* Correspondence address: Exponent, Inc., 2300 Chestnut St. Suite

150, Philadelphia, PA 19103, USA. Tel. : #1-215-751-0973; fax: #1-

215-751-0660.

E-mail address: skurtz@exponent.com (S.M. Kurtz).

Biomaterials 22 (2001) 1875}1881

A small punch test technique for characterizing the elastic

modulus and fracture behavior of PMMA bone cement

used in total joint replacement

V.L. Giddings , S.M. Kurtz

*, C.W. Jewett , J.R. Foulds , A.A. Edidin

Exponent, Inc., 149 Commonwealth Drive, Menlo Park, CA 94025, USA

Howmedica Osteonics, R&D Corporate, Allendale, NJ 07401, USA

Received 8 June 2000; received in revised form 28 September 2000; accepted 2 November 2000

Abstract

Polymethylmethacrylate (PMMA) bone cement is used in total joint replacements to anchor implants to the underlying bone.

Establishing and maintaining the integrity of bone cement is thus of critical importance to the long-term outcome of joint replacement

surgery. The goal of the present study was to evaluate the suitability of a novel testing technique, the small punch or miniaturized disk

bend test, to characterize the elastic modulus and fracture behavior of PMMA. We investigated the hypothesis that the crack

initiation behavior of PMMA during the small punch test was sensitive to the test temperature. Miniature disk-shaped specimens,

0.5 mm thick and 6.4 mm in diameter, were prepared from PMMA and Simplex-P bone cement according to manufacturers'

instructions. Testing was conducted at ambient and body temperatures, and the e!ect of test temperature on the elastic modulus and

fracture behavior was statistically evaluated using analysis of variance. For both PMMA materials, the test temperature had

a signi"cant e!ect on elastic modulus and crack initiation behavior. At body temperature, the specimens exhibited

`ductilea crack

initiation, whereas at room temperature

`brittlea crack initiation was observed. The small punch test was found to be a sensitive and

repeatable test method for evaluating the mechanical behavior of PMMA. In light of the results of this study, future small punch

testing should be conducted at body temperature.

2001 Elsevier Science Ltd. All rights reserved.

Keywords: Polymethylmethacrylate (PMMA); Bone cement; Small punch test; Temperature; Mechanical behavior; Elastic modulus; Fracture

toughness; Crack initiation; Body temperature

1. Introduction

The small punch test has been developed over the past

two decades to characterize the ductility and fracture

resistance of metals and polymers [1}11]. Also known as

the miniature disk bend test, the small punch test was

"rst developed for use in the electric power generation

industry [8}11]. Recently, the small punch testing tech-

nique has been used to evaluate the elastic and

large-deformation post-yield behavior of polymeric bio-

materials, focusing primarily on ultra-high molecular

weight polyethylene (UHMWPE) [1}7]. The miniature

specimen size has proven to be particularly useful when

investigating the local variations in mechanical behavior

that arise in UHMWPE total joint replacement compo-

nents after wear testing, long-term shelf aging, or im-

plantation. Although the small punch test has been used

to study a wide variety of semicrystalline polymers, such

as UHMWPE, HDPE, PTFE, and polyacetal, the mech-

anical behavior of polymethylmethacrylate (PMMA)

bone cement during small punch testing has yet to be

explored.

PMMA gained popularity in the early 1960s as a ma-

terial for securing orthopaedic implants to bone [12].

Although PMMA has been used successfully over the

past three decades, there is a concern that long-term

loosening of the prosthesis may be related to mechanical

failure of the underlying cement mantle [13}15]. Main-

taining the long-term integrity of bone cement, be it

through innovative preparation techniques or modi"ed

formulations, has received renewed interest, due in part

to its recent reclassi"cation by regulatory agencies in

Europe and United States [16]. As described in a recent

0142-9612/01/$ - see front matter

2001 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 0 0 ) 0 0 3 7 2 - 0

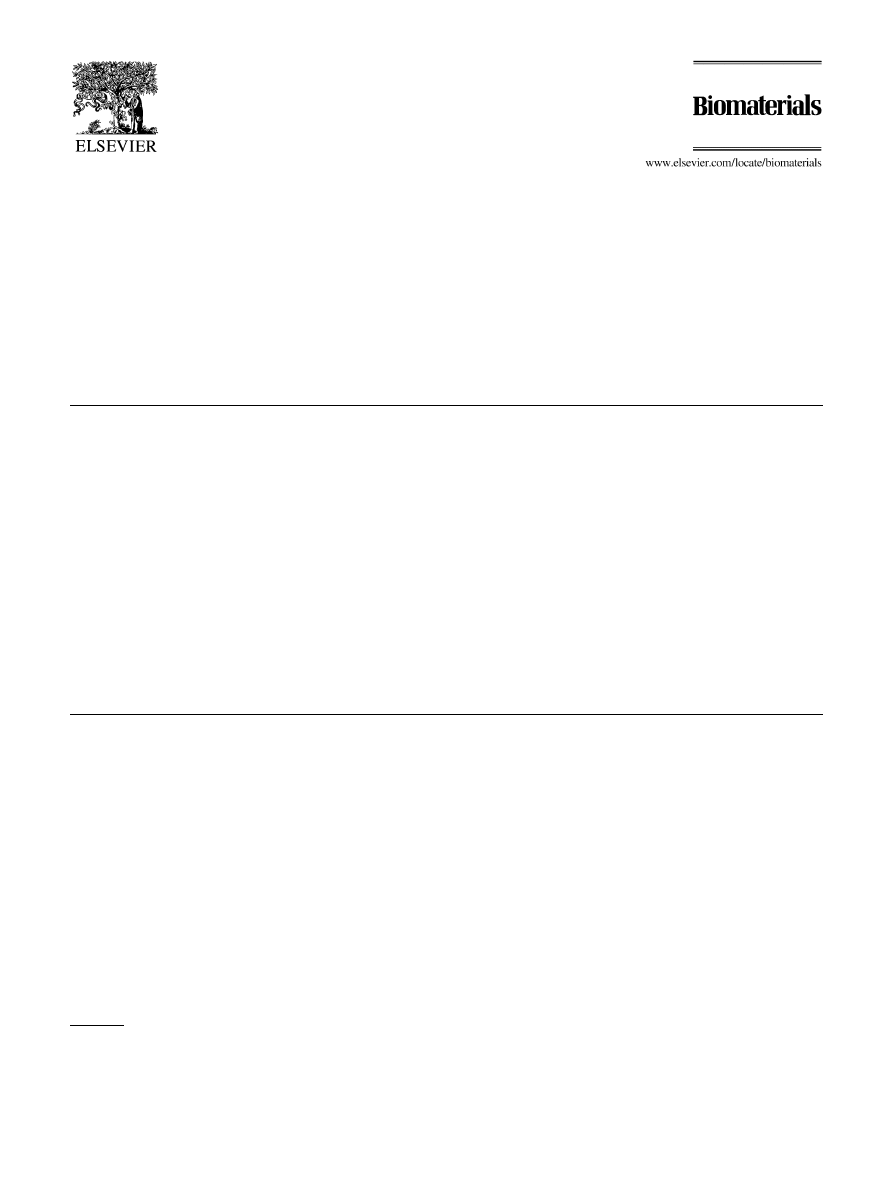

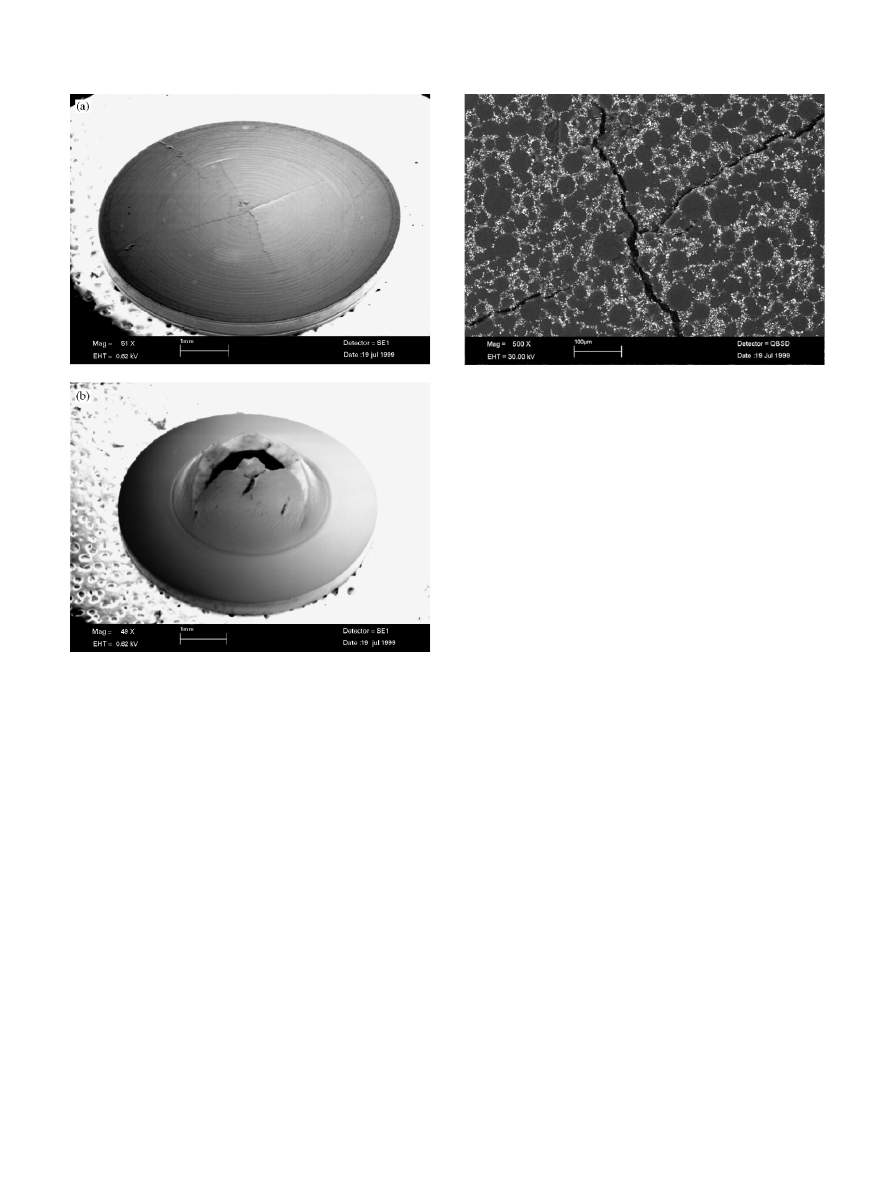

Fig. 1. Representative small punch test specimens prior to testing: (a)

PMMA; (b) Simplex-P. Microvoids 0.1}0.2 mm in diameter were ob-

served on the surface of the PMMA specimens, but not the Simplex-P

specimens.

monograph by KuKhn [16], over 60 di!erent types of

commercially available bone cement have been introduc-

ed into clinical practice worldwide.

The bulk material mechanical behavior of bone ce-

ment as derived from tests using conventional, standard

specimens, is known to depend upon numerous factors,

such as the formulation of the cement, the test conditions,

and conditions used to prepare the cement [13}16]. Con-

ventional specimen testing techniques have also shown

substantial variability in results, which hinders, and in

some cases, precludes interlaboratory comparisons of

test data [15,16]. Additional limitations in conventional

testing techniques are due to the discrepancy in size

between the test specimens and the cement mantles

in vivo, which typically range in thickness between 1 and

5 mm. Because of the relatively large specimen sizes,

conventional test techniques cannot be used to evaluate

the mechanical behavior of retrieved bone cement sam-

ples, or to predict the response of bone cement in vivo.

Due to the numerous di$culties associated with conven-

tional, standard specimen testing, miniature specimen

testing techniques, if developed, could a!ord important

advantages over standard test methods.

The primary objective of the present study was to

evaluate the feasibility of using the small punch test to

characterize the mechanical behavior of PMMA bone

cement. Speci"cally, we used the small punch test to

measure elastic modulus and fracture initiation behavior

for a generic PMMA and widely used bone cement

(Simplex P). Our research addressed the following two

questions: Can the small punch test di!erentiate between

di!erent PMMA formulations/mixing methods? Is the

mechanical behavior determined by the small punch test

sensitive to the test temperature? The long-term goal of

this research is to develop a reliable, reproducible, and

sensitive miniature specimen testing technique for the

evaluation of retrieved bone cement samples.

2. Materials and methods

Selected for this study were two types of PMMA that

were expected to represent a wide range of mechanical

behavior, thereby providing a simple means of identify-

ing the potential usefulness of the small punch test for

characterizing this family of polymers. Simplex-P (How-

medica Osteonics, Rutherford, NJ) was selected for

evaluation to provide an example of a widely used, clinic-

ally relevant bone cement. For details regarding the for-

mulation of Simplex-P, refer to a recent review by Lewis

[15] or a monograph by KuKhn [16]. We also evaluated

an industrial

`generica PMMA (Seta-Tray, Accuarte Set

Inc., Newark, NJ), which is typically used for laboratory

potting applications. One dose of each PMMA was pre-

pared according to the manufacturer's instructions. In

the case of the generic PMMA, the unsterilized polymer

beads and liquid monomer were hand mixed. The

Simplex-P, on the other hand, was sterilized and pre-

pared using a commercially available vacuum mixer

(Stryker Vacuum Mixing system: Howmedica Osteonics,

Rutherford, NJ). Specimens were prepared by pouring

the doughy but still #uid PMMA into a UHMWPE

mold with multiple cavities measuring 6.5 mm in dia-

meter and 25.4 mm in length. Specimens were allowed to

cure for 36 h at 203C, 60% relative humidity, and atmo-

spheric pressure, prior to being machined into miniature

small punch test specimens, each with a thickness of

0.5 mm and a diameter of 6.4 mm.

Due to the di!erences in formulation and preparation,

we expected variations in the size and distribution in

microvoids between the two PMMA materials. Scanning

electron microscopy (SEM) was conducted on represen-

tative specimens to characterize the size and extent of

voids. Numerous microvoids, typically 0.1}0.2 mm in

diameter, were observed in the hand-mixed PMMA spec-

imens (Fig. 1a) whereas the vacuum-mixed Simplex-P

1876

V.L. Giddings et al. / Biomaterials 22 (2001) 1875} 1881

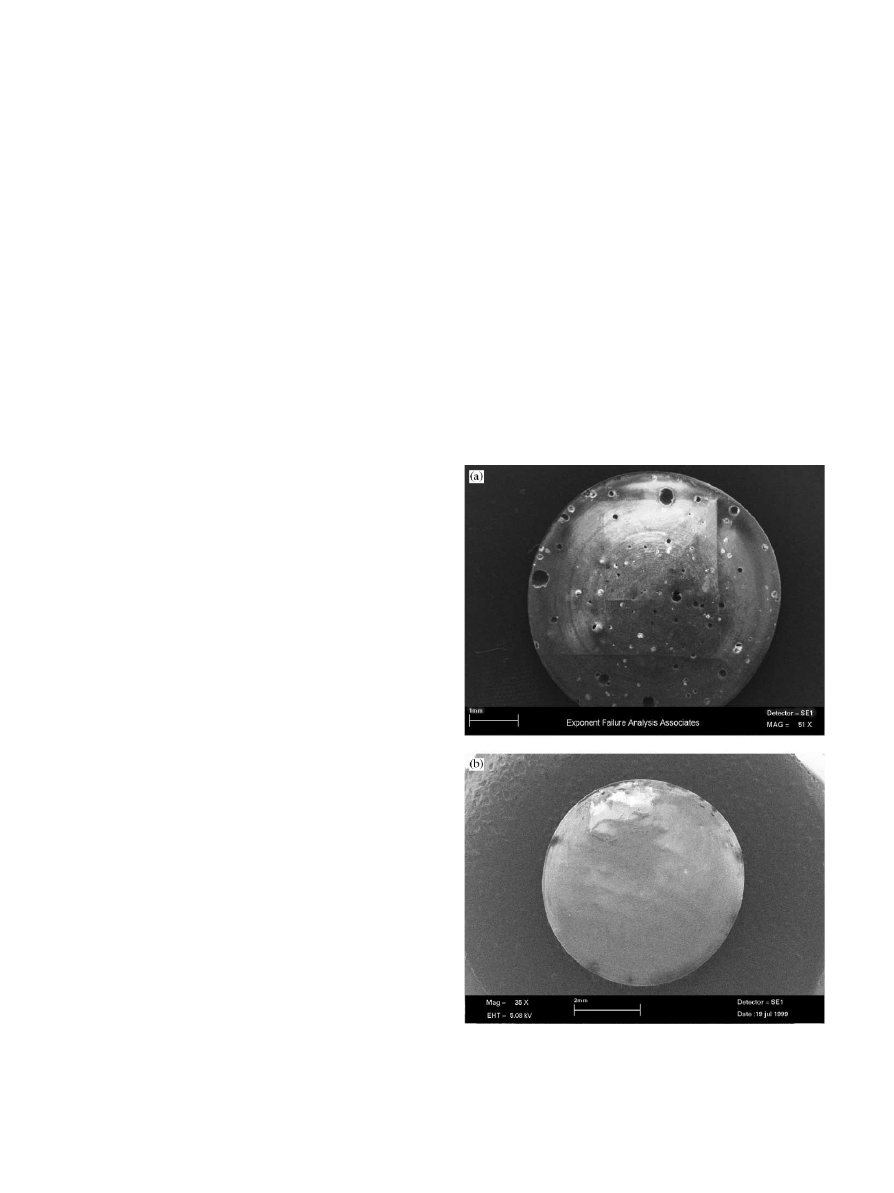

Fig. 2. Experimental setup for the small test for PMMA.

Fig. 3. Features of the small punch test load}displacement curve for

PMMA.

specimens were comparatively smooth and free of voids

at the surface of the specimens (Fig. 1b).

Mechanical tests were performed using a servohyd-

raulic testing machine. The small punch specimen was

held in place by a die and guide set-up, and deformed by

pushing the specimen against the die using a hemispher-

ical-head punch moving at a constant displacement rate

of 0.5 mm/min, as detailed previously [4,8] (Fig. 2). The

load and displacement were measured, and the back

(bulged) surface of the specimen was monitored by

a borescope and recorded such that the video was syn-

chronized with the measured load}displacement curve.

Thus, we were able to identify the onset or initiation of

cracking during the small punch test, with regard to both

point on the load}displacement curve and physical loca-

tion on the test specimen. Testing on both materials was

conducted at ambient and body temperatures (23.7$

0.63C and 37.3$0.23C, respectively).

The load}displacement curve was characterized by an

initial sti!ness, ultimate load, ultimate displacement, and

work to failure (Fig. 3). Based on previously validated

"nite element analyses of our small punch test apparatus

for a wide range of semicrystalline polymers, the initial

sti!ness of the load}displacement curve is proportional

to the elastic modulus of the material [2,4,7]

E"Ak,

(1)

where the elastic modulus (E) is in MPa when the initial

sti!ness (k) of the load}displacement curve is in N/mm.

The proportionality constant (A) is a function of Pois-

son's ratio and the frictional characteristics of the mater-

ial. The ultimate load and displacement were de"ned

based on the initiation of cracking in the specimen ob-

served via the synchronized video of the back surface of

the specimen. Work to failure, calculated from the area

under the load}displacement curve up to the point of

crack initiation, provided a measure of crack initiation

toughness.

After testing, selected specimens were examined using

a SEM to evaluate the fractured surfaces. The fractured

surfaces were examined and characterized using a vari-

able pressure SEM operating at 0.6}5.1 kV.

Previous "nite element simulations of the small punch

test, corroborated by small amplitude cyclic loading ex-

periments, have indicated that displacements in the range

of 0.064 mm are recoverable (i.e., elastic, representing the

range of applicability of Eq. (1)) [4]. Consequently, the

initial sti!ness of the load}displacement curves up to

a displacement of 0.064 mm was used to predict the

elastic modulus of the PMMA employing the "nite ele-

ment method according to our previously described ap-

proach [2,4,7]. A three-dimensional "nite element model

was created of the small punch test and validated in an

earlier study [2], so only the important highlights of the

technique are provided here. By parametrically varying

the elastic modulus in the "nite element model of the

small punch test, the relationship between elastic

modulus (E) and sti!ness (k), shown in Eq. (1), was ob-

tained [2,4]. Assuming a constant Poisson's ratio of 0.35

for PMMA [17], a range of elastic moduli were input

into the model, and the corresponding set of initial stif-

fnesses for the resulting load-de#ection curves was com-

puted for PMMA. Linear least-squares regression was

then used to obtain the material-speci"c relationship

between the elastic modulus and initial sti!ness of the

load-de#ection curves for PMMA (r

'0.99):

E"14.6k,

(2)

where, as in Eq. (1), the elastic modulus (E) is in MPa

when the initial sti!ness (k) of the load}displacement

curve is in N/mm.

V.L. Giddings et al. / Biomaterials 22 (2001) 1875} 1881

1877

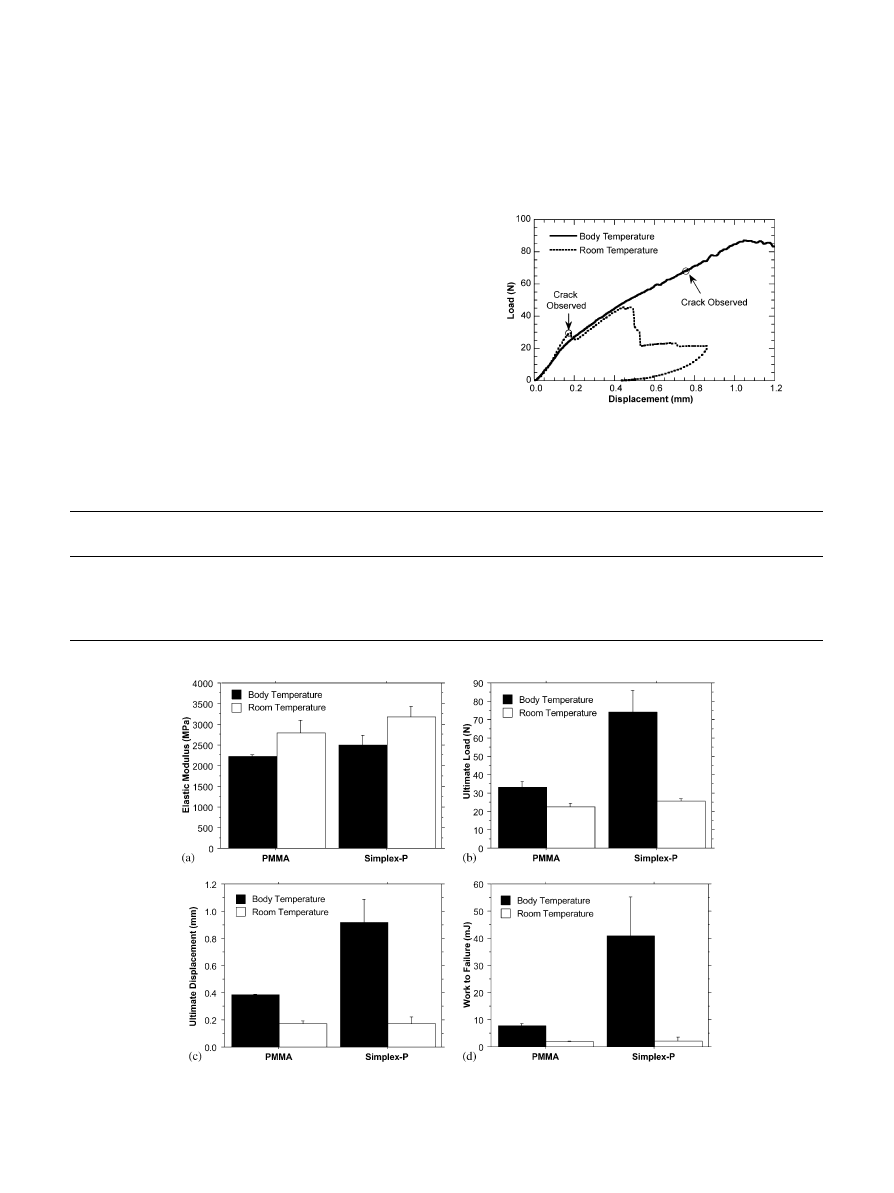

Fig. 5. E!ect of test temperature on elastic modulus (a), ultimate load (b), ultimate displacement (c), and work to failure (d) for PMMA and Simplex-P.

Table 1

Mechanical properties from the small punch tests

n

Temp

Modulus

Ultimate load

Ultimate disp.

Work to failure

(3C)

(MPa)

(N)

(mm)

(mJ)

PMMA

4

24.2$0.3

2790$297

22.4$2.4

0.174$0.021

2.05$0.26

2

37.5$0.4

2222$42

33.3$2.9

0.382$0.006

7.77$0.85

Simplex-P

3

23.1$0.3

3191$231

25.7$1.4

0.174$0.049

2.34$1.28

4

37.2$0.0

2504$233

74.1$11.8

0.915$0.173

40.8$14.6

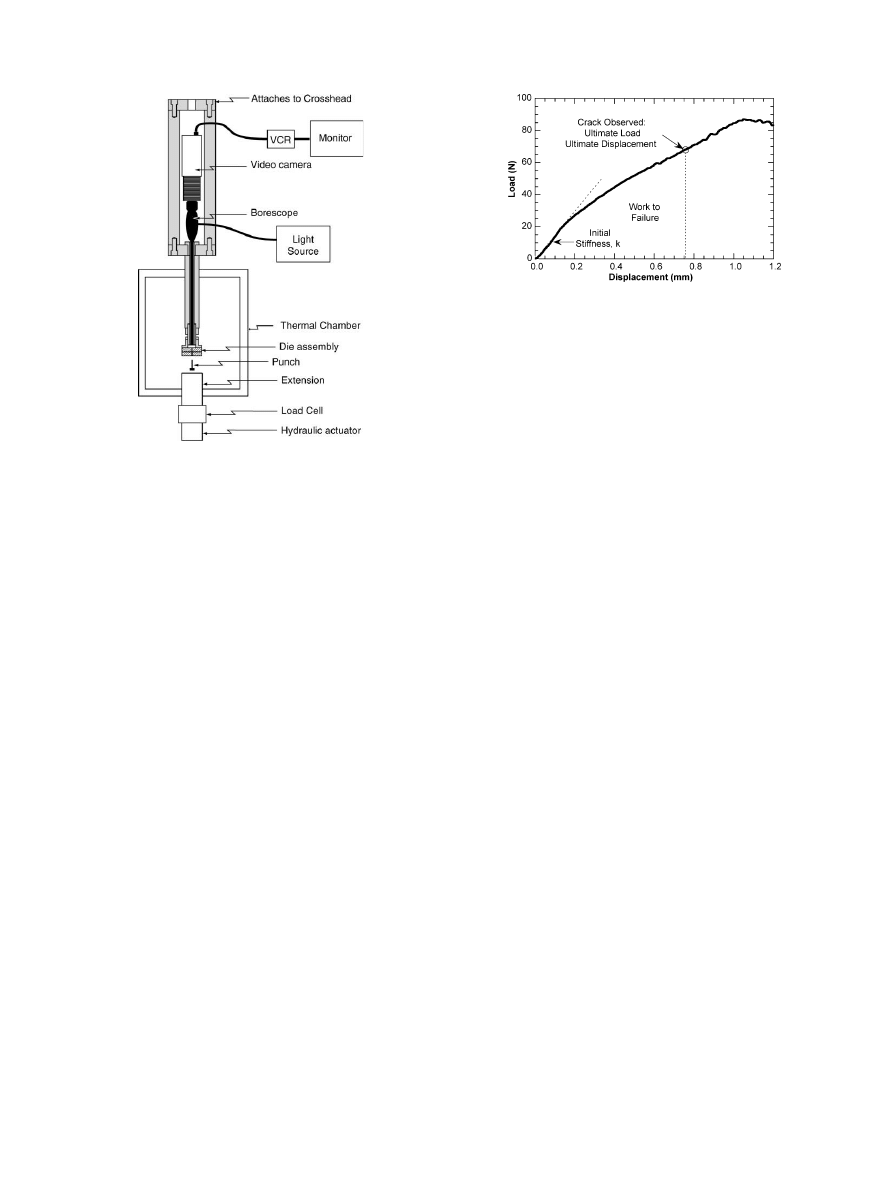

Fig. 4. Typical load}displacement curves for the Simplex-P specimens

at room temperature and body temperature.

Analysis of variance (ANOVA) was used to statistically

examine the e!ect on elastic modulus, ultimate displace-

ment, ultimate load, and work to failure of test temper-

ature and the type of PMMA material (generic vs.

Simplex-P). Statistical analysis was performed using

Statview 5.0.1 (SAS Institute, Cary, IN) and a p-value of

less than 0.05 was taken as signi"cant. Relative experi-

mental uncertainty was calculated for each of the metrics

of the small punch test by dividing the standard deviation

by the average value for each material group and temper-

ature condition [18].

3. Results

The mechanical behavior determined by the small

punch test was sensitive to the test temperature and type

of bone cement (Table 1). The room temperature small

punch test load}displacement curves showed limited in-

stability in the form of a load-drop coincident with ob-

served crack initiation. This instability was not present in

the body temperature tests (Fig. 4). These instabilities

were generally not large (limited load-drop) and

were followed by a monotonically rising load during

a crack propagation phase. On average, the experimental

1878

V.L. Giddings et al. / Biomaterials 22 (2001) 1875} 1881

Fig. 6. Representative Simplex-P specimens after testing at room tem-

perature (a) and body temperature (b).

Fig. 7. Surface of a fractured Simplex-P specimen after testing at room

temperature. The brittle fracture initiated at the center of the stellate

pattern and propagated between the polymer beads.

variability in the 13 tests we ran was found to be 7% for

elastic modulus, 10% for ultimate load, 15% for ultimate

displacement, and 29% for work to failure.

The elastic modulus was signi"cantly lower for both

cements when tested at body temperature as compared

with room temperature (Fig. 5a, p(0.002). The ultimate

load (Fig. 5b, p(0.0001), ultimate displacement (Fig. 5b,

p(0.0001), and work to failure (Fig. 5b, p(0.002) were

signi"cantly higher for both cements at body temper-

ature as compared with room temperature. Signi"cant

di!erences between the generic PMMA and the

Simplex-P were observed for the elastic modulus

(p(0.04), ultimate load (p(0.0005), ultimate displace-

ment (p(0.002), and work to failure (p(0.008). From

the videotapes of the deforming specimens, we observed

substantial di!erences in the mechanisms of crack initia-

tion as a function of temperature. At room temperature,

the specimens exhibited a radial crack initiation mode

(Fig. 6a), similar to brittle metal behavior [8]. At body

temperature, the specimens failed in a tearing mode

(Fig. 6b), previously observed in ductile metals behavior

and polymers [4,8].

Review of the videotapes of the back surface of the

specimens indicated that crack initiation did not occur at

the microvoids on the surface of the PMMA specimens.

Subsequent SEM of the fracture surfaces, conducted at

magni"cations of 500

;, con

"rmed that initiation occur-

red in the polymer matrix between the prepolymerized

beads (Fig. 7). Cracks were also observed to propagate

preferentially in the polymer matrix, rather than through

the prepolymerized beads (Fig. 7).

4. Discussion

We found a pronounced e!ect of temperature on elas-

tic behavior and crack initiation in the two bone cements

evaluated by the small punch test method. The bone

cements exhibited

`ductilea crack initiation patterns at

body temperature, while at room temperature the crack

initiation pattern was

`brittle,a suggesting that the

in vivo mechanism of cement fracture initiation may be

di!erent than at room temperature in vitro. The work to

initiate fracture in the specimens was signi"cantly higher

at body temperature, and this temperature sensitivity

was more pronounced for Simplex-P. Although, we did

not compute the fracture initiation toughness (J') from

these data, preliminary indications from these results

suggest that J' is temperature sensitive. The results of

this study highlight the importance of carrying out small

punch testing of bone cement at body temperature due to

the sensitivity of fracture initiation to temperature in this

material. The e!ect of temperature on crack propagation

V.L. Giddings et al. / Biomaterials 22 (2001) 1875} 1881

1879

resistance was not apparent from these data and will be

explored in future research.

The bulk mechanical behavior of bone cement is re-

ported to be sensitive to test temperature [13], but the

majority of recent studies have focused on mechanical

testing at either body or room temperature, and the

e!ects of temperature alone are typically confounded by

other changes in testing conditions (e.g., testing in air at

room temperature vs. in saline solution at body temper-

ature) [15]. When testing ordinary and antibiotic bone

cements in compression at room and body temperature,

Lee and colleagues noted an average reduction in elastic

modulus and ultimate compressive stress of about 4 and

10%, respectively [19]. In the present study, we observed

the average elastic modulus for both PMMA materials

decreased by 20}22% when the temperature increased

from 24 to 373C. The ultimate load, ultimate displace-

ment, and work to failure during the small punch test,

which were associated with crack initiation, were ob-

served to signi"cantly increase with increasing test tem-

perature. The temperature sensitivity of bone cement

mechanical behavior is likely due to the proximity to test

temperature of the glass transition temperature (T),

which in bone cement depends upon the details of the

formulation and storage condition [16]. In a recent com-

pilation of data for 26 di!erent bone cements, the

T ranged between 65 and 1003C after 24h under dry

storage conditions [16]. The temperature sensitivity of

bone cement mechanical behavior is hypothesized to be

speci"c to the formulation and storage conditions, due to

the sensitivity of T to these factors.

The presence of voids in bone cement has been asso-

ciated with deleterious consequences for fracture resist-

ance, due to the increased number of sites for crack

initiation [15,20]. Although the specimens prepared from

the generic PMMA had many more surface voids,

ranging in size from 0.1 to 0.2 mm in diameter, we ob-

served from the video record that cracks did not initiate

at these voids. Evidence of crack initiation and propaga-

tion was observed in the polymer matrix surrounding the

prepolymerized beads (Fig. 7). Recent research by

Topoleski and Vesnovsky suggests that the tendency for

cracks to propagate around polymer beads depends

upon both the formulation of the bone cement powder as

well as the radiopaci"er [21]. The crack propagation

initiation and propagation behavior observed in this

study may also be speci"c to the small punch test con"g-

uration.

The mechanical behavior of bone cement is well

known to be sensitive to formulation, preparation

method, and sterilization method [15,16]. In the present

study, the two test groups of PMMA materials had

di!erent formulations, di!erent mixing methods, and

were subjected to di!erent sterilization methods. Al-

though we observed signi"cant di!erences between the

di!erent test groups at body and room temperature, our

study was designed to evaluate the suitability of the small

punch test for evaluating bone cement. Our study was

not intended to evaluate the separate e!ects of formula-

tion, preparation method, or sterilization method. How-

ever, now that the suitability of the small punch test

technique has been established for PMMA, we expect to

use this technique in future experiments on di!erent bone

cement formulations and preparation conditions.

The small punch test was found to be a highly repro-

ducible and e!ective test method for evaluating PMMA

mechanical behavior. Research is ongoing to relate the

crack initiation behavior observed in the small punch test

with the fracture toughness parameters typically used in

conjunction with bulk (large) specimen testing tech-

niques. The ability to utilize small specimens makes the

small punch test method particularly attractive, as it can

be used to probe the elastic and fracture behavior of the

cement mantle around explanted devices. Future studies

will be directed to further exploring the formulation-

dependence, temperature-dependence, and preparation-

dependence of bone cements on the mechanical behavior

determined by the small punch test.

Acknowledgements

Special thanks to Jim Thompson, Howmedica Os-

teonics, for his assistance with specimen preparation.

Supported by a Research Grant from Howmedica Os-

teonics Corp.

References

[1] Edidin AA, Pruitt L, Jewett CW, Crane DJ, Roberts D, Kurtz

SM. Plasticity-induced damage layer is a precursor to wear in

radiation-cross-linked UHMWPE acetabular components for to-

tal hip replacement. Ultra-high-molecular-weight polyethylene.

J Arthroplasty 1999;14:616}27.

[2] Edidin AA, Jewett CW, Kwarteng K, Kalinowski A, Kurtz SM.

Degradation of mechanical behavior in UHMWPE after natural

and accelerated aging. Biomaterials 2000;21:1451}60.

[3] Edidin AA, Kurtz SM. The in#uence of mechanical behavior on

the wear of four clinically relevant polymeric biomaterials in a hip

simulator. J Arthroplasty 2000;15:321}31.

[4] Kurtz SM, Foulds JR, Jewett CW, Srivastav S, Edidin AA. Vali-

dation of a small punch testing technique to characterize the

mechanical behavior of ultra-high molecular weight polyethylene.

Biomaterials 1997;18:1659}63.

[5] Kurtz SM, Jewett CW, Foulds JR, Edidin AA. A miniature-

specimen mechanical testing technique scaled to the articulating

surface of polyethylene components for total joint arthroplasty.

J Biomed Mater Res (Appl Biomater) 1999;48:75}81.

[6] Kurtz SM, Pruitt LA, Jewett CW, Foulds JR, Edidin AA. Radi-

ation and peroxide crosslinking promote strain hardening behav-

ior and molecular alignment in UHMWPE during multiaxial

loading conditions. Biomaterials 1999;20:1449}62.

[7] Kurtz SM, Rimnac CM, Pruitt L, Jewett CW, Goldberg V, Edidin

AA. The relationship between the clinical performance and large

deformation mechanical behavior of retrieved UHMWPE tibial

inserts. Biomaterials 2000;21:283}91.

1880

V.L. Giddings et al. / Biomaterials 22 (2001) 1875} 1881

[8] Foulds JR, Woytowitz PJ, Parnell TK, Jewett CW. Fracture

toughness by small punch testing. J Testing Eval 1995;23:3}10.

[9] Mao X, Saito M, Takahashi H. Small punch test to predict ductile

fracture toughness JIc and brittle fracture toughness KIc. Scripta

Met Mater 1987;25:2481}5.

[10] Mao X, Shoji T, Takahashi H. Characterization of fracture

behavior in small punch test by combined recrystallization-

etch method and rigid plastic analysis. J Testing Eval 1987;

15:30}7.

[11] Manahan MP, Argon AS, Harling OK. The development of

a miniaturized disk bend test for the determination of postirradi-

ation mechanical properties. J Nucl Mater 1981;104:1545}50.

[12] Charnley J. Total hip replacement by low-friction arthroplasty.

Clin Orthop 1970;72:7}21.

[13] Saha S, Pal S. Mechanical properties of bone cement: a review.

J Biomed Mater Res 1984;18:435}62.

[14] Krause W, Mathis RS. Fatigue properties of acrylic bone cements:

review of the literature. J Biomed Mater Res 1988;22:37}53.

[15] Lewis G. Properties of acrylic bone cement: state of the art review.

J Biomed Mater Res 1997;38:155}82.

[16] KuKhn K-D. Bone cements: up-to-date comparison of physical and

chemical properties of commercial materials. Berlin: Springer,

2000.

[17] Williams JL, Johnson WJ. Elastic constants of composites formed

from PMMA bone cement and anisotropic bovine tibial cancel-

lous bone. J Biomech 1989;22:673}82.

[18] Taylor JR. An introduction to error analysis: the study of uncer-

tainties in physical measurements. Sausalito: University Science

Books, 1997.

[19] Lee AJC, Ling RSM, Vangala SS. The mechanical properties of

bone cements. J Med Engng Technol 1977;1:137}40.

[20] Linden U. Mechanical properties of bone cement. Importance of

the mixing technique. Clin Orthop 1991;272:274}8.

[21] Topoleski LD, Vesnovsky O. Does the type of radiopaci"er make

a di!erence in the fatigue crack propagation rate of PMMA bone

cement? Sixth World Congress of Biomaterials, 2000. p. 411.

V.L. Giddings et al. / Biomaterials 22 (2001) 1875} 1881

1881

Wyszukiwarka

Podobne podstrony:

Cessna 172XP Small Checklist

M 5202 Small color dress

2012 2 MAR Common Toxicologic Issues in Small Animals

Arctic sea ice extent small as never before

PRAWO MORSKIE sem IX v small

Marketing a small business

SMALL WORLD

mikro small all O5VOYBUT7X34PU2JJ4DUVHPFC5I2L3JHUJH7VQI

Bertrice Small Niewolnica miłości cz2

Caribbean Punch

Punch

Ściągawka + informator, Ściągawka na egzamin zawodowy - technik elektronik SMALL

Ściągawka + informator, Ściągawka na egzamin zawodowy - technik elektronik SMALL

Akerlof, Yellen Can small deviations from rationality make

ABC Small Business'u

ABC Small Bussines'u

więcej podobnych podstron