p50

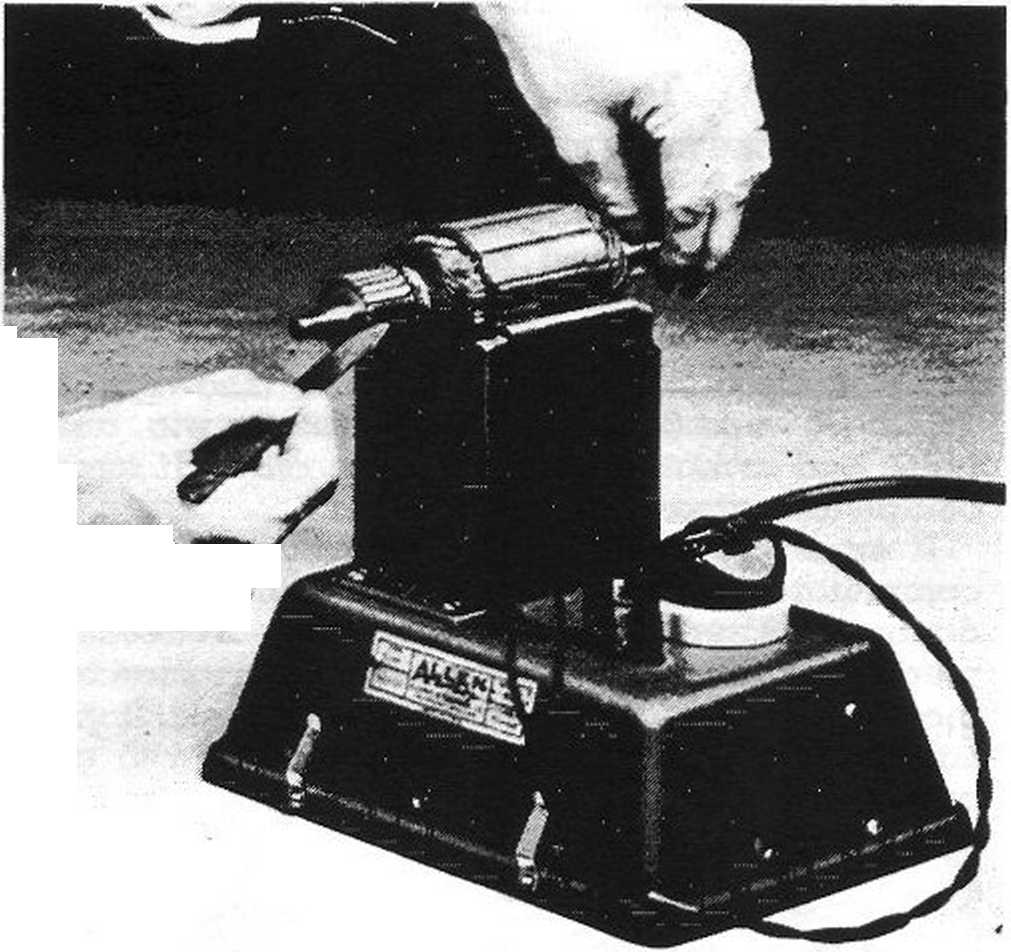

ILLUS. 38

TESTING ARMATURĘ FOR "SHORT"

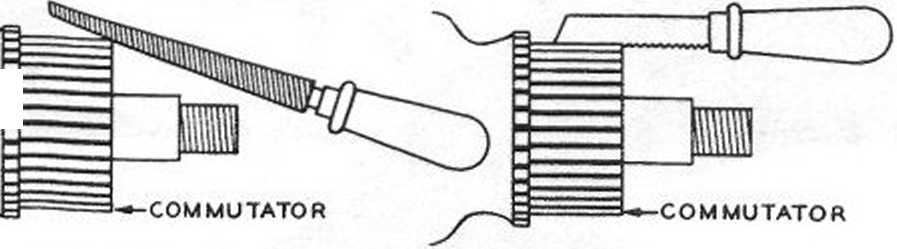

ILLUS. 39

TESTING ARMATURĘ FOR "OPEN

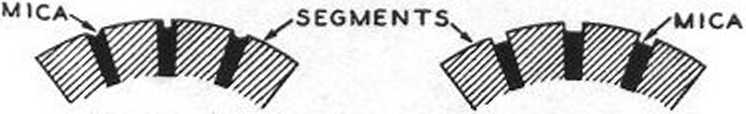

STARTING GROOVE IN MICA UNDERCUTTING MICA WITH PIECE WITH 3 CORNERED FILE OF HACKSAW BLADE

WRONG WAY RIGHT WAY

MICA MUST NOT BE LEFT MICA MUST BE CUT A WAY W|TH A THIN EDGE NEXT CLEAN BETWEEN SEGMENTS

TO SEGMENTS

ILLUS. 40

UNDERCUTTING COMMUTATOR MICA

"Growler" test for "short":

Place armaturę in "growler" and hołd piece of hacksaw blade in loose contact with armaturę core as shown in Illustration 38. Tum "growler" "ON." Rotate armaturę slowly one or morę fuli turns. If armaturę is shorted, hacksaw blade will be attracted to armaturę core and will vibrate violently at one or morę points around armaturę.

If short is found, thoroughly clean commutator as described under "ground" test and test again. If short still exists, armaturę must be replaced with a new one.

"Growler" test for "open":

Place armaturę in "growler" as shown in Illustra-tion 39 and tum "growler" "ON." Insert tip of hacksaw blade between segments that are closest in alignment with the point of contact of armaturę core and "growler" V. Make and break contact between segments with hacksaw blade.

A strong flash should be seen as contact is broken. No flash or a very weak flash indicates an open Circuit.

Repeat this test between all segments, turning armaturę so that each test is madę on the linę of contact between armaturę core and "growler" V. If an open Circuit is found, check for loose or broken wires at commutator connections. If nonę are found that can be repcrired, armaturę must be replaced with a new one.

Turning Down Commutator

If commutator is found wom and irregular, it should be turned down in a lathe and smoothed with 00 sandpaper. When turning, mount armaturę shaft on its bearing seats; do not mount on shaft centers.

Undercutting Commutator

After commutator has been turned down, the mica insulation between segments must be undercut to a depth of approximately .025". Unless mica is prop-erly undercut, brushes will not seat firmly against commutator segments and generator output will not be normal. Also, there will be excessive arcing at brushes.

Undercutting is usually done with a special undercutting machinę. However, if such a machinę is not available, it can be done as shown in Illustration 40.

After undercutting is completed, again smooth commutator with 00 sandpaper. It is also advisable to repeat "growler" check for "short" as there is a possibility of developing a "short" during the turning and undercutting operations. If so, it can very likely be corrected by móre thorough cleaning between segments and at ends of commutator.

Reassembling Generator

(ITEM NUMBERS REFER TO ILLUSTRATION 34)

1. If one or both field coils have to be reassem-bled, do this first. Remember that field coils are not alike and must not be interchanged. If one has to be replaced, be surę it is replaced with one of same type (See Illustration 41).

Thoroughly clean generator frame where pole shoe seats and also clean face of pole shoe that seats against frame. Tighten pole shoe screws as tight as possible, with a large screwdriver that fits well into

50

Wyszukiwarka

Podobne podstrony:

Jak pisać po angielsku StronaF 0 1 Prośba o otwarty termin płatności 0 1 Request for open account te

2.38 NT - pro BNP 55.00 2.39 Procalcytonina 59.00 2.40 HE4 60.00 2.41 Witamina D3

38 Technologie energooszczędne w materiałach budowlanych ZIMiPB 39 Nowoczesne materiał)’

60070 winieta 0 ELEKTRONIK SYSTEM ul. Piłsudskiego 38. 89-620 Chojnice tel.:(052) 39 50 100. fax: (0

38 Opisz cechy typowe dla CRM 39 Scharakteryzuj wybrane narzędzia CRM 40 Dlaczego warto wdrożyć

‘Letters___ Could gOYcrnmcnt and magie be closcly rclatcd? Matthews asks for open-mindedness among

GaUgle Oquake filetype: pdf for open source intelligence v

DYKTANDA GRAFICZNE (49) Tabela 37 Tabela 38 ABCDEFGHJ KLŁMNPR ABCDEFGHJ KLŁMNP Tabela 39 ABCDEFGHJ K

ISO/IEC DIS 10181-7 Information technology - Open Systems Interconnection - Security Frameworks for

38. Cele Wielostronnej Agencji Gwarancji Inwestycyjnych 39. Cele Międzynarodowego Centrum Rozwiązywa

38. Anderson R., Inżynieria zabezpieczeń, Warszawa 2007 39. Andr

więcej podobnych podstron