* Corresponding author. Tel.: #49-431-210-2660; fax: #49-431-

210-62660.

E-mail address: mohammed.es-souni@fh-kiel.de (M. Es-Souni).

Biomaterials 22 (2001) 2153}2161

On the transformation behaviour, mechanical properties

and biocompatibility of two NiTi-based shape

memory alloys: NiTi42 and NiTi42Cu7

Mohammed Es-Souni

*, Martha Es-Souni, Helge Fischer Brandies

Materials Testing and Joining, University of Applied Sciences, Fachhochschule Kiel, Grenzstrasse 3, D-24149 Kiel, Germany

Clinic of Orthodontics, Christian-Albrecht-University, Arnold Heller Strasse, D-24113 Kiel, Germany

Received 28 July 2000; accepted 20 November 2000

Abstract

The transformation behaviour, mechanical properties and cytotoxicity of a binary NiTi42 and a ternary NiTi42Cu7 alloy have been

investigated. The transformation temperatures were determined via di!erential scanning calorimetry, the mechanical properties have

been investigated in 3-point bending tests in the temperature range between 6 and 603C. The cytotoxicity tests were performed on

both alloys in cultured epithelial cells from human gingiva. The cytotoxicity investigations included both MTT tests and morphologi-

cal observations. It is shown that although the ternary alloy is characterised by a narrower hysteresis and superior mechanical

properties, including fatigue resistance, its cytotoxicity is higher than that of the binary alloy. This is thought to arise from the release

of copper ions in the medium, which upon atomic absorption spectroscopy measurements amount to approximately 2.8

g cm\ for

an incubation period of 7 days.

2001 Elsevier Science Ltd. All rights reserved.

Keywords: Shape memory alloys; NiTi; NiTiCu; Bending properties; Biocompatibility; Cytotoxicity

1. Introduction

NiTi-based shape memory alloys are being used in

many engineering and biomedical applications including

actuators, orthodontic arch wires, stents, etc.; more de-

tails about the mechanisms of the shape memory e!ect as

well as the potential applications of NiTi alloys may be

found in numerous review articles (e.g. [1}3]). The NiTi

shape memory alloys usually consist of binary alloys,

with Ni and Ti concentrations near the equiatomic com-

position. Their microstructures are generally processed

using complex thermomechanical treatments in order to

obtain suitable properties, e.g. thermal shape memory,

superelasticity, all-round memory e!ect, etc. However,

the binary alloys are known to be susceptible to thermal

cycling fatigue and the accompanying property modi"ca-

tion is a limiting factor in the long-term application of

such alloys [1,4]. A number of ternary NiTi-X alloys

have been introduced with the aim to improve the fatigue

properties and to decrease the thermal hysteresis range;

well-known ternary alloying elements are Cu and Fe

[1,4,5]. For a review on ternary NiTi-X and their proper-

ties see [1].

Particularly, Cu has been shown to dissolve in the B2

(austenite ) phase in a concentration up to 30 at%. How-

ever, NiTi}Cu solid solutions containing more than

10 at% are characterised by poor formability so that

alloys of technical interest usually contain Cu in the

range from 5 to 10 at%. The following e!ects of Cu on

the properties of NiTi-base alloys have been reported

[1,4,5]:

E Cu in the range from 5 to 15 at% changes the crystal-

lographic structure of the low-temperature phase. The

phase transformation of the austenite phase occurs

following the sequence: B2 (austenite, bcc)PB19

(martensite, orthorhombic)PB19

(martensite, mono-

clinic).

E The thermal hysteresis is reported to decrease from

40 K for the binary alloy to 11 K for NiTi}10 at%Cu.

E The stress of the superelastic hysteresis is decreased.

0142-9612/01/$ - see front matter

2001 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 (0 0 ) 0 0 4 0 6 - 3

E The fatigue resistance during thermal cycling is

increased.

The (thermo)mechanical properties of NiTi-base alloys

certainly constitute the outstanding and most perceptible

attribute for their use. However, in biomedical applica-

tions involving contact with live tissues, biocompatibility

issues may prove as crucial (if not more) as mechanical

behaviour. The binary NiTi alloys have been reported to

exhibit good biocompatibility due to their high corrosion

resistance [5}10]. However, detailed investigations using

human cell cultures are still rare.

The aim of the present paper is to describe and discuss

comparatively the properties of a binary NiTi and a ter-

nary NiTi}Cu alloy in terms of their transformation

behaviour, mechanical properties and biocompatibility.

2. Materials and methods

The alloys studied are

`Neosentalloy F 80a (GAC),

hereafter designed NiTi, and

`Thermo Active Copper

353C

a (Ormco/A-Company), hereafter designed NiTiCu.

The samples were in form of arch wires with rectangular

sections of 0.55

;0.40 mm. For the di

!erent investiga-

tions the straight ends of the wires were used. The chem-

ical compositions of the alloys were determined in an

analytical scanning electron microscope using EDS anal-

ysis. The following compositions (in wt%) were found:

Ni57, 6Ti42, 4 for the binary NiTi and Ni50, 7Ti42, 4Cu6,

9 for the ternary NiTiCu alloy, respectively.

The transformation behaviour was investigated using

di!erential scanning calorimetry (DSC) in the temper-

ature range from !80 to #803C at a rate of 10 K/min.

The samples weighing approximately 10 mg were gently

cut and ultrasonically cleaned in acetone before testing.

A base line was recorded before each test run. Three

batches were tested for each alloy with however repro-

ducible results in the range of accuracy of the system

($1 K).

The mechanical properties were investigated in 3-point

bending tests using a beam length of 12 mm. The load vs.

de#ection curves were recorded at 6, 22, 37 and 603C.

Heating and cooling of the specimens were conducted in

an oil bath of constant viscosity in the range of the

temperature investigated. The temperature was control-

led to$0.53C using a closed-circuit cooler/heater (hetof-

rig, Heto). In order to show the e!ects of loading and

unloading cycles on the mechanical properties, "ve cycles

were generally performed at each temperature. The sam-

ples were changed for each temperature run.

The biocompatibility of the chosen alloys was charac-

terised by means of the in vitro MTT cytotoxicity test

as

well

as

morphological

investigations

in

the

SEM on cultured epithelial cells from explants of human

gingiva.

The following gives a detailed description of the pro-

cedures for cell culture and the biocompatibility tests:

2.1. Cell culture of gingival epithelial cells from clinically

healthy gingival explants

Tissue explants from "ve subjects (not treated for

orthodontic failures) aged between 33 and 59 years, have

been used for this purpose. A modi"ed method for the

primary culture [11] and subculture of gingival epithelial

cells was used. Right after excision, the explants were cut

into cubes of about 1 mm

, and cultured in -MEM

(supplemented with 10% FCS, 2.5

g/ml AmphotericinB,

100 U/ml Penicillin and 100

g/ml Streptomycin, BIO-

CHROM) in sterilised non-treated culture dishes (FAL-

CON) at 373C, and 5% CO. The medium was changed

every 72 hours beginning with the "fth day after seeding.

A week after seeding,

-MEM was replaced for

keratinocyte-SFM (GIBCO BRL, Life technologies).

Under these conditions, only epithelial cell growth was

observed.

Approximately 11 days after seeding, epithelial cell

colonies spread around each explant, covering an area of

about 1 cm

. At this stage, the cells were subcultured. The

colonies were removed by treatment with 1.5 ml Tryp-

sin/EDTA (0.05/0.02%, BIOCHROM) per dish for 5 min

at 373C and 5% CO. The trypsin activity was blocked

by addition of 1.5 ml

-MEM (containing 10% FCS) per

dish. Subsequently the suspension was centrifuged for

7 min at 120

;g. The supernatant was carefully aspirated

and the cells resuspened in fresh SFM. For the MTT test,

10

cells were seeded per microwell.

2.2. Immunohistochemical staining

Prior to biotoxicity tests, the cultured cells were

stained immuno-histochemically in order to prove their

epithelial character. For this purpose, they were tested

for their staining capacity by anti-human cytokeratin

AE1, AE3 (DAKO), a typical epithelial cell marker. The

indirect staining procedure was used [12]. The anti-

cytokeratin A1/A3 and the alkaline phosphatase-con-

jugated rabbit anti-mouse immunoglobulins were used in

a dilution of 1/100 and 1/10, respectively. Dilutions were

performed with the ready to use antibody diluent

(DAKO). The fast red substrate system (DAKO) was

used

as

substrate

and

chromogen

in

the

im-

munocytochemical staining procedure. Counterstaining

was performed with hematoxylin (DAKO). Prior to

staining, monolayers of cells were cultured on coverslips.

After "xation in 2.5% glutaraldehyde for 30 min and

washing in PBS pH 7.2, the cell cultures were treated

with 0.5% Triton X100 (MERCK) in order to promote

antibody access. After permeabilization the monolayers

were brought in contact with the primary antibody for

30 min. After thorough washing in PBS, the coverslips

2154

M. Es-Souni et al. / Biomaterials 22 (2001) 2153}2161

were covered with the alkaline phosphatase-conjugated

rabbit

anti-mouse

immunoglobulins

for

another

30 min and washed subsequently in PBS. The "ltered

fast red substrate solution (DAKO) was then allowed to

react with the bound phosphatase for 20 min. Counter-

staining was performed by incubation in an aqueous

solution containing hematoxylin for 1 min followed by

washing in warm tap water. Coversplips were mounted

on slides in an aqueous mounting medium (Faramount,

DAKO) and observed in an NIKON Optiphot 2 light

microscope.

2.3. Alloy substrates and dimensions

The tested alloys were cut into pieces of 5 mm length,

0.40 mm thickness and 0.55 mm width when used in the

MTT test, otherwise pieces of 21.5 mm length were pre-

pared. They were "rst cleaned ultrasonically in absolute

alcohol and then heat sterilised at 1203C for 20 min.

2.4. MTT cytotoxicity test

For the cytotoxicity determination of the tested alloys,

the method of Tada et al. [13] was applied. The test was

performed in sterile 96-microtiter plates (COSTAR) at

373C

and

5%

CO equipped with two pieces

(2

;9.9 mm active surface) of the tested alloys. The

"l-

tered MTT solution (100

l/well, 5 mg/ml) was added to

the cell cultures (i) 24 h, (ii) 48 h and (iii) 72 h after seeding.

4 h after the MTT addition, cell lysis and formazan

solubilization were started by adding 100

l of the lysing

bu!er (10% SDS in 0.01

N

HCl pH 3.5) and incubating

the plates for 20 h at 373C and 5% CO. Wells contain-

ing cells but no alloys were used for negative controls.

The positive controls consisted of wells containing cells,

where the addition of lysing bu!er preceded the addition

of the MTT solution. For each alloy, blanks containing

the metal, but no cells, were prepared. All experiments

were carried out in triplicate. Prior to the determination

of the formazan formation by absorption measurements

at 550 nm in a microplate reader (DYNATECH, MR

5000), 175

l supernatent of each well were transferred

into a new plate. The incoherent background was deter-

mined by absorption measurements at 630 nm. Coherent

background, due to the phenol red absorption of the

SFM was expressed in the remaining absorption of the

blanks. All absorption measurements were then correc-

ted for this background e!ect by subtraction.

2.5. Atomic absorption spectroscopy (AAS) measurements

Preliminary AAS measurements were conducted on

the ternary alloy in order to investigate Cu-ion release.

For this purpose, one piece of the ternary alloy with an

active surface of 0.38 cm

was incubated in cell free

SFM-medium for 7 days at 373C and 5% CO. After

incubation, the medium was "ltered through a sterile

millipore "lter with a pore size of 0.2

m and sub-

sequently analysed. As a blank measurement, a sample-

free medium was used.

2.6. Morphological investigations in the SEM

Two millilitre of a cell suspension containing 10

C/ml

were seeded in wells of sterile 12-well culture plates

(COSTAR). Prior to seeding, the wells were equipped

with sterilised coverslips (d"13 mm) and NiTiCu or

NiTi samples. Sample free cell cultures were used as

negative controls. After incubation for 72 h at 373C and

5% CO the cell cultures were washed three times with

PBS (phosphate-bu!ered saline, pH 7.2, BIOCHROM),

"xed for 1 h in 2.5% glutaraldehyde (MERCK), dehy-

drated in alcohol solutions of increasing concentrations

(each step 10 min) and "nally critical point dried in

a critical point dryer (BALZERS Union). Immediately

after drying, the coverslip cultures and the alloys were

gold-sputter-coated (EMITECH) and analysed in a SEM

(PHILIPS, XL30).

3. Experimental results

3.1. Transformation behaviour

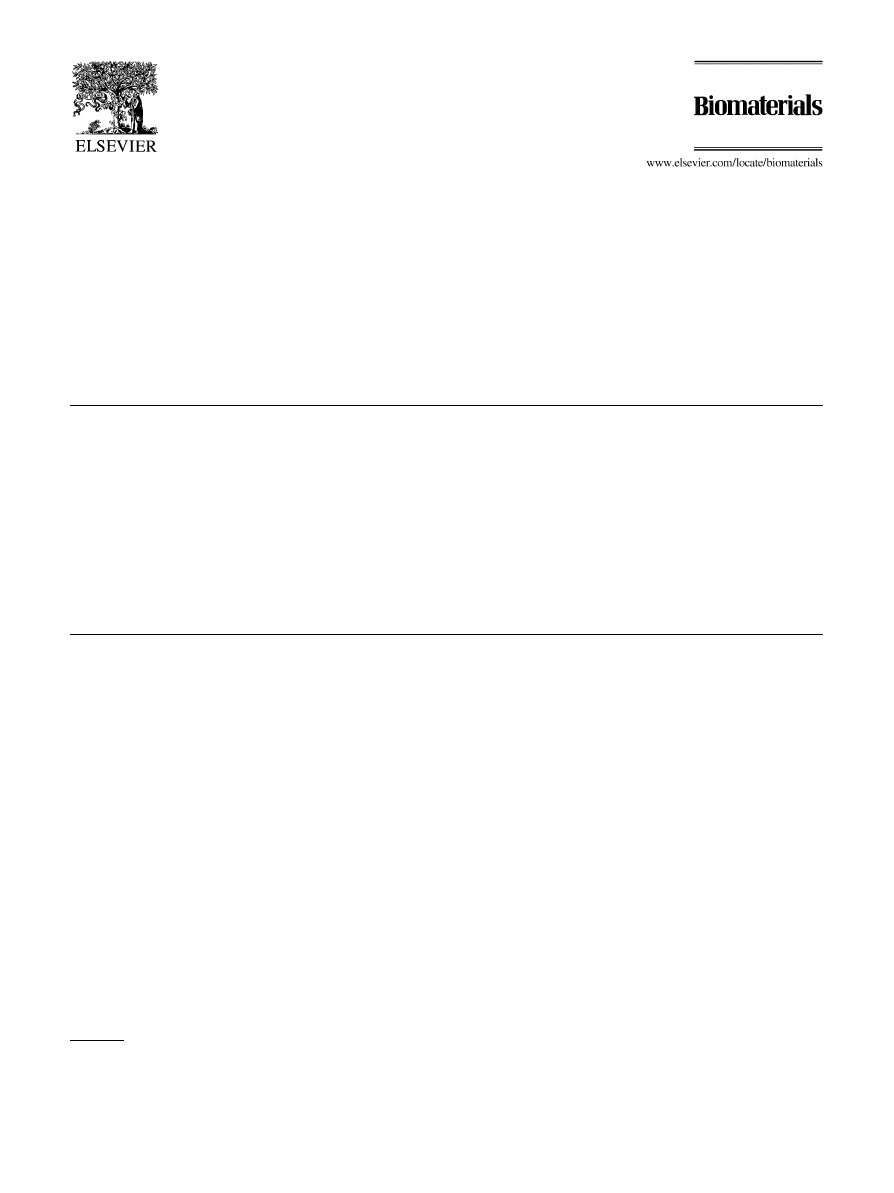

Fig. 1a and b show the DSC curves of both alloys

investigated. NiTiCu shows a direct transformation from

austenite to martensite, probably B19 whereas the binary

NiTi alloy transforms "rst to the trigonal R-phase before

the B19

transformation occurs at lower temperature.

The transformation temperatures are summarised in

Table 1.

The alloys show quite similar A temperatures, the

austenite}martensite hysteresis is however, as expected,

narrower in the case of the ternary alloy.

3.2. Mechanical properties

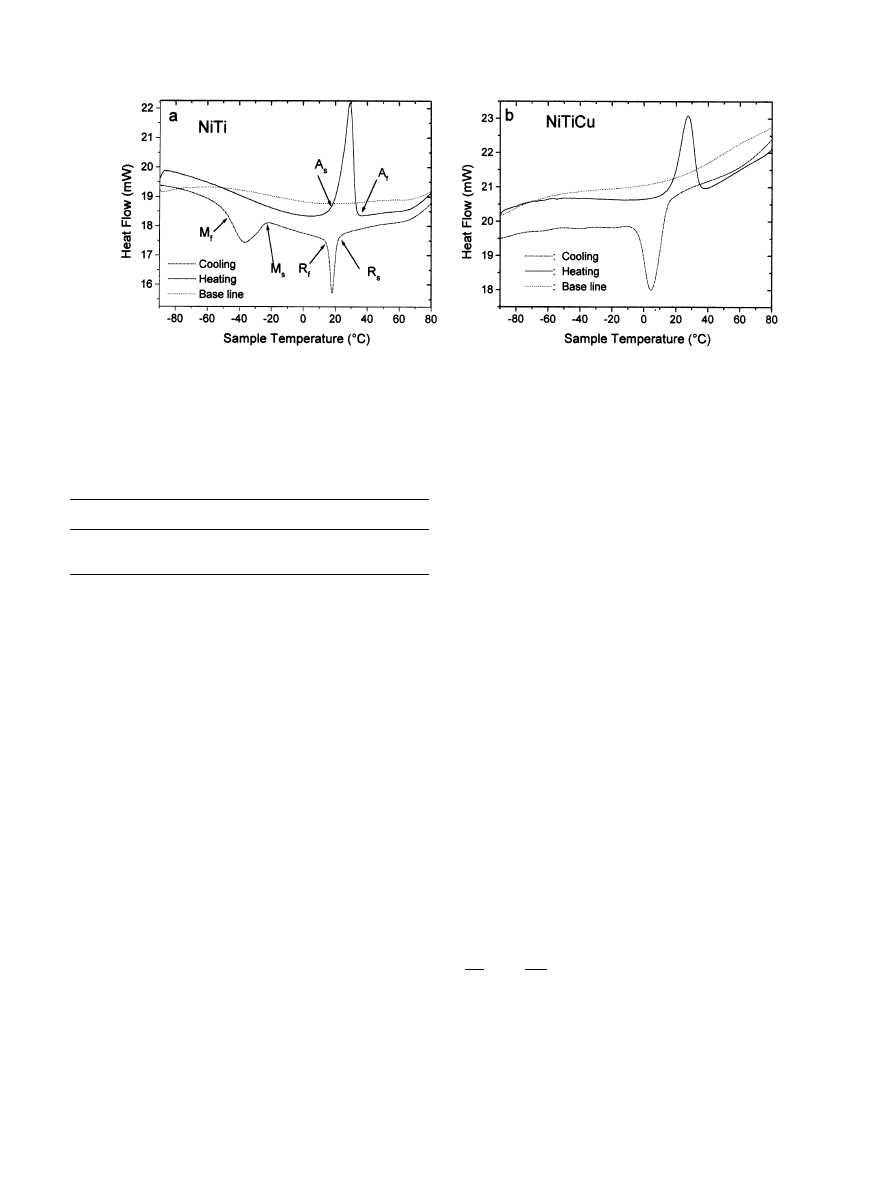

The stress}strain diagrams at di!erent temperatures

are shown in Figs. 2 and 3 as "ve loading and unloading

cycles . In Table 2, the results of the plateau stresses and

elastic moduli are summarised.

The overall deformation behaviour of both alloys is

quite similar: The strength increases drastically with tem-

perature due to the presence and/or thermal stabilisation

of the austenite phase. Furthermore both alloys show on

loading, particularly in the presence of the austenite

phase (temperature between A and A or above A)

a di!use stress peak followed by a yield drop before the

plateau stress, which denotes the progressive stress-in-

duced consumption of the austenite phase by the growing

martensite variants, is established. On unloading,

and before completion of the reverse transformation of

M. Es-Souni et al. / Biomaterials 22 (2001) 2153}2161

2155

Fig. 1. (a) and (b) DSC curves of the investigated alloys: NiTi (a) and NiTiCu (b). See also Table 1.

Table 1

Transformation temperatures of the alloys investigated. M: marten-

site-"nish; M: Martensite start; R: R-phase "nish; R: R-phase start;

A: Austenite start; A: Austenite "nish

Alloy

M (3C) M (3C) R (3C) R (3C) A (3C) A (3C)

NiTi42

!

59.0

!

23.4

15.3

21.0

21.8

32.7

NiTi42Cu7

!

4.0

14.2

*

*

17.8

34.0

martensite to austenite, a reverse peak stress is observed

at temperatures above A. However, at 603C, the peak

stress becomes more di!use and almost disappear, and

this is particularly true for the binary alloy, when the

specimen is subjected to loading/unloading cycles.

Nevertheless, a closer look at the stress}strain diagrams

reveals speci"c di!erences of the deformation behaviour

of the alloys investigated. At 63C, which is below the

R and above the M temperatures of the binary NiTi

alloy, the characteristic deformation behaviour of the

R-phase upon loading [14] can be seen. Following the

elastic deformation a stress plateau (though slightly in-

creasing) which is attributed to the movement of the

R-variants with preferential orientation to the stress axis

is established up to a strain of approximately 0.75%;

beyond that, the deformation continues elastically until

a smooth transition to a new plateau occurs which de-

notes the beginning of the stress-induced transformation

of the R-phase to the martensite. In contrast, the ternary

alloy shows only the martensitic

`plateaua which is in-

itiated at a relatively lower stress, and is characterised by

a slight, continuous increase of stress with increasing

deformation. At 223C, the deformation of the binary

alloy proceeds by the direct stress induced transforma-

tion of R to M, whereas the ternary alloy shows a defor-

mation behaviour proper to a martensitic}austenitic-

phase mixture with martensitic predominance. Further-

more the peak stress followed by a yield drop appears at

this temperature, which suggests that the peak stress is

closely related to the stress-induced transformation of

austenite to martensite. At 373C, both alloys are fully

austenitic and exhibit the superelastic deformation be-

haviour characterised by the superelastic hysteresis

which is however narrower in the case of the NiTiCu

ternary alloy. At this temperature, both alloys show

a good resistance against softening during loading}un-

loading cycles; the peak stresses remain practically un-

changed, and the plateau stresses, though somewhat

shifted towards lower values on cycling, are only margin-

ally a!ected. At higher temperatures, the properties of the

binary alloy are dramatically a!ected, particularly on

cycling. The peak stress disappears in the second

cycle,

the

remaining

deformation

increases

with

the cycle number and the superelastic properties are

gradually lost. In contrast the integrity of the properties

is only slightly a!ected in the case of NiTiCu alloy, apart

from a comparatively small amount of remaining defor-

mation which does not increase with increasing cycle

number.

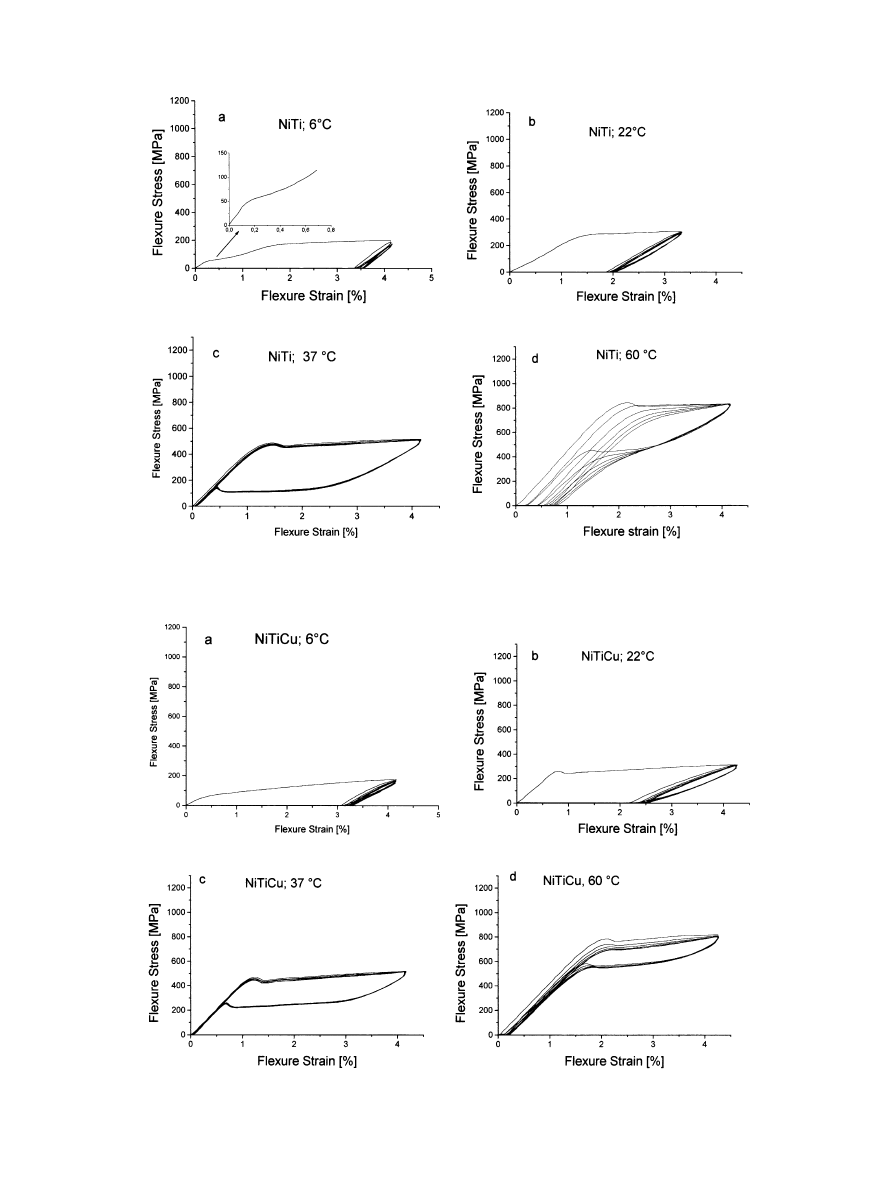

Fig. 4 shows plots of the plateau stresses vs. temper-

ature where for both alloys a linear relationship between

stress and temperature is well veri"ed. This indicates that

the stress to move the martensite plates or to induce the

martensitic transformation is well described by the

Clausius}Clapeyron equation [1]:

d

d¹

"!

H

¹

,

(

1)

where

is the stress, H the transformation enthalpy,

a transformation strain and ¹ the absolute temper-

ature. The calculated slopes of the linear intercept lines

yield similar values of 12 and 12.6 MPa/3C for the stress

rates for NiTi and NiTiCu, respectively.

2156

M. Es-Souni et al. / Biomaterials 22 (2001) 2153}2161

Fig. 2. Stress/strain diagrams of the binary NiTi alloy at di!erent temperatures: 63C (a), 223C (b), 373C (c) and 603C (d).

Fig. 3. Stress/strain diagrams of the ternary NiTiCu alloy at di!erent temperatures: 63C (a), 223C (b), 373C (c) and 603C (d).

M. Es-Souni et al. / Biomaterials 22 (2001) 2153}2161

2157

Table 2

Maximum and minimum plateau stresses as given by

o!set stresses

Alloy

max (MPa)

min (MPa) E-modul (GPa)

Temperature (3C)

Temperature (3C)

Temperature (3C)

6

22

37

60

6

22

37

60

6 22

37

60

NiTi

188 297 485 826

*

*

117 456

*

20

43

45.2

NiTiCu 110 258 471 782

*

*

237 570

17 33.4 41.6 42.9

Fig. 4. Plateau stresses versus temperature.

Fig. 5. (a) Cytokeratin AE1, AE3 stained epithelial cells. (b) Negative

control.

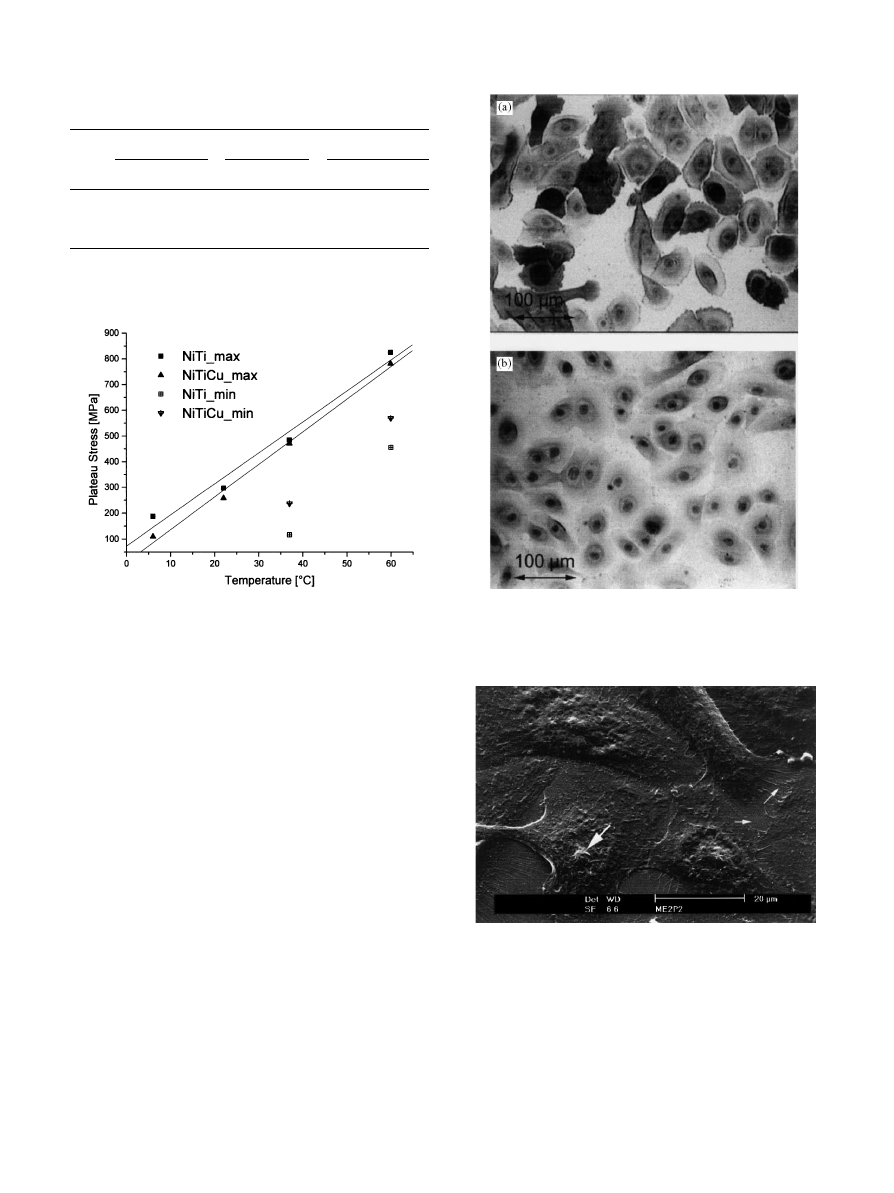

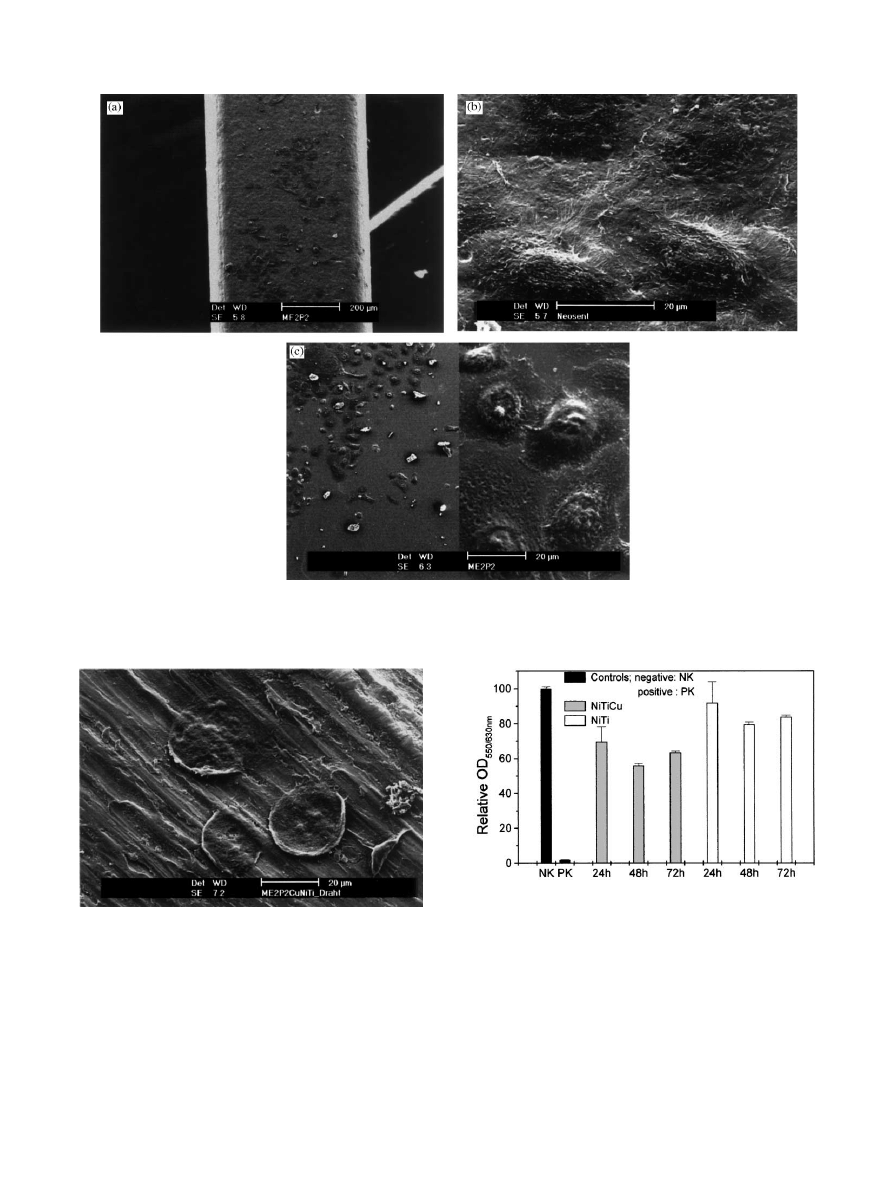

Fig. 6. Secondary electron micrograph (SE) of the epithelial cell mor-

phology in control cultures showing nuclei (bold arrow) and cytoplas-

mic projections ("ne arrow).

3.3. Biocompatibilty results

3.3.1. Morphological investigations

Monolayers of non-exposed gingival cell cultures (con-

trol culture) stained uniformly positive for cytokeratin,

a$rming that the cells are of epithelial origin. Light

microscopy (LM) investigations of the stains showed

a well-attached monolayer with the typical morphology

illustrated in Fig. 5.

The cells show distinct boarders and prominent nuclei.

SEM investigations con"rmed these facts: The cells

showed well-developed intercellular junctions, nuclei as

well as numerous cytoplasmic projections, Fig. 6. The

cells grown in the presence of the binary alloy adhered to

both metal and coverslip and exhibited a quite similar

morphology to the control cultures, Fig. 7a and b.

The cells grown in presence of the ternary alloy were

found to di!er in their morphological characteristics. The

cell growth and adhesion seemed to be poorer, e.g.

Fig. 8a, where detached cells can be seen. Furthermore,

a higher number of spherical cells with irregular plasma

membrane and missing cytoplasmatic projections were

found.

3.3.2. MTT in vitro cytotoxicity test

The MTT cytotoxicity tests were performed on

10

cells/100 l/well. The cells were exposed for 24, 48

and 72 h to the alloys.

2158

M. Es-Souni et al. / Biomaterials 22 (2001) 2153}2161

Fig. 7. (a) SE micrograph of the epithelial cells grown on the binary NiTi alloy. (b) Similar to Fig. 7a at higher magni"cation. (c) Dual magni"cation SE

micrograph of the epithelial cells grown on coverslip in the presence of the binary NiTi alloy.

Fig. 8. SE micrograph of the epithelial cells grown on the ternary

NiTiCu alloy.

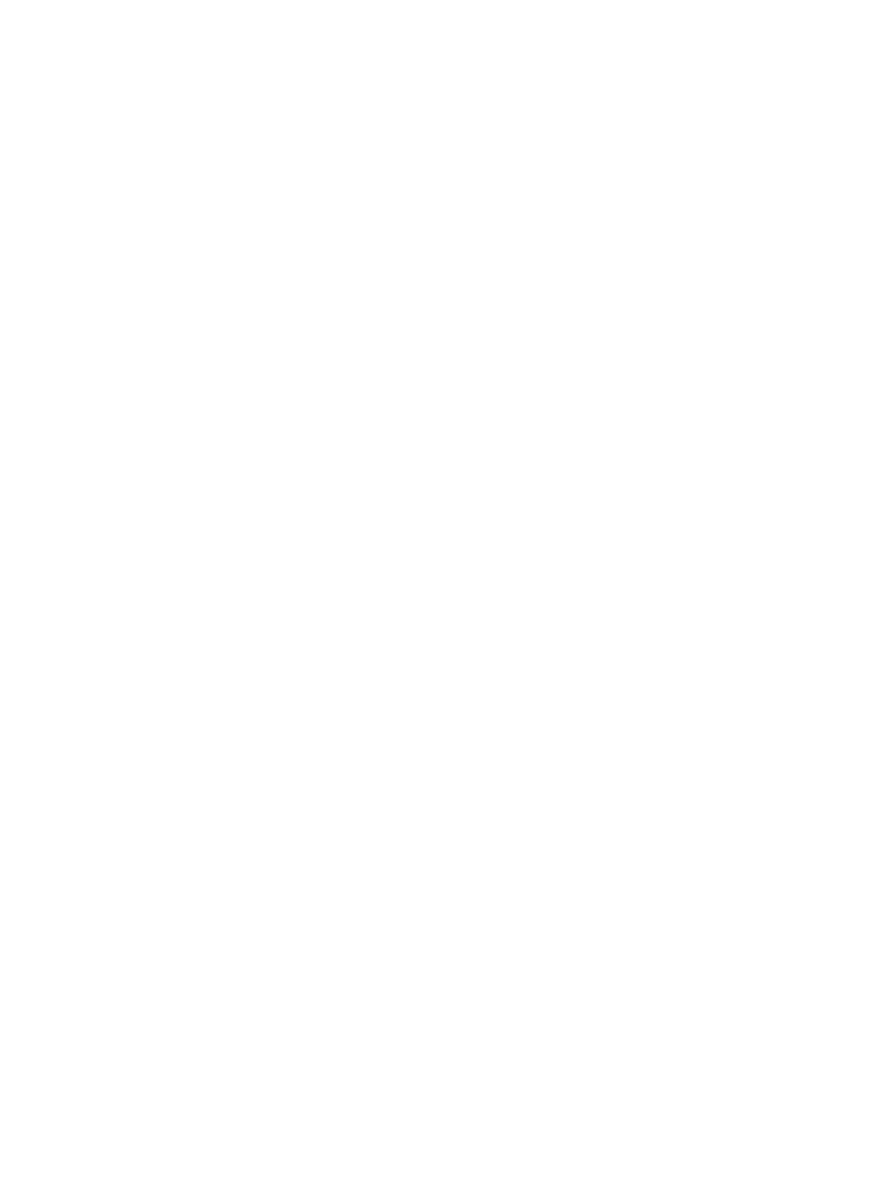

Fig. 9. Relative OD of formazan formation for both alloys for

di!erent incubation periods of 24, 48 and 72 h. The "gure also shows

negative (NK) and positive (PK) controls. The error bars denote the

standard error.

Fig. 9 shows that there is a di!erent response to for-

mazan formation depending on the alloy used. It can be

seen that the binary alloy leads to a loss of approximately

10}15% of viability with respect to the negative control,

whereas the ternary alloy induces a loss of viability of

about 30}38%. Statistical evaluation of the results using

the one-way Anova test yields a signi"cant di!erence

between both populations with p"0.0145 at the signi"-

cance level of 0.05. Due to the fact that the ternary alloy

contains 6.9% Cu, and that Cu is well known for its

cytotoxic e!ects [15], it was thought, that the loss of

viability might be attributed to the release of Cu-ions in

M. Es-Souni et al. / Biomaterials 22 (2001) 2153}2161

2159

the medium. Preliminary AAS measurements were con-

ducted on the medium after incubation with NiTiCu. The

results show that Cu is released to a concentration of

approximately 5.3$1.0

g cm\ after an incubation

period of 7 days at 373C. However, when this result is

corrected by the blank measurement of 2.5$1.0, a value

of 2.8$2.0

g cm\ is obtained which is close to the

result reported by Gil et al. [5] who found approximately

1.8

g cm\ after 7 days incubation of a similar alloy in

arti"cial saliva.

Fig. 9 also shows that when testing the incubation time

dependence of the MTT transformation within a sample

group, there seems to be a signi"cant di!erence in the

results obtained from cultures incubated with the sam-

ples for 24 h and 48 h. A longer incubation period of 72 h

does not change signi"cantly the MTT results in com-

parison to those of 48 h.

4. Discussion

4.1. Transformation behaviour and mechanical properties

The transformation behaviour of the alloys investi-

gated is quite di!erent because of di!erent thermo-

mechanical histories and chemical compositions. The

presence of copper in the ternary alloy is expected to

decrease the hysteresis of the martensite

austenite

transformation temperatures. The R-phase transforma-

tion in the binary alloy points to a thermomechanical

treatment making use of cold deformation [1,4] which

leads to the B19

martensite transformation being shifted

to lower temperatures. A direct comparison of the hyster-

esis of the alloys investigated is therefore not meaningful.

Comparison of the mechanical properties shows the

superior behaviour of the ternary NiTiCu alloy, parti-

cularly on loading}unloading cycles. The addition of

copper reduces the superelastic hysteresis stress and

allows higher unloading plateaus to be obtained which is

of particular interest for medical applications. The resist-

ance to softening during loading and unloading cycles at

higher temperatures is also considerably improved.

These properties have been attributed to the ease of

interface movement in the Cu alloyed NiTi [1] in com-

parison to the binary alloy, and the mechanical proper-

ties reported in the present work seem to con"rm this.

The appearance of the yield points on loading and un-

loading at temperatures above A suggests that for both

alloys a critical stress has to be overcome before the

austenite

martensite transformations take place, and is

in many aspects similar to LuKders deformation [14,16].

As the testing temperature is increased, the yield points

are considerably attenuated (NiTiCu) or disappear (NiTi)

on loading and unloading cycles. This is also accom-

panied by considerable softening. Due to the fact that

loading was always con"ned to the plateau region, we

attribute this softening to the build-up of residual stresses

which at these temperatures may arise from the forma-

tion of interface dislocations. The presence of residual

stresses may also rise the transformation temperature,

and the increasing

`remaininga deformation with in-

creasing the number of cycles may be a further support

for this mechanism. The improved behaviour of NiTiCu

over the binary alloy lies in the easier movement of

interphase boundaries as mentioned above.

4.2. Biocompatibility

In contrast to other biotoxicity studies [17,18], we did

not use commercially available cell lines, but cultivated

monolayers of gingival epithelial cells from primary cul-

tures of gingival explants. Prior to any cytotoxicity test it

was shown by means of immuno-cytochemical tests, that

the cells used were of epithelial origin.

The SEM and LM studies of cells grown in the pres-

ence of the binary alloy did not show any signi"cant

morphological di!erence to the control sample. Adher-

ence and growth were similar on both coverslip and

metal, although the adherence on the metal seemed less

pronounced than on the coverslip. Nevertheless a normal

morphology of the cells adhering on the NiTi was ob-

served, which stresses the biocompatibility of this alloy.

The results of the MTT-biotoxicity test con"rms this fact.

The formazan formation, which denotes the dehydrogen-

ase activity and thus the intact mitochondrial content of

the cells tested, decreases only by 10% after a 24 h incu-

bation period, and by additional 5%, when incubated for

48 or 72 h. This decrease might be attributed to a release

of Ni ions which have been shown in a recent study to be

highest in the "rst 2 days [9].

The results of the ternary alloy tested di!er from those

obtained for the binary alloy. Cell adhesion and growth

are less pronounced in the presence of NiTiCu. SEM

investigations of cells grown on coverslips in the presence

of the metal show a higher number of spherical, some-

times detached cells. These e!ects are more pronounced

on the alloy. The MTT-test con"rms these "ndings. In

fact there is a 30}38% decline of the dehydrogenase

activity obtained for incubation periods of 24 and 48 or

72 h, respectively. Gil et al. [5] show that Cu ions are

released to a higher concentration than Ni and Ti ions

and that the release rate is maximum in the initial incuba-

tion phase. Therefore, it is thought that the higher

cytotoxicity of the ternary alloy arises from the release of

Cu ions which are known for their cytotoxic e!ects.

Evidence for the release of the Cu ions could be also

found in this work using AAS. However, it should be

mentioned, that for both alloys no signi"cant change was

observed between an incubation period of 48 and 72 h.

This points to a time-dependent build up of a passive

layer on the alloy surfaces, which usually follows a para-

bolic law. This explains why the MTT results remain

2160

M. Es-Souni et al. / Biomaterials 22 (2001) 2153}2161

almost constant with increasing incubation time. The

formation of this passive layer will be investigated in

more detail using electron spectroscopic surface analysis

methods.

The present results show that the Cu addition to the

NiTi shape memory alloys a!ects their biocompatibility

in vitro. This may appear to disagree with the results of

Wen et al. [10], who claim that Cu does not a!ect the

biocompatibility in vivo of these alloys, although their

results show unambiguously higher corrosion rates with

increasing Cu content (see Fig. 1 of their work). Further-

more, reinterpreting their

`histomorphometrica results,

there seems to be a signi"cantly thicker capsule of con-

nective tissue covering the implant with the highest Cu

content after one month of implantation which points to

a lower biocompatibility. Nevertheless, it is thought that

the signi"cantly higher cytotoxicity of the ternary alloy

observed in the present work may arise from the speci"c

response of the epithelial cell cultures in an in vitro

test [19].

5. Conclusion

The present work reports a comparative study of the

properties, including biocompatibility, of a binary

NiTi42 and a ternary NiTi42Cu7 shape memory alloy.

The following conclusions may be inferred:

E The alloys are characterised by a di

!erent transforma-

tion behaviour. The binary alloy shows a R-phase

transition due to cold working while the ternary alloy

shows a direct austenitic to martensitic transforma-

tion.

E The ternary alloy shows superior mechanical proper-

ties. The superelastic hysteresis stress is lower resulting

in higher unloading plateau stresses, and the resistance

to softening during loading}unloading cycles is better.

E This study shows a signi

"cant di!erence in the in vitro

biocompatibility between the binary and ternary alloy.

The presence of the binary alloy leads to few mor-

phological changes and slight reduction of dehydro-

genase activity of epithelial cell cultures, whereas the

e!ect of the ternary alloy appears to be more pro-

nounced, obviously due to releasing of copper ions.

The biocompatibility may, however, be improved by

using passivated wires. This will be the subject of

a forthcoming study.

References

[1] Saburi T. Ti-Ni shape memory alloys. In: Otsuka K, Waymann

CM, editors. Shape memory materials. New York: Cambridge

University Press, 1998. p. 49}96.

[2] Melton KN. General applications of SMA's smart materials. In:

Otsuka K, Waymann CM, editors. Shape memory materials. New

York: Cambridge University Press, 1998. p. 220}39.

[3] Duerig TW. Present and future applications of shape memory and

superelastic materials. In: George EP, Takahashi S, Trolier-

McKinstry S, Uchino K, Wun-Fogle M, editors. Materials for

smart systems. Pittsburgh: Materials Research Society, 1995.

p. 497}506.

[4] Suzuki Y, Horikawa H. Thermal hysteresis in NiTi and Ni-Ti-X

alloys and their applications. In: Liu CT, Kunsmann H,

Otsuka K, Wuttig M, editors. Shape memory materials and

phenomena * Fundamental aspects and applications. Materials

for smart systems. Pittsburgh: Materials Research Society, 1992.

p. 403}6.

[5] Gil FJ, Planell JA. E!ect of copper addition on the super-

elastic behaviour of NiTi shape memory alloys for ortho-

dontic

applications.

J

Biomed

Mater

Res

1999;48(5):

682}8.

[6] Gil FJ, Manero JM, Planell JA. Relevant aspects in the clinical

applications of NiTi shape memory alloys. J Mater Sci Mater

Med 1996;7:403}6.

[7] Wever DJ, Veldhuizen AG, Sanders MM, Schakenrad JM,

van

Horn

JR.

The

cytotoxic,

allergic

and

genotoxic

activity of a

nickel-titanium alloy. Biomaterials 1997;18:

1115}20.

[8] RyhaKnen J, Kallioinen M, Tuukkanen J, Lehenkari P, Junila J,

NiemelaK E, Sanvik P, Serlo W. Bone modelling and cell-material

interface

response

induced

by

nickel}titanium

shape

memory

alloy

after

periosteal

implantation.

Biomaterials

1999;20:1309}17.

[9] Wever

DJ,

Veldhuizen

AG,

de

Vries

J,

Busscher

HJ,

Uges DRA, van Horn JR. Electrochemical and surface

characterization

of

a

nickel}titanium

alloy.

Biomaterials

1998;19:761}9.

[10] Wen X, Zhang N, Li X, Cao Z. Electrochemical and histomor-

phometric evaluation of the TiNiCu shape memory alloy. Biomed

Mater Eng 1997;7(1):1}11.

[11] Judd

DA,

Battista

PJ,

Behm

DD.

Culture

of

human

keratinocytes in de"ned serum-free medium. Focus 1997;19:

1:2}5.

[12] Bourne JA. Handbuch I der Immunoperoxydase FaKrbemethoden.

DAKO corporation, Carpenteria, CA. 1997. p. 16.

[13] Tada H, Shibo O, Kuroshima K, Koyama M, Tsukamoto K. An

improved colorimetric assay for interleukin-2. Immunol Methods

1986;93:157}65.

[14] Duerig TW, Melton KN. Di!use yield drop and snap

action in a NiTi alloy. In: George EP, Takahashi S, Trolier-

McKinstry S, Uchino K, Wun-Fogle M, editors. Materials for

smart systems. Pittsburgh: Materials Research Society, 1995.

p. 159}64.

[15] Scarino ML, Poverini R, Di Lullo G, Biseses G. Inhibition of

protein synthesis after exposure of Caco2 cells to heavy metals.

ATLA 1992;20:325}33.

[16] Orgeas L, Favier D. Stress induced martensitic transformation of

a NiTi alloy in isothermal shear, tension and compression. Acta

Mater 1998;46:5579}91.

[17] Grant DM, Lo WJ, Parker KG, Parker TL. Biocompatibility and

mechanical properties of low temperature deposited quaternary

(Ti, Al, V)N coating on Ti6Al4 V titanium alloy substrate. J Mater

Sci Mater Med 1996;7:579}84.

[18] Prigent H, Pellen-Mussi P, Cathelineau G, Bonnaure-Mallet M.

Evaluation of the biocompatibility of titanium}tantalum alloy

versus titanium. J Biomed Mater Res 1998;39:200}6.

[19] Wintermantel E, Suk-Woo H. Biokompatible Werksto!e und

Bauweisen. Berlin: Springer, 1998. p. 119}20.

M. Es-Souni et al. / Biomaterials 22 (2001) 2153}2161

2161

Wyszukiwarka

Podobne podstrony:

40 549 563 On the Precipitation Behaviour in Maraging Steels

Report on the Sexual Behavior o Robert F Young(1)

Notes on the Alchemical Transformation of Mecury

Phillip G Zimbardo A Situationist Perspective On The Psychology Of Evil Understanding How Good Peo

Begault Direct comparison of the impact of head tracking, reverberation, and individualized head re

The impact of network structure on knowledge transfer an aplication of

Parzuchowski, Purek ON THE DYNAMIC

Enochian Sermon on the Sacraments

GoTell it on the mountain

Interruption of the blood supply of femoral head an experimental study on the pathogenesis of Legg C

CAN on the AVR

Ogden T A new reading on the origins of object relations (2002)

On the Actuarial Gaze From Abu Grahib to 9 11

91 1301 1315 Stahl Eisen Werkstoffblatt (SEW) 220 Supplementary Information on the Most

Pancharatnam A Study on the Computer Aided Acoustic Analysis of an Auditorium (CATT)

Newell, Shanks On the Role of Recognition in Decision Making

BIBLIOGRAPHY I General Works on the Medieval Church

Chambers Kaye On The Prowl 2 Tiger By The Tail

więcej podobnych podstron