Mine ventilation and air-conditioning |

|

Face cooler

Other sources of heat and heat sinks, such as pipelines, have an additional influence on mine climate. The German coal industry's decision to introduce mechanised coal winning brought about a dramatic change in the conditions prevailing below ground. When the ECSC Treaty was drawn up in 1952 climate issues were generally of little or no significance for those responsible for operating Europe's coal industries. However, greater face concentration combined with an increase in winning depth was to generate increasing quantities of thermal energy, which in turn placed an additional burden on the underground climate. The workplace temperature limits that were imposed by a number of European countries reflected the efforts that were under way to introduce an acceptable ergonomic workplace threshold for underground personnel. As well as undertaking mine climate research, the first of the ECSC-funded projects also sought to acquire basic information into the occurrence and release of mine gas. This work was to run until the early 1970s, with some specific projects continuing until well after that date. Coal and the surrounding strata - though the latter are much less affected in this respect - contain certain quantities of mine gas that have been created as a result of the conversion of organic matter. This gas usually comprises 90 to 95% methane (CH4) and 2 to 4% carbon dioxide (CO2). As methane is explosive when mixed with air in certain proportions (4.4% by volume for the lower explosion limit and 16.5% by volume for the upper explosion limit) the problem of gas emission became a key part of the European Community's mine-safety R&D programme. On the basis of the fundamental research results, and especially the information relating to the nature of the coal itself, viable methods were developed for assessing the potential risk of an underground gas explosion. This included measuring the gas content and gas pressure, determining the desorption characteristics as a way of assessing the risk of gas outburst and measuring the gas permeability of the coal. Investigations were also carried out with a view to improving planning reliability and devising a better system for controlling gas emissions. Much of this work focused on studies that were aimed at identifying the gas-emission zones in and around the working face and the associated development of methods for calculating emission levels and optimising gas drainage techniques. The main parameters affecting the absorbed and free gas component of the coal, and the quantity of gas that is liable to be released from the solid, are: gas composition, temperature and moisture levels, ash content and the coal's pore ratio and structure. The systematic investigation of all these factors revealed that the phenomenon of gas emission was specific to the nature of the deposits. A series of part-overlapping and part-parallel investigations was therefore undertaken in the different coalfields of the coal-producing countries.

Two of the key objectives here were to establish the gas content of the deposits and to pre-calculate the gas make as a basis for improving existing gas-control techniques and developing new technology. Germany's decision to amend its Law on Energy Supply now provides an opportunity for mine-gas to be used in markets beyond that of colliery own consumption. Much greater emphasis is therefore being focused on developing methods for the extraction of methane before, during and after the coal winning phase.

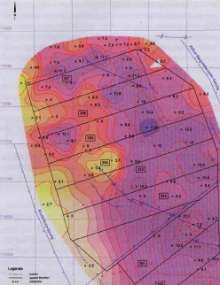

Gas content map

In Germany, for example, direct measurement of gas content (laboratory or desorption measuring equipment) was introduced as the standard method. This means that collieries are able to carry out their own independent gas-content analyses. The parameters required for indirect measurement (sorption method and gas pressure in the coal measures) were also investigated, but this process proved to be difficult to carry out. Reliable methods have still not been developed for measuring gas pressure in the working seam, although a viable laboratory technique does exist for determining the sorption isotherms. Nevertheless, the indirect method can be used for strata that are bored through at an oblique angle to the stratification because the borehole that has to be drilled in the surrounding rock can be effectively sealed.

From the early 1980s investigations were conducted in a number of coalfield areas in order to establish the relationship between the gas content and the depth/distance to the overburden measures. This generally involved using data from surface exploratory drillings to produce gas content maps. Gas-content analyses, which were carried out using the direct process and were based on surface and underground drill-core samples, showed that the gas content of the deposits tended to increase until it reached a maximum limit. This was an extremely important finding as far as the evaluation of new working panels was concerned.

The anticipated gas make is one of the basic parameters used for mine planning purposes. The pre-calculation processes are normally based on gas emission measurements, e.g. gas make monitoring. The release of gas into the coal face or mine roadways is the result of rock-mechanical de-stressing processes, which can be described using empirical gas-emission models. The gas-emission projections depend to a large extent on what is known about the formation of the gas-emission cavity around the face or drivage, the rate of gas discharge into this cavity and the gas content of the working seam and the adjacent seams. EU Member States have investigated these relationships and have now developed a standardised projection process. The gas-emission calculation is programmed for computer processing in the same way as the mine ventilation planning data and climate projections. Since 1985 two new methods have been proposed for calculating gas-emission rates. The first involves carrying out short-term gas-emission projections using continuous data recording and processing. The second comprises the use of "expert systems" that are designed to help assess irregular or sudden gas emission occurrences in those areas where emission calculations have previously proved unsuccessful. While these investigations were under way work also began on the first research projects to have as an objective the development of a procedure for the precise calculation and effective control of gas emissions in roadway drivages with auxiliary ventilation. In this connection it is worth noting that the German coal industry carried out trials with the French calculation method for roadway drivages. However, it was found that because of the different operating conditions this system required some adaptation before it could be used effectively. The first projects dealing with gas-emission control concentrated mainly on coal faces and sought in particular to investigate how operational factors affected gas emission levels. Gas drainage was considered to be the primary option here. Research into gas-emission control looked at a number of different methods with a view to developing them to full industrial status. These included rich-gas (CH4 < 22%) and lean-gas (CH4 > 3%) drainage, floor-gas drainage, preliminary gas drainage from the coal seam prior to coal extraction and drainage from gas collector roadways above or below the goaf. Apart from lean-gas drainage, all the abovementioned processes are now still in widespread use. These methods were subsequently developed and refined through a series of follow-up projects. They have now been adapted very effectively to suit a range of underground conditions and their application is based on the latest technical equipment (e.g. computer-controlled gas drainage stations above ground with utilisation of the extracted gas). The rich-gas extraction process, which was already a recognized technique when the ECSC research work began, is now used by every coal industry in the world. However, it first had to be adapted effectively to suit the different mining conditions prevailing in each country, which meant modifying not only the gas drainage equipment but also the layout of drainage circuit. Gas drainage rates and airflow levels are monitored by means of the latest measurement technology, which has also been either developed or refined by ECSC-funded research. In the 1970s the first successful trials were also carried out into the extraction of mine-gas from abandoned collieries, the objective being to protect operating collieries from gas inflow. While at the beginning of the ECSC research programme all gas drainage measures were aimed solely at protecting mine workings and active collieries from the risk of explosion, other important aspects have now come to the fore over the years - including the utilisation of mine gas as an energy commodity, both for economic reasons as well as on environmental grounds. Gas drainage trials based on surface boreholes drilled into the roof of the coal seam indicated that there was no detectable relief for the coal winning operation, at least as far as West-European mining conditions were concerned. However, tests involving long-reach boreholes (> 100 metres), which were drilled in order to collect the gas from the upper roof area of the gas drainage zone, did prove promising on a number of coal faces. The idea of gas drainage via long boreholes drilled parallel to the seam in the roof or floor beds of the gas-drainage zone is now being looked at again. Tests were also carried out in which the coal seam was split by hydro-fracturing from the surface in order to increase the strata's potential for the preliminary drainage and commercial-scale utilisation of the gas in the seam. Unfortunately these trials failed to achieve sustainable success. During the 1980s much greater attention was focused on the problem of controlling gas emissions on "high- performance coal faces"; this included gas extraction at the T-junction on retreat faces, gas drainage in strongly-inclined and steep deposits, gas drainage on working faces and the study of fluctuating gas-emission rates in and around residual pillars.

While the gas drainage measures proved to be fairly successful, tests aimed at controlling emission levels at the T-junction on retreat faces made little headway. The "window method" employed by the German coal industry, whether using windows or pipes and both with and without lean-gas extraction, failed to solve the problem. The "back return system" and "bleeder road system" developed to viability in the UK proved to be unsuitable for direct introduction into other coal industries. Because of the operational advantages of retreat mining over the advance method it was recognized that this area was in need of further research. For the sake of completeness we must also mention the research project entitled "Prevention and elimination of increased CH4 concentrations beneath the coal-face conveyor", which involved the use of slotted line-pans and air blower/suction units to draw air into and out of the bottom AFC strand. Neither system proved successful. The need for further research became a matter of irrelevance when the coal industry introduced totally-enclosed AFC floor pans. During the 1990s much greater use was made of models and computer simulation as a cost-effective alternative to large-scale field trials. Computer-assisted simulation is now used to investigate the build-up of localized gas accumulations and to assess the possibility of draining gas through the rock mass and goaf area. Other important fields of research include the drainage of gas from closed collieries and the commercial utilisation of mine-gas. Initial ECSC research work in the field of measurement technology focused on two objectives. The first was the development of equipment for measuring carbon-monoxide and oxygen content and the development of self-rescuer systems, and the second involved extensive research into the occurrence and release of methane gas imprisoned in the coal and surrounding strata. Here great emphasis was laid on the use of computer-assisted monitoring systems, whereby data on mine-gas levels, ventilation flow, pressure levels, temperatures etc. were transmitted to a central station for processing by computer (in the form of daily, weekly or even monthly logs). With a view to examining the particular conditions in one of the ECSC member countries funding was provided between 1988 and 1990 to develop a special type of cap-lamp which featured a gas monitoring unit with alarm function built into the feed cable between the battery and the head-piece. This system was designed for measuring methane, carbon monoxide and oxygen.

In the early 1990s research was also carried out with a view to developing a thermographic measurement and analysis system for locating concealed mine fires. However, this work was not taken any further because it was thought that the system lacked the resolution needed for underground application. A few years later greater success was achieved in the development of gas measuring equipment for the early detection of mine-fires. This involved the use of prototype versions of the gas-chromatograph system already approved for use below ground. Unfortunately no manufacturer could be found for this equipment because of the small production run required for the mining industry. Promising results have also been obtained in recent years in the development of processes for the automatic calibration of airflow and gas measuring devices fitted with electrochemical cells. The first development projects of the 1973 - 1976 period with the word "ventilation" in the title focused more on measurement technology (data collection and processing) than on mine ventilation proper. It was not until a few years later than research began to concentrate on mine ventilation in the general sense.

Auxiliary ventilation

One of the first projects investigated the operation of closed-circuit ventilation systems with auxiliary-fan control and the impact of this type of system on ventilation stability, pollutant concentration levels and climate changes in the underground workings. The problems associated with closed-circuit ventilation were again studied and re-assessed some years later as part of an investigation into combined auxiliary-ventilation installations. The industry was very keen to develop combined auxiliary-ventilation equipment and also to improve system reliability and availability. As a result of this interest an additional project was undertaken to investigate how the shut-down and start-up of auxiliary-ventilation equipment affected the stability of the main ventilation system. The impact of an underground fire on mine ventilation stability was first investigated as part of a research project in the early 1980s. Some ten years later this scenario was calculated using computer simulation and on this basis a better system was then developed for assessing airflow disruption as a result of a mine fire. In the early 1980s studies were also conducted to measure aerodynamic loss in shafts, air ducts and fan drifts due to poor geometrical design and the presence of fixtures, fittings and shaft conveyances. This scenario was also reconstructed in a series of model tests and the aerodynamic improvements realized as a result of the true-scale modelling work were subsequently introduced by the industry with great success. In the mid-1980s it was found that under certain conditions real cost savings could be made by regulating or reducing the airflow without compromising safety standards.

Several development projects also examined the problem of mine ventilation in the context of controlling gas emissions on the coal face. By switching from retreat-based ventilation to advance ventilation, and by introducing new ventilation systems (such as Y, H and W ventilation), effective solutions were found to operational problems.

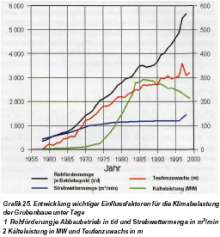

Diagram showing climate developments below ground

Initial investigations in this field of study sought to examine the heat-transfer processes taking place in the strata and the way in which thermal energy was transmitted from the workings into the mine air. Increasing face concentration has meant that heat transfer from the mineral and from electrical plant now has a much greater impact on the mine environment, with the result that these heat sources are now the subject of much closer scrutiny. Special attention has also be directed at the fact that much of this heat is not transferred in a dry state. In fact most of it is used for the evaporation of free moisture and is therefore responsible for increasing air humidity. In-situ measurement data were increasingly required to complement the theoretical research work, which was in turn backed up by laboratory measurements of the thermal conductivity of Carboniferous strata and coal. As a result, parameters were developed that could effectively reproduce actual conditions below ground - in spite of the complex nature of the underground heat-transfer relationships. As well as the physical characteristics of the strata, equivalent heat conductivity was also introduced in order to take account of additional thermodynamic effects. This parameter incorporates factors such as the amount of heat released by the extracted coal, the number of winning shifts and the method of roof control used (caving or stowing). The quantity of thermal energy generated by the electrical equipment was initially included as part of the equivalent heat conductivity factor. However, as electrical heat loss became increasingly important as far as the underground environment was concerned, this factor soon had to be treated as a separate consideration. A humidity characteristic was therefore developed that could take sufficient account of the effect of moist heat transfer. This parameter is designed to represent that proportion of the total surface area that is moisture covered. On longwall faces this figure will depend on the quantity of coal extracted and the method of roof control. In the case of mine roadways an important factor is whether the road is being used for coal conveying or not. Because of the large number of factors affecting heat transfer from the workings to the mine air, it was found that no firm characteristic values could be formulated. An extensive programme of measurements was carried out and the findings led to the development of characteristic fields. The measurements focused on establishing climate values as a function of the coal output and the general operational situation. Increasing attention was paid to measuring the actual electrical power consumption of the plant and equipment, which in some cases differed significantly from the rated power output. Different types of face layout were investigated. System variations included the type of support installation, the method of roof control, face length, coal output and the design of the winning equipment. Many different measurements were also taken in development roads, including different types of shotfired and mechanized drivages. As the underlying conditions of the workplaces tended to change from year to year, new measurements were constantly needed in order to fit the changing circumstances.

The measurements became ever more detailed in nature as measurement technology developed. While the first measured data were obtained manually, and involved considerable labour costs, recording equipment was gradually introduced in the course of time. Modern computer technology and data transmission systems eventually meant that the relevant data could be stored in the instrument itself for subsequent processing by computer or transferred directly to surface processing systems by means of remote transmission circuitry. This technology was also developed with the support of ECSC-funded research projects. Effective air conditioning depends on the successful synchronisation of three essential factors - refrigeration, cooling-agent transport and low-temperature transfer. During the development and introduction of air cooling equipment it became apparent that the air-conditioning system had to be designed to suit the individual conditions prevailing at the colliery and at the working faces. If the refrigeration requirement is expected to be low, or if cooling is only needed at a few localized workplaces and for a limited period of time, then a decentralized air-conditioning system is the most appropriate solution. This means that local areas are cooled by means of face chiller units. However, decentralized chilled-water machines can also be deployed to supply several air coolers, such as on a longwall face for example. Arrangements of this type save on the high investment costs that would be required for the design and construction of a centralized cooling installation. One of the disadvantages of this set-up, however, is that the equipment has to be sited in the harsh environment of the workplace, which often results in increased expenditure on maintenance and repair. When there is a large refrigeration requirement in remote areas of the mine air-cooling systems with centralized refrigeration plant are to be preferred to the decentralized system. In this case the expensive machinery and equipment is positioned at a fixed and well-protected location. The chilling medium is delivered to the individual cooler units through cold-water pipes. As the higher investment outlay required for this system is usually offset in the medium term by the relatively low operating costs, cooling installations of this type can operate at very low cost over long periods of time where there is a fairly high refrigeration requirement. Investigations have already confirmed the economic advantages of large-capacity centralized cooling installations.

The ECSC provided funding for research projects whose aim was to improve the cost efficiency of existing refrigeration systems. This work was based on the principle that the total refrigeration capacity installed at the workplace was not required over the entire operating life of the cooling equipment. Significant energy savings can be made, especially during scheduled shutdowns, when only the immediate refrigeration demand is covered. Calculations have shown that the capital outlay required for installing a control system is soon paid off in a short period of time. Mine climate measurements carried out on a number of production faces have shown that in many cases the cooling output can be substantially reduced during non-cutting periods without any risk of negative repercussions as far as the face climate is concerned when coal winning is resumed.

Another important facet of ECSC-funded research was the examination of new component technology in the field of underground air-conditioning with a view to driving further development. A focal point of this work was the investigation of mine cooling systems. The research began by testing the underground performance of commercially-available heat exchangers based on tried and tested technology. The finned-tube coolers were found to lack the mechanical stability needed for the harsh conditions encountered below ground and tended to become heavily contaminated because of the high humidity levels and dust concentrations present in the mine air. Water sprays proved ineffective as a long-term decontamination method, so the decision was taken to develop a new range of air coolers for underground application. The new vaned-tube coolers that were subsequently produced proved to be better suited for coal-mining use. Further investigations then showed that plain-tube cooler units yielded the best performance in the long term. This development work was driven by performance trials as well as by dust tests under laboratory conditions. The mining suppliers currently offer various designs of mine cooling equipment. All these coolers, and also the evaporators fitted to air cooling systems, feature smooth-tube units. Another interesting development has been the mist cooling system, which was occasionally used at one colliery to provide most of the air pre-cooling capacity. In this system the chilled water is sprayed directly into the mine air. For a given volumetric airflow and water throughput the direct- contact system is capable of transferring a larger cooling capacity than conventional mine coolers. However, as the infrastructural requirements for mist-type coolers are comparatively expensive, only a few collieries have opted to install this type of system. Further development work on face coolers has focused on minimising dust sensitivity and improving cooler performance, while at the same time reducing the size of the units. The latest face coolers are cylindrical in shape and are available in three sizes to suit different seam thicknesses.

Source: 50 years of ECSC Coal Research |

http://www.steinkohle-portal.de/en_content.php?id=646

Wyszukiwarka

Podobne podstrony:

Popular Mechanics Finding And Fixing Water And Air Leaks

6 4 1%20Ventilation%20in%20Air conditioned%20Premises

MANUAL Antipersonnel Mine M18A1 and M18 Claymore

VENTILATION AND COOLING IN UNDERGROUND MINES (2)

VENTILATION AND COOLING IN UNDERGROUND MINES

Filtration and Air Cleaning Systems

M37b2 Heating, Ventilation and AC 21 33

M37b1 Heating, Ventilation and AC 1 20

Popular Mechanics Finding And Fixing Water And Air Leaks

6 4 1%20Ventilation%20in%20Air conditioned%20Premises

MANUAL Antipersonnel Mine M18A1 and M18 Claymore

Law, Property Rights, and Air Pollution

An Examination of the Evolution of Army and Air Force

17 E85 Heating and Air Conditioning System

więcej podobnych podstron