GEISLINGER COUPLING

INSTRUCTION AND MAINTENANCE

MANUAL

Niigata Power System Co., Ltd.

M8090901A

- 1 -

Page

SECTION 1

: Structure...............................................................................................2

1.1

Working principle ..........................................................................................2

1.2

Structure........................................................................................................2

1.3

Name Plates...................................................................................................7

1.4

Specification of coupling..............................................................................10

SECTION 2

: Installation .........................................................................................15

2.1

Installation Tolerance .................................................................................15

2.1.1

Tolerance of distance between input and output shaft flanges..........15

2.1.2

Tolerance of center misalignment of input and output shaft.............15

2.1.3

Tolerance of angular misalignment of input and output shaft ..........15

2.2

Installation of Geislinger coupling .............................................................16

2.2.1

Installation procedure..........................................................................16

SECTION 3

:Operation .............................................................................................18

3.1

Lubrication Oil Filling Procedure ..............................................................18

SECTION 4

:Preventive Maintenance .....................................................................19

4.1

Periodical Preventive Maintenance............................................................19

4.2

Inspection Points and Replacement Criteria.............................................19

4.2.1

Inner Star .............................................................................................19

4.2.2

Flange and Lateral Plate .....................................................................19

4.2.3

Spring Block .........................................................................................20

4.2.4

Long Leaf ..............................................................................................20

4.2.5

Shim ......................................................................................................20

4.2.6

Oil Vent Mechanism at the center of Oil Stop Ring ...........................20

4.2.7

Bolt for Intermediate Piece..................................................................21

4.2.8

O-rings (for inner star and oil stop ring).............................................21

4.2.9

Other O-rings........................................................................................21

SECTION 5

:Disassembly.........................................................................................22

5.1

Disassembly.................................................................................................22

5.2

Disassembly lateral plate ...........................................................................23

SECTION 6

:Assembly..............................................................................................24

6.1

Assembly......................................................................................................24

6.2

Assembly of lateral plate ............................................................................25

- 2 -

SECTION 1

: Structure

1.1 Working

principle

In this coupling, since one end of each leaf spring is fixed with the outer

circumference part and the other is freely (loosely) held at the inner

circumference part, both outer and inner circumference parts can

relatively make much displacement by means of deflection of the leaf

spring.

The lubrication oil inside the coupling works to make the springs slide

smoothly when the leaf spring deflects.

It also absorbs energy and reduces vibration against torsion when it flows

through its damping clearance during spring deflection.

1.2 Structure

In this coupling, the inner member consists of an inner star and oil seal

ring. The outer member consists of a clamping ring, intermediate ring,

intermediate piece, spring block, etc. Leaf springs radiate between the

inner and outer parts and lubrication oil fills the inside spaces.

The inner and outer member are sealed by O-rings which prevent oil

leakage.

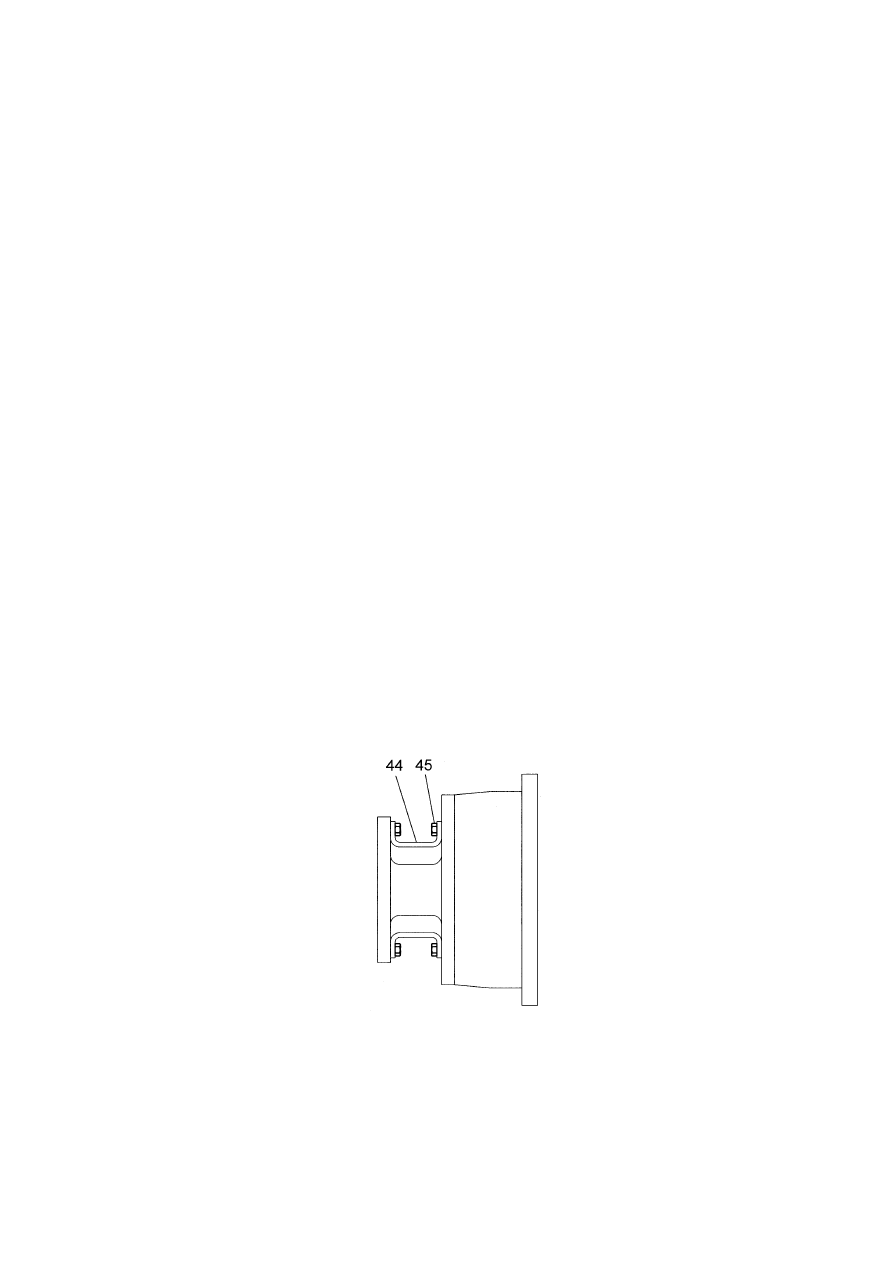

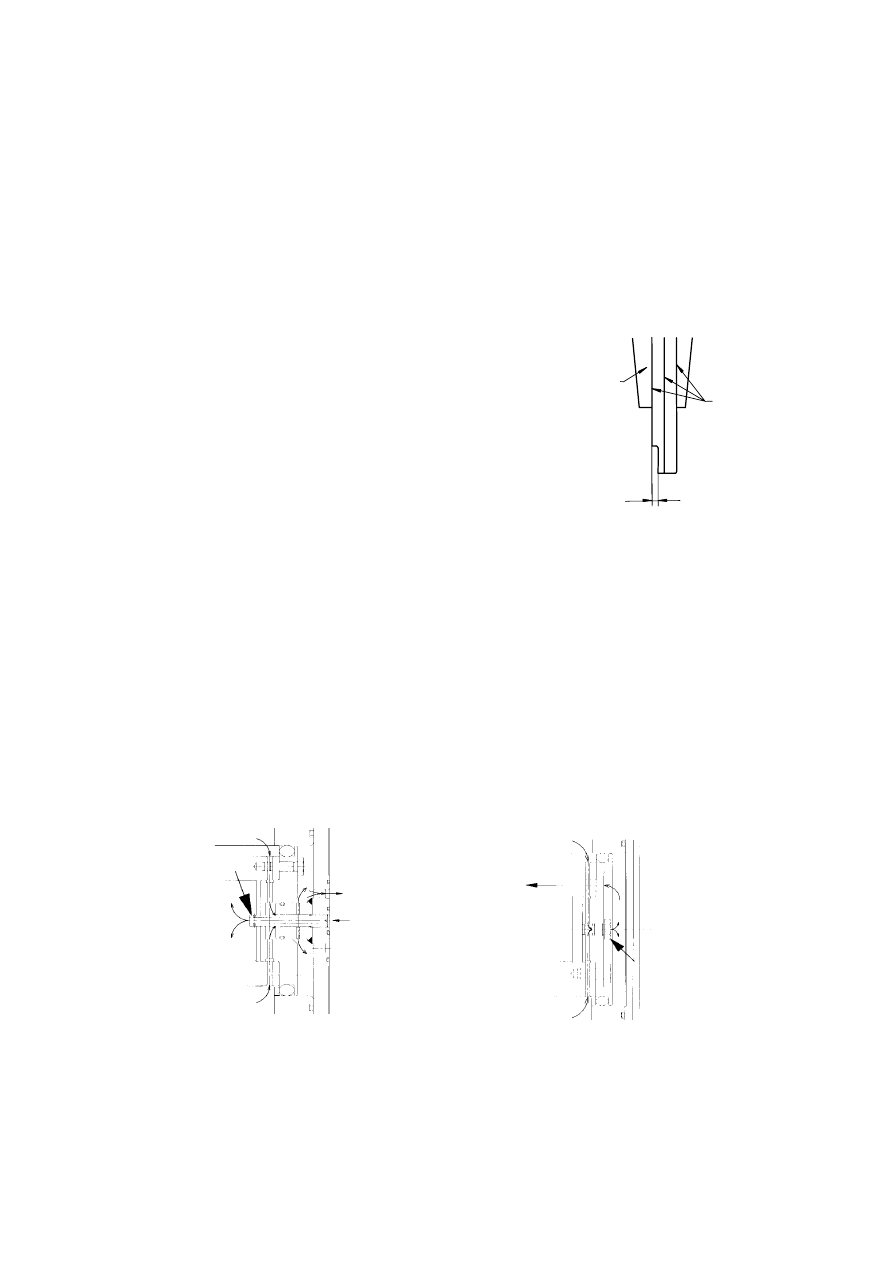

Supporting pieces, as shown in Figure 1-1, are attached to prevent O-ring

damage when the coupling is moved or transported.

44 Supporting pieces

45 Bolts

Figure 1-1

- 3 -

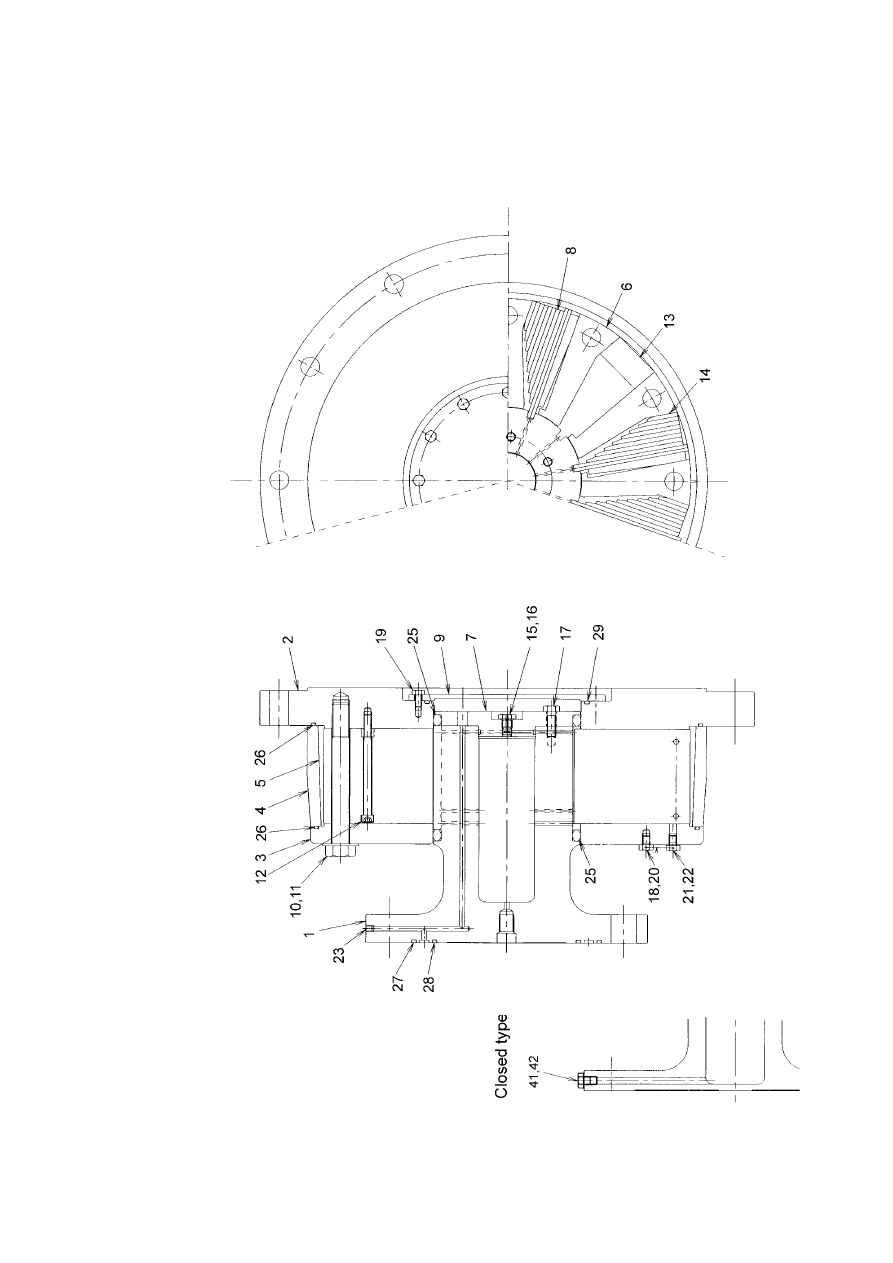

Figure. 1-2 Shows the Structure of the GEISLINGER COUPLING

(BC type)

- 4 -

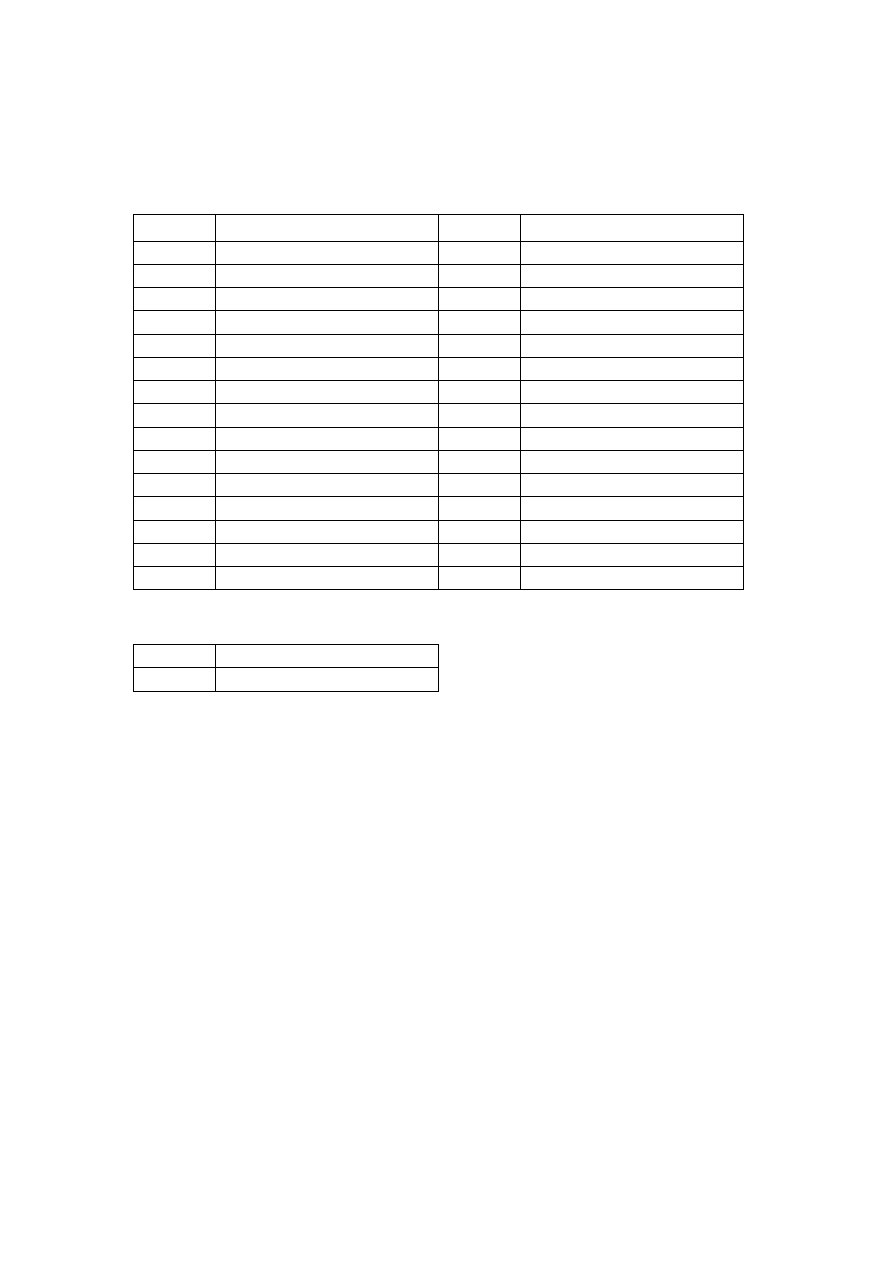

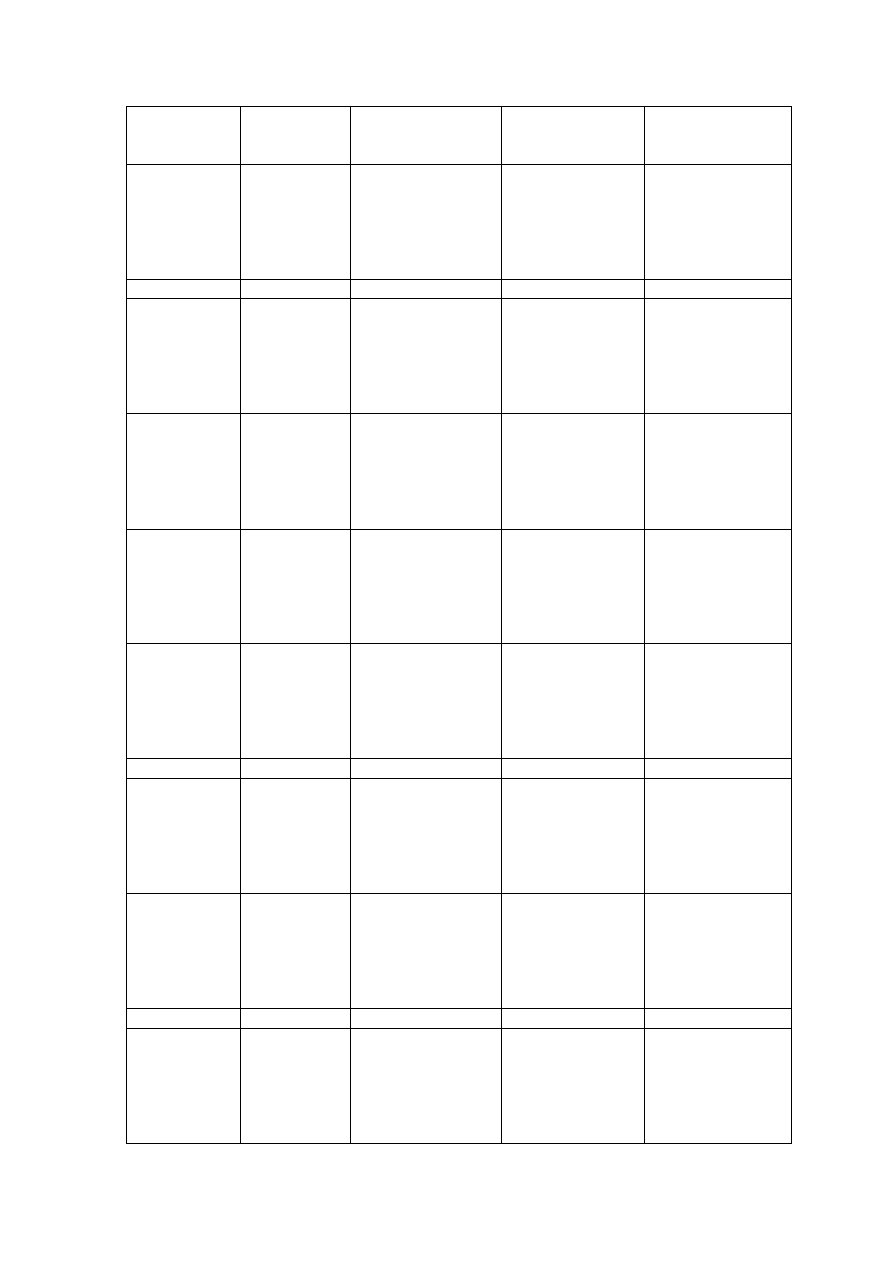

Table 1-1 shows parts names of the coupling ( BC type )

Table 1-1 Parts of BC type

Ref. No.

Part Name

Ref. No.

Part Name

1 Inner

star

16 Packing

2

Flange (Driving Side)

17

Bolt

3

Lateral Plate (Cover)

18

Wire

4 Clamping

Ring

19 Bolt

5 Intermediate

Ring

20 Plug

6

Intermediate Piece

21

Air Vent Plug

7

Oil Stop Ring

22

Packing

8 Spring

Block

23 Screw

9 Cover

24

10

Bolt for Intermediate Piece

25

O-rings

11

Conical Spring Washer

26

O-rings

12 Hexagon

Socket

Screw

27 O-rings

13 Intermediate

block

28 O-rings

14 Shim

29 O-rings

15 Plug

30

Closed type

41 Plug

42 Packing

- 5 -

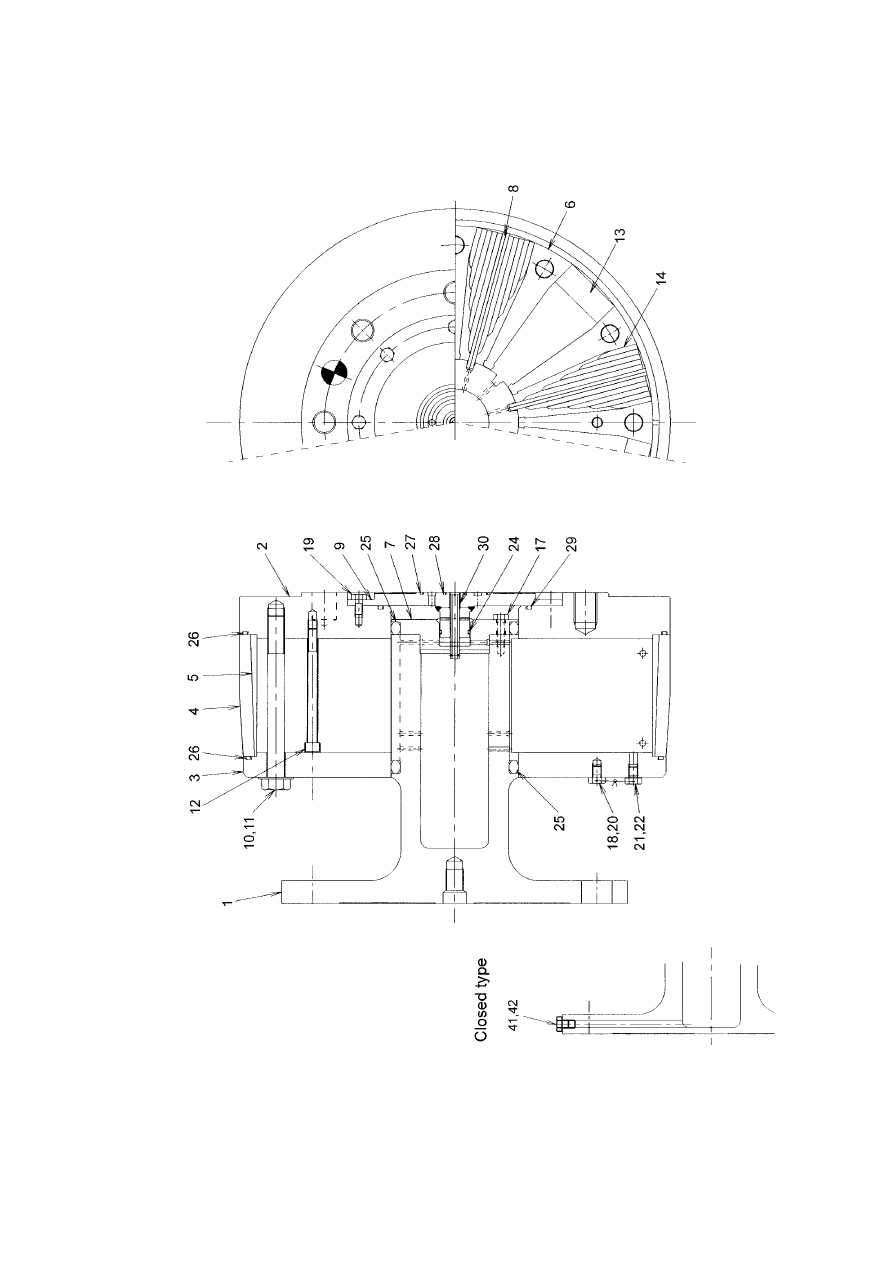

Figure. 1-3 Shows the Structure of the GEISLINGER COUPLING

(BE type)

- 6 -

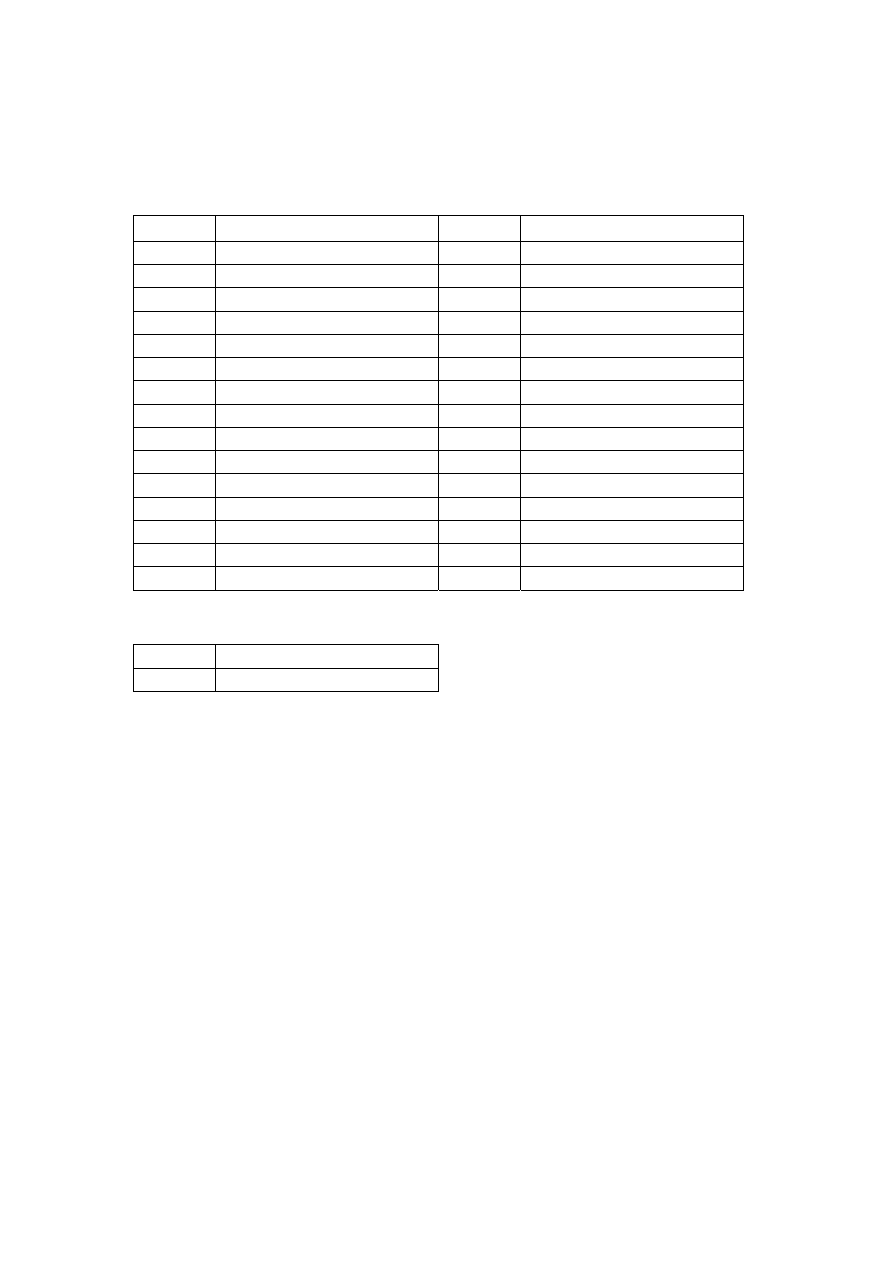

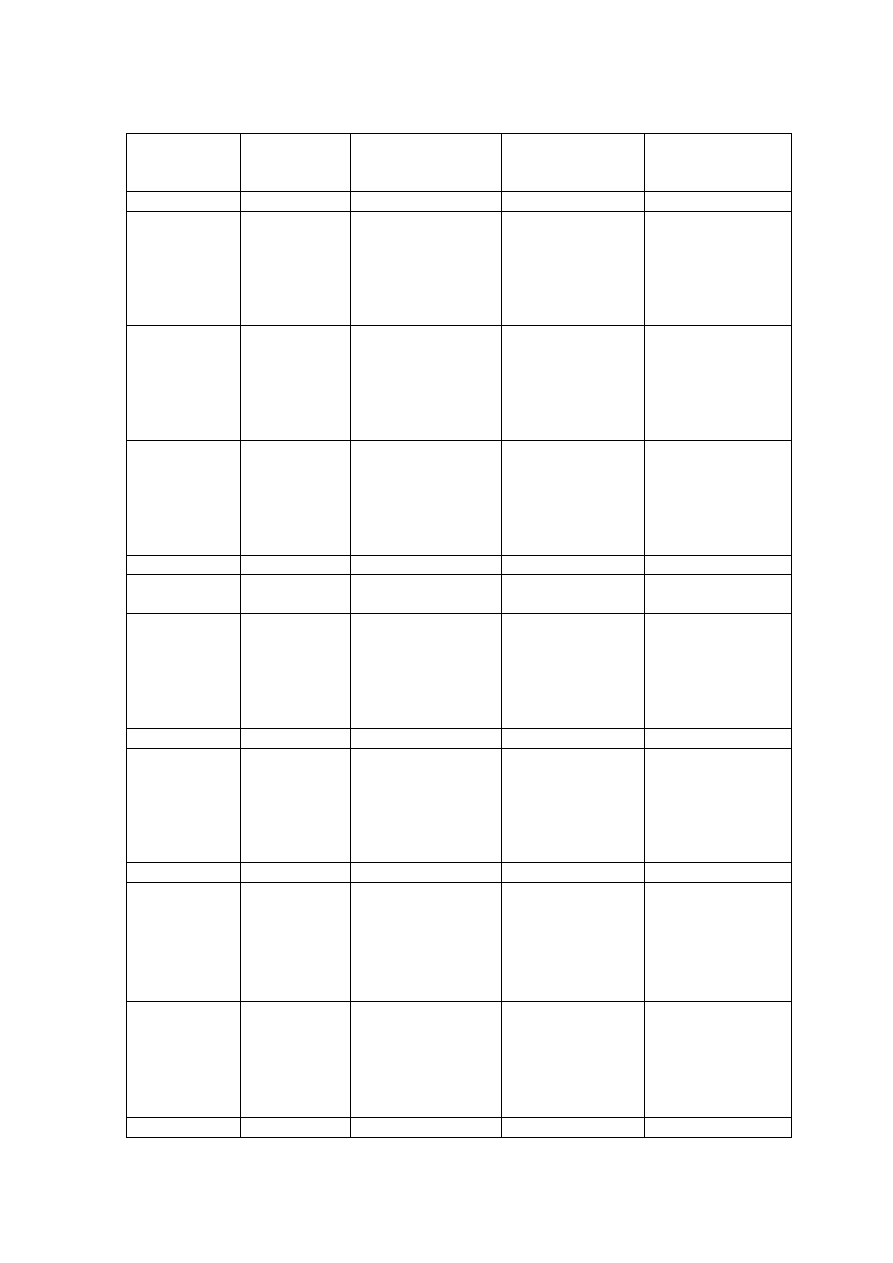

Table 1-2 shows parts names of the coupling ( BE type )

Table 1-2 Parts of BE type

Ref. No.

Part Name

Ref. No.

Part Name

1 Inner

star

16

2

Flange (Driving Side)

17

Bolt

3

Lateral Plate (Cover)

18

Wire

4 Clamping

Ring

19 Bolt

5 Intermediate

Ring

20 Plug

6

Intermediate Piece

21

Air Vent Plug

7

Oil Stop Ring

22

Packing

8 Spring

Block

23

9 Cover

24 O-rings

10

Bolt for Intermediate Piece

25

O-rings

11

Conical Spring Washer

26

O-rings

12 Hexagon

Socket

Screw

27 O-rings

13 Intermediate

block

28 O-rings

14 Shim

29 O-rings

15

30 Oil

Pipe

Closed type

41 Plug

42 Packing

- 7 -

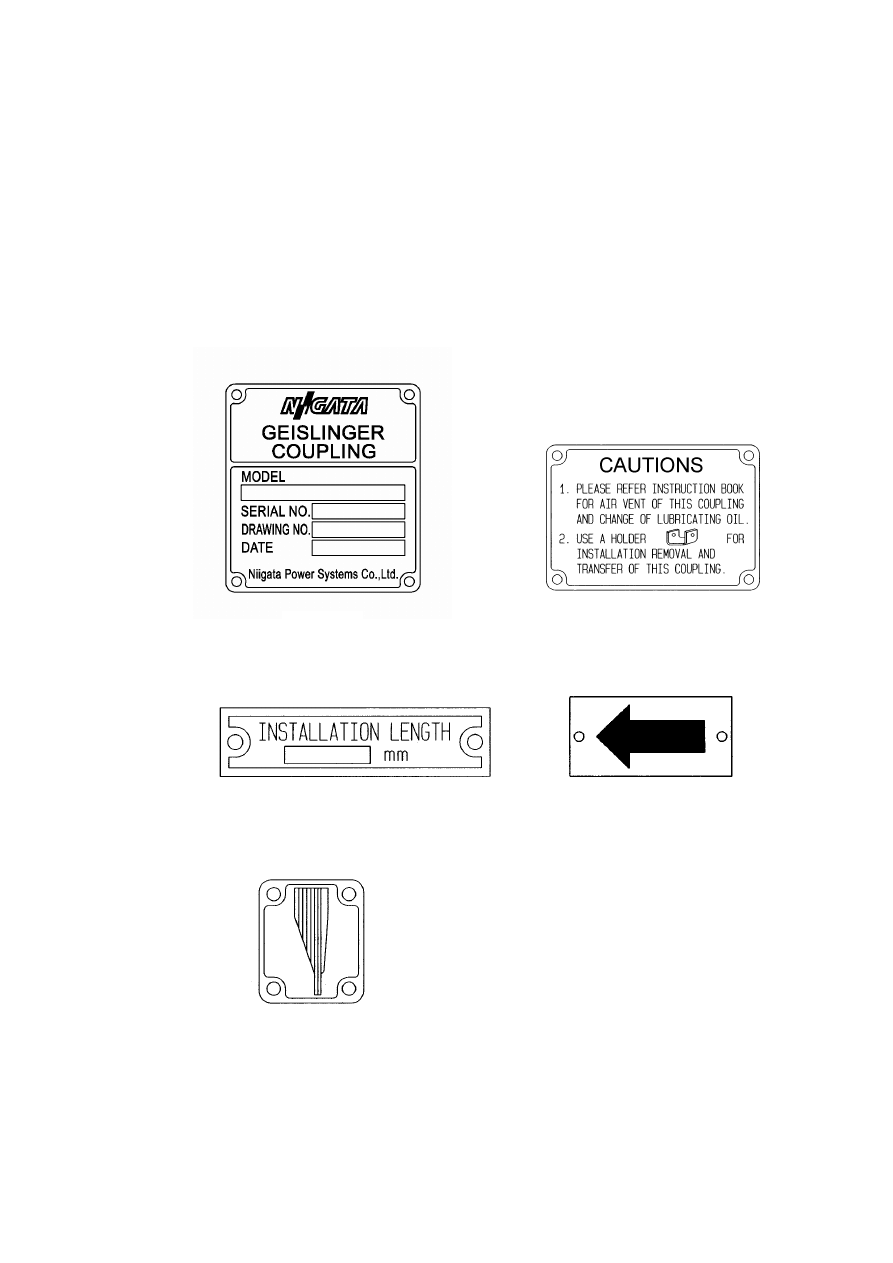

1.3 Name

Plates

All models of this Geislinger Coupling are equipped with name plates showing

Model, as shown in Figure 1, Precaution, as shown in Figure 2, and Installation

Length, as shown in Figure 3. These are mounted on the lateral plate.

In addition, non-reversible type couplings have two additional name plates on

the same side plate which show Rotating Direction, as shown in Figure 4, and

Spring Arrangement, as shown in Figure 5.

The followings are the descriptions of the respective nameplates.

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

- 8 -

Guide to Model Name Plate Figures

Model

(Example)

B E 56/15/140U-12 RO

RO :

means that filling/removing of

lubrication oil must be done from the

driving side plate.

In addition:

T :

indicates model which is equipped

with a thrust-ring for positioning on

the driving side plate.

R :

indicates model with bearings between

input side and output side.

S :

indicates model with an installed

dimension which is shorter than

standard

F :

indicates a coupling in which the

lubrication oil is sealed.

NO symbol :

means that filling/removing of

lubrication oil must be done

from inner star side.

:shows number of spring blocks.

:shows type of spring block.

:shows width of spring blocks

:shows maximum diameter of clamping

ring.

:shows flange shape of driving side plate.

:shows shape of inner star flange.

SERIAL NO. :

shows the number of serial products.

DRAWING NO. :

shows the assembly drawing number.

DATE :

shows the date of manufacture.

Meaning of descriptions on Installation Length name plate.

This shows the dimension between flanges where the coupling is installed.

Meaning of descriptions on Rotating Direction name plate.

This shows the rotating viewed from the inner star flange.

Meaning of descriptions on Spring Arrangement name plate.

This shows the spring Arrangement with the side plate removed.

- 9 -

After-Service and Parts Ordering

For after-service and/or parts ordering, contact any one of the following sections

which are also listed at the end of this manual;

Technical Service Section of Niigata Converter Co.,LTD. Or Niigata Engineering

Co.,LTD.

Our Branch Offices

Our Liaison Offices

Our Service Stations

When contacting us, please inform us for quick and correct response the model,

serial number, and assembly drawing numbers given on the name plates.

Since all parts for the Geislinger Coupling are specially designed and

manufactured by us, be sure to use genuine parts supplied by us for replacement.

- 10 -

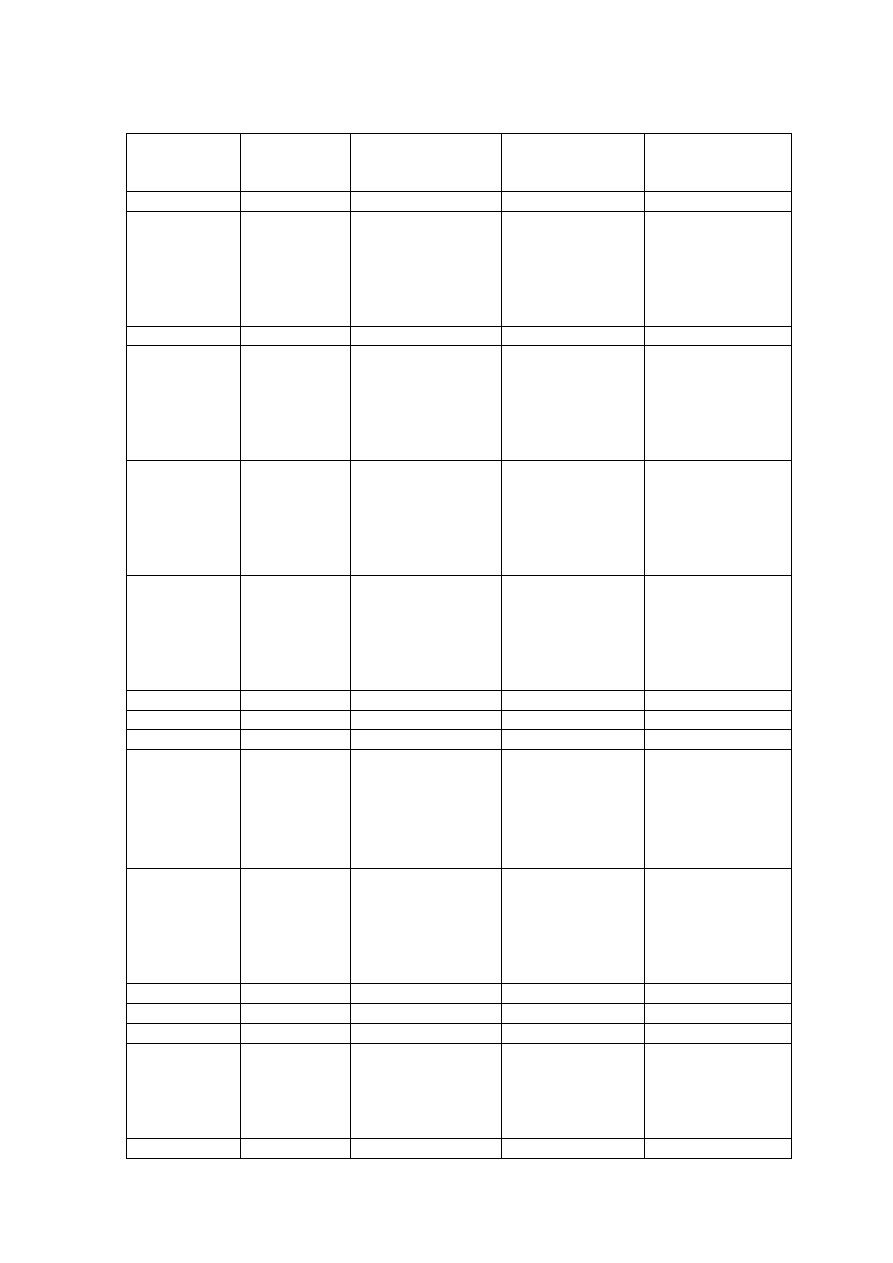

1.4

Specification of coupling

SPECIFICATION OF GEISLINGER COUPLING (BC and BE type)

Number of

Maximum

Maximum

Torsional

Spring Block

Permissible Speed

Permissible Torque

Stiffness

Model

min

-1

{rpm} kNm MNm/rad

41/5/55U 12

3400

10.18 0.142

06 6.3

0.074

07 7.4

0.086

08 8.4

0.098

09 9.5

0.110

10

10.5 0.123

41/7.5/85

12

3400

12.6 0.147

41/7.5/135U 12

3400

7.53

0.0425

48/7.5/3/1 12

2900

17.0

0.147

06 13.8

0.197

07 16.1

0.229

08 18.4

0.262

09 20.7

0.295

10 23.0

0.328

48/10/55U

12

2900

27.6 0.393

48/10/80H 12

2900

29.9

0.284

48/10/80N 12

2900

30.3

0.288

48/10/80U 08

2900

14.8

0.141

06 11.91

0.138

07 13.89

0.160

08 15.88

0.183

09 17.86

0.206

10 19.85

0.229

48/10/85

12

2900

23.82 0.275

06 6.6

0.037

07 7.7

0.043

08 8.8

0.049

09 9.9

0.056

10 11.0

0.062

48/10/140U

12

2900

13.2 0.074

56/12.5/80N 12

2600

52.1

0.495

06 18.7

0.216

07 21.8

0.251

08 24.9

0.287

09 28.1

0.323

10 31.2

0.359

56/12.5/85

12

2600

37.4 0.431

56/12.5/140U 12

2600

24.3

0.137

06 20.3

0.188

07 23.7

0.219

08 27.1

0.251

09 30.5

0.282

10 33.9

0.313

56/15/85U

12

2600

40.7 0.376

- 11 -

Number of

Maximum

Maximum

Torsional

Spring Block

Permissible Speed

Permissible Torque

Stiffness

Model

min

-1

{rpm} kNm MNm/rad

06 14.6

0.082

07 17.1

0.096

08 19.5

0.109

09 21.9

0.123

10 24.4

0.137

56/15/140U

12

2600

29.3 0.164

63/10/175H 10

2300

23.6

0.104

06 15.3

0.085

07 17.9

0.099

08 20.4

0.113

09 23.0

0.128

10 25.5

0.142

63/12.5/140U

12

2300

30.6 0.170

06 34.0

0.483

07 39.6

0.564

08 45.3

0.644

09 50.9

0.725

10 56.6

0.805

63/15/55U

12

2300

67.9 0.966

06 27.9

0.321

07 32.5

0.375

08 37.1

0.429

09 41.8

0.482

10 46.4

0.536

63/15/85

12

2300

55.7 0.643

06 19.3

0.135

07 22.5

0.158

08 25.7

0.181

09 28.9

0.203

10 32.1

0.226

63/15/140

12

2300

38.5 0.271

63/15/140U 12

2300

36.7

0.205

06 39.6

0.565

07 46.2

0.659

08 52.8

0.753

09 59.4

0.848

10 66.0

0.942

63/17.5/55U

12

2300

79.2 1.130

06 21.4

0.120

07 25.0

0.139

08 28.5

0.159

09 32.1

0.179

10 35.6

0.199

63/17.5/140U

12

2300

42.8 0.239

72/15/50N 14

2000

113

1.72

06 23.9

0.133

07 27.9

0.155

08 31.9

0.177

09 35.9

0.200

10 39.8

0.222

72/15/140U

12

2000

47.8 0.266

- 12 -

Number of

Maximum

Maximum

Torsional

Spring Block

Permissible Speed

Permissible Torque

Stiffness

Model

min

-1

{rpm} kNm MNm/rad

72/17.5/50N 14

2000

132

2.01

06 53.2

0.755

07 62.0

0.881

08 70.9

1.007

09 79.8

1.133

10 88.6

1.258

72/17.5/55U

12

2000

106.3 1.510

06 44.1

0.510

07 51.4

0.595

08 58.7

0.680

09 66.1

0.765

10 73.4

0.850

72/17.5/85

12

2000

88.1 1.020

06 40.4

0.374

07 47.1

0.436

08 53.8

0.499

09 60.5

0.561

10 67.3

0.623

72/17.5/85U

12

2000

80.7 0.748

72/20/55U 12

2000

121.4

1.73

10 76.9

0.713

72/20/85U

12

2000

93.6 0.855

06 31.9

0.178

07 37.2

0.207

08 42.5

0.237

09 47.8

0.266

10 53.1

0.296

72/20/140U

12

2000

63.7 0.355

80/17.5/55U 12

1800

124.8

1.77

06 50.60

0.580

07 59.03

0.677

08 67.46

0.773

09 75.89

0.870

10 84.33

0.967

80/17.5/85

12

1800

101.19 1.160

80/20/55U

12

1800

143 2.03

06 38.5

0.217

07 44.9

0.253

08 51.3

0.289

09 57.8

0.325

10 64.2

0.361

80/20/140U

12

1800

77.0 0.433

06 80.0

1.140

07 93.3

1.330

08 106.7

1.520

09 120.0

1.710

10 133.3

1.900

80/22.5/55U

12

1800

160.0 2.280

80/22.5/140U 12

1800

86.6

0.487

- 13 -

Number of

Maximum

Maximum

Torsional

Spring Block

Permissible Speed

Permissible Torque

Stiffness

Model

min

-1

{rpm} kNm MNm/rad

90/20/50N 14

1600

234

3.55

06 94.3

1.35

07 110.0

1.58

08 125.7

1.80

09 141.4

2.03

10 157.1

2.25

90/20/55U

12

1600

188.5 2.70

90/22.5/50U 14

1600

237

3.59

06 86

0.99

07 100

1.16

08 115

1.32

09 129

1.49

10 143

1.65

90/22.5/85

12

1600

172 1.98

06 80.0

0.745

07 93.3

0.869

08 106.6

0.993

09 119.9

1.118

10 133.3

1.242

90/22.5/85U

12

1600

159.9 1.490

06 56.4

0.321

07 65.8

0.374

08 75.2

0.427

09 84.6

0.481

10 94.0

0.534

90/22.5/140U

12

1600

112.8 0.641

90/22.5/200U 08

1600

65.3

0.250

90/25/50U 14

1600

263

3.99

90/25/85 12

1600

187

2.20

06 89.1

0.825

07 103.9

0.963

08 118.7

1.100

09 133.6

1.238

10 148.4

1.375

90/25/85U

12

1600

178.1 1.650

06 62.8

0.356

07 73.2

0.415

08 83.7

0.475

09 94.1

0.534

10 104.6

0.593

90/25/140U

12

1600

125.5 0.712

100/20/80N 12

1300

255

2.42

100/25/50N 14

1300

361

5.47

100/25/50U 14

1300

329

4.98

08 134.9

2.405

10 168.6

3.007

12 202.4

3.608

14 236.1

4.209

100/25/55

16

1300

269.8 4.810

100/25/135N 12

1300

223

1.26

- 14 -

Number of

Maximum

Maximum

Torsional

Spring Block

Permissible Speed

Permissible Torque

Stiffness

Model

min

-1

{rpm} kNm MNm/rad

06 81.3

0.465

07 94.8

0.542

08 108.3

0.619

09 121.9

0.697

10 135.4

0.774

100/25/140U

12

1300

162.5 0.929

06 115.0

1.320

07 134.2

1.540

08 153.3

1.760

09 172.5

1.980

10 191.7

2.200

110/20/85

12

1300

230.0 2.640

110/25/50N 14

1300

439

6.66

110/30/80U 12

1300

328

3.12

110/30/50N 14

1300

527.0

8.010

110/30/50U 14

1300

481.0

7.300

125/22.5/135U 12

1100

216

1.22

06 124.2

0.700

07 144.8

0.817

08 165.5

0.933

09 186.2

1.050

10 206.9

1.167

125/25/140U

12

1100

248.3 1.400

125/25/200U 10

1100

121.0

0.464

125/30/47U 14

1100

705

10.6

125/35/50N 14

1100

802

12.2

- 15 -

SECTION 2

: Installation

2.1 Installation

Tolerance

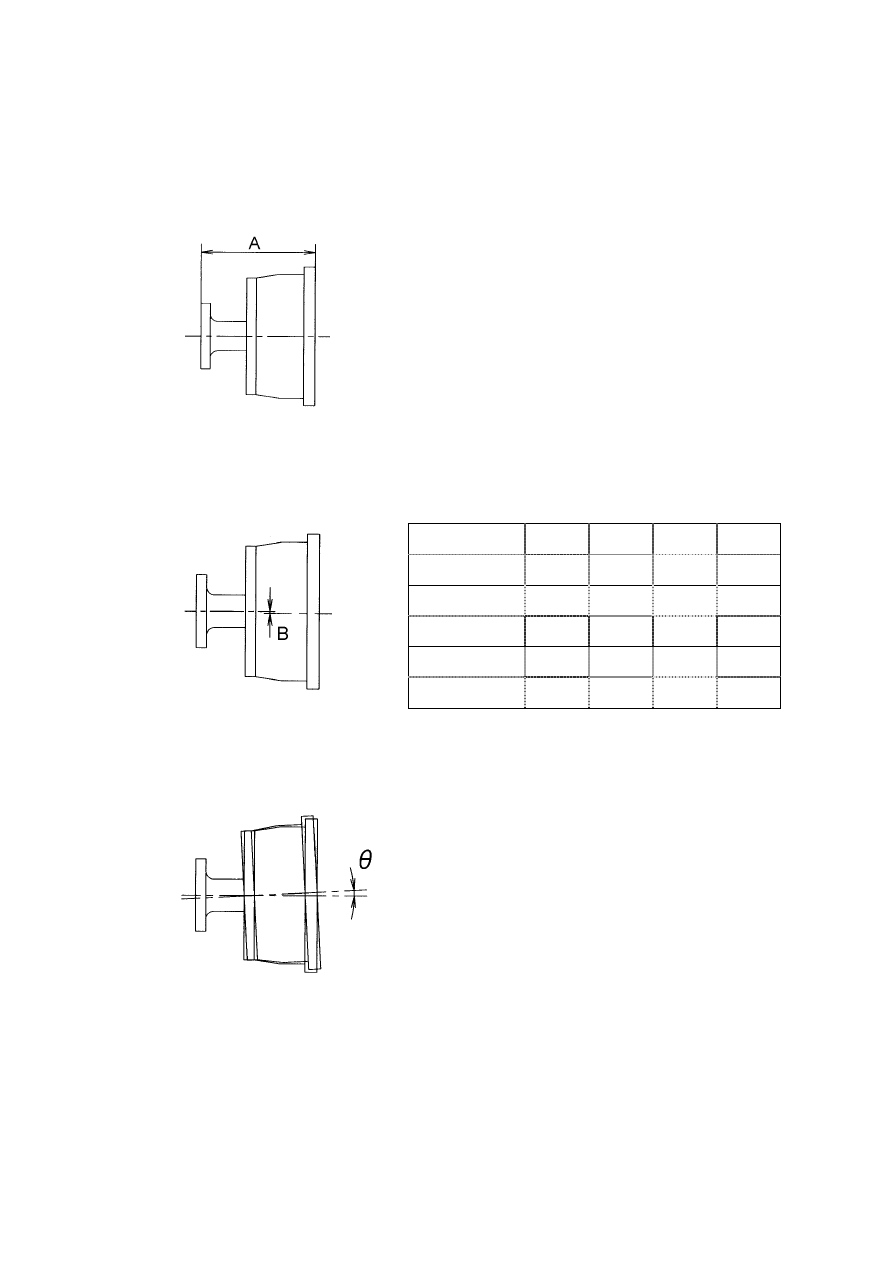

2.1.1 Tolerance of distance between input and output shaft flanges

Distance (A) between input and output

shaft flanges must be adjusted within the

tolerance as follows ;

A = Installation Length ± 0.5 mm

( This tolerance applies to all models, and

installation length are listed on the name

plate. )

Figure 2-1

2.1.2 Tolerance of center misalignment of input and output shaft

Figure 2-2

2.1.3 Tolerance of angular misalignment of input and output shaft

Tolerance θ applies to all models.

θ

= Less than 0.02 deg.

Figure 2-3

Model

41 48 56 63

Dimension B ±0.11 ±0.12 ±0.15 ±0.17

Model

72 80 90 100

Dimension B ±0.20 ±0.22 ±0.25 ±0.27

Model 110

125

Dimension B ±0.30 ±0.32

- 16 -

2.2

Installation of Geislinger coupling

CAUTION : Be sure to use supporting piece when moving the coupling.

2.2.1 Installation procedure

STEP 1 :Apply grease to the grooves on the face of flange. And then O-rings are

fitted to the grooves.

STEP 2 :Adjustment of Distance between input and output shaft flanges.

According to 2-1-1, Distance between input and output shaft flanges is

adjusted.

STEP 3 :Outer-member of the coupling is fitted to the shaft flange, If Adjustment

is done without the coupling fixing to the shaft flange, Check the

misalignment by STEP 7.

STEP 4

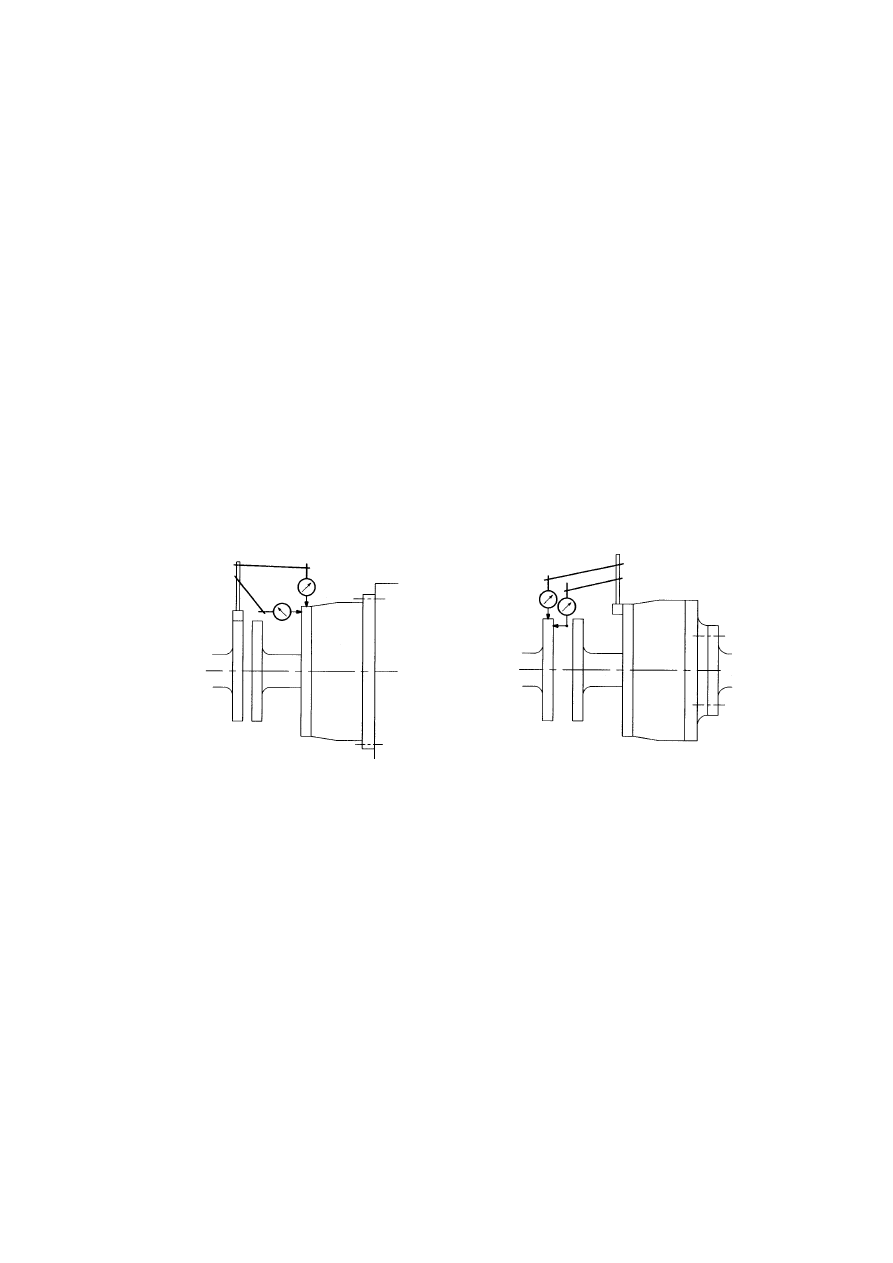

:Setting of the Dial-gauge is shown in Figure 2-4.

(BC type) (BE type)

Figure 2-4

STEP

5 :Turning the shaft flange, which is fitted the Dial-gauge, or

Outer-member of the coupling. Measure center misalignment on outer

circumference (REMARK 1) and angular misalignment on side surface

(REMARK 2). Position of input and output shaft flanges must be settled

so that the deviations are less than the values shown 2-1-1 and 2-1-3.

(REMARK 1) : Tolerance of center misalignment is twice as much as the value of

2-1-2.

(REMARK 2) : Tolerance of angular misalignment is as follows ;

Distance from shaft center to measurement point x 0.0007 mm

- 17 -

STEP 6 :Remove the Dial-gauge and supporting piece, Fix the inner-star flange

to the other flange.

STEP 7 :After fixing the coupling, set the Dial-gauge (shown in Figure 2-4).

Center misalignment and angular misalignment are measured so that to

confirm the deviations are less than the values shown 2-1.

Above procedure is standard installation procedure, but it is estimated that

operating condition is different from primary condition. In that case, it is necessary

installation with consideration of that difference.

- 18 -

SECTION 3

:Operation

During operation, the inside of the coupling is always filled with lubrication oil.

However, after internal inspection, it must be refilled with oil. Also, after long

periods of unused, refilling may be necessary. Fill the coupling with oil according

to the following procedure before operation.

3.1

Lubrication Oil Filling Procedure

STEP 1 :Turn the shaft so that any one of the air vent plugs (21) on the side

plate(cover)(3) comes to the top.

STEP 2 :Remove all air vent plugs (21). ( Remove lock-wire before removing

plugs. )

STEP 3 :This step applies only to closed oil type couplings. Remove the plug (41)

for oil feeding hole located at the outer circumference of the inner star

flange (1).

STEP 4 :Operate priming pump or manual pump and confirm that oil comes out

from the air vent plug hole located at the bottom. Then, fasten the air

vent plug (21) at the bottom with copper packing (22).

STEP 5 :When oil filled the coupling, air bubbles come out with oil from the top

plug hole. Fasten the air vent plug (21) with copper packing (22) after all

bubbles come out.

STEP 6 :This step applies only to closed oil type couplings. Fasten the plug (41)

with copper packing to oil feed hole at inner star flange (1).

Since copper packing (22) are used for air vent plugs (21), attention must be paid

not to use them for wire –lock plugs (20) which are located next to the air vent

plugs (21).

- 19 -

1.0

SECTION 4

:Preventive Maintenance

4.1

Periodical Preventive Maintenance

Table 4-1 shows the standard time for inspection.

Time for Inspection

Items to be Inspected

Before Operation

( In case of operation after long periods of unused.)

・

Vent air inside the coupling as described in

Clause 3-1.

・

For closed oil type:

Check amount of oil by inserting oil level gauge

into oil feed hole located on inner star flange .

Add oil if level is low.

After 1000 Hours

of Operation

(For closed type only)

Replace oil after 1000 hours of operation

Every 2 Years

Disassemble the coupling for inspection and clean

inside according to the maintenance schedule of the

engine. Replace parts if necessary.

But within 2 years, when LO in the coupling would be

predicted inferior quality or abnormal condition was

detected on the coupling. Coupling should be

disassembled and to be inspected inside.

( Table 4-1)

4.2

Inspection Points and Replacement Criteria

4.2.1 Inner Star

Remove inner star and check for abrasion at grooved

part. If it is predicted abrasion will extend deeper than

1.0 mm before the next inspection, replace the inner

star.

Since hardening reaches a depth of only 0.8 - 1.0 mm,

any abrasion beyond this point will progress rapidly.

4.2.2 Flange and Lateral Plate

After removing inner star, check the extend of abrasion where each parts

contact the inner O-ring.

If the abrasion is over 0.5 mm replace the plate.

- 20 -

1.0

Leaf

Shim

4.2.3 Spring Block

Check each lapped leaf for damage. This check can be made by viewing from the

block side after removing the lateral plate.

If damage exists, replace the whole block unless the damage is confirmed to the

end of the longest leaf in the block.

4.2.4 Long Leaf

Check the long leaf for the damage or wear at the

tip after removing the inner star. If it is predicted

that wear will go beyond 1.0 mm before the next

inspection, or if the damage is detected, replace

the long leaf.

The thickness of the long leaf without any wear is

shown in Appendix - 1.

4.2.5 Shim

Check the shim inserted between the leaves of the spring block and replace

them with new ones if they are worn.

4.2.6 Oil Vent Mechanism at the center of Oil Stop Ring

(Applies only to Oil Circulation type)

For oil venting, a plug is used to the type in which oil is fed from the inner star

flange, and a pipe is used on the type in which oil is fed from the Flange.

Check the clearance of the oil-hole shown in Figure 4-1 and Figure 4-2 and

clean them if they are closed by sludge.

Figure 4-1 Figure 4-2

- 21 -

4.2.7 Bolt for Intermediate Piece

These bolts are not removed except when replacing spring block and long leaf,

or for some other special reason. Whenever the coupling is removed, however,

check the bolt for tightness and oil leakage.

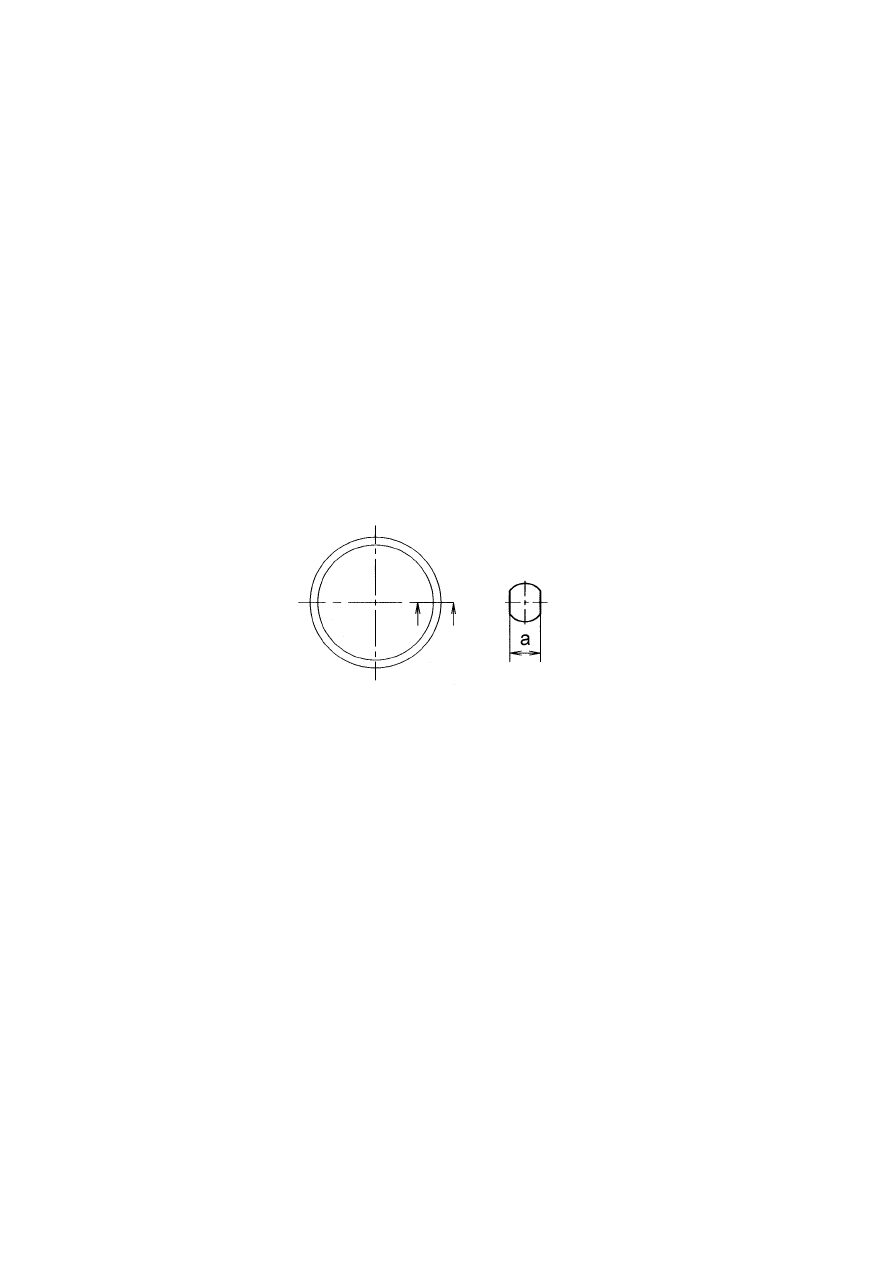

4.2.8 O-rings (for inner star and oil stop ring)

Take O-ring out of its groove and check it visually for cracks, tears or damage.

Also measure the dimension of “a” shown in Figure 4-3 and check for fatigue

and wear of the O-ring.

Appendix – 2 shows the replacement criteria, O-rings must be replaced every

two years during regular disassembly and inspection.

Appearance

Replace with new ones if cracks, cuts or tears exist.

Figure 4-3

4.2.9 Other O-rings

Remove O-rings from grooves and check them visually. O-rings must be

replaced when they are cut or if oil leakage is recognized, and also when

disassembly and inspection are carried out every two years.

- 22 -

SECTION 5

:Disassembly

5.1 Disassembly

Prior to disassembly, put marks on parts for re-assembling.

Disassembly work should be done on a floor covered with papers or wooden

plates; special care should be taken not to damage O-rings.

STEP 1

:Loosen coupling bolts of inner star flange.

CAUTION :For the type with oil feed from inner star flange, an oil pan is required

to receive the oil which will come out when the coupling bolts are

loosened.

STEP 2 :Fix the inner star firmly with the outer member by attaching the 2

support pieces (44).

STEP 3 :Loosen all coupling bolts of flanges, and lift up the whole coupling by

crane. Since the total length of the coupling would be shortened 5-10 mm

by fastening the bolts of the support pieces (44), it should be easily

removed.

STEP 4

:Put the coupling down on the floor facing the Flange ( 2)(driving) up.

STEP 5 :This STEP is applied to only oil circulation type models. Loosen and

remove the cover bolts (19).

STEP 6 :Loosen the plug (15) on oil stop ring ( 7). ( For the type in which oil is

feed from inner star. )

STEP 7

:Loosen the oil stop ring bolts (17) and remove it.

Note - If it is not easily removed, use the removed bolts (17) as pulleys

for easy removing.

STEP 8 :Turn the coupling upside-down. (Inner star flange ( 1) faces up.) At this

time, on oil pan is required to receive the lubrication oil which will flow

out.

STEP 9 :Loosen the bolts (45) on support pieces (44) and pull the inner star ( 1)

out gently.

STEP 10 :Loosen all bolts (10) for the intermediate piece, and remove the lateral

plate ( 3) (cover). At this time, put a mark on the bolt-heads and lateral

plate ( 3) (cover) as matching-mark for re-assembly. ( But only if no

torque wrench is available.)

- 23 -

STEP 11 :Loosen the centering bolt (12) by using a hexagonal wrench.

STEP 12 :Clean all disassembled parts with gasoline, kerosene or light oil, and dry

them up. (After cleaning and drying, anticorrosive should be applied.)

CAUTION :As some special tools and facilities are necessary for disassembly of

clamping ring (4), intermediate ring (5), intermediate piece (6), spring

block (8) and intermediate block (13) (hereinafter called ″Complete set

of spring block ″ ), please contact our service stations when it is

necessary to disassembly them.

5.2 Disassembly

lateral

plate

Disassembling lateral plate only on installation coupling to the both flanges

STEP 1

:Put fitting mark lateral plate (3) and clamping ring (4) . In the case of no

torque wrench for bolt (10), tightening mark is also put on the bolt and

lateral plate. Then loosen all bolts (10)

STEP 2 :With hanging lateral plate (3) , take off lateral plate. This time, be

careful not to damage o-ring (25) and inner circumference of lateral plate.

This face and o-ring are important to seal LO of inside coupling.

- 24 -

SECTION 6

:Assembly

6.1 Assembly

STEP 1 :Put the flange (2) horizontally on the floor facing the O-ring groove, and

apply enough grease in O-ring grooves. Then insert O-rings (26).

STEP 2 :Put the complete set of spring block on the flange (2). Set the

identification marks made before disassembling to each other.

STEP

3 :Measure the gap of inner circumference between flange(2) and

intermediate pieces(6) by depth micrometer. Put the complete set of

spring block in such a way that each gaps are same.

STEP 4

: Fasten the bolts(12), fix the complete set of spring block and flange (2).

STEP 5 :Apply enough grease in the O-ring grooves on the lateral plate (cover)

and insert O-ring (26).

STEP 6 :Put the lateral plate (3) on the complete set of spring block and set the

identification marks made before disassembling to each other.

STEP 7 :Fasten 4 bolts (10) with conical spring washers (11) slightly. Measure

the gap of inner circumference between the lateral plate (3) and

intermediate pieces (6) by depth micrometer. Adjust the lateral plate in

such way that each gap is same. Then fasten 4 bolts in order to avoid

moving the lateral plate (3). When tightening these bolts, coat LOCTITE

222 between conical spring washer (11) and bolts(10), and coat LOCTITE

271 between lateral plate (3) and bolts(10). Then fasten all bolts on

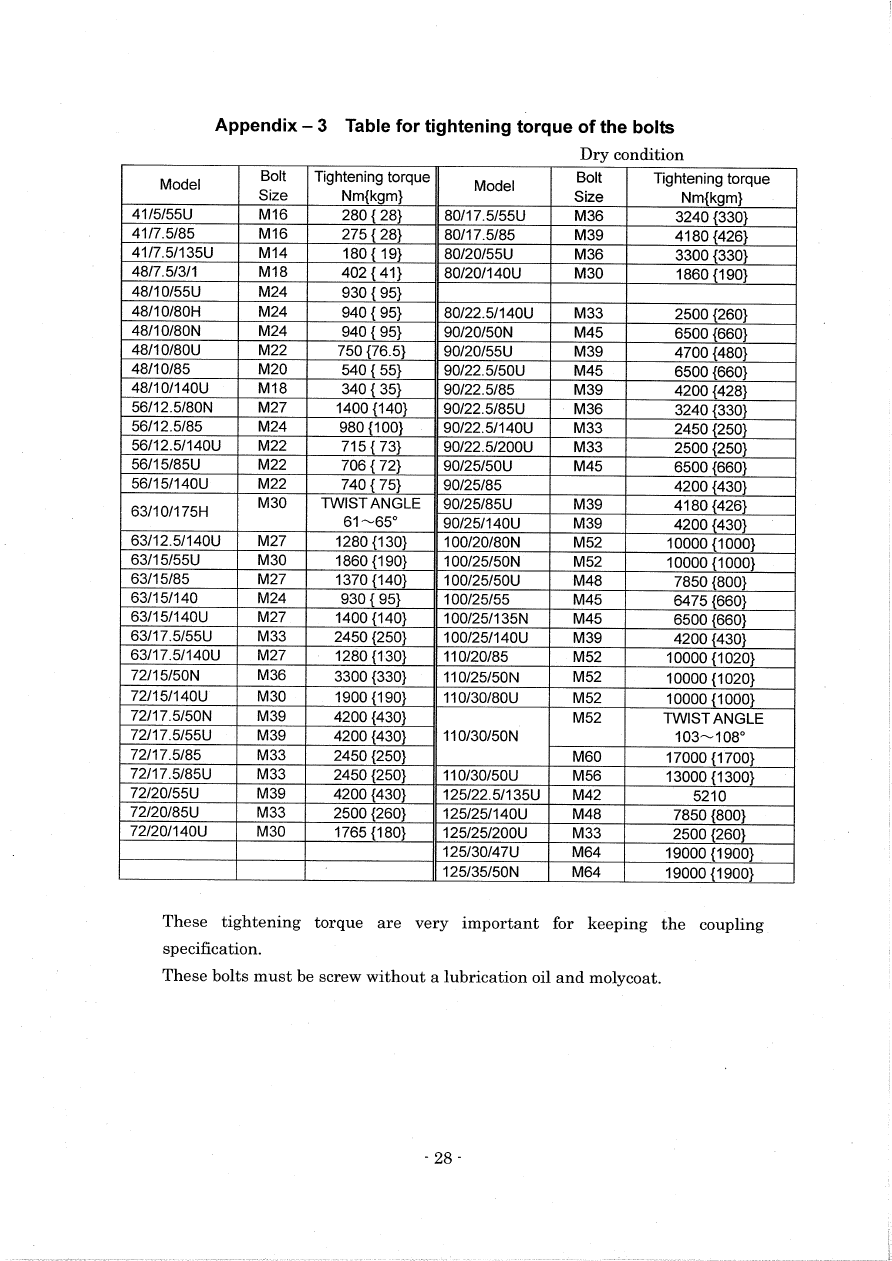

standard torque. Tightening torque: see Appendix - 3

STEP 8

: Stand the inner star (1) so that its flange faces down.

Apply grease to O-ring groove and then insert O-ring (25)..

STEP 9

:Fit support pieces (44) to inner star flange.

STEP 10 :Turn the set assembled in STEP 7 upside down ( flange (2) faces up ) and

lift it up. Then, match the marks with those of inner star (1) and put the

assembled set down over the inner star (1) .When the support pieces (44)

reach the lateral plate (3), attach them to each other.

STEP 11 :Apply enough grease to O-ring groove of the oil stop ring (7) , and insert

O-ring (25).

STEP 12 : Put the oil stop ring (7). on the inner star (1) and fasten bolts(17).

STEP 13 : Fasten the plug (15) with copper packing (16) in the center of the oil

stop ring (7). ( But only for the type of which oil is feed from inner star

flange (1). )

- 25 -

STEP 14 : Apply grease to O-ring groove on the cover side of flange (2) and insert

O-ring (29) in the groove.

STEP 15 : Put the cover (9) on gently and fasten it with bolts (19).

Lubrication oil must be filled inside the coupling in accordance with clause 3-1

before re-starting operation.

6.2

Assembly of lateral plate

In the case of disassembling lateral plate only on installation coupling to the both

flanges, Installation procedure is as follows.

STEP 1 :Install lateral plate with tightening 4 bolts(10) slightly. Turn the engine

and measure center misalignment on outer circumference of lateral plate

(3). Center misalignment should be within 0.1mm.

STEP 2 :Tighten all bolts (10) according to standard torque which shows in

Appendix 3. In the case of no torque wrench, tight by tightening mark.

- 26 -

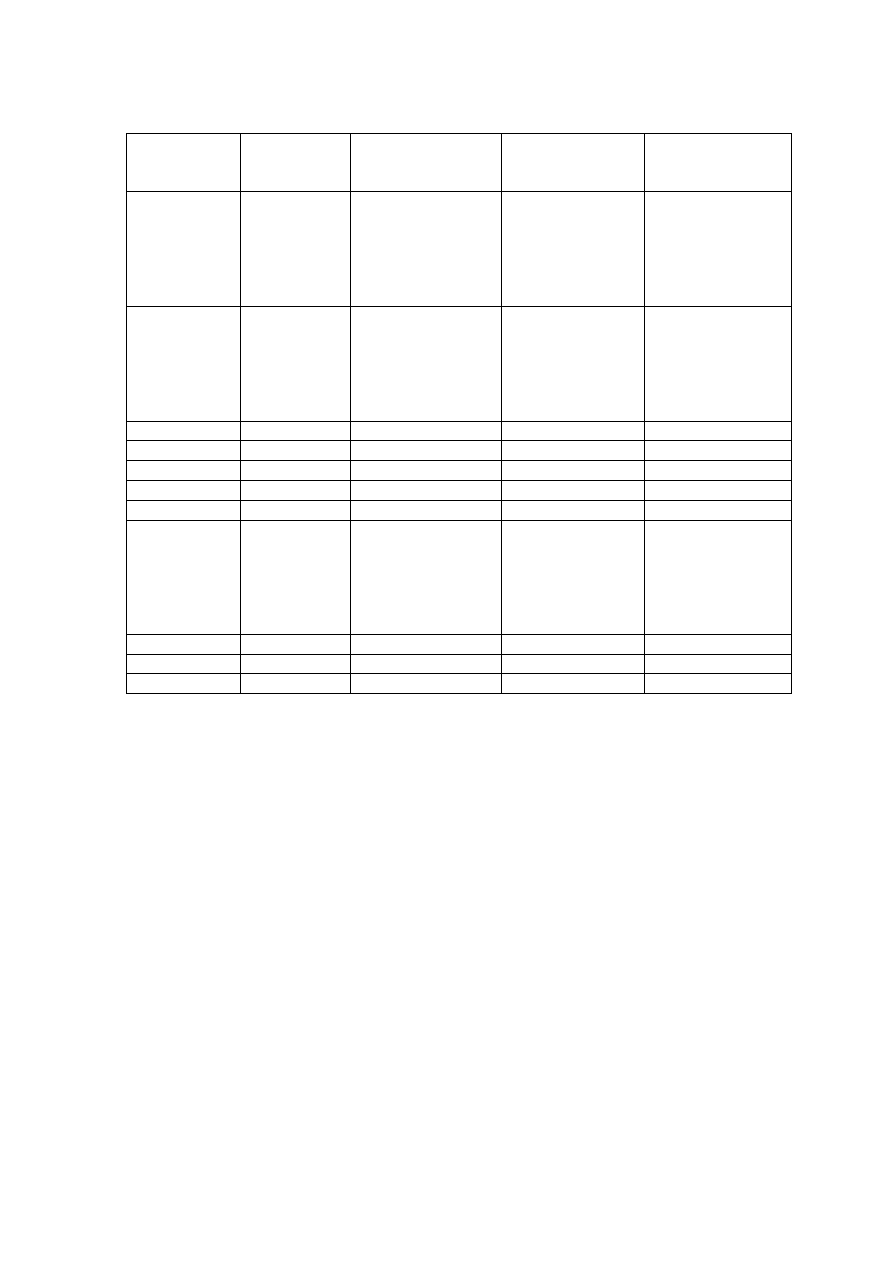

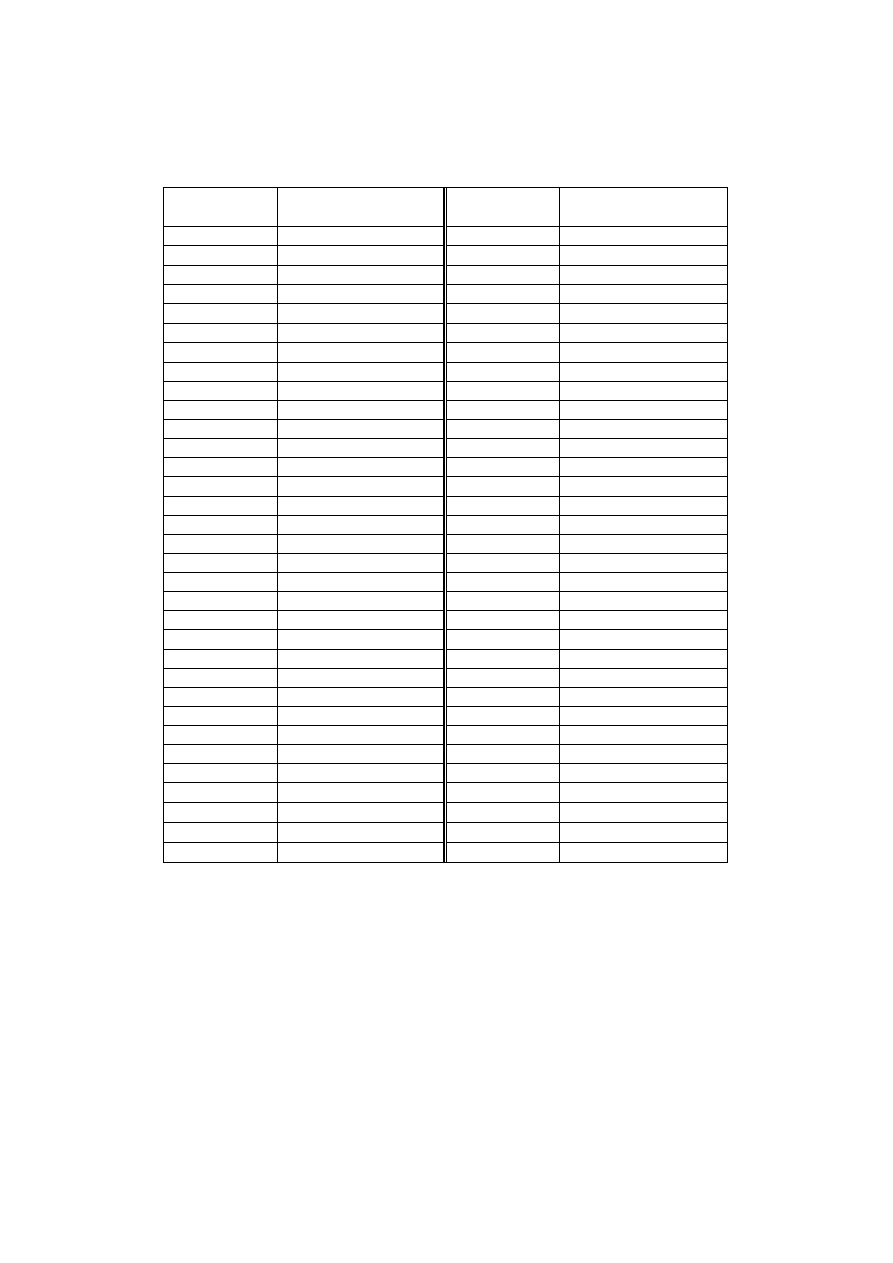

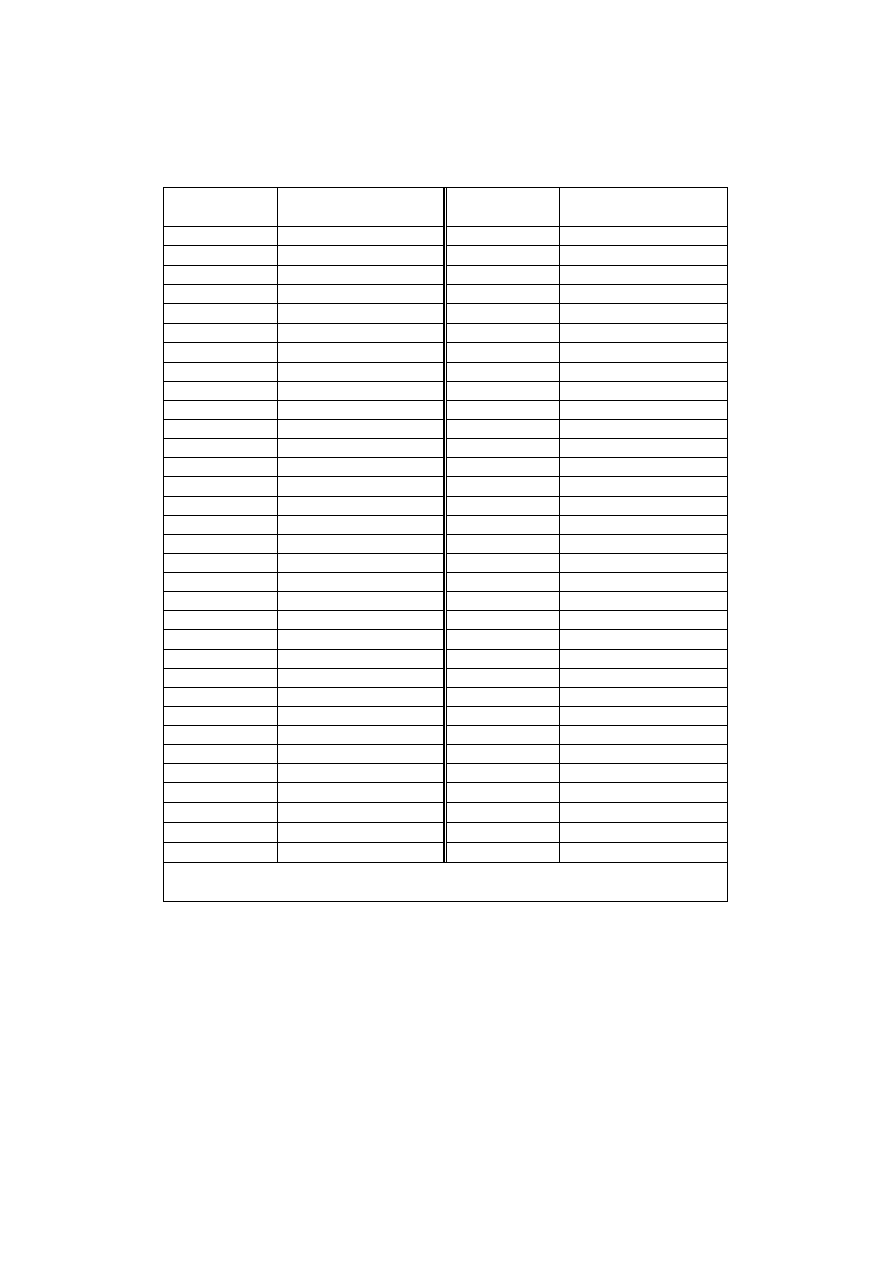

Appendix – 1 Table for thickness of long leaf

Thickness without wears

Thickness of Long Leaf

Thickness of Long Leaf

Model

mm

Model

mm

41/5/55U 4.60

80/17.5/55U

8.30

41/7.5/85 3.70

80/17.5/85

6.40

41/7.5/135U 3.40

80/20/55U 8.30

48/7.5/3/1 4.40

80/20/140U

5.95

48/10/55U 5.40

80/22.5/55U 8.30

48/10/80H 4.70

80/22.5/140U

5.95

48/10/80N 4.70

90/20/50N

14.30

48/10/80U 4.15

90/20/55U 9.55

48/10/85 4.25

90/22.5/50U

10.80

48/10/140U 3.75

90/22.5/85 7.40

56/12.5/80N 5.40

90/22.5/85U 6.50

56/12.5/85 4.65

90/22.5/140U

6.80

56/12.5/140U 4.25 90/22.5/200U

6.45

56/15/85U 4.10

90/25/50U

10.80

56/15/140U 4.25

90/25/85 7.40

63/10/175H 5.05

90/25/85U 6.50

63/12.5/140U 4.75 90/25/140U 6.80

63/15/55U 6.65

100/20/80N

8.85

63/15/85 5.15

100/25/50N

14.30

63/15/140 5.55

100/25/50U

12.00

63/15/140U 4.75

100/25/55 13.40

63/17.5/55U 6.65

100/25/135N

9.05

63/17.5/140U 4.75 100/25/140U 7.70

72/15/50N 10.45

110/20/85 9.10

72/15/140U 5.35

110/25/50N

15.90

72/17.5/50N 10.45

110/30/80U 8.70

72/17.5/55U 7.70

110/30/50N 15.90

72/17.5/85 5.95

110/30/50U

13.20

72/17.5/85U 5.25

125/22.5/135U

10.20

72/20/55U 7.70

125/25/140U

9.50

72/20/85U 5.25

125/25/200U

7.70

72/20/140U 5.35

125/30/47U

17.00

125/35/50N

18.10

- 27 -

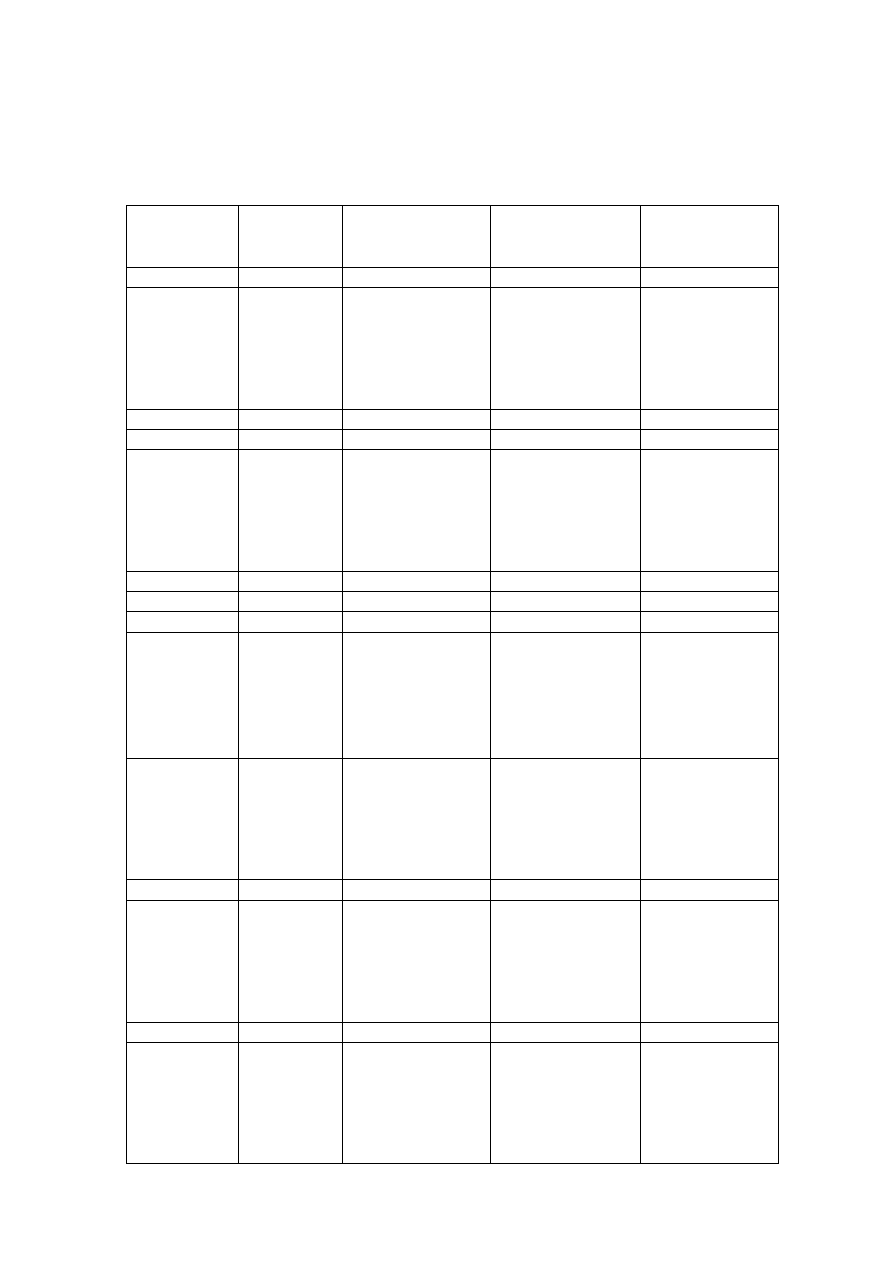

Appendix – 2 Table for O-ring dimension

Dimension (a)

Dimension (a)

Model

mm

Model

mm

41/5/55U 9.0

80/17.5/55U

16.2

41/7.5/85 9.0

80/17.5/85

16.2

41/7.5/135U 9.0

80/20/55U 16.2

48/7.5/3/1 10.8

80/20/140U

16.2

48/10/55U 10.8

80/22.5/55U 16.2

48/10/80H 10.8

80/22.5/140U

16.2

48/10/80N 10.8

90/20/50N 18.0

48/10/80U 10.8

90/20/55U 18.0

48/10/85 10.8

90/22.5/50U

18.0

48/10/140U 10.8

90/22.5/85 18.0

56/12.5/80N 12.6

90/22.5/85U 18.0

56/12.5/85 12.6

90/22.5/140U

18.9

56/12.5/140U 12.6 90/22.5/200U

17.1

56/15/85U 12.6

90/25/50U 17.1

56/15/140U 12.6

90/25/85 18.0

63/10/175H 13.5

90/25/85U 18.0

63/12.5/140U 13.5 90/25/140U 18.9

63/15/55U 13.5

100/20/80N

19.8

63/15/85 13.5

100/25/50N

19.8

63/15/140 13.5

100/25/50U

19.8

63/15/140U 13.5

100/25/55 19.8

63/17.5/55U 13.5

100/25/135N

19.8

63/17.5/140U 13.5 100/25/140U 19.8

72/15/50N 15.3

110/20/85 21.6

72/15/140U 15.3

110/25/50N 21.6

72/17.5/50N 15.3

110/30/80U 21.6

72/17.5/55U 15.3

110/30/50N 21.6

72/17.5/85 15.3

110/30/50U

21.6

72/17.5/85U 15.3

125/22.5/135U

24.3

72/20/55U 15.3

125/25/140U

24.3

72/20/85U 15.3

125/25/200U

24.3

72/20/140U 15.3

125/30/47U 24.3

125/35/50N

24.3

Appearance

Replace with new ones if cracks, cuts or tears exist.

Niigata Power System Co., Ltd.

2756-3,Higasiko 5-chome,Seiromachi,Kitakanbara-gun,Niigata 957-0101

Japan

TEL +81-25-256-3515 FAX +81-25-256-3532

Document Outline

- INSTRUCTION MANUAL FOR GEISLINGER COUPLING

- PAGE

- SECTION 1 STRUCTURE

- SECTION 2 INSTALLATION

- 2.1 INSTALLATION TOLERANCE

- 2.2 INSTALLATION OF GEISLINGER COUPLING

- SECTION 3 OPERATION

- SECTION 4 PREVENTIVE MAINTENANCE

- SECTION 5 DISASSEMBLY

- SECTION 6 ASSEMBLY

- APPENDIX-1 TABLE FOR THICKNESS OF LONG LEAF

- APPENDIX-2 TABLE FOR O-RING DIMENSION

- APPENDIX-3 TABLE OF TIGHTENING TORQUE OF THE BOLTS

Wyszukiwarka

Podobne podstrony:

05 Instrukcje warunkoweid 5533 ppt

DJ F1 S1 Instruction Manual

05 Instrukcje Sterujaceid 5708

cw 05 instrukcja id 121376 Nieznany

ONESTER 158 01 05 Instrukcja i Schemat

BSA Instruction Manual D14

05- INSTRUKCJA BHP PRZY OBSŁUDZE PRASY HYDRAULICZNEJ, Instrukcje BHP, VII - ELEKTRYKA

Instruction Manual

05.Instrukcja rozmrazania i mycia urządzeń, Haccp-Dokumentacja-przykład

05 Instrukcje Sterujace

05 Instrukcja montażu AW10

05 MICROLOGIC 2 0 5 0 MANUAL

05 instrukcja dla gracza B, studia kierunek administracja, gra negocjacyjna

05 Instrukcja Geol, Studia- geodezja, Semestr I

KLAMSTER 170 01 05 Instrukcja i Schemat

ICOM instruction manual[1]

05 instrukcja

więcej podobnych podstron