hoverplatform

Product Oetails Company Profile

I Description of workshop air cushion yehicle

Air cushion vehicle is a new means of transportation. tts principle is to form one layer of air film between air cushion and earth and make the hovercar 'suspend*. So now the friction between air cushion vehicle and earth is very smali and a slight thrust can push the air cushion vehicle which is bearing hundreds tons move easily.

Comparing to traditional transportation measures, air cushion yehicle is safer, higher efficiency, morę flexible and stable and of course much cheaper!

Air cushion yehicles are widely used in manufacturing transformers, diesels. locomotives, automotives etc. and logistic transportation industry as well.

II Main features of workshop air cushion yehicle

1) Stable function: suitable for continuous stable working, Iow ncise, few maintenance

2) Manuał level adjusting, free from unbalance loading or Ikjuid object sloshing

3) Fault diagnosing: automatic self-diagnosing, easy maintaining

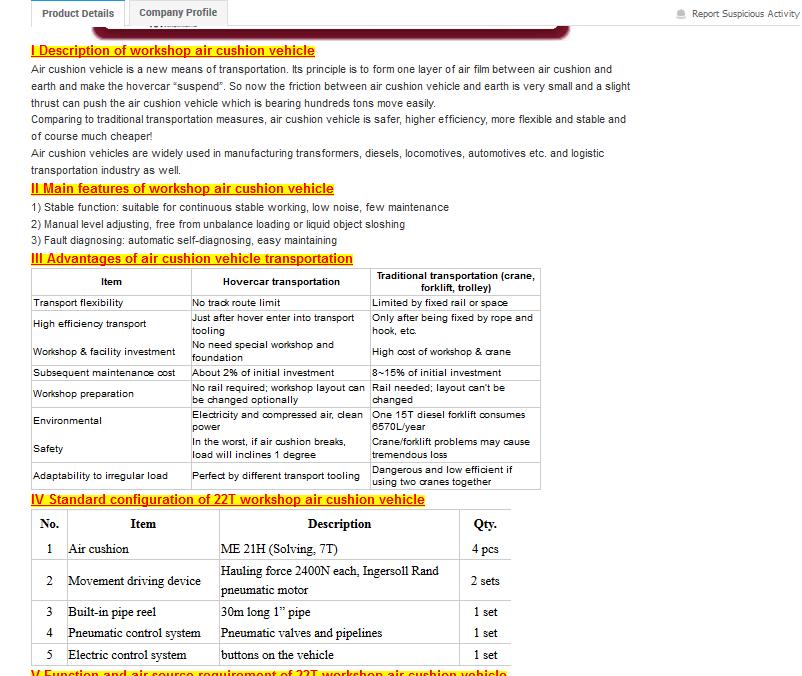

III Advantaqes of air cushion yehicle transportation

|

Item |

Hovercar transportation |

Traditional transportation (orane, forklift, trolley) |

|

Transport flexibility |

No track route limit |

Limited by fixed raił or space |

|

High effidency transport Workshop & faality investment |

Just after hover enter into transport tooling No need spedal workshop and foundation |

Only after being fixed by ropę and hook. etc. High cost of workshop & orane |

|

Subseguent maintenance cost |

About2% of initial investment |

8'-15% of initial inyestment |

|

Workshop preparation |

No raił reguired; workshop layout can be changed optionally |

Raił needed; layout can’t be changed |

|

Environmental Safety |

Electridty and compressed air. dean power In the worst. if air cushion breaks. load will indines 1 degree |

One 15T diesel forklift consumes 6570L'year Crane.'forklift problems may cause tremendous loss |

|

Adaptability to irregular load |

Perfect by different transport tooling |

Dangerous and Iow effident if using two cranes tcgether |

IV Standard confiauration of 22T workshop air cushion yehicle

|

No. |

Item |

Description |

Qty. |

|

1 |

Air cushion |

ME 21H (Sohing, 7T) |

4 pcs |

|

2 |

\Iovement driving device |

Hauling force 2400N each, Ingersoll Rand pneumatic motor |

2 sets |

|

3 |

Built-in pipę reel |

3 Om long 1” pipę |

1 set |

|

4 |

Pneumatic control system |

Pneumatic valves and pipelines |

1 set |

|

5 |

Electric control system |

buttons on the yehicle |

1 set |

Wyszukiwarka

Podobne podstrony:

hoverplatform Product Details Company Profile Report Suspcious Activity Quick Details H-21-22 3600

hoverplatform/ LDescription of workshop air cushion yehicle Air cushion vehicle is a new means of tr

10630 Materiały na zaliczenie nr1 H Ciosek vocabulary company profilesElectronics 1 A Electronics is

Tmpl 0102 COMPANY PROFILE PRODUCTSMOBILEWORLD.COMBEST MOBILE DEVICES & ACCESSORIES CATALOG ACCES

FOCIS O N CATALYSTS COMPANY NEWS developmenl of cellulosic ethanol and to expand ethanol production

Chariots of Fire Chariots of Fire 1 2 2ii CHARIOTS OF FIREFrom the ENIGMA PRODUCTION, LADD COMPANY

hoverplatform 2g V Function and air source reguirement of 22T workshop air cushion yehicle No. Ite

f3 4 source codę description of class X The source filename (withoul the . j ava exten$ion) must be

img112 (5) Wstęp S/.esnastowieczne również dzieło W. Harrisona, A Description of England, zbliżone u

9. Wierzcholski K., Chizhik S., Miszczak A.: The theoretical description of f

Amendment history Datę of effect Issue Description of amendment May 2001 4 Formal adoption of

• Forecasting and Strategie Studies Center - Head - dr R. Machnikowski 2.5General description o

Obraz (80) UNIT 3The Concept of Seąuentiality in the Description of Signs ~)GOAL To explain why sequ

więcej podobnych podstron