®

C18 ACERT

™

448 bkW / 600 bhp

1750 rpm

Industrial

Image shown may not reflect

actual engine

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore......................................................145.0 mm (5.71 in)

Stroke.....................................................183.0 mm (7.2 in)

Displacement.................................... 18.1 L (1,104.53 in3)

Aspiration...............................Turbocharged Aftercooled

Compression Ratio...................................................16.3:1

Rotation (from flywheel end).............. Counterclockwise

Weight, Net Dry (approximate kg. lb).. 1673 kg (3688 lb)

FEATURES

Emissions

Meets U.S. EPA Tier 3, EU Stage IIIA and China

Stage II emissions requirements. FM approved. UL

approved - US and Canada. Meets NFPA 20

requirements.

Worldwide Supplier Capability

Caterpillar

- Casts engine blocks, heads, cylinder liners, and

flywheel housings

- Machines critical components

- Assembles complete engine

- Factory-designed systems built at Caterpillar ISO

9001:2000 certified facilities

Ownership of these manufacturing processes

enables Caterpillar to produce high quality,

dependable product.

Testing

Prototype testing on every model:

- proves computer design

- verifies system torsional stability

- functionality tests every model

Every Caterpillar engine is dynamometer tested

under full load to ensure proper engine

performance.

Full Range of Attachments

Wide range of bolt-on system expansion

attachments, factory designed and tested.

Unmatched Product Support Offered Through

Worldwide Caterpillar Dealer Network

More than 1,800 dealer outlets

Caterpillar factory-trained dealer technicians service

every aspect of your industrial engine

99.7% of parts orders filled within 24 hours

worldwide

Caterpillar parts and labor warranty

Preventive maintenance agreements available for

repair before failure options

Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to

determine:

- internal engine component condition

- presence of unwanted fluids

- presence of combustion by-products

Web Site

For all your industrial power requirements, visit

www.cat-industrial.com.

2 November 2009

4:29 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

448 bkW (600 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System

Dual turbocharger: front and rear inlet, 237.0 mm (5

in)

Separate Circuit Aftercooled (SCAC)

Charging System

Charging alternator 24 volt, 50 amp

Control System

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation

Power compensation for fuel temperature

Programmable low and high idle and total engine

limit (TEL)

Electronic diagnostics and fault logging

Engine monitoring and protection system (speeds,

temperature, pressure)

J1939 Broadcast (diagnostic, engine status and

control)

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, gear driven, centrifugal

Heat exchanger (installed)

Expansion tank

Exhaust System

Exhaust manifold, dry

Dual turbo: exhaust elbow, dry 203 mm (8 in)

Flywheels and Flywheel Housing

Flywheel, SAE #1

Flywheel housing, SAE #1

SAE standard rotation

Fuel System

Electronic unit injector

Fuel filter, secondary, mid-mount (LH 2 micron high

performance)

Fuel transfer pump, LH front

Fuel priming pump, LH mid-mount

Fuel sample valve, mounted on fuel filter base

Primary filter / water separator

Instrumentation

Instrument panel, LH

Engine oil pressure gauge

Voltmeter gauge

Water temperature gauge

Tachometer / engine hour meter

Lube System

Crankcase breather, front valve cover

Oil cooler, RH (dual)

Oil filter, RH

Oil pan, front sump

Oil filler, LH front

Oil dipstick, LH front

Oil pump

Mounting System

Front and rear support

Power Take-Offs

Flywheel and stub shaft

Protection System

Stop-Start System, automatic (compatible with

NFPA 20 requirements, able to be energized from

either of two battery sources and capable of manual

starter actuation)

Starting System

24 volt, LH electric starting motor

Jacket water heater (3 kW, 120-240 volt)

General

Vibration damper and guard

Paint, Caterpillar fire pump red

Lifting eyes

Automatic variable timing, electronic

Electronic installation kit, 70 pin connector

(connectors, pins, sockets)

Literature, Owner and Operator's Manual

2

2 November 2009

4:29 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

448 bkW (600 bhp)

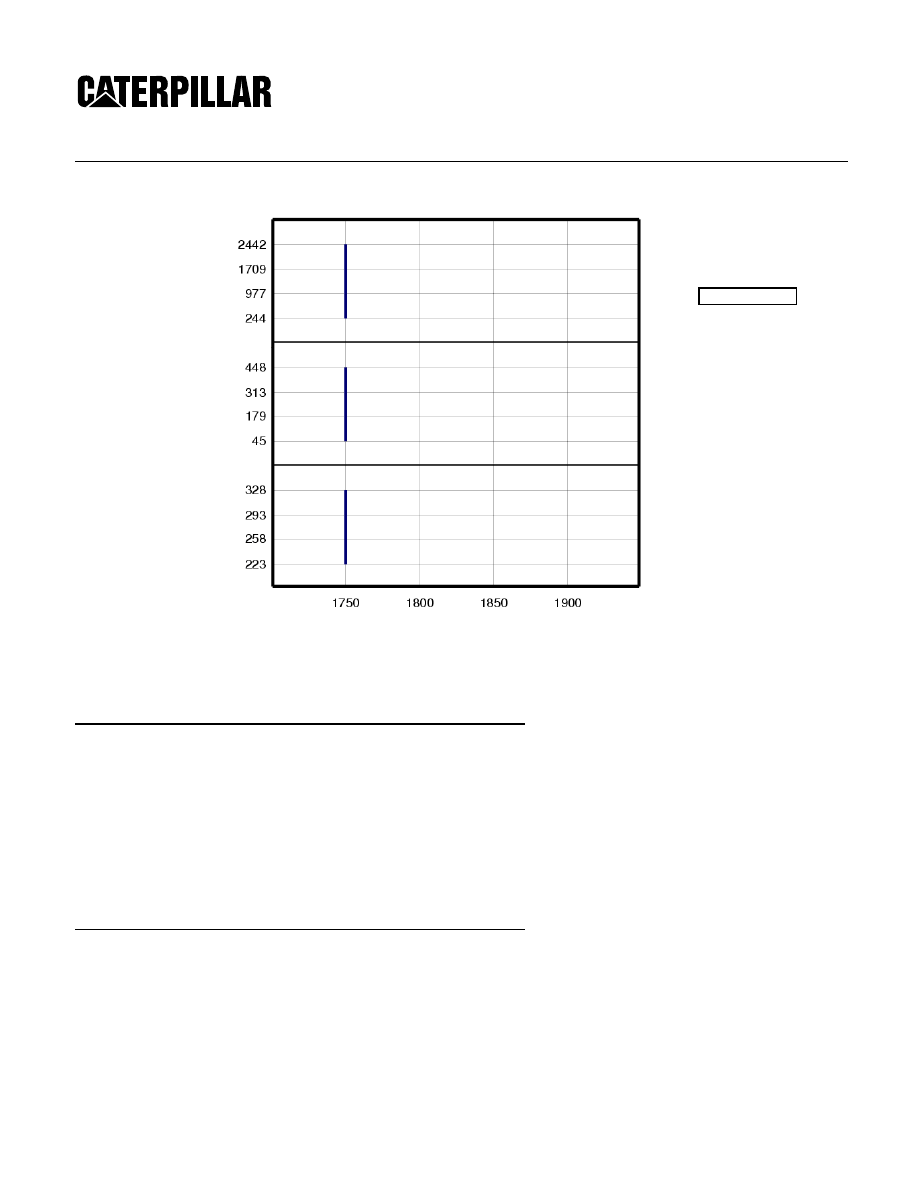

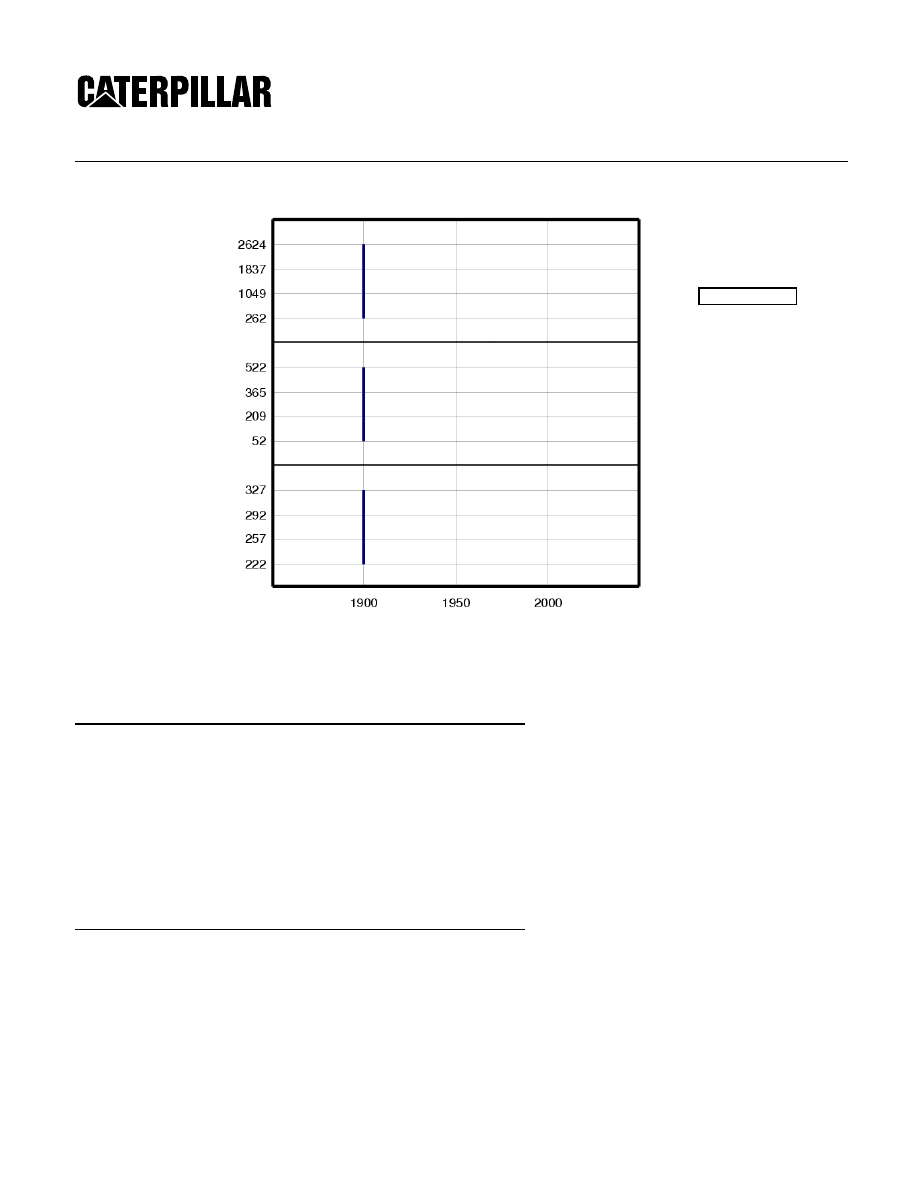

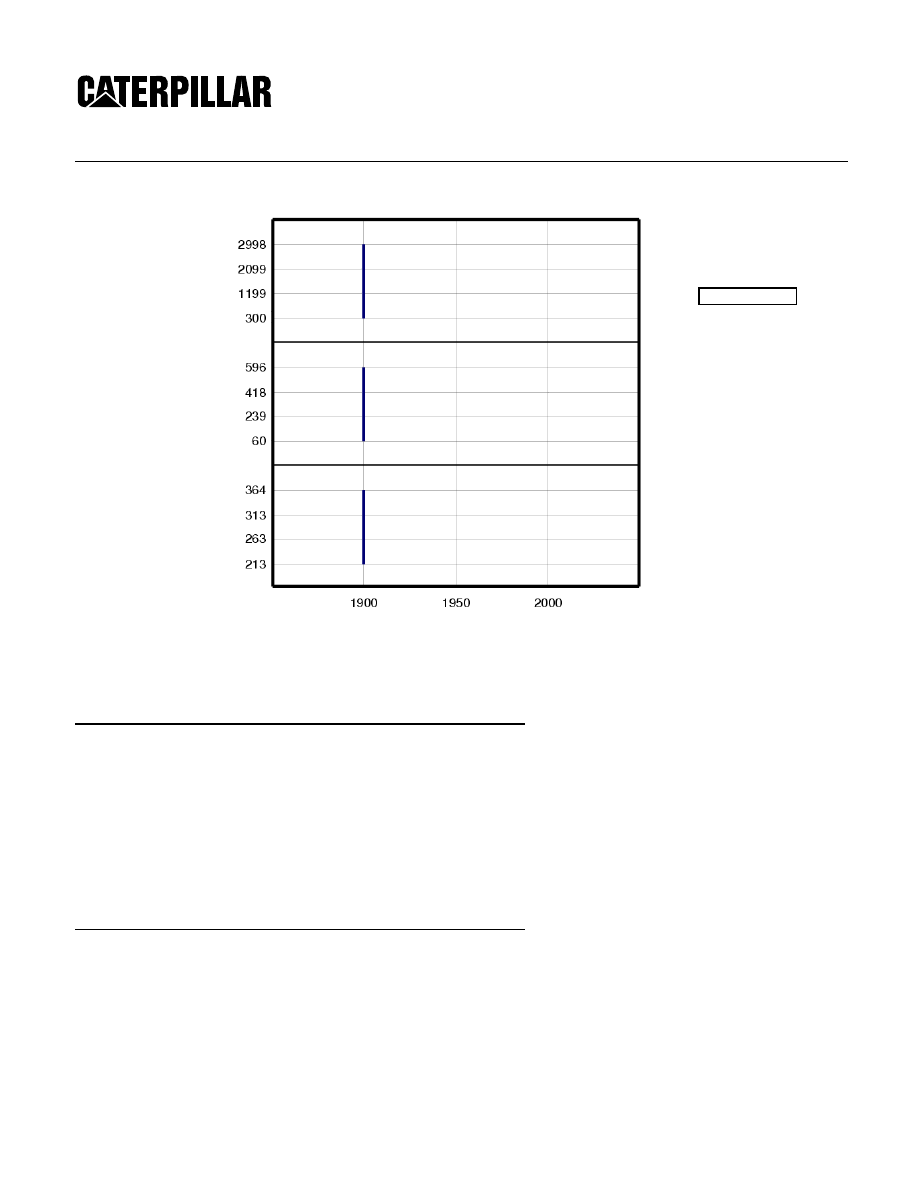

PERFORMANCE CURVES

IND - E - EM0068-00

Torque

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Metric

Engine Speed

rpm

Engine Power

kW

Torque N•m

BSFC g/kW-hr Fuel Rate L/hr

1750

448

2442

222.7

118.8

1750

403

2198

225.4

108.2

1750

358

1954

227.1

96.9

1750

336

1831

228.2

91.3

1750

313

1709

230.3

86.0

1750

45

244

327.9

17.5

1750

224

1221

242.7

64.7

1750

179

977

240.1

51.2

1750

134

733

236

37.8

1750

112

610

232.6

31.0

1750

90

488

243.1

25.9

1750

269

1465

235.5

75.4

3

2 November 2009

4:29 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

448 bkW (600 bhp)

RATINGS AND CONDITIONS

Standby Fire Pump Ratings represent the output

which may be utilized to drive stationary fire pumps

where the pumping equipment has been sized

according to NFPA 20 guidelines and for expected

use of 30 hours per year where pump demand is

about 90% or less of the certified power. Standby

fire pump ratings are not equivalent to IND-E or any

other standard Industrial ratings.

Engine Performance Diesel Engines — 7 liter and

higher

All rating conditions are based on SAE J1995, inlet

air standard

conditions of 99 kPa (29.31 in. Hg) dry barometer

and 25ºC (77ºF)

temperature. Performance measured using a

standard fuel with fuel

gravity of 35º API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29º C (84.2º F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length

1889.0 mm

(2) Width

1091.0 mm

(3) Height

1379.7 mm

Note: Do not use for installation design.

See general dimension drawings for

detail (Drawing # null ).

Performance Number: EM0068-00

Feature Code: C18DF01 Arr. Number: 3311789

Materials and specifications are subject to change without notice.

15476131

© 2009 Caterpillar

All rights reserved.

The International System of Units (SI) is used in this publication.

CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

®

C18 ACERT

™

448 bkW / 600 bhp

1900 rpm

Industrial

Image shown may not reflect

actual engine

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore......................................................145.0 mm (5.71 in)

Stroke.....................................................183.0 mm (7.2 in)

Displacement.................................... 18.1 L (1,104.53 in3)

Aspiration...............................Turbocharged Aftercooled

Compression Ratio...................................................16.3:1

Rotation (from flywheel end).............. Counterclockwise

Weight, Net Dry (approximate kg. lb).. 1673 kg (3688 lb)

FEATURES

Emissions

Meets U.S. EPA Tier 3, EU Stage IIIA and China

Stage II emissions requirements. FM approved. UL

approved - US and Canada. Meets NFPA 20

requirements.

Worldwide Supplier Capability

Caterpillar

- Casts engine blocks, heads, cylinder liners, and

flywheel housings

- Machines critical components

- Assembles complete engine

- Factory-designed systems built at Caterpillar ISO

9001:2000 certified facilities

Ownership of these manufacturing processes

enables Caterpillar to produce high quality,

dependable product.

Testing

Prototype testing on every model:

- proves computer design

- verifies system torsional stability

- functionality tests every model

Every Caterpillar engine is dynamometer tested

under full load to ensure proper engine

performance.

Full Range of Attachments

Wide range of bolt-on system expansion

attachments, factory designed and tested.

Unmatched Product Support Offered Through

Worldwide Caterpillar Dealer Network

More than 1,800 dealer outlets

Caterpillar factory-trained dealer technicians service

every aspect of your industrial engine

99.7% of parts orders filled within 24 hours

worldwide

Caterpillar parts and labor warranty

Preventive maintenance agreements available for

repair before failure options

Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to

determine:

- internal engine component condition

- presence of unwanted fluids

- presence of combustion by-products

Web Site

For all your industrial power requirements, visit

www.cat-industrial.com.

2 November 2009

4:32 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

448 bkW (600 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System

Dual turbocharger: front and rear inlet, 237.0 mm (5

in)

Separate Circuit Aftercooled (SCAC)

Charging System

Charging alternator 24 volt, 50 amp

Control System

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation

Power compensation for fuel temperature

Programmable low and high idle and total engine

limit (TEL)

Electronic diagnostics and fault logging

Engine monitoring and protection system (speeds,

temperature, pressure)

J1939 Broadcast (diagnostic, engine status and

control)

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, gear driven, centrifugal

Heat exchanger (installed)

Expansion tank

Exhaust System

Exhaust manifold, dry

Dual turbo: exhaust elbow, dry 203 mm (8 in)

Flywheels and Flywheel Housing

Flywheel, SAE #1

Flywheel housing, SAE #1

SAE standard rotation

Fuel System

Electronic unit injector

Fuel filter, secondary, mid-mount (LH 2 micron high

performance)

Fuel transfer pump, LH front

Fuel priming pump, LH mid-mount

Fuel sample valve, mounted on fuel filter base

Primary filter / water separator

Instrumentation

Instrument panel, LH

Engine oil pressure gauge

Voltmeter gauge

Water temperature gauge

Tachometer / engine hour meter

Lube System

Crankcase breather, front valve cover

Oil cooler, RH (dual)

Oil filter, RH

Oil pan, front sump

Oil filler, LH front

Oil dipstick, LH front

Oil pump

Mounting System

Front and rear support

Power Take-Offs

Flywheel and stub shaft

Protection System

Stop-Start System, automatic (compatible with

NFPA 20 requirements, able to be energized from

either of two battery sources and capable of manual

starter actuation)

Starting System

24 volt, LH electric starting motor

Jacket water heater (3 kW, 120-240 volt)

General

Vibration damper and guard

Paint, Caterpillar fire pump red

Lifting eyes

Automatic variable timing, electronic

Electronic installation kit, 70 pin connector

(connectors, pins, sockets)

Literature, Owner and Operator's Manual

2

2 November 2009

4:32 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

448 bkW (600 bhp)

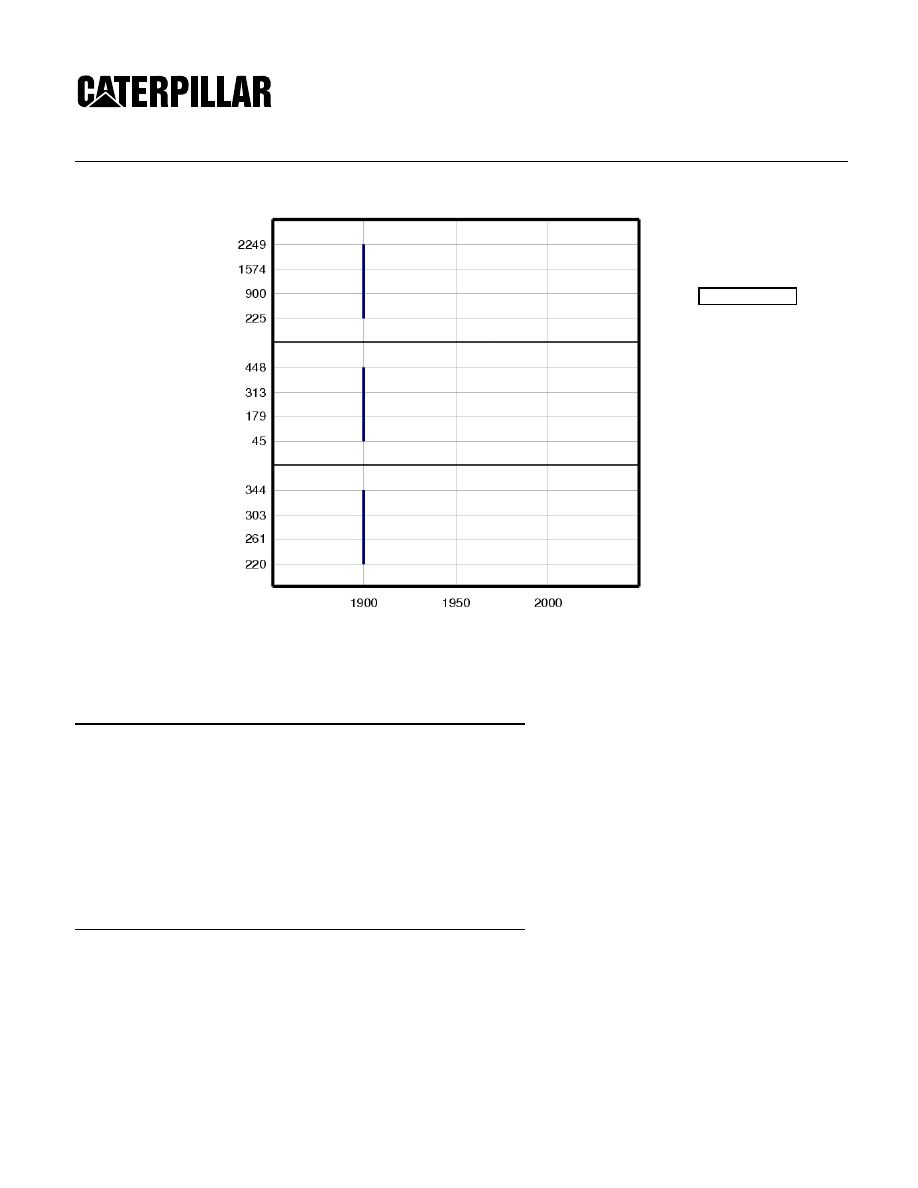

PERFORMANCE CURVES

IND - E - EM0067-00

Torque

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Metric

Engine Speed

rpm

Engine Power

kW

Torque N•m

BSFC g/kW-hr Fuel Rate L/hr

1900

448

2249

219.8

117.3

1900

403

2024

226

108.5

1900

358

1799

233.1

99.5

1900

336

1687

236.7

94.7

1900

313

1574

239.6

89.5

1900

45

225

344.3

18.4

1900

224

1125

247.7

66.1

1900

179

900

246.6

52.6

1900

134

675

244.7

39.2

1900

112

562

243.2

32.4

1900

90

450

254.8

27.2

1900

269

1349

244.4

78.2

3

2 November 2009

4:32 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

448 bkW (600 bhp)

RATINGS AND CONDITIONS

Standby Fire Pump Ratings represent the output

which may be utilized to drive stationary fire pumps

where the pumping equipment has been sized

according to NFPA 20 guidelines and for expected

use of 30 hours per year where pump demand is

about 90% or less of the certified power. Standby

fire pump ratings are not equivalent to IND-E or any

other standard Industrial ratings.

Engine Performance Diesel Engines — 7 liter and

higher

All rating conditions are based on SAE J1995, inlet

air standard

conditions of 99 kPa (29.31 in. Hg) dry barometer

and 25ºC (77ºF)

temperature. Performance measured using a

standard fuel with fuel

gravity of 35º API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29º C (84.2º F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length

1889.0 mm

(2) Width

1091.0 mm

(3) Height

1379.7 mm

Note: Do not use for installation design.

See general dimension drawings for

detail (Drawing # null ).

Performance Number: EM0067-00

Feature Code: C18DF01 Arr. Number: 3311789

Materials and specifications are subject to change without notice.

15476130

© 2009 Caterpillar

All rights reserved.

The International System of Units (SI) is used in this publication.

CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

®

C18 ACERT

™

448 bkW / 600 bhp

2100 rpm

Industrial

Image shown may not reflect

actual engine

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore......................................................145.0 mm (5.71 in)

Stroke.....................................................183.0 mm (7.2 in)

Displacement.................................... 18.1 L (1,104.53 in3)

Aspiration...............................Turbocharged Aftercooled

Compression Ratio...................................................16.3:1

Rotation (from flywheel end).............. Counterclockwise

Weight, Net Dry (approximate kg. lb).. 1673 kg (3688 lb)

FEATURES

Emissions

Meets U.S. EPA Tier 3, EU Stage IIIA and China

Stage II emissions requirements. FM approved. UL

approved - US and Canada. Meets NFPA 20

requirements.

Worldwide Supplier Capability

Caterpillar

- Casts engine blocks, heads, cylinder liners, and

flywheel housings

- Machines critical components

- Assembles complete engine

- Factory-designed systems built at Caterpillar ISO

9001:2000 certified facilities

Ownership of these manufacturing processes

enables Caterpillar to produce high quality,

dependable product.

Testing

Prototype testing on every model:

- proves computer design

- verifies system torsional stability

- functionality tests every model

Every Caterpillar engine is dynamometer tested

under full load to ensure proper engine

performance.

Full Range of Attachments

Wide range of bolt-on system expansion

attachments, factory designed and tested.

Unmatched Product Support Offered Through

Worldwide Caterpillar Dealer Network

More than 1,800 dealer outlets

Caterpillar factory-trained dealer technicians service

every aspect of your industrial engine

99.7% of parts orders filled within 24 hours

worldwide

Caterpillar parts and labor warranty

Preventive maintenance agreements available for

repair before failure options

Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to

determine:

- internal engine component condition

- presence of unwanted fluids

- presence of combustion by-products

Web Site

For all your industrial power requirements, visit

www.cat-industrial.com.

2 November 2009

4:26 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

448 bkW (600 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System

Dual turbocharger: front and rear inlet, 237.0 mm (5

in)

Separate Circuit Aftercooled (SCAC)

Charging System

Charging alternator 24 volt, 50 amp

Control System

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation

Power compensation for fuel temperature

Programmable low and high idle and total engine

limit (TEL)

Electronic diagnostics and fault logging

Engine monitoring and protection system (speeds,

temperature, pressure)

J1939 Broadcast (diagnostic, engine status and

control)

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, gear driven, centrifugal

Heat exchanger (installed)

Expansion tank

Exhaust System

Exhaust manifold, dry

Dual turbo: exhaust elbow, dry 203 mm (8 in)

Flywheels and Flywheel Housing

Flywheel, SAE #1

Flywheel housing, SAE #1

SAE standard rotation

Fuel System

Electronic unit injector

Fuel filter, secondary, mid-mount (LH 2 micron high

performance)

Fuel transfer pump, LH front

Fuel priming pump, LH mid-mount

Fuel sample valve, mounted on fuel filter base

Primary filter / water separator

Instrumentation

Instrument panel, LH

Engine oil pressure gauge

Voltmeter gauge

Water temperature gauge

Tachometer / engine hour meter

Lube System

Crankcase breather, front valve cover

Oil cooler, RH (dual)

Oil filter, RH

Oil pan, front sump

Oil filler, LH front

Oil dipstick, LH front

Oil pump

Mounting System

Front and rear support

Power Take-Offs

Flywheel and stub shaft

Protection System

Stop-Start System, automatic (compatible with

NFPA 20 requirements, able to be energized from

either of two battery sources and capable of manual

starter actuation)

Starting System

24 volt, LH electric starting motor

Jacket water heater (3 kW, 120-240 volt)

General

Vibration damper and guard

Paint, Caterpillar fire pump red

Lifting eyes

Automatic variable timing, electronic

Electronic installation kit, 70 pin connector

(connectors, pins, sockets)

Literature, Owner and Operator's Manual

2

2 November 2009

4:26 AM

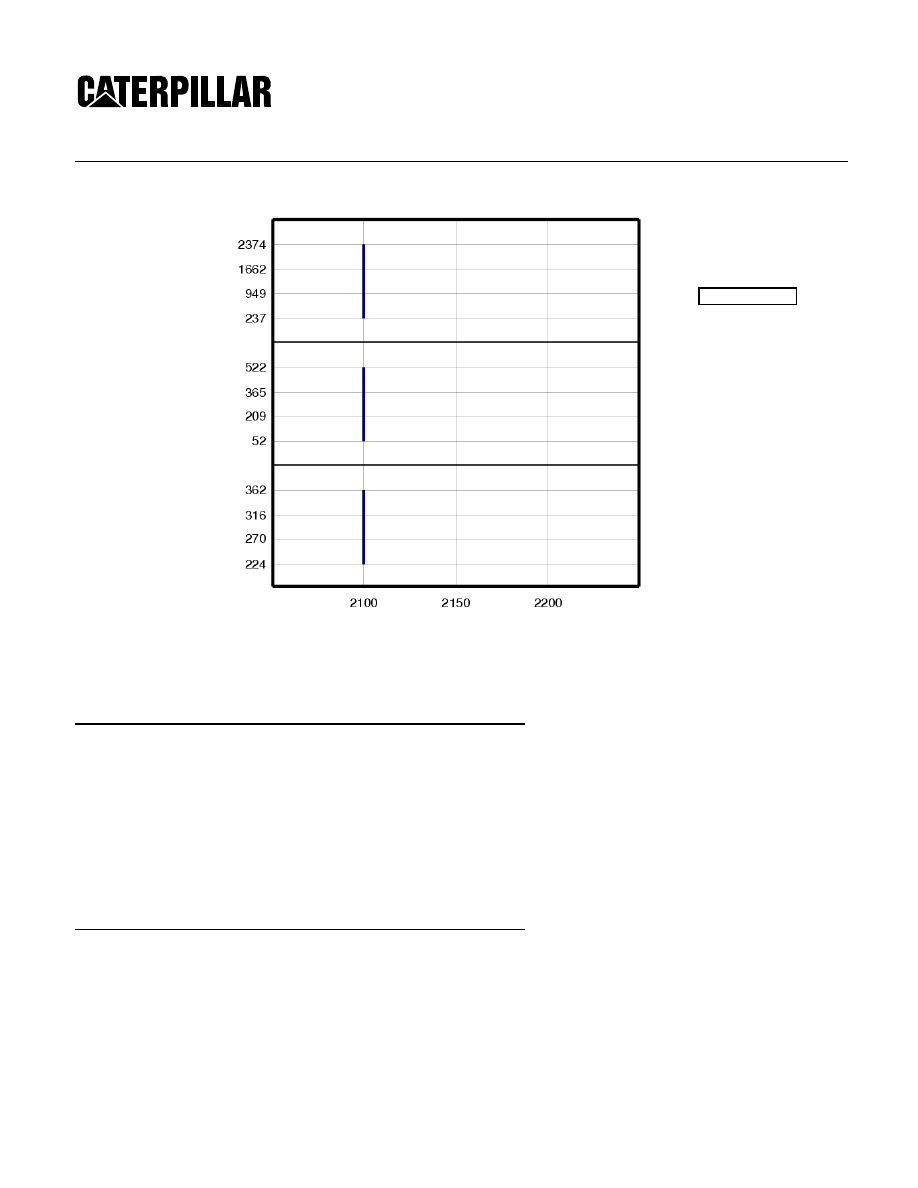

®

C18 ACERT

™

INDUSTRIAL ENGINE

448 bkW (600 bhp)

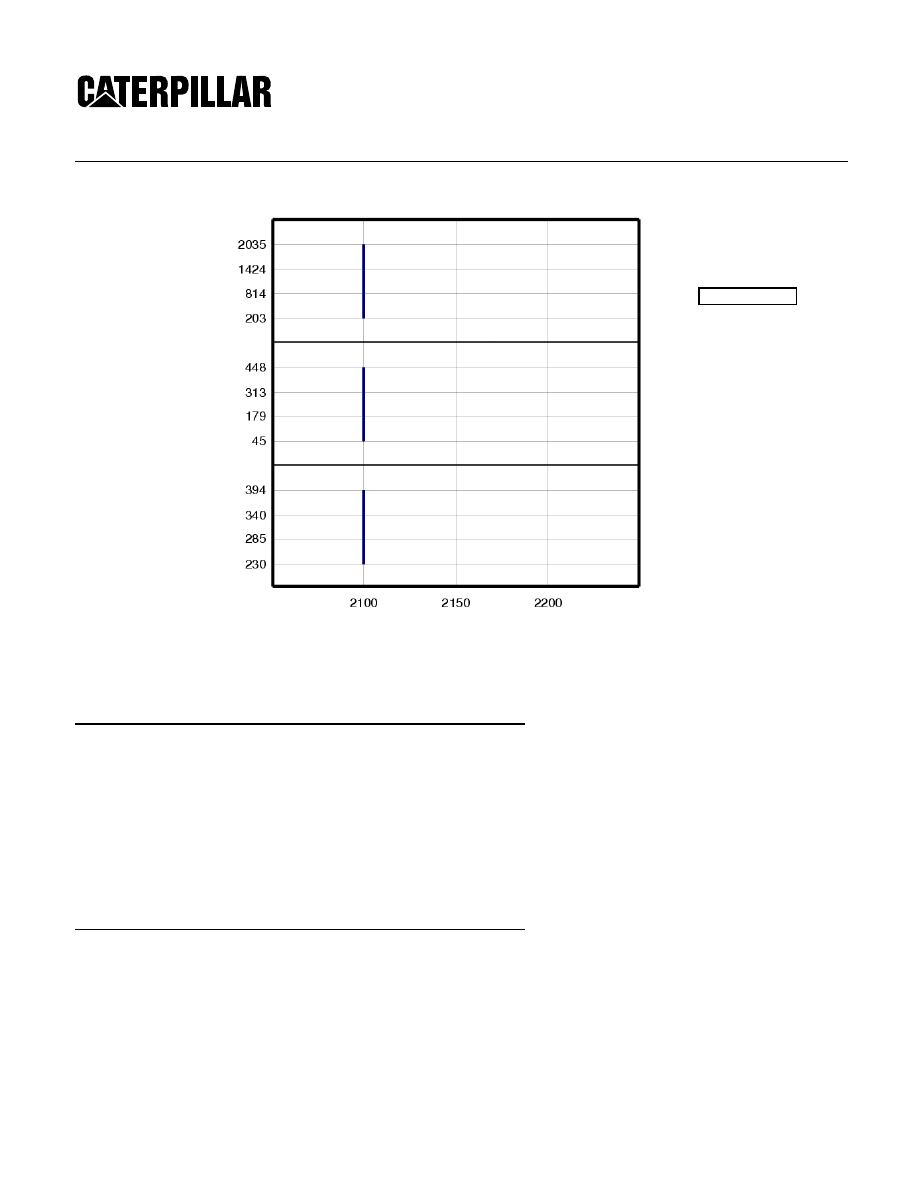

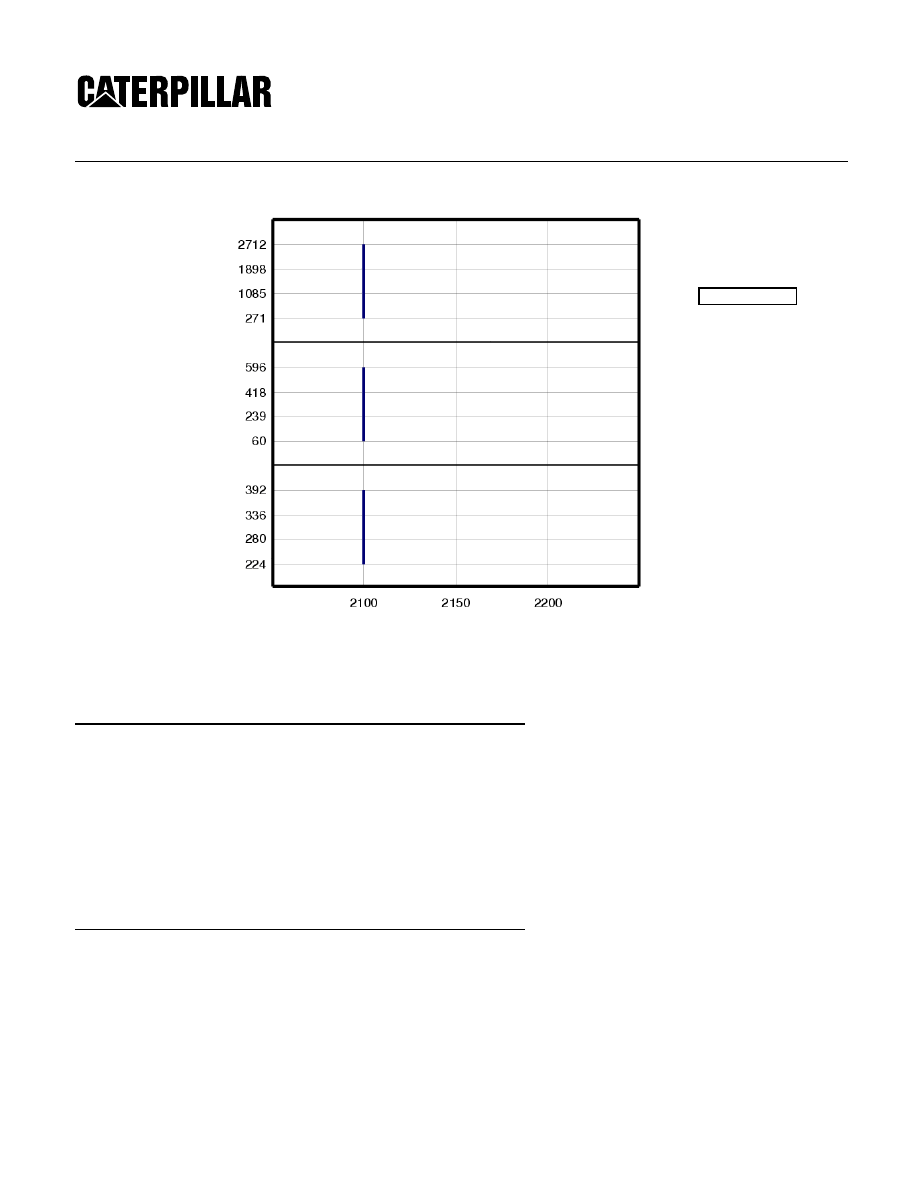

PERFORMANCE CURVES

IND - E - EM0066-00

Torque

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Metric

Engine Speed

rpm

Engine Power

kW

Torque N•m

BSFC g/kW-hr Fuel Rate L/hr

2100

313

1424

253.8

94.8

2100

269

1221

263.7

84.4

2100

224

1017

274.6

73.2

2100

179

814

271.8

58.0

2100

134

610

267.1

42.7

2100

336

1526

249.1

99.7

2100

90

407

277.9

29.6

2100

45

203

394.5

21.0

2100

448

2035

229.8

122.6

2100

403

1831

237.5

114.0

2100

358

1628

245.2

104.6

2100

112

509

263.4

35.1

3

2 November 2009

4:26 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

448 bkW (600 bhp)

RATINGS AND CONDITIONS

Standby Fire Pump Ratings represent the output

which may be utilized to drive stationary fire pumps

where the pumping equipment has been sized

according to NFPA 20 guidelines and for expected

use of 30 hours per year where pump demand is

about 90% or less of the certified power. Standby

fire pump ratings are not equivalent to IND-E or any

other standard Industrial ratings.

Engine Performance Diesel Engines — 7 liter and

higher

All rating conditions are based on SAE J1995, inlet

air standard

conditions of 99 kPa (29.31 in. Hg) dry barometer

and 25ºC (77ºF)

temperature. Performance measured using a

standard fuel with fuel

gravity of 35º API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29º C (84.2º F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length

1889.0 mm

(2) Width

1091.0 mm

(3) Height

1379.7 mm

Note: Do not use for installation design.

See general dimension drawings for

detail (Drawing # null ).

Performance Number: EM0066-00

Feature Code: C18DF01 Arr. Number: 3311789

Materials and specifications are subject to change without notice.

15476115

© 2009 Caterpillar

All rights reserved.

The International System of Units (SI) is used in this publication.

CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

®

C18 ACERT

™

522 bkW / 700 bhp

1750 rpm

Industrial

Image shown may not reflect

actual engine

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore......................................................145.0 mm (5.71 in)

Stroke.....................................................183.0 mm (7.2 in)

Displacement.................................... 18.1 L (1,104.53 in3)

Aspiration...............................Turbocharged Aftercooled

Compression Ratio...................................................16.3:1

Rotation (from flywheel end).............. Counterclockwise

Weight, Net Dry (approximate kg. lb).. 1673 kg (3688 lb)

FEATURES

Worldwide Supplier Capability

Caterpillar

- Casts engine blocks, heads, cylinder liners, and

flywheel housings

- Machines critical components

- Assembles complete engine

- Factory-designed systems built at Caterpillar ISO

9001:2000 certified facilities

Ownership of these manufacturing processes

enables Caterpillar to produce high quality,

dependable product.

Testing

Prototype testing on every model:

- proves computer design

- verifies system torsional stability

- functionality tests every model

Every Caterpillar engine is dynamometer tested

under full load to ensure proper engine

performance.

Full Range of Attachments

Wide range of bolt-on system expansion

attachments, factory designed and tested.

Unmatched Product Support Offered Through

Worldwide Caterpillar Dealer Network

More than 1,800 dealer outlets

Caterpillar factory-trained dealer technicians service

every aspect of your industrial engine

99.7% of parts orders filled within 24 hours

worldwide

Caterpillar parts and labor warranty

Preventive maintenance agreements available for

repair before failure options

Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to

determine:

- internal engine component condition

- presence of unwanted fluids

- presence of combustion by-products

Web Site

For all your industrial power requirements, visit

www.cat-industrial.com.

2 November 2009

4:37 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

522 bkW (700 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System

Dual turbocharger: front and rear inlet, 237.0 mm (5

in)

Separate Circuit Aftercooled (SCAC)

Charging System

Charging alternator 24 volt, 50 amp

Control System

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation

Power compensation for fuel temperature

Programmable low and high idle and total engine

limit (TEL)

Electronic diagnostics and fault logging

Engine monitoring and protection system (speeds,

temperature, pressure)

J1939 Broadcast (diagnostic, engine status and

control)

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, gear driven, centrifugal

Heat exchanger (installed)

Expansion tank

Exhaust System

Exhaust manifold, dry

Dual turbo: exhaust elbow, dry 203 mm (8 in)

Flywheels and Flywheel Housing

Flywheel, SAE #1

Flywheel housing, SAE #1

SAE standard rotation

Fuel System

Electronic unit injector

Fuel filter, secondary, mid-mount (LH 2 micron high

performance)

Fuel transfer pump, LH front

Fuel priming pump, LH mid-mount

Fuel sample valve, mounted on fuel filter base

Primary filter / water separator

Instrumentation

Instrument panel, LH

Engine oil pressure gauge

Voltmeter gauge

Water temperature gauge

Tachometer / engine hour meter

Lube System

Crankcase breather, front valve cover

Oil cooler, RH (dual)

Oil filter, RH

Oil pan, front sump

Oil filler, LH front

Oil dipstick, LH front

Oil pump

Mounting System

Front and rear support

Power Take-Offs

Flywheel and stub shaft

Protection System

Stop-Start System, automatic (compatible with

NFPA 20 requirements, able to be energized from

either of two battery sources and capable of manual

starter actuation)

Starting System

24 volt, LH electric starting motor

Jacket water heater (3 kW, 120-240 volt)

General

Vibration damper and guard

Paint, Caterpillar fire pump red

Lifting eyes

Automatic variable timing, electronic

Electronic installation kit, 70 pin connector

(connectors, pins, sockets)

Literature, Owner and Operator's Manual

2

2 November 2009

4:37 AM

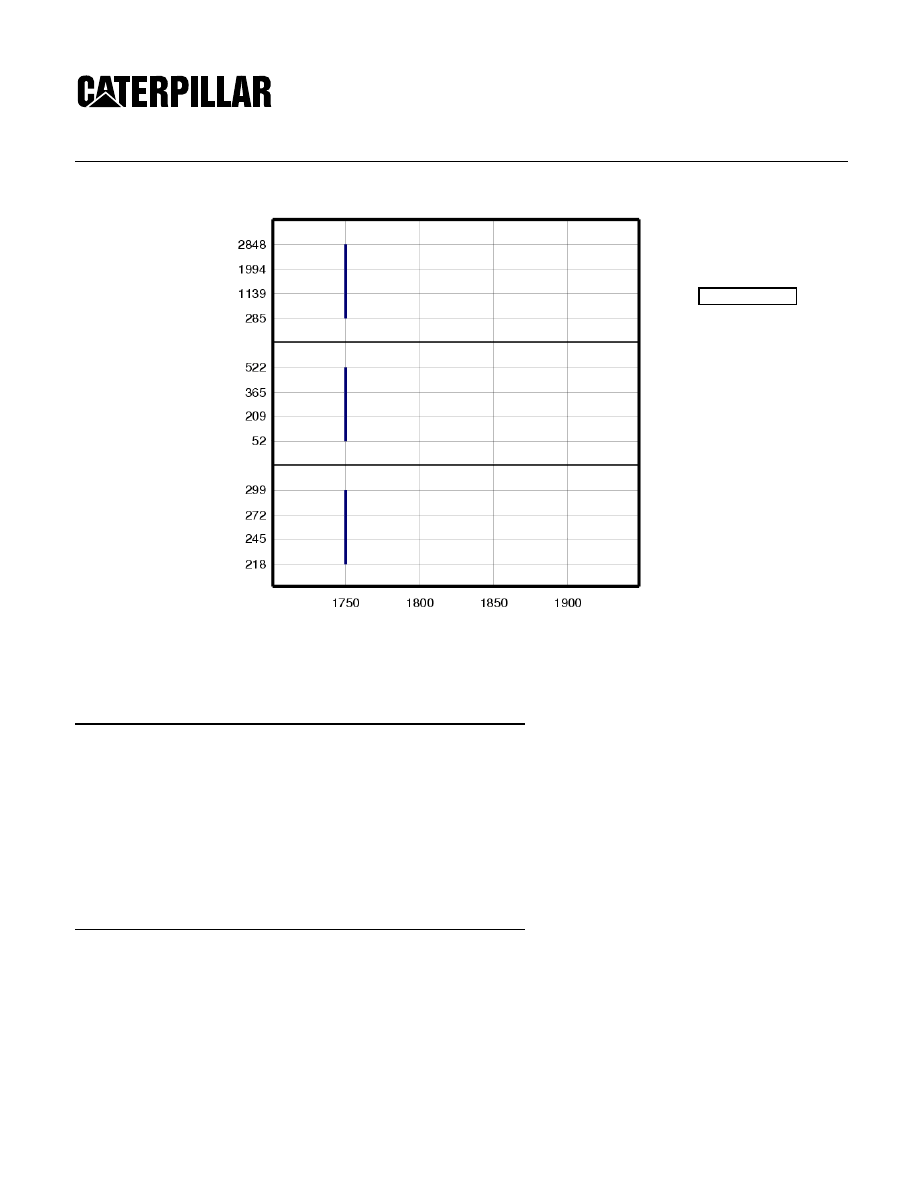

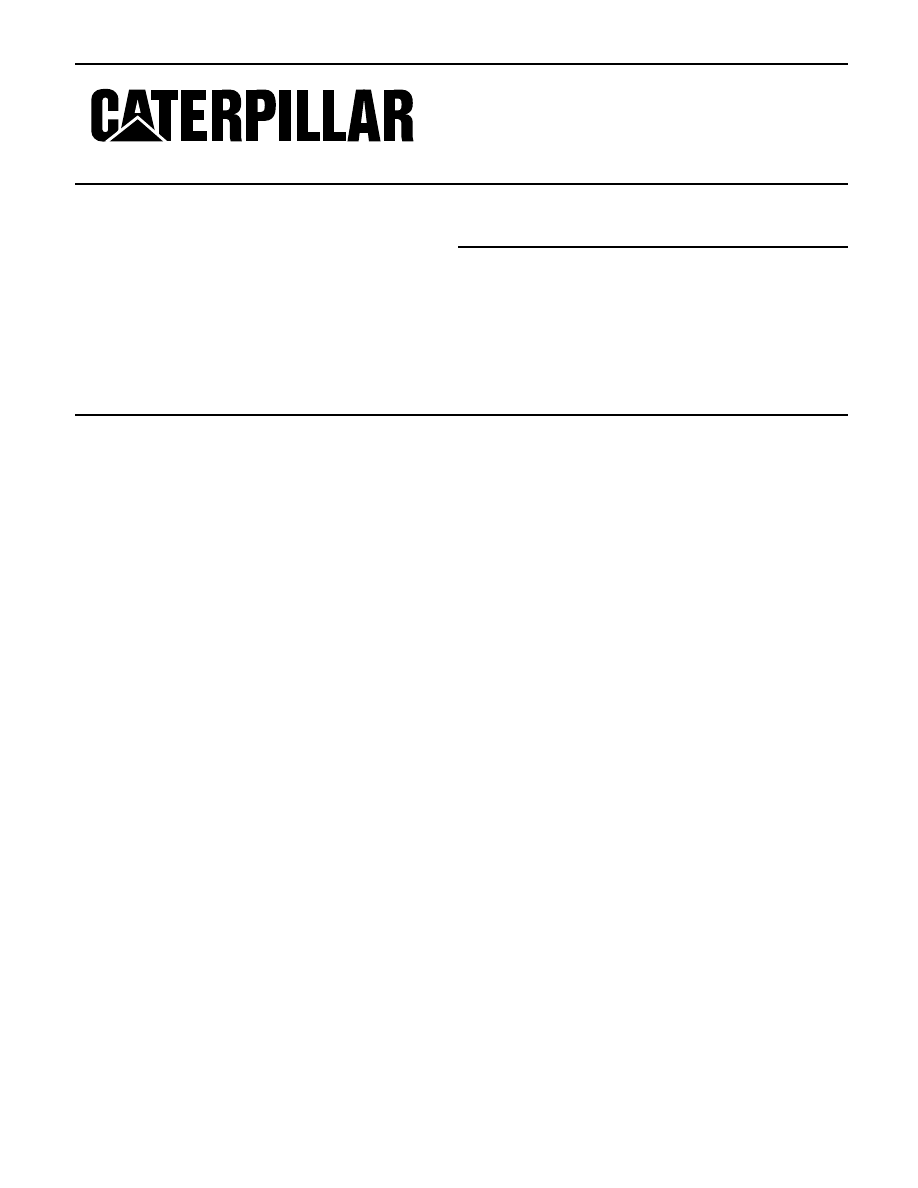

®

C18 ACERT

™

INDUSTRIAL ENGINE

522 bkW (700 bhp)

PERFORMANCE CURVES

IND - E - DM9853-01

Torque

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Metric

Engine Speed

rpm

Engine Power

kW

Torque N•m

BSFC g/kW-hr Fuel Rate L/hr

1750

522

2848

217.6

135.4

1750

470

2564

222.2

124.4

1750

418

2279

225

112.0

1750

392

2136

226.8

105.8

1750

365

1994

229.1

99.8

1750

52

285

299.4

18.6

1750

261

1424

243.1

75.6

1750

209

1139

242.8

60.4

1750

157

855

242.3

45.2

1750

131

712

242

37.6

1750

104

570

249

31.0

1750

313

1709

235

87.7

3

2 November 2009

4:37 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

522 bkW (700 bhp)

RATINGS AND CONDITIONS

Standby Fire Pump Ratings represent the output

which may be utilized to drive stationary fire pumps

where the pumping equipment has been sized

according to NFPA 20 guidelines and for expected

use of 30 hours per year where pump demand is

about 90% or less of the certified power. Standby

fire pump ratings are not equivalent to IND-E or any

other standard Industrial ratings.

Engine Performance Diesel Engines — 7 liter and

higher

All rating conditions are based on SAE J1995, inlet

air standard

conditions of 99 kPa (29.31 in. Hg) dry barometer

and 25ºC (77ºF)

temperature. Performance measured using a

standard fuel with fuel

gravity of 35º API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29º C (84.2º F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length

1889.0 mm

(2) Width

1091.0 mm

(3) Height

1379.7 mm

Note: Do not use for installation design.

See general dimension drawings for

detail (Drawing # null ).

Performance Number: DM9853-01

Feature Code: C18DF02 Arr. Number: 3149713

Materials and specifications are subject to change without notice.

15474964

© 2009 Caterpillar

All rights reserved.

The International System of Units (SI) is used in this publication.

CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

®

C18 ACERT

™

522 bkW / 700 bhp

1900 rpm

Industrial

Image shown may not reflect

actual engine

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore......................................................145.0 mm (5.71 in)

Stroke.....................................................183.0 mm (7.2 in)

Displacement.................................... 18.1 L (1,104.53 in3)

Aspiration...............................Turbocharged Aftercooled

Compression Ratio...................................................16.3:1

Rotation (from flywheel end).............. Counterclockwise

Weight, Net Dry (approximate kg. lb).. 1673 kg (3688 lb)

FEATURES

Worldwide Supplier Capability

Caterpillar

- Casts engine blocks, heads, cylinder liners, and

flywheel housings

- Machines critical components

- Assembles complete engine

- Factory-designed systems built at Caterpillar ISO

9001:2000 certified facilities

Ownership of these manufacturing processes

enables Caterpillar to produce high quality,

dependable product.

Testing

Prototype testing on every model:

- proves computer design

- verifies system torsional stability

- functionality tests every model

Every Caterpillar engine is dynamometer tested

under full load to ensure proper engine

performance.

Full Range of Attachments

Wide range of bolt-on system expansion

attachments, factory designed and tested.

Unmatched Product Support Offered Through

Worldwide Caterpillar Dealer Network

More than 1,800 dealer outlets

Caterpillar factory-trained dealer technicians service

every aspect of your industrial engine

99.7% of parts orders filled within 24 hours

worldwide

Caterpillar parts and labor warranty

Preventive maintenance agreements available for

repair before failure options

Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to

determine:

- internal engine component condition

- presence of unwanted fluids

- presence of combustion by-products

Web Site

For all your industrial power requirements, visit

www.cat-industrial.com.

2 November 2009

4:43 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

522 bkW (700 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System

Dual turbocharger: front and rear inlet, 237.0 mm (5

in)

Separate Circuit Aftercooled (SCAC)

Charging System

Charging alternator 24 volt, 50 amp

Control System

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation

Power compensation for fuel temperature

Programmable low and high idle and total engine

limit (TEL)

Electronic diagnostics and fault logging

Engine monitoring and protection system (speeds,

temperature, pressure)

J1939 Broadcast (diagnostic, engine status and

control)

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, gear driven, centrifugal

Heat exchanger (installed)

Expansion tank

Exhaust System

Exhaust manifold, dry

Dual turbo: exhaust elbow, dry 203 mm (8 in)

Flywheels and Flywheel Housing

Flywheel, SAE #1

Flywheel housing, SAE #1

SAE standard rotation

Fuel System

Electronic unit injector

Fuel filter, secondary, mid-mount (LH 2 micron high

performance)

Fuel transfer pump, LH front

Fuel priming pump, LH mid-mount

Fuel sample valve, mounted on fuel filter base

Primary filter / water separator

Instrumentation

Instrument panel, LH

Engine oil pressure gauge

Voltmeter gauge

Water temperature gauge

Tachometer / engine hour meter

Lube System

Crankcase breather, front valve cover

Oil cooler, RH (dual)

Oil filter, RH

Oil pan, front sump

Oil filler, LH front

Oil dipstick, LH front

Oil pump

Mounting System

Front and rear support

Power Take-Offs

Flywheel and stub shaft

Protection System

Stop-Start System, automatic (compatible with

NFPA 20 requirements, able to be energized from

either of two battery sources and capable of manual

starter actuation)

Starting System

24 volt, LH electric starting motor

Jacket water heater (3 kW, 120-240 volt)

General

Vibration damper and guard

Paint, Caterpillar fire pump red

Lifting eyes

Automatic variable timing, electronic

Electronic installation kit, 70 pin connector

(connectors, pins, sockets)

Literature, Owner and Operator's Manual

2

2 November 2009

4:43 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

522 bkW (700 bhp)

PERFORMANCE CURVES

IND - E - EM0023-01

Torque

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Metric

Engine Speed

rpm

Engine Power

kW

Torque N•m

BSFC g/kW-hr Fuel Rate L/hr

1900

522

2624

221.8

138.0

1900

470

2361

226.3

126.7

1900

418

2099

231.5

115.2

1900

392

1968

234.3

109.4

1900

365

1836

237.6

103.5

1900

52

262

326.9

20.3

1900

261

1312

251.9

78.4

1900

209

1049

247

61.5

1900

157

787

238.9

44.6

1900

131

656

232.4

36.2

1900

104

525

241.8

30.1

1900

313

1574

244.4

91.3

3

2 November 2009

4:43 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

522 bkW (700 bhp)

RATINGS AND CONDITIONS

Standby Fire Pump Ratings represent the output

which may be utilized to drive stationary fire pumps

where the pumping equipment has been sized

according to NFPA 20 guidelines and for expected

use of 30 hours per year where pump demand is

about 90% or less of the certified power. Standby

fire pump ratings are not equivalent to IND-E or any

other standard Industrial ratings.

Engine Performance Diesel Engines — 7 liter and

higher

All rating conditions are based on SAE J1995, inlet

air standard

conditions of 99 kPa (29.31 in. Hg) dry barometer

and 25ºC (77ºF)

temperature. Performance measured using a

standard fuel with fuel

gravity of 35º API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29º C (84.2º F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length

1889.0 mm

(2) Width

1091.0 mm

(3) Height

1379.7 mm

Note: Do not use for installation design.

See general dimension drawings for

detail (Drawing # null ).

Performance Number: EM0023-01

Feature Code: C18DF02 Arr. Number: 3149713

Materials and specifications are subject to change without notice.

15476014

© 2009 Caterpillar

All rights reserved.

The International System of Units (SI) is used in this publication.

CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

®

C18 ACERT

™

522 bkW / 700 bhp

2100 rpm

Industrial

Image shown may not reflect

actual engine

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore......................................................145.0 mm (5.71 in)

Stroke.....................................................183.0 mm (7.2 in)

Displacement.................................... 18.1 L (1,104.53 in3)

Aspiration...............................Turbocharged Aftercooled

Compression Ratio...................................................16.3:1

Rotation (from flywheel end).............. Counterclockwise

Weight, Net Dry (approximate kg. lb).. 1673 kg (3688 lb)

FEATURES

Worldwide Supplier Capability

Caterpillar

- Casts engine blocks, heads, cylinder liners, and

flywheel housings

- Machines critical components

- Assembles complete engine

- Factory-designed systems built at Caterpillar ISO

9001:2000 certified facilities

Ownership of these manufacturing processes

enables Caterpillar to produce high quality,

dependable product.

Testing

Prototype testing on every model:

- proves computer design

- verifies system torsional stability

- functionality tests every model

Every Caterpillar engine is dynamometer tested

under full load to ensure proper engine

performance.

Full Range of Attachments

Wide range of bolt-on system expansion

attachments, factory designed and tested.

Unmatched Product Support Offered Through

Worldwide Caterpillar Dealer Network

More than 1,800 dealer outlets

Caterpillar factory-trained dealer technicians service

every aspect of your industrial engine

99.7% of parts orders filled within 24 hours

worldwide

Caterpillar parts and labor warranty

Preventive maintenance agreements available for

repair before failure options

Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to

determine:

- internal engine component condition

- presence of unwanted fluids

- presence of combustion by-products

Web Site

For all your industrial power requirements, visit

www.cat-industrial.com.

2 November 2009

4:41 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

522 bkW (700 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System

Dual turbocharger: front and rear inlet, 237.0 mm (5

in)

Separate Circuit Aftercooled (SCAC)

Charging System

Charging alternator 24 volt, 50 amp

Control System

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation

Power compensation for fuel temperature

Programmable low and high idle and total engine

limit (TEL)

Electronic diagnostics and fault logging

Engine monitoring and protection system (speeds,

temperature, pressure)

J1939 Broadcast (diagnostic, engine status and

control)

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, gear driven, centrifugal

Heat exchanger (installed)

Expansion tank

Exhaust System

Exhaust manifold, dry

Dual turbo: exhaust elbow, dry 203 mm (8 in)

Flywheels and Flywheel Housing

Flywheel, SAE #1

Flywheel housing, SAE #1

SAE standard rotation

Fuel System

Electronic unit injector

Fuel filter, secondary, mid-mount (LH 2 micron high

performance)

Fuel transfer pump, LH front

Fuel priming pump, LH mid-mount

Fuel sample valve, mounted on fuel filter base

Primary filter / water separator

Instrumentation

Instrument panel, LH

Engine oil pressure gauge

Voltmeter gauge

Water temperature gauge

Tachometer / engine hour meter

Lube System

Crankcase breather, front valve cover

Oil cooler, RH (dual)

Oil filter, RH

Oil pan, front sump

Oil filler, LH front

Oil dipstick, LH front

Oil pump

Mounting System

Front and rear support

Power Take-Offs

Flywheel and stub shaft

Protection System

Stop-Start System, automatic (compatible with

NFPA 20 requirements, able to be energized from

either of two battery sources and capable of manual

starter actuation)

Starting System

24 volt, LH electric starting motor

Jacket water heater (3 kW, 120-240 volt)

General

Vibration damper and guard

Paint, Caterpillar fire pump red

Lifting eyes

Automatic variable timing, electronic

Electronic installation kit, 70 pin connector

(connectors, pins, sockets)

Literature, Owner and Operator's Manual

2

2 November 2009

4:41 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

522 bkW (700 bhp)

PERFORMANCE CURVES

IND - E - EM0024-01

Torque

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Metric

Engine Speed

rpm

Engine Power

kW

Torque N•m

BSFC g/kW-hr Fuel Rate L/hr

2100

522

2374

224.2

139.5

2100

470

2136

228.2

127.8

2100

418

1899

237.2

118.1

2100

392

1780

242.7

113.2

2100

365

1662

247.3

107.7

2100

52

237

361.7

22.5

2100

261

1187

262.5

81.7

2100

209

949

259.3

64.5

2100

157

712

254.1

47.4

2100

131

593

249.9

38.9

2100

104

475

262.3

32.6

2100

313

1424

255.8

95.5

3

2 November 2009

4:41 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

522 bkW (700 bhp)

RATINGS AND CONDITIONS

Standby Fire Pump Ratings represent the output

which may be utilized to drive stationary fire pumps

where the pumping equipment has been sized

according to NFPA 20 guidelines and for expected

use of 30 hours per year where pump demand is

about 90% or less of the certified power. Standby

fire pump ratings are not equivalent to IND-E or any

other standard Industrial ratings.

Engine Performance Diesel Engines — 7 liter and

higher

All rating conditions are based on SAE J1995, inlet

air standard

conditions of 99 kPa (29.31 in. Hg) dry barometer

and 25ºC (77ºF)

temperature. Performance measured using a

standard fuel with fuel

gravity of 35º API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29º C (84.2º F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length

1889.0 mm

(2) Width

1091.0 mm

(3) Height

1379.7 mm

Note: Do not use for installation design.

See general dimension drawings for

detail (Drawing # null ).

Performance Number: EM0024-01

Feature Code: C18DF02 Arr. Number: 3149713

Materials and specifications are subject to change without notice.

15476015

© 2009 Caterpillar

All rights reserved.

The International System of Units (SI) is used in this publication.

CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

®

C18 ACERT

™

597 bkW / 800 bhp

1750 rpm

Industrial

Image shown may not reflect

actual engine

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore......................................................145.0 mm (5.71 in)

Stroke.....................................................183.0 mm (7.2 in)

Displacement.................................... 18.1 L (1,104.53 in3)

Aspiration...............................Turbocharged Aftercooled

Compression Ratio...................................................16.3:1

Rotation (from flywheel end).............. Counterclockwise

Weight, Net Dry (approximate kg. lb).. 1673 kg (3688 lb)

FEATURES

Worldwide Supplier Capability

Caterpillar

- Casts engine blocks, heads, cylinder liners, and

flywheel housings

- Machines critical components

- Assembles complete engine

- Factory-designed systems built at Caterpillar ISO

9001:2000 certified facilities

Ownership of these manufacturing processes

enables Caterpillar to produce high quality,

dependable product.

Testing

Prototype testing on every model:

- proves computer design

- verifies system torsional stability

- functionality tests every model

Every Caterpillar engine is dynamometer tested

under full load to ensure proper engine

performance.

Emissions

Meets U.S. EPA Tier 2 emissions requirements. FM

approved. UL approved - US and Canada. Meets

NFPA 20 requirements.

Full Range of Attachments

Wide range of bolt-on system expansion

attachments, factory designed and tested.

Unmatched Product Support Offered Through

Worldwide Caterpillar Dealer Network

More than 1,800 dealer outlets

Caterpillar factory-trained dealer technicians service

every aspect of your industrial engine

99.7% of parts orders filled within 24 hours

worldwide

Caterpillar parts and labor warranty

Preventive maintenance agreements available for

repair before failure options

Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to

determine:

- internal engine component condition

- presence of unwanted fluids

- presence of combustion by-products

Web Site

For all your industrial power requirements, visit

www.cat-industrial.com.

2 November 2009

4:47 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

597 bkW (800 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System

Dual turbocharger: front and rear inlet, 237.0 mm (5

in)

Separate Circuit Aftercooled (SCAC)

Charging System

Charging alternator 24 volt, 50 amp

Control System

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation

Power compensation for fuel temperature

Programmable low and high idle and total engine

limit (TEL)

Electronic diagnostics and fault logging

Engine monitoring and protection system (speeds,

temperature, pressure)

J1939 Broadcast (diagnostic, engine status and

control)

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, gear driven, centrifugal

Heat exchanger (installed)

Expansion tank

Exhaust System

Exhaust manifold, dry

Dual turbo: exhaust elbow, dry 203 mm (8 in)

Flywheels and Flywheel Housing

Flywheel, SAE #1

Flywheel housing, SAE #1

SAE standard rotation

Fuel System

Electronic unit injector

Fuel filter, secondary, mid-mount (LH 2 micron high

performance)

Fuel transfer pump, LH front

Fuel priming pump, LH mid-mount

Fuel sample valve, mounted on fuel filter base

Primary filter / water separator

Instrumentation

Instrument panel, LH

Engine oil pressure gauge

Voltmeter gauge

Water temperature gauge

Tachometer / engine hour meter

Lube System

Crankcase breather, front valve cover

Oil cooler, RH (dual)

Oil filter, RH

Oil pan, front sump

Oil filler, LH front

Oil dipstick, LH front

Oil pump

Mounting System

Front and rear support

Power Take-Offs

Flywheel and stub shaft

Protection System

Stop-Start System, automatic (compatible with

NFPA 20 requirements, able to be energized from

either of two battery sources and capable of manual

starter actuation)

Starting System

24 volt, LH electric starting motor

Jacket water heater (3 kW, 120-240 volt)

General

Vibration damper and guard

Paint, Caterpillar fire pump red

Lifting eyes

Automatic variable timing, electronic

Electronic installation kit, 70 pin connector

(connectors, pins, sockets)

Literature, Owner and Operator's Manual

2

2 November 2009

4:47 AM

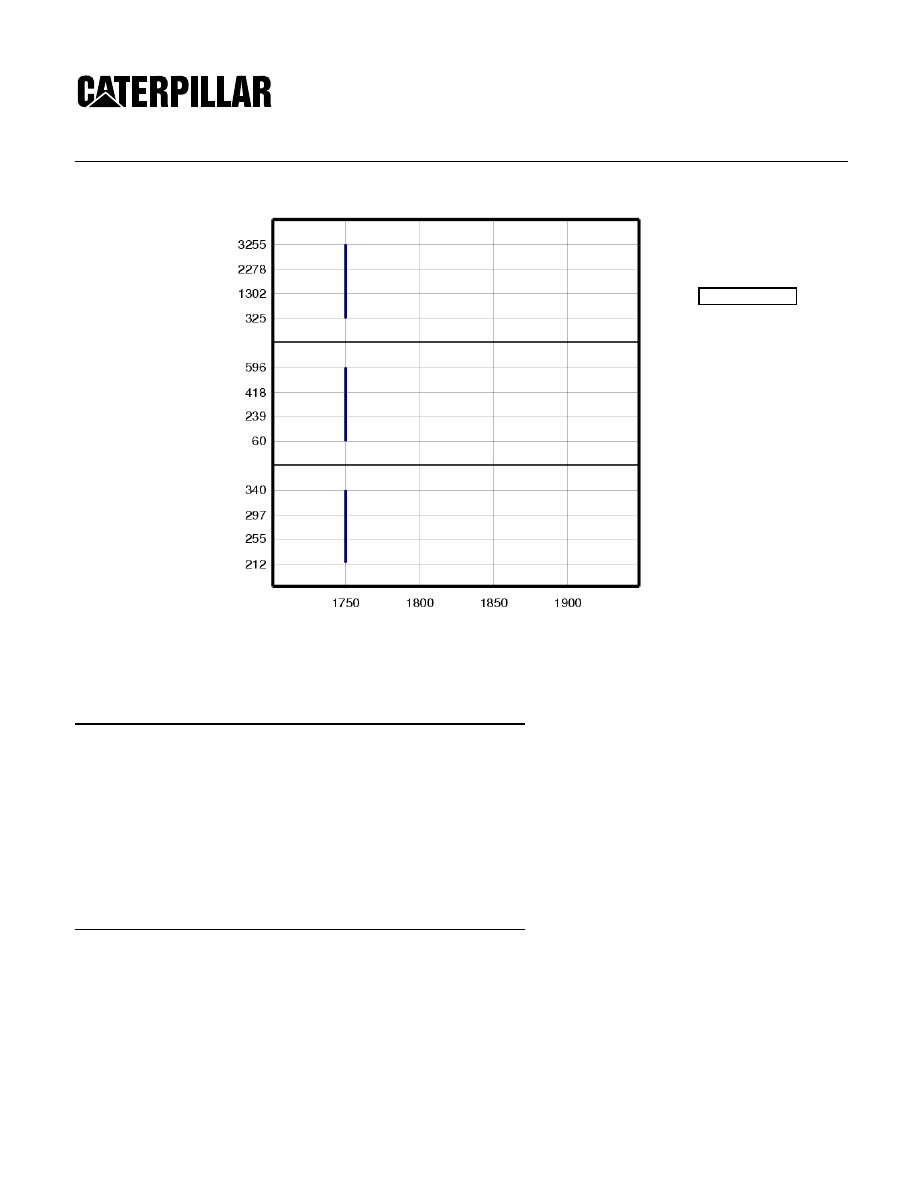

®

C18 ACERT

™

INDUSTRIAL ENGINE

597 bkW (800 bhp)

PERFORMANCE CURVES

IND - E - DM9854-01

Torque

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Metric

Engine Speed

rpm

Engine Power

kW

Torque N•m

BSFC g/kW-hr Fuel Rate L/hr

1750

597

3255

212.5

151.1

1750

537

2929

213

136.3

1750

477

2604

215.8

122.8

1750

447

2441

217.5

116.0

1750

418

2278

218

108.5

1750

60

325

339.9

24.2

1750

298

1627

221

78.6

1750

239

1302

225.3

64.1

1750

179

976

234.4

50.0

1750

149

814

242.6

43.1

1750

119

651

257.4

36.6

1750

358

1953

219.2

93.5

3

2 November 2009

4:47 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

597 bkW (800 bhp)

RATINGS AND CONDITIONS

Standby Fire Pump Ratings represent the output

which may be utilized to drive stationary fire pumps

where the pumping equipment has been sized

according to NFPA 20 guidelines and for expected

use of 30 hours per year where pump demand is

about 90% or less of the certified power. Standby

fire pump ratings are not equivalent to IND-E or any

other standard Industrial ratings.

Engine Performance Diesel Engines — 7 liter and

higher

All rating conditions are based on SAE J1995, inlet

air standard

conditions of 99 kPa (29.31 in. Hg) dry barometer

and 25ºC (77ºF)

temperature. Performance measured using a

standard fuel with fuel

gravity of 35º API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29º C (84.2º F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length

1889.0 mm

(2) Width

1091.0 mm

(3) Height

1379.7 mm

Note: Do not use for installation design.

See general dimension drawings for

detail (Drawing # null ).

Performance Number: DM9854-01

Feature Code: C18DF03 Arr. Number: 3149714

Materials and specifications are subject to change without notice.

15474965

© 2009 Caterpillar

All rights reserved.

The International System of Units (SI) is used in this publication.

CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

®

C18 ACERT

™

597 bkW / 800 bhp

1900 rpm

Industrial

Image shown may not reflect

actual engine

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore......................................................145.0 mm (5.71 in)

Stroke.....................................................183.0 mm (7.2 in)

Displacement.................................... 18.1 L (1,104.53 in3)

Aspiration...............................Turbocharged Aftercooled

Compression Ratio...................................................16.3:1

Rotation (from flywheel end).............. Counterclockwise

Weight, Net Dry (approximate kg. lb).. 1673 kg (3688 lb)

FEATURES

Worldwide Supplier Capability

Caterpillar

- Casts engine blocks, heads, cylinder liners, and

flywheel housings

- Machines critical components

- Assembles complete engine

- Factory-designed systems built at Caterpillar ISO

9001:2000 certified facilities

Ownership of these manufacturing processes

enables Caterpillar to produce high quality,

dependable product.

Testing

Prototype testing on every model:

- proves computer design

- verifies system torsional stability

- functionality tests every model

Every Caterpillar engine is dynamometer tested

under full load to ensure proper engine

performance.

Emissions

Meets U.S. EPA Tier 2 emissions requirements. FM

approved. UL approved - US and Canada. Meets

NFPA 20 requirements.

Full Range of Attachments

Wide range of bolt-on system expansion

attachments, factory designed and tested.

Unmatched Product Support Offered Through

Worldwide Caterpillar Dealer Network

More than 1,800 dealer outlets

Caterpillar factory-trained dealer technicians service

every aspect of your industrial engine

99.7% of parts orders filled within 24 hours

worldwide

Caterpillar parts and labor warranty

Preventive maintenance agreements available for

repair before failure options

Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to

determine:

- internal engine component condition

- presence of unwanted fluids

- presence of combustion by-products

Web Site

For all your industrial power requirements, visit

www.cat-industrial.com.

2 November 2009

4:51 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

597 bkW (800 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System

Dual turbocharger: front and rear inlet, 237.0 mm (5

in)

Separate Circuit Aftercooled (SCAC)

Charging System

Charging alternator 24 volt, 50 amp

Control System

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation

Power compensation for fuel temperature

Programmable low and high idle and total engine

limit (TEL)

Electronic diagnostics and fault logging

Engine monitoring and protection system (speeds,

temperature, pressure)

J1939 Broadcast (diagnostic, engine status and

control)

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, gear driven, centrifugal

Heat exchanger (installed)

Expansion tank

Exhaust System

Exhaust manifold, dry

Dual turbo: exhaust elbow, dry 203 mm (8 in)

Flywheels and Flywheel Housing

Flywheel, SAE #1

Flywheel housing, SAE #1

SAE standard rotation

Fuel System

Electronic unit injector

Fuel filter, secondary, mid-mount (LH 2 micron high

performance)

Fuel transfer pump, LH front

Fuel priming pump, LH mid-mount

Fuel sample valve, mounted on fuel filter base

Primary filter / water separator

Instrumentation

Instrument panel, LH

Engine oil pressure gauge

Voltmeter gauge

Water temperature gauge

Tachometer / engine hour meter

Lube System

Crankcase breather, front valve cover

Oil cooler, RH (dual)

Oil filter, RH

Oil pan, front sump

Oil filler, LH front

Oil dipstick, LH front

Oil pump

Mounting System

Front and rear support

Power Take-Offs

Flywheel and stub shaft

Protection System

Stop-Start System, automatic (compatible with

NFPA 20 requirements, able to be energized from

either of two battery sources and capable of manual

starter actuation)

Starting System

24 volt, LH electric starting motor

Jacket water heater (3 kW, 120-240 volt)

General

Vibration damper and guard

Paint, Caterpillar fire pump red

Lifting eyes

Automatic variable timing, electronic

Electronic installation kit, 70 pin connector

(connectors, pins, sockets)

Literature, Owner and Operator's Manual

2

2 November 2009

4:51 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

597 bkW (800 bhp)

PERFORMANCE CURVES

IND - E - EM0021-01

Torque

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Metric

Engine Speed

rpm

Engine Power

kW

Torque N•m

BSFC g/kW-hr Fuel Rate L/hr

1900

597

2998

213.2

151.6

1900

537

2698

215.5

137.9

1900

477

2398

217.8

123.9

1900

447

2248

219.1

116.8

1900

418

2099

220.2

109.6

1900

60

300

363.6

25.9

1900

298

1499

226.5

80.5

1900

239

1199

232.6

66.2

1900

179

899

243.7

52.0

1900

149

749

252.9

45.0

1900

119

600

270

38.4

1900

358

1799

222.8

95.1

3

2 November 2009

4:51 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

597 bkW (800 bhp)

RATINGS AND CONDITIONS

Standby Fire Pump Ratings represent the output

which may be utilized to drive stationary fire pumps

where the pumping equipment has been sized

according to NFPA 20 guidelines and for expected

use of 30 hours per year where pump demand is

about 90% or less of the certified power. Standby

fire pump ratings are not equivalent to IND-E or any

other standard Industrial ratings.

Engine Performance Diesel Engines — 7 liter and

higher

All rating conditions are based on SAE J1995, inlet

air standard

conditions of 99 kPa (29.31 in. Hg) dry barometer

and 25ºC (77ºF)

temperature. Performance measured using a

standard fuel with fuel

gravity of 35º API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29º C (84.2º F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length

1889.0 mm

(2) Width

1091.0 mm

(3) Height

1379.7 mm

Note: Do not use for installation design.

See general dimension drawings for

detail (Drawing # null ).

Performance Number: EM0021-01

Feature Code: C18DF03 Arr. Number: 3149714

Materials and specifications are subject to change without notice.

15476012

© 2009 Caterpillar

All rights reserved.

The International System of Units (SI) is used in this publication.

CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

®

C18 ACERT

™

597 bkW / 800 bhp

2100 rpm

Industrial

Image shown may not reflect

actual engine

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore......................................................145.0 mm (5.71 in)

Stroke.....................................................183.0 mm (7.2 in)

Displacement.................................... 18.1 L (1,104.53 in3)

Aspiration...............................Turbocharged Aftercooled

Compression Ratio...................................................16.3:1

Rotation (from flywheel end).............. Counterclockwise

Weight, Net Dry (approximate kg. lb).. 1673 kg (3688 lb)

FEATURES

Worldwide Supplier Capability

Caterpillar

- Casts engine blocks, heads, cylinder liners, and

flywheel housings

- Machines critical components

- Assembles complete engine

- Factory-designed systems built at Caterpillar ISO

9001:2000 certified facilities

Ownership of these manufacturing processes

enables Caterpillar to produce high quality,

dependable product.

Testing

Prototype testing on every model:

- proves computer design

- verifies system torsional stability

- functionality tests every model

Every Caterpillar engine is dynamometer tested

under full load to ensure proper engine

performance.

Emissions

Meets U.S. EPA Tier 2 emissions requirements. FM

approved. UL approved - US and Canada. Meets

NFPA 20 requirements.

Full Range of Attachments

Wide range of bolt-on system expansion

attachments, factory designed and tested.

Unmatched Product Support Offered Through

Worldwide Caterpillar Dealer Network

More than 1,800 dealer outlets

Caterpillar factory-trained dealer technicians service

every aspect of your industrial engine

99.7% of parts orders filled within 24 hours

worldwide

Caterpillar parts and labor warranty

Preventive maintenance agreements available for

repair before failure options

Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to

determine:

- internal engine component condition

- presence of unwanted fluids

- presence of combustion by-products

Web Site

For all your industrial power requirements, visit

www.cat-industrial.com.

2 November 2009

4:49 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

597 bkW (800 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System

Dual turbocharger: front and rear inlet, 237.0 mm (5

in)

Separate Circuit Aftercooled (SCAC)

Charging System

Charging alternator 24 volt, 50 amp

Control System

Electronic governing, PTO speed control

Programmable ratings

Cold mode start strategy

Automatic altitude compensation

Power compensation for fuel temperature

Programmable low and high idle and total engine

limit (TEL)

Electronic diagnostics and fault logging

Engine monitoring and protection system (speeds,

temperature, pressure)

J1939 Broadcast (diagnostic, engine status and

control)

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, gear driven, centrifugal

Heat exchanger (installed)

Expansion tank

Exhaust System

Exhaust manifold, dry

Dual turbo: exhaust elbow, dry 203 mm (8 in)

Flywheels and Flywheel Housing

Flywheel, SAE #1

Flywheel housing, SAE #1

SAE standard rotation

Fuel System

Electronic unit injector

Fuel filter, secondary, mid-mount (LH 2 micron high

performance)

Fuel transfer pump, LH front

Fuel priming pump, LH mid-mount

Fuel sample valve, mounted on fuel filter base

Primary filter / water separator

Instrumentation

Instrument panel, LH

Engine oil pressure gauge

Voltmeter gauge

Water temperature gauge

Tachometer / engine hour meter

Lube System

Crankcase breather, front valve cover

Oil cooler, RH (dual)

Oil filter, RH

Oil pan, front sump

Oil filler, LH front

Oil dipstick, LH front

Oil pump

Mounting System

Front and rear support

Power Take-Offs

Flywheel and stub shaft

Protection System

Stop-Start System, automatic (compatible with

NFPA 20 requirements, able to be energized from

either of two battery sources and capable of manual

starter actuation)

Starting System

24 volt, LH electric starting motor

Jacket water heater (3 kW, 120-240 volt)

General

Vibration damper and guard

Paint, Caterpillar fire pump red

Lifting eyes

Automatic variable timing, electronic

Electronic installation kit, 70 pin connector

(connectors, pins, sockets)

Literature, Owner and Operator's Manual

2

2 November 2009

4:49 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

597 bkW (800 bhp)

PERFORMANCE CURVES

IND - E - EM0022-01

Torque

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Metric

Engine Speed

rpm

Engine Power

kW

Torque N•m

BSFC g/kW-hr Fuel Rate L/hr

2100

597

2712

225.2

160.2

2100

537

2441

223.8

143.2

2100

477

2170

224.9

128.0

2100

447

2034

226

120.5

2100

418

1899

227.4

113.2

2100

60

271

392.3

27.9

2100

298

1356

236.2

84.0

2100

239

1085

243.3

69.2

2100

179

814

255.1

54.4

2100

149

678

264.5

47.0

2100

119

542

284

40.4

2100

358

1627

231.1

98.6

3

2 November 2009

4:49 AM

®

C18 ACERT

™

INDUSTRIAL ENGINE

597 bkW (800 bhp)

RATINGS AND CONDITIONS

Standby Fire Pump Ratings represent the output

which may be utilized to drive stationary fire pumps

where the pumping equipment has been sized

according to NFPA 20 guidelines and for expected

use of 30 hours per year where pump demand is

about 90% or less of the certified power. Standby

fire pump ratings are not equivalent to IND-E or any

other standard Industrial ratings.

Engine Performance Diesel Engines — 7 liter and

higher

All rating conditions are based on SAE J1995, inlet

air standard

conditions of 99 kPa (29.31 in. Hg) dry barometer

and 25ºC (77ºF)

temperature. Performance measured using a

standard fuel with fuel

gravity of 35º API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29º C (84.2º F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length

1889.0 mm

(2) Width

1091.0 mm

(3) Height

1379.7 mm

Note: Do not use for installation design.

See general dimension drawings for

detail (Drawing # null ).

Performance Number: EM0022-01

Feature Code: C18DF03 Arr. Number: 3149714

Materials and specifications are subject to change without notice.

15476013

© 2009 Caterpillar

All rights reserved.

The International System of Units (SI) is used in this publication.

CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

Document Outline

- Spec sheet C18DF01 NFPA 1750 RPM

- Spec sheet C18DF01 NFPA 1900 RPM

- Spec sheet C18DF01 NFPA 2100 RPM

- Spec sheet C18DF02 NFPA 1750 RPM

- Spec sheet C18DF02 NFPA 1900 RPM

- Spec sheet C18DF02 NFPA 2100 RPM

- Spec sheet C18DF03 NFPA 1750 RPM

- Spec sheet C18DF03 NFPA 1900 RPM

- Spec sheet C18DF03 NFPA 2100 RPM

Wyszukiwarka

Podobne podstrony:

Cat C18 ACERT Spec Sheets Commercial

LG G3 D850 Spec Sheet R1

Airtronic D2 D4 D5 Spec sheet

mazda3 takuya spec sheet

Hydronic D5 C Spec sheet

AOC 416V 416V Spec Sheet

Hydronic D5 SC S E Spec sheet

8000CD spec sheet

8000S spec sheet

Cukrzyca ciężarnych 2012 spec anestetyczki

download Finanse międzynarodowe FINANSE MIĘDZYNARODOWE WSZiM ROK III SPEC ZF

CW2006EX Mill Turn data sheet web

Klanarchia character sheet Color1

freespan spec guide

cx5500 data sheet enus

Fireborn Scion Character Sheet

KidWorld GM Cheat Sheet

więcej podobnych podstron