r55

11 Analiza technologiczności konstrukcji odlewu 187

11 Analiza technologiczności konstrukcji odlewu 187

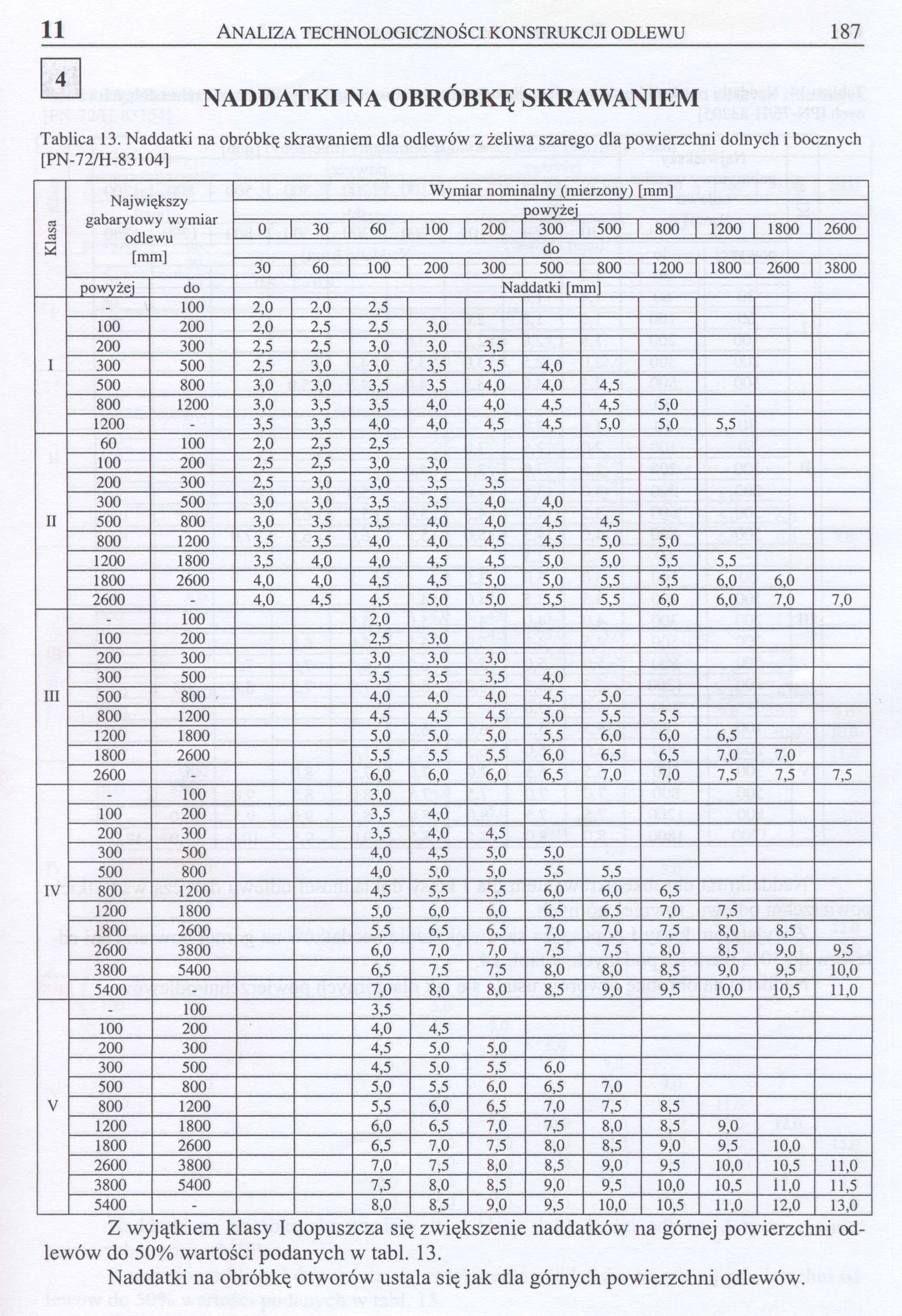

NADDATKI NA OBRÓBKĘ SKRAWANIEM

Tablica 13. Naddatki na obróbkę skrawaniem dla odlewów z żeliwa szarego dla powierzchni dolnych i bocznych [PN-72/H-83104]

|

Klasa |

Największy gabarytowy wymiar odlewu [mm] |

Wymiar nominalny (mierzony) [mm] | |||||||||||

|

powyżej | |||||||||||||

|

0 | 30 | 60 | 100 | 200 | 300 | 500 | 800 | 1200 | 1800 | 2600 | |||||||||||||

|

do | |||||||||||||

|

30 | 60 | 100 | 200 | 300 | 500 | 800 | 1200 | 1800 | 2600 | 3800 | |||||||||||||

|

powyżej |

do |

Naddatki [mm] | |||||||||||

|

I |

- |

100 |

2,0 |

2,0 |

2,5 | ||||||||

|

100 |

200 |

2,0 |

2,5 |

2,5 |

3,0 | ||||||||

|

200 |

300 |

2,5 |

2,5 |

3,0 |

3,0 |

3,5 | |||||||

|

300 |

500 |

2,5 |

3,0 |

3,0 |

3,5 |

3,5 |

4,0 | ||||||

|

500 |

800 |

3,0 |

3,0 |

3,5 |

3,5 |

4,0 |

4,0 |

4,5 | |||||

|

800 |

1200 |

3,0 |

3,5 |

3,5 |

4,0 |

4,0 |

4,5 |

4,5 |

5,0 | ||||

|

1200 |

- |

3,5 |

3,5 |

4,0 |

4,0 |

4,5 |

4,5 |

5,0 |

5,0 |

5,5 | |||

|

II |

60 |

100 |

2,0 |

2,5 |

2,5 | ||||||||

|

100 |

200 |

2,5 |

2,5 |

3,0 |

3,0 | ||||||||

|

200 |

300 |

2,5 |

3,0 |

3,0 |

3,5 |

3,5 | |||||||

|

300 |

500 |

3,0 |

3,0 |

3,5 |

3,5 |

4,0 |

4,0 | ||||||

|

500 |

800 |

3,0 |

3,5 |

3,5 |

4,0 |

4,0 |

4,5 |

4,5 | |||||

|

800 |

1200 |

3,5 |

3,5 |

4,0 |

4,0 |

4,5 |

4,5 |

5,0 |

5,0 | ||||

|

1200 |

1800 |

3,5 |

4,0 |

4,0 |

4,5 |

4,5 |

5,0 |

5,0 |

5,5 |

5,5 | |||

|

1800 |

2600 |

4,0 |

4,0 |

4,5 |

4,5 |

5,0 |

5,0 |

5,5 |

5,5 |

6,0 |

6,0 | ||

|

2600 |

- |

4,0 |

4,5 |

4,5 |

5,0 |

5,0 |

5,5 |

5,5 |

6,0 |

6,0 |

7,0 |

7,0 | |

|

III |

- |

100 |

2,0 | ||||||||||

|

100 |

200 |

2,5 |

3,0 | ||||||||||

|

200 |

300 |

3,0 |

3,0 |

3,0 | |||||||||

|

300 |

500 |

3,5 |

3,5 |

3,5 |

4,0 | ||||||||

|

500 |

800 |

4,0 |

4,0 |

4,0 |

4,5 |

5,0 | |||||||

|

800 |

1200 |

4,5 |

4,5 |

4,5 |

5,0 |

5,5 |

5,5 | ||||||

|

1200 |

1800 |

5,0 |

5,0 |

5,0 |

5,5 |

6,0 |

6,0 |

6,5 | |||||

|

1800 |

2600 |

5,5 |

5,5 |

5,5 |

6,0 |

6,5 |

6,5 |

7,0 |

7,0 | ||||

|

2600 |

- |

6,0 |

6,0 |

6,0 |

6,5 |

7,0 |

7,0 |

7,5 |

7,5 |

7,5 | |||

|

IV |

- |

100 |

3,0 | ||||||||||

|

100 |

200 |

3,5 |

4,0 | ||||||||||

|

200 |

300 |

3,5 |

4,0 |

4,5 | |||||||||

|

300 |

500 |

4,0 |

4,5 |

5,0 |

5,0 | ||||||||

|

500 |

800 |

4,0 |

5,0 |

5,0 |

5,5 |

5,5 | |||||||

|

800 |

1200 |

4,5 |

5,5 |

5,5 |

6,0 |

6,0 |

6,5 | ||||||

|

1200 |

1800 |

5,0 |

6,0 |

6,0 |

6,5 |

6,5 |

7,0 |

7,5 | |||||

|

1800 |

2600 |

5,5 |

6,5 |

6,5 |

7,0 |

7,0 |

7,5 |

8,0 |

8,5 | ||||

|

2600 |

3800 |

6,0 |

7,0 |

7,0 |

7,5 |

7,5 |

8,0 |

8,5 |

9,0 |

9,5 | |||

|

3800 |

5400 |

6,5 |

7,5 |

7,5 |

8,0 |

8,0 |

8,5 |

9,0 |

9,5 |

10,0 | |||

|

5400 |

- |

7,0 |

8,0 |

8,0 |

8,5 |

9,0 |

9,5 |

10,0 |

10,5 |

11,0 | |||

|

V |

- |

100 |

3,5 | ||||||||||

|

100 |

200 |

4,0 |

4,5 | ||||||||||

|

200 |

300 |

4,5 |

5,0 |

5,0 | |||||||||

|

300 |

500 |

4,5 |

5,0 |

5,5 |

6,0 | ||||||||

|

500 |

800 |

5,0 |

5,5 |

6,0 |

6,5 |

7,0 | |||||||

|

800 |

1200 |

5,5 |

6,0 |

6,5 |

7,0 |

7,5 |

8,5 | ||||||

|

1200 |

1800 |

6,0 |

6,5 |

7,0 |

7,5 |

8,0 |

8,5 |

9,0 | |||||

|

1800 |

2600 |

6,5 |

7,0 |

7,5 |

8,0 |

8,5 |

9,0 |

9,5 |

10,0 | ||||

|

2600 |

3800 |

7,0 |

7,5 |

8,0 |

8,5 |

9,0 |

9,5 |

10,0 |

10,5 |

11,0 | |||

|

3800 |

5400 |

7,5 |

8,0 |

8,5 |

9,0 |

9,5 |

10,0 |

10,5 |

11,0 |

11,5 | |||

|

5400 |

- |

8,0 |

8,5 |

9,0 |

9,5 |

10,0 |

10,5 |

11,0 |

12,0 |

13,0 | |||

Z wyjątkiem klasy I dopuszcza się zwiększenie naddatków na górnej powierzchni odlewów do 50% wartości podanych w tabl. 13.

Naddatki na obróbkę otworów ustala się jak dla górnych powierzchni odlewów.

Wyszukiwarka

Podobne podstrony:

r54 2 11 Analiza technologiczności konstrukcji odlewu 185OTWORY WYKONYWANE W ODLEWACH Odlewy że

11. Analiza statyczno-wytrzymałościowa przekryć kryształowych o konstrukcji

M Feld TBM483 483 11.2. Technologiczność konstrukcji części klasy korpus RYS. 11.2. Otwór dokładny w

M Feld TBM502 502 11. Projektowanie procesu technologicznego części klasy korpus RYS. 11.33. Rozwiąz

IMG911 Technotogicinołć konstrukcjiCzasy obróbki 11 *w(l + fc) 10. Ciąć tj = 4.99(1 + 0,12) = 5,59 4

r48 Rys. 1. Zmiany konstrukcyjne w wyniku analizy technologiczności odlewu

r64 Rys. VII,11. Przykłady naddatków technologicznych usprawniających zasilanie odlewu: a) przylew n

kpiup0073 1.11. Technołogiczność konstrukcji elementów obrabianych skrawaniem 571.11. Technołogiczno

28483 IMG872 11 Technologiczność konstrukcji *»"*#**»" 0,16 ♦ 0,32 ■ l,28mfnZabieg 3: Nnkl

Poznaj C++ w$ godziny0217 208 Godzina 14 licz: 5 ANALIZA: W linii 11 zaszła ważna zmiana. Przeciążyl

IMAG0788 Literatura PODSTAWY KONSTRUOWANIA ODLEWÓW KONCEPCJA TECHNOLOGICZNA WYKONANIA ODLEWU Fe

2.1. Technologie warstwy fizycznej sieci 802.11 Standard IEEE 802.11 definiuje pięć technologii wars

więcej podobnych podstron