In-tube solid phase micro-extraction–gas chromatography of

volatile compounds in aqueous solution

Boon Chong Dennis Tan,

a

Philip J. Marriott,*

a

Hian Kee Lee

b

and Paul D. Morrison

a

a

Royal Melbourne Institute of Technology, Department of Applied Chemistry, GPO Box

2476V, Melbourne, Victoria 3001, Australia. E-mail: Philip.Marriott@rmit.edu.au

b

National University of Singapore, Department of Chemistry, 10 Kent Ridge Crescent,

Singapore 119260, Singapore

Received 2nd March 1999, Accepted 30th March 1999

This paper describes the use of conventional coated capillary gas chromatography columns for sorption of organic

solutes from aqueous solution, with subsequent gas chromatographic analysis. The essential principles are similar

to those of solid phase extraction (SPE) and solid phase micro-extraction (SPME); this approach may be referred

to as in-tube solid phase micro-extraction (ITSPME). The technique was evaluated using toluene in water as the

initial test solute, and a mixture of BTEX solutes (benzene, toluene, ethylbenzene, xylenes) in Milli-Q water was

used to further characterise ITSPME. A 1 m length of capillary GC column was used for sorption of analytes from

aqueous solution passed through the capillary by using nitrogen pressure. Collection of small fractions of aqueous

solution issuing from the capillary enabled a sorption profile to be generated, with initial fractions depleted in

analyte. A Boltzmann curve could be fitted to the sorption profile data, exhibiting good agreement with

experimental data. For recovery of sorbed toluene, a single 100

mL aliquot of hexane was passed through the

column as a stripping solvent. The back-extraction step was quantitative. Equilibrium extraction of solutes shows

that the total amount of recovered solute is proportional to its initial concentration in the extracted aqueous

solution and allows distribution constants to be readily estimated. For BTEX solutes, K values were similar to

those reported for SPME and literature K

ow

values. For toluene, log K decreases from 2.47 to 1.48 when the

sorption column temperature increases from 20 to 30 °C; adding salt or reducing the pH of the aqueous solution

increases the degree of extraction of phenols, agreeing with general considerations on solute partitioning

behaviour.

Introduction

Solvent free sample preparation methods or those employing

less organic solvent are becoming increasingly important

1

and

may induce a major change in analytical methodology.

2

Practical alternatives to existing sample preparation methods

may therefore need to be formulated. Solid phase extraction

(SPE) and solid phase micro-extraction (SPME) have emerged

as efficient, popular alternative extraction techniques.

3

A broad

array of applications have been reported, such as determining

octanol–water partition coefficients,

4

detecting BTEX in water

5

and analysing pesticide solutions. Gas-phase extraction and a

variety of headspace applications are available. Whilst these

show that SPE and SPME are good alternative methods, basic

principles still require evaluation.

6

An effective alternative to

these techniques is presented in this paper, in-tube solid phase

micro-extraction (ITSPME). Recently, Pawliszyn and co-

workers have reported the automation of a similar approach

involving coupling of the extraction column to high-perform-

ance liquid chromatography (HPLC).

6

By extension, ITSPME

should also have the potential to be coupled to other analytical

instruments, such as gas chromatography (GC) or capillary

electrophoresis (CE).

ITSPME utilizes similar principles to SPME. Exhaustive

extraction might not occur, with equilibrium partitioning of the

analyte between the sample solution and the extraction medium

(the stationary phase coated to the inner walls of the extracting

capillary column). The sorbing phase can be selected according

to the type of analytes to be determined, e.g., a non-polar phase

if the analyte of interest is non-polar.

1,7

In ITSPME, analyte

solution is passed through the capillary at a reasonably slow

flow rate. The amount of analyte sorbed by the stationary phase

at equilibrium is directly related to its concentration in the

sample solution, which can be described in a similar manner to

SPME

1,4

by equation (1):

M

KV

C

V

KV

V

s

sample

sample s

s

sample

=

+

(1)

where M

s

is the mass of an analyte sorbed by the stationary

phase, V

s

and V

sample

are the volumes of the stationary phase and

the sample passing through the capillary column, respectively,

K is the partition coefficient of the analyte between the

stationary phase and the sample matrix, and C

sample

is the initial

concentration of the analyte in the sample in mass per unit

volume. As in SPME, if V

sample

is large (V

sample

> KV

s

), the

amount of the analyte extracted

8

is:

M

s

= KC

sample

V

s

(2)

Following aqueous sample extraction, the sorbed analyte can be

stripped from the stationary phase with minimum amount of

organic solvent, and the extract analysed by GC-FID. In

addition, the aqueous solution can be monitored both prior to

extraction and also in the stream which issues from the

extraction capillary. The problem of analysing aqueous samples

has been addressed.

9

Conceptually, ITSPME should preserve

the advantages of SPE and SPME, but may offer potential

benefits regarding quantitation and automation. ITSPME may

use conventional capillary GC columns for sorption, with

thermally stable, non-extractable bonded phases making the

phase more robust than thick film phases on fibres. Conversely,

thick films are not readily prepared for wall-coated capillary

columns. Thus, ITSPME possesses complementary advantages

to SPME, as outlined in this paper.

Analyst, 1999, 124, 651–655

651

Experimental

Reagents

All reagents used were of analytical reagent grade. Benzene,

toluene, ethylbenzene, o-xylene, m-xylene, p-xylene, m-ni-

trophenol, p-cresol, p-tert-butylphenol, 2,4-dichlorophenol,

2,4,6-trichlorophenol, acetone, hexane, methanol, potassium

chloride, sodium chloride, concentrated hydrochloric acid and

2-hexanone were purchased from BDH (Sydney, Australia) or

Aldrich (Sydney, Australia); Milli-Q water (Millipore, Bedford,

MA, USA) was used throughout. The following stock standard

solutions were prepared in water and hexane (BTEX analysis)

or methanol (phenols analysis): 100 mg L

21

toluene, 100

mg L

21

ethylbenzene, and mixtures of 100 mg L

21

of each

component of BTEX and 100 mg L

21

of each component of

phenols. 2-Hexanone (100 mg L

21

) in hexane solution and 100

mg L

21

o-xylene in methanol were also prepared. In order to

ensure that the chemicals were adequately dissolved in the

solvent, 0.5 mL of acetone was used to dissolve the reagent first,

followed by dilution as required with solvent Milli-Q water or

hexane.

5,10

The effect of pH and salt on efficiency of extraction

in the ITSPME technique was examined. A pH 2 buffer was

prepared with 25 mL of 0.2 m KCl and 6.5 mL of 0.2 m HCl in

100 mL of water, and saturated salt solutions were prepared

with NaCl.

Instrumentation

A Shimadzu GC 17A with an autosampler and FID detector

(Shimadzu Scientific Instruments, Rydalmere, NSW, Australia)

was used for all gas chromatographic analyses. The fused silica

capillary column used for GC was 30 m

3 0.25 mm with 0.25

mm film thickness BPX5 phase (SGE International, Ringwood,

Australia). The conditions for the analysis were as follows.

BTEX analysis: column flow approximately 1.9 mL min

21

;

linear velocity approximately 35.6 cm s

21

; column oven at

93 °C (this temperature allowed acceptable analysis time

without causing the toluene peak to overlap with trace acetone

solvent peak); injection port at 250 °C with split injection (split

ratio 1 : 20); FID detector at 320 °C. Phenols analysis: column

flow approximately 1.4 mL min

21

; linear velocity approx-

imately 30 cm s

21

. The injector, operated in splitless mode, was

maintained at 200 °C; the FID detector was at 275 °C. The

temperature program was 50 °C for 1 min, ramp to 190 °C at

10 °C min

21

, final hold time 1 min at 190 °C.

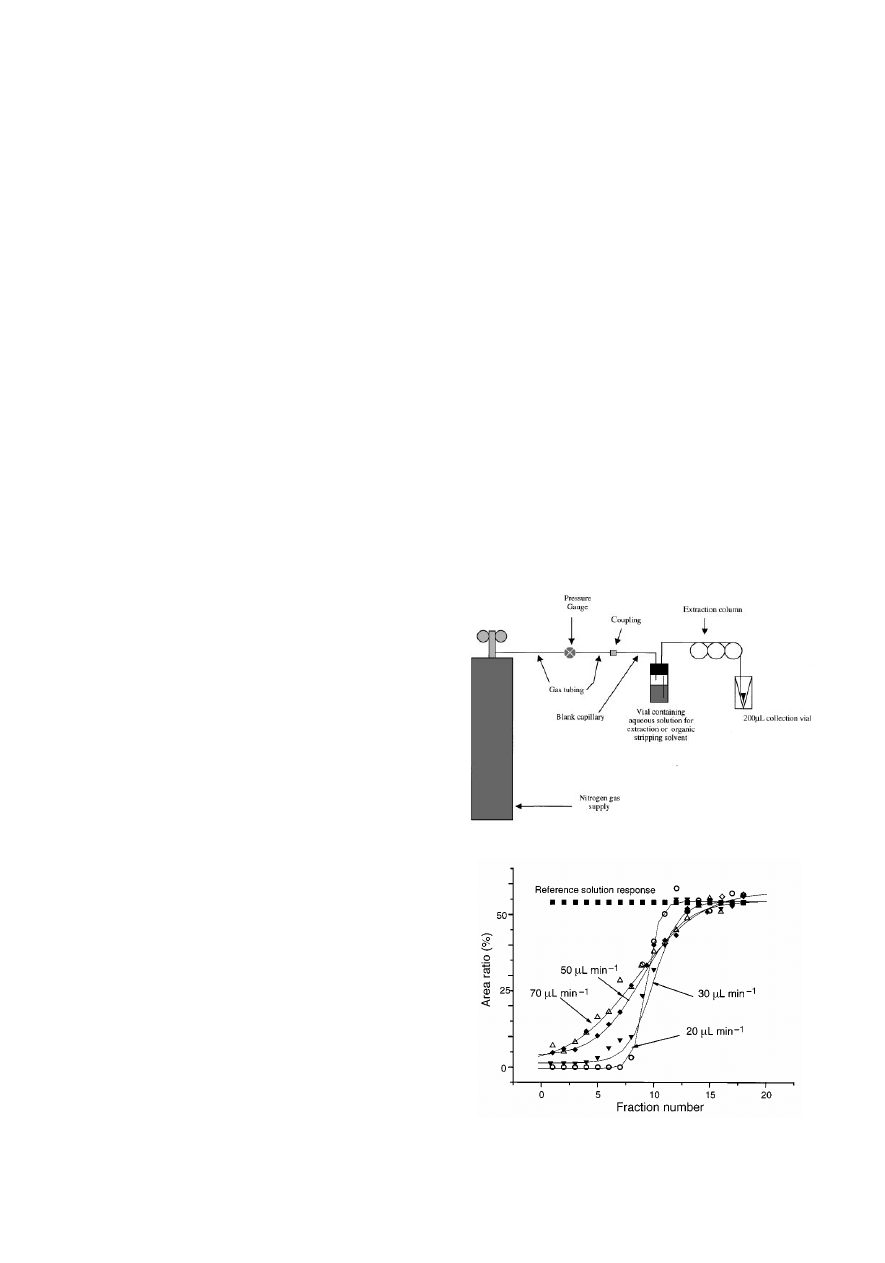

In-tube solid phase micro-extraction (ITSPME). To

perform extraction of BTEX and phenols using ITSPME, 2

different types of capillary GC columns were used. The first was

1 m long, 0.25 mm internal diameter with 3.5

mm thick BP1

(100% methylsiloxane) stationary phase, while the second was

1 m long, 0.32 mm internal diameter with 1

mm thick BP20

(polyethylene glycol) stationary phase (both columns from SGE

International, Ringwood, Australia). Nitrogen gas was used to

provide head pressure to the sample vial to force the aqueous

solution through the capillary (Fig. 1). Most extractions were

carried out at 20 °C and the capillary may be immersed in a

water bath for temperature control. Two forms of extraction

were performed, forward extraction and back extraction, as

described below.

Forward extraction. A volume of solution (in water) was

prepared at the desired concentration from the stock solution. It

was then forced through the capillary by applying nitrogen head

pressure. Solution was passed through as a continuous stream,

and collected in separate vials in 100

mL volumes or fractions.

A suitable internal standard was added in the fractions. The

analytical results of the collected aliquots could be used to

generate a sorption profile. A separate standard was prepared in

water to serve as a reference solution against which the

collected aliquots could be compared. The extraction experi-

ment may be conducted with different linear velocities of

aqueous solution passing through the capillary column, by

means of controlling the head pressure of nitrogen in the vial

using control gauge pressure.

Back extraction. After a specific volume of solute in water at

a fixed concentration was passed through the extraction

capillary column, the capillary was dried with a nitrogen flow

and then a minimum volume of organic solvent was passed

through the extracting capillary to strip the sorbed solute. A

suitable internal standard was added, and the solution was

analysed by using GC-FID. The result was then compared with

the calibration plot from a series of standard solutions in the

same organic solvent to estimate the amount of recovered

solute.

Results and discussion

Sorption profiles

Using forward extraction, four sorption profiles of aqueous

toluene passing through the 1 m capillary GC column at flow

rates of 20, 30, 50 and 70

mL min

21

were obtained. The 100

mL

fractions collected were analysed by GC-FID after addition of

the internal standard. Each flow rate was repeated 3 times and

Fig. 2 presents representative results from individual studies.

Fig. 1

Experimental set up for the ITSPME technique.

Fig. 2

Experimental sorption profiles for toluene at different flow rates.

Lines of best fit based on a Boltzmann distribution are shown for each set

of data. (2) 20

mL min

21

; (!) 30

mL min

21

; (/) 50

mL min

21

; (Ω) 70

mL min

21

.

652

Analyst, 1999, 124, 651–655

Variation in peak areas or area ratios may arise from (i) injection

volume uncertainty, or (ii) variation in volume of either the

collected toluene fraction or the added ethylbenzene volume.

The toluene volume has the greatest uncertainty since the 100

mL volumes collected could not be controlled with precision. An

alternative procedure would involve weighing the collection

vial. For the 20

mL min

21

flow data, the absence of toluene in

fractions up to fraction 4 is noted; fraction 13 and later fractions

have essentially the same level of toluene as that in the reference

solution, shown as a broken line in Fig. 2, indicating 100%

‘breakthrough’. As the flow rate, and hence velocity, of the

aqueous toluene through the extracting capillary increases,

extraction is less complete for the early collected fractions, and

traces of toluene could be detected in fraction 1 of the sorption

profiles for faster flow rates. The curves also become less steep

than those at slow velocities. Experimental uncertainties meant

that data for the extraction profile did not precisely fit a smooth

curve; however, a Boltzmann-type curve could be fitted to

experimental data, as seen for the sorption profile data in Fig. 2.

The steepness of the curve increased for slower flow rates.

Integration of the Boltzmann equation can be used to give an

estimate of the total sorbed solute amount.

Determination of partition coefficient, K, for toluene

between water and BP1 phase

The 1 m BP1 capillary has a stationary phase volume of 2750

nL. Each 100

mL fraction of aqueous solution passing through

the capillary has a maximum amount of 2

mg of toluene that can

be sorbed, with less sorbed when breakthrough occurs. Using

results for a 20

mL min

21

flow of aqueous toluene, the total

amount of toluene sorbed by the capillary is 16.2

mg (Table 1).

Using K = C

s

/C

m

(where C

s

is the concentration in the

stationary phase and C

m

the concentration in the mobile phase)

the K value of toluene between water and stationary phase can

be calculated. At equilibrium (i.e., at 100% breakthrough) C

s

=

16.2

mg per 2750 nL = 5801 mg L

21

and C

m

is the

concentration of the original toluene standard, i.e., C

m

= 20

mg L

21

. Thus, log K = 2.47, which is in good agreement with

the K value determined by equation (2), log K

ow

and log K

determined from SPME (Table 2)

8,11–16

reported for the same

temperature. Recovery of the sorbed toluene by back extraction

should yield 81 mg L

21

of toluene (16.2

mg per 100 mL of

hexane, diluted 1 : 1 with IS solution). The 100

mL hexane strip,

with an added IS, was found to contain 66 mg L

21

toluene,

indicating a recovery of about 80% toluene; again, the volume

uncertainty can lead to error in the calculated value.

Determination of partition coefficient, K, for BTEX

compounds

K values for BTEX compounds were determined as above, in

triplicate. A 2.5 mL mixture of BTEX (each 20 mg L

21

) in

Milli-Q water was passed through the capillary and it was

assumed that each solute reached 100% sorption. Results

showed that different analytes had different recoveries, and

hence a different affinity for the stationary phase of the

extraction column. K values are reported and compared to

literature log K

ow

and log K (SPME) values (for a BP1-like

coating fibre) (Table 2). Good agreement was found, so

apparently the methyl siloxane stationary phase behaves

similarly to octanol in the octanol–water partition experiment.

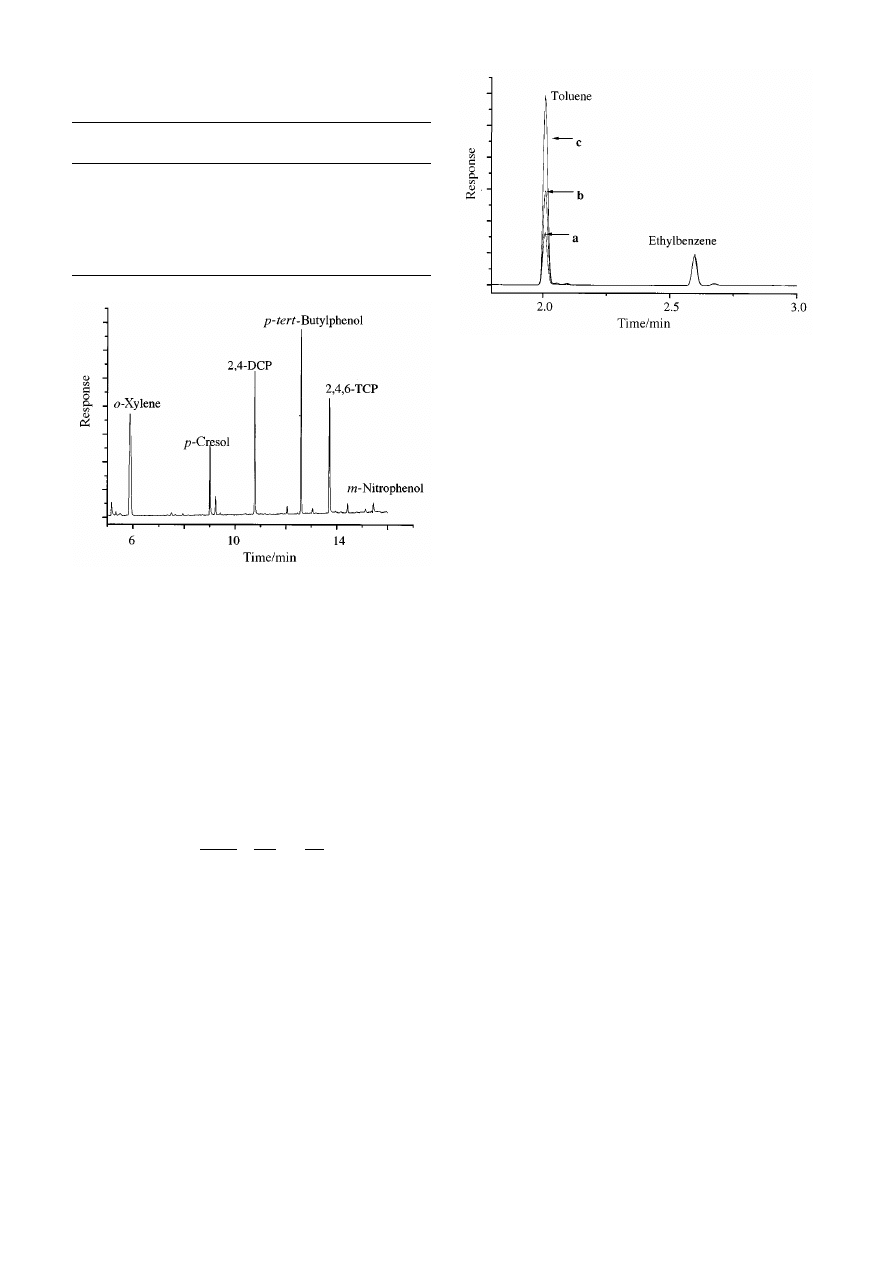

Dependence of ITSPME on extraction temperature,

solution pH and salt content

The back extraction procedure for 20 mg L

21

toluene was

repeated at least 4 times with the same piece of capillary to

ensure that the extraction was consistent. The extraction was

then carried out at a temperature of 30 °C, with a decrease in the

amount of toluene sorbed expected and confirmed (Fig. 3).

Increasing the temperature decreases the analyte C

s

; in other

words, there is less affinity for the stationary phase. Log K at

30 °C is estimated to be 1.48 and a temperature increase of

10 °C decreases the value of K by a factor of 10. This result is

as expected from chromatographic results, where higher

temperature gives a smaller retention volume in GC and in

HPLC, and so smaller k and K values. Since salt affects solute

solubility, a further study to test ITSPME for extraction of

phenols from aqueous solution showed that both saturated salt

solution and lowering the solution pH increase the extent of

extraction by up to 10–20 times. For example, from Table 3

data, the peak for 2,4,6-TCP increases by about 3.5-fold, and p-

tert-butylphenol by about 25-fold. Fig. 4 is a representative GC

trace of the extraction of the saturated salt, pH 2 buffered,

aqueous solution. Since pKa values of phenols are

!7, there is

Table 1

Estimated amount of toluene sorbed per 100

mL of aqueous solution for the 20 mL min

21

sorption profile at 20 °C

Fraction number

1

2

3

4

5

6

7

8

9

10

11

12

13

Total

Toluene sorbed/

mg

2

2

2

2

2

1.7

1.6

1.3

0.9

0.5

0.2

0

0

16.2

Table 2

Distribution coefficient, K, data determined by ITSPME in

comparison with literature log K

ow

and log K (SPME) (for 100% methyl

siloxane coating)

BTEX

compound

Log K

(ITSPME)

a

Log K

ow

Log K (SPME)

b

Benzene

1.77 (7.4)

2.13

17

, 2.13

15

2.30

11

, 2.10

12

, 2.30

8

Toluene

2.47 (4.2)

2.69

17

, 2.69

15

2.88

11

, 2.53

12

, 2.88

8

Ethylbenzene

2.75 (3.9)

2.84

13

, 3.15

15

3.33

11

, 2.72

12

, 3.33

8

p- and m-Xylene 2.81 (4.8)

3.15

14

3.31

11

, 3.31

8

o-Xylene

2.69 (5.0)

2.77

14

, 2.77

15

3.26

11

, 2.82

12

, 3.26

8

a

Experimental value, this work; triplicate determinations; %rsd values in

parentheses.

b

Values quoted for SPME studies.

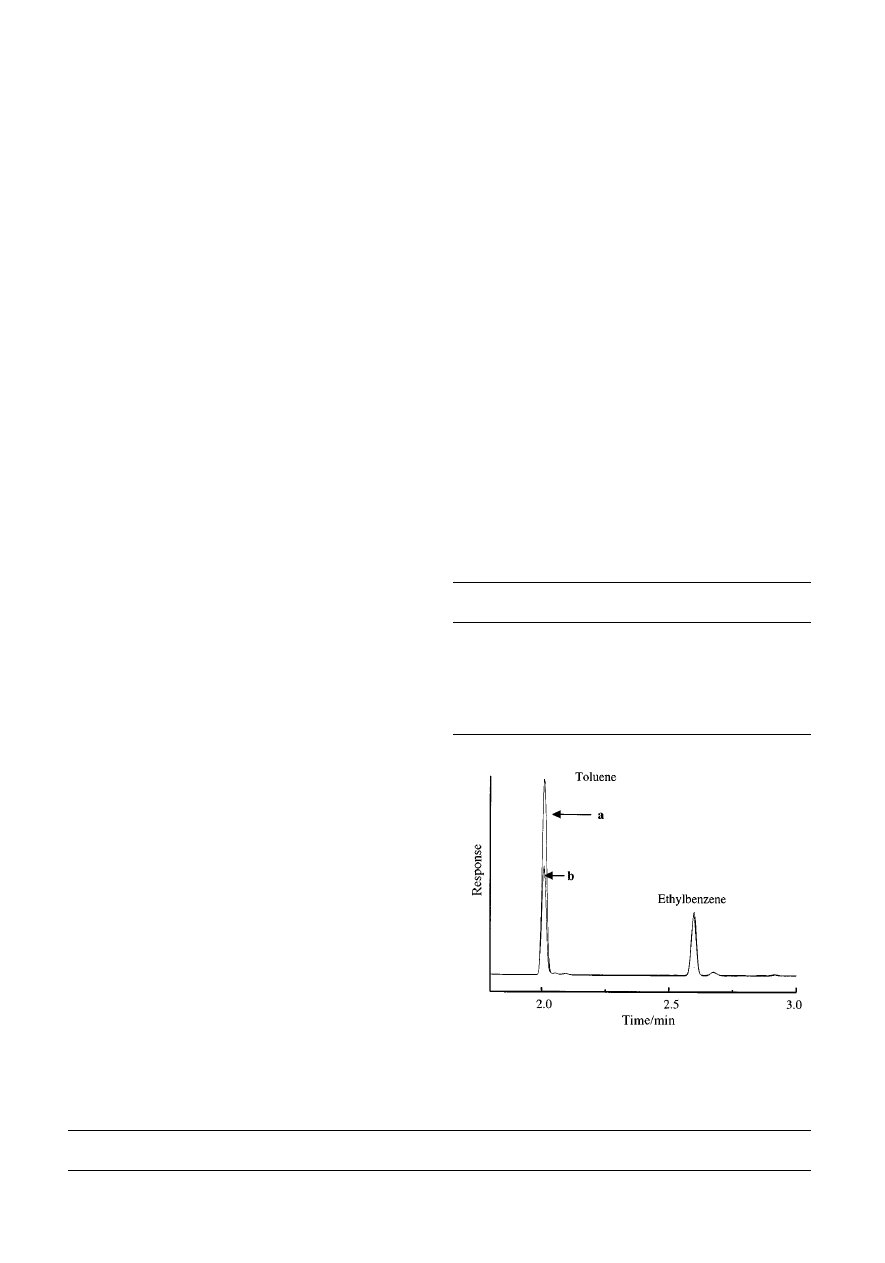

Fig. 3

Chromatograms of the hexane strip with different temperatures

used for the aqueous extraction of 20 mg L

21

of toluene. Curve a, extraction

capillary at 20 °C; curve b, extraction capillary at 30 °C.

Analyst, 1999, 124, 651–655

653

only a moderate increase in extracted amounts with reduction in

pH.

Linearity of ITSPME extraction of toluene from water

Equilibrium extraction conditions are established between the

aqueous and stationary phase, so concentration and recovered

solute should be linearly correlated.

11,16

According to chroma-

tographic theory, the partition ratio, k, is [equation (3)]

k

C V

C V

N

N

K

V

V

=

=

=

s s

m m

s

m

s

m

(3)

where N

s

and N

m

are the number of moles of toluene in the

stationary phase and mobile phase, respectively, and V

s

and V

m

are the volumes of the respective phases (note that V

m

/V

s

is

normally referred to as the phase ratio). Rearranging the

expression (3), and substituting C

m

V

m

for N

m

, gives

N

s

= KV

s

C

m

= AC

m

where A = KV

s

= constant at a given temperature. Back

extraction of 10, 20 and 40 mg L

21

aqueous solutions of

toluene, with added internal standard, was conducted in

triplicate with an %RSD of about 4% for each concentration.

Fig. 5 shows an overlay of one representative GC trace for each

extracted concentration. The calibration graph of concentration

versus area ratio (toluene/IS) had an R

2

of 0.999. The gradient

of the line allows determination of the partition coefficient if the

volume of the stationary phase is known. The slope A is

approximately 0.83 mL, giving an estimated log K value of

2.48, which is close to the previous estimation of log K for

toluene between water and BP1 stationary phase.

Conclusions

Initial studies have proven ITSPME to be an effective extraction

technique. Due to the availability of different polarity stationary

phases, optimised extractions for target analytes of interest in

routine analysis should be possible. If the extraction column is

directly connected to the analytical column, maximum mass

conservation in transferring the sorbed analyte to the analytical

step can be realised. The first experiments using this have been

encouraging. A solvent vent or waste line is required, and rather

than solvent stripping, thermal desorption of extracted analyte

will be explored with refocussing of the analyte at the head of

the analytical column to minimise band broadening. A simple

solution to this problem will be to use a recently demonstrated

cryogenic technique to focus the target analyte band on the

analytical column prior to chromatographic analysis.

18

This

preconcentration effect makes ITSPME suitable for sample

preparation for trace analysis.

Results presented here were logical and in agreement with

expectations. The K values determined by ITSPME are

comparable to those obtained with SPME and literature K

ow

values. It is anticipated that ITSPME will be suitable for routine

analysis. The extraction capillary column can be re-used; thus

far, there have been no carry-over problems, nor any evidence

of performance deterioration in the extracting column. Bonded

phase capillary columns are stable to organic solvent flushing.

Large particulate material may require filtration prior to

extraction, and, if necessary, a water rinse can be included

between sorption and back extraction.

Acknowledgement

The authors wish to thank SGE International, Ringwood,

Australia for providing the GC capillary columns for perform-

ing the extractions and Shimadzu Scientific Instruments,

Rydalmere, Australia for GC facilities.

References

1

Z. Zhang, M. J. Yang and J. Pawliszyn, Anal. Chem., 1994, 66,

844A.

2

D. Noble, Anal. Chem., 1993, 65, 693A.

3

C. L. Arthur and J. Pawliszyn, Anal. Chem., 1990, 62, 2145.

Table 3

Comparison of extracted amounts of phenols (10 mg L

21

each)

from different aqueous matrices, as area ratio per cent of phenol peak/

xylene internal standard

Milli-Q water

pH 2 buffer

pH 2 buffer

+ salt

a

p-Cresol

10.1 (4.0)

b

11.3 (6.2)

27.0 (3.7)

2,4-DCP

8.2 (9.6)

11.7 (3.4)

55.1 (2.0)

p-tert-butylphenol

21.3 (2.8)

25.2 (9.1)

72.3 (4.3)

2,4,6-TCP

1.9 (6.2)

5.8 (3.5)

47.1 (5.5)

m-Nitrophenol

0.7 (14.3)

1.6 (12.5)

4.5 (17.8)

a

Refer to Fig. 4 for the chromatogram of this solution.

b

%RSD (n =

3) values in parentheses.

Fig. 4

Chromatogram of phenols sorbed from solution saturated with salt

and buffered to pH 2. BP20 polyethylene glycol capillary used for sorption,

with phenols back extracted from the capillary with 190

mL methanol. o-

Xylene (10

mL of 25 mg L

21

concentration) was added to collected

methanol as internal standard.

Fig. 5

Chromatograms of the hexane strip for aqueous extractions of

toluene aqueous solution concentrations of (a) 10 mg L

21

, (b) 20 mg L

21

and (c) 40 mg L

21

. Ethylbenzene is added to each extracted solution as

internal standard at 25 mg L

21

.

654

Analyst, 1999, 124, 651–655

4

J. R Dean, W. R. Tomlinson, V. Makovskaya, R. Cumming, M.

Hetheridge and M. Comber, Anal. Chem., 1996, 68, 130.

5

S. P. Thomas, R. Sri Ranjan, G. R. B. Webster and L. P. Sarna,

Environ. Sci. Technol., 1996, 30, 1521.

6

J. Pawliszyn and R. Eisert, Anal. Chem., 1997, 69, 3140.

7

R. G. Belardi and J. Pawliszyn, Water Pollut. Res. J. Can., 1989, 24,

179.

8

C. L. Arthur, D. W. Potter, K. D. Buchholz, S. Motlagh and J.

Pawliszyn, LC-GC, 1992, 10, 656.

9

K. Grob, Split and Splitless Injection in Capillary Gas Chromato-

graphy with some remarks on PTV Injection; Huthig Verlag,

Heidelberg, Germany, 1993.

10

C. L. Arthur, L. M. Killam, K. D. Buchholz, J. Pawliszyn and J. P.

Berg, Anal. Chem., 1992, 64, 1960.

11

D. W. Potter and J. Pawliszyn, J. Chromatogr., 1992, 625, 247.

12

C. L. Arthur, L. M. Killam, S. Motlagh, D. W. Potter and J.

Pawliszyn, Environ. Sci. Technol., 1992, 26, 979.

13

C. T. Chiou, D. W. Schmedding and M. Manes, Environ. Sci.

Technol., 1982, 16, 4.

14

K. Verschuren, Handbook of Environmental Data on Organic

Chemicals, Van Nostrand Reinhold, New York, USA, 2nd edn.,

1983.

15

C. T. Chiou, Environ. Sci. Technol., 1985, 19, 57.

16

L. P. Sarna, G. R. B. Webster, M. R. Friesen-Fischer and R. Sri

Ranjan, J. Chromatogr. A, 1994, 677, 201.

17

T. Fujita, J. Iwasa and C. Hansch, J. Am. Chem. Soc., 1964, 86,

5175.

18

R. M. Kinghorn and P. J. Marriott, Anal. Chem., 1997, 69, 2582.

Paper 9/02567G

Analyst, 1999, 124, 651–655

655

Wyszukiwarka

Podobne podstrony:

Comparison of Different Fibers in the Solid Phase Microextra

Solid phase microextraction for the detection of termite cut

Solid phase microextraction for the analysis of biological s

Application of Solid Phase Microextraction Gas Chromatograp

Solid phase microextraction coupled to gas chromatography a

AIRBORNE SAMPLES SOLID PHASE extraction

bioanalitical apllications solid phase extraction

Solid Phase Microextraction Analyses of Flavor Compounds in

AIRBORNE SAMPLES SOLID PHASE extraction

Solid phase microextration in biomedical analysis

Solid phase microextraction for herbicide determination in

Kinetics of solid phase extraction and solid phase microextr

Solid phase microextraction in pesticide residue analysis

Trends in solid phase microextraction for

Gas Chromatpgraphy Overview

Polypeptide Synthesis, Solid Phase Method

kwasy gas chromatography

więcej podobnych podstron