166 Introduction - AIR CONDITIONING CASING AND COMPONENTS

CLIMATE CONTROL WITH AUTOMATIC TEMPERATURE CONTROL

Presentation

The climate control system is the following type:

automatic temperature - ventilation - distribution control

with recirculation

with direction of the flows.

The user can select the desired air flow and temperature.

A special control unit manages the operation of the system.

The control unit implements the thermaladjustment according to the signals received from the:

outside air temperature sensor

inside air temperature sensor

vent outlet treated air temperature sensors

solar radiation sensor

According to the signals received, operates the following are operated to reach and maintain a comfortable temperature inside the

passenger compartment:

mixture actuator

recirculation actuator

distribution actuator

electric fan

compressor.

In addition, the control unit operates the heated rear windscreen via the integrated services control unit.

The climate control system basically consists of:

air intake unit

air filter unit

electric fan

air conditioning unit

mixture unit

heater unit

distribution unit.

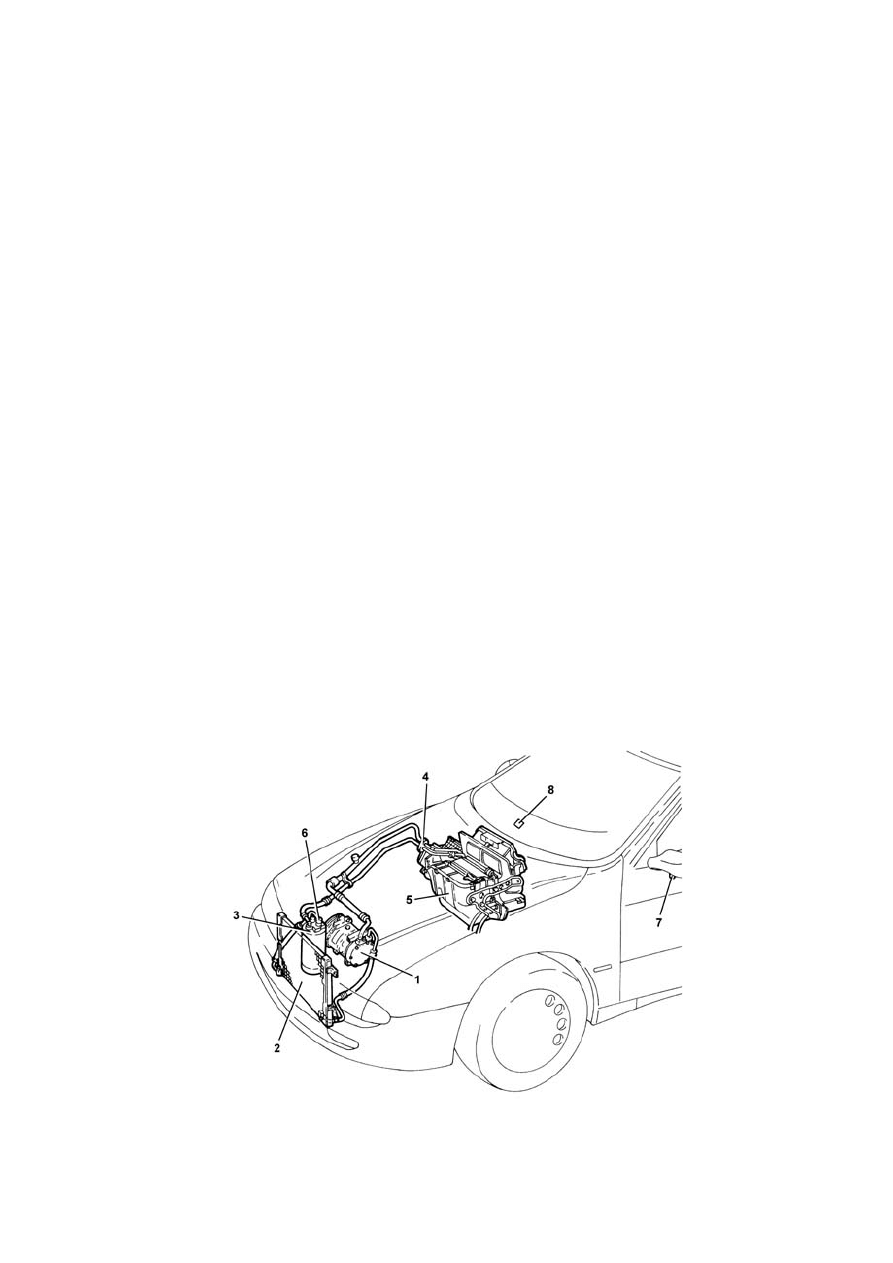

1, Air conditioning compressor

2, Air conditioning condenser

3, Drier filter

4, Expansion valve

Strona 1 z 9

eLearn - Contents

2010/10/14

file://F:\alfa\eLearn\Web\tempcontent2.html

5, Evaporator unit

6, 4 stage pressure switch

7, Outside air temperature sensor

8, Solar radiation sensor

Air intake unit

The air intake unit makes it possible to:

let outside air enter the passenger compartment

circulate the air inside the passenger compartment.

An actuator, controlled by the control unit, moves the air intake flap into the two different positions.

Air filter unit

This consists of a filter which makes it possible to reduce pollution, pollen and some unpleasant odours.

Ventilation unit

This consists of a brushles motor which, depending on the voltage applied to the inlet circuit, regulates the speed of the fan and

consequently the air flow rate.

Air conditioning unit

It consists of:

a compressor

an expansion valve

an evaporator

a condenser

a drier filter

pipes

a 4 stage pressure switch

It makes it possible to cool and/or dehumidify the air introduced into the passenger compartment.

Mixture unit

It consists of special flaps and ducts which allow the temperature of the air introduced into the passenger compartment to be controlled.

Heater unit

It consists of a radiator supplied by the engine coolant which allows the air introduced into the passenger compartment to be heated.

Distribution unit

It consists of a series of flaps and ducts with special vents.

It allows the air to be distributed to the various parts of the passenger compartment.

Climate control controls

The user interface, integrated in the ICS system, for the climate control system consists of:

controls

a monitor with a colour display.

The climate control system controls appear on a single page by pressing the "CLIMA" button.

The following are displayed:

internal temperature set (in ° C or in °F)

fan setting symbol

air distribution symbol (windscreen, centre of vehicle, floor)

defrost symbol (defrost ventilation activated/deactivated)

recirculation symbol (recirculaion activated/deactivated)

"MANUAL" or "AUTO" or "FULL AUTO" warning for modification of manual setting or automatic operation.

Operating logics

Starting transition

This logic is designed so as not to create problems for the user (cold air jets and/or demisting of the front window) in certain temperature

conditions during starting.

Strona 2 z 9

eLearn - Contents

2010/10/14

file://F:\alfa\eLearn\Web\tempcontent2.html

During the starting transition with "FULL AUTO" operation, the following functions are implemented:

initial air distribution to "FLOOR" and then "DEF"

air mixture flap completely open (maximum heat)

recirculation air flap in "dynamic air" position

compressor enabled

increasing variation in the air flow rate until a level calculated by the control unit is reached.

This logic is interrupted by possible requests for:

maximum cold (LO)

maximum heat (HI)

defrost (FRONT).

Maximum heat request (hi)

This is activated by setting a temperature value above 28° C corresponding to "HI".

To satisfy this requirement the system exits from the automatic control of the thermal adjustment ((FULL AIUTO) and modifies the

system functions as described below:

air mixture flap completely open (maximum heat).

automatic air distribution: distribution flaps in "FLOOR" position

manual air distribution: position of distribution flaps dependent on the preselected setting.

automatic ventilation: maximum permissible flow rate

manual ventilation: with flow rate corresponding to that preselected.

The interruption of the ventilation function takes place when the key is turned to the OFF position, or when the "OFF" button is operated

or when the "defrost" button is operated.

Maximum cold request (lo)

This is activated by setting a temperature value below 16° C corresponding to "LO".

To satisfy this requirement the system exits the automatic thermal adjustment control (FULL AUTO) and modifies the system functions as

follows:

air mixture flap completely closed (maximum cold)

automatic air distribution: distribution flaps in "VENT" position

manual air distribution: distribution flaps position dependent on the preselected setting.

automatic ventilation: maximum permissible flow rate

manual ventilation: flow rate corresponding to that preselected.

recirculation: air intake flap forced into recirculation position.

The interruption of the recirculation function occurs if the ignition is turned to the OFF position or if the "OFF" button is operated or if the

"defrost" button is operated.

Defrost request

It is activted using the "FRONT" button and manages the air flow rate depending on the temperature of the treated air coming out of the

vents designed to demist the windows inside the passenger compartment.

The management of the defrost involves the system functions as described below:

compressor enabled.

air distribution initially to "FLOOR" and then "DEF".

air mixture flap completely open (maximum heat)

Ventilation: the management of the automatic air flow rate depends on the temperature of the treated air.

recirculation: the air intake flap is forced into the dynamic position.

heated rear windscreen management: the heated rear windscreen is activated by the integrated services electronic control unit, in

accordance with an operating logic (see DESCRIPTIONS AND OPERATION: Integrated multiservices control unit - 5505).

This function is interrupted by operating the "OFF" button.

- maximum cold (LO)

- maximum heat (HI).

"full-auto" operation request

The completely automatic thermal adjustment control is implemented by pressing the AUTO button with the temperature setting between

16° C and 28° C.

"auto" operation request

The partial thermo-dynamically controlled thermal adjustment is implemented by:

The defrost function has priority over the following request:

Strona 3 z 9

eLearn - Contents

2010/10/14

file://F:\alfa\eLearn\Web\tempcontent2.html

pressing the AUTO button with the temperature setting between 16° C and 28° C and

modifying one of the following parameters: air flow rate, air distribution and recirculation.

This function is interrupted by operating:

the "OFF" button

by the maximum heat request (HI)

by the maximum cold request (LO)

Compressor engagement

The compressor is enabled with the:

evaporator temperature close to 5 ° C

defrost function selected

recirculation function switched off and outside temperature above 5 ° C.

The compressor is disabled with the:

recirculation function engaged and the outside temperature below - 5 ° C

recirculation function switched off and the outside temperature 3 ° C.

The compressor can also be switched off by operating the multi-stage pressure switch controlling the circuit or by the injection/ignition

control unit (see DESCRIPTIONS AND OPERATION: Injection/ignition system - 1056).

System components

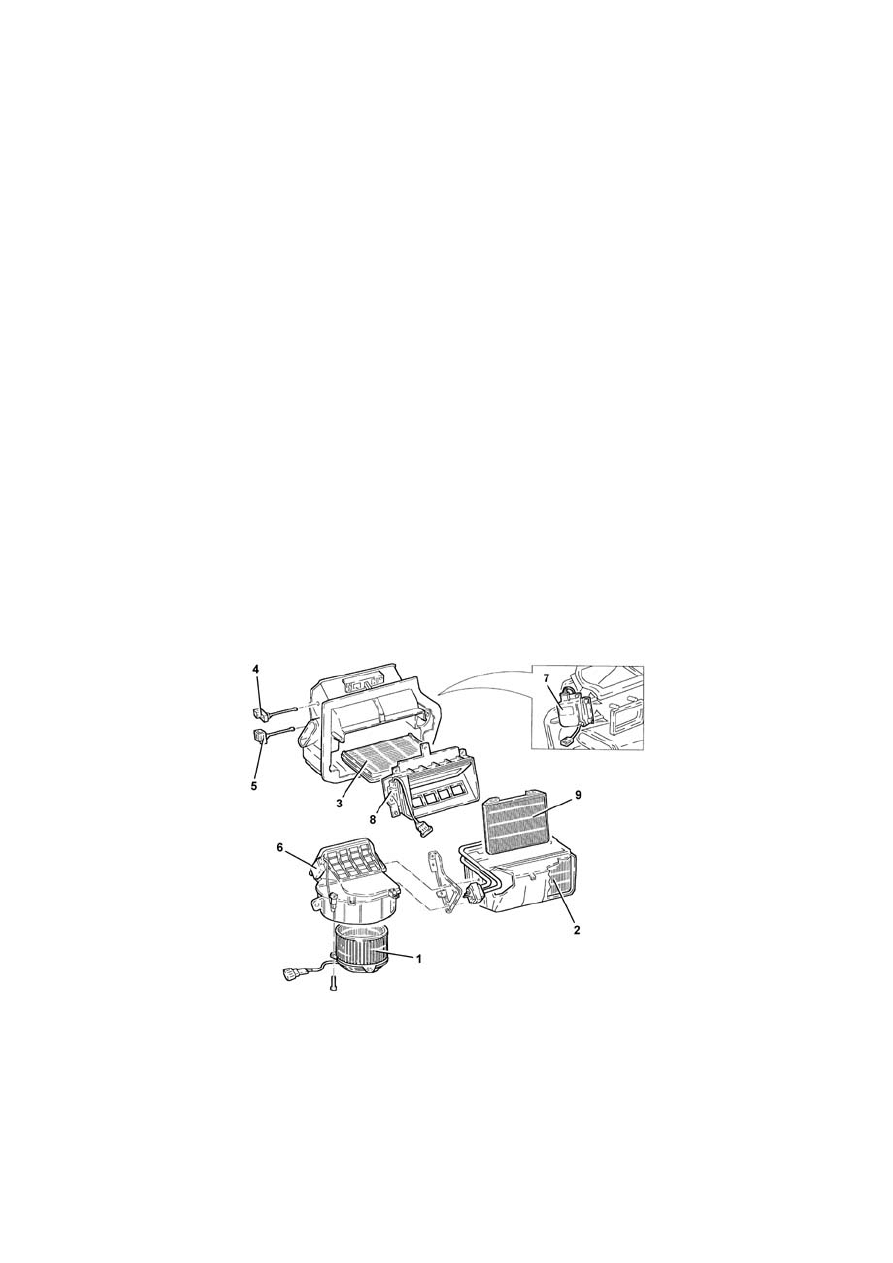

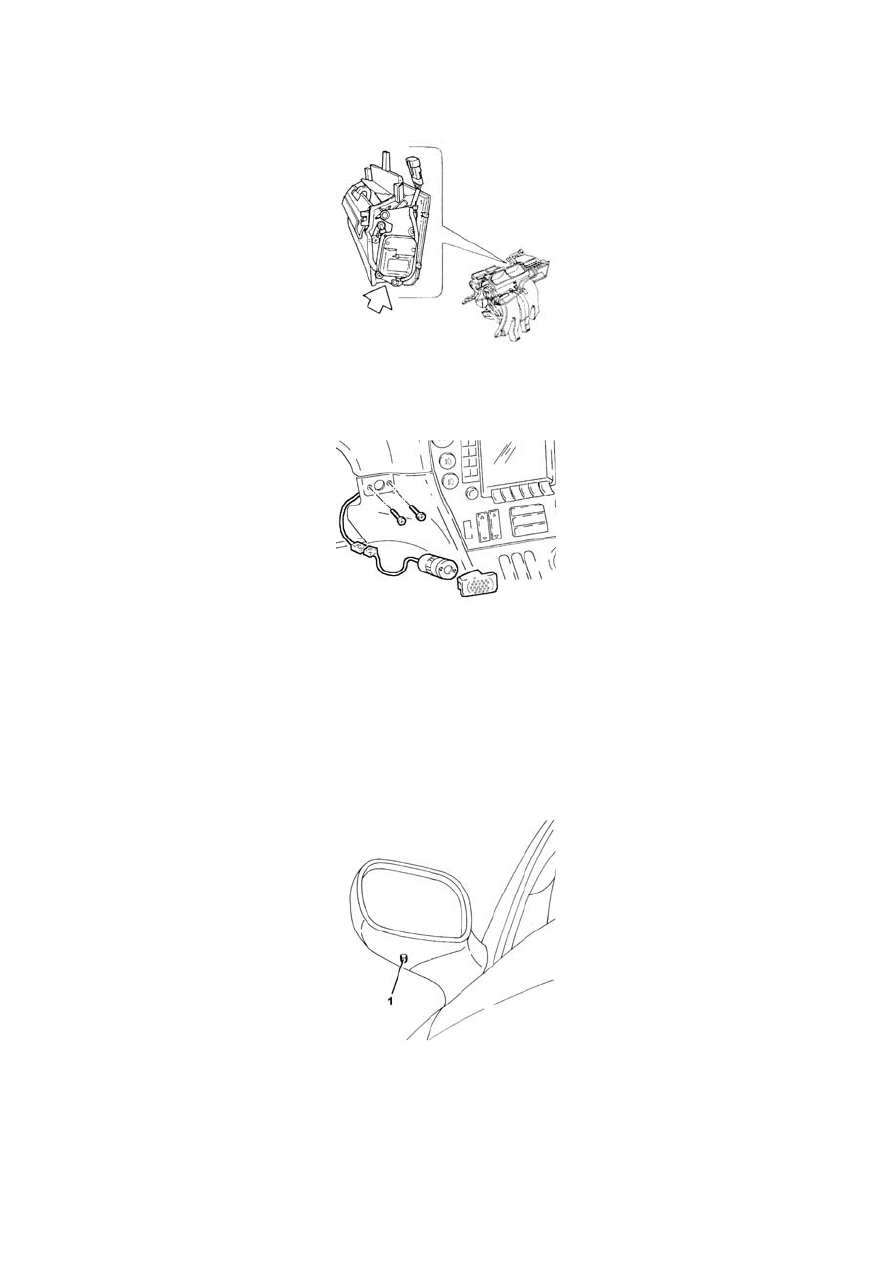

Duct/distributor unit

This consists of three modules which inside contain:

the electric fan

the evaporator

the heater radiator

Upper mixed air temperature sensor

Lower mixed air temperature sensor

All the flaps are operated by special actuators controlled by the control unit.

1, Electric fan

2, Evaporator

3, Heater radiator

4, Upper mixed air temperature sensor

5, Lower mixed air temperature sensor

6, Outside/recirculation air flap actuator

7, Air distribution flaps actuator

8, Mixed air flaps actuator

9, Combined filter element

Air distribution

Strona 4 z 9

eLearn - Contents

2010/10/14

file://F:\alfa\eLearn\Web\tempcontent2.html

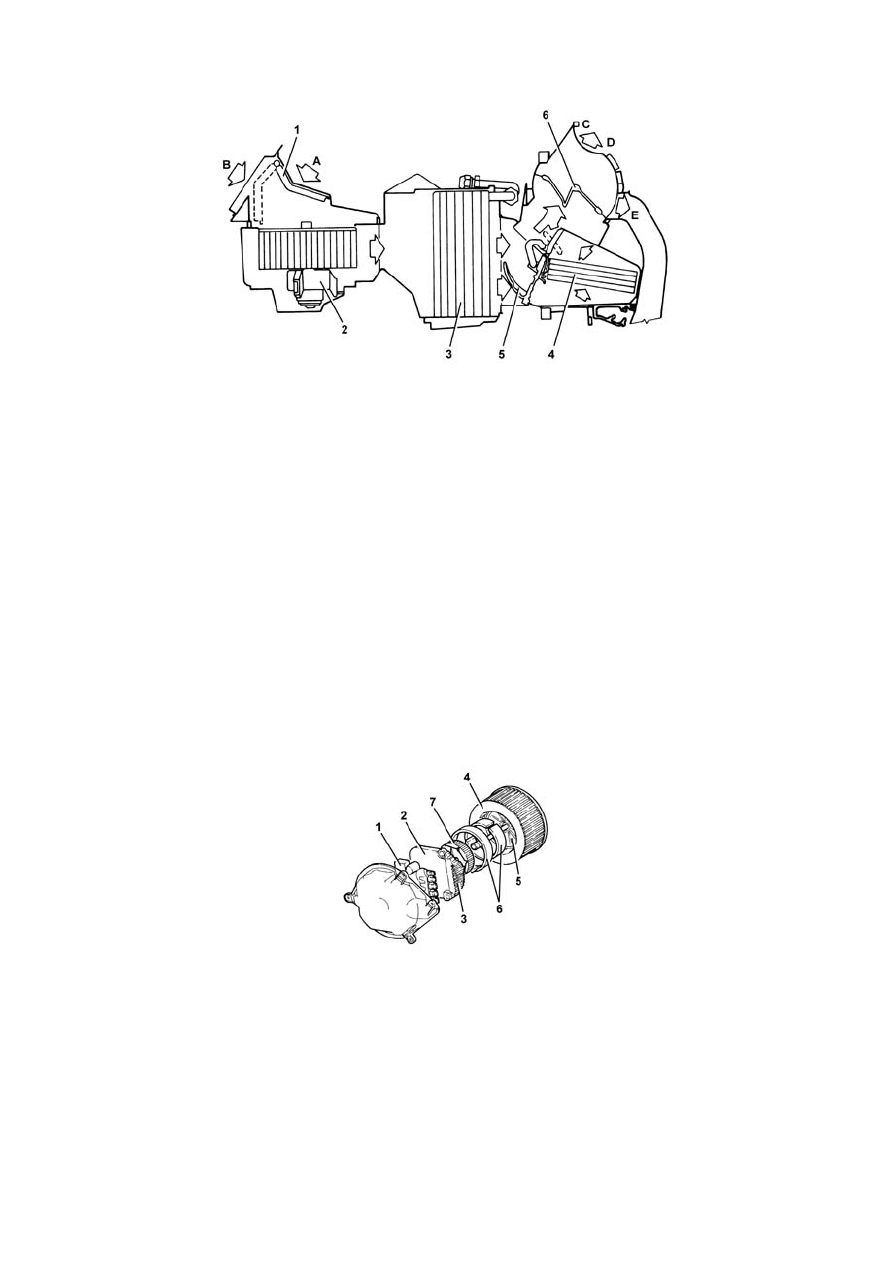

1, Intake/recirculation air flap

2, Electric fan

3, Evaporator

4, Heater radiator

5, Mixed air flap

6, Air distribution flap

A, Recirculation air flow

B, Outside air flow

C, Windscreen/side windows air flow

D, Centre and side vents air flow

E, Lower and rear vents air flow

Electric fan

The ventilation unit is made up of a brushless type direct current motor which, by means of the voltage applied to the intake circuit,

makes it possible to control the fan speed and consequently the air flow rate using a PWM signal.

The lack of brushes and commutator allows:

a reduction in inertia and wear

the lack of electrical and mechanical leaks

improved reliability, power and acceleration for the same torque.

The absence of the commutator eliminates problems of discharges between the terminals; the function of the commutator is carried out

by an external electronic switching circuit which produces the current in the induction winding.

There are less vibrations with this type of motor and lower consumption than compared with traditional linear control motors.

1, Electronic components inserted in an impermeable system

2, Card for electronics and connections

3, Support for motor and semiconductor heat dissipator

4, Centrifugal fan with high output and low noise

5, Motor cooling fan

6, Rotors with ferrite magnets

7, Laminated stator and winding

Combined filter element

The air introduced into the passenger compartment from the outside passes through a combined filter, i.e. consisting of two layers:

the first "particle" layer has the task of trapping the small particles of fine dust and pollen

Strona 5 z 9

eLearn - Contents

2010/10/14

file://F:\alfa\eLearn\Web\tempcontent2.html

the second "active charcoal" layer is designed to trap certain pollutant elements (odours) in the atmosphere.

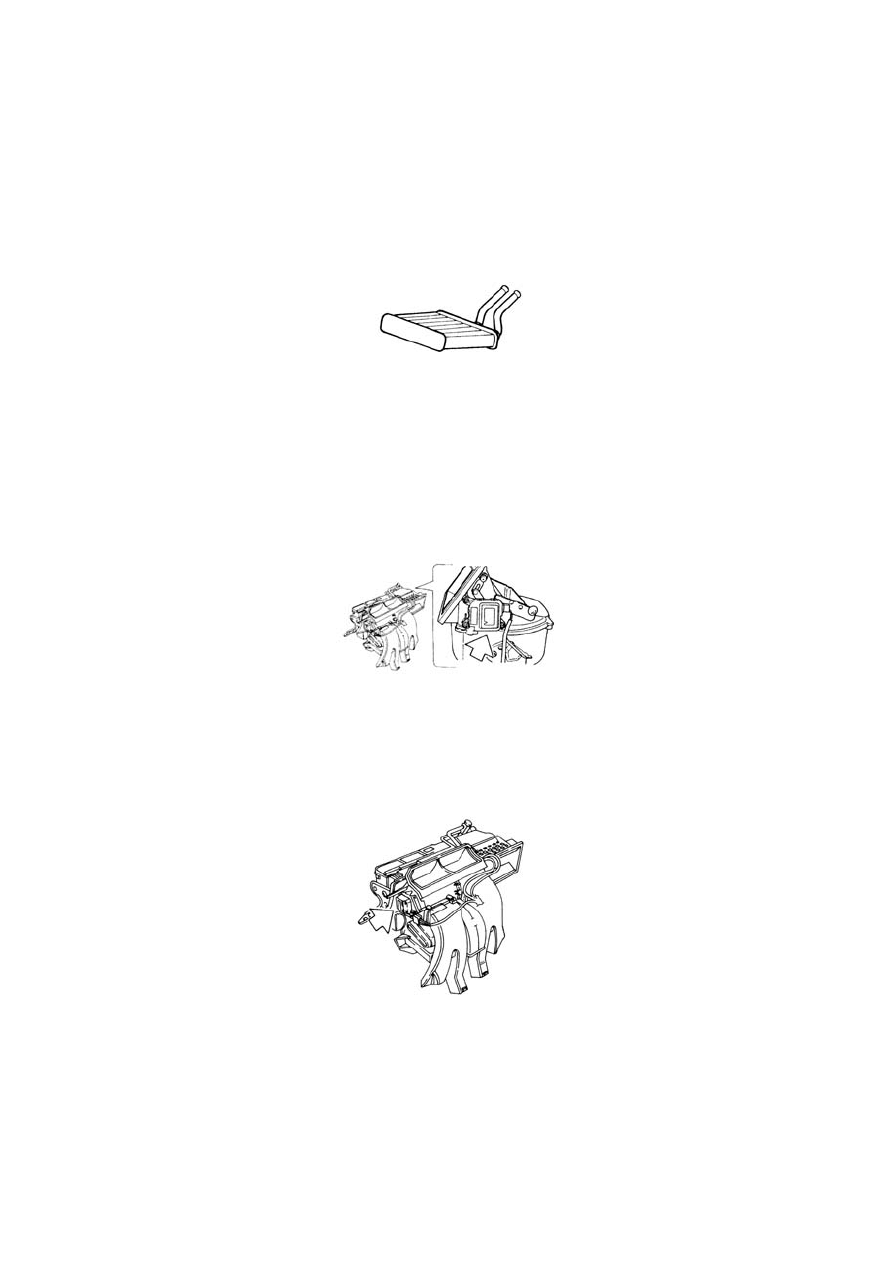

Heater radiator

This is a heat exchanger connected to the engine cooling circuit by means of special pipes: - one draws in hot water from the engine and

allows the heating of the air introduced into the passenger compartment

- one allows the return of the coolant to the engine.

Outside/recirculation air flap actuator

This activates the rotation of the outside/recirculation air flap in the two extreme position "dynamic air" and "recirculation" without an

intermediate position, through the command received from the electronic control unit.

A motor controls the rotary movement of a drive pin which acts directly on the flap.

It receives a 12 V supply and if the polarity is reversed, it is possible to rotate it in a clockwise or an anti-clockwise direction.

The actuator is not fitted with a feedback potentiometer and therefore it is controlled by the control unit by checking the current

absorption.

Air distribution flaps actuator

This operates the rotation of the two air distribution flaps according to the command from the electronic control unit.

A motor controls the rotary movement of a drive pin which acts directly on the flaps if supplied with a variable duty-cycle signal.

A potentiometer detects the effective position and acts with feedback to the control unit checking the complete travel between the

extreme positions.

Mixed air flaps actuator

It operates the rotation of the two mixed air flaps according to the command from the electronic control unit.

A motor controls the rotary movement of a drive pin which acts directly on the mixture flaps if supplied with a duty-cycle signal.

A potentiometer detects the effective position and acts with feedback to the control unit checking the complete travel between the

extreme positions.

Strona 6 z 9

eLearn - Contents

2010/10/14

file://F:\alfa\eLearn\Web\tempcontent2.html

Passenger compartment air temperature sensor

It is an NTC sensor (R = 2.2 kOhm at 25 ° C).

The sensor is "ventilated", i.e. it incorporates a small fan (operated by a brushless motor).

The latter is always supplied so that the temperature reading is not affected by the hot air inside the dashboard.

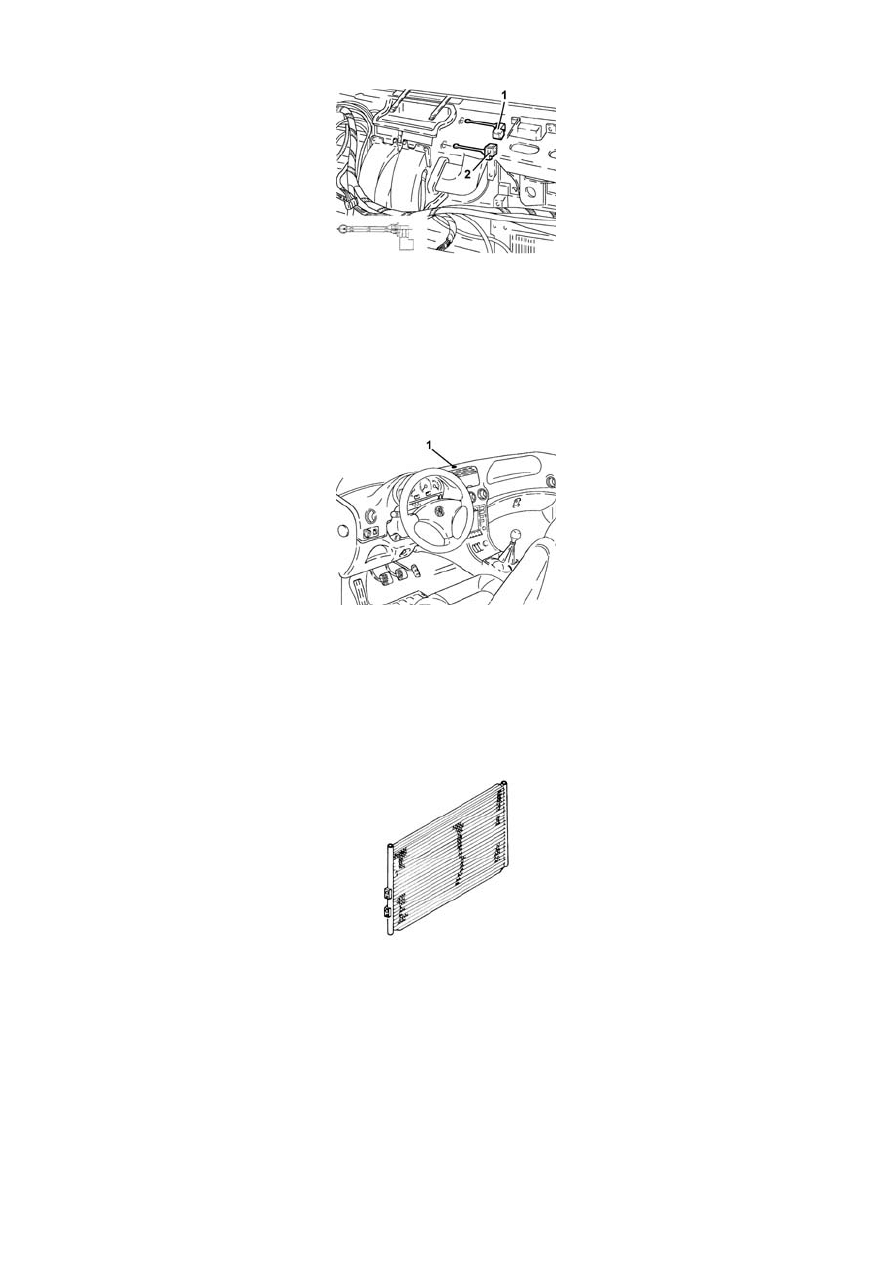

Outside air temperature sensor

This is an NTC type sensor fitted on the left external rear view mirror.

Specifications:

R = 100 Kohm at - 20 ° C

R = 55 Kohm at - 10 ° C

R = 32.625 Kohm at 0 ° C

R = 20 Kohm at + 10 ° C

R = 12.5 Kohm at + 20 ° C

R = 8 Kohm at + 30 ° C

R = 5 Kohm at + 40 ° C

1, Outside air temperature sensor

Mixed air temperature sensors

These are NTC type sensors and differ only through their colour.

Strona 7 z 9

eLearn - Contents

2010/10/14

file://F:\alfa\eLearn\Web\tempcontent2.html

1, Upper mixed air temperature sensor

2, Lower mixed air temperature sensor

Specifications:

R = 42.326 Kohm at - 5 ° C

R = 32.650 Kohm at 0 ° C

R = 19.899 Kohm at + 10 ° C

R = 12.492 Kohm at + 20 ° C

R = 8.057 Kohm at + 30 ° C

Solar radiation sensor

It is the photodiode type and is located in the dashboard, near the windscreen.

1, Solar radiation sensor

Air conditioning condenser

This is a heat exchanger positioned in front of the engine radiator.

The structure is the coil type. Each individual pipe contains up to 14 fluid ducts.

The coolant, in a gaseous state, passes through the condenser pipes and liquefies (at an average temperature of 60° C).

The outside of the condenser comes into contact with the air produced by the vehicle moving forwards. When the vehicle is stationary or

driving in traffic, the air is produced by the same fan used by the engine radiator.

An insufficient heat exchange in the condenser increases the pressure in the system and causes the incomplete condensation of the fluid

with a considerable reduction in the efficiency of the system.

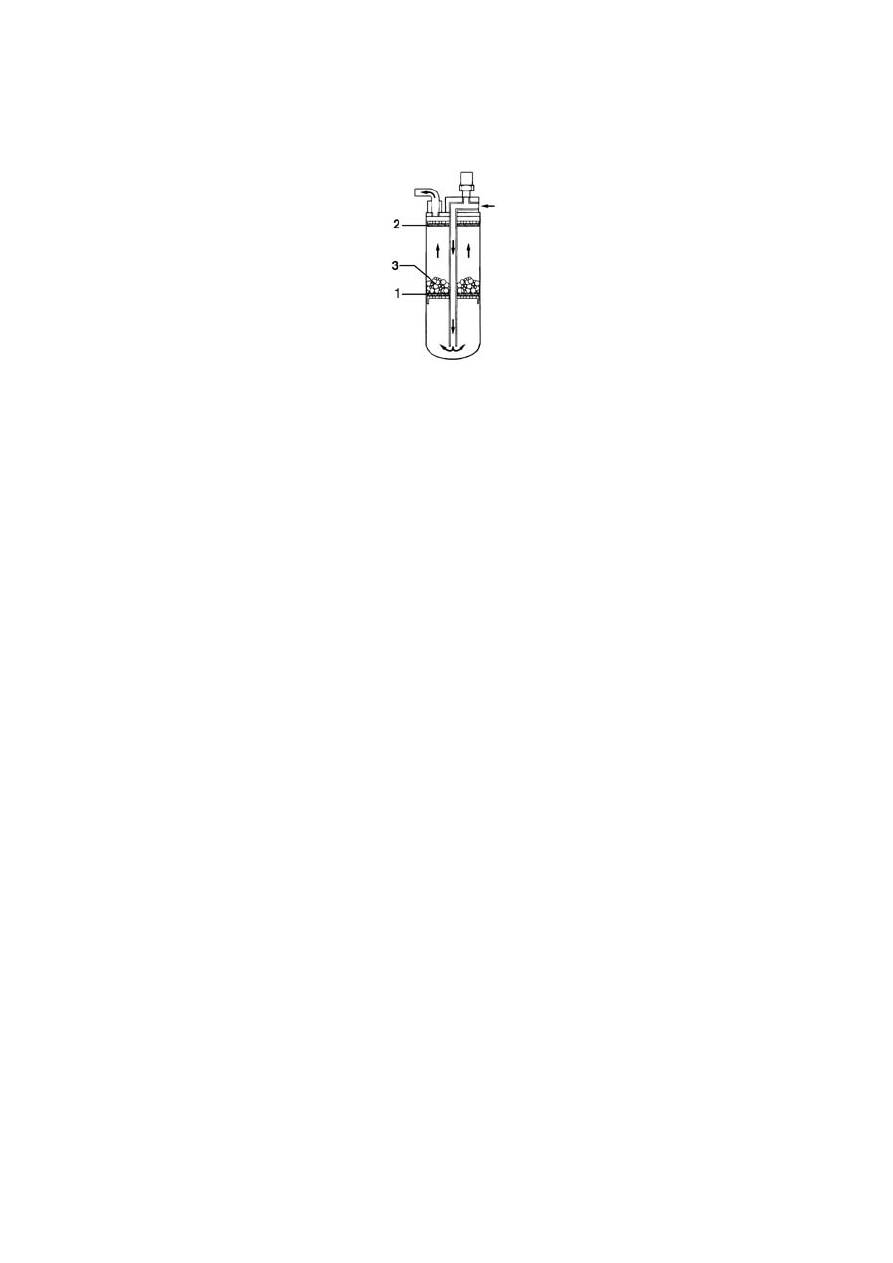

Drier filter/accumulator

It is fitted on the pipe between the condenser and the expansion valve and mainly acts:

as an accumulator for the coolant

as a filter element

as a drying element.

The filter accumulates the majority of the system coolant (in a liquid state) and separates the coolant in a liquid state from that in a

gaseous state.

Humidity in the system can be extremely damaging because:

if it comes in contact with the coolant it produces chloride and fluoride acids which corrode the system components and cause

them to deteriorate

Strona 8 z 9

eLearn - Contents

2010/10/14

file://F:\alfa\eLearn\Web\tempcontent2.html

it causes the formation of ice in the expansion valve.

There are substances inside the filter (SILICAGEL and activated aluminium) which absorb the moisture in the coolant.

For this reason the filters and all the system components should be stored in a dry atmosphere with all the connectors sealed until they

are fitted.

1, Filtering layer

2, Filtering layer

3, Silicagel

Strona 9 z 9

eLearn - Contents

2010/10/14

file://F:\alfa\eLearn\Web\tempcontent2.html

Wyszukiwarka

Podobne podstrony:

Prawo cywilne - opis terminów, Elementy Prawa

Opis zajęć.elementy soc, Dziennikarstwo i komunikacja społeczna (KUL) I stopień, Rok 1, semestr 1, E

opis klimatyzacji

niemiecki opis klimatu

Elementy klimatu

klimatex venta airwasher opis czesci

Producenci i dystrybutorzy nawiewnikow i innych elementow wentylacyjnych, Pomoce naukowe, Wentylacja

Lazarus opis elementów

Lazarus opis elementów

Elementy automatyki stosowane w nowoczesnych centralach wentylacyjnych i klimatyzacyjnych ( Politech

anemometr, Inżynieria środowiska, inż, Semestr II, Meteorologia z elementami klimatologii, laborator

Opis zawodu Mechanik klimatyzacji

Wiatromierz Wilda, Inżynieria środowiska, inż, Semestr II, Meteorologia z elementami klimatologii, l

Cisnienie atmosferyczne-referat 5, Inżynieria środowiska, inż, Semestr II, Meteorologia z elementami

Anemometr (2), Inżynieria środowiska, inż, Semestr II, Meteorologia z elementami klimatologii, labor

Wiatromierz Wilda, Inżynieria środowiska, inż, Semestr II, Meteorologia z elementami klimatologii

Psychrometr Assmana, Inżynieria środowiska, inż, Semestr II, Meteorologia z elementami klimatologii

Badanie i naprawa elektronicznych elementów klimatyzacji

Zasada działania, Zasada działania i opis elementów rębaka

więcej podobnych podstron