SPECIFICATIONS

I-6, 4-Stroke-Cycle-Diesel

Displacement . . . . . . . . . . . . . . . . . . . 18.1 L (1106 in

3

)

Rated Engine Speed . . . . . . . . . . . . . . . . . . . . . . 1800

Bore. . . . . . . . . . . . . . . . . . . . . . . . . . . 145 mm (5.7 in.)

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . 183 mm (7.2 in.)

Aspiration . . . . . . . . . . . . . Turbocharged-Aftercooled

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic

Cooling System . . . . . . . . . . . . . . . . . . . . Keel-Cooled/

Heat-Exchanger Cooled

Weight, Net Dry (approx.)

Keel-Cooled. . . . . . . . . . . . . . . . . . 1539 kg (3394 lb)

Heat Exchanger-Cooled . . . . . . . 1673 kg (3688 lb)

Refill Capacity

Cooling System . . . . . . . . . . . . . . . 45.8 L (12.1 gal)

Lube Oil System . . . . . . . . . . . . . . . . 64 L (16.9 gal)

Oil Change Interval . . . . . . . . . . . . . . . . . . . 500 hours

Caterpillar Diesel Engine Oil 10W30 or 15W40

Rotation (from flywheel end) . . . . . Counterclockwise

Flywheel and flywheel

housing. . . . . . . . . . . . . . SAE No. 1 and SAE No. 0

Flywheel Teeth

SAE No. 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

SAE No. 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maximum Exhaust

Backpressure . . . . . . . . . . 6.7 kPa (26.9 in. water)

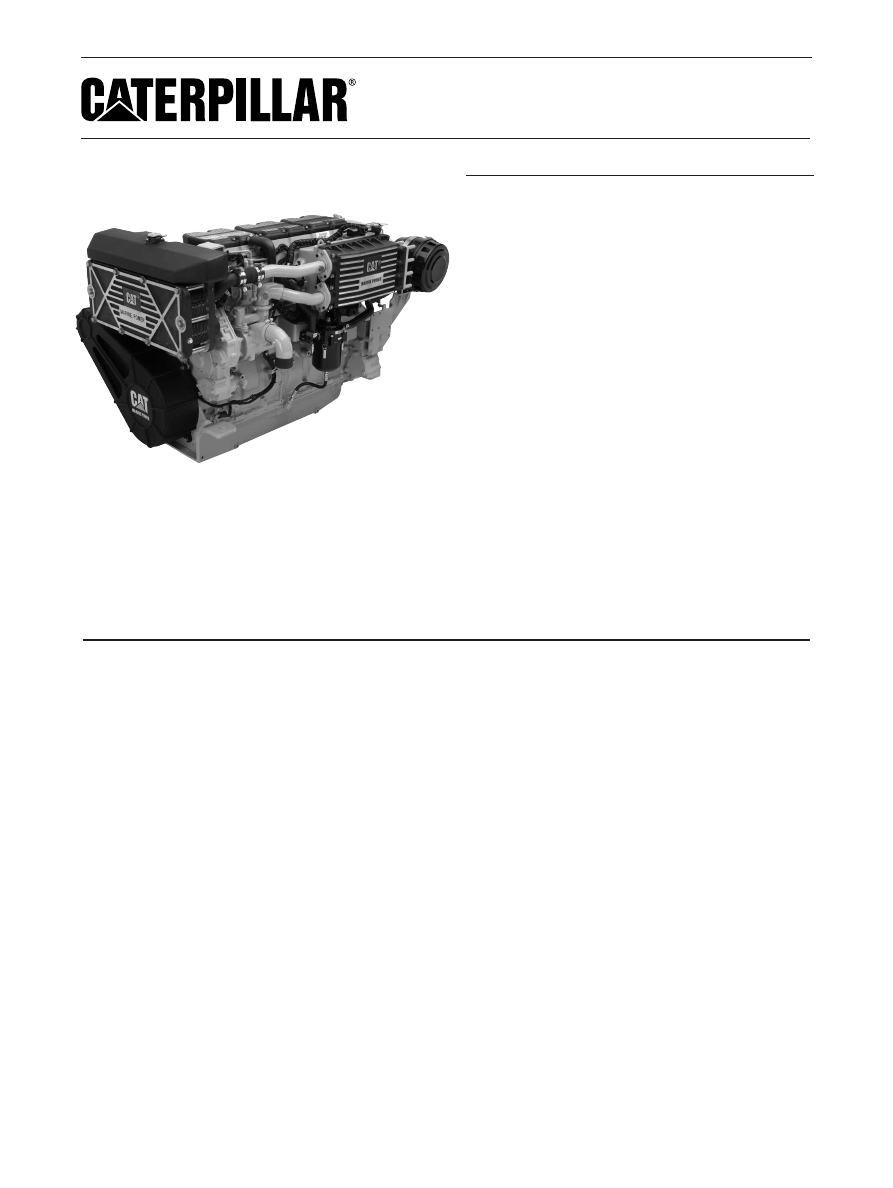

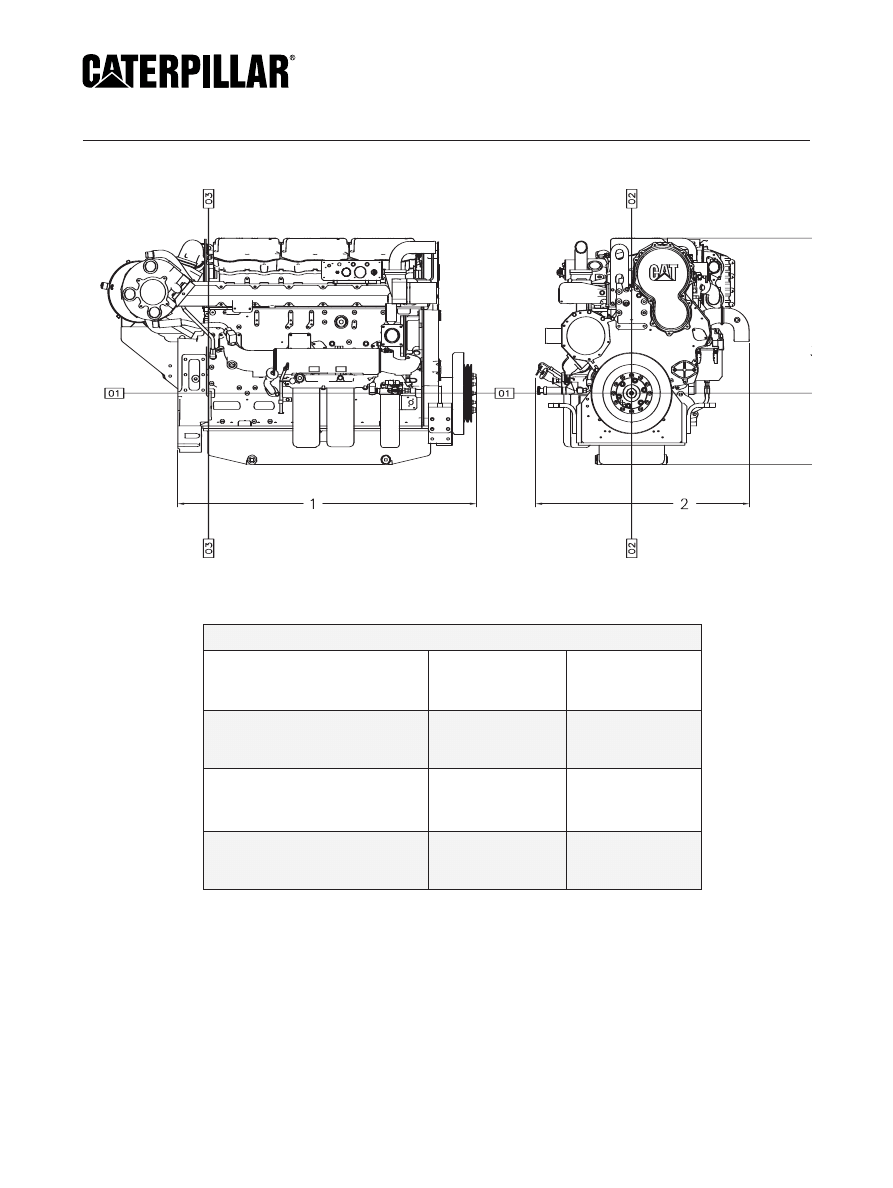

C18 ACERT™

MARINE PROPULSION

339 bkW

(454 bhp)

LEHM7331-01

Page 1 of 4

Image may not reflect

actual engine

STANDARD EQUIPMENT

Air Inlet System

Corrosion-resistant sea water aftercooler, air

cleaner/fumes disposal (closed system), jacket

water cooled turbocharger, turbocharger inlet OD

straight connection

Control System

Electronic governing (A4), programmable low idle,

electronic diagnostics and fault logging, fuel/air

ratio control, electronic throttle position sensor

Cooling System

Thermostat and housing, block heater (1500W,

120V AC current), gear-driven jacket water pump,

self priming, gear-driven sea water pump with

bronze impeller, titanium plate type heat exchanger

or separate circuit keel cooling

Exhaust System

Watercooled exhaust manifold and turbocharger,

round-flanged outlet

Flywheel and Flywheel Housings

Standard SAE No. 1 flywheel and flywheel housing,

113 teeth, SAE standard rotation; optional SAE

No. 0 flywheel and flywheel housing, 136 teeth,

SAE standard rotation

Fuel System

Fuel filter, RH service on port, LH service on

starboard; fuel transfer pump; fuel priming pump;

flexible fuel lines

Instrumentation

Electric service meter, instrument panel (24V),

start/stop switch, emergency stop button,

maintenance due light, diagnostic light, warning

light, maintenance clear switch, start motor

magnetic switch, 15 and 3A breakers

Lube System

Crankcase breather; oil cooler; spin-on oil filter, RH

service on port, LH service on starboard; center

sump deep oil pan; oil filler; dipstick, RH service on

port, LH service on starboard; gear-driven oil pump

Mounting System

Adjustable front support

Power Take-Offs

Hydraulic pump drive, SAE A, 11 tooth spline,

46 ft-lbs max torque, counterclockwise as viewed

from front of the engine looking into the drive and

turns 1.41 x engine speed, 292 mm crankshaft

pulley, 15.88 mm width

General

Vibration damper; lifting eyes, RH or LH service

options; literature; variable engine wiring; upper

rear-facing customer wiring connector and service

tool connections

ISO Certification

Factory-designed systems built at Caterpillar

ISO 9001:2000 certified facilities.

C18 ACERT™

MARINE PROPULSION

339 bkW (454 bhp)

LEHM7331-01

Page 2 of 4

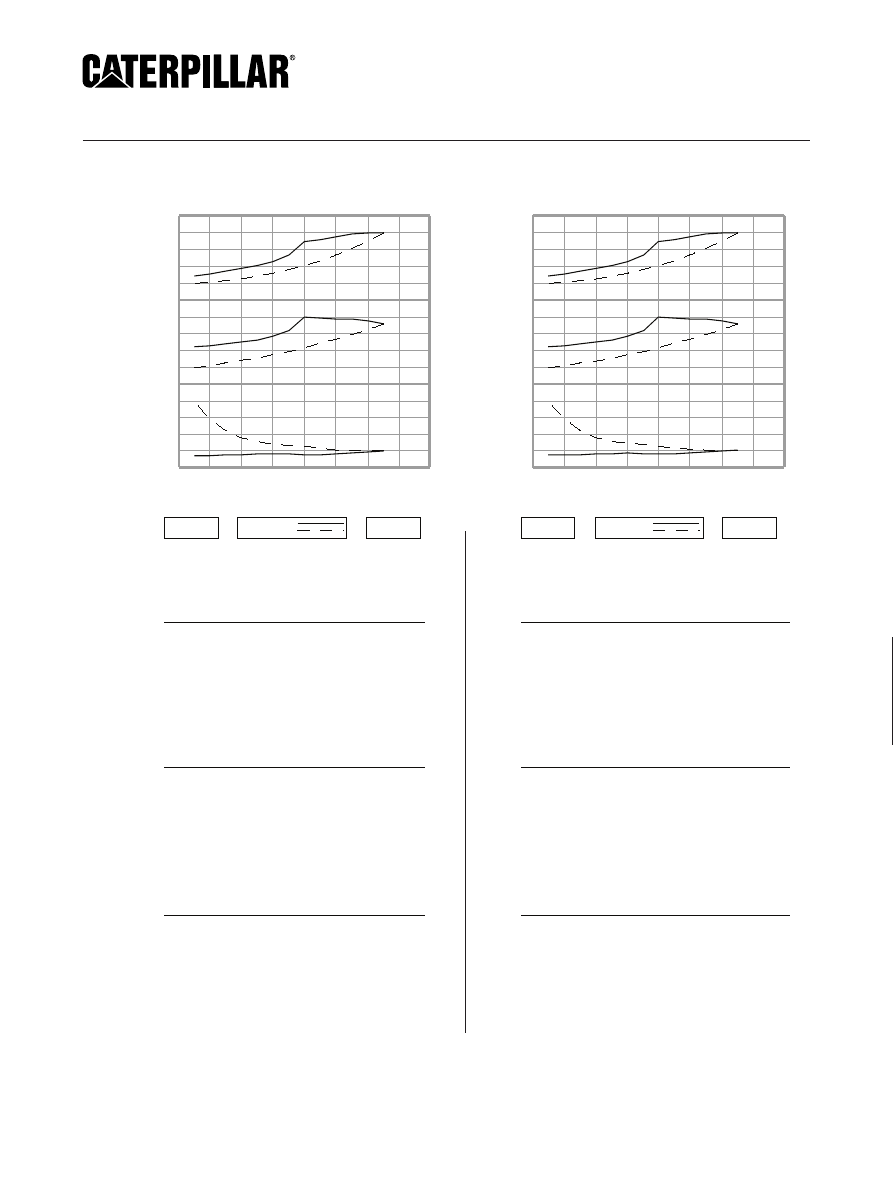

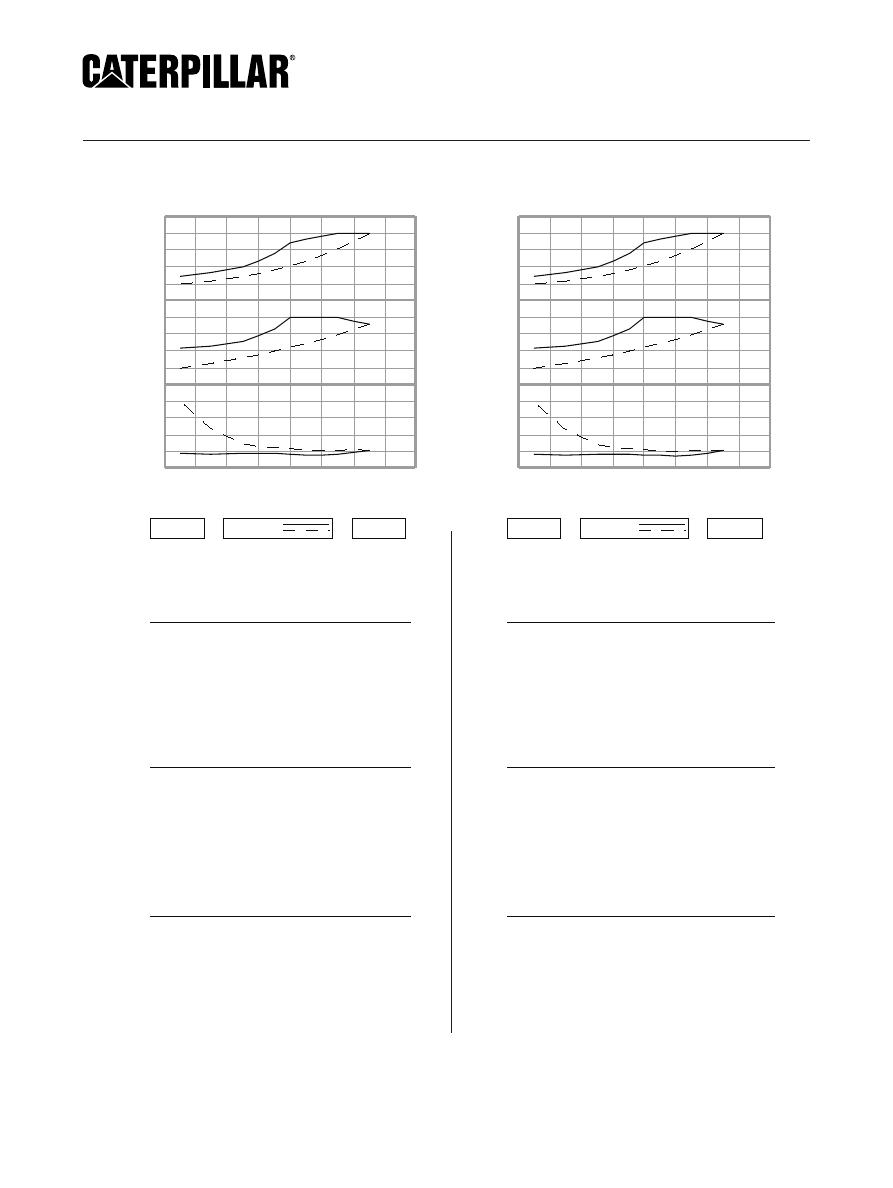

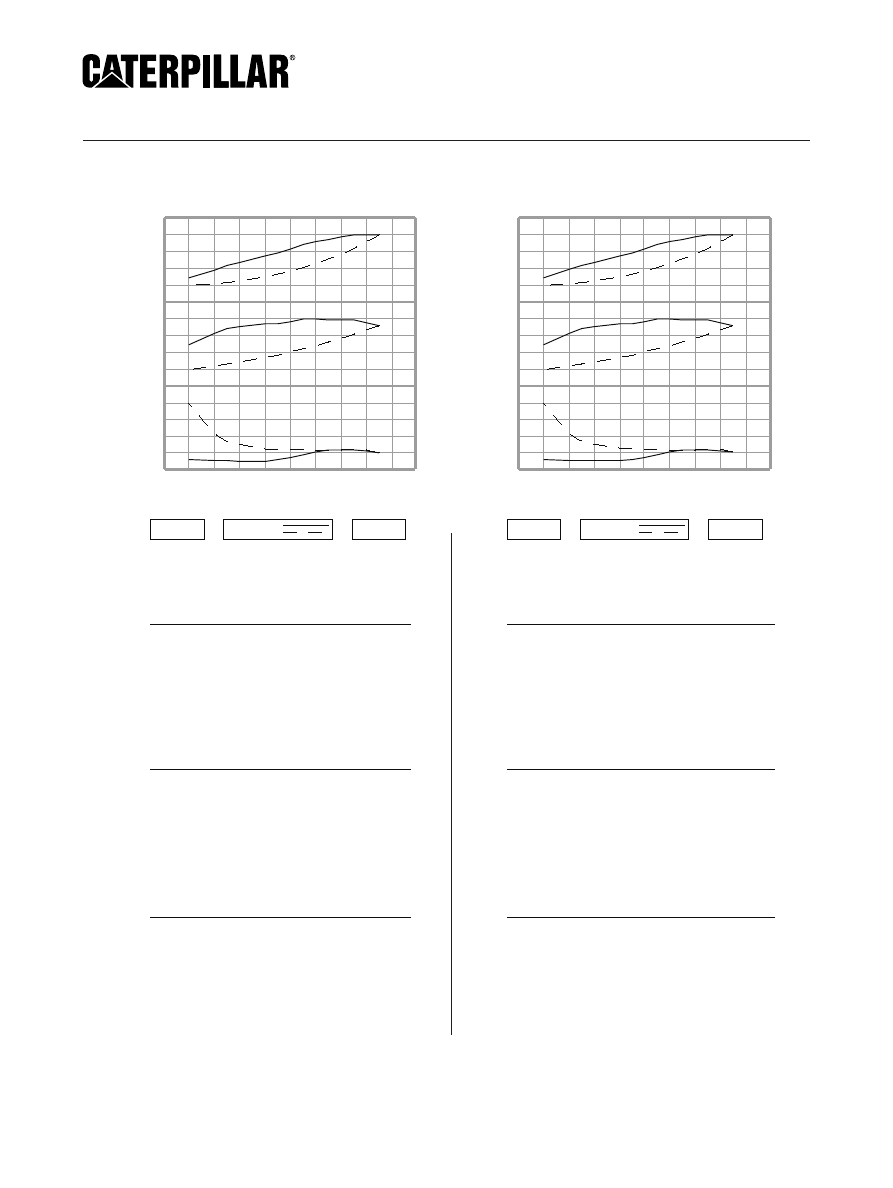

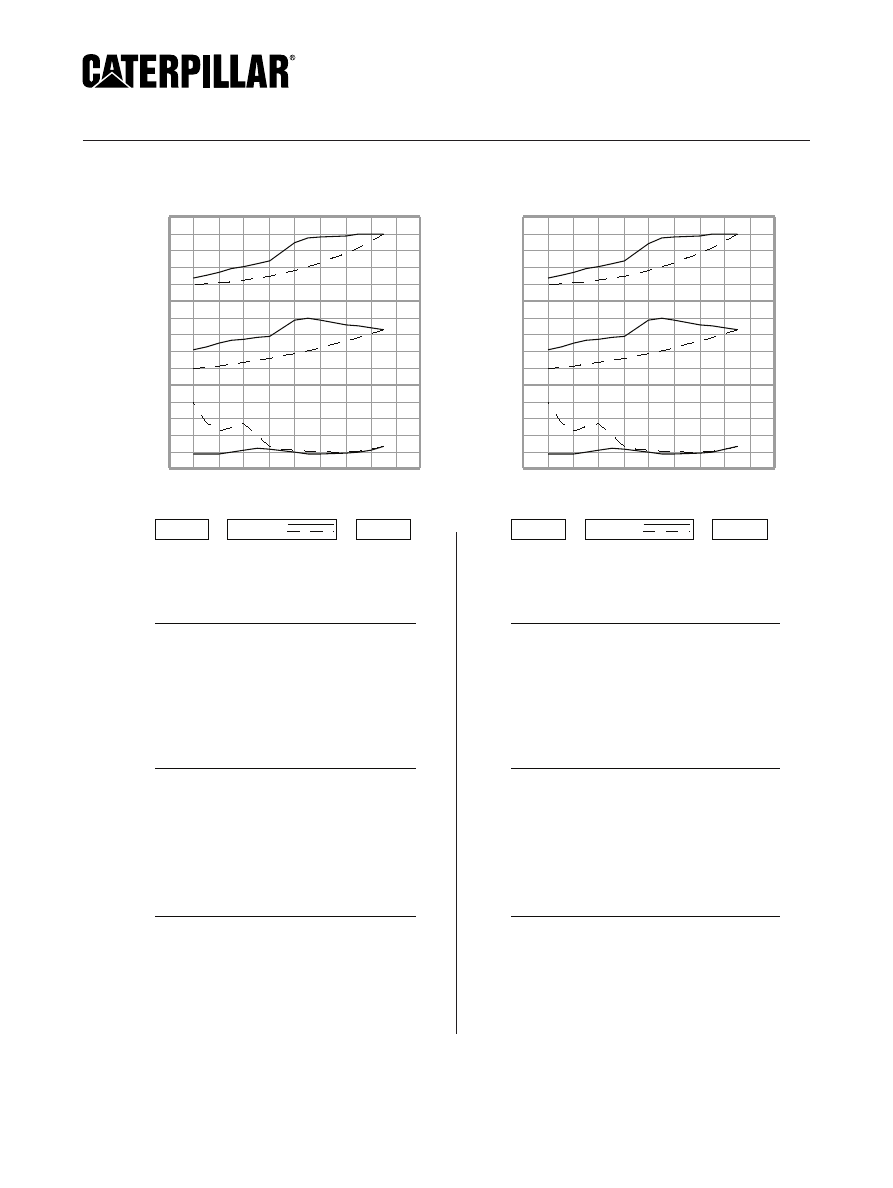

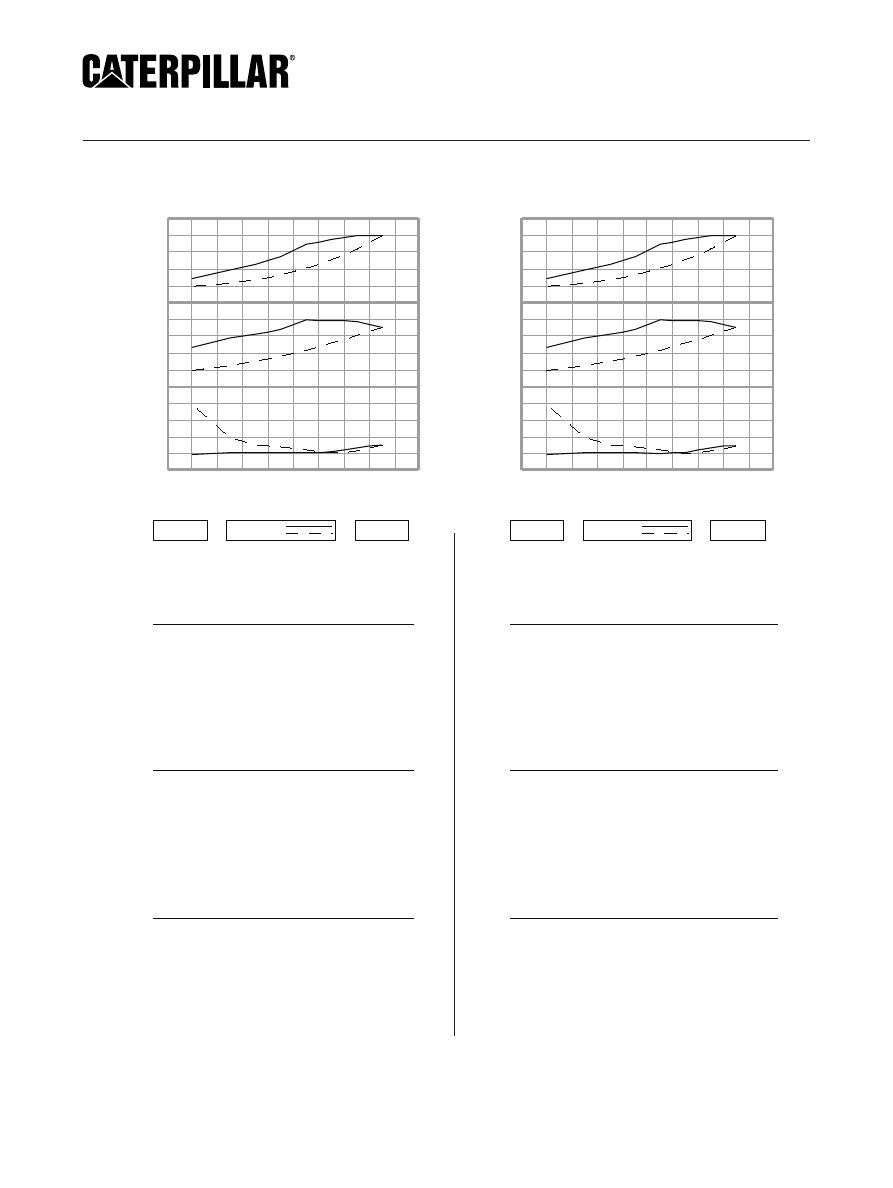

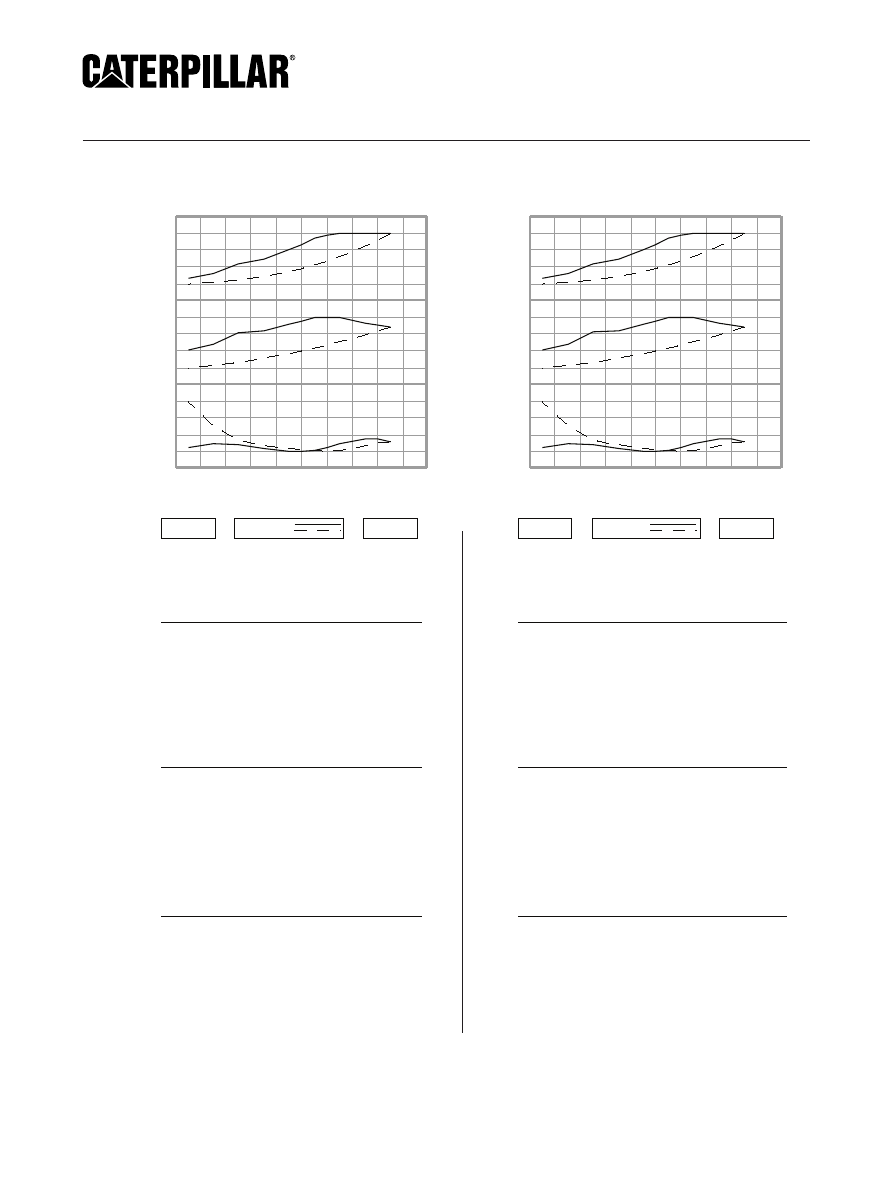

PERFORMANCE CURVES

Turbocharged-Aftercooled

A Rating — 339 bkW (454 bhp) @ 1800 rpm

DM9574-00

Marine Engine Performance

339 kW (454 hp) @ 1800 rpm

C18 DITA

A-RATING - DM9574-00

B

S

F

C

g

/k

W

-h

r

E

n

g

in

e

P

o

w

er

kW

T

o

rq

u

e

N

•m

Engine Speed - rpm

700

900

1100

1300

1500

1700

1900

338

230

121

13

2057

1438

819

200

293

266

239

212

B

S

F

C

lb

/h

p

-h

r

E

n

g

in

e

P

o

w

er

h

p

T

o

rq

u

e

lb

-f

t

Engine Speed - rpm

700

900

1100

1300

1500

1700

1900

454

308

162

17

1517

1061

604

148

.482

.437

.392

.347

Metric

Maximum Power

Prop Demand

339 kW

English

Maximum Power

Prop Demand

454 hp

Performance Data

Performance Data

Engine

Speed

rpm

Engine

Power

kW

Engine

Torque

N•m

BSFC

g/kW-hr

Fuel

Rate

L/hr

Maximum

Power

Data

Engine

Speed

rpm

Engine

Power

hp

Engine

Torque

lb-ft

BSFC

lb/hp-hr

Fuel

Rate

gph

Maximum

Power

Data

1800

338.5

1796

212.1

85.6

1800

453.9

1325

.349

22.6

1700

338.5

1901

210.1

84.8

1700

453.9

1402

.345

22.4

1600

333.0

1987

208.6

82.8

1600

446.6

1465

.343

21.9

1500

313.0

1993

207.0

77.2

1500

419.7

1470

.340

20.4

1400

295.0

2012

205.6

72.3

1400

395.6

1484

.338

19.1

1200

197.0

1568

206.3

48.4

1200

264.2

1156

.339

12.8

1100

154.0

1337

206.6

37.9

1100

206.5

986

.340

10.0

1000

126.0

1203

206.3

31.0

1000

169.0

887

.339

8.2

900

106.0

1125

205.7

26.0

900

142.1

830

.338

6.9

700

74.0

1009

204.0

18.0

700

99.2

744

.335

4.8

600

61.0

971

203.4

14.8

600

81.8

716

.334

3.9

Prop

Demand

Data

Prop

Demand

Data

1800

338.5

1796

212.1

85.6

1800

453.9

1325

.349

22.6

1700

285.2

1602

211.9

72.0

1700

382.5

1182

.348

19.0

1600

237.7

1419

212.3

60.2

1600

318.8

1047

.349

15.9

1500

195.9

1247

213.4

49.8

1500

262.7

920

.351

13.2

1400

159.3

1086

215.8

41.0

1400

213.6

801

.355

10.8

1200

100.3

798

220.6

26.4

1200

134.5

589

.363

7.0

1100

77.3

671

222.6

20.5

1100

103.7

495

.366

5.4

1000

58.0

554

226.7

15.7

1000

77.8

409

.373

4.1

900

42.3

449

234.5

11.8

900

56.7

331

.386

3.1

700

19.9

272

265.3

6.3

700

26.7

201

.436

1.7

600

12.5

200

293.1

4.4

600

16.8

148

.482

1.2

Cubic prop demand curve with 3.0 exponent for displacement

hulls only.

Power produced at the flywheel will be within standard

tolerances up to 50°C (122°F) combustion air temperature

measured at the air cleaner inlet, and fuel temperature

up to 52°C (125°F) measured at the fuel filter base.

Power rated in accordance with NMMA procedure as

crankshaft power. Reduce crankshaft power by 3% for

propeller shaft power.

PD-DM9574-00.pdf

Created on 09/20/2007 21:00

© 2007 Caterpillar All Rights Reserved

For most current information, please refer to TMI.

C18 ACERT™

MARINE PROPULSION

339 bkW (454 bhp)

LEHM7331-01

Page 3 of 4

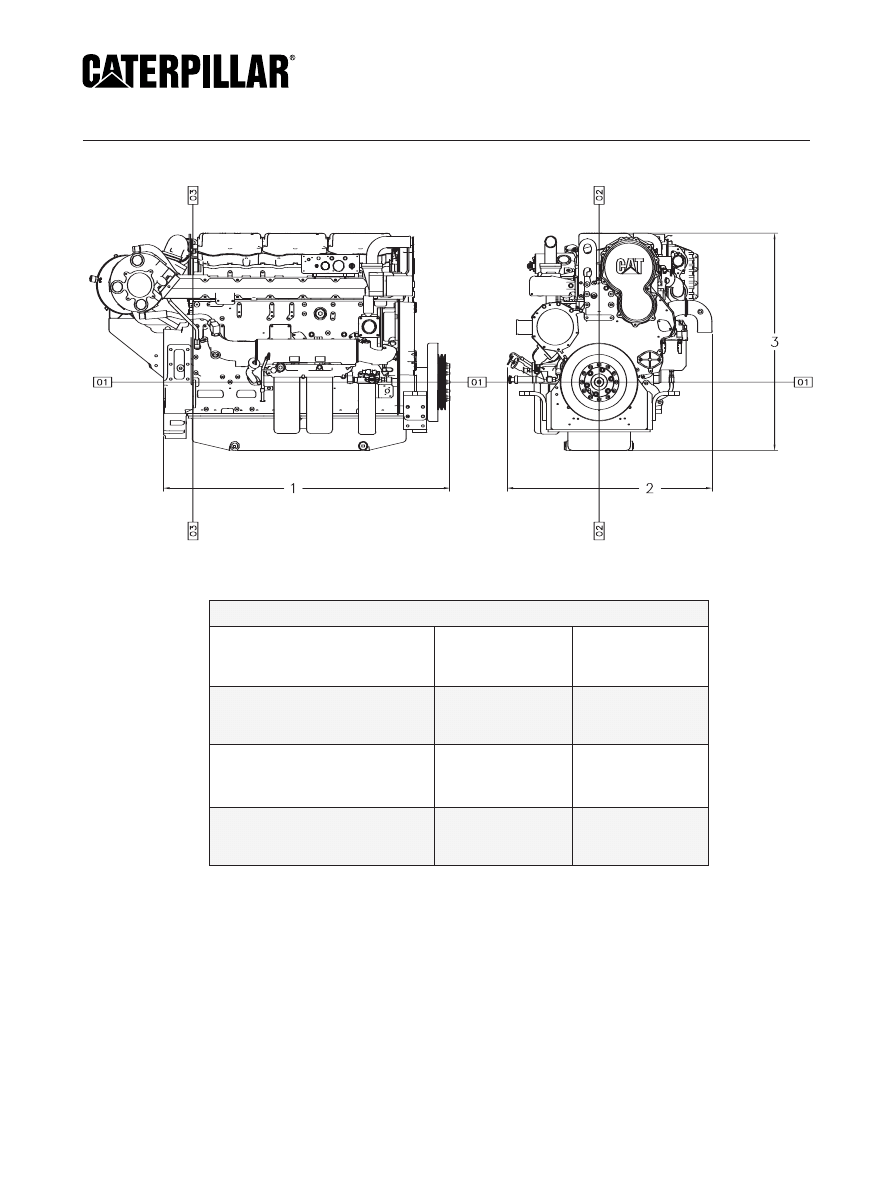

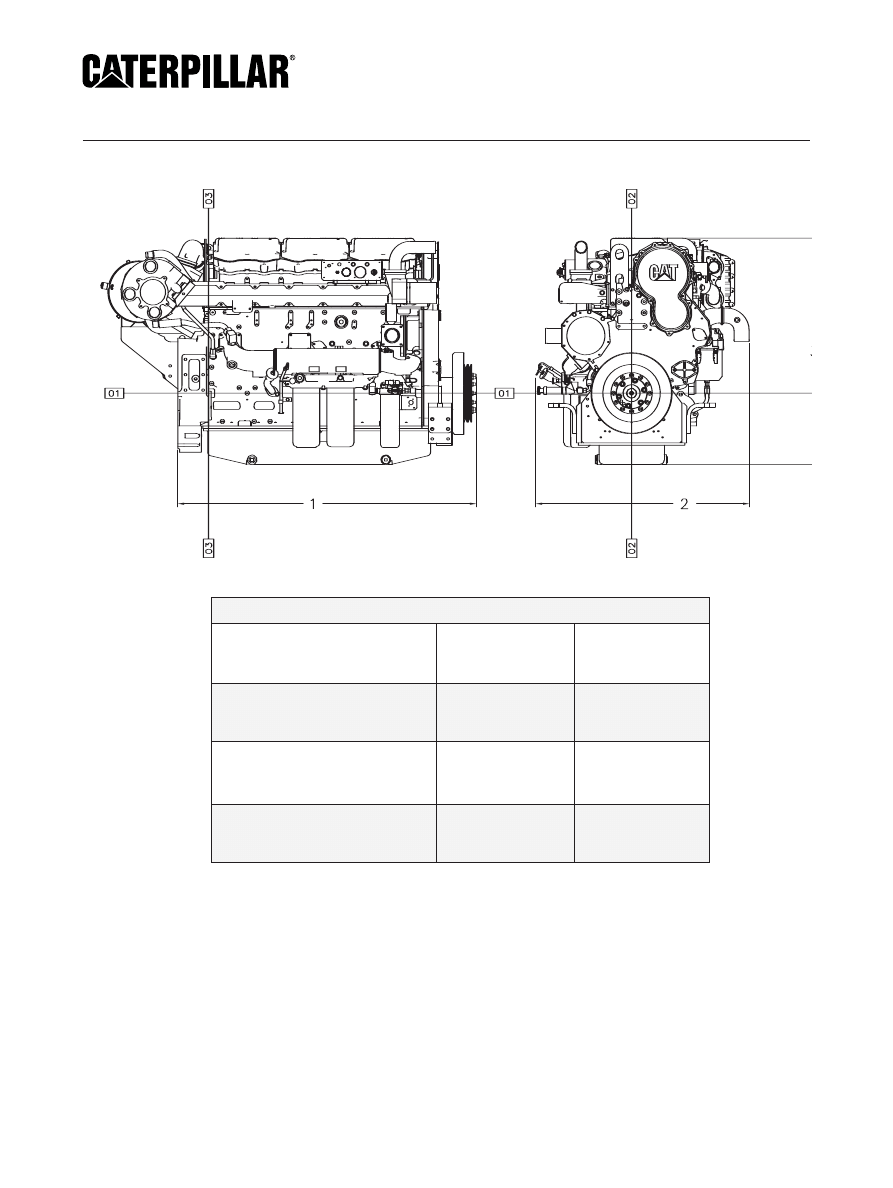

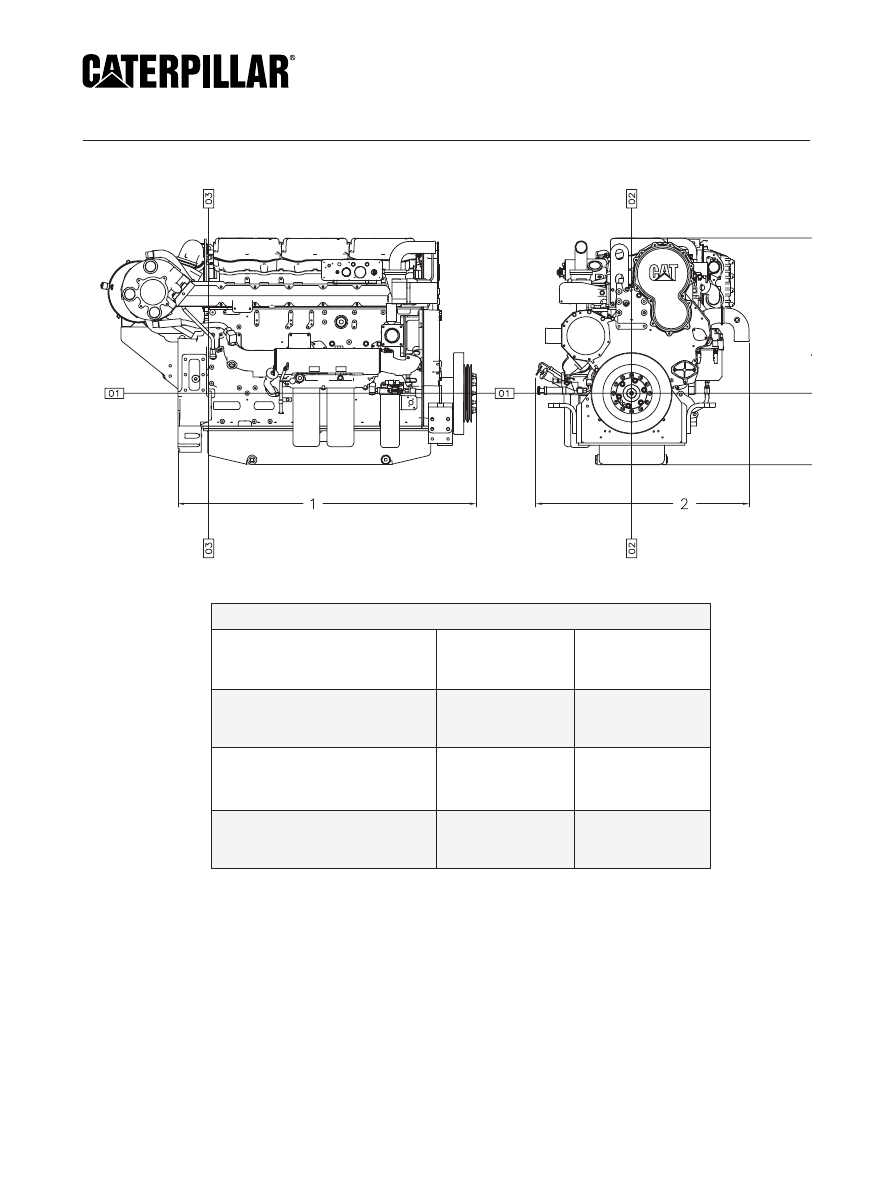

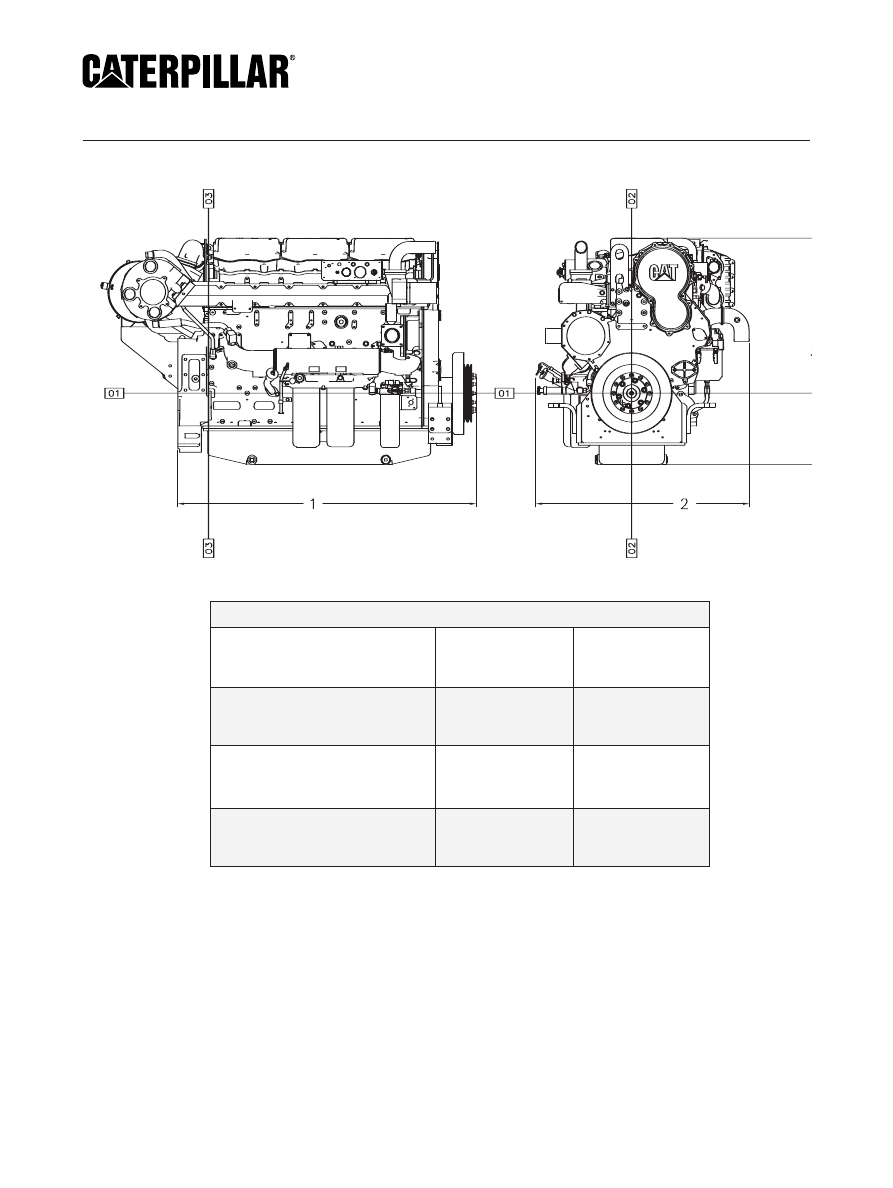

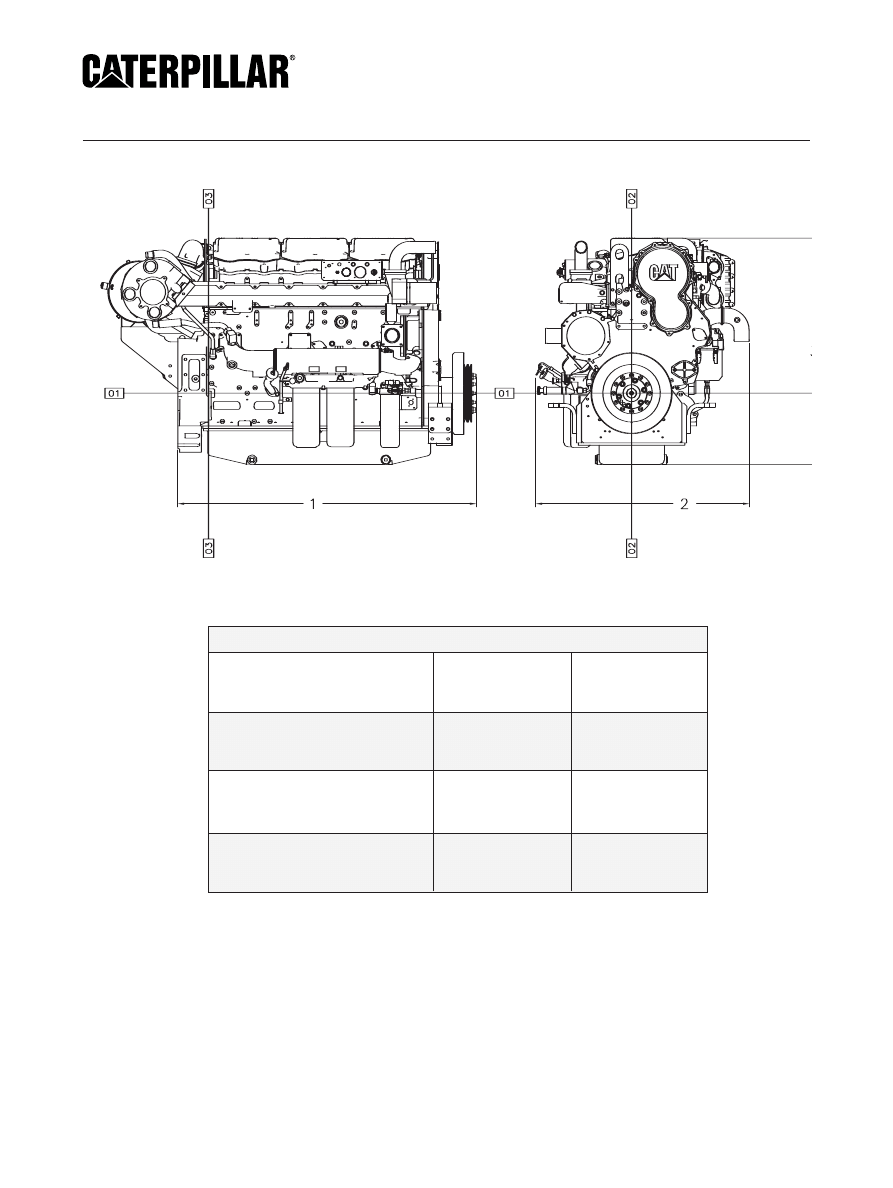

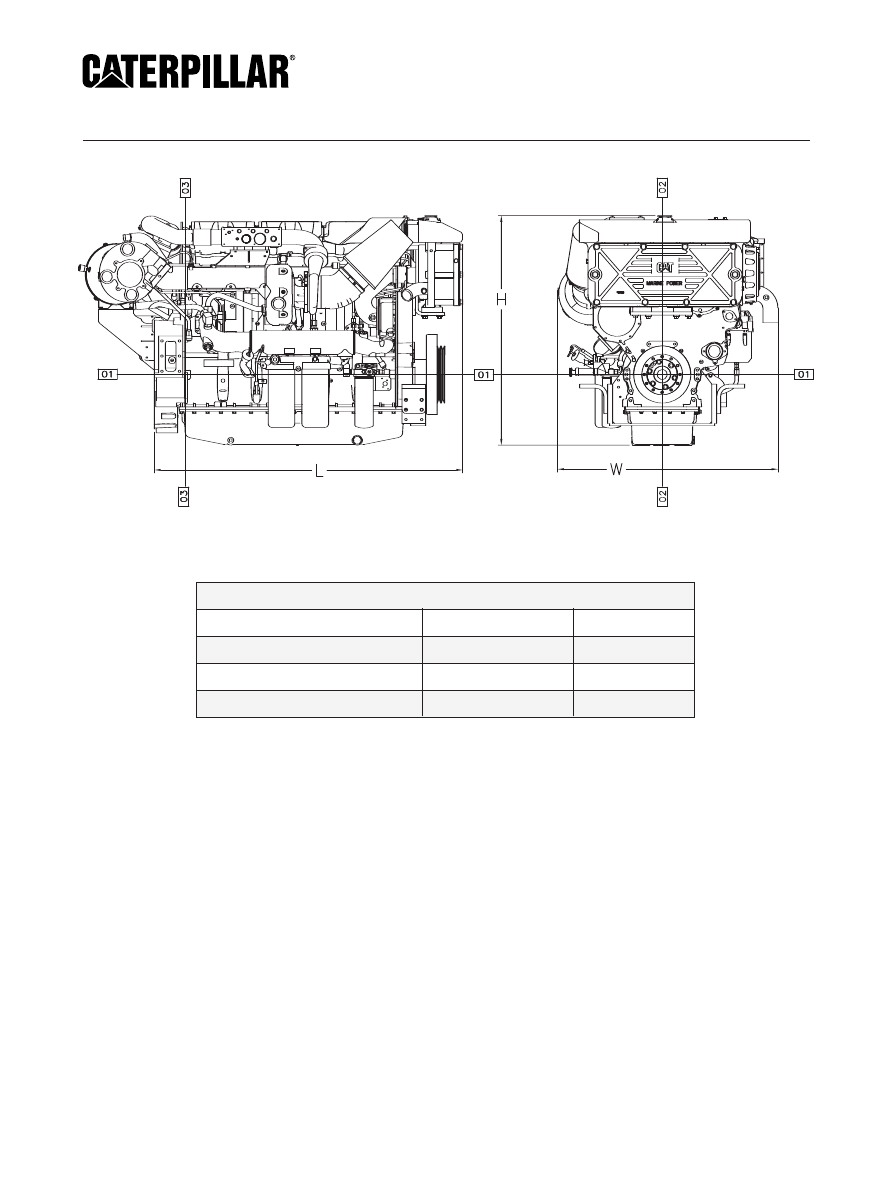

ENGINE DIMENSIONS

C18 ACERT Engine Dimensions (approx.)

Length to Flywheel Housing

Heat-Exchanger Cooled

1504.8 mm

59.24 in.

Keel-Cooled

1504.8 mm

59.24 in.

Width

Heat-Exchanger Cooled

1077.2 mm

42.41 in.

Keel-Cooled

1077.2 mm

42.41 in.

Height

Heat-Exchanger Cooled

1143.9 mm

45.04 in.

Keel-Cooled

1143.9 mm

45.04 in.

Weight (dry)

Heat-Exchanger Cooled

1673 kg

3688 lb

Keel-Cooled

1539 kg

3394 lb

Note: Do not use for installation design. See general dimension drawings

for detail (Drawing #315-3171).

RATING DEFINITIONS AND CONDITIONS

A Rating (Unrestricted Continuous)

Typical applications: For vessels operating at

rated load and rated speed up to 100% of the time

without interruption or load cycling (80% to 100%

load factor). Typical applications could include but

are not limited to vessels such as freighters,

tugboats, bottom drag trawlers, or deep river

tugboats. Typical operation ranges from 5000 to

8000 hours per year.

Power at declared engine speed is in accordance

with ISO3046-1:2002E. Caterpillar maintains

ISO9001:1994/QS-9000 approved engine test

facilities to assure accurate calibration of test

equipment. Electronically controlled engines are set

at the factory at the advertised power corrected to

standard ambient conditions. The published fuel

consumption rates are in accordance with ISO3046.

Fuel rates are based on fuel oil of 35° API [16°C

(60°F)] gravity having an LHV of 42 780 kJ/kg

(18,390 Btu/lb) when used at 29°C (85°F) and

weighing 838.9 g/L (7.001 lb/U.S. gal). Additional

ratings may be available for specific customer

requirements. Consult your Caterpillar

representative for additional information.

Performance No.: DM9574-00

©2008 Caterpillar

U.S. Sourced

All rights reserved.

LEHM7331-01 (1-08)

Materials and specifications are subject to change without notice.

The International System of Units (SI) is used in this publication.

Performance data is calculated in accordance with tolerances and conditions stated in this specification sheet and is only intended for purposes of

comparison with other manufacturers’ engines. Actual engine performance may vary according to the particular application of the engine and operating

conditions beyond Caterpillar’s control.

Power produced at the flywheel will be within standard tolerances up to 49°C (120°F) combustion air temperature measured at the air cleaner inlet, and fuel

temperature up to 52°C (125°F) measured at the fuel filter base. Power rated in accordance with NMMA procedure as crankshaft power. Reduce crankshaft

power by 3% for propeller shaft power.

CAT, CATERPILLAR, their respective logos, ACERT, “Caterpillar Yellow” and the POWER EDGE trade dress, as well as corporate and product identity

used herein, are trademarks of Caterpillar and may not be used without permission.

C18 ACERT™

MARINE PROPULSION

339 bkW (454 bhp)

SPECIFICATIONS

I-6, 4-Stroke-Cycle-Diesel

Displacement . . . . . . . . . . . . . . . . . . . 18.1 L (1106 in

3

)

Rated Engine Speed . . . . . . . . . . . . . . . . . . . . . . 1800

Bore. . . . . . . . . . . . . . . . . . . . . . . . . . . 145 mm (5.7 in.)

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . 183 mm (7.2 in.)

Aspiration . . . . . . . . . . . . . Turbocharged-Aftercooled

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic

Cooling System . . . . . . . . . . . . . . . . . . . . Keel-Cooled/

Heat-Exchanger Cooled

Weight, Net Dry (approx.)

Keel-Cooled. . . . . . . . . . . . . . . . . . 1539 kg (3394 lb)

Heat Exchanger-Cooled . . . . . . . 1673 kg (3688 lb)

Refill Capacity

Cooling System . . . . . . . . . . . . . . . 45.8 L (12.1 gal)

Lube Oil System . . . . . . . . . . . . . . . . 64 L (16.9 gal)

Oil Change Interval . . . . . . . . . . . . . . . . . . . 500 hours

Caterpillar Diesel Engine Oil 10W30 or 15W40

Rotation (from flywheel end) . . . . . Counterclockwise

Flywheel and flywheel

housing. . . . . . . . . . . . . . SAE No. 1 and SAE No. 0

Flywheel Teeth

SAE No. 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

SAE No. 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maximum Exhaust

Backpressure . . . . . . . . . . 6.7 kPa (26.9 in. water)

C18 ACERT™

MARINE PROPULSION

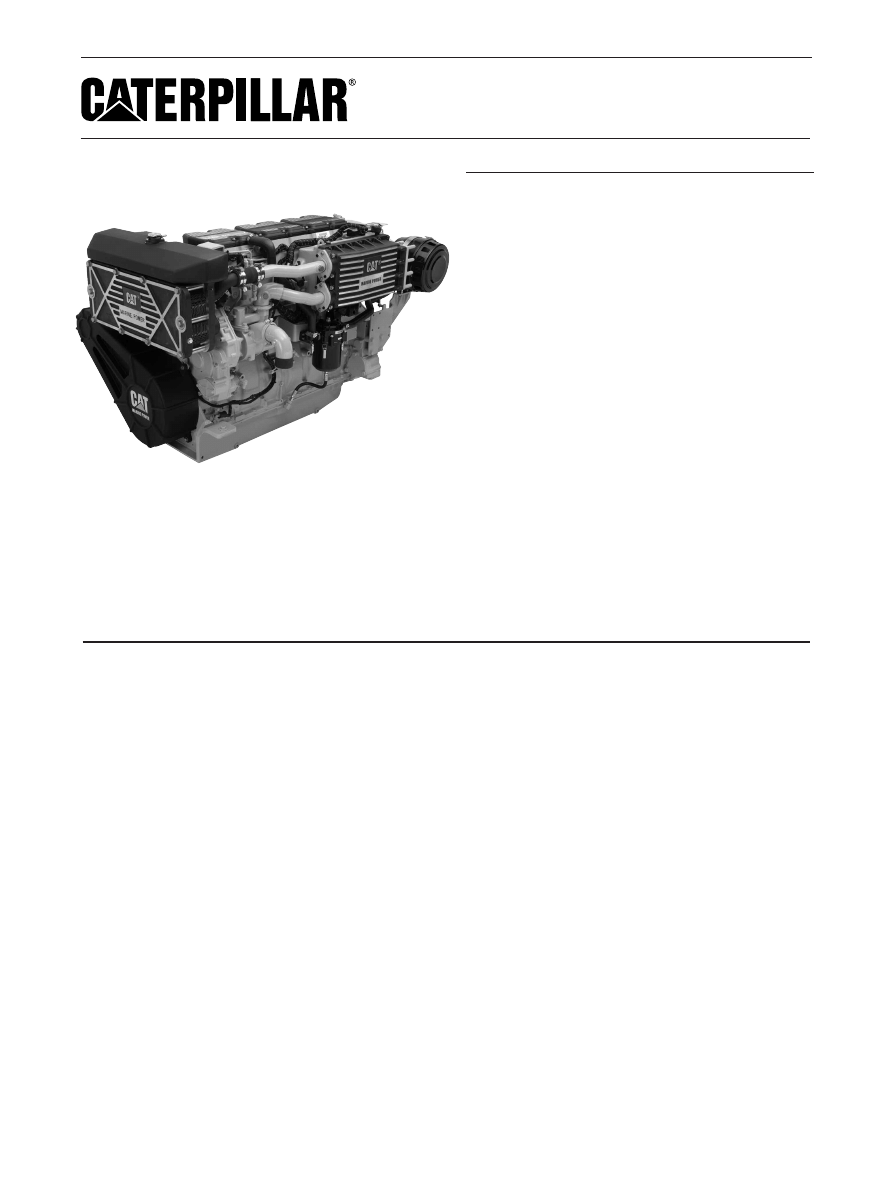

357 bkW

(479 bhp)

LEHM7355-01

Page 1 of 4

Image may not reflect

actual engine

STANDARD EQUIPMENT

Air Inlet System

Corrosion-resistant sea water aftercooler, air

cleaner/fumes disposal (closed system), jacket

water cooled turbocharger, turbocharger inlet OD

straight connection

Control System

Electronic governing (A4), programmable low idle,

electronic diagnostics and fault logging, fuel/air

ratio control, electronic throttle position sensor

Cooling System

Thermostat and housing, block heater (1500W,

120V AC current), gear-driven jacket water pump,

self priming, gear-driven sea water pump with

bronze impeller, titanium plate type heat exchanger

or separate circuit keel cooling

Exhaust System

Watercooled exhaust manifold and turbocharger,

round-flanged outlet

Flywheel and Flywheel Housings

Standard SAE No. 1 flywheel and flywheel housing,

113 teeth, SAE standard rotation; optional SAE

No. 0 flywheel and flywheel housing, 136 teeth,

SAE standard rotation

Fuel System

Fuel filter, RH service on port, LH service on

starboard; fuel transfer pump; fuel priming pump;

flexible fuel lines

Instrumentation

Electric service meter, instrument panel (24V),

start/stop switch, emergency stop button,

maintenance due light, diagnostic light, warning

light, maintenance clear switch, start motor

magnetic switch, 15 and 3A breakers

Lube System

Crankcase breather; oil cooler; spin-on oil filter, RH

service on port, LH service on starboard; center

sump deep oil pan; oil filler; dipstick, RH service on

port, LH service on starboard; gear-driven oil pump

Mounting System

Adjustable front support

Power Take-Offs

Hydraulic pump drive, SAE A, 11 tooth spline,

46 ft-lbs max torque, counterclockwise as viewed

from front of the engine looking into the drive and

turns 1.41 x engine speed, 292 mm crankshaft

pulley, 15.88 mm width

General

Vibration damper; lifting eyes, RH or LH service

options; literature; variable engine wiring; upper

rear-facing customer wiring connector and service

tool connections

ISO Certification

Factory-designed systems built at Caterpillar

ISO 9001:2000 certified facilities.

LEHM7355-01

Page 2 of 4

C18 ACERT™

MARINE PROPULSION

357 bkW (479 bhp)

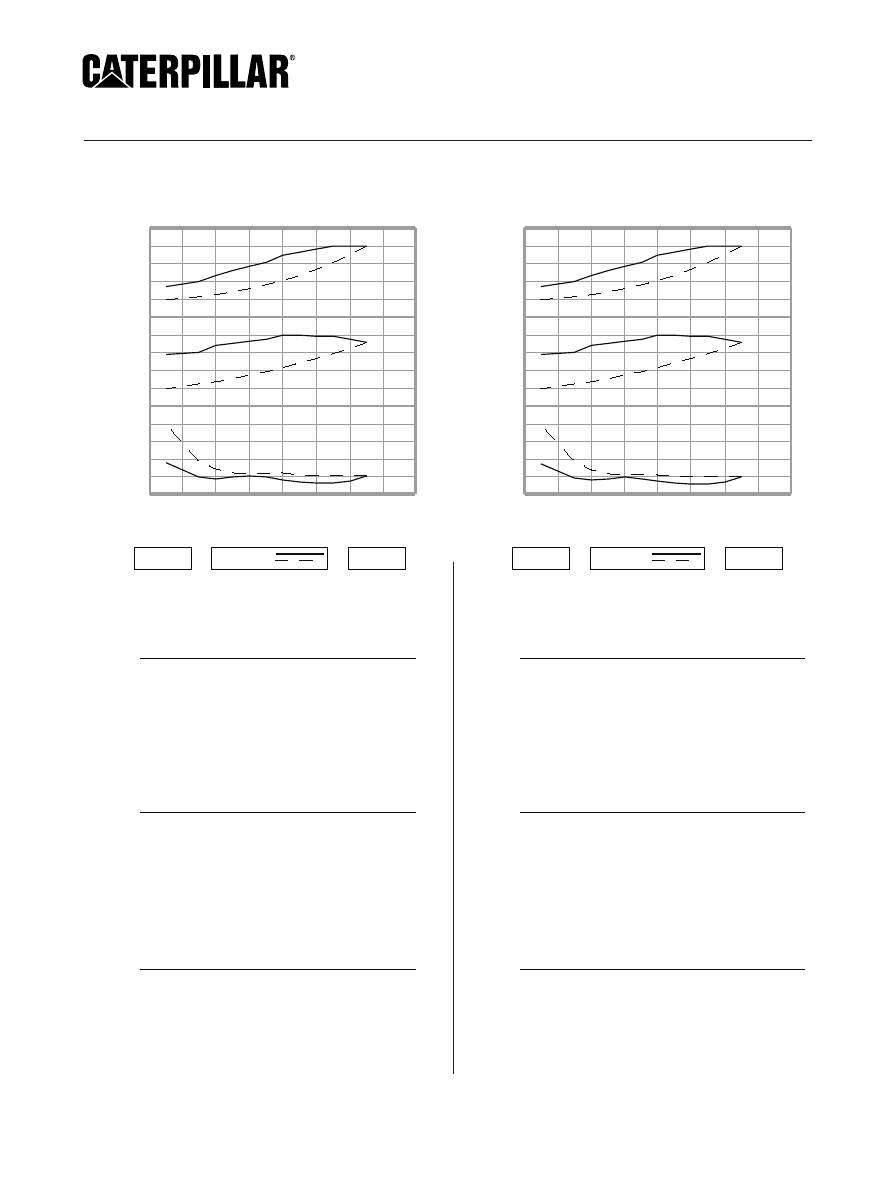

PERFORMANCE CURVES

Turbocharged-Aftercooled

A Rating — 357 bkW (479 bhp) @ 1800 rpm

DM9569-00

Marine Engine Performance

357 kW (479 hp) @ 1800 rpm

C18 DITA

A-RATING - DM9569-00

B

S

F

C

g

/k

W

-h

r

E

n

g

in

e

P

o

w

er

kW

T

o

rq

u

e

N

•m

Engine Speed - rpm

700

900

1100

1300

1500

1700

1900

357

242

128

13

2155

1507

858

210

282

258

234

210

B

S

F

C

lb

/h

p

-h

r

E

n

g

in

e

P

o

w

er

h

p

T

o

rq

u

e

lb

-f

t

Engine Speed - rpm

700

900

1100

1300

1500

1700

1900

479

325

171

18

1589

1111

633

155

.464

.425

.386

.347

Metric

Maximum Power

Prop Demand

357 kW

English

Maximum Power

Prop Demand

479 hp

Performance Data

Performance Data

Engine

Speed

rpm

Engine

Power

kW

Engine

Torque

N•m

BSFC

g/kW-hr

Fuel

Rate

L/hr

Maximum

Power

Data

Engine

Speed

rpm

Engine

Power

hp

Engine

Torque

lb-ft

BSFC

lb/hp-hr

Fuel

Rate

gph

Maximum

Power

Data

1800

357.0

1894

211.3

89.9

1800

478.7

1397

.347

23.7

1700

357.0

2006

207.4

88.3

1700

478.7

1479

.341

23.3

1600

357.0

2131

205.4

87.4

1600

478.7

1572

.338

23.1

1500

337.0

2145

204.4

82.1

1500

451.9

1582

.336

21.7

1400

316.0

2155

204.5

77.0

1400

423.8

1589

.336

20.3

1300

290.0

2130

205.5

71.0

1300

388.9

1571

.338

18.8

1200

215.8

1717

206.5

53.1

1200

289.4

1266

.339

14.0

1100

168.6

1464

206.5

41.5

1100

226.1

1080

.339

11.0

1000

126.7

1210

206.1

31.1

1000

169.9

892

.339

8.2

800

88.6

1057

205.7

21.7

800

118.8

780

.338

5.7

600

60.2

957

206.4

14.8

600

80.7

706

.339

3.9

Prop

Demand

Data

Prop

Demand

Data

1800

357.0

1894

211.3

89.9

1800

478.7

1397

.347

23.7

1700

300.7

1689

212.2

76.1

1700

403.2

1246

.349

20.1

1600

250.7

1496

211.3

63.2

1600

336.2

1103

.347

16.7

1500

206.6

1315

210.3

51.8

1500

277.1

970

.346

13.7

1400

168.0

1146

211.0

42.2

1400

225.3

845

.347

11.1

1300

134.5

988

213.2

34.2

1300

180.4

729

.351

9.0

1200

105.8

842

214.7

27.1

1200

141.9

621

.353

7.2

1100

81.5

707

215.8

21.0

1100

109.3

521

.355

5.5

1000

61.2

585

219.8

16.0

1000

82.1

431

.361

4.2

800

31.3

374

242.9

9.1

800

42.0

276

.399

2.4

600

13.2

210

282.4

4.5

600

17.7

155

.464

1.2

Cubic prop demand curve with 3.0 exponent for displacement

hulls only.

Power produced at the flywheel will be within standard

tolerances up to 50°C (122°F) combustion air temperature

measured at the air cleaner inlet, and fuel temperature

up to 52°C (125°F) measured at the fuel filter base.

Power rated in accordance with NMMA procedure as

crankshaft power. Reduce crankshaft power by 3% for

propeller shaft power.

PD-DM9569-00.pdf

Created on 09/21/2007 06:59

© 2007 Caterpillar All Rights Reserved

For most current information, please refer to TMI.

C18 ACERT™

MARINE PROPULSION

357 bkW (479 bhp)

LEHM7355-01

Page 3 of 4

ENGINE DIMENSIONS

C18 ACERT Engine Dimensions (approx.)

Length to Flywheel Housing

Heat-Exchanger Cooled

1504.8 mm

59.24 in.

Keel-Cooled

1504.8 mm

59.24 in.

Width

Heat-Exchanger Cooled

1077.2 mm

42.41 in.

Keel-Cooled

1077.2 mm

42.41 in.

Height

Heat-Exchanger Cooled

1143.9 mm

45.04 in.

Keel-Cooled

1143.9 mm

45.04 in.

Weight (dry)

Heat-Exchanger Cooled

1673 kg

3688 lb

Keel-Cooled

1539 kg

3394 lb

Note: Do not use for installation design. See general dimension drawings

for detail (Drawing #315-3171).

RATING DEFINITIONS AND CONDITIONS

A Rating (Unrestricted Continuous)

Typical applications: For vessels operating at

rated load and rated speed up to 100% of the time

without interruption or load cycling (80% to 100%

load factor). Typical applications could include but

are not limited to vessels such as freighters,

tugboats, bottom drag trawlers, or deep river

tugboats. Typical operation ranges from 5000 to

8000 hours per year.

Power at declared engine speed is in accordance

with ISO3046-1:2002E. Caterpillar maintains

ISO9001:1994/QS-9000 approved engine test

facilities to assure accurate calibration of test

equipment. Electronically controlled engines are set

at the factory at the advertised power corrected to

standard ambient conditions. The published fuel

consumption rates are in accordance with ISO3046.

Fuel rates are based on fuel oil of 35° API [16°C

(60°F)] gravity having an LHV of 42 780 kJ/kg

(18,390 Btu/lb) when used at 29°C (85°F) and

weighing 838.9 g/L (7.001 lb/U.S. gal). Additional

ratings may be available for specific customer

requirements. Consult your Caterpillar

representative for additional information.

Performance No.: DM9569-00

©2008 Caterpillar

U.S. Sourced

All rights reserved.

LEHM7355-01 (1-08)

Materials and specifications are subject to change without notice.

The International System of Units (SI) is used in this publication.

Performance data is calculated in accordance with tolerances and conditions stated in this specification sheet and is only intended for purposes of

comparison with other manufacturers’ engines. Actual engine performance may vary according to the particular application of the engine and operating

conditions beyond Caterpillar’s control.

Power produced at the flywheel will be within standard tolerances up to 49°C (120°F) combustion air temperature measured at the air cleaner inlet, and fuel

temperature up to 52°C (125°F) measured at the fuel filter base. Power rated in accordance with NMMA procedure as crankshaft power. Reduce crankshaft

power by 3% for propeller shaft power.

CAT, CATERPILLAR, their respective logos, ACERT, “Caterpillar Yellow” and the POWER EDGE trade dress, as well as corporate and product identity

used herein, are trademarks of Caterpillar and may not be used without permission.

C18 ACERT™

MARINE PROPULSION

357 bkW (479 bhp)

SPECIFICATIONS

I-6, 4-Stroke-Cycle-Diesel

Displacement . . . . . . . . . . . . . . . . . . . 18.1 L (1106 in

3

)

Rated Engine Speed . . . . . . . . . . . . . . . . . . . . . . 2100

Bore. . . . . . . . . . . . . . . . . . . . . . . . . . . 145 mm (5.7 in.)

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . 183 mm (7.2 in.)

Aspiration . . . . . . . . . . . . . Turbocharged-Aftercooled

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic

Cooling System . . . . . . . . . . . . . . . . . . . . Keel-Cooled/

Heat-Exchanger Cooled

Weight, Net Dry (approx.)

Keel-Cooled. . . . . . . . . . . . . . . . . . 1539 kg (3394 lb)

Heat Exchanger-Cooled . . . . . . . 1673 kg (3688 lb)

Refill Capacity

Cooling System . . . . . . . . . . . . . . . 45.8 L (12.1 gal)

Lube Oil System . . . . . . . . . . . . . . . . 64 L (16.9 gal)

Oil Change Interval . . . . . . . . . . . . . . . . . . . 500 hours

Caterpillar Diesel Engine Oil 10W30 or 15W40

Rotation (from flywheel end) . . . . . Counterclockwise

Flywheel and flywheel

housing. . . . . . . . . . . . . . SAE No. 1 and SAE No. 0

Flywheel Teeth

SAE No. 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

SAE No. 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maximum Exhaust

Backpressure . . . . . . . . . . 6.7 kPa (26.9 in. water)

C18 ACERT™

MARINE PROPULSION

412 bkW

(553 bhp)

LEHM7499-01

Page 1 of 4

Supersedes LEHM7499-00 and LEHM7357-01

Image may not reflect

actual engine

STANDARD EQUIPMENT

Air Inlet System

Corrosion-resistant sea water aftercooler, air

cleaner/fumes disposal (closed system), jacket

water cooled turbocharger, turbocharger inlet OD

straight connection

Control System

Electronic governing (A4), programmable low idle,

electronic diagnostics and fault logging, fuel/air

ratio control, electronic throttle position sensor

Cooling System

Thermostat and housing, block heater (1500W,

120V AC current), gear-driven jacket water pump,

self priming, gear-driven sea water pump with

bronze impeller, titanium plate type heat exchanger

or separate circuit keel cooling

Exhaust System

Watercooled exhaust manifold and turbocharger,

round-flanged outlet

Flywheel and Flywheel Housings

Standard SAE No. 1 flywheel and flywheel housing,

113 teeth, SAE standard rotation; optional SAE

No. 0 flywheel and flywheel housing, 136 teeth,

SAE standard rotation

Fuel System

Fuel filter, RH service on port, LH service on

starboard; fuel transfer pump; fuel priming pump;

flexible fuel lines

Instrumentation

Electric service meter, instrument panel (24V),

start/stop switch, emergency stop button,

maintenance due light, diagnostic light, warning

light, maintenance clear switch, start motor

magnetic switch, 15 and 3A breakers

Lube System

Crankcase breather; oil cooler; spin-on oil filter, RH

service on port, LH service on starboard; center

sump deep oil pan; oil filler; dipstick, RH service on

port, LH service on starboard; gear-driven oil pump

Mounting System

Adjustable front support

Power Take-Offs

Hydraulic pump drive, SAE A, 11 tooth spline,

46 ft-lbs max torque, counterclockwise as viewed

from front of the engine looking into the drive and

turns 1.41 x engine speed, 292 mm crankshaft

pulley, 15.88 mm width

General

Vibration damper; lifting eyes, RH or LH service

options; literature; variable engine wiring; upper

rear-facing customer wiring connector and service

tool connections

ISO Certification

Factory-designed systems built at Caterpillar

ISO 9001:2000 certified facilities.

C18 ACERT™

MARINE PROPULSION

412 bkW (553 bhp)

LEHM7499-01

Page 2 of 4

Supersedes LEHM7499-00 and LEHM7357-01

PERFORMANCE CURVES

Turbocharged-Aftercooled

B Rating — 412 bkW (553 bhp) @ 2100 rpm

DM9570-00

B

S

F

C

g

/k

W

-h

r

E

n

g

in

e

P

o

w

er

kW

T

o

rq

u

e

N

•m

Engine Speed - rpm

600

800 1000 1200 1400 1600 1800 2000 2200

412

278

144

10

2135

1474

814

153

330

294

257

221

B

S

F

C

lb

/h

p

-h

r

E

n

g

in

e

P

o

w

er

h

p

T

o

rq

u

e

lb

-f

t

Engine Speed - rpm

600

800 1000 1200 1400 1600 1800 2000 2200

553

373

193

13

1575

1087

600

113

.543

.483

.423

.363

Metric

Maximum Power

Prop Demand

412 kW

English

Maximum Power

Prop Demand

553 hp

Performance Data

Performance Data

Engine

Speed

rpm

Engine

Power

kW

Engine

Torque

N•m

BSFC

g/kW-hr

Fuel

Rate

L/hr

Maximum

Power

Data

Engine

Speed

rpm

Engine

Power

hp

Engine

Torque

lb-ft

BSFC

lb/hp-hr

Fuel

Rate

gph

Maximum

Power

Data

2100

412.1

1874

221.2

108.7

2100

552.6

1382

.364

28.7

2000

412.1

1968

223.5

109.8

2000

552.6

1451

.367

29.0

1900

412.1

2071

225.5

110.8

1900

552.6

1527

.371

29.3

1800

393.6

2088

227.0

106.5

1800

527.8

1540

.373

28.1

1700

374.4

2103

226.6

101.1

1700

502.1

1551

.373

26.7

1500

335.4

2135

215.9

86.3

1500

449.8

1575

.355

22.8

1400

295.5

2016

210.1

74.0

1400

396.3

1487

.345

19.5

1200

243.3

1936

202.3

58.7

1200

326.3

1428

.333

15.5

1000

189.4

1809

202.8

45.8

1000

254.0

1334

.333

12.1

800

132.3

1580

204.3

32.2

800

177.4

1165

.336

8.5

600

70.6

1124

206.1

17.4

600

94.7

829

.339

4.6

Prop

Demand

Data

Prop

Demand

Data

2100

412.0

1873

221.2

108.7

2100

552.5

1381

.364

28.7

2000

355.9

1699

227.4

96.5

2000

477.3

1253

.374

25.5

1900

305.1

1534

228.1

83.0

1900

409.1

1131

.375

21.9

1800

259.5

1376

225.9

69.9

1800

348.0

1015

.371

18.5

1700

218.6

1228

223.9

58.3

1700

293.1

906

.368

15.4

1500

150.1

956

225.8

40.4

1500

201.3

705

.371

10.7

1400

122.1

833

226.7

33.0

1400

163.7

614

.373

8.7

1200

76.9

612

229.4

21.0

1200

103.1

451

.377

5.5

1000

44.5

425

238.5

12.6

1000

59.7

313

.392

3.3

800

22.8

272

264.1

7.2

800

30.6

201

.434

1.9

600

9.6

153

330.0

3.8

600

12.9

113

.543

1.0

Cubic prop demand curve with 3.0 exponent for displacement

hulls only.

Power produced at the flywheel will be within standard

tolerances up to 50°C (122°F) combustion air temperature

measured at the air cleaner inlet, and fuel temperature

up to 52°C (125°F) measured at the fuel filter base.

Power rated in accordance with NMMA procedure as

crankshaft power. Reduce crankshaft power by 3% for

propeller shaft power.

PD-DM9570-00.pdf

Created on 09/19/2007 21:01

© 2007 Caterpillar All Rights Reserved

For most current information, please refer to TMI.

C18 ACERT™

MARINE PROPULSION

412 bkW (553 bhp)

LEHM7499-01

Page 3 of 4

Supersedes LEHM7499-00 and LEHM7357-01

ENGINE DIMENSIONS

C18 ACERT Engine Dimensions (approx.)

Length to Flywheel Housing

Heat-Exchanger Cooled

1504.8 mm

59.24 in.

Keel-Cooled

1504.8 mm

59.24 in.

Width

Heat-Exchanger Cooled

1077.2 mm

42.41 in.

Keel-Cooled

1077.2 mm

42.41 in.

Height

Heat-Exchanger Cooled

1143.9 mm

45.04 in.

Keel-Cooled

1143.9 mm

45.04 in.

Weight (dry)

Heat-Exchanger Cooled

1673 kg

3688 lb

Keel-Cooled

1539 kg

3394 lb

Note: Do not use for installation design. See general dimension drawings

for detail (Drawing #315-3171).

RATING DEFINITIONS AND CONDITIONS

B Rating (Heavy Duty)

Typical applications: For vessels operating at

rated load and rated speed up to 80% of the time, or

10 hours out of 12, with some load cycling (40% to

80% load factor). Typical applications could include

but are not limited to vessels such as mid-water

trawlers, purse seiner, crew and supply boats,

ferries, or towboats. Typical operation ranges from

3000 to 5000 hours per year.

Power at declared engine speed is in accordance

with ISO3046-1:2002E. Caterpillar maintains

ISO9001:1994/QS-9000 approved engine test

facilities to assure accurate calibration of test

equipment. Electronically controlled engines are set

at the factory at the advertised power corrected to

standard ambient conditions. The published fuel

consumption rates are in accordance with ISO3046.

Fuel rates are based on fuel oil of 35° API [16°C

(60°F)] gravity having an LHV of 42 780 kJ/kg

(18,390 Btu/lb) when used at 29°C (85°F) and

weighing 838.9 g/L (7.001 lb/U.S. gal). Additional

ratings may be available for specific customer

requirements. Consult your Caterpillar

representative for additional information.

Performance No.: DM9570-00

©2008 Caterpillar

U.S. Sourced

All rights reserved.

LEHM7499-01 (2-08)

Materials and specifications are subject to change without notice.

Supersedes LEHM7499-00 and LEHM7357-01

The International System of Units (SI) is used in this publication.

Performance data is calculated in accordance with tolerances and conditions stated in this specification sheet and is only intended for purposes of

comparison with other manufacturers’ engines. Actual engine performance may vary according to the particular application of the engine and operating

conditions beyond Caterpillar’s control.

Power produced at the flywheel will be within standard tolerances up to 49°C (120°F) combustion air temperature measured at the air cleaner inlet, and fuel

temperature up to 52°C (125°F) measured at the fuel filter base. Power rated in accordance with NMMA procedure as crankshaft power. Reduce crankshaft

power by 3% for propeller shaft power.

CAT, CATERPILLAR, their respective logos, ACERT, “Caterpillar Yellow” and the POWER EDGE trade dress, as well as corporate and product identity

used herein, are trademarks of Caterpillar and may not be used without permission.

C18 ACERT™

MARINE PROPULSION

412 bkW (553 bhp)

SPECIFICATIONS

I-6, 4-Stroke-Cycle-Diesel

Displacement . . . . . . . . . . . . . . . . . . . 18.1 L (1106 in

3

)

Rated Engine Speed . . . . . . . . . . . . . . . . . . . . . . 1800

Bore. . . . . . . . . . . . . . . . . . . . . . . . . . . 145 mm (5.7 in.)

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . 183 mm (7.2 in.)

Aspiration . . . . . . . . . . . . . Turbocharged-Aftercooled

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic

Cooling System . . . . . . . . . . . . . . . . . . . . Keel-Cooled/

Heat-Exchanger Cooled

Weight, Net Dry (approx.)

Keel-Cooled. . . . . . . . . . . . . . . . . . 1539 kg (3394 lb)

Heat Exchanger-Cooled . . . . . . . 1673 kg (3688 lb)

Refill Capacity

Cooling System . . . . . . . . . . . . . . . 45.8 L (12.1 gal)

Lube Oil System . . . . . . . . . . . . . . . . 64 L (16.9 gal)

Oil Change Interval . . . . . . . . . . . . . . . . . . . 500 hours

Caterpillar Diesel Engine Oil 10W30 or 15W40

Rotation (from flywheel end) . . . . . Counterclockwise

Flywheel and flywheel

housing. . . . . . . . . . . . . . SAE No. 1 and SAE No. 0

Flywheel Teeth

SAE No. 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

SAE No. 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maximum Exhaust

Backpressure . . . . . . . . . . 6.7 kPa (26.9 in. water)

C18 ACERT™

MARINE PROPULSION

448 bkW

(600 bhp)

LEHM7356-01

Page 1 of 4

Image may not reflect

actual engine

STANDARD EQUIPMENT

Air Inlet System

Corrosion-resistant sea water aftercooler, air

cleaner/fumes disposal (closed system), jacket

water cooled turbocharger, turbocharger inlet OD

straight connection

Control System

Electronic governing (A4), programmable low idle,

electronic diagnostics and fault logging, fuel/air

ratio control, electronic throttle position sensor

Cooling System

Thermostat and housing, block heater (1500W,

120V AC current), gear-driven jacket water pump,

self priming, gear-driven sea water pump with

bronze impeller, titanium plate type heat exchanger

or separate circuit keel cooling

Exhaust System

Watercooled exhaust manifold and turbocharger,

round-flanged outlet

Flywheel and Flywheel Housings

Standard SAE No. 1 flywheel and flywheel housing,

113 teeth, SAE standard rotation; optional SAE

No. 0 flywheel and flywheel housing, 136 teeth,

SAE standard rotation

Fuel System

Fuel filter, RH service on port, LH service on

starboard; fuel transfer pump; fuel priming pump;

flexible fuel lines

Instrumentation

Electric service meter, instrument panel (24V),

start/stop switch, emergency stop button,

maintenance due light, diagnostic light, warning

light, maintenance clear switch, start motor

magnetic switch, 15 and 3A breakers

Lube System

Crankcase breather; oil cooler; spin-on oil filter, RH

service on port, LH service on starboard; center

sump deep oil pan; oil filler; dipstick, RH service on

port, LH service on starboard; gear-driven oil pump

Mounting System

Adjustable front support

Power Take-Offs

Hydraulic pump drive, SAE A, 11 tooth spline,

46 ft-lbs max torque, counterclockwise as viewed

from front of the engine looking into the drive and

turns 1.41 x engine speed, 292 mm crankshaft

pulley, 15.88 mm width

General

Vibration damper; lifting eyes, RH or LH service

options; literature; variable engine wiring; upper

rear-facing customer wiring connector and service

tool connections

ISO Certification

Factory-designed systems built at Caterpillar

ISO 9001:2000 certified facilities.

C18 ACERT™

MARINE PROPULSION

448 bkW (600 bhp)

LEHM7356-01

Page 2 of 4

PERFORMANCE CURVES

Turbocharged-Aftercooled

A Rating — 448 bkW (600 bhp) @ 1800 rpm

DM9571-00

Marine Engine Performance

448 kW (600 hp) @ 1800 rpm

C18 DITA

A-RATING - DM9571-00

B

S

F

C

g

/k

W

-h

r

E

n

g

in

e

P

o

w

er

kW

T

o

rq

u

e

N

•m

Engine Speed - rpm

700

900

1100

1300

1500

1700

1900

448

304

160

17

2730

1908

1086

264

264

247

230

213

B

S

F

C

lb

/h

p

-h

r

E

n

g

in

e

P

o

w

er

h

p

T

o

rq

u

e

lb

-f

t

Engine Speed - rpm

700

900

1100

1300

1500

1700

1900

600

407

215

22

2013

1407

801

195

.433

.406

.379

.352

Metric

Maximum Power

Prop Demand

448 kW

English

Maximum Power

Prop Demand

600 hp

Performance Data

Performance Data

Engine

Speed

rpm

Engine

Power

kW

Engine

Torque

N•m

BSFC

g/kW-hr

Fuel

Rate

L/hr

Maximum

Power

Data

Engine

Speed

rpm

Engine

Power

hp

Engine

Torque

lb-ft

BSFC

lb/hp-hr

Fuel

Rate

gph

Maximum

Power

Data

1800

447.5

2374

213.4

113.9

1800

600.1

1751

.351

30.1

1700

447.5

2514

209.0

111.5

1700

600.1

1854

.344

29.5

1600

447.5

2671

207.1

110.5

1600

600.1

1970

.340

29.2

1500

419.9

2673

206.8

103.5

1500

563.1

1971

.340

27.3

1400

396.6

2705

207.9

98.3

1400

531.8

1995

.342

26.0

1300

371.7

2730

209.9

93.0

1300

498.5

2013

.345

24.6

1200

316.0

2515

212.2

79.9

1200

423.8

1855

.349

21.1

1100

281.3

2442

213.3

71.5

1100

377.2

1801

.351

18.9

1000

247.1

2360

212.2

62.5

1000

331.4

1741

.349

16.5

800

163.0

1946

212.6

41.3

800

218.6

1435

.350

10.9

600

116.2

1849

226.6

31.4

600

155.8

1364

.373

8.3

Prop

Demand

Data

Prop

Demand

Data

1800

447.5

2374

213.4

113.9

1800

600.1

1751

.351

30.1

1700

377.0

2118

214.7

96.5

1700

505.6

1562

.353

25.5

1600

314.3

1876

214.0

80.2

1600

421.5

1384

.352

21.2

1500

259.0

1649

213.3

65.8

1500

347.3

1216

.351

17.4

1400

210.6

1436

214.6

53.9

1400

282.4

1059

.353

14.2

1300

168.6

1238

216.0

43.4

1300

226.1

913

.355

11.5

1200

132.6

1055

215.7

34.1

1200

177.8

778

.355

9.0

1100

102.1

887

215.2

26.2

1100

136.9

654

.354

6.9

1000

76.7

733

216.4

19.8

1000

102.9

541

.356

5.2

800

39.3

469

229.3

10.7

800

52.7

346

.377

2.8

600

16.6

264

263.6

5.2

600

22.3

195

.433

1.4

Cubic prop demand curve with 3.0 exponent for displacement

hulls only.

Power produced at the flywheel will be within standard

tolerances up to 50°C (122°F) combustion air temperature

measured at the air cleaner inlet, and fuel temperature

up to 52°C (125°F) measured at the fuel filter base.

Power rated in accordance with NMMA procedure as

crankshaft power. Reduce crankshaft power by 3% for

propeller shaft power.

PD-DM9571-00.pdf

Created on 09/19/2007 21:01

© 2007 Caterpillar All Rights Reserved

C18 ACERT™

MARINE PROPULSION

448 bkW (600 bhp)

LEHM7356-01

Page 3 of 4

ENGINE DIMENSIONS

C18 ACERT Engine Dimensions (approx.)

Length to Flywheel Housing

Heat-Exchanger Cooled

1504.8 mm

59.24 in.

Keel-Cooled

1504.8 mm

59.24 in.

Width

Heat-Exchanger Cooled

1077.2 mm

42.41 in.

Keel-Cooled

1077.2 mm

42.41 in.

Height

Heat-Exchanger Cooled

1143.9 mm

45.04 in.

Keel-Cooled

1143.9 mm

45.04 in.

Weight (dry)

Heat-Exchanger Cooled

1673 kg

3688 lb

Keel-Cooled

1539 kg

3394 lb

Note: Do not use for installation design. See general dimension drawings

for detail (Drawing #315-3171).

C18 ACERT™

MARINE PROPULSION

448 bkW (600 bhp)

RATING DEFINITIONS AND CONDITIONS

A Rating (Unrestricted Continuous)

Typical applications: For vessels operating at

rated load and rated speed up to 100% of the time

without interruption or load cycling (80% to 100%

load factor). Typical applications could include but

are not limited to vessels such as freighters,

tugboats, bottom drag trawlers, or deep river

tugboats. Typical operation ranges from 5000 to

8000 hours per year.

Power at declared engine speed is in accordance

with ISO3046-1:2002E. Caterpillar maintains

ISO9001:1994/QS-9000 approved engine test

facilities to assure accurate calibration of test

equipment. Electronically controlled engines are set

at the factory at the advertised power corrected to

standard ambient conditions. The published fuel

consumption rates are in accordance with ISO3046.

Fuel rates are based on fuel oil of 35° API [16°C

(60°F)] gravity having an LHV of 42 780 kJ/kg

(18,390 Btu/lb) when used at 29°C (85°F) and

weighing 838.9 g/L (7.001 lb/U.S. gal). Additional

ratings may be available for specific customer

requirements. Consult your Caterpillar

representative for additional information.

Performance No.: DM9571-00

©2008 Caterpillar

U.S. Sourced

All rights reserved.

LEHM7356-01 (1-08)

Materials and specifications are subject to change without notice.

The International System of Units (SI) is used in this publication.

Performance data is calculated in accordance with tolerances and conditions stated in this specification sheet and is only intended for purposes of

comparison with other manufacturers’ engines. Actual engine performance may vary according to the particular application of the engine and operating

conditions beyond Caterpillar’s control.

Power produced at the flywheel will be within standard tolerances up to 49°C (120°F) combustion air temperature measured at the air cleaner inlet, and fuel

temperature up to 52°C (125°F) measured at the fuel filter base. Power rated in accordance with NMMA procedure as crankshaft power. Reduce crankshaft

power by 3% for propeller shaft power.

CAT, CATERPILLAR, their respective logos, ACERT, “Caterpillar Yellow” and the POWER EDGE trade dress, as well as corporate and product identity

used herein, are trademarks of Caterpillar and may not be used without permission.

SPECIFICATIONS

I-6, 4-Stroke-Cycle-Diesel

Displacement . . . . . . . . . . . . . . . . . . . 18.1 L (1106 in

3

)

Rated Engine Speed . . . . . . . . . . . . . . . . . . . . . . 2100

Bore. . . . . . . . . . . . . . . . . . . . . . . . . . . 145 mm (5.7 in.)

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . 183 mm (7.2 in.)

Aspiration . . . . . . . . . . . . . Turbocharged-Aftercooled

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic

Cooling System . . . . . . . . . . . . . . . . . . . . Keel-Cooled/

Heat-Exchanger Cooled

Weight, Net Dry (approx.)

Keel-Cooled. . . . . . . . . . . . . . . . . . 1539 kg (3394 lb)

Heat Exchanger-Cooled . . . . . . . 1673 kg (3688 lb)

Refill Capacity

Cooling System . . . . . . . . . . . . . . . 45.8 L (12.1 gal)

Lube Oil System . . . . . . . . . . . . . . . . 64 L (16.9 gal)

Oil Change Interval . . . . . . . . . . . . . . . . . . . 500 hours

Caterpillar Diesel Engine Oil 10W30 or 15W40

Rotation (from flywheel end) . . . . . Counterclockwise

Flywheel and flywheel

housing. . . . . . . . . . . . . . SAE No. 1 and SAE No. 0

Flywheel Teeth

SAE No. 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

SAE No. 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maximum Exhaust

Backpressure . . . . . . . . . . 6.7 kPa (26.9 in. water)

C18 ACERT™

MARINE PROPULSION

500 bkW

(671 bhp)

LEHM7358-01

Page 1 of 4

Image may not reflect

actual engine

STANDARD EQUIPMENT

Air Inlet System

Corrosion-resistant sea water aftercooler, air

cleaner/fumes disposal (closed system), jacket

water cooled turbocharger, turbocharger inlet OD

straight connection

Control System

Electronic governing (A4), programmable low idle,

electronic diagnostics and fault logging, fuel/air

ratio control, electronic throttle position sensor

Cooling System

Thermostat and housing, block heater (1500W,

120V AC current), gear-driven jacket water pump,

self priming, gear-driven sea water pump with

bronze impeller, titanium plate type heat exchanger

or separate circuit keel cooling

Exhaust System

Watercooled exhaust manifold and turbocharger,

round-flanged outlet

Flywheel and Flywheel Housings

Standard SAE No. 1 flywheel and flywheel housing,

113 teeth, SAE standard rotation; optional SAE

No. 0 flywheel and flywheel housing, 136 teeth,

SAE standard rotation

Fuel System

Fuel filter, RH service on port, LH service on

starboard; fuel transfer pump; fuel priming pump;

flexible fuel lines

Instrumentation

Electric service meter, instrument panel (24V),

start/stop switch, emergency stop button,

maintenance due light, diagnostic light, warning

light, maintenance clear switch, start motor

magnetic switch, 15 and 3A breakers

Lube System

Crankcase breather; oil cooler; spin-on oil filter, RH

service on port, LH service on starboard; center

sump deep oil pan; oil filler; dipstick, RH service on

port, LH service on starboard; gear-driven oil pump

Mounting System

Adjustable front support

Power Take-Offs

Hydraulic pump drive, SAE A, 11 tooth spline,

46 ft-lbs max torque, counterclockwise as viewed

from front of the engine looking into the drive and

turns 1.41 x engine speed, 292 mm crankshaft

pulley, 15.88 mm width

General

Vibration damper; lifting eyes, RH or LH service

options; literature; variable engine wiring; upper

rear-facing customer wiring connector and service

tool connections

ISO Certification

Factory-designed systems built at Caterpillar

ISO 9001:2000 certified facilities.

C18 ACERT™

MARINE PROPULSION

500 bkW (671 bhp)

LEHM7358-01

Page 2 of 4

PERFORMANCE CURVES

Turbocharged-Aftercooled

B Rating — 500 bkW (671 bhp) @ 2100 rpm

DM9572-00

Marine Engine Performance

500 kW (671 hp) @ 2100 rpm

C18 DITA

B-RATING - DM9572-00

B

S

F

C

g

/k

W

-h

r

E

n

g

in

e

P

o

w

er

kW

T

o

rq

u

e

N

•m

Engine Speed - rpm

600

800 1000 1200 1400 1600 1800 2000 2200

500

337

174

12

2915

2005

1096

186

291

266

241

216

B

S

F

C

lb

/h

p

-h

r

E

n

g

in

e

P

o

w

er

h

p

T

o

rq

u

e

lb

-f

t

Engine Speed - rpm

600

800 1000 1200 1400 1600 1800 2000 2200

671

452

234

16

2150

1479

808

137

.478

.437

.396

.355

Metric

Maximum Power

Prop Demand

500 kW

English

Maximum Power

Prop Demand

671 hp

Performance Data

Performance Data

Engine

Speed

rpm

Engine

Power

kW

Engine

Torque

N•m

BSFC

g/kW-hr

Fuel

Rate

L/hr

Maximum

Power

Data

Engine

Speed

rpm

Engine

Power

hp

Engine

Torque

lb-ft

BSFC

lb/hp-hr

Fuel

Rate

gph

Maximum

Power

Data

2100

500.0

2274

223.8

133.4

2100

670.5

1677

.368

35.2

2000

500.0

2387

218.9

130.5

2000

670.5

1760

.360

34.5

1900

500.0

2513

215.9

128.7

1900

670.5

1853

.355

34.0

1800

483.4

2565

214.5

123.6

1800

648.3

1892

.353

32.7

1600

470.8

2810

212.8

119.4

1600

631.4

2072

.350

31.5

1400

410.5

2800

214.8

105.1

1400

550.5

2065

.353

27.8

1200

241.7

1923

219.5

63.2

1200

324.1

1418

.361

16.7

1000

184.1

1758

218.6

48.0

1000

246.9

1297

.359

12.7

900

161.4

1713

214.8

41.3

900

216.4

1263

.353

10.9

700

100.1

1366

212.6

25.4

700

134.2

1007

.350

6.7

600

75.0

1194

212.4

19.0

600

100.6

881

.349

5.0

Prop

Demand

Data

Prop

Demand

Data

2100

500.0

2274

223.8

133.4

2100

670.5

1677

.368

35.2

2000

431.9

2062

219.9

113.2

2000

579.2

1521

.362

29.9

1900

370.3

1861

217.0

95.8

1900

496.6

1373

.357

25.3

1700

265.3

1490

215.6

68.2

1700

355.8

1099

.354

18.0

1600

221.1

1320

216.4

57.1

1600

296.5

974

.356

15.1

1400

148.1

1011

218.4

38.6

1400

198.6

746

.359

10.2

1300

118.6

871

219.5

31.0

1300

159.0

642

.361

8.2

1100

71.9

624

242.5

20.8

1100

96.4

460

.399

5.5

900

39.4

418

254.3

11.9

900

52.8

308

.418

3.1

700

18.5

253

260.3

5.7

700

24.8

187

.428

1.5

600

11.7

186

290.8

4.0

600

15.7

137

.478

1.1

Cubic prop demand curve with 3.0 exponent for displacement

hulls only.

Power produced at the flywheel will be within standard

tolerances up to 50°C (122°F) combustion air temperature

measured at the air cleaner inlet, and fuel temperature

up to 52°C (125°F) measured at the fuel filter base.

Power rated in accordance with NMMA procedure as

crankshaft power. Reduce crankshaft power by 3% for

propeller shaft power.

PD-DM9572-00.pdf

Created on 09/19/2007 21:01

© 2007 Caterpillar All Rights Reserved

For most current information, please refer to TMI.

C18 ACERT™

MARINE PROPULSION

500 bkW (671 bhp)

LEHM7358-01

Page 3 of 4

ENGINE DIMENSIONS

C18 ACERT Engine Dimensions (approx.)

Length to Flywheel Housing

Heat-Exchanger Cooled

1504.8 mm

59.24 in.

Keel-Cooled

1504.8 mm

59.24 in.

Width

Heat-Exchanger Cooled

1077.2 mm

42.41 in.

Keel-Cooled

1077.2 mm

42.41 in.

Height

Heat-Exchanger Cooled

1143.9 mm

45.04 in.

Keel-Cooled

1143.9 mm

45.04 in.

Weight (dry)

Heat-Exchanger Cooled

1673 kg

3688 lb

Keel-Cooled

1539 kg

3394 lb

Note: Do not use for installation design. See general dimension drawings

for detail (Drawing #315-3171).

RATING DEFINITIONS AND CONDITIONS

B Rating (Heavy Duty)

Typical applications: For vessels operating at

rated load and rated speed up to 80% of the time, or

10 hours out of 12, with some load cycling (40% to

80% load factor). Typical applications could include

but are not limited to vessels such as mid-water

trawlers, purse seiner, crew and supply boats,

ferries, or towboats. Typical operation ranges from

3000 to 5000 hours per year.

Power at declared engine speed is in accordance

with ISO3046-1:2002E. Caterpillar maintains

ISO9001:1994/QS-9000 approved engine test

facilities to assure accurate calibration of test

equipment. Electronically controlled engines are set

at the factory at the advertised power corrected to

standard ambient conditions. The published fuel

consumption rates are in accordance with ISO3046.

Fuel rates are based on fuel oil of 35° API [16°C

(60°F)] gravity having an LHV of 42 780 kJ/kg

(18,390 Btu/lb) when used at 29°C (85°F) and

weighing 838.9 g/L (7.001 lb/U.S. gal). Additional

ratings may be available for specific customer

requirements. Consult your Caterpillar

representative for additional information.

Performance No.: DM9572-00

©2008 Caterpillar

U.S. Sourced

All rights reserved.

LEHM7358-01 (1-08)

Materials and specifications are subject to change without notice.

The International System of Units (SI) is used in this publication.

Performance data is calculated in accordance with tolerances and conditions stated in this specification sheet and is only intended for purposes of

comparison with other manufacturers’ engines. Actual engine performance may vary according to the particular application of the engine and operating

conditions beyond Caterpillar’s control.

Power produced at the flywheel will be within standard tolerances up to 49°C (120°F) combustion air temperature measured at the air cleaner inlet, and fuel

temperature up to 52°C (125°F) measured at the fuel filter base. Power rated in accordance with NMMA procedure as crankshaft power. Reduce crankshaft

power by 3% for propeller shaft power.

CAT, CATERPILLAR, their respective logos, ACERT, “Caterpillar Yellow” and the POWER EDGE trade dress, as well as corporate and product identity

used herein, are trademarks of Caterpillar and may not be used without permission.

C18 ACERT™

MARINE PROPULSION

500 bkW (671 bhp)

SPECIFICATIONS

I-6, 4-Stroke-Cycle-Diesel

Displacement . . . . . . . . . . . . . . . . . . . 18.1 L (1106 in

3

)

Rated Engine Speed . . . . . . . . . . . . . . . . . . . . . . 2100

Bore. . . . . . . . . . . . . . . . . . . . . . . . . . . 145 mm (5.7 in.)

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . 183 mm (7.2 in.)

Aspiration . . . . . . . . . . . . . Turbocharged-Aftercooled

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic

Cooling System . . . . . . . . . . . . . . . . . . . . Keel-Cooled/

Heat-Exchanger Cooled

Weight, Net Dry (approx.)

Keel-Cooled. . . . . . . . . . . . . . . . . . 1539 kg (3394 lb)

Heat Exchanger-Cooled . . . . . . . 1673 kg (3688 lb)

Refill Capacity

Cooling System . . . . . . . . . . . . . . . 45.8 L (12.1 gal)

Lube Oil System . . . . . . . . . . . . . . . . 64 L (16.9 gal)

Oil Change Interval . . . . . . . . . . . . . . . . . . . 500 hours

Caterpillar Diesel Engine Oil 10W30 or 15W40

Rotation (from flywheel end) . . . . . Counterclockwise

Flywheel and flywheel

housing. . . . . . . . . . . . . . SAE No. 1 and SAE No. 0

Flywheel Teeth

SAE No. 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

SAE No. 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maximum Exhaust

Backpressure . . . . . . . . . . 6.7 kPa (26.9 in. water)

C18 ACERT™

MARINE PROPULSION

533 bkW

(715 bhp)

LEHM7359-01

Page 1 of 4

Image may not reflect

actual engine

STANDARD EQUIPMENT

Air Inlet System

Corrosion-resistant sea water aftercooler, air

cleaner/fumes disposal (closed system), jacket

water cooled turbocharger, turbocharger inlet OD

straight connection

Control System

Electronic governing (A4), programmable low idle,

electronic diagnostics and fault logging, fuel/air

ratio control, electronic throttle position sensor

Cooling System

Thermostat and housing, block heater (1500W,

120V AC current), gear-driven jacket water pump,

self priming, gear-driven sea water pump with

bronze impeller, titanium plate type heat exchanger

or separate circuit keel cooling

Exhaust System

Watercooled exhaust manifold and turbocharger,

round-flanged outlet

Flywheel and Flywheel Housings

Standard SAE No. 1 flywheel and flywheel housing,

113 teeth, SAE standard rotation; optional SAE

No. 0 flywheel and flywheel housing, 136 teeth,

SAE standard rotation

Fuel System

Fuel filter, RH service on port, LH service on

starboard; fuel transfer pump; fuel priming pump;

flexible fuel lines

Instrumentation

Electric service meter, instrument panel (24V),

start/stop switch, emergency stop button,

maintenance due light, diagnostic light, warning

light, maintenance clear switch, start motor

magnetic switch, 15 and 3A breakers

Lube System

Crankcase breather; oil cooler; spin-on oil filter, RH

service on port, LH service on starboard; center

sump deep oil pan; oil filler; dipstick, RH service on

port, LH service on starboard; gear-driven oil pump

Mounting System

Adjustable front support

Power Take-Offs

Hydraulic pump drive, SAE A, 11 tooth spline, 46 ft-

lbs max torque, counterclockwise as viewed from

front of the engine looking into the drive and turns

1.41 x engine speed, 292 mm crankshaft pulley,

15.88 mm width

General

Vibration damper; lifting eyes, RH or LH service

options; literature; variable engine wiring; upper

rear-facing customer wiring connector and service

tool connections

ISO Certification

Factory-designed systems built at Caterpillar

ISO 9001:2000 certified facilities.

C18 ACERT™

MARINE PROPULSION

533 bkW (715 bhp)

LEHM7359-01

Page 2 of 4

PERFORMANCE CURVES

Turbocharged-Aftercooled

C Rating — 533 bkW (715 bhp) @ 2100 rpm

DM9568-00

Marine Engine Performance

533 kW (715 hp) @ 2100 rpm

C18 DITA

C-RATING - DM9568-00

B

S

F

C

g

/k

W

-h

r

E

n

g

in

e

P

o

w

er

kW

T

o

rq

u

e

N

•m

Engine Speed - rpm

600

800 1000 1200 1400 1600 1800 2000 2200

533

359

186

12

2809

1939

1068

198

289

263

238

212

B

S

F

C

lb

/h

p

-h

r

E

n

g

in

e

P

o

w

er

h

p

T

o

rq

u

e

lb

-f

t

Engine Speed - rpm

600

800 1000 1200 1400 1600 1800 2000 2200

715

482

249

17

2072

1430

788

146

.475

.433

.391

.349

Metric

Maximum Power

Prop Demand

533 kW

English

Maximum Power

Prop Demand

715 hp

Performance Data

Performance Data

Engine

Speed

rpm

Engine

Power

kW

Engine

Torque

N•m

BSFC

g/kW-hr

Fuel

Rate

L/hr

Maximum

Power

Data

Engine

Speed

rpm

Engine

Power

hp

Engine

Torque

lb-ft

BSFC

lb/hp-hr

Fuel

Rate

gph

Maximum

Power

Data

2100

533.0

2424

223.9

142.3

2100

714.8

1788

.368

37.6

2000

533.0

2545

222.7

141.5

2000

714.8

1877

.366

37.4

1900

533.0

2679

220.1

139.8

1900

714.8

1976

.362

36.9

1800

515.1

2733

216.9

133.2

1800

690.8

2016

.357

35.2

1700

488.9

2746

213.8

124.6

1700

655.6

2025

.351

32.9

1600

462.2

2759

212.4

117.0

1600

619.8

2035

.349

30.9

1500

441.3

2809

212.1

111.6

1500

591.8

2072

.349

29.5

1300

316.5

2325

212.4

80.1

1300

424.4

1715

.349

21.2

1200

273.5

2176

212.8

69.4

1200

366.8

1605

.350

18.3

900

173.4

1840

212.7

44.0

900

232.5

1357

.350

11.6

600

84.4

1343

210.3

21.2

600

113.2

990

.346

5.6

Prop

Demand

Data

Prop

Demand

Data

2100

533.0

2424

223.9

142.3

2100

714.8

1788

.368

37.6

2000

460.4

2198

219.4

120.4

2000

617.4

1621

.361

31.8

1900

394.8

1984

215.4

101.4

1900

529.4

1463

.354

26.8

1800

335.7

1781

212.5

85.0

1800

450.2

1314

.349

22.5

1700

282.8

1588

212.0

71.5

1700

379.2

1171

.349

18.9

1600

235.7

1407

214.5

60.3

1600

316.1

1038

.353

15.9

1500

194.2

1237

217.2

50.3

1500

260.4

912

.357

13.3

1300

126.4

929

221.5

33.4

1300

169.5

685

.364

8.8

1200

99.5

791

223.1

26.4

1200

133.4

583

.367

7.0

900

42.0

445

237.5

11.9

900

56.3

328

.390

3.1

600

12.4

198

288.9

4.3

600

16.6

146

.475

1.1

Cubic prop demand curve with 3.0 exponent for displacement

hulls only.

Power produced at the flywheel will be within standard

tolerances up to 50°C (122°F) combustion air temperature

measured at the air cleaner inlet, and fuel temperature

up to 52°C (125°F) measured at the fuel filter base.

Power rated in accordance with NMMA procedure as

crankshaft power. Reduce crankshaft power by 3% for

propeller shaft power.

PD-DM9568-00.pdf

Created on 09/19/2007 21:00

© 2007 Caterpillar All Rights Reserved

For most current information, please refer to TMI.

C18 ACERT™

MARINE PROPULSION

533 bkW (715 bhp)

LEHM7359-01

Page 3 of 4

ENGINE DIMENSIONS

C18 ACERT Engine Dimensions (approx.)

Length to Flywheel Housing

Heat-Exchanger Cooled

1504.8 mm

59.24 in.

Keel-Cooled

1504.8 mm

59.24 in.

Width

Heat-Exchanger Cooled

1077.2 mm

42.41 in.

Keel-Cooled

1077.2 mm

42.41 in.

Height

Heat-Exchanger Cooled

1143.9 mm

45.04 in.

Keel-Cooled

1143.9 mm

45.04 in.

Weight (dry)

Heat-Exchanger Cooled

1673 kg

3688 lb

Keel-Cooled

1539 kg

3394 lb

Note: Do not use for installation design. See general dimension drawings

for detail (Drawing #315-3171).

RATING DEFINITIONS AND CONDITIONS

C Rating (Maximum Continuous)

Typical applications: For vessels operating at

rated load and rated speed up to 50% of the time,

or 6 hours out of 12, with cyclical load and speed

(20% to 80% load factor). Typical applications

could include but are not limited to vessels such as

ferries, harbor tugs, fishing boats, offshore service

boats, displacement hull yachts, or short trip

coastal freighters. Typical operation ranges from

2000 to 4000 hours per year.

Power at declared engine speed is in accordance

with ISO3046-1:2002E. Caterpillar maintains

ISO9001:1994/QS-9000 approved engine test

facilities to assure accurate calibration of test

equipment. Electronically controlled engines are set

at the factory at the advertised power corrected to

standard ambient conditions. The published fuel

consumption rates are in accordance with ISO3046.

Fuel rates are based on fuel oil of 35° API [16°C

(60°F)] gravity having an LHV of 42 780 kJ/kg

(18,390 Btu/lb) when used at 29°C (85°F) and

weighing 838.9 g/L (7.001 lb/U.S. gal). Additional

ratings may be available for specific customer

requirements. Consult your Caterpillar

representative for additional information.

Performance No.: DM9568-00

©2008 Caterpillar

U.S. Sourced

All rights reserved.

LEHM7359-01 (1-08)

Materials and specifications are subject to change without notice.

The International System of Units (SI) is used in this publication.

Performance data is calculated in accordance with tolerances and conditions stated in this specification sheet and is only intended for purposes of

comparison with other manufacturers’ engines. Actual engine performance may vary according to the particular application of the engine and operating

conditions beyond Caterpillar’s control.

Power produced at the flywheel will be within standard tolerances up to 49°C (120°F) combustion air temperature measured at the air cleaner inlet, and fuel

temperature up to 52°C (125°F) measured at the fuel filter base. Power rated in accordance with NMMA procedure as crankshaft power. Reduce crankshaft

power by 3% for propeller shaft power.

CAT, CATERPILLAR, their respective logos, ACERT, “Caterpillar Yellow” and the POWER EDGE trade dress, as well as corporate and product identity

used herein, are trademarks of Caterpillar and may not be used without permission.

C18 ACERT™

MARINE PROPULSION

533 bkW (715 bhp)

SPECIFICATIONS

I-6, 4-Stroke-Cycle-Diesel

Displacement . . . . . . . . . . . . . . . . . . . 18.1 L (1106 in

3

)

Rated Engine Speed . . . . . . . . . . . . . . . . . . . . . . 2200

Bore. . . . . . . . . . . . . . . . . . . . . . . . . . . 145 mm (5.7 in.)

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . 183 mm (7.2 in.)

Aspiration . . . . . . . . . . . . . Turbocharged-Aftercooled

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic

Cooling System . . . . . . . . . . Heat Exchanger Cooled

Weight, Net Dry (approx.). . . . . . . . 1673 kg (3688 lb)

Refill Capacity

Cooling System . . . . . . . . . . . . . . . 45.8 L (12.1 gal)

Lube Oil System . . . . . . . . . . . . . . . . 64 L (16.9 gal)

Oil Change Interval . . . . . . . . . . . . . . . . . . . 500 hours

Caterpillar Diesel Engine Oil 10W30 or 15W40

Rotation (from flywheel end) . . . . . Counterclockwise

Flywheel and flywheel

housing . . . . . . . . . . . . . . . SAE No. 1 or SAE No. 0

Flywheel Teeth

SAE No. 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

SAE No. 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maximum Exhaust

Backpressure . . . . . . . . . . 6.7 kPa (26.9 in. water)

C18 ACERT™

MARINE PROPULSION

651 bkW

(873 bhp)

LEHM8112-00

Page 1 of 4

Image may not reflect

actual engine

STANDARD EQUIPMENT

Air Inlet System

Corrosion-resistant sea water aftercooler, air

cleaner/fumes disposal (closed system), jacket

water cooled turbocharger, turbocharger inlet OD

straight connection

Control System

Electronic governing (A4), programmable low idle,

electronic diagnostics and fault logging, fuel/air

ratio control, electronic throttle position sensor

Cooling System

Thermostat and housing, block heater (1500W,

120V AC current), gear-driven jacket water pump,

self priming, gear-driven sea water pump with

bronze impeller, titanium plate type heat exchanger

Exhaust System

Watercooled exhaust manifold and turbocharger,

round-flanged outlet

Flywheel and Flywheel Housings

Standard SAE No. 1 flywheel and flywheel housing,

113 teeth, SAE standard rotation; optional SAE

No. 0 flywheel and flywheel housing, 136 teeth,

SAE standard rotation

Fuel System

Fuel filter, RH service on port, LH service on

starboard; fuel transfer pump; fuel priming pump;

flexible fuel lines

Instrumentation

Electric service meter, instrument panel (24V),

start/stop switch, emergency stop button,

maintenance due light, diagnostic light, warning

light, maintenance clear switch, start motor

magnetic switch, 15 and 3A breakers

Lube System

Crankcase breather; oil cooler; spin-on oil filter, RH

service on port, LH service on starboard; center

sump deep oil pan; oil filler; dipstick, RH service on

port, LH service on starboard; gear-driven oil pump

Mounting System

Adjustable front support

Power Take-Offs

Hydraulic pump drive, SAE A, 11 tooth spline,

46 ft-lbs max torque, counterclockwise as viewed

from front of the engine looking into the drive and

turns 1.41 x engine speed, 292 mm crankshaft

pulley, 15.88 mm width

General

Vibration damper; lifting eyes, RH or LH service

options; literature; variable engine wiring; upper