

features. Because the stress state and strain rate di!er

between the alloys in the mouth (bending with tension)

and the specimen in a tensile machine (pure tension),

di!erent dimple morphology such as the shape and size

are shown in Fig. 7(b) and (f ). However, both micro-

graphs show only shallow primary dimples and low duc-

tility. Fromthese common features, it was concluded that

the wire was broken by the occlusion of hydrogen in the

mouth. Titanium alloys are known as hydrogen absorb-

ent alloys [10]. In these alloys, hydrogen absorption can

occur not only in a solution of dissolved hydrogen ions,

but also in ambient air.

4.2. Mechanism of hydrogen embrittlement

The most probable mechanism for the absorption of

hydrogen within the alloy is inter-atomic di!usion from

the surface inward. Grain boundaries, dislocations in the

vicinity of impurity atoms and precipitated particles are

the positions for hydrogen accumulation [12,13]. When

the alloy is loaded, the absorption of hydrogen might be

accelerated because of expanded interatomic space and

increased density of dislocations. In this study, hydrogen

uptake is thought to be due to the following process, i.e.,

the gaseous hydrogen, which was generated by electroly-

sis was absorbed into the alloy, and di!used through it.

The surface layer of the wire was "rst embrittled by the

hydrogen. The hydrogen absorption of the wire, which

was set as an orthodontic attachment was accelerated

because the alloy was under tension. When the wire is

kept under the transformation (critical stress) stress-state,

hydrogen absorption might be accelerated.

4.3. Hydrogen absorption in oral cavity

It is not clear that the Ni}Ti alloy can naturally absorb

the hydrogen in saliva [9]. However, there are several

possible electrode systems in the mouth. One possible

systemis electric current due to electrolytic action in the

mouth. The galvanic currents between gold and amal-

gamwere determined in aerated arti"cial saliva kept at

2260

K. Yokoyama et al. / Biomaterials 22 (2001) 2257}2262

Fig. 7. Fractography of the Ni}Ti superelastic wires. (a) and (b) Ni}Ti superelastic wire which was broken in the oral cavity during use. (c) and (d)

as-received Ni}Ti superelastic wire. (e) and (f ) the wire which had been charged with hydrogen at current density of 1 A/m

for 120 h. Primary dimpling

is responsible for plastic deformation and secondary dimpling occurs only in high ductile fracture surfaces.

373C, and were reported to reach 2 A/m

[20]. Relative

position, shape, size and constitution of the restorated

alloys are the factors that determine the current density

in an oral cavity. Other factors are temperature, amount

and quality of saliva and the oral structure. Galvanic

current between the wire and the stainless-steel bracket is

also considered an electrolytic system. From these dis-

cussions, the current density of 1 A/m

used in this study

is not a high current, but is a possible condition in the

mouth. It is reasonable to assume that fretting corrosion

contributes to the hydrogen intake of the alloy with an

oxide "lm. Repassivation of titaniumand titaniumalloys

in water or saline can be represented as follows:

Ti#2HOPTiO#4H>#4e\.

(1)

For nickel and nickel alloys,

Ni#HOPNiO#2H>#2e\.

(2)

In these equations, hydrogen ions might act much in the

same way as does the hydrogen ion generated by the

electro-chemical reaction used in this research.

K. Yokoyama et al. / Biomaterials 22 (2001) 2257}2262

2261

4.4. Process to failure of the wire

In orthodontic treatments, Ni}Ti superelastic ar-

chwire, which was set in the mouth sustains a functional

stress of about 200 MPa. The wire, which was restricted

by brackets, was always kept at about 10% strain if the

wire did not undergo plastic deformation. When the alloy

absorbs hydrogen, the critical stress of martensite trans-

formation becomes higher, as shown in Fig. 3. Galvanic

currents and fretting corrosion can accelerate the absorp-

tion of hydrogen. This result suggested that the ortho-

dontic force increased with the increase of the critical

stress. At the same time, ductility of the alloy decreased

with the increase of hydrogen absorption. When the

strain restriction exceeds the fracture strain, the wire,

which had become brittle, may often fracture. The exact

process leading to the fracture of Ni}Ti wire, including

placement of the wire and skill of the orthodontist will be

considered further in a future paper.

Acknowledgements

This study was supported by the University of

Tokushima.

References

[1] Humbeeck JV, Stalmans R, Besselink PA. Shape memory alloys.

In: Helsen JA, Breme HJ, editors. Metals as biomaterials. Chi-

chester: Wiley, 1988. p. 73}100.

[2] Melton KN, Mercier O. Fatigue of NiTi thermoelastic marten-

sites. Acta Metall 1979;27:137}44.

[3] Oshida Y, Miyazaki S. Corrosion and biocompatibility of shape

memory alloys. Zairyo-to-Kankyo 1991;40:834}44.

[4] Shabalovskaya SA. On the nature of the biocompatibility and on

medical applications of NiTi shape memory and superelastic

alloys. Bio Med Mater Eng 1996;6:267}89.

[5] KimH, Johnson JW. Corrosion of stainless steel, nickel}titanium,

coated nickel}titanium, and titanium orthodontic wires. Angle

Orthod 1999;69:39}44.

[6] Rondelli G, Vicentini B. Localized corrosion behaviour in

simulated human body #uids of commercial Ni}Ti orthodontic

wires. Biomaterials 1999;20:785}92.

[7] Wever DJ, Veldhuizen AG, Sanders MM, Schakenraad JM, Horn

van

JR.

Cytoxicity,

allergic

and

genotoxic

activity

of

a nickel}titaniumalloy. Biomaterials 1997;18:1115}20.

[8] Wever DJ, Veldhuizen AG, Vries de J, Busscher HJ, Uges DRA,

Horn van JR. Electrochemical and surface characterization of

a nickel}titaniumalloy. Biomaterials 1998;19:761}9.

[9] Harris EF, Newman SM, Nicholson JA. Nitinol arch wire in

a simulated oral environment; Changes in mechanical properties.

AmJ Orthod Dentofac Orthop 1988;93:508}13.

[10] Nelson HG, Williams DP, Stein JE. Environmental hydrogen

embrittlement of

}

titaniumalloy: E

!ect

of microstructure.

Metall Trans 1972;3:469}75.

[11] BeachemCD. A new model for hydrogen-assisted cracking: hy-

drogen embrittlement. Metall Trans 1972;3A:437}51.

[12] Hirth JP. E!ects of hydrogen on the properties of iron and steel.

Metall Trans 1980;11A:861}90.

[13] Nagumo M. Fundamental aspects of hydrogen embrittlement of

iron. Materia Jpn 1994;33:914}21.

[14] Maslenkov SB, Budigina NB, Shorshorov MKH, Flomenblit

YUM. Shape memory e!ects, phase and structural transforma-

tions caused by hydrogen in alloys of the Ti}Ni system. Phys Met

Metallogr 1988;66:90}6.

[15] Adachi Y, Wade N, Hosoi Y. E!ect of hydrogen on the shape

memory e!ect and transformation behavior of Ti}Ni alloy. J Jpn

Inst Metals 1990;54:525}31.

[16] Asaoka T, Yamashita H, Saito H, Ishida Y. E!ect of a small

amount of hydrogen on pseudo-elastic properties of Ti}Ni alloy.

J Jpn Inst Metals 1993;57:1123}9.

[17] Ryhanen J, Niemi E, Serlo W, Niemela E, Sandvik P, Pernu H,

Salo T. Biocompatibility of nickel}titanium shape memory metal

and its corrosion behavior in human cell cultures. J Biomed

Mater Res 1997;35:451}7.

[18] Kerr WR. The e!ect of hydrogen as temporary alloying element

on the microstructure and tensile properties of Ti}6Al}4 V. Metall

Trans 1985;16A:1077}87.

[19] Yoshimura H, Kimura K, Hayashi M, Ishii M, Takamura J.

Ultra-"ne equiaxed grains obtained by process of hydrogenation:

aging and dehydrogenation in

# type titaniumalloys. J Jpn

Inst Metals 1991;55:1375}81.

[20] Holland RI. Galvanic currents between gold and amalgam. Scand

J Dent Res 1980;88:269}72.

2262

K. Yokoyama et al. / Biomaterials 22 (2001) 2257}2262

Wyszukiwarka

Podobne podstrony:

Shock Wave Deformation and Fracture of Zirconium Dioxide Ceramics of Various Fractional Composition

Degradable Polymers and Plastics in Landfill Sites

Legg Calve Perthes disease The prognostic significance of the subchondral fracture and a two group c

Degradable Polymers and Plastics in Landfill Sites

Szewczyk, Rafał; Długoński, Jerzy Pentachlorophenol and spent engine oil degradation by Mucor ramos

Unexplained Fractures in Infants and Child Abuse The Case for Re

Postmodernity and Postmodernism ppt May 2014(3)

Scoliosis and Kyphosis

L 3 Complex functions and Polynomials

4 Plant Structure, Growth and Development, before ppt

Osteoporosis ľ diagnosis and treatment

05 DFC 4 1 Sequence and Interation of Key QMS Processes Rev 3 1 03

Literature and Religion

lec6a Geometric and Brightness Image Interpolation 17

Historia gry Heroes of Might and Magic

Content Based, Task based, and Participatory Approaches

Lecture10 Medieval women and private sphere

więcej podobnych podstron