pg& 2

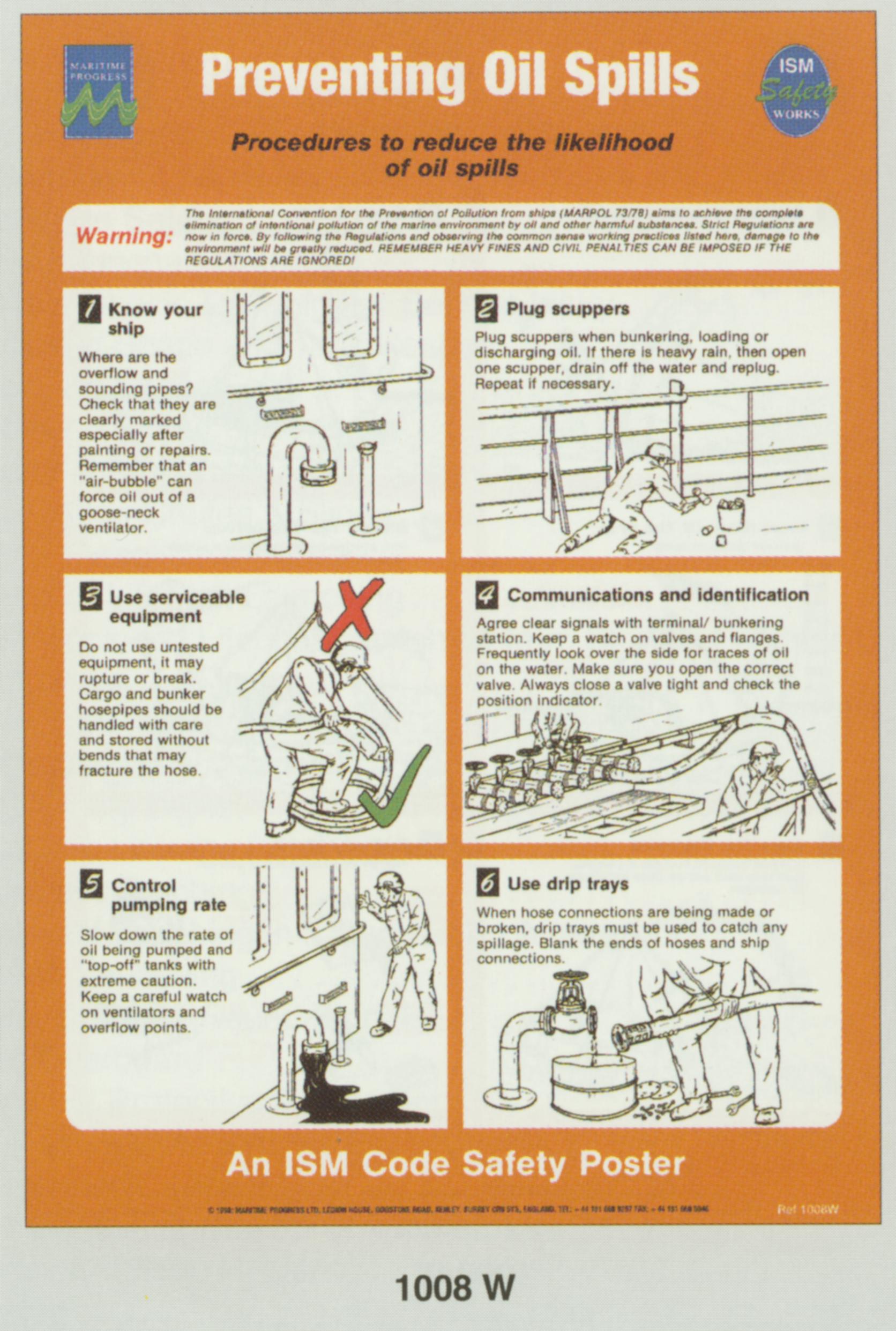

Procedures to reduce the likelihood of oil spills

UOKRS ^

Ł

Ttm IntarnatKHial ContmnUon to* Ib* Praaanfor ot PoMudon trom atup* (UARPOL 7179) *>ma to acht*** ttr* co*np**ta ... . attminatton af udanttonat poduUor ot tha mirto* wronmrt by ott ano otbar harmtut aubatancaa Sirtcl P*gwt*t>ont ara

W 3 mino: r>°w •* *>/c# By todomrmg tha Hagutal-on* and obaa*mng lh* oommon aanaa morktng praciteaa Uatad bata da 9 anatronnwnt mtu ba graatty raducad HEMEUBEP «EAVY FtNES AND Cl VIi PEN Al TlES CAN BE IUPOSED I PEOULA7IONS AHE IGNOPFD’

domaga to i

id if The

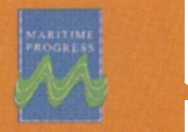

Q Know your ship

Where are the over1tow and sounding pipes? Check that they are clearty marked especialty after pałnting or repaira Remem ber that an "air-bubtote" can force oil out of a goose-neck ventiialor

Q Use seryiceable equlpment

Do not use untested equipment. it may rupture or break.

Cargo and bunker hosepipcs should be handled with care and stored without bends that may fracture the hose

b

Slow down the ratę of oil bemg pumped and "top-ofr tanks with extreme caution.

Keep a careful watch on ventilators and overflow pointa

i

Pług scuppers when bunkering. loading or dtscharging oil. If there is heavy raln then open one scupper. drain off the water and replug Repeat if necesaary.

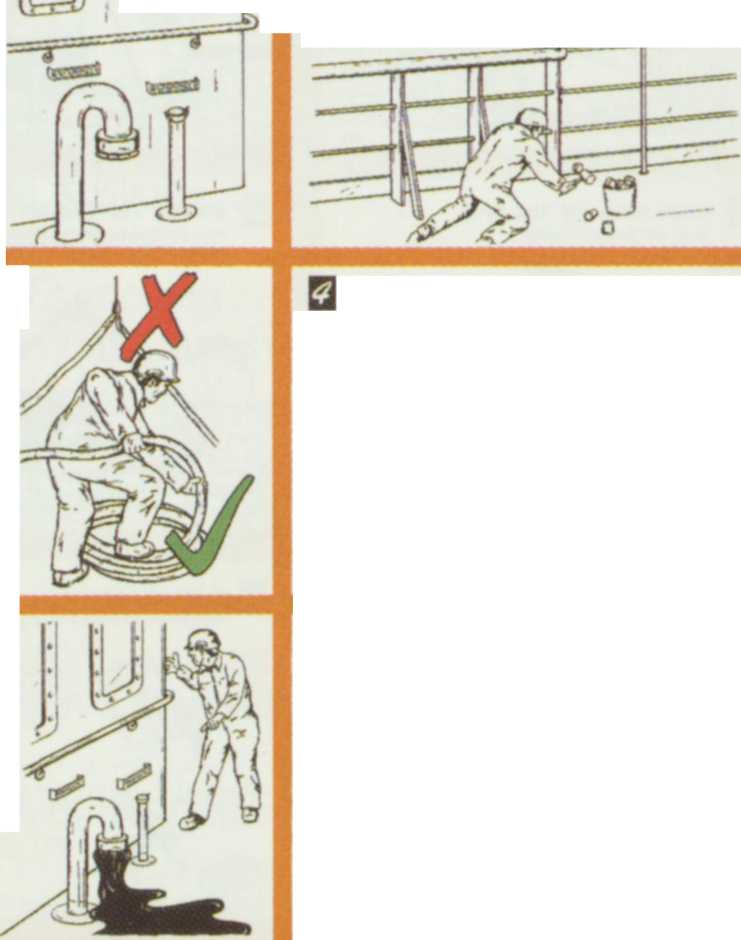

Communications and identificatlon

Agree elear aignala with terminal/ bunkering station Keep a watch on valves and flangea Frequently iook over the aide for tracea of oil on the water Make surę you open the correct valve Alwaya cloae a valve tight and check the position indicator

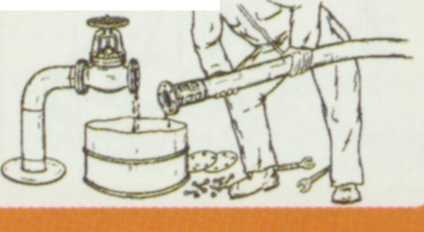

When hose connections are being madę or broken. drip trays must be uaed to catch any spił lagę Blank the ends of hoses and ship connections

ar* imkmkuh.«i *n

\mmtm. •«n,M

Wyszukiwarka

Podobne podstrony:

pg( 4 Recommended procedures to minimise the effect of an oil spili Ttm łnt9mmt1on1J Corwntśon ku tt

reduced to a minimum, the number of inscriptions was still too great to allow the map to serve pract

CBS 710 Automatic Loudness Controller The Model 710 is designed to reduce those portions of the audi

Technique of Taxation The essence of the Institute’s proposal reduces to this. The growth of product

Configuring an Answer File to Autoniate the Mini-Setup Wizard You can reduce the amount of configura

help1 3 Too much tension on the llne will break It. One way to remedy thls Is to reduce the drag, wh

230

JC3S8* DIGITAL MOD1FICATION OF CRlMNRY GATE VAI.VE CHAR CTRRISTICS AS A WAY TO REDUCE THE FUEL CONSU

PRECEDENT AMY SMITH D-LAB This iteration reduced the amount of materiał necessary, was easier to con

Future Perfect Progressive rttrl to emphasize or show that it will be a long time fule ; = to emphas

00014 L28ee5aa5f5654405d1c5056d87a4de 13 An Overview and Perspective on Control Charting enough to

00169 ?8fdc7697ba8e0e2234fcfe61c09204 170 McWilliams satisfy ^3 = r/0 = T] + T2. In addition to exa

img016 (86) 25. Whose responsibility is it to ensure the safety of pedestrians whi

więcej podobnych podstron