7

9

25274 75349

0 5>

CIRCUIT

CELLAR

®

www.circuitcellar.com

T H E M A G A Z I N E F O R C O M P U T E R A P P L I C AT I O N S

$4.95 U.S. ($5.95 Canada)

#154 May 2003

ANALOG TECHNIQUES

Cable Tester

Auto G-Force Meter

Temperature Controller

DTMF Decoding

Use the Cypress PSoC

™

instead of an MCU for

more flexibility, fewer parts and lower cost.

The versatile PSoC

™

Programmable System-on-Chip

™

is

the world’s first mixed signal array that lets you custom

configure the exact functions you need. And it has an

on-chip controller to manage your application and run

the configuration process.

Graphically select, place, and interconnect

the peripherals you want and adapt the

architecture with PSoC Designer

™

software

Dynamically reconfigure a single PSoC

chip multiple times—changing functionality

on the fly in any application

Reduce BOM cost by reducing the number

of external components

MCU

later.

Cypress,

PSoC,

Programmable-System-on-Chip

and

PSoC

Designer

are

trademarks

of

Cypress

Semiconductor

Corporation.

©2002

Cypress

Semiconductor

Corporation.

All

other

Trademarks

are

the

property

of

their

respective

owners.

There are many more blocks to work with—

and thousands of configurations to choose from.

PSoC Designer

™

software is free for download, with

full-featured emulation hardware starting at $248.

Option #8926

8-bit PWM

Inverting Amplifier

IrDA

Transmitter

11-bit

Delta Sigma A/D

Band Pass Filter

Analog

Comparator

8-bit Counter

8-bit DAC

24-bit Timer

Low Pass Filter

Option #1530

Analog

Comparator

Instrumentation

Amplifier

12-bit

Incremental A/D

Notch Filter

16-bit CRC

Option #625

Analog

Comparator

16-bit PWM

Programmable

Gain Amplifier

Instrumentation

Amplifier

IrDA

Transmitter

11-bit

Delta Sigma A/D

8-bit DAC

12-bit

Incremental A/D

Band Pass Filter

8-bit Counter

Option #4237

CPU

Analog

Comparator

Your Customized Mixed Signal

platform in 60 minutes or less

Build your custom PSoC

™

with programmable analog

and digital functions from our extensive library.

To learn more about our innovative PSoC solutions

and to enter a drawing to win a PSoC Development

Digital Oscilloscopes

•

2 Channel Digital Oscilloscope

•

100 MSa/s

max single shot rate

•

32K samples per channel

•

Advanced Triggering

•

Only 9 oz and 6.3” x 3.75” x 1.25”

•

Small, Lightweight, and Portable

•

Parallel Port

interface to PC

•

Advanced Math options

•

FFT Spectrum Analyzer options

DSO-2102S

$525

DSO-2102M

$650

Each includes

Oscilloscope

,

Probes, Interface Cable, Power

Adapter, and software for

Win95/98, WinNT, Win2000

and DOS.

•

40 to 160 channels

•

up to 500 MSa/s

•

Variable Threshold

•

8 External Clocks

•

16 Level Triggering

•

up to 512K samples/ch

•

Optional Parallel Interface

•

Optional 100 MSa/s Pattern Generator

LA4240-32K (200MHz, 40CH)

$1350

LA4280-32K (200MHz, 80CH)

$2000

LA4540-128K (500MHz, 40CH)

$1900

LA4580-128K (500MHz, 80CH)

$2800

LA45160-128K (500MHz, 160CH)

$7000

Logic Analyzers

• 24 Channel Logic Analyzer

• 100MSa/S max sample rate

• Variable Threshold Voltage

• Large 128k Buffer

• Small, Lightweight and Portable

• Only 4 oz and 4.75” x 2.75” x 1”

• Parallel Port Interface to PC

• Trigger Out

• Windows 95/98 Software

LA2124-128K (100MSa/s, 24CH)

Clips, Wires, Interface Cable, AC

Adapter and Software

$800

All prices include Pods and Software

ne of our goals at

Circuit Cellar is to bring

you a variety of projects—from the serious and

complex to the lighthearted and fun. Each teaches

valuable techniques that you can use in your own

real-world applications. You can replicate the projects you read about, or

you can apply the techniques in a new way to suit your own needs. We

also look for fascinating emerging technologies that we think can bene-

fit you. This month, we’ve included a little bit of everything.

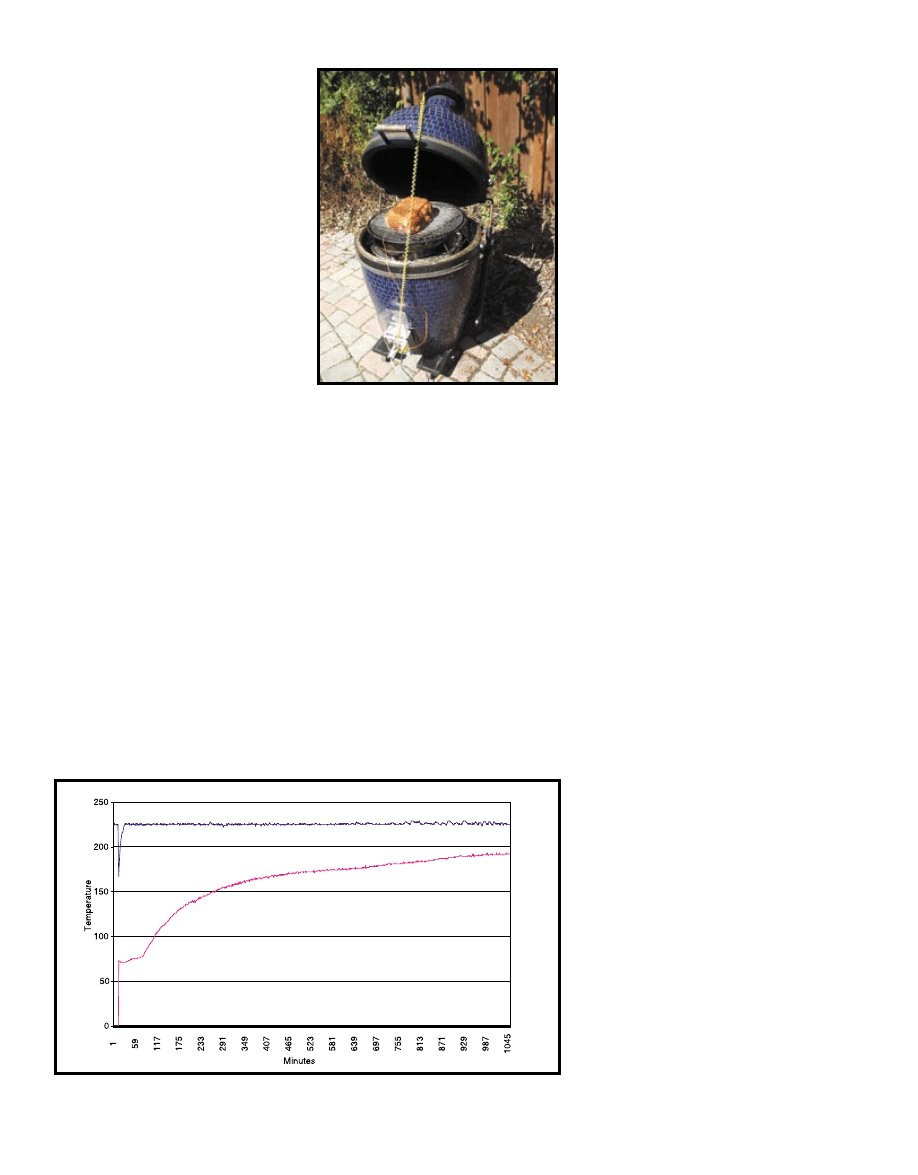

We start with a bit of levity. It’s almost summer, and that means bar-

becue. For an ordinary person, that might mean rolling out the gas grill

from the garage to grill hot dogs and hamburgers. But, for an engineer,

it means a project. John Moyer used his engineering prowess to design

a sophisticated grill that’s sure to make him the envy of every other guy

in the neighborhood (p. 28). Rather than use the average Weber or

George Foreman grill, he opted for a unique ceramic cooker. As any

die-hard barbecue fan knows, slow cooking meat to get that perfect

barbecue flavor takes days. Most people just don’t have that kind of

time to tend the fire. So, John designed an automatic temperature con-

troller to tend the fire for him. With a microprocessor, thermocouple,

and some other parts, he’s now able to prepare beef brisket the way it

should be done, and not get fired for leaving work to check the meat.

Why be content with a purchase when you know you can make it

better? And, how about testing that product to see what you’ve actually

bought? When you look at factory specs, you might wonder how accu-

rate they are. Did the manufacturer fudge the numbers at all? Are they

attainable only under a precise set of optimum circumstances? With an

accelerometer from Analog Devices and a PIC microcontroller, Ross

Tsukashima set out to test the limits of his new car (p. 24). As is often the

case, the testing equipment available off the shelf wasn’t an option, so he

built his own G-force meter specially designed to meet his goals. You’ll

want to read on to find out if his New Beetle lives up to its reputation.

We think you’ll be equally interested in reading about Zoltan

Molnar’s Bluetooth application (p. 44). With the trend toward wireless

firmly in place, Bluetooth is gaining popularity. Zoltan focused on a spe-

cific mode of connectivity—using only HCI interfaces. He created

Blueport, an interface that enables you to connect simple embedded

systems to the complex Bluetooth protocol stack. Despite having limited

resources and no external RAM, you can achieve this type of wireless

connectivity with a creative solution. That’s great news for engineers

working primarily with 8-bit microcontrollers.

4

Issue 154 May 2003

www.circuitcellar.com

CIRCUIT CELLAR

®

EDITORIAL DIRECTOR/FOUNDER

Steve Ciarcia

MANAGING EDITOR

Jennifer Huber

TECHNICAL EDITOR

C.J. Abate

WEST COAST EDITOR

Tom Cantrell

CONTRIBUTING EDITORS

Ingo Cyliax

Fred Eady

George Martin

George Novacek

Jeff Bachiochi

NEW PRODUCTS EDITOR

John Gorsky

PROJECT EDITORS

Steve Bedford

Ken Davidson

David Tweed

ADVERTISING

PUBLISHER

Dan Rodrigues

E-mail: dan@circuitcellar.com

ASSOCIATE PUBLISHER / DIR. OF SALES

Sean Donnelly

Fax: (860) 871-0411

(860) 872-3064

E-mail: sean@circuitcellar.com

Cell phone: (860) 930-4326

ADVERTISING COORDINATOR

Valerie Luster

Fax: (860) 871-0411

(860) 875-2199

E-mail: val.luster@circuitcellar.com

ADVERTISING ASSISTANT

Deborah Lavoie

Fax: (860) 871-0411

(860) 875-2199

E-mail: debbie.lavoie@circuitcellar.com

CONTACTING CIRCUIT CELLAR

SUBSCRIPTIONS:

INFORMATION: www.circuitcellar.com or subscribe@circuitcellar.com

To Subscribe: (800) 269-6301, www.circuitcellar.com/subscribe.htm, or

subscribe@circuitcellar.com

PROBLEMS: subscribe@circuitcellar.com

GENERAL INFORMATION:

TELEPHONE: (860) 875-2199 Fax: (860) 871-0411

INTERNET: info@circuitcellar.com, editor@circuitcellar.com, or www.circuitcellar.com

EDITORIAL OFFICES: Editor, Circuit Cellar, 4 Park St., Vernon, CT 06066

NEW PRODUCTS: New Products, Circuit Cellar, 4 Park St., Vernon, CT 06066

newproducts@circuitcellar.com

AUTHOR CONTACT:

E-MAIL: Author addresses (when available) are included at the end of each article.

CIRCUIT CELLAR®, THE MAGAZINE FOR COMPUTER APPLICATIONS (ISSN 1528-0608) and Circuit Cellar Online are pub-

lished monthly by Circuit Cellar Incorporated, 4 Park Street, Suite 20, Vernon, CT 06066 (860) 875-2751. Periodical rates paid at

Vernon, CT and additional offices.

One-year (12 issues) subscription rate USA and possessions $21.95, Canada/Mexico

$31.95, all other countries $49.95. Two-year (24 issues) subscription rate USA and possessions $39.95, Canada/Mexico

$55, all other countries $85.

All subscription orders payable in U.S. funds only via VISA, MasterCard, international postal money

order, or check drawn on U.S. bank.

Direct subscription orders and subscription-related questions to Circuit Cellar Subscriptions, P.O. Box 5650, Hanover, NH

03755-5650 or call (800) 269-6301.

Postmaster:

Send address changes to Circuit Cellar, Circulation Dept., P.O. Box 5650, Hanover, NH 03755-5650.

For information on authorized reprints of articles,

contact Jeannette Ciarcia (860) 875-2199 or e-mail jciarcia@circuitcellar.com.

Circuit Cellar® makes no warranties and assumes no responsibility or liability of any kind for errors in these programs or schematics or for the

consequences of any such errors. Furthermore, because of possible variation in the quality and condition of materials and workmanship of read-

er-assembled projects, Circuit Cellar® disclaims any responsibility for the safe and proper function of reader-assembled projects based upon or

from plans, descriptions, or information published by Circuit Cellar®.

The information provided by Circuit Cellar® is for educational purposes. Circuit Cellar® makes no claims or warrants that readers have a right to

build things based upon these ideas under patent or other relevant intellectual property law in their jurisdiction, or that readers have a right to

construct or operate any of the devices described herein under the relevant patent or other intellectual property law of the reader’s jurisdiction.

The reader assumes any risk of infringement liability for constructing or operating such devices.

Entire contents copyright © 2001 by Circuit Cellar Incorporated. All rights reserved. Circuit Cellar and Circuit Cellar INK are registered trademarks

of Circuit Cellar Inc. Reproduction of this publication in whole or in part without written consent from Circuit Cellar Inc. is prohibited.

CHIEF FINANCIAL OFFICER

Jeannette Ciarcia

CUSTOMER SERVICE

Elaine Johnston

ACCOUNTANT

Jeff Yanco

ART DIRECTOR

KC Prescott

GRAPHIC DESIGNER

Mary Turek

STAFF ENGINEER

John Gorsky

QUIZ COORDINATOR

David Tweed

TASK

MANAGER

Cover photograph Chris Rakoczy—Rakoczy Photography

PRINTED IN THE UNITED STATES

o

Variety is the Spice of Life

jennifer.huber@circuitcellar.com

Con

fide

ntia

l

CANbus

Starter Packs

available for almost

any board format: PCI, ISA, PCMCIA, PC104,

VME, cPCI, etc. with software for most

OS’s inc. all Win, Linux, QNIX, etc.

CAN/Ethernet bridges, industrial

computing and automation solutions

Industry leaders worldwide trust and

specify Janz AG’s ISO9000 systems.

www.saelig.com • saelig@aol.com

check out what’s new at www.saelig.com!

by

Janz

for

all

computers

ALSO:

SMD PROTOTYPING ADAPTER PCBs

S C A L A B L E L E D D I S P L A Y P A N E L S

TEMPERATURE-HUMIDITY MONITORS

T H E R M O C O U P L E P . C . A D A P T E R S

ENVIRONMENTAL MON. SYSTEMS

WILKE BASIC TIGER CONTROLLERS

Saelig Co. brings to USA unique, easy-to-use control and

instrumentation products from overseas. Customers inc:

Intel, Compaq, Philips, NEC, Kodak, Nokia, US Military,

Microsoft, Dell, Xerox, Universities, T.I., Harris, Sony,

J&J, Thomson, Sandisk, General Dynamics, H-P, etc.

DrDAQ

Educational datalogger

ADC-212/100

12-bit 100MHz PC scope

Euroquartz

crystals & oscillators

TRAKIT

manufacturing software

K3 / K2

self-powered isol/non-isol RS232-485

USB-485i

isolated USB<>RS485

PCI93LV/C

PCIbus I2C adapter

ANT8

USB logic analyzer

BIT2000

simple factory control

US232

USB-serial port adapter

TDS2020F

Forth-based datalogger/controller

USB TRACKER 110

USB bus analyzer

FT232BM / FT245BM

single ic USB solution - no programming!

JANZ - CANbus

CAN interface cards - all formats

DS2200C

USB PC scope

Turns your PC into a high-

speed scope. Sampling

rates up to 100MS/s for sin-

gle shot signals (and up to

5GS/s for repetitive signals)

with 12-bit resolution. With

FREE software, your PC

becomes a powerful 2-chan-

nel scope and spectrum

analyzer. - $1090

DrDAQ plugs into a PC

for datalogging at

school, college, indus-

try. Built-in sensors for

light, sound, temp. or

add pH sensor and run

one of the many sug-

gested science experi-

ments!

- only $99!

US232 is a 6ft USB-RS232

self-powered converter

cable which instantly and

reliably solves the problem

of laptops with no serial

ports, or legacy RS232

devices that need to be

updated to USB IN ONLY 5

MINUTES!

Buy in bulk to

update your products - $39!

"After looking at a number of packages

both large and small we have found

TRAKIT

TM

to be the most cost effective

solution for inventory management in the

manufacturing environment available for

the small to medium size company. It

contains most of the commonly used

features of the larger programs as well as

maintaining the user ease of the smaller

programs. Some of the more advanced

features of Trakit are more successfully

implemented than packages costing

many times more. Better and easier to

use than P&V" (S.P. Ltd)

TRAKIT

manufacturing

- Inventory Management

- Bills of Materials

- Build Schedule

- Sales Orders

- Instant Builds

- Purchase Ordering

- Request for Quote

- Reminders

- Reports

K2

9p-9p self-powered RS-422/485 converter

K3

9p-9p isolated RS-422/485 converter

K3-232

9p-9p isolated RS232 converter

K232-ISOL

25p -25p RS232

K422-ISOL

25p -25p RS422

K485-ISOL

25p -25p RS485

KD485-STD

DINrail-mount

RS-232/485/20mA isolators

KD485-PROG

DINrail-mount

RS-232/485/20mA isolators

C-programmable for protocol/MODbus

conversion. Program to convert custom needs.

USB-485i offers self-

powered USB to RS485

conversion with optical

isolation to 1kV. Baud

rates 184bps - 3Mbps.

Link-selectable half-duplex

mode enables the 485

transmit-buffer when data

ready. Three-point isolated

serial communciations.

200 kS/s 12-bit dual-channel USB scope adapter for

PC. Unique software looks like a “Digital Scope”

right on your PC screen!

Built-in squarewave

generator. Weighs <8oz.

Only $189!! For details:

www.usb-instruments.com

USB protocol analyzer displays USB packets sent,

decodes descriptors, detects errors in peripherals or

drivers and measures their performance.

Ideal for anyone developing

USB peripherals,

embedded soft-

ware or drivers.

Software is easy

to use - learn all

about USB. $799!

Make PCs talk I2C easily with this industry-standard

card, available in 2 - 6V bus version for low-volt I2C

systems. Optional WINI2C/PCI software gives you a

windows-interface to develop

and debug I2C bus systems.

Monitor software lets you

transparently monitor I2C bus

activity . Other bus-versions

available too! Please call!

Build a custom PCMCIA or CF

card datalogger or controller

- quickly!

Wizard high-level

software completes your

project in hours not weeks.

Store GPS or CANbus data.

TDS2020F is the low-power

controller of choice for sure

LONGEVITY - this one won’t

disappear like so many other

obsolete boards. Ask us why!

Join all the industry leaders

who are using this easy-use

USB ic. Single chip USB-

232 solution comes with all

Windows/Mac/Linux drivers.

UART ASIC-based so no

software development is

needed! No knowledge of

USB needed either! Byte-

wide version FT245BM too!

Euroquartz is one Europe’s largest manufacturers and

supplier of quartz crystals, oscillators, filters and

frequency-related products. They design & manufacture

a comprehensive range of frequency-related components

including custom-made filters, high

reliability oscillators for defence

applications and radiation tolerant

oscillators for high-altitude apps.

EQ-HM oscillators reduce EMI using

Spread Spectrum Technology

to slowly shift center frequency.

Easily construct small control systems communicating

through Intranet/Internet. BIT2000 is the ideal solution

for process control, building

monitoring, data logging,

alarm systems and other

industrial uses. BIT2000

can communicate with

many types of equipment

through the fast multidrop

RS485 based bus and a

standard RS232 serial port.

At last!

This tiny pocketable USB-based and USB-

powered device is the answer to your need for an eco-

nomical logic analyzer that you can take anywhere.

About the size of a small matchbox, ANT8 can sample

eight channels at up to 500 million samples-per-sec.

Ant8 offers simple or complex

triggering, upgradeable soft-

ware. View the captured eight

digital channel traces on your

PC. Save or print screens for

reference or notes! $199!

6

Issue 154 May 2003

CIRCUIT CELLAR

®

www.circuitcellar.com

DTMF-Controlled Remote Switching System

Bluetooth Interface for Embedded Systems

Updating the Home Control System

Part 3: The Complete Upgrade Solution

I

New ICE Age

MPLAB ICE 2000 Replaces PICMASTER

I

Making Sense of the Gerber File Format

I

COLUMNS

ISSUE

Advertiser’s Index

June Preview

Priority Interrupt

Steve Ciarcia

4

8

11

94

96

154

12

24

36

28

FEA

TURES

Contest-Related Article

62

80

44

74

54

70

Check out AVR today at www.atmel.com/ad/fastavr

Introducing the Atmel AVR

®

. An 8-bit MCU that

can help you beat the pants off your competition.

AVR is a RISC CPU running single cycle instructions.

With its rich, CISC-like instruction set and 32 working registers,

it has very high code density and searingly fast execution–up to

16 MIPS. That’s 12 times faster than conventional 8-bit micros.

We like to think of it as 16-bit performance at an 8-bit price.

With up to 128 Kbytes of programmable Flash and EEPROM,

AVR is not only up to 12 times faster than the MCU you’re using

now. It’s probably 12 times smarter, too.

And when you consider that it can help slash months off your

development schedule and save thousands of dollars in project

cost, it could make you look pretty smart, too.

AVR comes in a wide range of package and performance

options covering a huge number of consumer and industrial

applications. And it’s supported by some of the best development

tools in the business.

So get your project started right. Check out AVR today at

www.atmel.com/ad/fastavr. Then register to qualify for your free

evaluation kit and bumper sticker. And get ready to take on the world.

Our AVR microcontroller is

probably 12 times faster than

the one you’re using now.

(It’s also smarter.)

AVR 8-bit RISC Microcontrollers

© 2002 Atmel Corporation. Atmel and the Atmel logo are registered trademarks of Atmel Corporation.

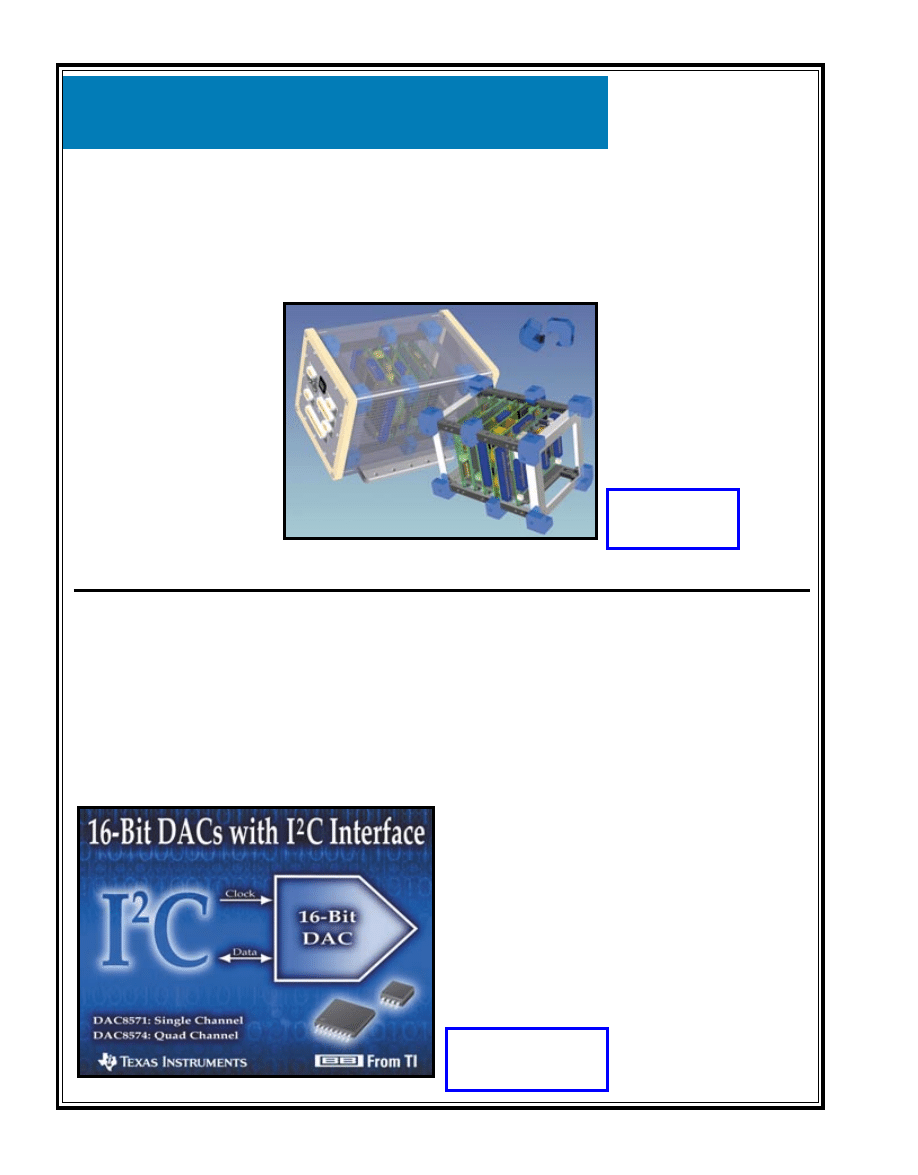

SHOCK AND VIBRATION ISOLATORS

The PC/104 Shock Rocks line of shock and vibration

mitigation products is designed to enhance the durabil-

ity of embedded PC/104 computer systems that under-

go mechanical stress.

Made of 59 durometer Silastic(r) silicone rubber

material, these compact

shock isolators successfully

reduce G-force frequencies on

three axes by up to a factor of

10, making them well suited

for a wide variety of mobile,

airborne, shipboard, space,

and other demanding applica-

tions common to the aero-

space, defense, medical, and

transportation fields.

Designed to attach to the

outside perimeter of a 4

″

× 4

″

PC/104 railed card cage,

Shock Rocks isolate all

points of contact between a

NEWS

8

Issue 154 May 2003

CIRCUIT CELLAR

®

www.circuitcellar.com

NEW PRODUCT

Edited by John Gorsky

removable aluminum card cage and its surrounding

enclosure. Mounting PC/104 modules within a card cage

in this way eliminates the need for traditional PCB

standoffs/spacers; it provides a much simpler board

removal method over PC/104 containers using compres-

sion-mounted rubber rails.

Depending on the size of

the card cage, between eight

and 12 Shock Rocks are typi-

cally attached. Packaging

PC/104 systems in such a

configuration can provide a

NEMA 4× environmental

protection together with sig-

nificant shock/vibration tol-

erance.

The Shock Rocks cost $10.

Parvus Corp.

(801) 483-1533

www.parvus.com

out additional glue logic, enabling the simultaneous

update of up to 64 channels.

The DAC8571 and DAC8574 also support an I

2

C

high-speed mode, allowing rapid 188-ksps DAC

update rates at 3.4-MHz clock speed. The DAC8571

consumes only 170 µA of the supply current at 5 V,

and the DAC8574 consumes 950 µA of current at

5 V. A per-channel, power-down mode reduces the

maximum supply current to 1 µW. A power-on reset

circuit ensures that the DACs power up at 0 V and

remain there until a valid write occurs. Both convert-

ers operate on a single 2.7- to 5.5-V supply.

Both devices feature rail-to-rail outputs, 10-µs set-

tling, true 16-bit monotonic performance, a 94-dB sig-

nal-to-noise ratio, and less than 1-mV offset drift over

the –40° to 105°C temperature range. The DAC8571

offers less than 1-mV offset error at 25°C. An external

reference voltage is required to set the output voltage

range of both DACs.

The DAC8571 comes in an MSOP-8 package and

costs $2.83 in 1000-piece quantities. The DAC8574

comes in a TSSOP-16 package and costs $9.75 in 1000-

piece quantities.

Texas Instruments, Inc.

(800) 336-5236

www.ti.com

LOW-POWER, 16-BIT DACs WITH I

2

C

The DAC8571 and DAC8574 are the industry’s first

low-power, 16-bit DACs with an I

2

C interface. These

devices are ideal for portable systems, including industri-

al process control, instrumentation, and data acquisition.

The DAC8571 (single channel) and DAC8574 (quad

channel) use an I

2

C-compatible two-wire serial interface

to support high-precision, high-channel-count data

acquisition systems. With their broadcast feature,

multiple devices can work on the same I

2

C bus with-

www.circuitcellar.com

CIRCUIT CELLAR

®

Issue 154 May 2003

9

NEWS

NEW PRODUCT

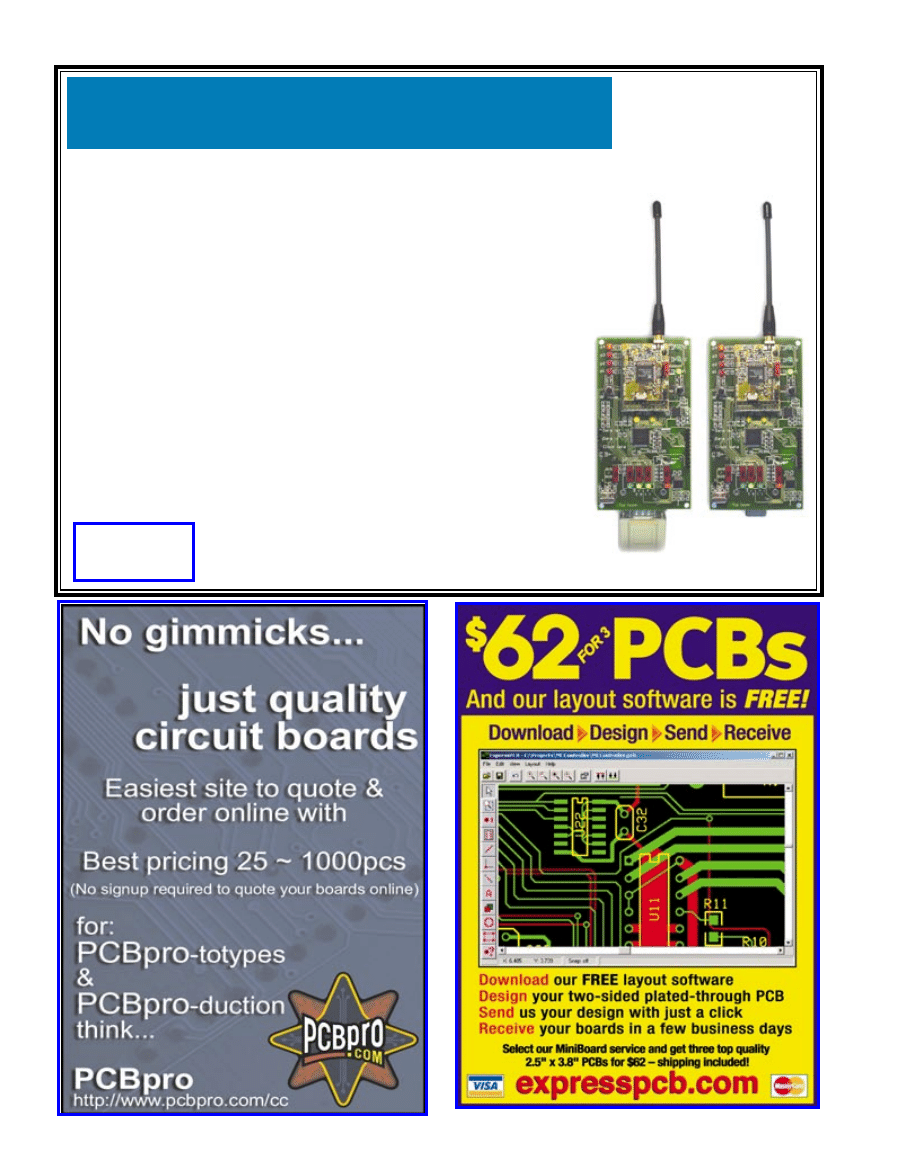

LOW-COST TRANSCEIVER DEVELOPMENT PLATFORM

The XE1202SK starter kit is a new low-cost development platform that

enables the demonstration of two-way communication between two radio

boards. The kit can be used to facilitate “out of the box” range-testing

demonstrations. A PC graphical user interface enables a simple but practical

development environment for evaluation of the RF transceiver. The

XE1202SK performs basic functions with a ping-pong demo as the default

configuration, plus features such as XE1202 register configuration and trans-

mission/reception of a serial data stream between two units.

The kit includes two main boards, RF modules, instructions, and software.

The tool kit enables RF evaluation of the XE1202SK basic functions of config-

uration in Transmitter, Receiver, or Sleep mode, frequency deviation selec-

tion, filter bandwidth, and output power management.

The XE1202SK enables the demonstration of two-way communication

between two radio boards and practical demonstration with a ping-pong

demo. You can also use it to perform range and site survey testing, and evalu-

ate the RF transceiver through a user-friendly PC GUI interface. The demo

can be customized with user settings. There are three frequencies and four

output powers to choose from.

The starter kit costs $250.

10

Issue 154 May 2003

CIRCUIT CELLAR

®

www.circuitcellar.com

NEWS

NEW PRODUCT

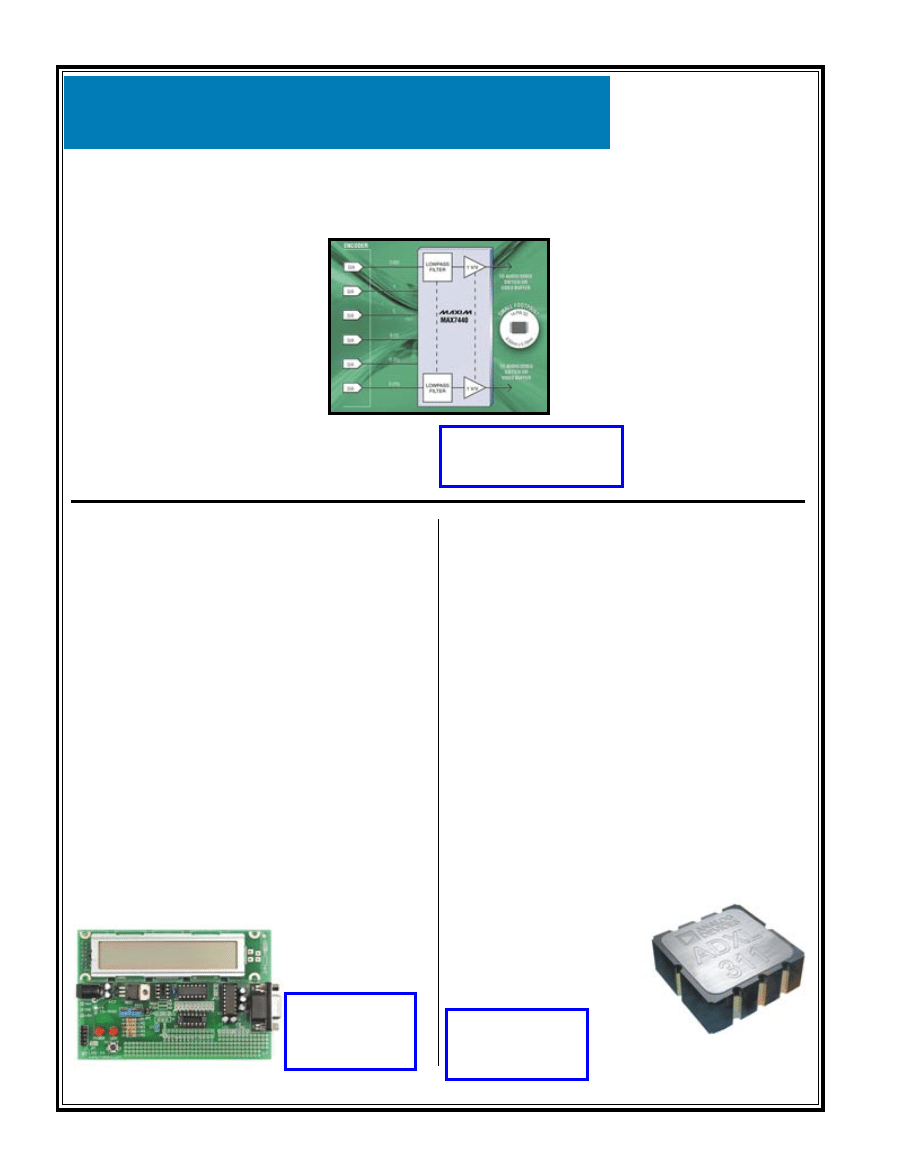

SIX-CHANNEL VIDEO RECONSTRUCTION FILTER

The MAX7440, MAX7441, and MAX7442 are the

industry’s first six-channel video reconstruction filters.

These devices are ideal for antialias-

ing and digital-to-analog reconstruc-

tion video applications such as set-

top boxes, DVD players, hard-disk

recorders, and personal video

recorders. Each channel of the

device combines a continuous-time

low-pass filter with high-frequency

boost options and a unity-gain

amplifier. High performance and

integration make these devices ideal

for European STBs using SCART

connectors.

The MAX7440, MAX7441, and MAX7442 support

composite video (CVBS), S-Video (Y/C), and component

(RGB or Y Pr Pb) video signals for both NTSC and PAL.

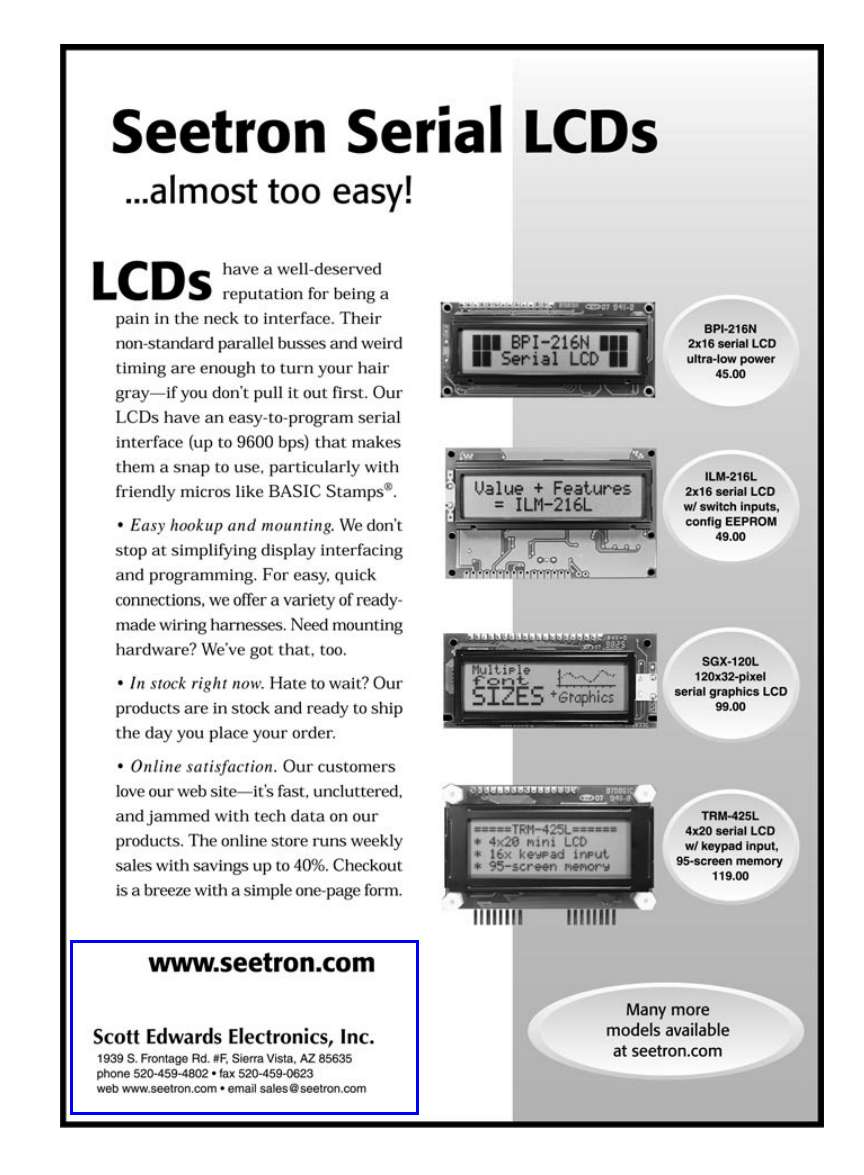

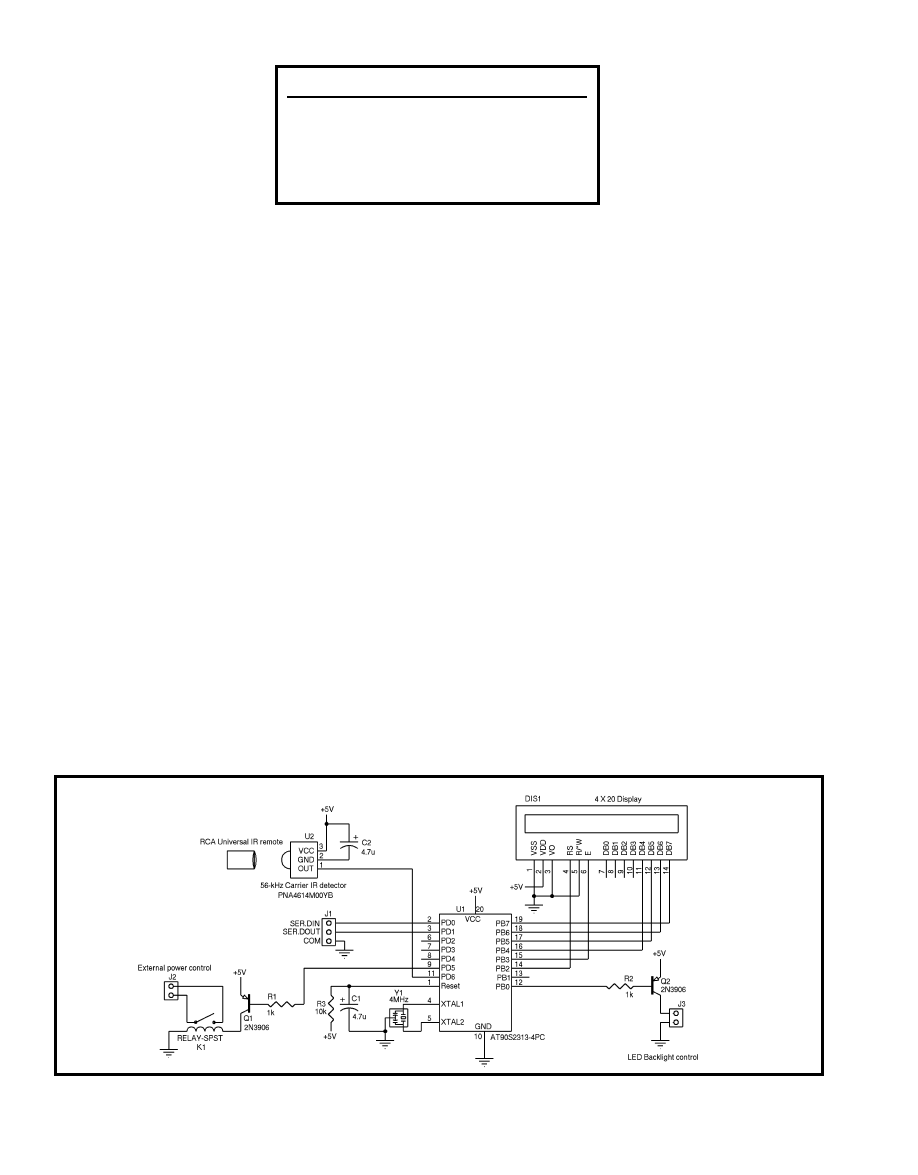

PIC EXPERIMENTER BOARD

The LAB-X4 experimenter board is designed to

accommodate both the 8-pin PIC12F675 and its 14-pin

counterpart, the PIC16F676. The experimenter board

provides all the circuitry required by the MCU to oper-

ate: a 5-V power supply and reset circuit, an RS-232 seri-

al port, a 2 × 20 LCD module with a serial controller,

and basic analog and digital I/O.

With the assembled LAB-X4, you can develop a vari-

ety of applications for the PIC12F675 and PIC16F676.

For example, the LCD can display the time of day. You

can use the LAB-X4 to make a robot brain that controls

RC servos. The RS-232 serial port can be used for two-

way communication with your computer.

The LAB-X4 can run programs written in assembler,

C, PicBasic, or PicBasic Pro. The included samples are

for PicBasic and PicBasic Pro. There are also precompiled

hex files that you can use if you don’t have a compiler.

The experimenter board can be connected directly to

a device programmer for in-circuit serial programming.

It can be erased and reprogrammed in seconds, allowing

you to quickly test changes to your program code.

The LAB-X4 is available preassembled for $125 or as

a bare PCB for just $25. Both versions come with full

documentation,

including schemat-

ics, a parts list, and

sample programs.

MicroEngineering

Labs, Inc.

(719) 520-5323

www.melabs.com

FULLY INTEGRATED MEMS ACCELEROMETER

The ADXL311 is a fully integrated, low-power, low-g

MEMS accelerometer.

The ADXL311 uses the reliable iMEMS surface

micromachining technology with proven circuit, sensor,

and process reliability performance of better than 1 FIT

(failure in time). The device, along with future low-cost

iMEMS accelerometers, will play a significant role in

enabling tilt- and motion-sensing features in many cost-

sensitive applications.

The ADXL311 is a dual-axis,

±

2-g (at full-scale)

accelerometer with analog outputs that can measure

both dynamic acceleration (vibration) and static acceler-

ation (gravity). The accelerometer integrates moving

microscopic silicon parts and sophisticated signal condi-

tioning to produce a complete two-axis accelerometer

on a single monolithic IC. It features low-power require-

ments—200 µA per axis at 3-V operation. The typical

noise floor is 300 µg per root hertz at 3-V operation and

allows signals below 5 mg to be resolved for bandwidths

below 60 Hz. The ADXL311 is packaged in a 5 mm × 5

mm × 2 mm eight-lead her-

metic LCC package and pro-

vides an accurate low-power

method of measuring tilt,

shock, and vibration.

The ADXL311 is priced at

$2.50 in quantities greater

than 10,000 units.

Analog Devices, Inc.

(781) 937-1428

www.analog.com

The filter achieves 40 dB of stopband rejection at 27 MHz

with a maximum flat passband of only

±

0.5-dB ripple.

High-frequency boost circuitry pro-

vides picture sharpness adjustment

without degradation in the stopband

attenuation.

These devices save board space

and insertion costs by replacing up

to 30 discrete components. The

MAX7440, MAX7441, and MAX7442

are packaged in a 14-pin SO in the

–40 to 85° C extended temperature

range. The ICs start at $1.21 in

1000-piece quantities.

www.circuitcellar.com

CIRCUIT CELLAR

®

Issue 154 May 2003

11

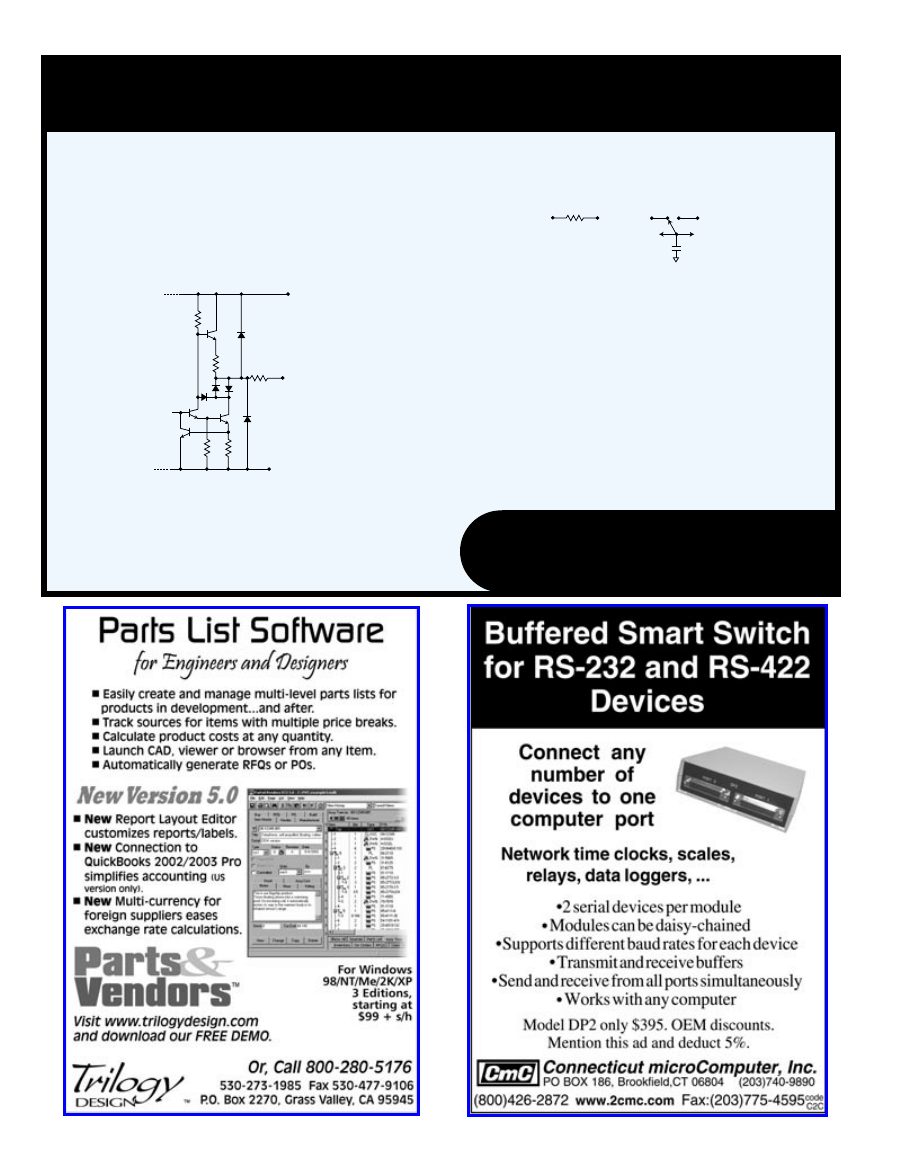

Problem 3

—

Are the two circuits below equivalent?

Explain.

Contributed by Dave Tweed

Problem 4

—

Some filters have flat passbands and roll

off smoothly in their transition regions. Other filters accept

a small amount of ripple in their passbands in order to

achieve steeper transitions. What is the implication in the

time domain of these ripples?

Contributed by Dave Tweed

What’s your EQ?

—

The answers are posted at

www.circuitcellar.com/eq.htm

You may contact the quizmasters at eq@circuitcellar.com

CIRCUIT CELLAR

—

What is the func-

Test Y

Your E

EQ

Problem 1

—

The output stage of a generic ’1488 RS-

232 driver is shown below. The input stage has an out-

put impedance of roughly 10 K

Ω

and functions so that

Q1 is basically either cut off or saturated. One of the

functions of an RS-232 driver is to limit the drive current

to approximately 10 mA. Does this circuit accomplish

that? If so, show how it does it for both output states.

Contributed by Dave Tweed

Problem 2

—

What is the function of D3 in the circuit

in question 1?

Contributed by Dave Tweed

Edited by Dave Tweed

Q2

D4

70

6200

300

Output

+V

D5

D1

Q1

Q3

D3

D2

70

Q4

3700

From input

stage

V–

V1

R

C

F

V2

a)

b)

12

Issue 154 May 2003

CIRCUIT CELLAR

®

www.circuitcellar.com

remember the

first time someone

asked me to design a

cable tester. I was a

bright-eyed co-op student on a sum-

mer work term. My boss asked me to

design a cable tester to find the faults

in the printer cables we were manu-

facturing. To test the cables, we’d nor-

mally plug one end into the printer,

the other end into a computer, and

then print. Of course, if the cables

were miswired, tracing the problem

required a manual pin-to-pin investi-

gation with an ohmmeter. Verifying

25 to 36 connections by hand turned

out to be a tad time consuming, to say

the least. To do the job, I was given an

Apple II computer (this was some

time ago), a Basic compiler, and a

handful of decoders and multiplexers.

After thinking about the problem, I

got busy and came up with a design

that accurately pinpointed the cable

wiring problems.

The reason I mention that incident

is because today, almost 25 years later,

many of the same problems still exist.

There aren’t any general-purpose, inex-

pensive methods for testing cables.

Technology has made some advances,

so we now have more computing

power than the Apple II available in

an 18-pin DIP package. Compilers are

also much better. After seeing my

company’s production personnel strug-

gle to test a multitude of cables, I

experienced déjà vu. What they really

needed was a modern version of the

tester I had designed in my university

days. Of course, this updated design

would be based on a PIC processor and

use a modern freeware language called

JAL (see Photo 1). [1] At the time, I

wanted to minimize development

costs, so buying a PIC C compiler was

out of the question. Take a look at the

sidebar for a brief description of JAL.

DESIGN ON A SHOESTRING

To minimize hardware complexity, I

initially looked at the PICs with the

highest number of input/output pins.

Unfortunately, our largest cable had

31 pins, requiring a PIC with at least

64 pins (including power and ground).

I could have used a PIC17C766 with

84 pins and 66 I/O ports, but it’s quite

pricey—almost five times the cost of

the part I chose. Then there was the

problem of exposing the PIC’s pins to

static discharges. In addition, the

cables might have been wired so badly

that outputs were driving other out-

puts. Consequently, all of the I/O con-

nections were first buffered, so that in

the case of any damage, the produc-

General-Purpose Cable

Tester

l

Michael built his first

cable tester with an

Apple II, Basic compil-

er, and several

decoders and multi-

plexers. Twenty-five

years later, it’s still

hard to find cost-effec-

tive, general-purpose

cable testers. So he’s

at it again, but this

time he’s armed with

a PIC micro and JAL.

Michael Griebling

FEATURE

ARTICLE

Stand-Alone or with a GUI

Command

PIC Reply

Function

Pxx yy<CR>

OK<CR>

Program EEPROM location xx (hex) with data yy (decimal) and reply

NPR<CR>

Programming EEPROM failed

NAK<CR>

Illegal EEPROM address, invalid pin number, or other errors

Tyy<CR>

Vzzzzzzzz<CR> Test pin yy (decimal 1-32) and return result vector zzzz (hex)

NAK<CR>

Communication error or illegal pin number

Table 1—

Take a look at the host commands and the PIC reply. Sending a host command

P3F 20

programs EEP-

ROM location 0x3F with 0x20. The host command

T10

causes pin 10 to be pulsed low and the resultant vector

reply from the PIC should be VFFFFFDFF.

www.circuitcellar.com

CIRCUIT CELLAR

®

Issue 154 May 2003

13

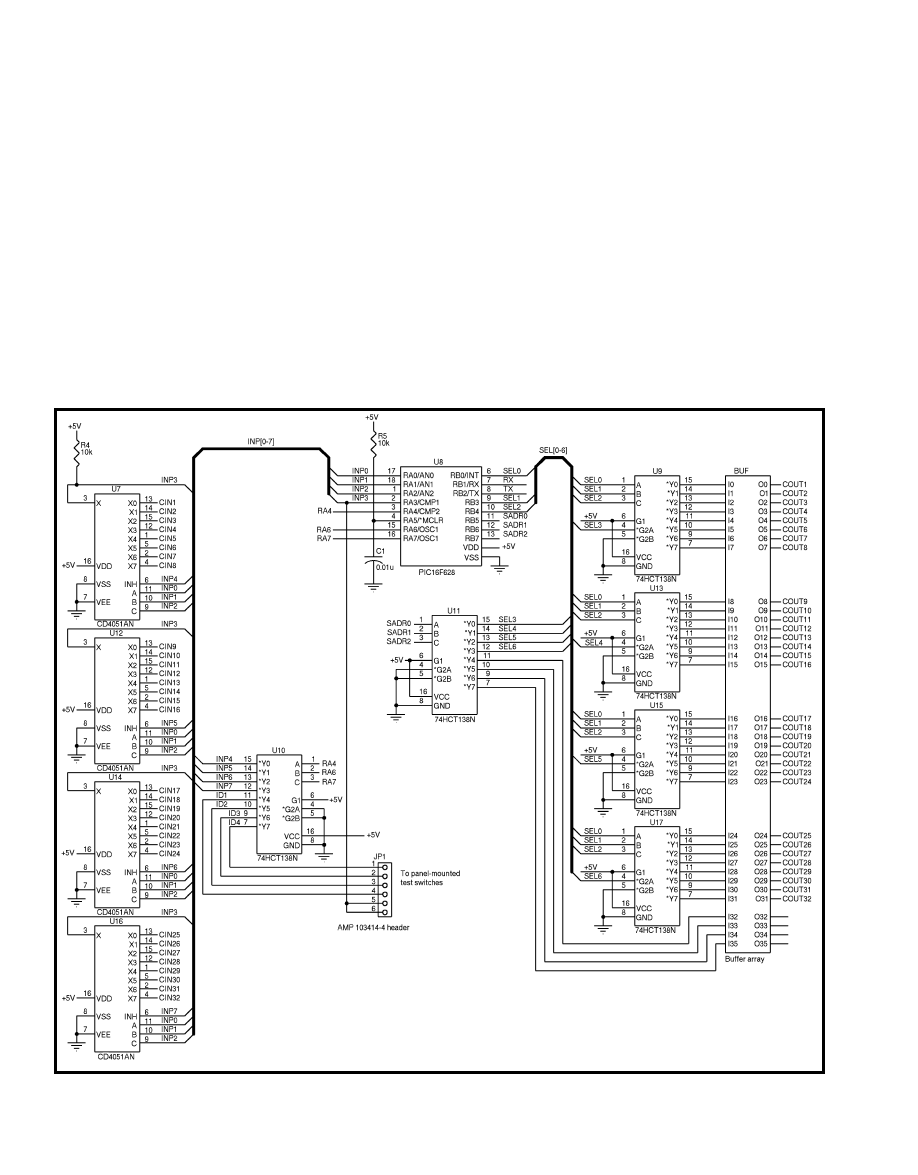

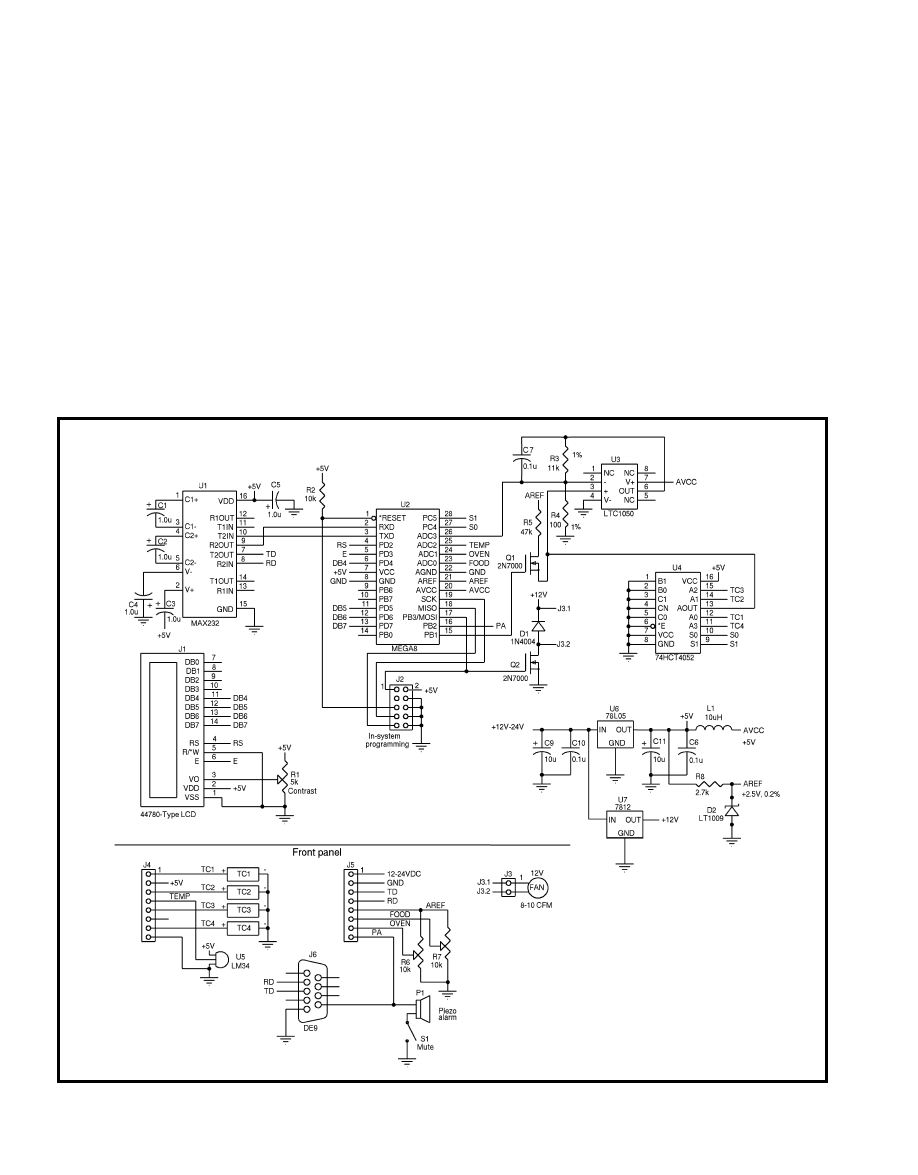

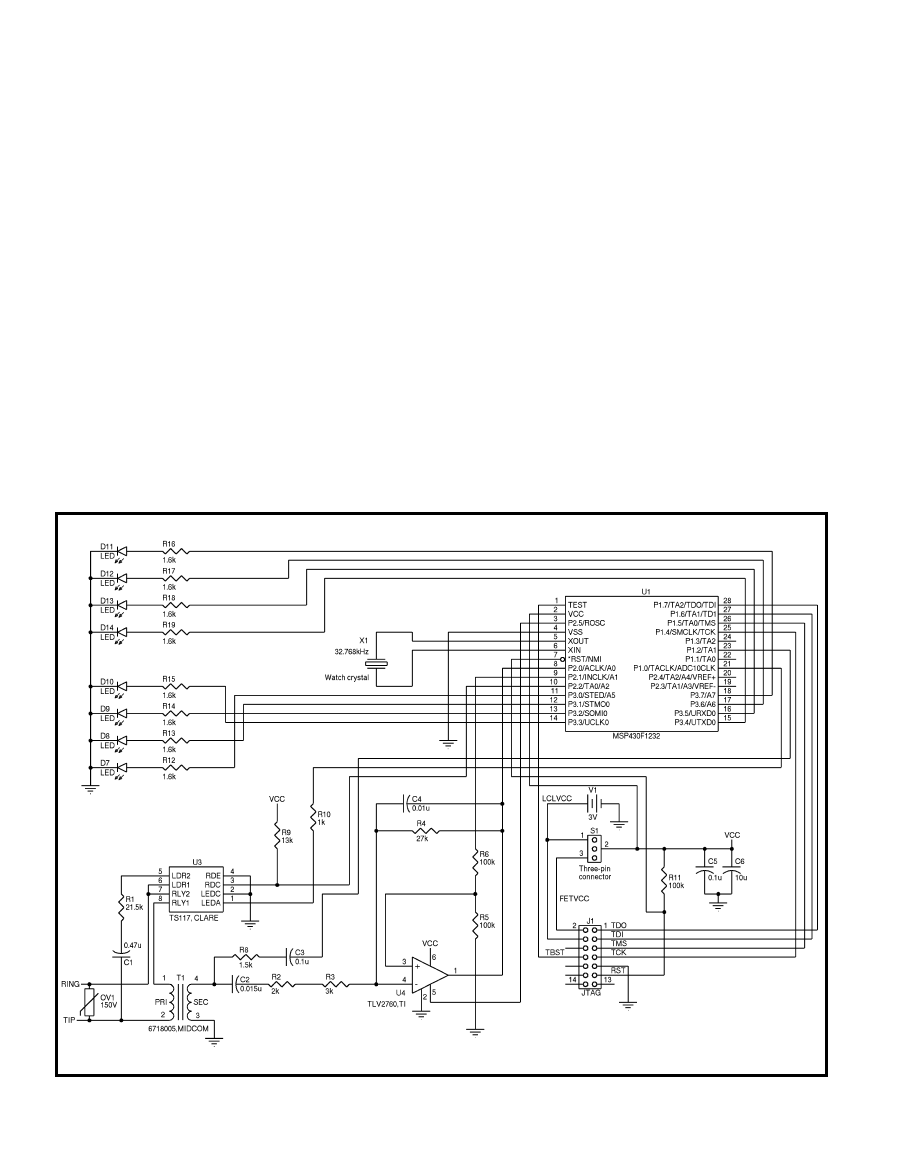

GOD’S IN THE DETAILS

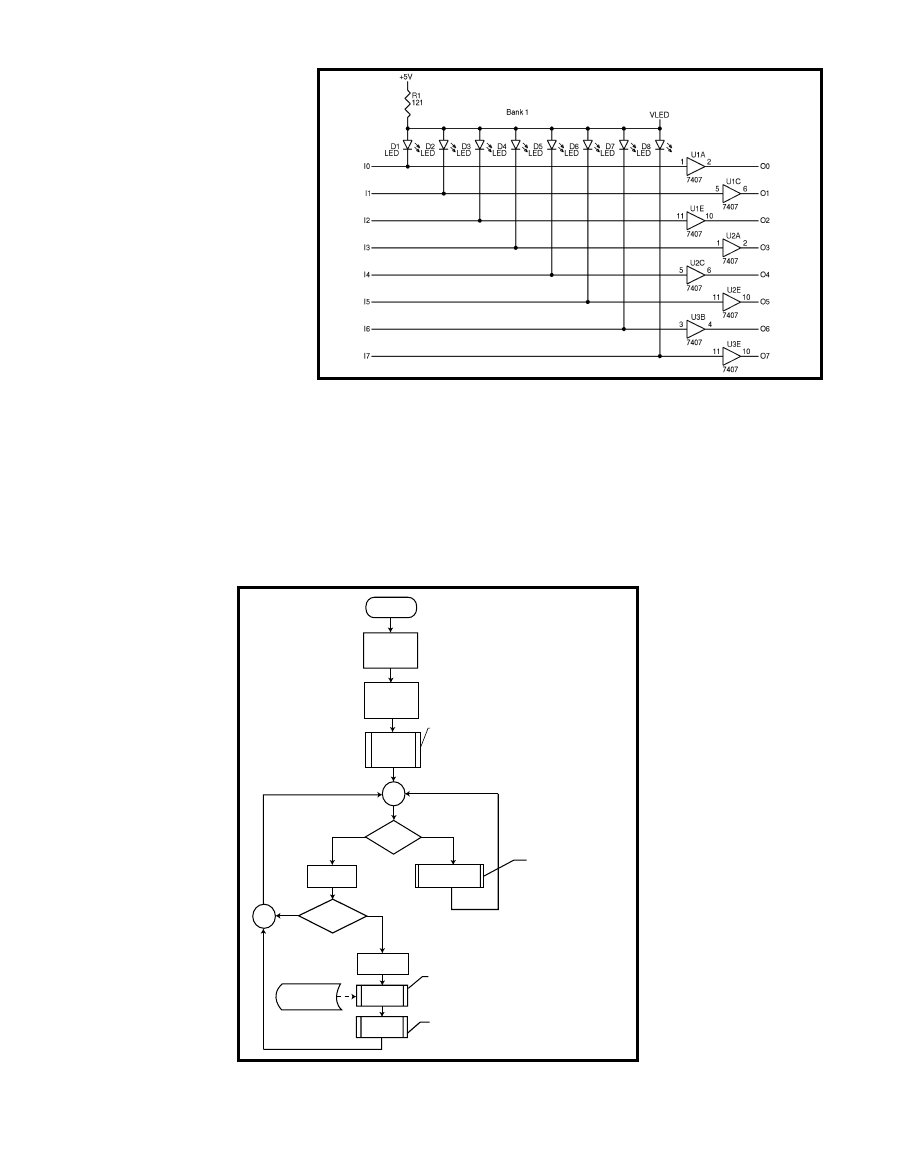

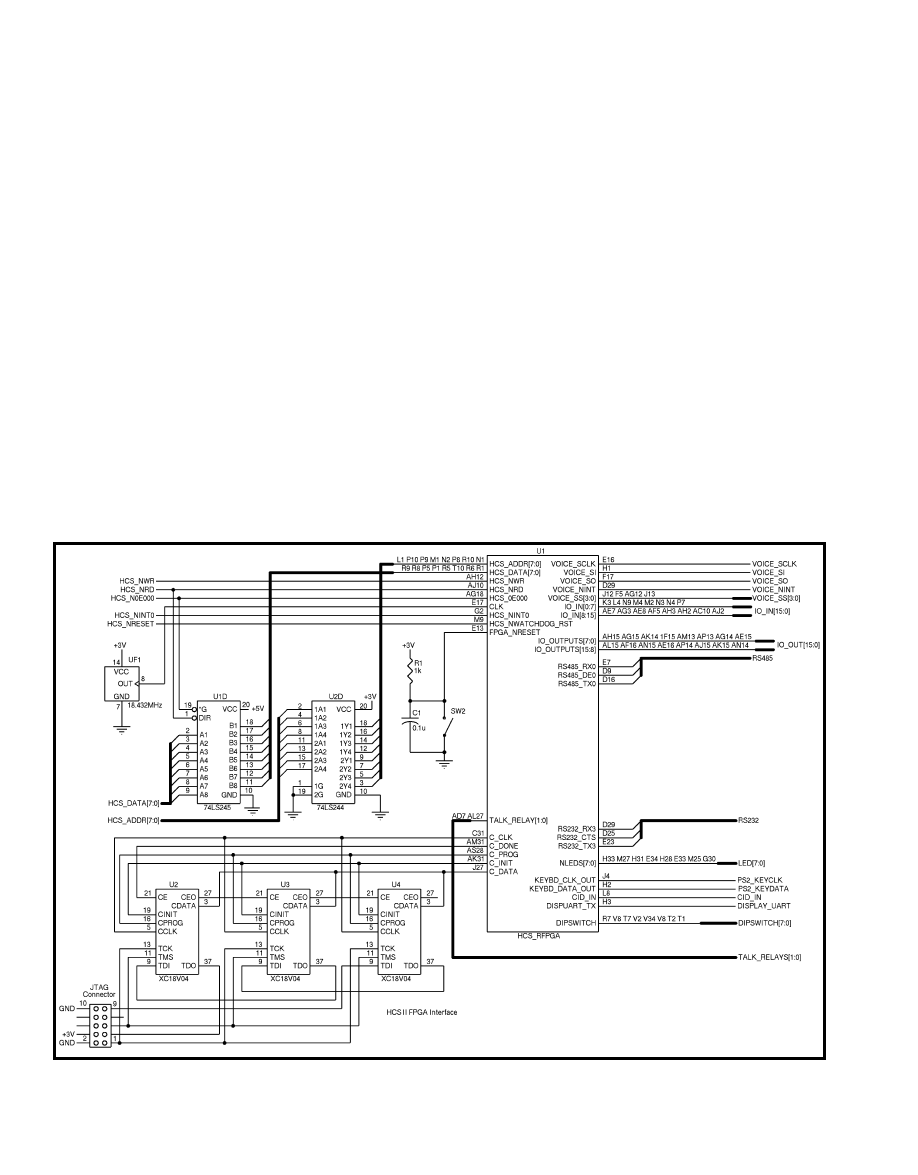

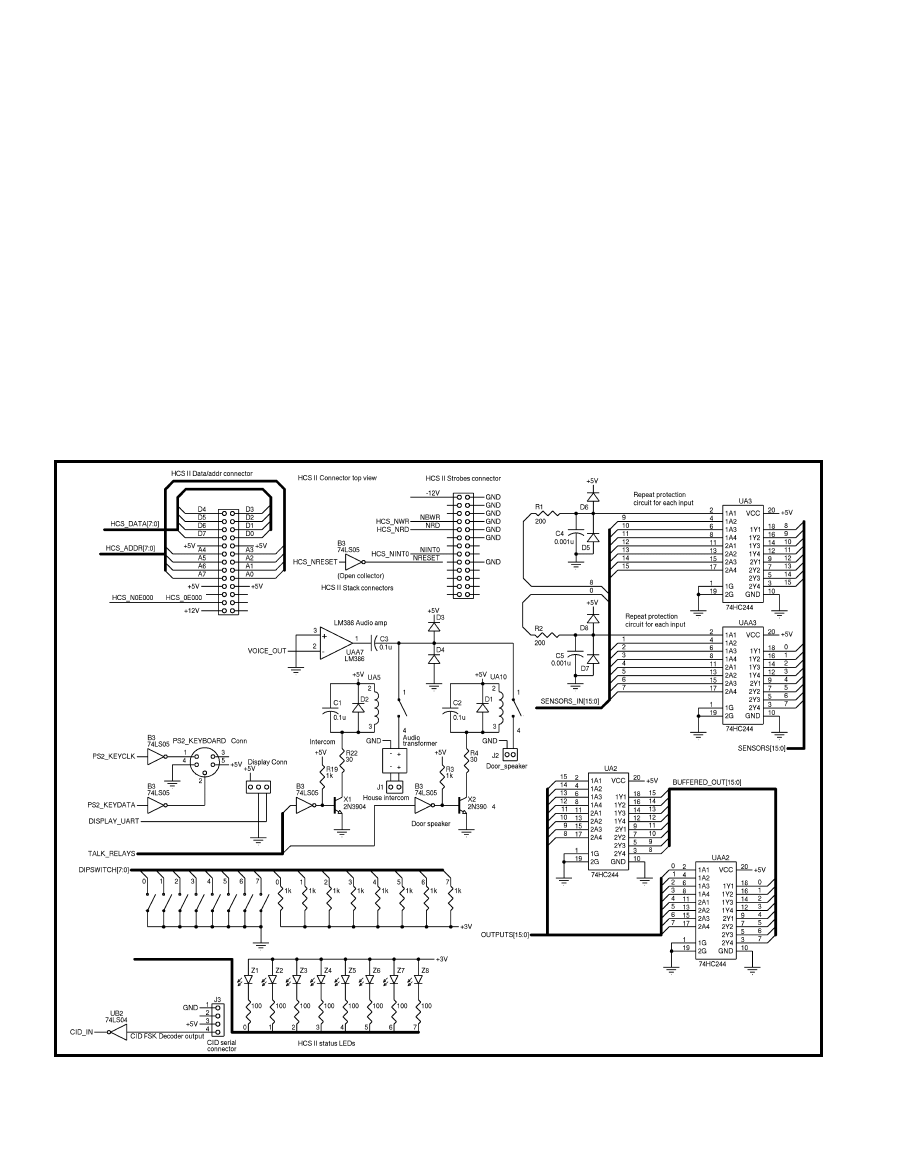

Figure 2 shows the detailed

schematic of the PIC16F628

processor and surrounding cir-

cuitry. [2] The cable pin driver

signals are generated by five

74HCT138 decoders based on

a 6-bit address supplied by the

PIC. The lower three bits

select one of eight outputs

from U9, U13, U15, and U17,

which are applied to the pin

driver circuitry (Figure 3).

The upper three bits select

one of the four decoders and

also generate four status LED

driver signals.

The buffer array (7407)

drives the pin LEDs and provides the

open-collector isolation for the 32 cable-

drive pins. The buffers are arranged in

four banks of eight bits. Figure 3 shows

the detail of a single bank. Eight LEDs

monitor the pin drive status so that

when a particular pin is being driven

(grounded), the corresponding LED

illuminates. Note that a single resistor

suffices for all 32 LEDs, because only

one output pin is driven at a time. An

open-collector buffer is located after

the LED so cable short circuits don’t

cause multiple LEDs to illuminate.

At the receiving end of the cable, U7,

U12, U14, and U16 form a 32-input

multiplexer that selects one of the cable

inputs at a time (see Figure 2). The PIC

selects a particular input using a 6-bit

address, where the lower three bits

tion staff could easily replace a cheap,

socketed driver and not the more

expensive PIC, which would then

need to be reprogrammed and retested.

A second requirement was to give

the operator a visible way to know

that the test is in progress and which

wiring connections are incorrect when

operating in Stand-Alone mode. My

solution was to equip the cable tester

with a series of LEDs—one for each

pin—that would show when a particu-

lar pin was driven and could double as

a simple fault display.

When operating independently, up

to four different cables can be tested,

one at a time, based on vectors stored

in the internal EEPROM. The individ-

ual tests are initiated when one of

four push buttons is pressed.

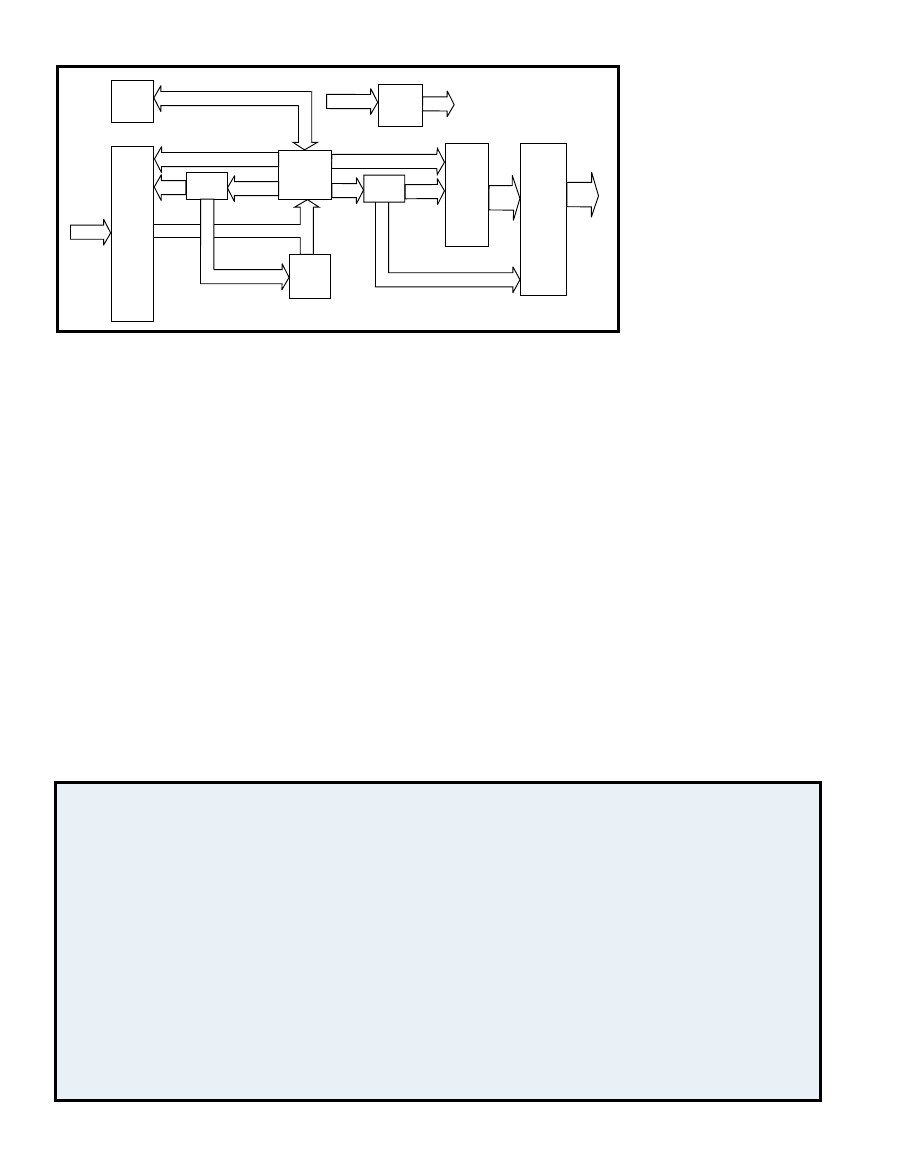

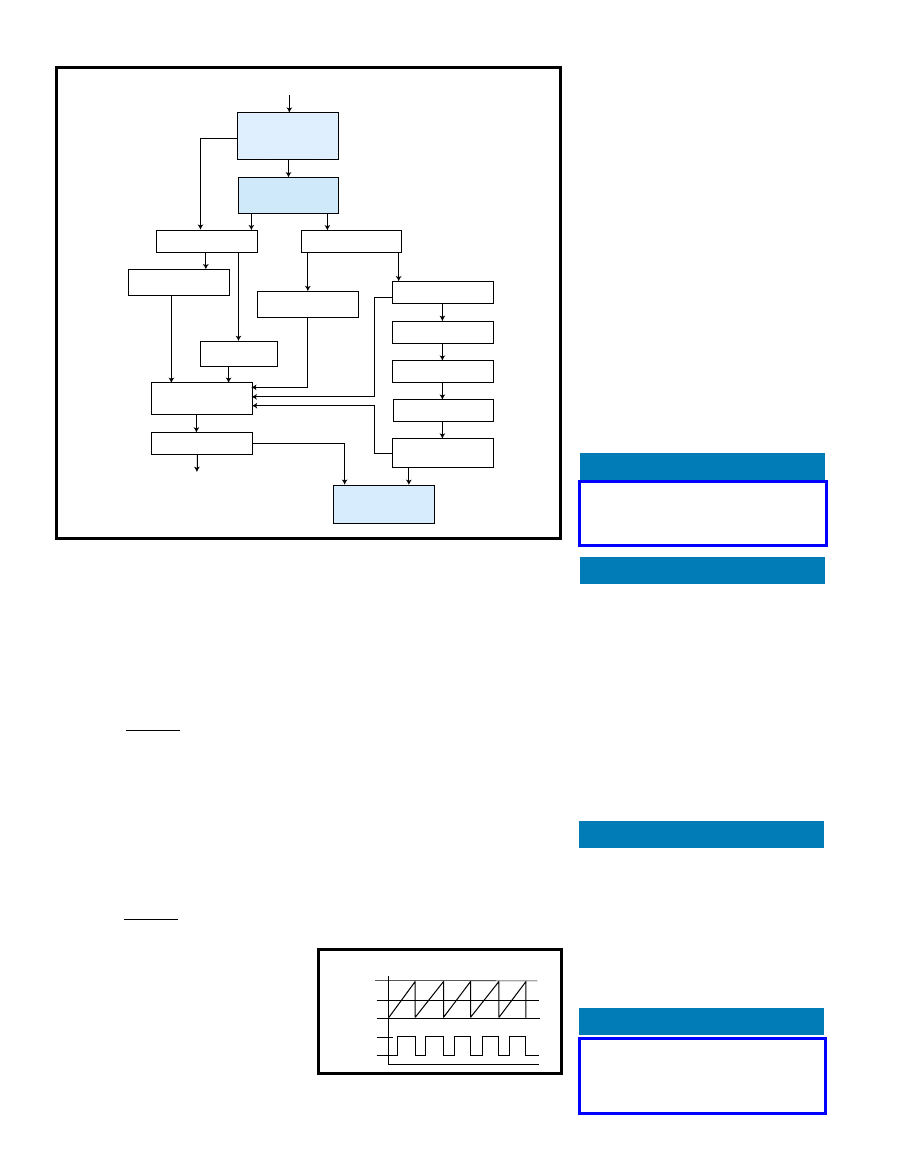

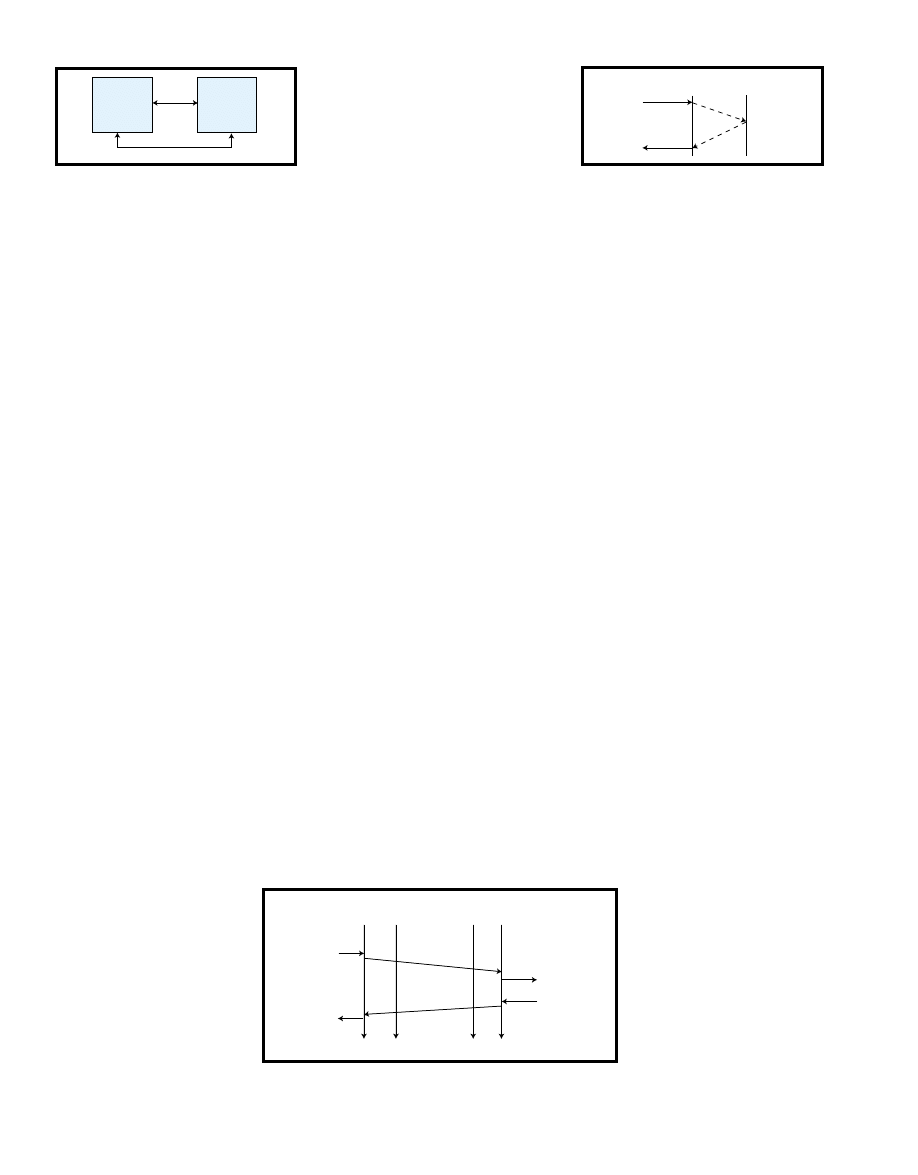

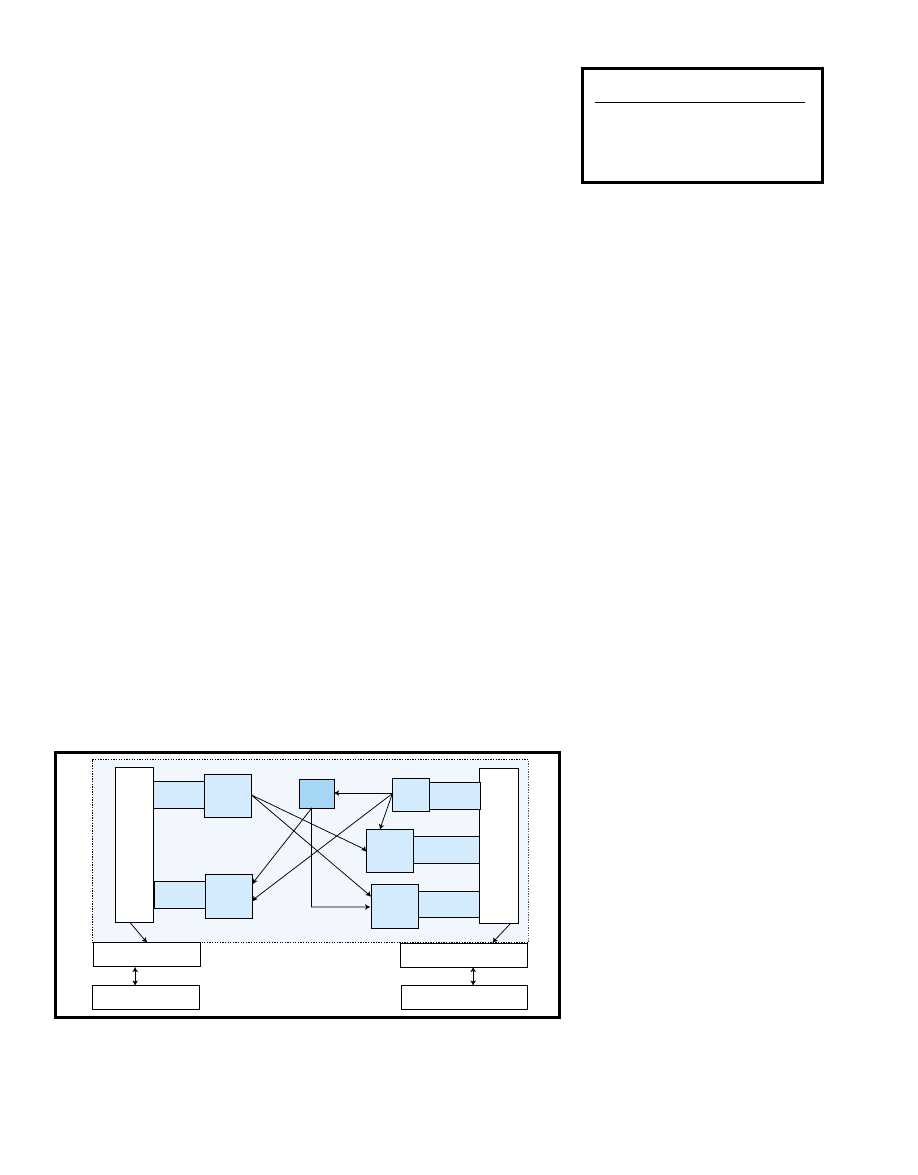

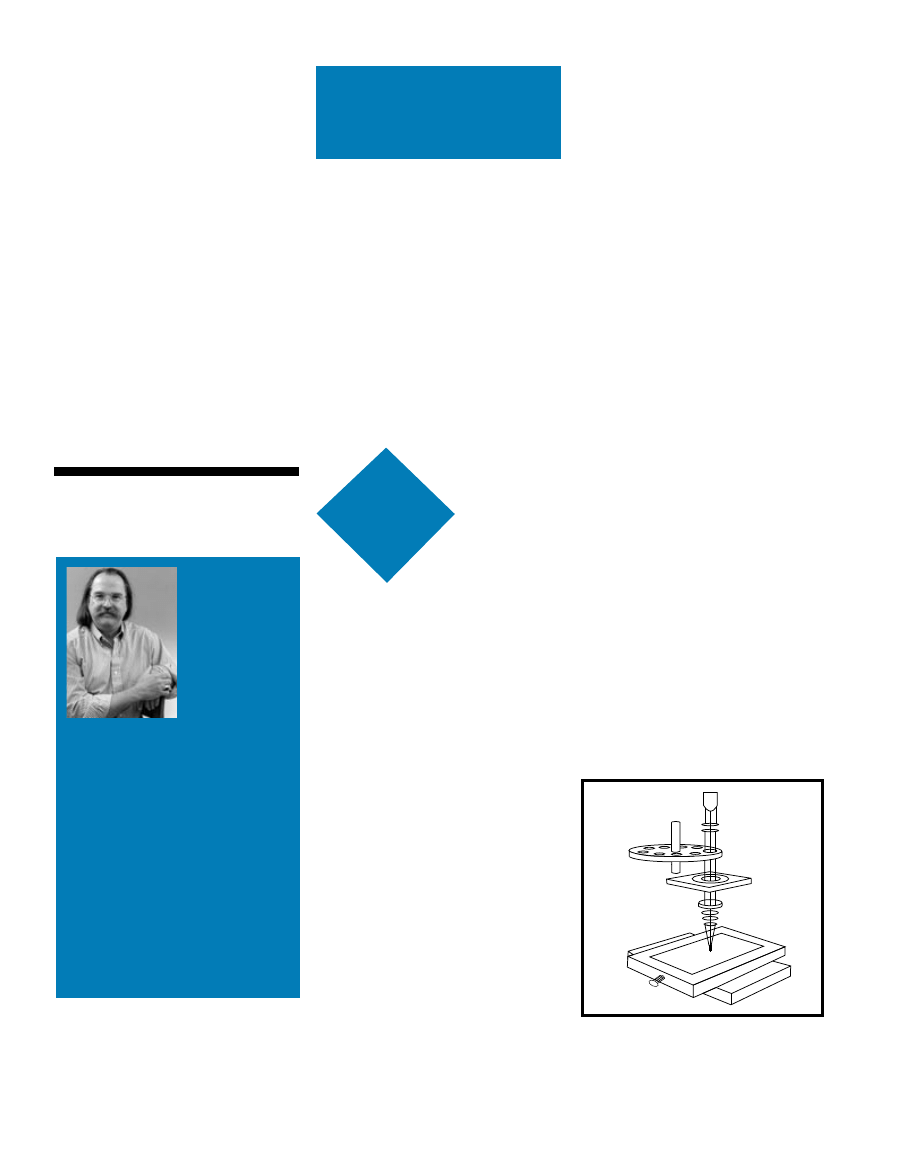

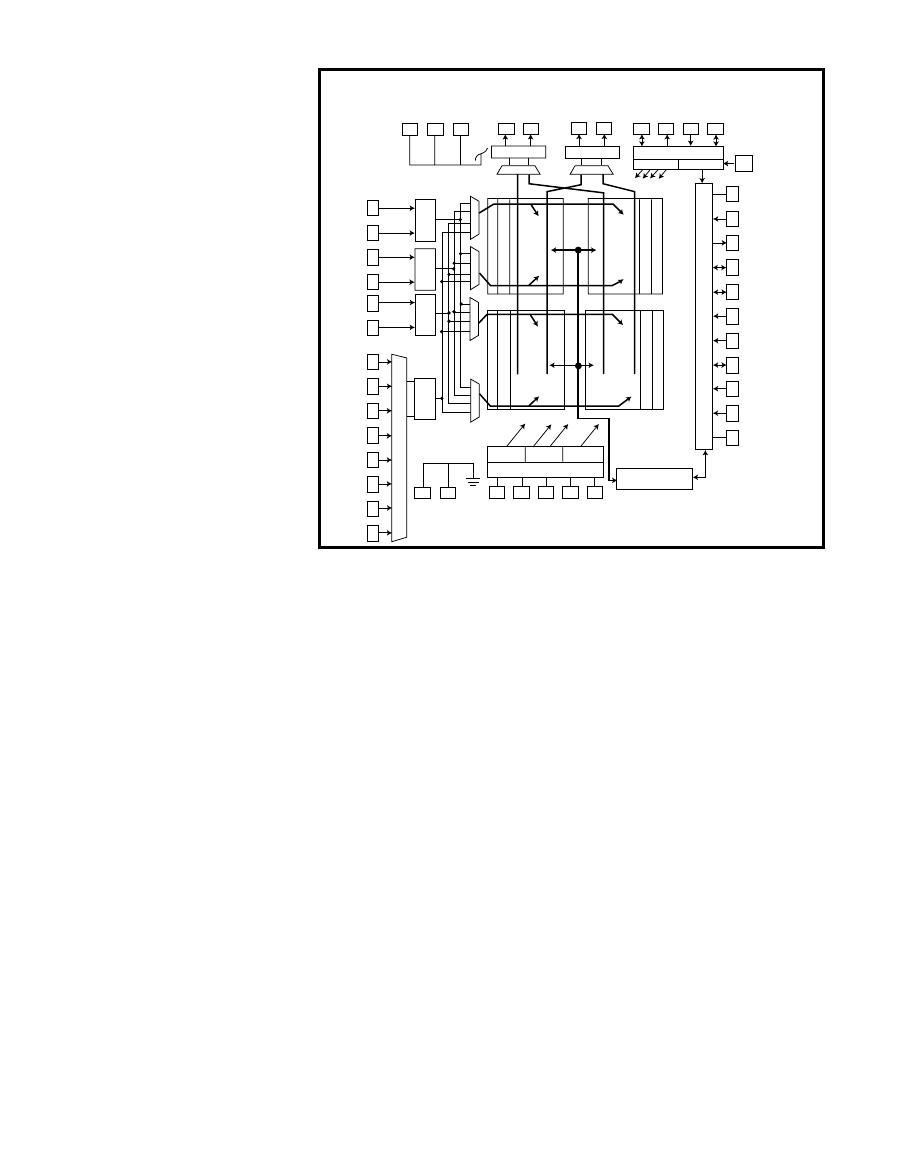

Figure 1 illustrates the basic hard-

ware components used in the cable

tester. The central PIC processor drives

a five-to-32 decoder that strobes each

cable pin sequentially. A second three-

to-eight decoder is used to either select

the pin output strobes or drive four sta-

tus LEDs. The cable-drive signals are

buffered with open-collector, high-volt-

age drivers, which prevent cable short

circuits from damaging any pin drivers.

On the receiving-cable end, a 32-to-one

analog multiplexer is controlled by the

PIC to select one cable pin at a time. A

second three-to-eight decoder selects

either the analog multiplexer or one of

the four test-select switches. Remote

mode is also available when a PC-based

program is connected to the cable tester

with a standard RS-232 serial cable.

A BRIEF HISTORY OF JAL

Developed by Wouter van Ooijen, just another lan-

guage (JAL) was patterned after Ada, the military stan-

dard language. But if you’re familiar with Pascal, you

should have no trouble understanding JAL. You’ll find

the software free of charge at www.voti.nl/jal. The

author would like to be notified via e-mail, postcard, or

letter for any significant use.

When I spoke to Wouter, he said he created JAL

because he did not like any of the PIC16F84’s low-cost,

high-level languages. Also, he thought implementing a

high-level language seemed like a worthwhile project.

Since its creation in 1999, a small but devoted group

of embedded programmers has been using JAL. The

group meets via a mailing list located at groups.

yahoo.com/group/jallist/.

In its present incarnation, JAL supports Microchip PIC

(e.g., PIC16C84, ’16F84, ’12C508, ’12C509, and ’16F877)

and Ubicom SX (e.g., SX18 and SX28) microcontrollers as

targets. It provides conditions, statements, expressions,

subprograms, and variables. Available data types include

bits, bytes, and universal integers. Structured data types

such as arrays and records are not yet available. A pro-

gram can be split into separate files that are all included

in the main source code file; however, separate compila-

tion isn’t supported so that global optimizations can be

performed more easily.

A separate Windows IDE called JalCC is available at

oase.uci.kun.nl/~mientki/PIC/JALcc.htm. It has been

adapted by Stef Mientki from the BricxCC IDE. Stef and

others are actively supporting it.

RS-232 IF

32-to-1

MUX

C

IN

1-32

3-to-8

Decode

Test

switches

PIC16F628

RX/TX

A0-A2 (INP0-2)

INP4-7

A4, A6, A7

A3 (INP3)

ID1-4

5-V

Switcher

9–32 V In

5 V

ID1-4

B0, B3, B4

3-to-8

Decode

B6–B7

SEL3-6

5-to-32

Decode

DRV

1-32

C

OUT

1-32

OC Buffers

and

LEDs

SEL0-3

ID1-4

Figure 1—

Look at the PIC16F628 surrounded by address decoders and input multiplexers. A 5-V switcher powers the circuitry,

and an RS-232 interface connects to an external PC to download cable definitions and/or operate as a slave tester.

14

Issue 154 May 2003

CIRCUIT CELLAR

®

www.circuitcellar.com

select one of eight inputs and the upper

three bits select a particular multiplexer

via U10, a three-to-eight decoder.

In addition to sampling the cable

inputs, this circuitry also provides puls-

es to the four test-select push buttons.

One common end of each push button

is tied to the INP3 or multiplexer input

to the PIC. Thus, by sequentially

selecting outputs Y4 through Y7 of

U10 and monitoring the INP3 input, a

simple keyboard-style scanning func-

tion is provided. R4 provides a needed

pull-up for the INP3 multiplexer input;

however, at 10 k

Ω

, it tends to slow

down the cable tester when cables

with a lot of capacitance are tested.

The RS-232 interface is a straightfor-

ward implementation that is driven by

the PIC’s serial interface pins. The

interface operates at 9600 bps; it’s used

to download new cable vectors to the

EEPROM for stand-alone operation, or

you can use it to remotely control

cable testing when implemented with

the PC-based software. You may down-

load the RS-232 schematic from the

Circuit Cellar

ftp site.

The 5-V power supply is a simple

switcher-based design with an

LM2670 adjustable Buck mode regula-

tor. [3] You may download a schemat-

ic diagram of the 5-V power supply

from the Circuit Cellar ftp site.

I chose an LM2670 3-A regulator

instead of a linear regulator, because

it’s a stock item used in my company’s

products. The power consumption of

the cable tester is negligible, so the

existing part is admittedly overkill.

Switching regulators are much more

efficient than linear regulators. This

may be a consideration if the cable

tester were to be battery powered.

ROOM FOR GROWTH

With some minor software and hard-

ware changes, it should be possible to

easily expand the size of cables that

can be tested up to 60 pins. The Y4-

to-Y7 outputs of U10 would each drive

an additional CD4051 analog multi-

plexer, and the upper four pins would

serve as the manual-test push button

Figure 2—

The Microchip PIC16F628 microcontroller drives 74HCT138 address decoders that are buffered by open-collector drivers. At the input CD4051 MUXes multiplex the

cable inputs to a single input pin, INP3.

EFFORT…BIG

PRIZES!

Innovate with the HC08 from Motorola

Innovate with the HC08 from Motorola

These products incorporate SuperFlash

®

technology licensed from SST. Motorola and the stylized M Logo are registered in the U.S.

Patent and Trademark Office. All other product or service names are the property of their respective owners. © Motorola, Inc. 2002

68HC908QT4 Demonstration Kit

Flash Innovation 2003 Design Contest

Enter our Flash Innovation

2003 Design Contest

involving our new HC08

Q-Family. You may be

eligible to win a 60” thin

plasma screen HDTV

or one of several other

exciting prizes. We are

offering prizes valued

together at more

than $30,000.

Innovate with the HC08!

Motorola’s HC08 Q-Family

of 8-bit microcontrollers

is available in small

8- and 16-pin packaging.

With Flash, you gain the

flexibility to reprogram

in-application and

in-circuit, which helps

make field upgrades

easy and inexpensive.

Take advantage of

our 68HC908QT4

Demonstration Kit,

which has everything

you should need to

get started.

Entries can be from the

very simple to the most

intricate. Innovation,

architectural elegance

and quality of design are

the keys to success in

Flash Innovation 2003.

DEADLINE FOR ENTRIES: JUNE 30, 2003

For information on entering and for contest rules,

visit us at

SMALL

P

ARTS,

LOW

-COST

TOOL,

LITTLE

EFFORT

…BIG

PRIZES!

16

Issue 154 May 2003

CIRCUIT CELLAR

®

www.circuitcellar.com

the first character is a

P (i.e., program

EEPROM location), it expects to get a

two-digit hexadecimal address followed

by a space, and then a two-digit deci-

mal data byte terminated by a

<CR>.

The legal range of the address is from

0x00 to 0x7F, and the pin number is a

decimal number from one to 32. A

value of zero is used to indicate that the

pin is not connected. The pin number

is written to EEPROM at the specified

address. If all goes well, the PIC replies

with an

OK<CR> (note that <CR> indi-

cates a single byte containing a carriage

return or 0x0D), otherwise an

NPR<CR>

response indicates that there was an

error during EEPROM programming. A

NAK<CR> reply indicates that an invalid

address or pin number was received.

If the first character is a

T (i.e., test

pin), it expects a two-digit decimal pin

number representing the pin to be tested

with a range from one to 32. The com-

mand must be terminated with a car-

riage return (

<CR>). In response, the PIC

will drive the specified pin low, read all

the input pins (compressed into a 32-bit

word), and reply with a

V followed by

the eight-digit hexadecimal number rep-

resenting the input pin test result. The

reply word’s least significant bit repre-

sents the state of input pin 1. You may

download the complete PIC source

code from the Circuit Cellar ftp site.

scan. Similarly, the Y4-to-Y7 outputs of

U11 would drive four more 74HC138

decoders, and the upper four bits would

be dedicated to the status LEDs.

ALL IN THE SOFTWARE

Obviously, the hardware design for

the cable tester is basic. You’ll find

it’s easy to build even with wire-wrap-

ping techniques. Providing additional

functionality in software is the key to

keeping down costs. With this in

mind, I deliberately kept the hardware

simple and performed most of the

work in the software.

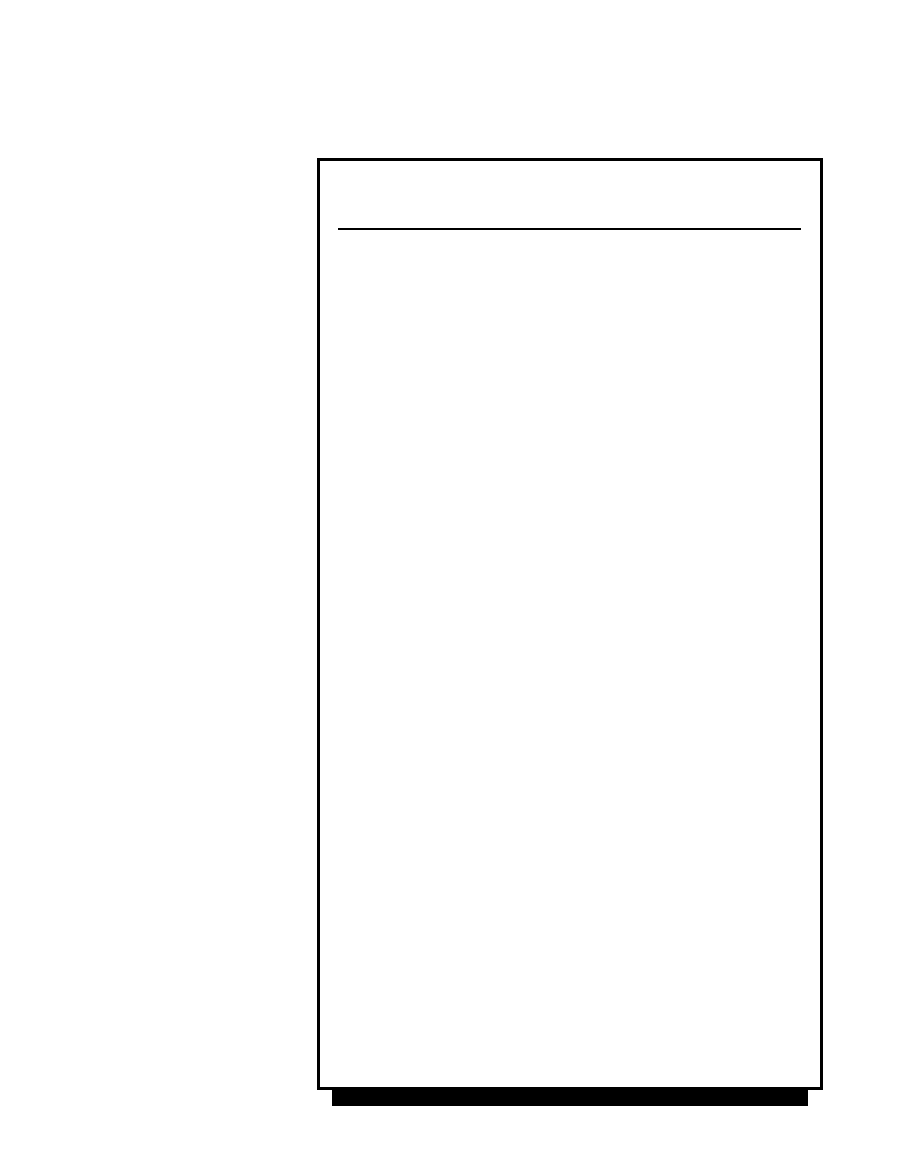

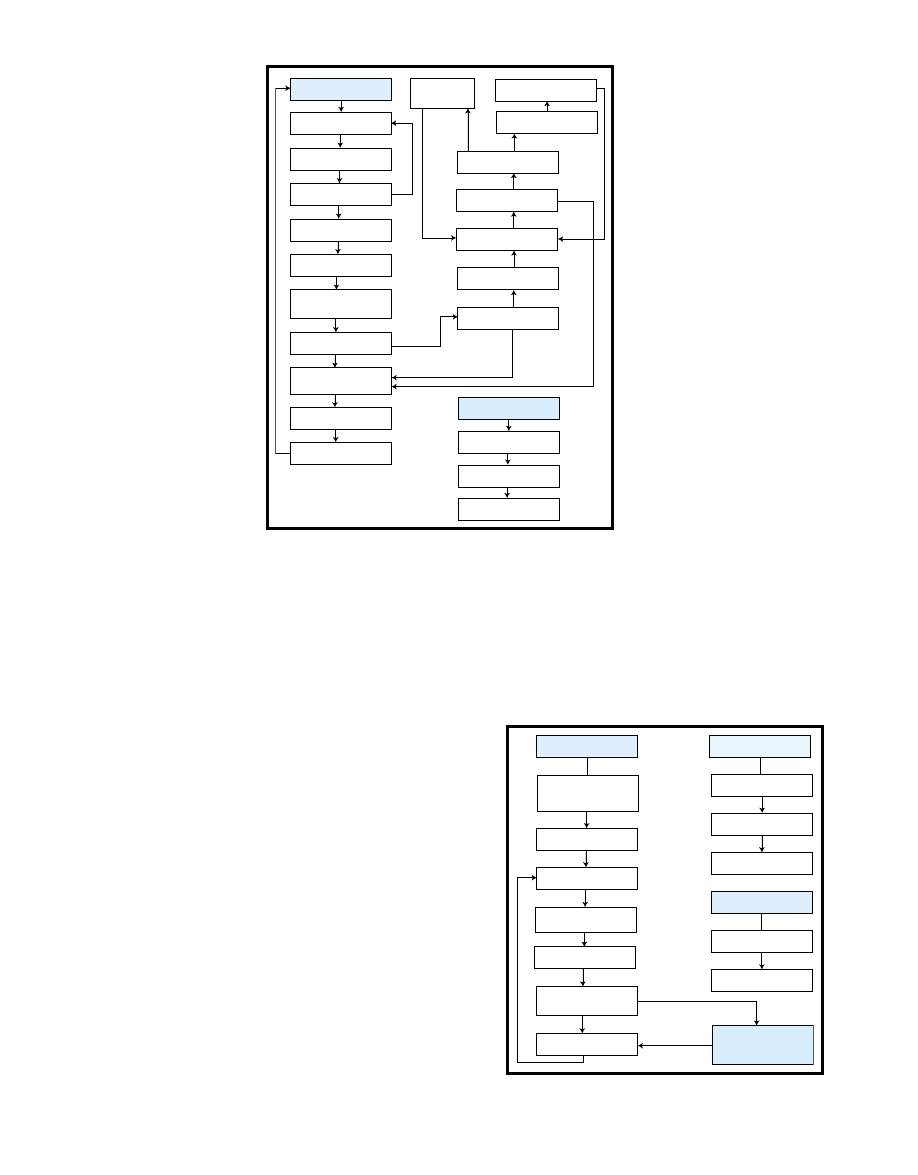

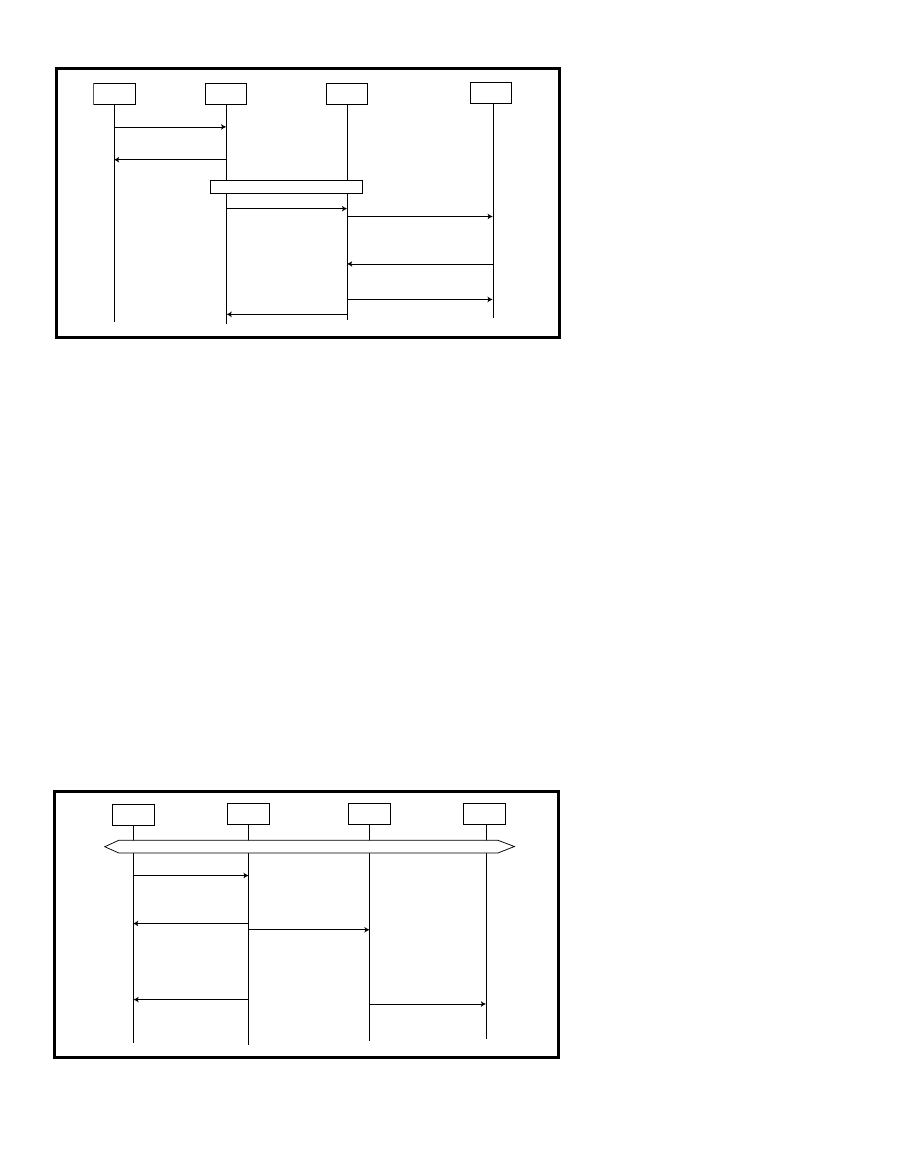

The top-level software flowchart is

shown in Figure 4. Initially, the PIC

sets up the I/O ports and the serial

communication port. Next, the Ready

LED is turned on and a brief identifying

message is sent via the RS-232 seri-

al port. Then, the program enters a

busy-wait loop, alternately polling

the manual-test push buttons and

the serial-input data-received flag.

When serial data is received, the

GetCommand routine is called to

acquire a complete host command.

Table 1 shows the available com-

mands and their syntax. Otherwise,

if serial data isn’t received, the PIC

scans the test push buttons. If a

button is pressed, the PIC will clear

any logged faults from a previous

test, call the

TestCable routine to

perform the stand-alone cable test,

and call the

errReport routine to

display any fault codes via the pin

and status LEDs.

YOUR WISH, MY COMMAND

Listing 1 shows the

GetCommand

routine. The active character is

returned with the

rsGet routine. If

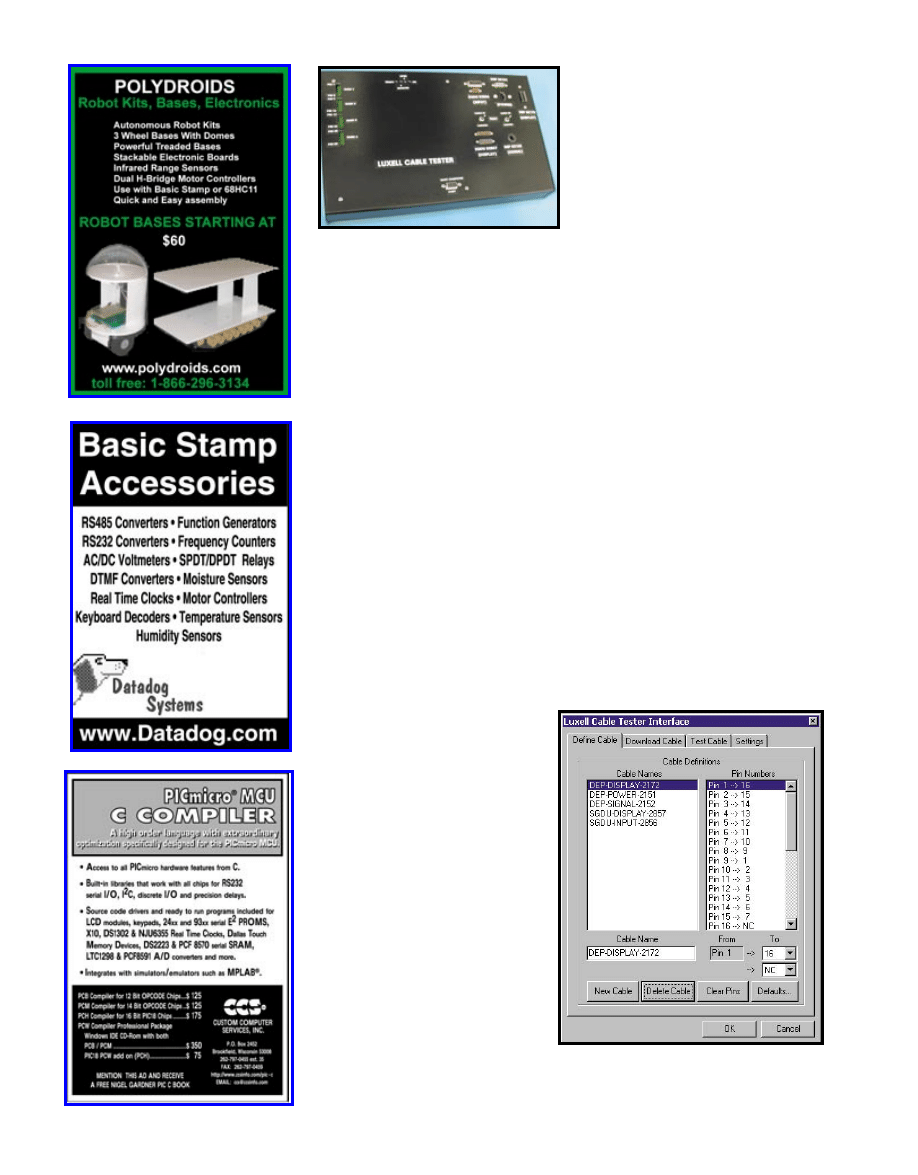

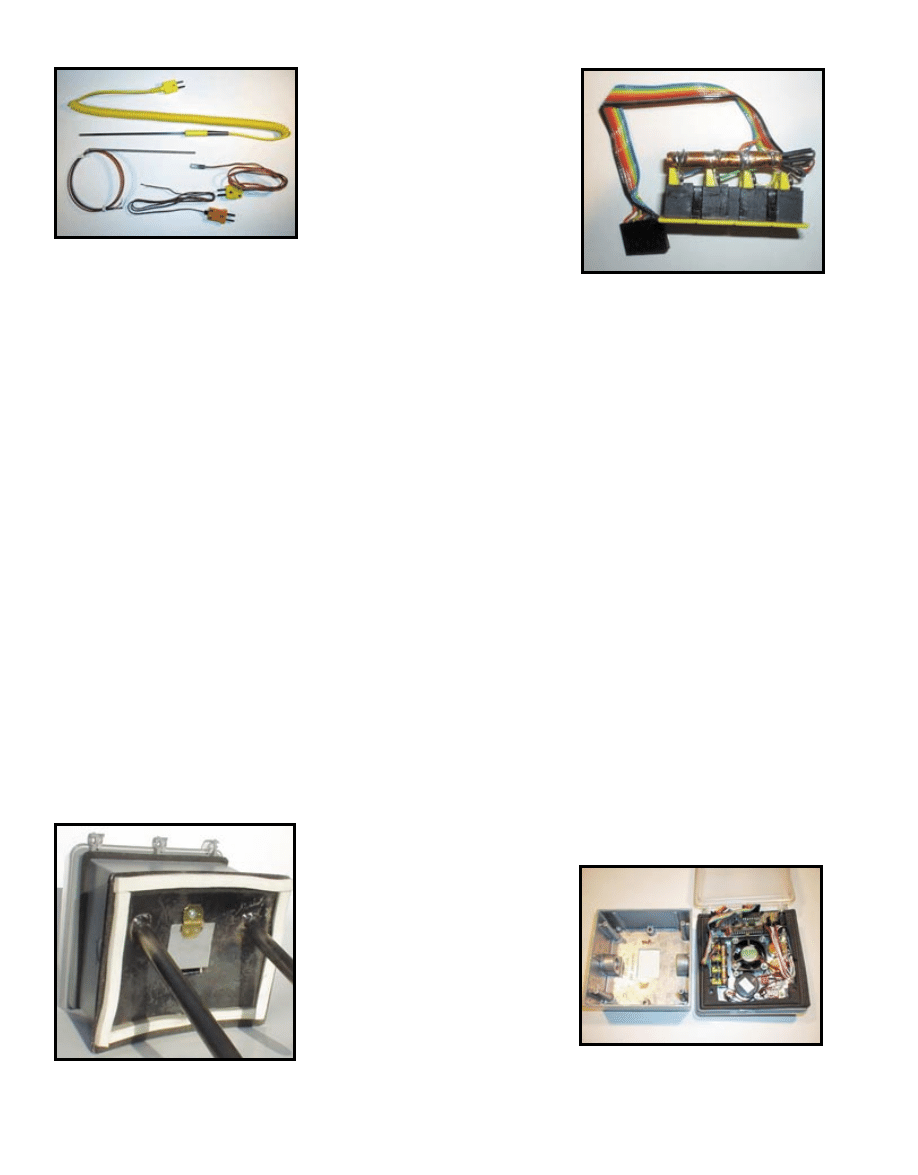

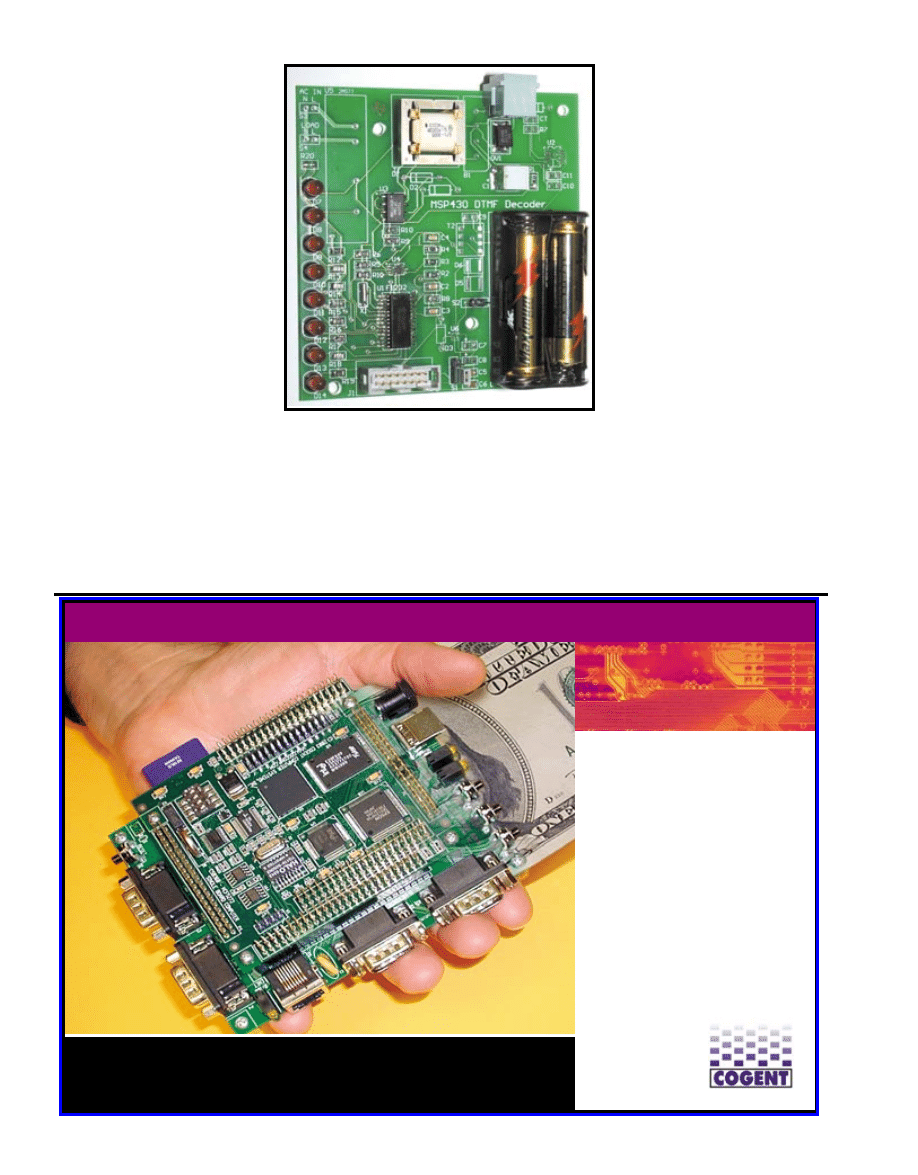

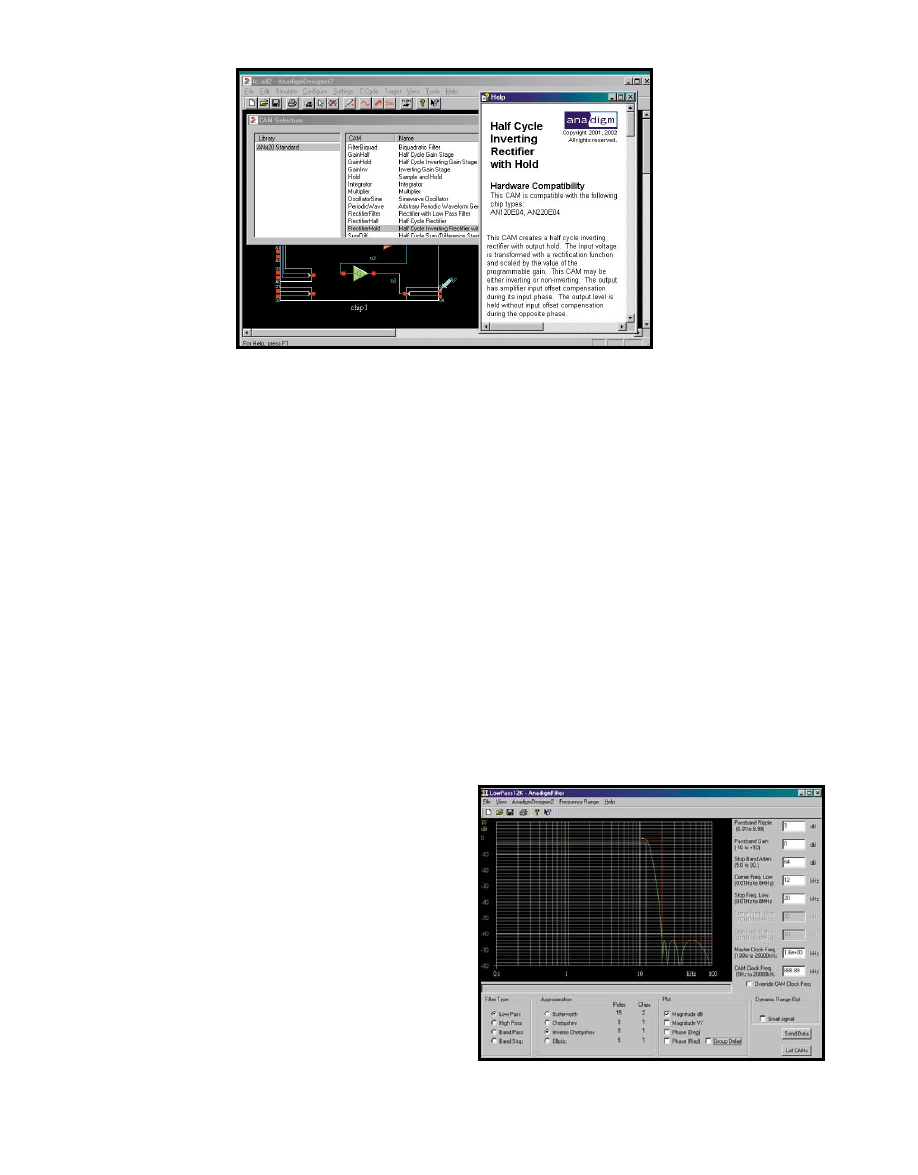

Photo 2—

A cable is selected from the leftmost list. The pin

definitions for that cable are shown in the rightmost list.

Clicking on a pin allows the pin connection to be altered

using the pop-up menus below the second list.

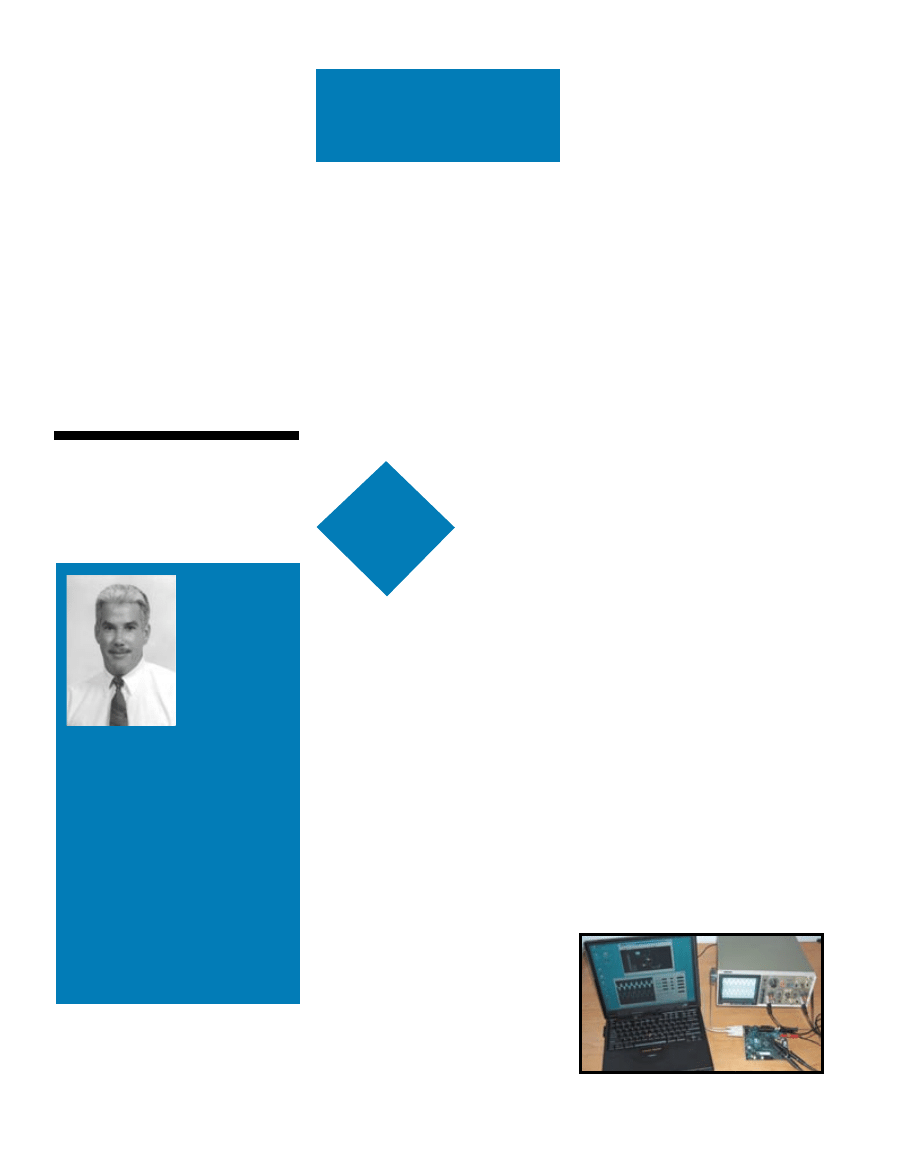

Photo 1—

A total of five cables can be tested when

the tester is operating as a slave to a host computer.

The pin LEDs are visible to the left of the photo, and

the status LEDs are located at the top left.

June 2–5, 2003

Donald E. Stephens

Convention Center

Rosemont, IL (Chicago)

Bigger!

Bigger!

America’s Largest Sensors Event

Just Got

More coverage of:

•

Biosensors

•

Wireless Networking

•

Smart Solutions and

Intelligent Systems

•

MEMS/MST

•

Nanotechnology

•

Plus an expanded 2-Day

Business of Sensors Symposium

Don’t delay. Register by April 21 for advance registration rates and receive

FREE exhibit hall and Industry Networking Reception admission (a $65 value).

www.cir.sensorsexpo.com or 800-331-5706.

Be sure to reference priority code 71 when registering.

Dean Kamen,

featured

speaker

at the “Spir

it of

Innovation”

luncheon

One badge gives you access

to three great shows:

—Sensors Expo & Conference

—International Robots & Vision Show and Conference

—Industrial Fastener & Forming International Exhibition and Conference

www.circuitcellar.com

CIRCUIT CELLAR

®

Issue 154 May 2003

19

STAND-ALONE AND DELIVER

When operating in Stand-Alone

mode, the cable tester uses the contents

of EEPROM to define one of four test

vectors to use during testing. You may

download additional EEPROM informa-

tion from the Circuit Cellar ftp site.

The EEPROM address represents an

implied pin number. Memory address

0x00 represents pin 1 for cable 1 and

address 0x7F represents pin 32 for

cable 4. The contents of each memory

location identify the pin that is con-

nected to the implied pin number. For

example, assume EEPROM location

0x10 holds a value 0x08. This means

that for cable 1, connector A, pin 17 is

connected to connector B, pin 8. (Note

that connector A is driven as connec-

tor B is read as an input.)

There are some limitations to the

Stand-Alone mode implied by the

fixed EEPROM size. Only a cable with

one-to-one or many-to-one pin map-

ping is supported. This means one or

more pins on connector A can be tied

to only one unique connection on

connector B.

If you were willing to

sacrifice the ability of

testing four cables and

instead limit the cable

tester to one cable at a

time, you could support

any pin mapping, because

you could hold an entire

32-bit result vector in

EEPROM for each pin of a

32-pin cable. In that case,

you would need 128 bytes

of EEPROM to store the

result vectors to allow

the testing of any cable.

In my case, most of the

cables I had to test were

either many-to-one or

one-to-one pin mappings,

so this wasn’t an issue.

There are no limitations

when using the PC-based

cable tester interface.

When testing a cable,

the

TestCable routine

begins by driving pin 1

low via the

pdrvStart()

function (see Listing 2).

Next, all 32 input pins

are scanned and assem-

bled—using

prcvScanAll()—into a

32-bit result vector that’s kept in vari-

ables

b0, b1, b2, and b3. Note that b0

holds the most significant byte corre-

sponding to input pins 25 through 32.

The most significant bit of this byte

represents input pin 32. Then, the

result vector is then bit-wise inverted,

and the algorithm uses the current pin

that’s driven to index the EEPROM

cable vectors and retrieves the pin

number (

tpin) that should be driven.

Assuming that

tpin is

nonzero (i.e., is not open-

circuit), you can check

whether or not the bit cor-

responding to

tpin is set

in

b0 to b3 using the

vecIsSet() function. If

this bit is set, the corre-

sponding bit in the

b0-to-b3

result vector is cleared and

the algorithm continues.

If the bit isn’t set, which

means you’ve detected an

open circuit, an open-cir-

cuit error is set using the

errSet() function.

Next, a test is performed

to see whether any other bit

is set that would indicate a

short circuit from the driv-

ing pin to the shorted pin.

If another bit is found set

in the result vector, the

errSet() function is called

with a short-circuit error.

The

pdrvNext() function

drives the next pin in

sequence, and the afore-

mentioned steps are repeat-

ed to detect any errors

for this pin.

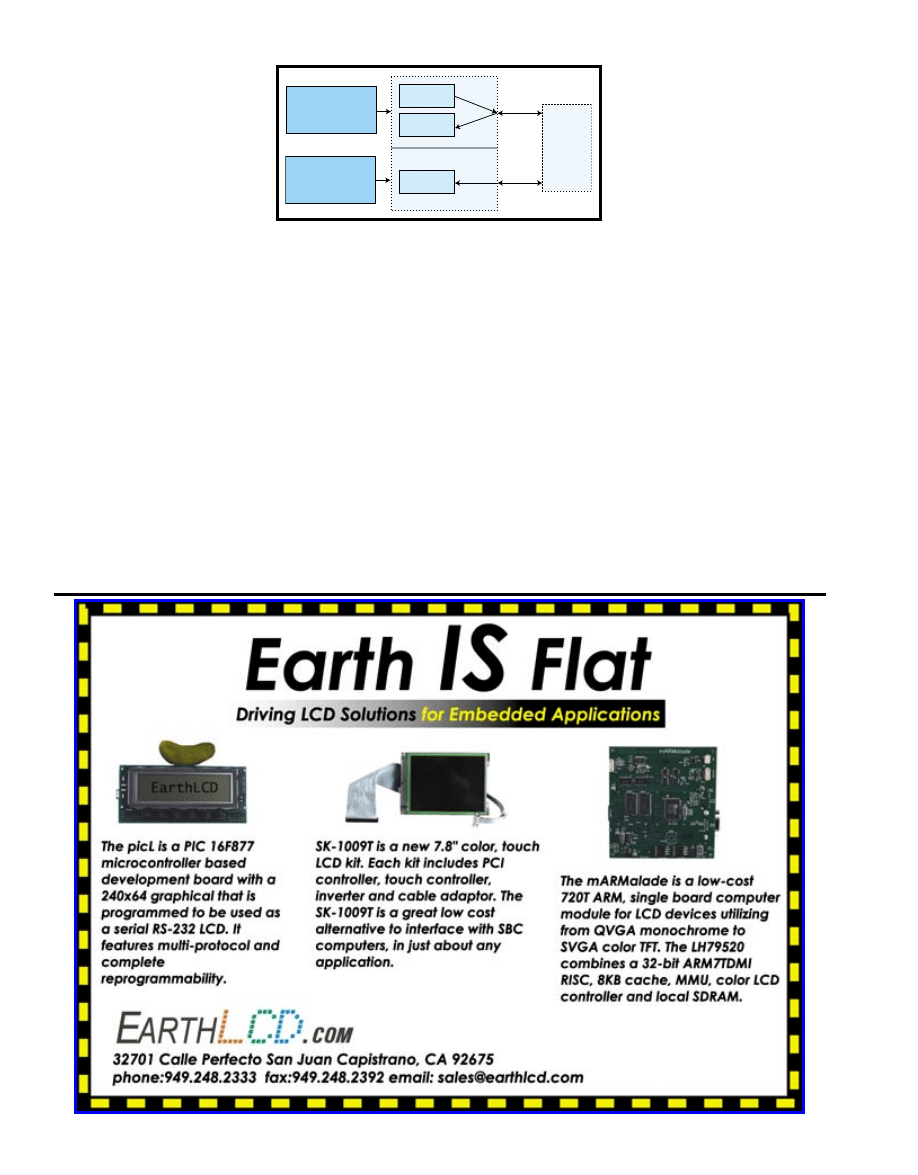

Reset

Initialize I/O

and RS-232

port

Turn on

Ready LED

rsGreeting

Display initial greeting

on any attached

RS-232 device

SCI input?

N

Y

Scan push

buttons

GetCommand

Active

button?

N

Y

Clear logged

test errors

TestCable

EEPROM

cable vectors

errReport

Sequentially drive all

outputs, verify results against

EEPROM cable vectors and log errors

Flash pin LED and the

Open/Close LEDs to

report any logged

errors

Process commands

from the host computer

to write cable vectors

to EEPROM or execute

a test vector and return

the results

Figure 4—

The top-level PIC software shows the initialization, stand-alone, and remote-

cable test paths. The

GetCommand

routine provides cable definition downloads and

remote test capabilities.

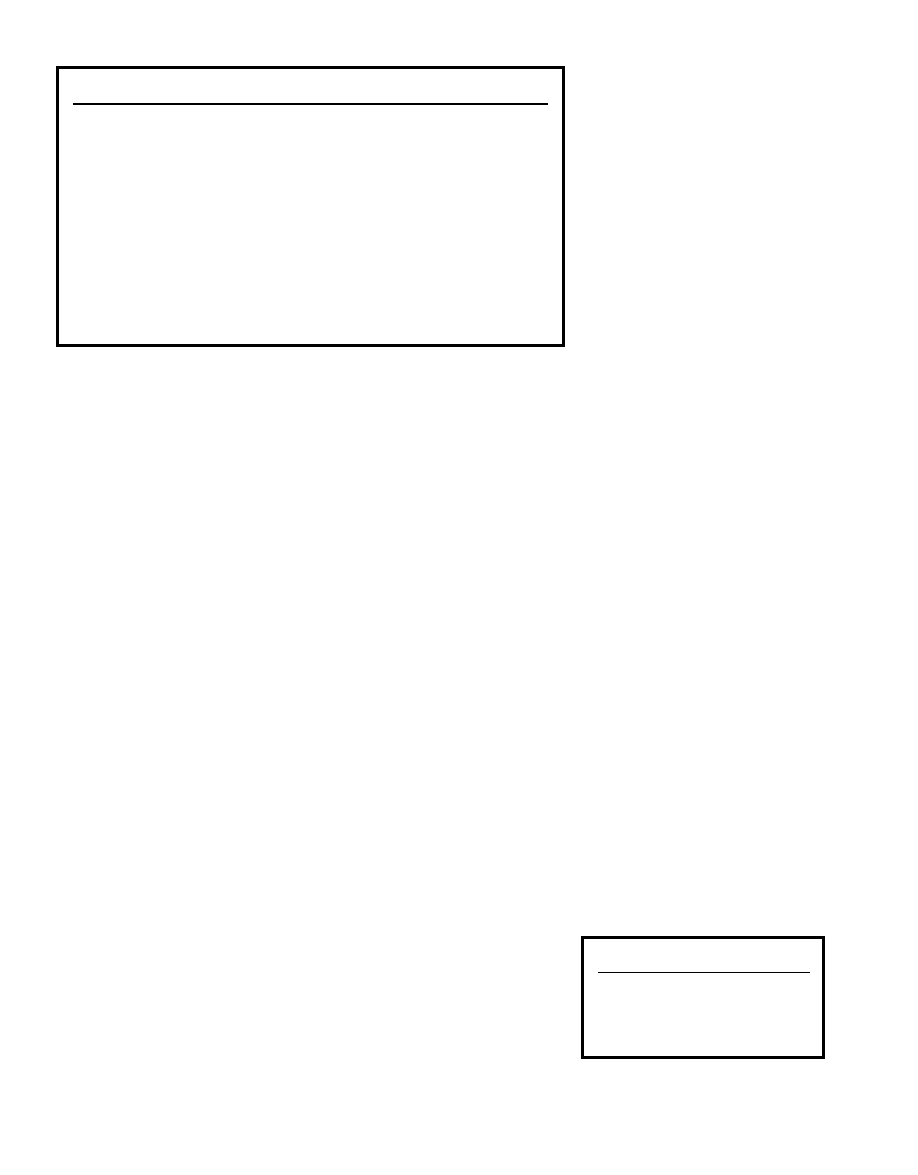

Figure 3—

The 7407 open-collector buffers isolate the cable to be tested so that only the driven LED illuminates.

These drivers also provide high-voltage protection against accidental ESD discharges into the cable tester pins.

20

Issue 154 May 2003

CIRCUIT CELLAR

®

www.circuitcellar.com

If you’re observant, you’ll discover

the

rsPut() and rsPutHex() func-

tions strewn about the code. These rou-

tines provide an external diagnostic

capability when the stand-alone cable

tester is connected to an external ter-

minal or terminal emulator on a PC.

For each tested pin, a report is generat-

ed containing the result vector, the

source and destination pins, and the

pass/fail test condition. A typical report

would be

V00000001 0701T<CR>. This

means the test was performed from

connector A, pin 7 to connector B, pin 1

with a result vector of 0x00000001 (or

pin 1 is active). It passed successfully.

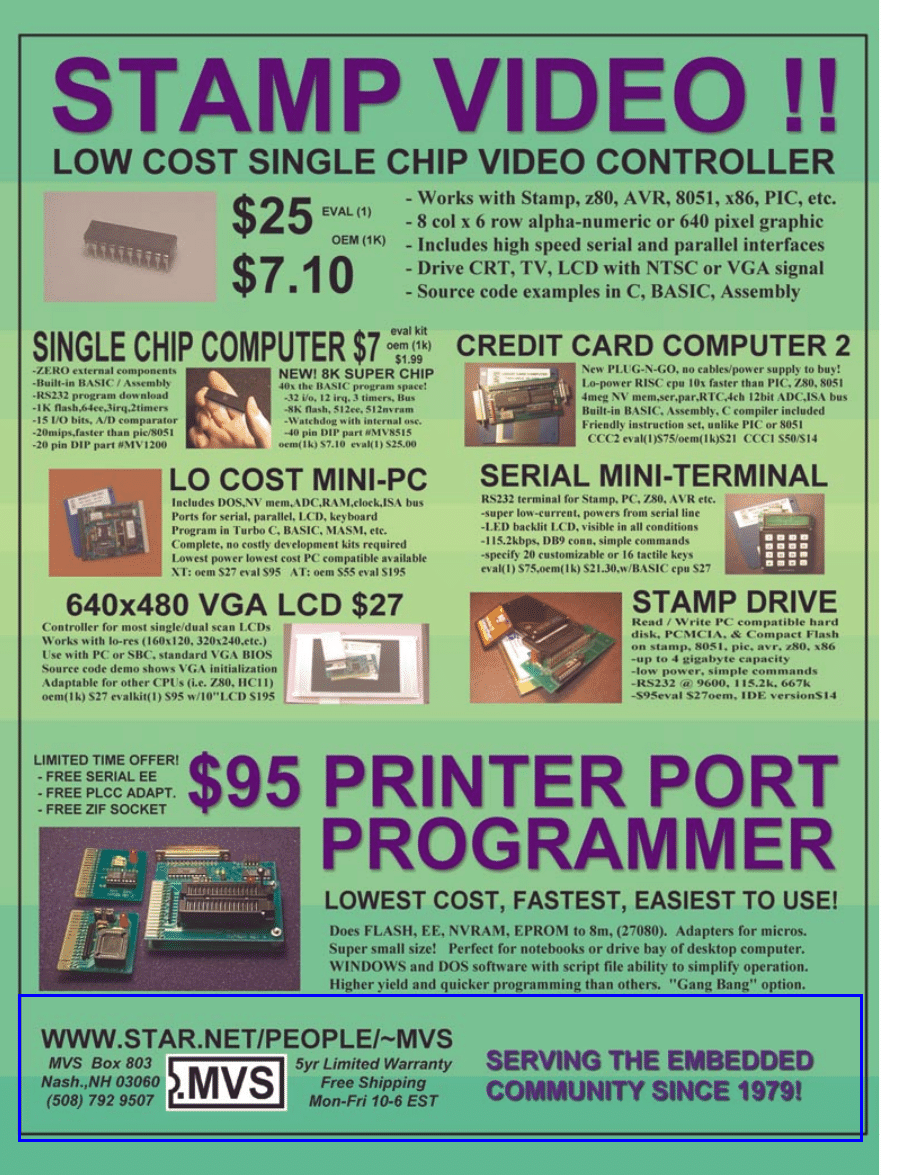

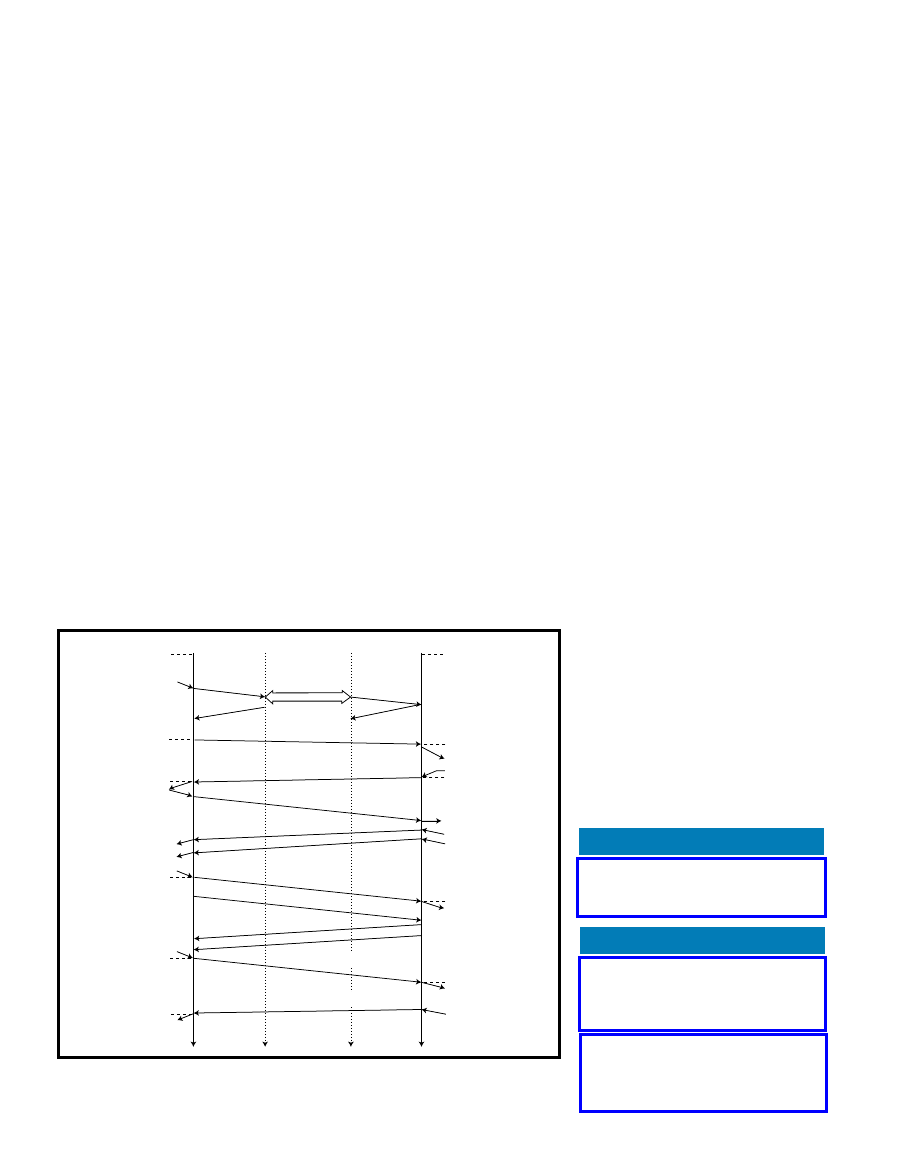

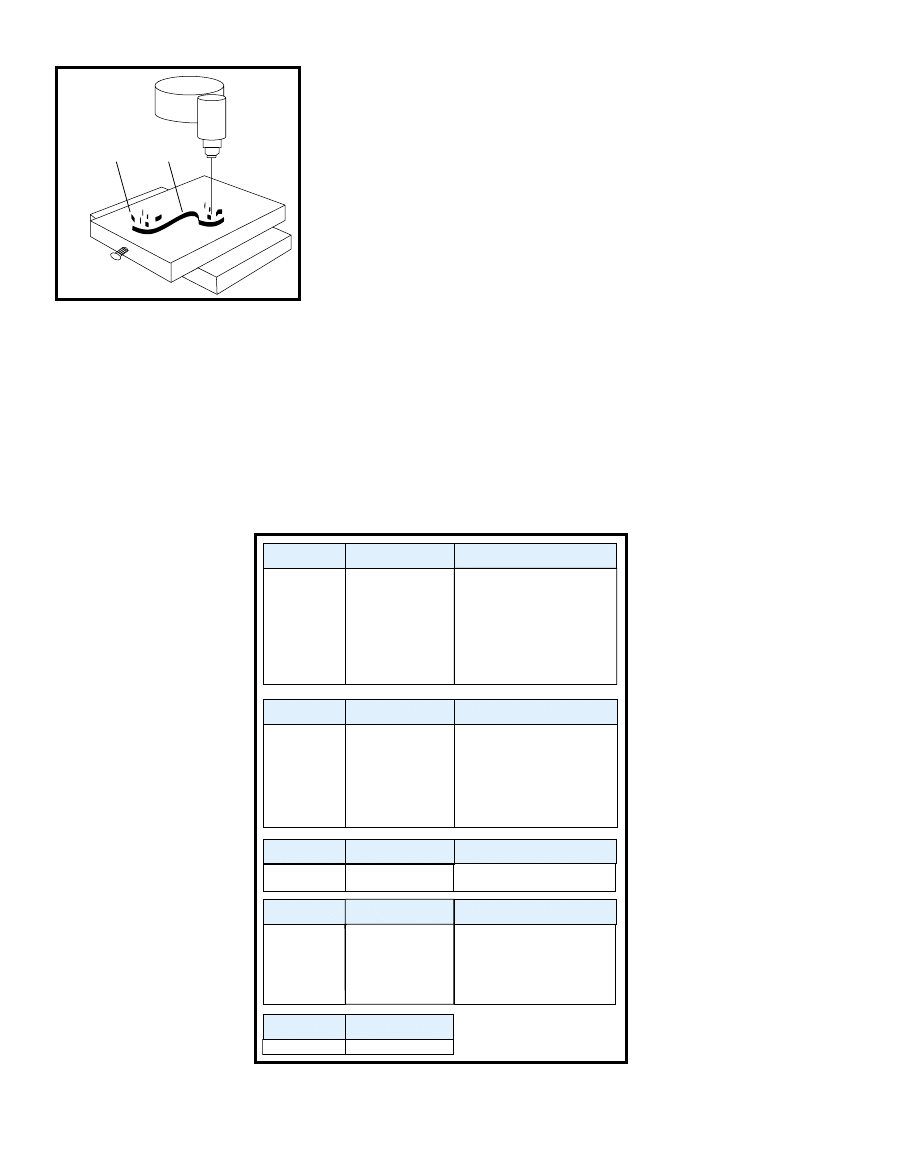

HOW IT WORKS

Several examples will clarify how

the cable tester detects open and short

circuits. If pin 1 is driven as shown in

Figure 5a, there are four possible out-

comes: an open circuit where the

result vector becomes 11111111111;

one pin (6) is driven to give a result

vector of 11111011111 (see Figure 5b);

multiple pins (6 and 9) are driven to

give a result vector of 11011011111

(see Figure 5c); or multiple pins (1 and

4) are connected to the same pin to

give a result vector of 11111011111

(see Figure 5d).

Figure 5a illustrates an open-circuit

result. Depending on whether or not

the current pin test vector should be

open circuited, this could be either an

error or a valid result. Figure 5b shows

the most typical case of a one-to-one

mapping, where a pin on one side of the

cable is connected to a pin on another

side of the cable. If the required pin

isn’t found where it’s expected, an

open-circuit fault is generated.

Figure 5c shows a one-to-many pin

mapping. In Stand-Alone mode, the

cable tester cannot handle this particu-

lar scenario. There is a reason for this.

Because you can store only one pin con-

nection for each pin that’s driven, you

have no way of showing multiple pins

connected to the driving pin. Of course,

any one-to-many mapping can be easily

turned into a many-to-one mapping

simply by reversing the cable ends.

Figure 5d illustrates a many-to-one

pin mapping. This scenario is support-

ed in Stand-Alone mode because each

pin on the drive side has stored a sin-

gle connection in EEPROM. Thus,

pins 1 and 4 will be connected to pin 6.

Naturally, these examples are sim-

plified and, in the real world, will

often be combined. Thus, many-to-

many connections may be found

together with some pins shorted and

others remaining open.

Listing 1—

The

GetCommand()

function is responsible for processing commands received from the host

computer. Two modes are available: the first programs the PIC EEPROM with a received data byte; the sec-

ond initiates a pin test and responds with a test vector.

procedure GetCommand is

var byte adr,

--Write EEPROM address

data

--EEPROM data to write

inbuf = rsGet()

--Looking for Pxx yy<CR> command

if inbuf == "P" then

--Get the EEPROM address

adr = rsGetHex()

if ! CheckNum(adr, 0x7F) then return end if

--Get space character

if ! CheckChar(" ") then return end if

--Get the pin number

data = rsGetNum()

if ! CheckNum(data, 32) then return end if

inbuf = rsGet()

if inbuf != ASCII_CR then

--Error: expecting <CR>

rsPutNak()

return

end if

--Program EEPROM data

if vecProgram(adr, data) then

rsPutOK()

--Programmed location OK

else

rsPutNProg()

--Error: couldn't program EEPROM

end if

--Looking for Txx<CR> command

elsif inbuf == "T" then

data = rsGetNum()

if ! CheckNum(data, 32) then return end if

inbuf = rsGet()

if inbuf != ASCII_CR | data == 0 then

--Error: expecting <CR>

rsPutNak()

return

end if

--Output test vector to pins

pdrvPut(data - 1)

--Scan the inputs

var byte b0, b1, b2, b3

prcvScanAll(b0, b1, b2, b3)

if ! DEBUG then pdrvPut(POWER_LED) end if

--Output the scanned results

rsPut = "V"

rsPutHex(b0)

rsPutHex(b1)

rsPutHex(b2)

rsPutHex(b3)

rsPut = ASCII_CR

--Otherwise we have an error

else

GetCR()

rsPutNak()

end if

end procedure

www.circuitcellar.com

CIRCUIT CELLAR

®

Issue 154 May 2003

21

GETTING SOME RESPECT

These days, if you don’t have a fancy

GUI, nobody gives you any respect.

The PC-based cable-test program was

designed to provide a friendly interface

to define, modify, and download test

cables from a PC and get some respect

from people who’d rather deal with

software than hardware. Another

advantage of the PC-based interface is

that cable-test results can be saved to

disk. This provides a permanent

record of each cable’s test for quality

assurance or audit purposes.

Take a look at Photo 2. After the

program starts, it displays several

panes: four tabbed panes comprising a

definition pane to define the cables; a

download pane to program the PIC

EEPROM with up to four cable defini-

tions; a test pane to remotely test a

selected cable; and a settings pane

that changes some default behaviors

(e.g., where the cable definitions are

stored and which COM port to use

(not working)).

The default cable definition directo-

ry is located in the installation direc-

tory under the name “Cables.” I

wouldn’t advise changing any of the

default settings unless, like me, you

know what you’re doing.

The PC-based software program is

connected via a serial link (9600 bps,

8 bits, no parity, 1 stop bit) to the

cable tester. You may download the

executable for this program from the

Circuit Cellar

ftp site. Installation is

straightforward. The program should

operate on any PC running Windows

95/98 or NT. It has not been tested

under Windows 2000 or XP, but it

should work.

There are some limitations, as well.

Only COM port 1 is currently sup-

ported, because I didn’t have good

serial interface driver routines for

C++. So, I used the default serial class,

which was terrible. Another limita-

tion is that if you’re entering text in

an input string and hit Enter, the pro-

gram will exit.

CABLE BY ANY OTHER NAME

To define a new cable, click on the

Define Cable tab. If preinstalled cables

exist in your Cables directory, they

will appear in the list box as shown in

Photo 2. The pin definitions appear in

another scrolling list to the right of

the cable names. The highlighted

cable’s pins are always shown. If a par-

ticular pin connection is highlighted,

it can be edited by selecting different

To connections in the area below the

pin definitions. Up to two connec-

tions per pin can be selected.

As you know, the cable tester only

understands single-pin connections. It

will happily lock up and die if you try

to download a cable with a double-pin

connection. So, why include this fea-

ture? Well, when using the PC to

remotely test cables, double-pin con-

nections are allowed because the PC

performs the cable test.

Listing 2—

The

TestCable()

function performs the stand-alone cable testing functions. EEPROM test

vectors are compared with the cable to prepare a fault log and, at the test’s conclusion, flash the pin and

status LEDs to give a fault indication.

procedure TestCable (byte in vector) is

var byte tpin,

--Current test vector pin ID

dpin

--Current driving pin ID

--Drive each pin sequentially

pdrvStart()

while ! pdrvDone() loop

--Scan all the inputs

var byte b0, b1, b2, b3

prcvScanAll(b0, b1, b2, b3)

if ! DEBUG then pdrvPut(POWER_LED) end if

--Negate the test vectors

b0 = ! b0

b1 = ! b1

b2 = ! b2

b3 = ! b3

--Look up desired pin connection

dpin = pdrvPin()

tpin = vecLookup(vector, dpin)

rsPut = "V"

rsPutHex(b0)

rsPutHex(b1)

rsPutHex(b2)

rsPutHex(b3)

rsPut = " "

rsPutHex(dpin)

rsPutHex(tpin)

--Test whether the connection is good

if tpin != 0 then

if vecIsSet(tpin, b0, b1, b2, b3) then

vecClrBit(tpin, b0, b1, b2, b3)

rsPut = "T"

else

--Generate an open-circuit error

errSet(OPEN, dpin, tpin)

rsPut = "F"

end if

end if

rsPut = ASCII_CR

var byte vbit = 1

while vbit <= 32 loop

if vecIsSet(vbit, b0, b1, b2, b3) then

errSet(SHORT, dpin, vbit)

end if

vbit = vbit + 1

end loop

pdrvNext()

--Drive the next pin

end loop

end procedure

22

Issue 154 May 2003

CIRCUIT CELLAR

®

www.circuitcellar.com

Michael Griebling graduated from the

University of Waterloo with a BSEE.

He has been designing embedded

hardware, software, and firmware in

the aerospace industry for the past

20 years. Currently, he’s the senior

electrical engineer for the High

Performance Display group at Luxell

Technologies located in Mississauga,

Ontario. His interests include pro-

gramming in obscure computer lan-

guages (e.g., Ada, Oberon-2, JAL, and

Modula-2), learning about neural net-

works and fuzzy logic systems, and

helping with the HCS II. You may

reach him at mgriebling@luxell.com.

To create a new cable, click on the

New Cable button. An empty cable

with all NC connections should

appear highlighted. Change the name

by editing the Cable Name field.

Click on pins to change the pin con-

nections using the pop-up menus

located below the pin list.

When you’re done, you can exit the

program, because cable definitions are

always stored on disk. Be cautious

with older operating systems. They

still may have an eight-character

name limit for files, because the cable

definitions are stored as files in the

Cables directory with the cable name

as the file name. Select a cable to

either delete the entire cable by click-

ing on the Delete Cable button or

clear the pin numbers by clicking on

the Clear Pins button.

GET DOWNLOADING

Click on the Download Cable tab to

view the download pane. The same

cables that were defined will be avail-

able from each of the pop-up menus

for cables 1 through 4.

After the cables to be downloaded

are selected, click on the Download

Cables button to initiate the down-

load to the cable tester. (Don’t forget

to connect the PC to the cable tester.)

A progress indicator will show the

download status. If any cables are left

blank, they will not be downloaded.

REMOTE TESTING

Click on the Test Cable tab to view

the cable-test pane. The same cables

that were defined will be available for

the Cable ID pop-up menu. There are

also two fields used to fill in an opera-

tor’s name and a work order identifier

for cable-test reports that will be kept on

file. A date will be automatically added.

Click on the Test Cable button (it

helps the test to pass if a cable is con-

nected), and a series of pass/fail mes-

sages will appear in the report win-

dow. Wait until the test is completed

(all 32 pins are always tested, even if

only two pins are used), and then click

on the Save Report button to save the

test results to disk. You may down-

load a sample test report from the

Circuit Cellar

ftp site.

THAT’S ALL FOLKS

Although the cable tester program

tour was a bit of a whirlwind, it’s fair-

ly easy to use thanks to the GUI. You

shouldn’t have any problems, but if

any arise, you may reach me via e-

mail. Because of my current workload,

I can’t promise an immediate

response, but I will eventually reply.

The cable tester has been actively

used in my company’s production area

Cable under test

0

1

1

1

1

1

1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

1

1

1

1

1

1

1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

Pin Drive

Vector Pin

Cable under test

0

1

1

1

1

1

1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

1

1

1

1

1

0

1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

Pin Drive

Vector Pin

Cable under test

0

1

1

1

1

1

1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

1

1

1

1

1

0

1

1

0

1

1

1

2

3

4

5

6

7

8

9

10

11

Pin Drive

Vector Pin

Cable under test

0

1

1

0

1

1

1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

1

1

1

1

1

0

1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

Pin Drive

Vector Pin

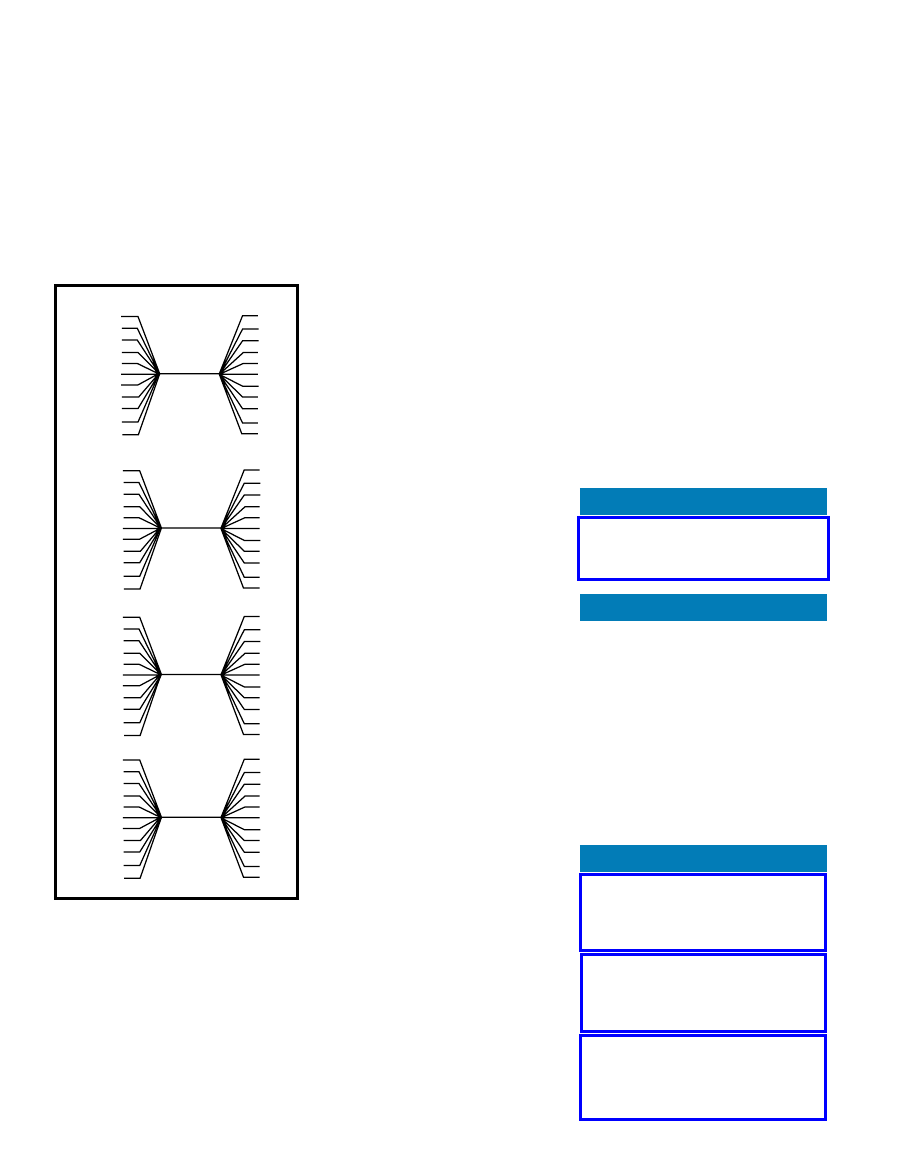

Figure 5a—

If the EEPROM pin number is zero or

open circuit, this result is valid; however, in all other

cases, this would be an open-circuit fault condition.

b—

If the target pin location does not match the inter-

nal EEPROM pin number, an open-circuit fault is gen-

erated.

c—

This pattern cannot be supported in Stand-

Alone mode. When operating with an external host,

checks are performed to determine whether or not

all of the target pins do in fact map to the driving pin.

If a pin is not found, it is flagged as a short circuit.

d—

The tester handles this situation like the one-to-

one mapping where any missing connection is

detected as an open-circuit fault. Any unexpected

connections are logged as short-circuit faults.

a)

b)

c)

d)

PROJECT FILES

REFERENCES

[1] W. van Ooijen, JAL Manual,

1999.

[2] Microchip Technology, Inc.,

PIC16F62X Flash-based 8-bit

CMOS Microcontroller

,

DS40300C, 2003.

[3] National Semiconductor Corp.,

LM2670 Simple Switcher High

Efficiency 3A Step-Down

Voltage Regulator with Sync

,

DS100942, 2000.

SOURCES

PIC16F628 Microcontroller

Microchip Technology, Inc.

(408) 792-7200

www.microchip.com

LM2670 Switching regulator

National Semiconductor Corp.

(800) 272-9959

www.national.com

74HCT138 Decoder

Philips Semiconductors

(800) 326-6586

www.semiconductors.philips.com

for almost a year. So far, no problems

have been reported.

Finally, I would like to thank every-

one at Luxell for helping to make this

project possible. Happy testing!

I

Flash

Facts

$49

.95

($199 Value)

Now for a limited time

ZiLOG redefines 8-bit with the new Z8 Encore!

™

family

of flash microcontrollers that simplifies your development

process, increases design productivity and gives you

more functionality than any other 8-bit MCU in history.

But don’t take our word for it.

Visit us at www.zilog.com/Z8encore2 or

call us at 866-498-3626 and receive our complete

development kit for only $49.95.

Act now because when this special introductory

offer ends, the kit will sell for $199.95!

Z8 Encore!

™

will be available in all standard flash memory

configurations from 4K to 64K. Incorporated into new

designs or upgrading from existing 8-bit (including Z8

®

)

architectures, this next-generation MCU has features

and performance that leaves the competition in the dust.

The Z8 Encore!

™

Test Drive Kit Includes

Hardware

• Evaluation Board

• Target Interface Module Board

• Serial Cable

• Universal Power Supply

Software

• ZDS II IDE with full

version C-compiler

• Sample Code

• Device Drivers

• Documentation CD

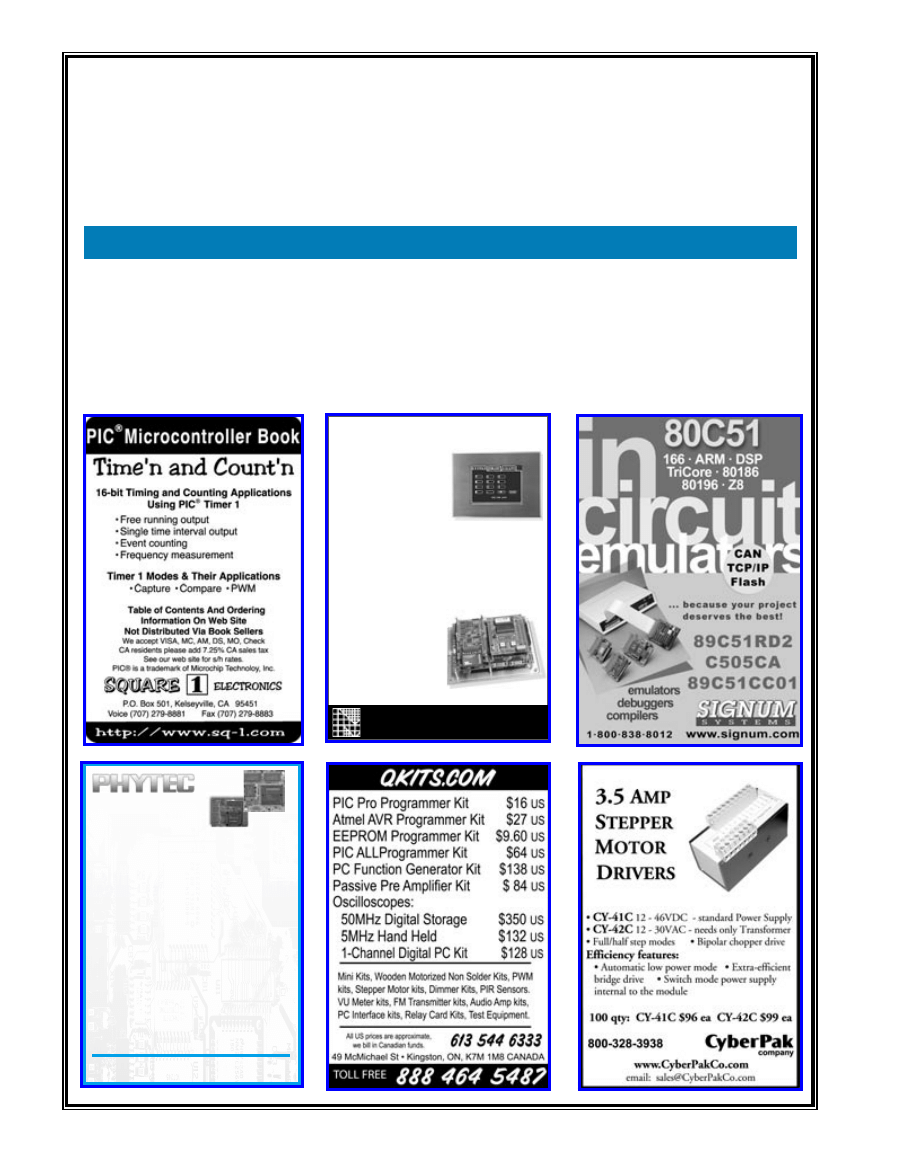

The New Z8 Encore!

™

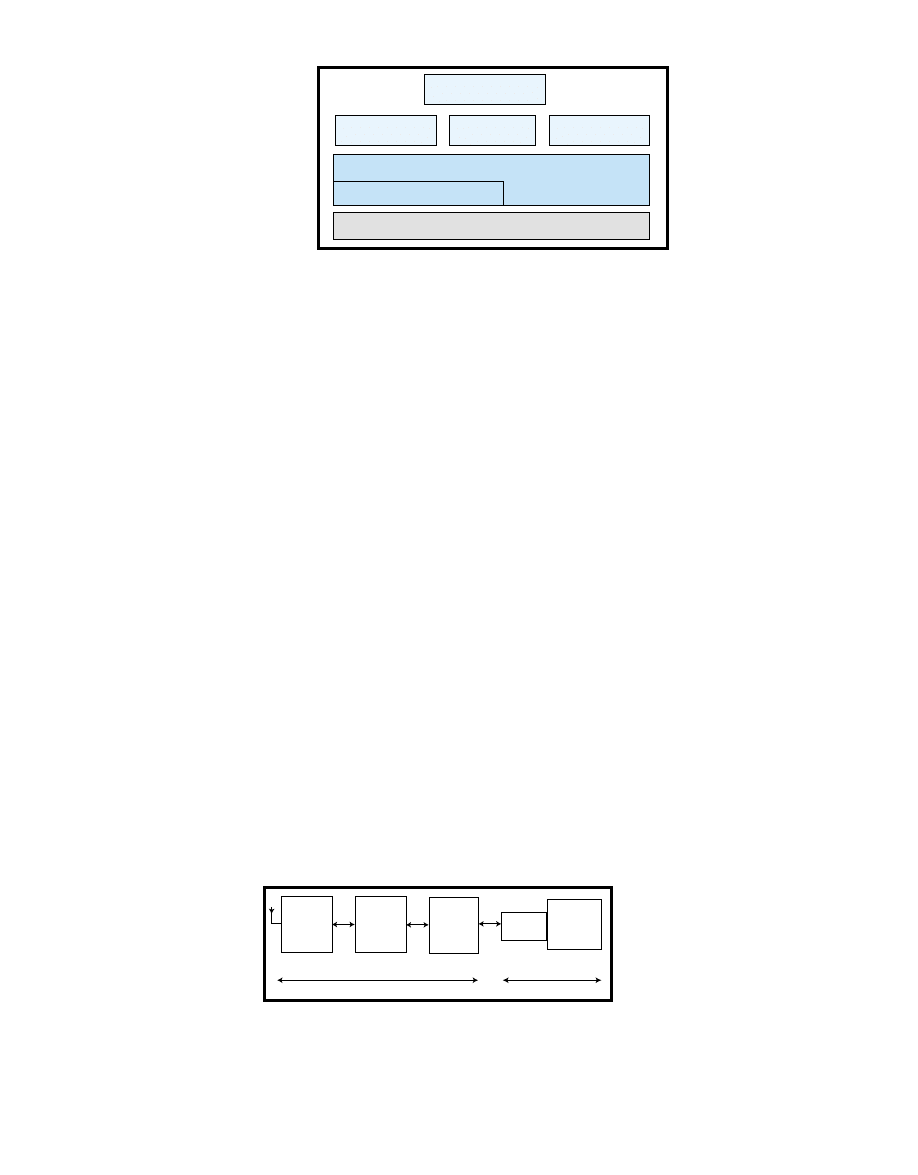

MCU Block Diagram

10-bit A/D

Converter

Port A Port B Port C Port D Port E Port F Port G Port H

16-bit Timer

w/PWM

16-bit Timer

w/PWM

16-bit Timer

w/PWM

16-bit Timer

w/PWM

I

2

C

SPI

UART 0

UART 1

Watch-Dog

Timer

Crystal

Oscillator

Register File

4K X 8

DMA

Controller

Interrupt

Controller

eZ8

20MHz

CPU

Reset

Control

On-Chip

Debugger

Flash

Program

Memory

64K X 8

THE

THE

Z8

ENCORE!

™

ZiLOG, Z8 Encore! and Z8 are trademarks or registered trademarks of Zilog Inc. in the United States and in other countries. Other logos, product names and service names mentioned herein may be trademarks of the companies with which they are associated.

This comparison is valid as of 9/27/2002.

FEATURE

ZILOG

MOTOROLA

ZILOG

MOTOROLA

Z8F6403

MC68HC908AS60A

Z8F3202

MC68HC908GP32

Actual CPU Speed

20MHz

8MHz

20MHz

8MHz

On board DMA

Yes

No

Yes

No

High Speed Flash

64K

60K

32K

32K

SRAM

4K Bytes

2K

Bytes

2K Bytes

512

Bytes

A/D Converter

10-bit

8-bit

10-bit

8-bit

SPI & I

2

C

Both

No

I

2

C

Both

No

I

2

C

UARTs

2 (9-bit)

1

(8-bit)

2 (9-bit)

1

(8-bit)

16-bit Timers

4

Multi-mode 2

Multi-channel

4

Multi-mode 2

Multi-channel

Independent

Synchronous

Independent

Synchronous

Timers

Timers

Timers

Timers

24

Issue 154 May 2003

CIRCUIT CELLAR

®

www.circuitcellar.com

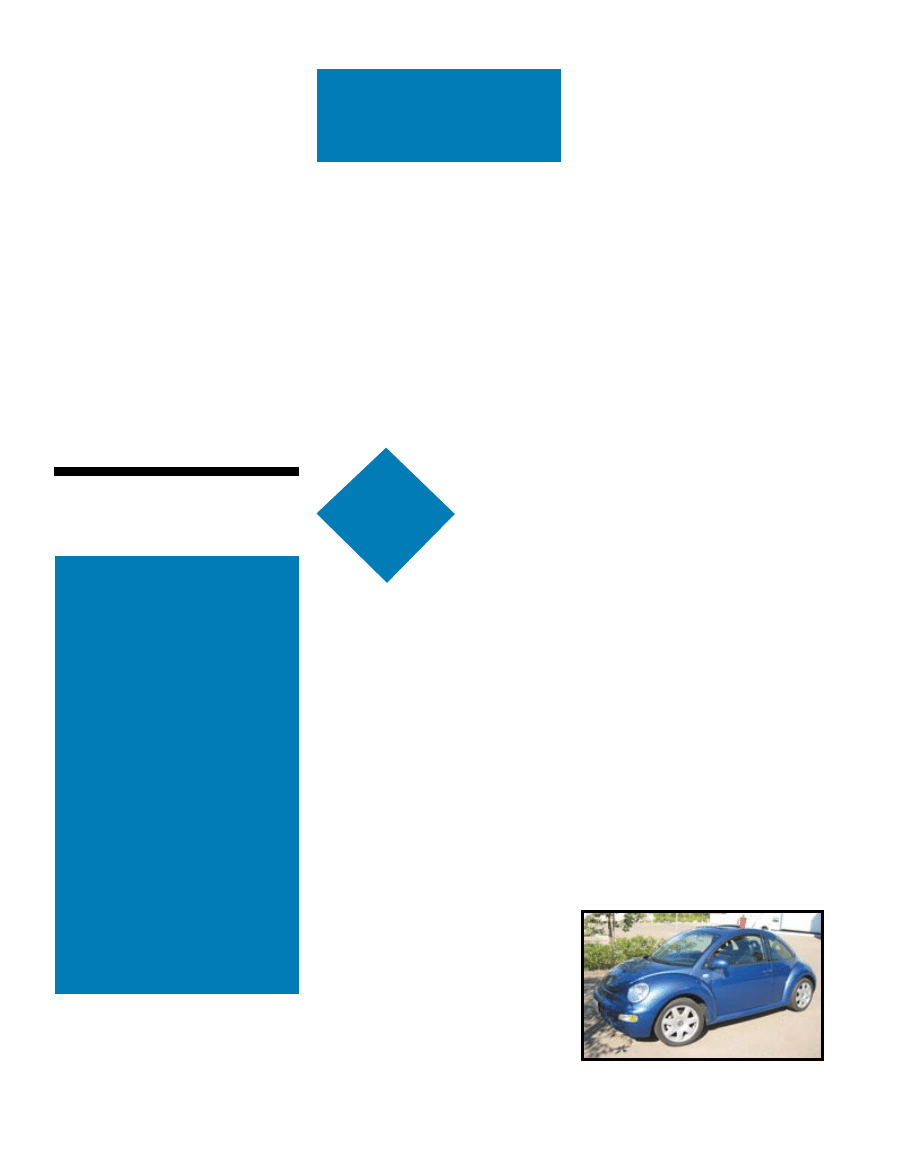

t was time to

buy a new car. Oh,

I probably could have

squeezed another

10,000 miles out of my old ride, but

quite honestly, I had become bored

with it. I was tired of sitting every day

in the same old interior, hearing the

same old creaks and rattles. I wanted

something new, something exciting,

and something, well, different.

So, being your typical obsessive

engineer, I pored over mountains of

brochures, bought stacks of car maga-

zines, and clicked through hundreds

(perhaps thousands) of on-line road

tests in search of the perfect vehicle. I

analyzed stopping distances and safety

ratings, and evaluated cornering val-

ues and slalom times. These figures

and more were charted, noted, and

mulled over again and again. But

unbeknownst to me, my decision had

been made for me several weeks

before—by my teenage daughter.

“Dad, you have to get a New Beetle.

They’re so cute!” she pressed, signifi-

cantly pruning my decision tree to one

of mere price, color, and interior.

“No dad, you have got buy the

blue one.”

OK, price and interior. Well, at

least it was different.

Not long after my purchase (I

ordered the blue lagoon paint option

with black leather seats), I began won-

dering how the car’s performance fig-