Combustion, Explosion, and Shock Waves, Vol. 38, No. 3, pp. 295–300, 2002

Spontaneous Combustion of Brown-Coal Dust. Experiment,

Determination of Kinetic Parameters, and Numerical Modeling

UDC 536.46+541.124/128

S. P. Amel’chugov,

1

V. I. Bykov,

2

and S. B. Tsybenova

3

Translated from Fizika Goreniya i Vzryva, Vol. 38, No. 3, pp. 48–54, May–June, 2002.

Original article submitted May 7, 2001.

To study spontaneous combustion and explosion of brown-coal dust, an experimental

setup was designed and a method for analysis of these processes was proposed. Kinetic

parameters (activation energy and preexponent) of the brown coal from the Irsha–

Borodino deposit were determined. It was shown in experiments that, for certain

coal/oxidizer ratios, the explosion has a two-stage character. The repeated explosion

of dust is caused by thermal activation of coal at the first stage of the explosion. Math-

ematical models for a qualitative description of spontaneous combustion of brown-coal

dust are considered.

Key words: brown coal, spontaneous combustion of dust, kinetic parameters, nu-

merical modeling.

INTRODUCTION

Fires and explosions are typical of all stages of han-

dling of coal. Spontaneous combustion is the main rea-

son for fires at fuel stores and coal-conveying systems

(50–60%). Every sixth fire at thermal power plants or

boiler houses is also caused by spontaneous combustion.

It was shown in [1–5] that ability of coals to ignite

spontaneously strongly depends on the kinetic param-

eters of this process, i.e., activation energy and preex-

ponent. These parameters were found to change when

coal is heated to 500–600 K; in this case, the coal be-

comes more reactive, i.e., its thermal activation occurs.

In this work, an explosion of coal dust in a cylindrical

vessel was studied experimentally. It was found that,

for a certain fuel/oxidizer ratio, a second explosion can

follow the first explosion as a result of thermal activa-

tion of coal at the first stage. As mathematical models,

equations governing the material and thermal balance

in a tube reactor were used. Calculations performed for

the kinetic parameters of spontaneous combustion of

1

Institute of Fire Prevention,

Siberian Branch, Krasnoyarsk 660036.

2

Institute of Computational Modeling,

Siberian Division, Russian Academy of Sciences,

Krasnoyarsk 660036.

3

Krasnoyarsk State Technical University,

Krasnoyarsk 660074; bykov@fivt.kgtu.runnet.ru.

brown coal from the Irsha–Borodino deposit show that

the models proposed are in qualitative agreement with

the experiment.

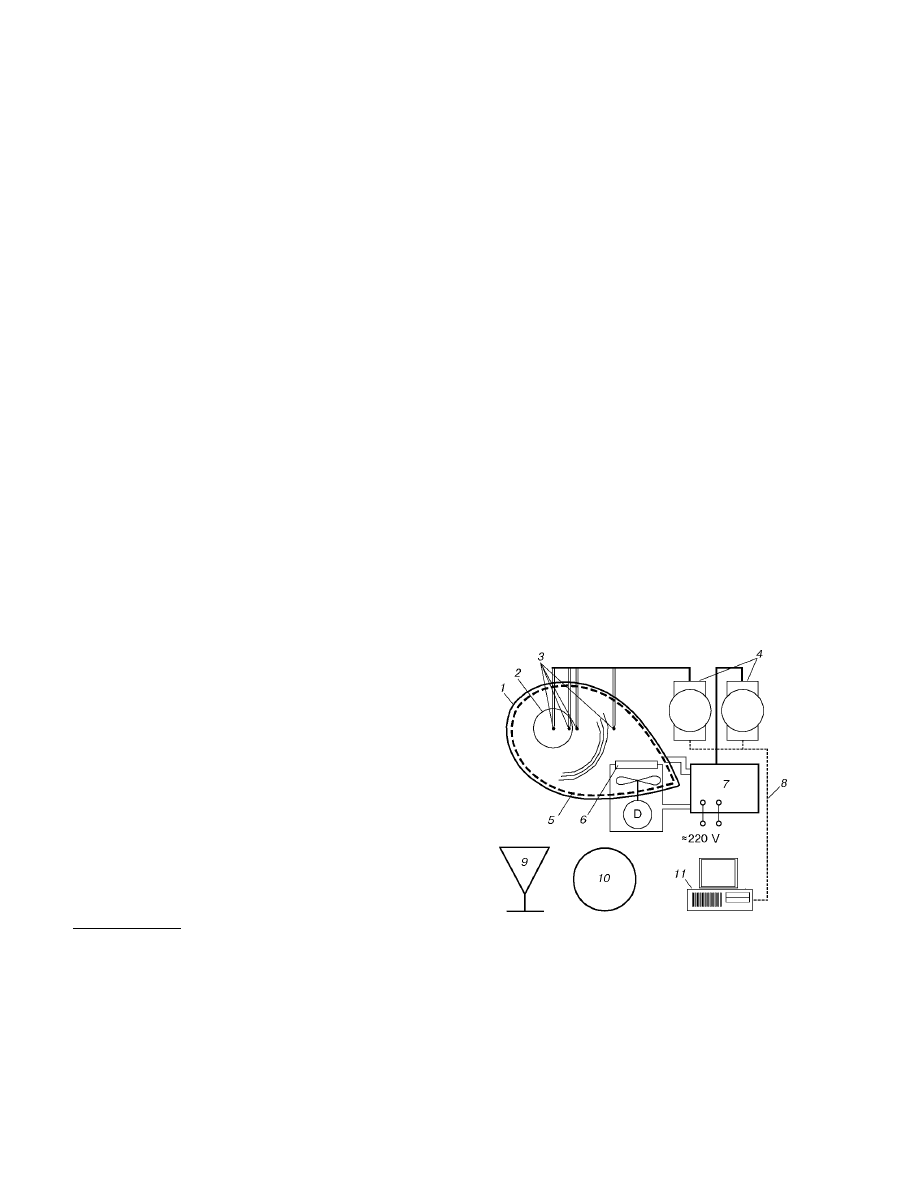

Fig. 1. Diagram of the setup for determining kinetic

parameters of spontaneous combustion of brown

coal: 1) thermostat shell; 2) reaction vessel; 3) ther-

mocouples; 4) modules of data collection and control;

5) main heater; 6) auxiliary heater; 7) module of

power supply and control; 8) RS-485 communication

line; 9) balance; 10) drying cabinet; 11) computer.

0010-5082/02/3803-0295 $27.00 c

2002

Plenum Publishing Corporation

295

296

Amel’chugov, Bykov, and Tsybenova

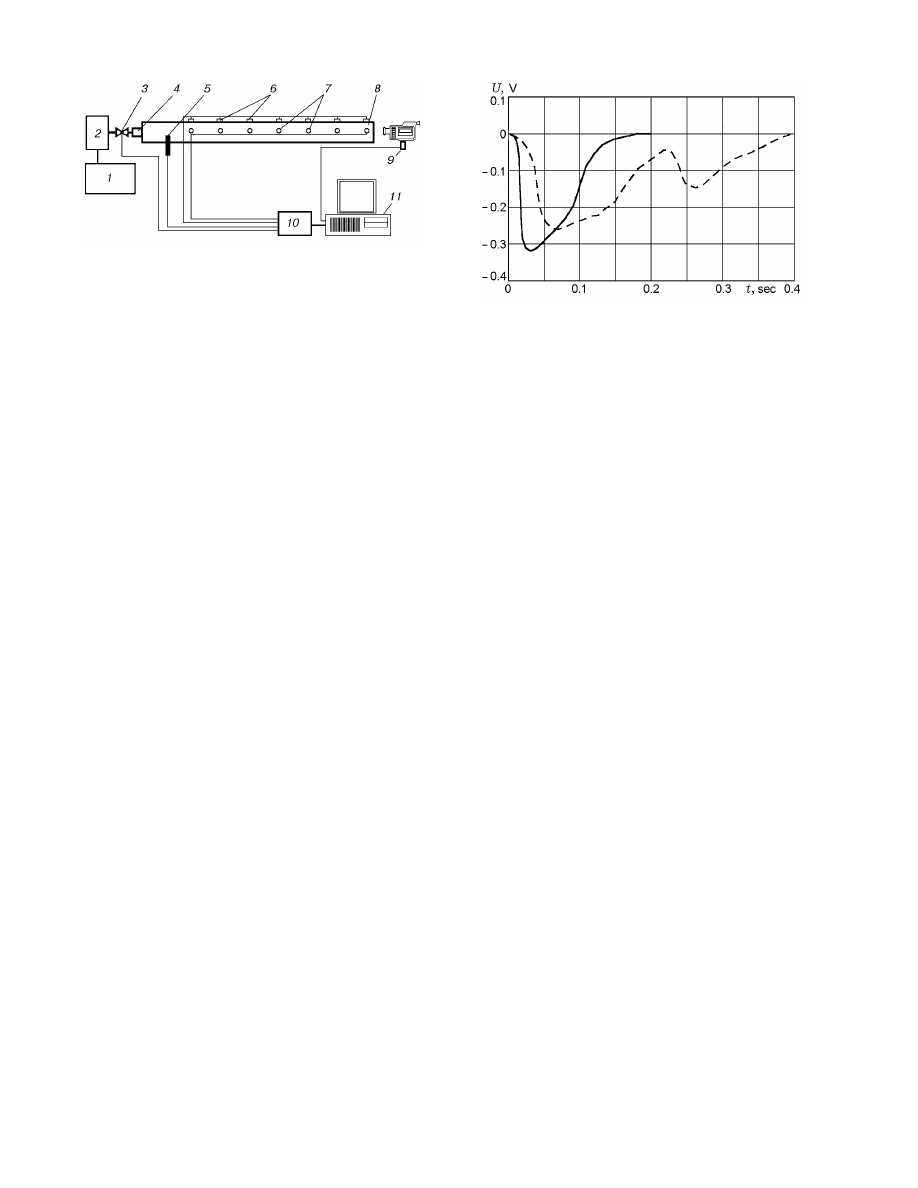

Fig. 2. Experimental setup for analysis of explosion

of natural-fuel dust in long channels: 1) compressor;

2) vessel with compressed air; 3) valve; 4) sprayer;

5) igniter; 6) temperature-sensitive elements; 7) pho-

todiodes; 8) explosion channel; 9) video camera;

10) high-speed recorder; 11) computer.

METHOD OF ANALYSIS

OF SPONTANEOUS COMBUSTION

The kinetic parameters of spontaneous combustion

were determined by the calorimetric method. The dry-

air thermostat was the main part of the setup (Fig. 1).

A cylinder made of thin brass mesh served as a reac-

tion vessel. In the tests, Chromel–Alumel thermocou-

ples were used to record the temperature at four or more

points (in the thermostat, near the wall, and at the cen-

ter and boundary of the reaction vessel).

The experiments were performed on coal in the fol-

lowing states: just after mining, after oxidation in air

for 36 h (which corresponds to transportation time),

and after thermal activation. The thermal activation

was performed by heating a sample of brown coal in air

until indications of combustion were observed (intense

smoking and smouldering grains) and subsequent cool-

ing in an inert medium. Experimental results are listed

in Table 1.

It was found that the reactivity and, hence, fire

and explosion hazard of brown-coal dust increase in the

series: oxidized, recently mined, and thermoactivated

coals.

METHOD OF ANALYSIS

OF COAL-DUST EXPLOSION

IN A LONG CHANNEL

The propagation velocity of the combustion front of

suspended dust was studied using an experimental setup

shown schematically in Fig. 2. The explosion channel

was a steel tube 100 mm in diameter and 2000 mm

long. To produce a uniform dust cloud inside the ex-

plosion chamber, a conical spayer with an injector was

used.

The dust was ignited when it passed through

Fig. 3. Dynamics of signals from photodiodes for

explosion of coal dust: the solid curve refers to active

dust and the dashed curve to oxidized dust.

a tube heater. The temperature variation during for-

mation and propagation of the combustion front along

the channel was recorded by Chromel–Alumel thermo-

couples distributed along the channel.

Signals from

the thermocouples and photodiodes were recorded by

a high-speed recorder (the measurement interval was

1–10 msec), displayed on the screen of a digital os-

cilloscope, and recorded on a magnetic medium. The

concentration of suspended dust was determined by the

mass of the dust sample. Moreover, high-speed record-

ing of the dynamics of the brown-coal dust ignition was

performed with variation in different parameters of the

process.

Figure 3 shows the dynamics of coal-dust explosion

according to optical measurements performed for sam-

ples of coal dust (fraction to 80 µm) of different degree

of oxidation. The corresponding experimental data for

dust of different fractions and degree of oxidation are

given in Table 2. An analysis of these data shows that,

during explosion, the brown-coal dust is activated upon

thermal heating and becomes more reactive, whereas

the effective activation energy of spontaneous combus-

tion decreases.

MATHEMATICAL MODELING

We use three simple models that describe qualita-

tively spontaneous combustion of coal dust in a cylindri-

cal reactor under various thermal and physicochemical

assumptions. First of all, this is an ideal-displacement

regime in a tube. In this case, one-dimensional steady

profiles of the temperature and concentration distri-

bution along the reactor were considered. Moreover,

regimes of spontaneous combustion for excess oxygen

were studied with allowance for a considerable change

Spontaneous Combustion of Brown-Coal Dust

297

TABLE 1

Kinetic Parameters of Spontaneous Combustion of Brown Coal

of the Irsha–Borodino Deposit

Coal

Activation energy, kJ/mole

Preexponent, sec

−1

Recently mined

40.4

0.61

· 10

8

Oxidized

53.2

0.84

· 10

9

Activated

35.0

0.62

· 10

7

TABLE 2

Experimental Data on Explosion of Brown-Coal Dust

Type of sensor

Characteristics of coal dust

Mean time

Fraction, µm

Degree of oxidation

required to reach the maximum, msec

<80

A

27

Photoelectric

<80

O

60

80–160

A

45

<80

A

390

Thermoelectric

80–160

A

430

80–160

O

460

160–180

A

350

Note. A and O stand for activated and oxidized coal dust, respectively.

in the latter. Particular attention was given to sponta-

neous combustion with allowance for the so-called ther-

mal activation of coal. In the first two cases, a one-

stage process occurred, whereas a three-stage process

was observed in the third case. The aim of modeling

was to describe qualitatively the main specific features

of spontaneous combustion of coal dust and to deter-

mine physicochemical and thermophysical parameters

responsible for spontaneous combustion.

Reaction X

→ P (Coal → Product). In the

steady case, the mathematical model of a tube reactor

with a single exothermic reaction comprises the equa-

tions of material and thermal balance [6, 7]:

u

dX

dl

=

−k(T )X,

(1)

c

p

ρu

dT

dl

= (

−∆H)k(T )X +

4h

d

(T

w

− T ).

Here

k(T ) = k

0

exp(

−E/RT )

(2)

is the reaction-rate constant, k

0

is the preexponent, E is

the activation energy, R is the universal gas constant,

T is the current temperature, X is the current concen-

tration of coal dust, T

w

is the temperature of the reactor

wall, l is the variable length of the reactor, h is the co-

efficient of heat transfer from the wall of the reactor

to its volume, d is the diameter of the reactor, ρ, c

p

,

and u are the density, heat capacity, and feeding rate

of the reactive mixture, respectively, and (

−∆H) is the

thermal effect of the reaction. The length of the reactor

varies within the limits

0 6 l 6 l

f

,

(3)

where l

f

is the total length of the cylindrical reactor.

The conditions at the input of the reactor are written

as

X(0) = X

0

,

T (0) = T

0

,

(4)

where X

0

and T

0

are the concentration and temperature

of the reactive mixture at the input of the reactor. In

model (1), the first-order reaction is considered, and it is

assumed that the process occurs under oxygen excess,

which can be accepted as a first approximation if the

concentration of coal dust is small.

Calculations according to model (1) were per-

formed for the following parameters:

k

0

= 8.4

×

10

7

sec

−1

, E = 53,200 J/mole, R = 8.31 J/(mole

· K),

(

−∆H) = 900 J/mole, T

w

= 283 K, T

0

= 325 K,

X

0

= 5

· 10

−4

g/cm

3

, l

f

= 200 cm, d = 10 cm,

ρ = 5

· 10

−4

g/cm

3

, c

p

= 1.13 J/(g

· K), u = 100 cm/sec,

and h = 0.006 J/(cm

2

· sec· K). Conditions under which

coal dust is ignited spontaneously were determined for

298

Amel’chugov, Bykov, and Tsybenova

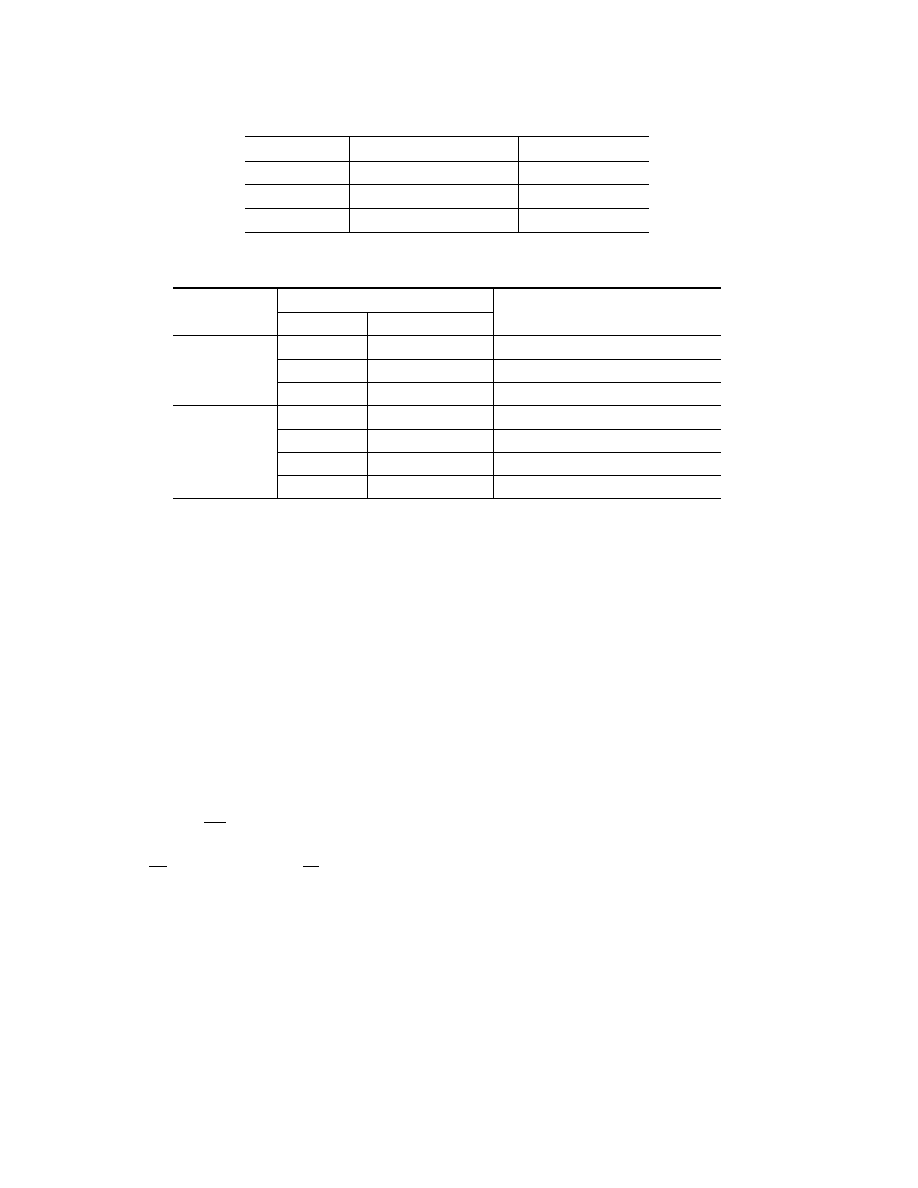

Fig. 4.

Profiles of temperature (a) and concentra-

tion of coal dust (b) in a cylindrical reactor for varied

temperature at the input of the reactor.

varied parameters T

0

, X

0

, h, T

w

, and u. Some calcula-

tion results are shown in Fig. 4.

It was found that the conditions of spontaneous

combustion and location and temperature of the “hot

spot” are highly sensitive to the conditions at the in-

put to the reactor and heat-exchange conditions: for a

certain critical value of the parameter varied, the tem-

perature increases abruptly, which can be characterized

as a thermal explosion of coal dust in the tube. An

example of this steady temperature distribution along

the reactor is shown in Fig. 4, where the input tem-

perature is the varied parameter. A similar effect is

observed when the temperature of the reactor wall is

varied. Thus, model (1)–(4) describes the phenomenon

qualitatively and can be used as the simplest model of

spontaneous combustion of coal dust in the tube.

Reaction O

2

+ X

→ P. To take into account

the variation in the oxidizer concentration, we modify

system (1)–(4):

u

dX

dl

=

−k(T )X · O

2

,

u

dO

2

dl

=

−k(T )X · O

2

,

(5)

c

p

ρu

dT

dl

= (

−∆H)k(T )X · O

2

+

4h

d

(T

w

− T ).

Here the kinetics corresponds to the second-order reac-

tion and O

2

is the concentration of oxygen. The no-

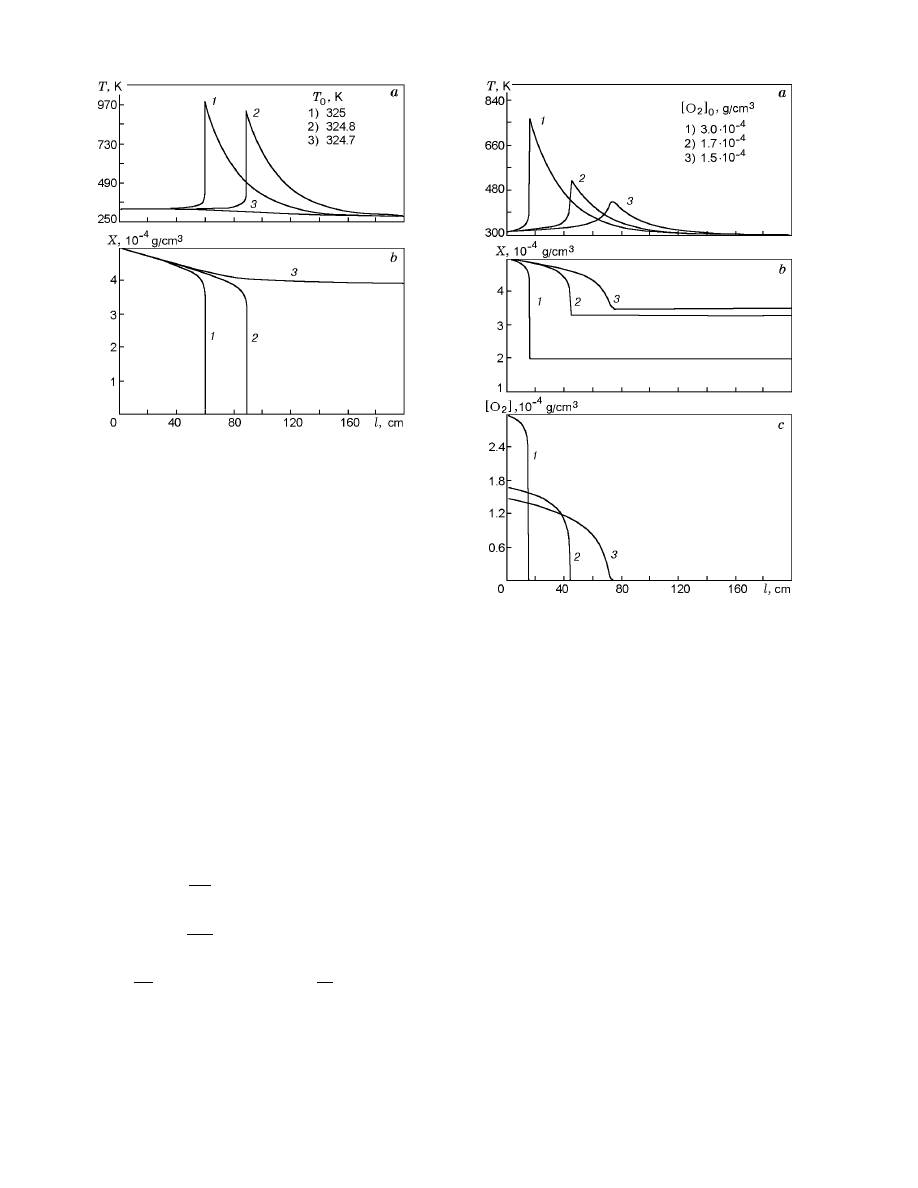

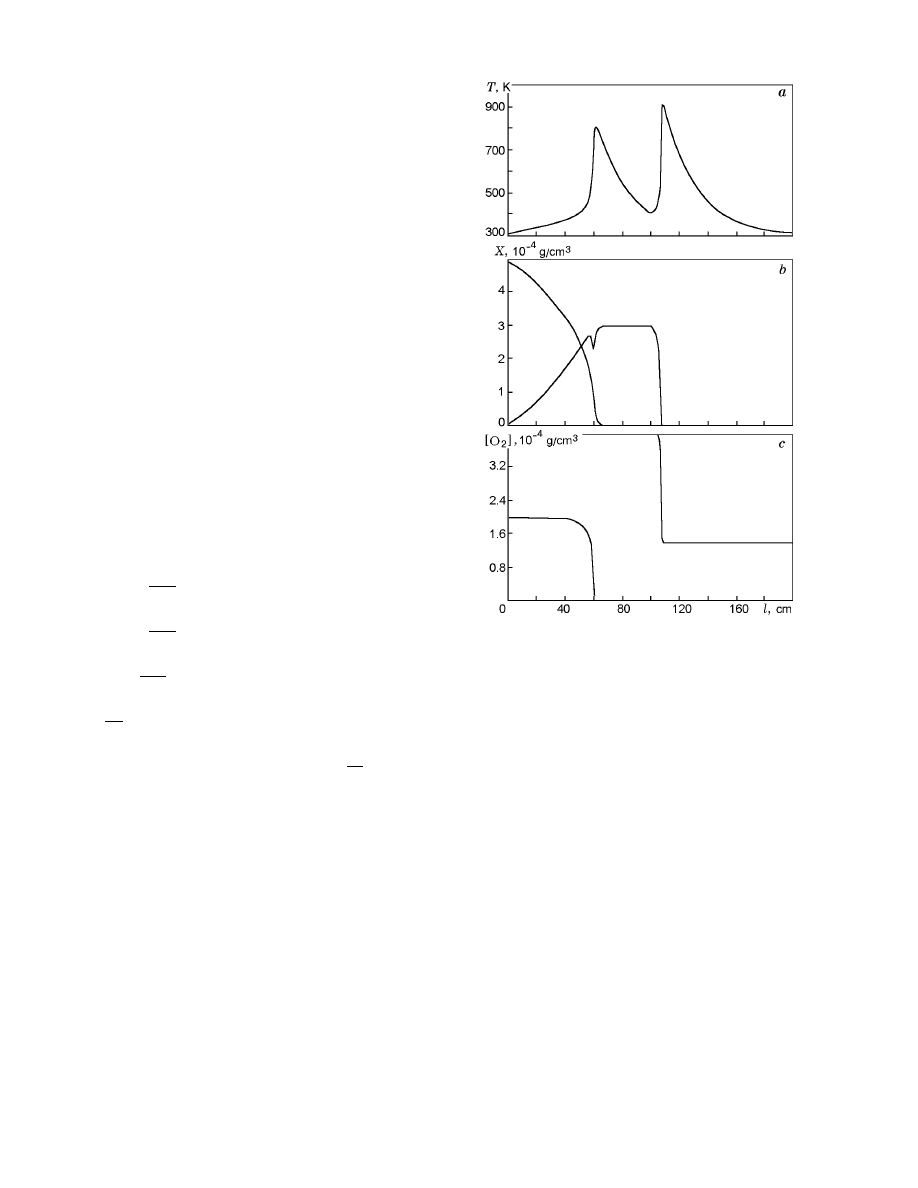

Fig. 5. Profiles of the coal-dust temperature (a) and

concentrations of coal dust (b) and oxygen (c) with

varied concentration of the oxidizer at the input to

the reactor.

tation used in system (5) coincides with that consid-

ered above, and conditions (2)–(4) are the same. Fig-

ure 5 shows the characteristic profiles of coal and oxy-

gen concentrations and temperature for different con-

centrations O

2

at the input of the reactor.

These

profiles were obtained for the following parameters:

k

0

= 0.84

· 10

9

sec

−1

, E = 53,200 J/mole, R =

8.31 J/(mole

· K), (−∆H) = 900 J/mole, T

w

= 300 K,

T

0

= 310 K, X

0

= 5

· 10

−4

g/cm

3

, u = 100 cm/sec, and

h = 0.006 J/(cm

2

· sec · K). Here the preexponent k

0

dif-

fers from that in the above-considered scheme. The rea-

son is that the kinetic parameters correspond to differ-

ent conditions: above, we considered the reaction under

the assumption of constant amount of oxygen, whereas

its variation is taken into account in system (5).

Calculations show that the degree of the coal burn-

out strongly depends on the oxidizer content. For a

sufficient amount of oxygen, the temperature increases

Spontaneous Combustion of Brown-Coal Dust

299

abruptly near the input to the reactor, which can be

interpreted as intense spontaneous combustion of coal

dust. As the concentration O

2

at the input to the re-

actor decreases, the temperature profiles become more

smooth, and the characteristic time of variation in the

concentration of reagents increases. Thus, the concen-

tration of the oxidizer is one of the factors determining

spontaneous combustion of brown-coal dust.

Three-Stage Scheme with Thermal Activa-

tion. A physicochemical analysis shows that coal can

be activated upon heating, i.e., its ability to ignite

spontaneously increases since the activation energy in

(2) decreases. Therefore, in addition to the one-stage

reactions considered above, we study the three-stage

scheme:

Stage 1.

O

2

+ X

1

→ P;

Stage 2.

X

1

→ X

2

;

Stage 3.

O

2

+ X

2

→ P

(6)

(X

1

and X

2

are the initial and activated coals, respec-

tively). Stage 1 corresponds to the above-considered

reaction of coal oxidation, stage 2 to coal activation

(transition from the initial coal X

1

to the activated coal

X

2

), and stage 3 to oxidation of the activated coal. The

activation energy of this reaction is much smaller than

the activation energy in the first stage. Scheme (6) cor-

responds to the following thermokinetic model:

u

dX

1

dl

=

−k

1

(T )O

2

X

1

− k

2

(T )X

1

,

u

dX

2

dl

=

−k

2

(T )X

2

− k

3

(T )O

2

X

2

,

u

dO

2

dl

=

−k

1

(T )O

2

X

1

− k

3

(T )O

2

X

2

,

(7)

c

p

ρu

dT

dl

= (

−∆H

1

)k

1

(T )O

2

X

1

+ (

−∆H

2

)k

2

(T )X

1

+ (

−∆H

3

)k

3

(T )O

2

X

2

+

4h

d

(T

w

− T ).

Here k

i

(T ) (i = 1, 2, and 3) are the constants of

the rates at stages 1, 2, and 3 [see (6)] and (

−∆H

i

)

(i = 1, 2, and 3) are the thermal effects of these re-

actions. Figure 6 shows some profiles of the reagent

concentrations and temperature. In the calculations,

the following kinetic and thermophysical parameters

were used:

k

0

1

= 0.84

· 10

9

sec

−1

, k

0

2

= 1200 sec

−1

,

k

0

3

= 0.62

· 10

9

sec

−1

, E

1

= 53, 200 J/mole, E

2

=

20,000 J/mole, E

3

= 40,000 J/mole, (

−∆H

1

) =

900 J/mole, (

−∆H

2

) = 400 J/mole, (

−∆H

3

) =

1100 J/mole, T

w

= 300 K, and T

0

= 310 K.

The first peak of temperature in Fig. 6 corresponds

to spontaneous combustion of the initial coal. In this

case, oxygen burns out completely, and the combustion

Fig. 6. Profiles of coal-dust temperature (a) and con-

centrations of coal dust (b) and oxygen (c) for the

three-stage scheme with thermal activation.

of dust is terminated. The concentration of the acti-

vated coal increases in the first interval of combustion

and stabilizes at the middle of the cylindrical reactor.

For l

≈ 60 cm, a small-amplitude jump in the con-

centration of X

2

is observed. This is an indication of

combustion of the activated coal, which is rapidly ter-

minated due to the lack of the oxidizer. A new portion

of the oxidizer is supplied at the middle of the reactor

(l = 100 cm), which leads to a secondary burst of coal

dust. In this case, the activated coal burns.

As in the case of one-stage reactions, the combus-

tion regimes and ignition conditions in model (7) are

highly sensitive to the input conditions and conditions

of heat exchange with the ambient medium. The three-

stage scheme (6) taking into account thermal activation

of coal allows one to describe qualitatively the process of

secondary spontaneous combustion of coal dust within

the framework of the simple model (7).

300

Amel’chugov, Bykov, and Tsybenova

CONCLUSIONS

The calculation results are in qualitative agreement

with the experimental data. It was not the aim of this

work to obtain a quantitative description of the pro-

cesses using the models considered. Therefore, detailed

statistic characteristics of the experiment are not given

in this paper. For calculations, the standard thermo-

physical parameters were taken from [8–10] and the ki-

netic parameters E and k

0

for gas suspension of coal

were borrowed from [2, 5].

Experiments and mathematical modeling of spon-

taneous combustion of brown-coal dust allowed us to

reveal the main factors that determine the critical con-

ditions of combustion. The fire and explosion safety of

coal dust is determined by the kinetic processes of its

spontaneous combustion, ignition, and explosion prop-

agation.

This is of significant practical importance.

Explosions of coal dust mixtures at heat power engi-

neering plants are characterized by secondary explo-

sions (puffs) in the suspended mixture. These explo-

sions also occur when fire extinguishers are used or when

the direction and velocity of air flows change abruptly,

etc.

If, at a certain moment of time, ignition con-

ditions are formed in the presence of a combustible

medium and oxidizer (oxygen contained in air), an ig-

nition source appears. Ignition of this mixture occurs

in the deflagration-combustion regime. Some dangerous

factors of combustion are observed: combustion prod-

ucts are formed, volume temperature increases, and coal

dust is activated.

This implies the following important conclusion.

To prevent the action of dangerous factors of an ex-

plosion on objects, it is necessary to control these pro-

cesses. At present, however, explosion and fire protec-

tion of heat power engineering plants is based on passive

systems (easily removable structures, explosion valves,

filling of window openings, etc.), which are not effec-

tive means of prevention of accidents in coal-feed paths.

This problem can be solved with the help of mathemat-

ical modeling of spontaneous combustion of coal dust.

Detailed calculations of the macrokinetics of these pro-

cesses for parameters varied within a wide range allow

one to develop scientifically justified methods and spec-

ifications of estimating the fire and explosion safety of

coal-feed paths at modern power plants.

REFERENCES

1. Ya. S. Kiselev, V. Ya. Kiselev, and S. P. Amel’chugov,

“Conditions for spontaneous ignition of the Eastern

coals,” Pozharovzryvobezopasnost’, No. 3, 7–21 (1992).

2. S. P. Amel’chugov, “Effect of carbon dioxide on spon-

taneous combustion of brown coals,” Pozharovzryvobe-

zopasnost’, No. 2, 25–27 (1992).

3. D. M. Zakharenko and S. P. Amel’chugov, “Automated

system of explosion suppression and fire protection of

fuel-feed paths at the Abakan thermoelectric plant,” Sib.

Vestn. Pozhar. Bezopasnosti, No. 2, 42–47 (1999).

4. S. P. Amel’chugov, V. I. Bykov, and S. B. Tsybenova,

“Simulation of coal-dust ignition in a tube reactor,”

in: Problems of Usage of the Kansk–Achinsk Coals at

Electric Power Plants (Abstracts of All-Russian Conf.),

Krasnoyarsk (2000), pp. 320–321.

5. S. P. Amel’chugov, “Thermophysical characteristics of

spontaneous combustion of brown coals and methods of

its suppression,” Candidate Dissertation in Tech. Sci.,

Krasnoyarsk (1996).

6. S. B. Tsybenova, “Parametric analysis of the basic mod-

els of the theory of chemical reactors and combustion

theory,” Candidate Dissertation in Tech. Sci., Krasno-

yarsk (1999).

7. V. I. Bykov and S. B. Tsybenova, “Parametric anal-

ysis of some basic models of the combustion theory,”

in: Chemical Physics of Combustion (collected scien-

tific papers dedicated to the 70th Anniversary of Acad.

G. I. Ksandopulo) [in Russian], Almaty (1999), pp. 133–

135.

8. T. V. Vilenskii and D. M. Khzmalyan, Dynamics of

Combustion of Dust-Like Fuel [in Russian], ´

Energiya,

Moscow (1977).

9. V. I. Babii and Yu. F. Kuvaev, Combustion of Coal

Dust and Calculation of a Coal-Dust Plume [in Russian],

´

Energoatomizdat, Moscow (1986).

10. A. A. Shatil’, Furnace Processes and Devices (Analy-

sis and Calculations) [in Russian], Joint-Stock Company

“NPO CKTI,” St. Petersburg (1997).

Wyszukiwarka

Podobne podstrony:

Influence of extraction parameters and medium on efficiency

Computer Modelling with CATT Acoustic Theory and Practice of Diffusion Reflection and Array Modelin

Prowstawanie pzebieg pożaru Process of spontaneous combustion

Historical Dictionary of Medieval Philosophy and Theology (Brown & Flores) (2)

56 793 814 Thermal Fatique of a Tool Steel Experiment and Numerical Simulation

Martin Predicted and experimental results of acoustic parameters in the new Symphony Hall in Pamplo

Insensitive Semantics~ A Defense of Semantic Minimalism and Speech Act Pluralism

Estimation of Dietary Pb and Cd Intake from Pb and Cd in blood and urine

Development of Carbon Nanotubes and Polymer Composites Therefrom

Analysis of soil fertility and its anomalies using an objective model

Modeling of Polymer Processing and Properties

DICTIONARY OF AUSTRALIAN WORDS AND TERMS

A Chymicall treatise of the Ancient and highly illuminated Philosopher

Song of Myself Individuality and Free Verse

Extensive Analysis of Government Spending and?lancing the

Comparison of Human Language and Animal Communication

The?onomic Emergence of China, Japan and Vietnam

Hoban The Lion of Boaz Jachin and Jachin Boaz

więcej podobnych podstron