A

t first, there was a lot of excite-

ment over that high-profile

project your ready mix compa-

ny was so proud to have a part

in. Then came the bad news. The cylinder

compressive strength test results are low.

The contractor is blaming your company.

He claims it was bad concrete. You think

otherwise.

To aid the investigation, cores will be tak-

en and tested. Knowing the in-place charac-

teristics of the concrete and how they affect

the measured compressive strength of the

cores can go a long way toward establish-

ing that the low-strength cylinders were not

the result of bad concrete.

In-place strength

Concrete coring is generally deemed nec-

essary by unacceptably low laboratory-

cured or field-cured cylinder strengths.

Therefore, core strengths should be ob-

tained from the in-place concrete that repre-

sents the low cylinder strengths. Unfortu-

nately, in practice, the cores aren’t always

removed from locations in the structure rep-

resented by low cylinder strength results.

Fo r example, if 150 cubi c yards ar e

placed in a wall, ACI 318 “Building Code

Requirements for Reinforced Concrete” re-

quires only one strength test. Concrete for

the one strength test is removed from a

middle portion of a single truck. Assuming

8 cubic yards per ready mix truck, it takes

19 truckloads of concrete to fill the wall.

Because ACI 318 requires that cores be re-

moved from the area in question, that

means locating the suspect concrete from

that one truckload.

If accurate placement records are avail-

able, the area of low strength concrete may

be located and cores removed. However,

choosing core locations based on placement

records does not confirm that the one truck-

load of concrete tested is the only low-

strength concrete in the wall. Although re-

moving cores from a suspected low-strength

area satisfies ACI 318 criteria for sampling,

other locations may need testing.

For instance, the one truckload of suspect-

ed low-strength concrete may actually repre-

sent the quality of concrete in other truck-

loads. Using a nondestructive technique to

locate the suspect truckload of concrete pro-

vides a comparison for locating other poten-

tial low-strength areas.

Occasionally, the contractor determines

the area of suspect concrete by pointing to

an arbitrary location. Alternatively, the test-

ing laboratory may core concrete in a loca-

An under-

standing

of concrete

core test-

ing can be

invaluable

when

in-place

concrete

quality is

questioned

By Bruce A.

Suprenant

Core strength variation

of in-place concrete

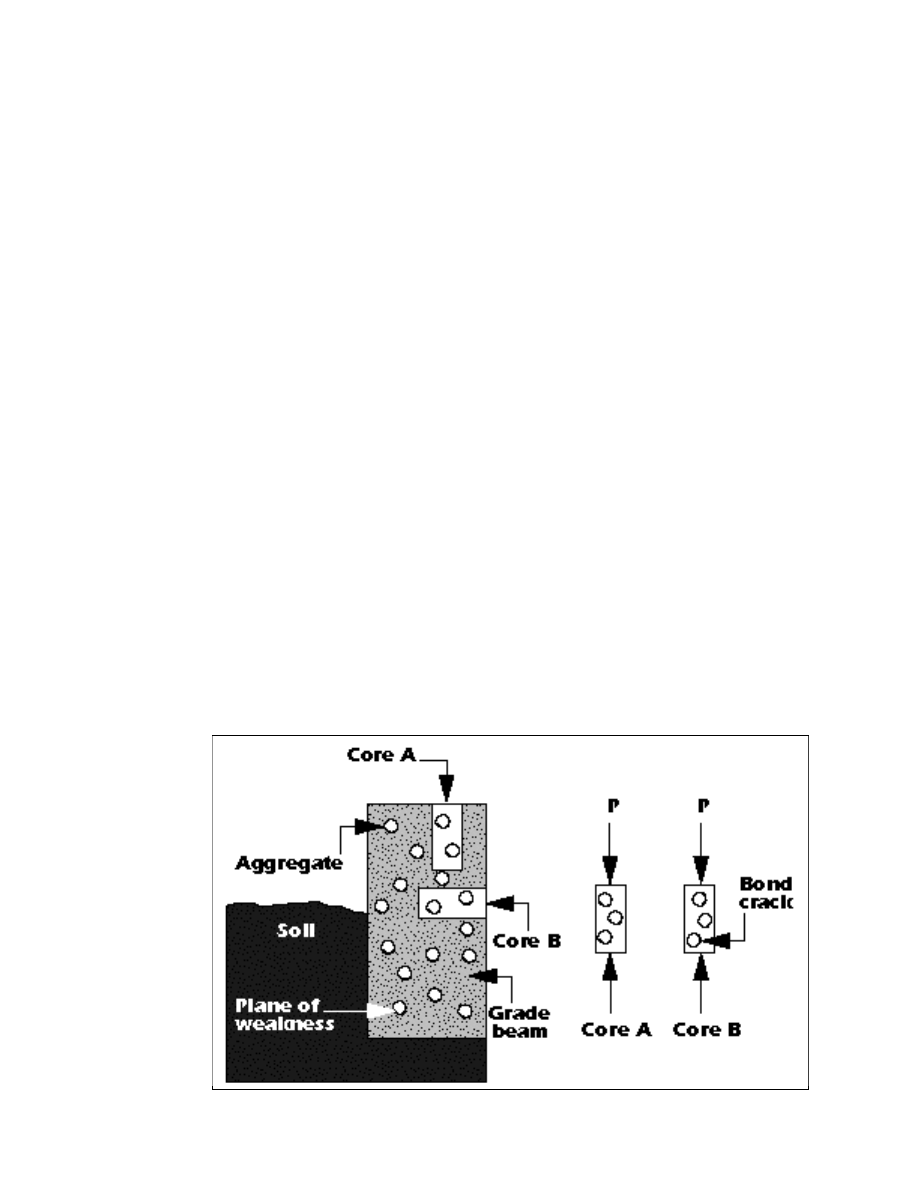

F i g u r e 1 .

Pl a nes of

weakness under coarse

aggregate particles due

to bleeding.

tion accessible to its equipment.

While accurate placement records

are beneficial, verification by a

nondestructive testing technique is

pr ud ent. Id eall y, the engin eer

should be involved in determining

the location for core testing.

Low cylinder strengths may be

due to errors in sampling or testing

and not due to inadequate concrete.

Engineers must decide whether the

low cylinder strength indicates poor

testing, a bad truckload of concrete,

or a bad placement, then, if neces-

sary, plan an appropriate core test-

ing program.

Cores vs. cylinders

Cores do not serve the same pur-

pose as cylinders. Strength of stan-

dard cylinders represents the quality

of concrete delivered. Cylinder com-

pressive strength represents the

quality of concrete batching, mixing,

and transportation, as well as the

sampling, preparation, handling, cur-

ing, and testing of the cylinders.

Strength of cores represents the in-

place concrete strength. In addition

to concrete batching, mixing, and

transportation, core compressive

strengths represent the quality of

placement, consolidation, and cur-

ing, and the techniques for obtaining

and testing cores. Therefore, the re-

lationship between core and cylinder

strength varies because of the char-

acteristics that each specimen repre-

sents.

Coring direction

Cores obtained by drilling in the

direction of concrete casting may

provide a higher strength than cores

obtained by drilling perpendicular

to the direction of casting . The

strength difference due to drilling

direction is generally attributed to

bleeding in fresh concrete, which

creates a weak paste pocket under

coarse aggregate particles (Figure 1).

Because of the bleedwater, the

paste-to-coarse aggregate bond be-

low the aggregate particles may be

w e a k e r .

A load applied parallel to the weak

bond opens a crack, creating a

strength-decreasing flaw. However, a

load applied perpendicular to the

weak bond closes the crack, mini-

mizing the effect of the bleedwater

layer. If this theory holds true, reduc-

ing bleedwater minimizes the effect

of coring direction. Thus, any factor

that affects bleeding, such as the

concrete mix design, mix ingredients,

air content, and placement and con-

solidation techniques, also deter-

mines the strength difference of

cores drilled vertically or horizontal-

ly.

Most slabs and foundations are

cored parallel to the direction of

casting, resulting in no associated

reduction in strength. Walls and

columns are cored perpendicular to

the direction of casting, thus a re-

duction in strength may occur.

The data on the effect of coring

direction is contradictory. It is quite

likely that the compressive strength

of cores drilled horizontally are

stronger than cores drilled vertically.

Practical considerations, however,

like variations in placement, consoli-

dation, and mix variability might ob-

scure a coring direction difference

that is discernible only under pre-

cise control of the mix and con-

struction practices. The current prac-

tice in the industry is to neglect any

effect of coring direction.

Top-to-bottom strength

variation

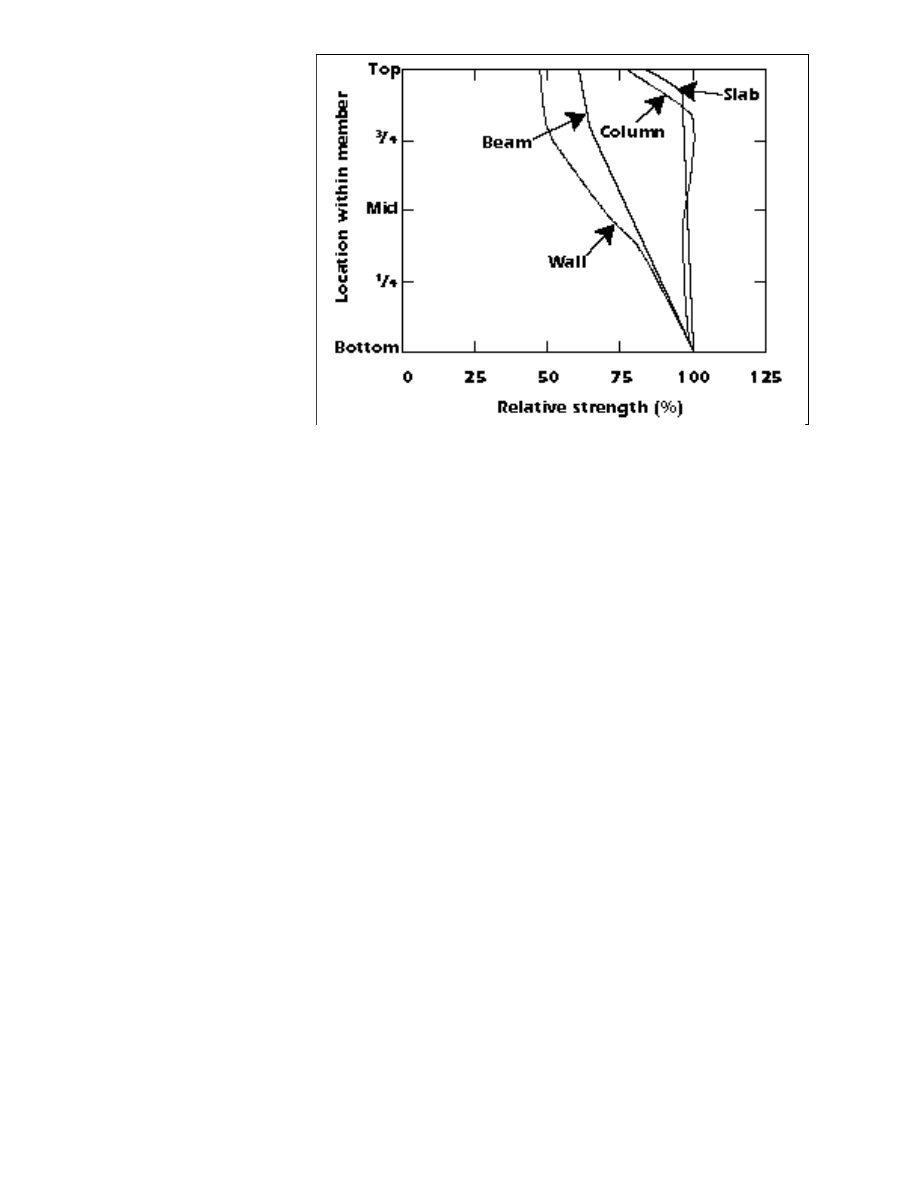

It is generally acknowledged that

concrete strength varies within a sin-

gle element. The strength variations

shown in Figure 2 should not be

considered as absolute numbers.

Figure 2 is very useful, however,

when planning a nondestructive sur-

vey to determine the likelihood of a

low-strength cylinder or core loca-

t i o n s .

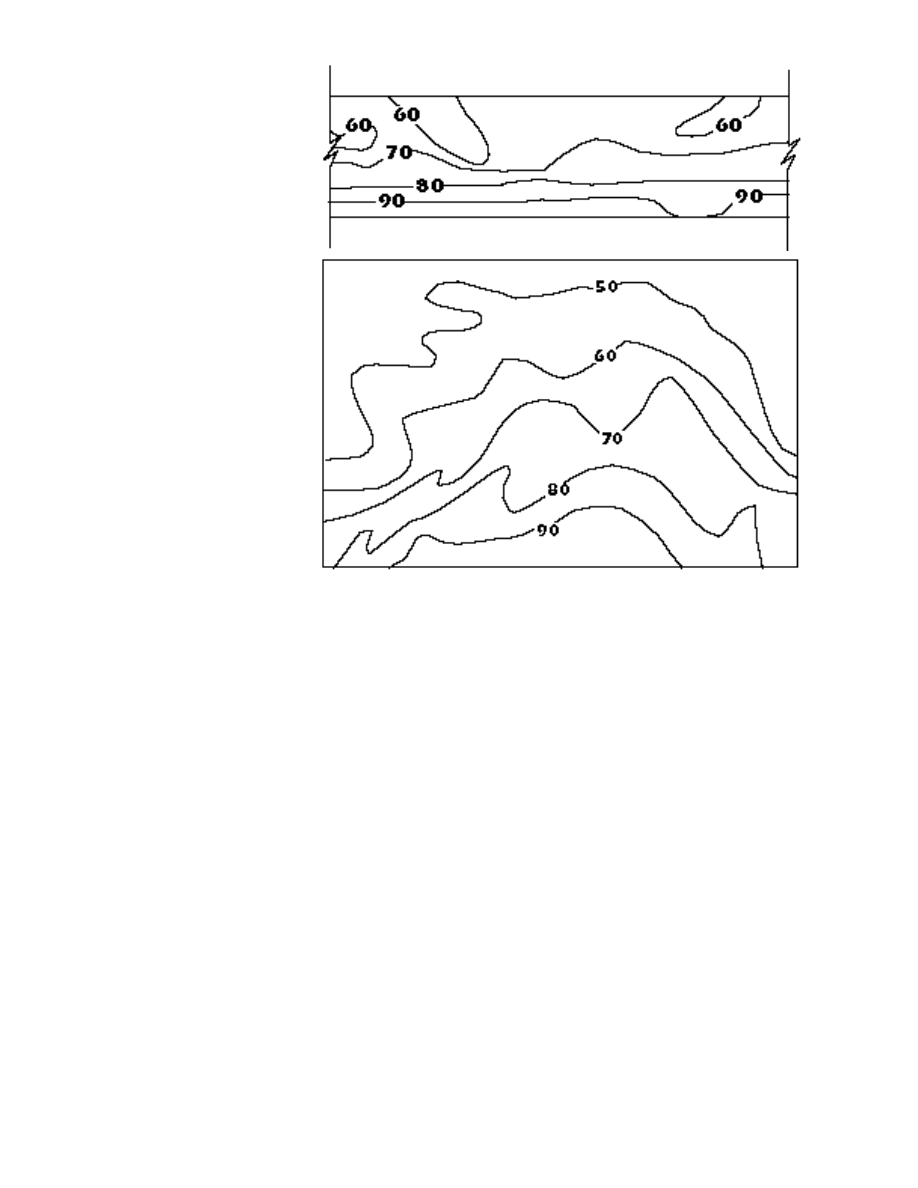

Laboratory test results indicate two

apparent causes of the strength vari-

ation: strength increase at the bot-

tom attributed to greater static pres-

sures caused by the concrete above

and strength decrease at the top at-

tributed to higher water-cement ra-

tios as a result of bleedwater (Figure

3 ) .

Consolidation

A contractor’s consolidation effort

has a significant effect on concrete

strength. It is estimated that between

5% and 20% of air is entrapped while

placing concrete. Vibrators reduce

the amount of entrapped air by con-

solidating the concrete. The core’s

compressive strength represents the

Figure 2.

Estimated within-member strength variation.

degree of consolidation achieved by

workers and their equipment.

Some state highway departments

studied how the spacing of im-

mersed vibrators affects core com-

pr essive str eng th . On sli pfor m

pavers the vibrators are fixed at a

set spacing. Concrete directly in the

path of the vibrators is consolidated

better than concrete between the

vibrators. Vibrator spacing is cho-

sen based on the radius of influ-

ence, usually 24 inches.

Cores removed from the path of

the vibrator are stronger and denser

than cores removed between vibra-

tors. Cores removed from the bot-

tom are stronger and denser than

those removed from the top. Work

by several highway departments

shows that a reasonable maximum

decrease in a pavement core’s unit

weight compared to the unit weight

of an ASTM cylinder is 4%. This

corresponds to a loss in compres-

sive strength of about 1200 psi.

Effects of curing

The thermal history and curing of

cores is quite different than for stan-

dard cylinders. The structure’s ther-

mal environment might be better or

worse than that provided by labora-

tory curing. Also, most structures

aren’t moist cured like a standard

ASTM cylinder. Field curing is un-

likely to be as good as moist curing.

Field concrete may be subjected

to cold- or hot-weather curing con-

ditions. High temperatures can low-

er concrete strength but lower tem-

peratures could actually produce

stronger concrete at later ages.

The methods for obtaining and

testing a core obscure the effects of

curing. Curing dramatically affects

the concrete surface, but has less of

an effect on the interior concrete.

The outer concrete protects the in-

ner concrete’s humidity and temper-

ature conditioning. When cores are

tested, the restraint of the testing

procedure makes most concrete

cores fail within the middle portion

of the core. Weak outer edges, af-

fected by curing methods, are not

usually represented by the core fail-

ure mode or the resulting test value.

The test results presented indicate

that for vertical members such as

walls and columns, curing had little

effect on core strengths. For slabs,

however, curing is critical to achiev-

ing adequate core strength.

Recommendations for core

locations

For a core drilled perpendicular

to a horizontal surface, ASTM C 42

states, “The location shall be, when

possible, so that its axis is perpen-

dicular to the bed of the concrete

as originally placed and not near

formed joints or obvious edges of a

unit of deposit.” For a core drilled

perpendicular to a vertical surface

or a battered surface, ASTM C 42

states the core “shall be taken from

near the middle of a unit of deposit

when possible and not near formed

joints or obvious edges of a unit of

deposit.”

The Concrete Society Working

Party recommends that “the section

of core to be tested should not in-

clude the top 20%, to a limit of 12

inches, of the lift concerned. The

top 2 inches should not be includ-

ed in any case.” The Nati ona l

Ready Mixed Concrete Association

(NRMCA) r ecommends again st

drilling cores from the top layers of

columns, slabs, walls, or footings.

NRMCA indicates that cores from

the top layer s are 10% to 20%

weaker than cores from the middle

or lower portion. ✥

This article is based on publication

185, “Understanding Concrete

Core Testing,” published by the

National Ready Mixed Concrete

Association (NRMCA). For more in-

formation or to order a copy, con-

tact NRMCA, 900 Spring St., Silver

Spring MD 20910 (phone: 301-

587-1400, fax: 301.585.4219).

Figure 3.

Typical relative percentage strength contours for a beam (top) and for a wall (bottom).

PUBLICATION #J950134

Copyright © 1995, The Aberdeen Group

All rights reserved

Wyszukiwarka

Podobne podstrony:

making tea in place experiences of women engaged in a japanese tea ceremony

Johnson Summary brief shades of embeddedness Tie strengh and obligations in direct selling parties

Natural variations detected in the isotopic composition of copper possible applications to archeolo

Cleaning In Place Technology(1)

Clean In Place Review

Cleaning In Place Systems

Evaluation of in vitro anticancer activities

Top of Volcano Blown of in Blast!

Cleaning in Place

Cleaning In Place Technology(1)

Clean In Place Review

Laurence M Janifer Agent in Place

variation of 7979 for claire opis

Rohloff 2004 Chemotypical variation of tansy

tekst Selena Gomez Wizards Of Waverly Place Thame po polsku

Prepositions of time, place and transport

więcej podobnych podstron