* Corresponding author.

Biomaterials 21 (2000) 469}473

Ion-beam-assisted deposition (IBAD) of hydroxyapatite coating layer

on Ti-based metal substrate

Jae-Man Choi

!, Hyoun-Ee Kim!,*, In-Seop Lee"

!School of Materials Science and Engineering, Seoul National University, Seoul 151-742, South Korea

"Research Center of Orthopaedic & Rehabilitation Engineering, Inchon 403-120, South Korea

Received 12 February 1999; accepted 22 August 1999

Abstract

A hydroxyapatite layer was formed on the surface of a Ti-based alloy by ion-beam-assisted deposition. The deposition methodo-

logy comprised of an electron beam vaporizing a pure hydroxyapatite target, while an Ar ion beam was focused on the metal substrate

to assist deposition. All deposited layers were amorphous, regardless of the current level of the ion beam. The bond strength between

the layer and the substrate increased steadily with increasing current, while the dissolution rate in a physiological saline solution

decreased remarkably. These improvements were attributed to an increase in the Ca/P ratio of the layer. Without ion beam assistance,

the Ca/P ratio was much lower than the stoichiometric HAp (Ca/P"1.67). With ion-beam assistance, the Ca/P ratio of the layer

increased presumably due to the high sputtering rate of P compared to that of Ca from the layer being coated.

( 2000 Elsevier

Science Ltd. All rights reserved.

Keywords: Hydroxyapatite; Coating; Metal implant; IBAD; Ca/P ratio

1. Introduction

To improve bioactivity of metal implants, hydroxy-

apatite (HAp: Ca10(PO4)6(OH)2) or other calcium

phosphates are generally applied as a coating [1]. Be-

cause of the chemical and crystallographic similarities

with the inorganic components of human bones, HAp or

calcium phosphate layers lead to direct bonding or

earlier stabilization of implants with the surrounding

bones or tissues [2}4].

In addition to bioactivity, the bond strength of a coat-

ing layer with the metal substrate is a very important

factor. If the layer is separated from the implant during

actual applications in human body, the detached frag-

ments have very adverse e!ects on the implant or the

tissue surrounding it [5]. Another important property

that the coating layer should possess is a low dissolution

rate in aqueous solutions. If the dissolution rate is faster

than bone growth or implants stabilization, the coating is

useless. The dissolution rate of crystalline HAp has been

observed to be very low, while that of the amorphous

phase was considerably high [1].

Various techniques, such as sputtering [6}9], electron

beam deposition [7], laser deposition [11,12], and

plasma spraying [13}19] have been employed to deposit

HAp or other calcium phosphate layers on various metal

substrates. Among these, plasma spraying is most widely

used because of its simplicity and versatility. Regardless

of the coating methodology, amorphous layers are gener-

ally formed on metal substrates, which have a high

dissolution rate in aqueous solutions. Therefore, the

layers are subsequently heat-treated at approximately

6003C in order to convert the amorphous phase into

a crystalline phase [16}20]. However, the heat treatment

causes cracks in the layer due to a thermal expansion

mismatch between the coated layer and the metal sub-

strate. This leads to a severe reduction in bond strength

[16}19].

In this study, thin hydroxyapatite layers were depos-

ited on a Ti}6Al}4V alloy by an ion-beam-assisted de-

position (IBAD) method. The e!ect of ion beam intensity

on the layer-substrate bond strength in addition to the

layer dissolution rate in a physiological saline solution

was investigated.

0142-9612/00/$ - see front matter

( 2000 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 9 9 ) 0 0 1 8 6 - 6

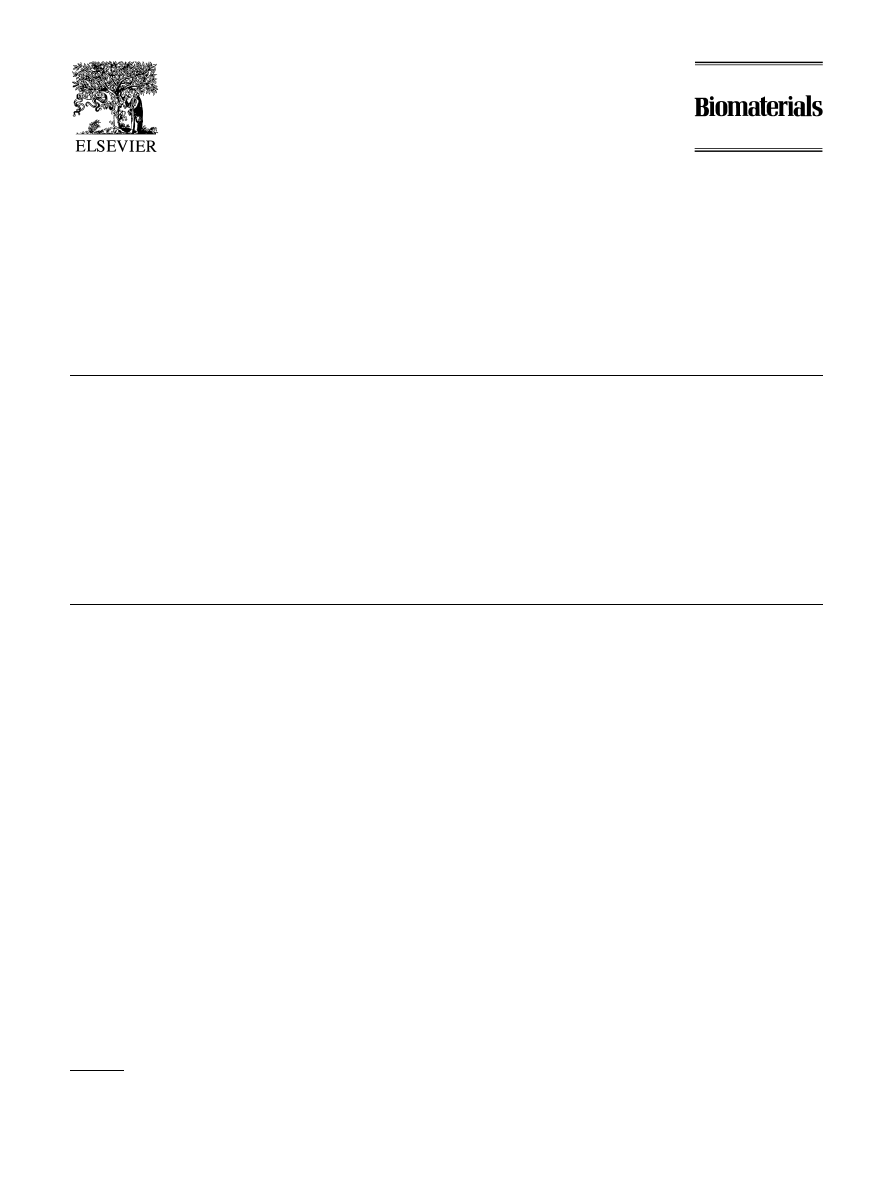

Fig. 1. XRD patterns of coating layers after heat treatment in vacuum

at 6303C. Ion beam currents are (A) 0 A, (B) 0.6 A, (C) 0.8 A, and (D)

1.0A. (

v) TCP, (h) HAp, and ( ) Ti.

2. Experimental procedure

The deposition target was synthesized by sintering a

commercial Ca10(PO4)6(OH)2 powder (Alfa Aesar Co.,

Ward Hill, MA, USA) in air at 12003C for 2 h. A com-

mercial Ti}6Al}4V alloy (Supra Alloys Inc., Camarillo,

CA, USA) was used as a substrate after machining into

disk of 25 mm in diameter and 2 mm in thickness. The

substrate surface was ground with SiC and subsequently

polished with diamond slurries down to 1

lm.

Thin hydroxyapatite layers were deposited on the

metal substrate by utilizing an ion-beam assisted depos-

ition (IBAD) technique. Using a cryopump (OB-10, Helix

Technology, Mans"eld, MA, USA), the chamber was

evacuated to a pressure of 10

~7 Torr. Subsequently, Ar

gas (P"10

~4 Torr) was introduced to the chamber.

Whilst an electron beam (Telemark, Fremont, CA, USA)

at 8.5 kV and about 0.1 A was evaporating the target, the

end-hall type ion gun (Mark II, Commonwealth Scient-

i"c, Alexandria, VA, USA) was applied to the metal

substrate surface to assist the deposition. The voltage was

"xed at 130 V and the current level was gradually increased

up to 1.0 A. The substrate was rotated at 8 rpm during

deposition in order to improve coating layer uniformity.

The deposited layers were analyzed by X-ray di!rac-

tometer (XRD, M18XHF, Mac Science, Yokohama,

Japan), energy dispersive spectroscopy (EDS, Oxford

Instruments, Bucks, England), and Fourier transform

infrared spectroscopy (FTIR, Model Equinox 55, Bruker,

Karlsruhe, Germany). The thickness of the layer was

measured by a surface pro"ler (Model P-10, Tencor,

Santa Clara, CA, USA) after making a step through an

etching process. The morphology of the layer was ob-

served by scanning electron microscopy (SEM, JSM-

5310, JEOL, Tokyo, Japan). The e!ect of heat treatment

in a vacuum (3

]10~3 Torr) at 630

3C for 1 h on the layer

phase and morphology was also investigated.

The dissolution rate of the deposited layer in a physio-

logical saline solution was measured with the surface

pro"ler. After half of the coating layer on the specimen

was covered with a water-resistant tape, it was then

immersed in the solution. The dissolution rate was esti-

mated from the "lm thickness dissolved during the dis-

solution period.

The bond strength of the coating layer was measured

using an adhesion testing apparatus (Sebastian V, Quad

Group, Spokane, WA, USA). A stud pre-coated by the

manufacturer using an epoxy of a proprietary composi-

tion was adhered to the coating layer by curing the epoxy

at 1503C for 1 h. The stud with a diameter of 3.6 mm was

pulled with a loading rate of 4.5 mm/min until the failure

of the coating layer, and the bond strength was deter-

mined from the maximum load recorded. Care was taken

to minimize the e!ect of epoxy penetration and non-

uniform failure of the coating layer. At least 10 measure-

ments were made for each experimental condition.

3. Results and discussion

The current level of the ion beam had signi"cant e!ects

on the deposited layer composition. Before heat treat-

ment, all the coating layers in this experiment were

amorphous with a thickness of approximately 700 nm.

To estimate the composition, the layers were heat-treated

in a vacuum (3

]10~3 Torr) at 630

3C for 1 h and ana-

lyzed by XRD. The XRD patterns of the layers after the

heat treatment are shown in Fig. 1. When the ion beam

was not used to assist deposition, tricalcium phosphate

(TCP: Ca3(PO4)2) was formed after heat treatment,

Fig. 1(A). When an ion beam with the current of 0.6 A

was applied to the substrate during deposition, the com-

position of the layer was unchanged (Fig. 1(B)). However,

when the current of the ion beam was increased to 0.8 A,

weak HAp peaks were detected instead of TCP peaks as

shown in Fig. 1(C), which became stronger as the ion

beam current was increased to 1.0 A (Fig. 1(D)). These

XRD patterns indicated that the composition of the

coating layer was strongly in#uenced by the ion beam

assistance.

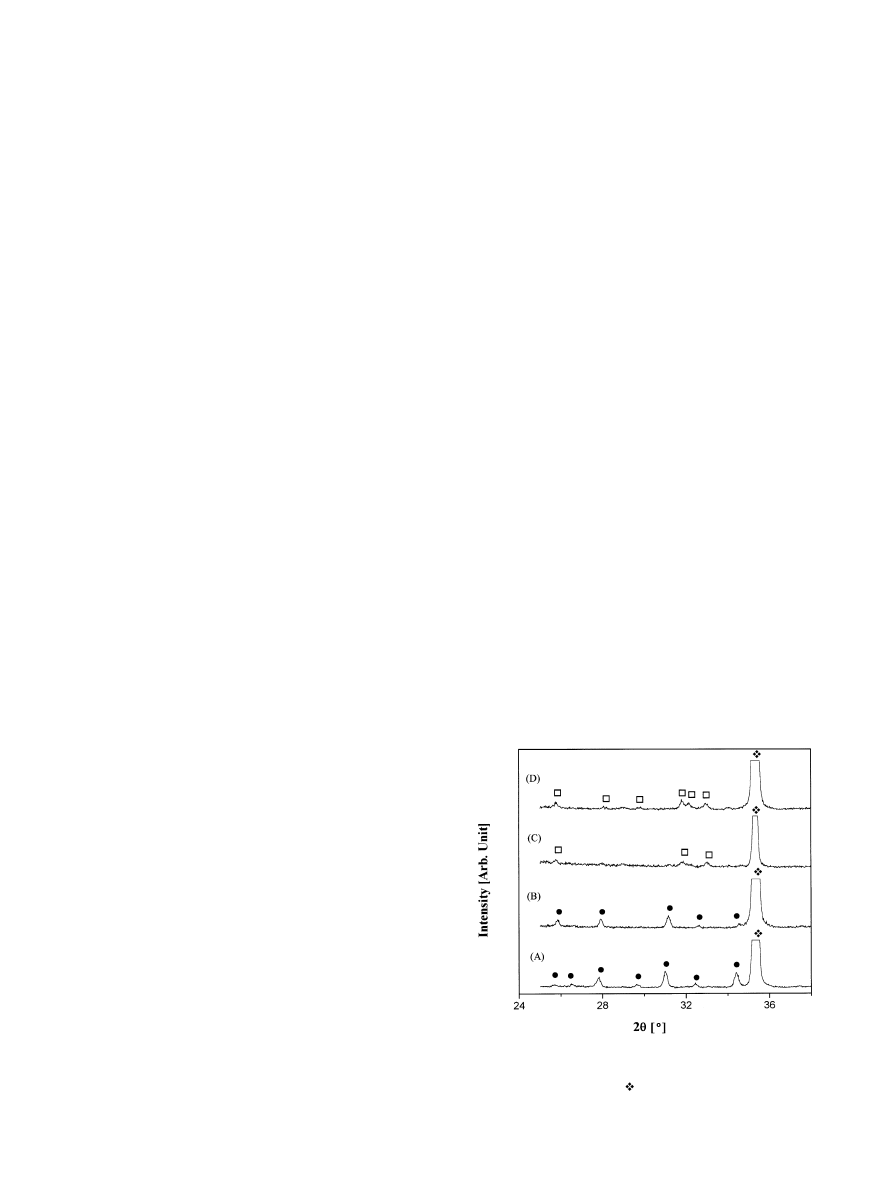

The e!ect of ion-beam assistance was also observed by

EDS analyses. Without the ion-beam assistance, the

coating had a low Ca/P ratio (Ca/P"1.1) as seen in

Fig. 2. At an ion beam current of 0.6 A, the Ca/P ratio

was not signi"cantly changed. However, the Ca/P ratio

increased remarkably when the current was further in-

creased to 0.8 or 1.0 A. The coating layer Ca/P ratios

observed were still smaller than those for stoichiometric

TCP (Ca/P"1.5) or HAp (Ca/P"1.67). Therefore, the

layers deposited, even after heat treatments, were not

100% crystalline TCP or HAp, but a mixture of crystal-

line and amorphous phases.

470

J.-M. Choi et al. / Biomaterials 21 (2000) 469 }473

Fig. 3. FTIR spectra of the coating layers after the heat treatment. Ion

beam currents are (A) 0 A, (B) 0.6 A, (C) 0.8 A, and (D) 1.0 A.

Fig. 2. Ca/P ratio of the coating layer depending on the current level

for the ion beam.

Fig. 4. Layer}metal substrate bond strengths, before and after heat

treatment, as a function of ion beam current.

The e!ect of ion beam current on the coating layer

structure was also observed by FTIR spectroscopy

(Fig. 3). When the ion beam was o! or the current level

was low (0.6 A), no OH

~ stretch was detected after heat

treatment. However, when the ion beam current was

increased to 0.8 or 1.0 A, an OH

~ stretch was clearly

observed by FTIR spectroscopy [14,20].

These variations in composition have an e!ect on the

properties of the deposited layers. The bond strengths are

shown in Fig. 4 as a function of the ion beam current,

before and after the heat treatment. Before the heat

treatment, the bond strength increased steadily with in-

creasing current. Ion bombardment during deposition is

known to broaden the atomic intermixed zone, thereby

increasing the adhesion strength between the coating

layer and the substrate [21].

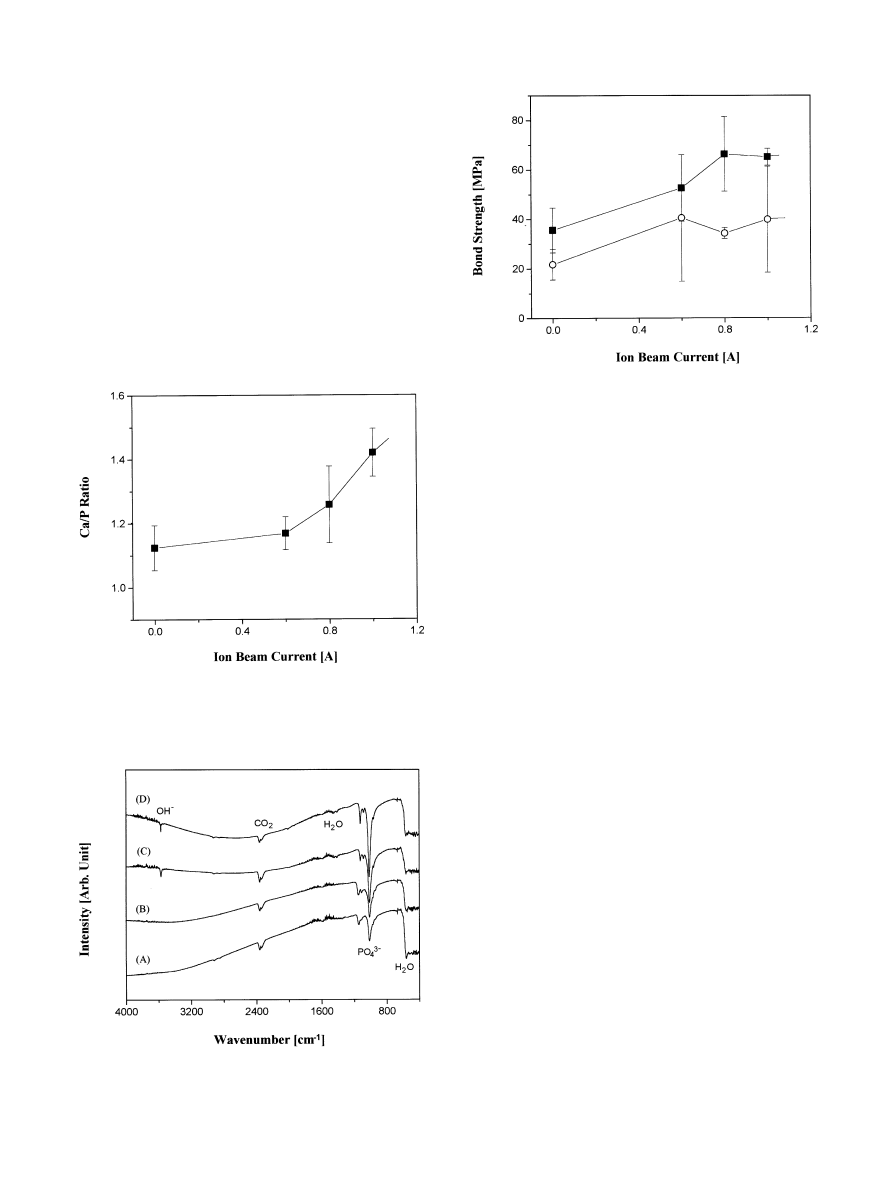

The bond strength decreased as a result of heat treat-

ment as has been frequently observed by other investiga-

tors [16}19]. SEM micrographs of the coating layer

before and after the heat treatment are shown in Fig. 5.

The morphologies were more or less similar regardless of

the current level. Before the heat treatment, the layer was

rather featureless as shown in Fig. 5(A). The lines at the

interface are Wallner lines frequently observed when

hard coating layers are detached from a metal substrate

[10]. After heat treatment, however, the layer became

severely cracked (Fig. 5(B)) apparently due to a thermal

expansion mismatch between the substrate and the layer

[22]. The reduction in bond strength as a result of heat

treatment is clearly due to these cracks. In addition to

cracks, the micrograph also indicates that the metal sur-

face was slightly oxidized, presumably by OH in the

coating layer [22]. The epoxy used to attach the coating

layer to the stud may have penetrated through the cracks

formed on the heat-treated specimen. Therefore, the

bond strengths after heat treatment might be even lower

than observed [14].

Despite the reduction in bond strength, heat treatment

has been carried out in order to crystallize the coating

layer. Otherwise, the dissolution rate of the layer in

a physiological solution is too high for actual applica-

tions [16}20]. In this study, when an ion beam was used

to assist deposition, the dissolution rate was reduced

remarkably even in the absence of heat treatment as

shown in Fig. 6. With ion-beam assistance, the dissolu-

tion rate decreased by more than a factor of 10. There-

fore, by employing ion-beam assistance technique, a HAp

coating layer that has a high bond strength and at the

same time a low dissolution rate can be deposited on

a metal substrate.

J.-M. Choi et al. / Biomaterials 21 (2000) 469 }473

471

Fig. 5. SEM micrographs of the coating layer (A) before and (B) after

the heat treatment.

Fig. 6. Dissolution rate of the coating layer in physiological saline

solution.

Fig. 8. Deposition rate of the coating layer as a function of ion beam

current.

Fig. 7. FTIR spectra of the coating layer before heat treatment. Ion

beam currents are (A) 0 A, (B) 0.6 A, (C) 0.8 A, and (D) 1.0 A.

The low dissolution rate observed is believed to be

related to the structure of the layer. As manifested by

XRD, EDS and FTIR analyses, the Ca/P ratio of the

layer increased remarkably by applying the ion beam. By

increasing the Ca/P ratio, there is a high chance for the

layer to be similar to crystalline HAp, which is supported

by FTIR spectroscopy. As seen in Fig. 7, when the cur-

rent level of the ion beam was high (0.8 and 1.0 A), broad

OH

~ peaks were observed even before heat treatment.

Therefore, with ion-beam assistance, the composition

and structure of the coating layer appears to become

similar to crystalline HAp, which has a low dissolution

rate.

Application of the ion beam to the deposited layer not

only consolidated it but also resulted in sputtering by

impacting ions. The deposition rate, therefore, decreased

with increasing current level as shown in Fig. 8. This

sputtering e!ect is deemed to have a!ected the layer

Ca/P ratio. When a HAp layer was deposited on a metal

substrate by a r.f. sputtering method, the Ca/P ratio of

472

J.-M. Choi et al. / Biomaterials 21 (2000) 469 }473

the layer was much higher than that of the target [23].

This discrepancy suggests that Ca has higher sputtering

yield compared to P. Therefore, to obtain a stoichiomet-

ric HAp layer by the r.f. sputtering method, the Ca/P

ratio of the target should be lower than 1.67 [21]. How-

ever, in this experiment, the sputtering e!ect by the ion

beam decreased the relative concentration of P, resulting

in the observed increases in the Ca/P ratio in the layer.

4. Conclusions

The bond strength of a HAp coating layer with a metal

substrate and the dissolution rate of such layer in

a physiological saline solution was improved signi"-

cantly by applying an Ar ion beam during deposition.

Even though amorphous, the composition and structure

of the coating layer became similar to that of crystalline

HAp as a result of ion beam assistance. The higher

sputtering e$ciency of Ca compared to that of P was

attributed to the observed increase in the Ca/P ratio of

the coating layer.

Acknowledgements

We thank Dr. Mark C. Barnes for his helpful com-

ments when reviewing the manuscript.

References

[1] Lace"eld WR. Hydroxyapatite coating. Ann NY Acad Sci 1988;

523:72}80.

[2] Hench LL. Bioceramics. J Am Ceram Soc 1998;81:1705}28.

[3] Suchanek W, Yoshimura M. Processing and properties of hy-

droxyapatite-bases biomaterials for use as hard tissue replace-

ment implants. J Mater Res 1998;13:94}117.

[4] LeGeros RZ. Biodegradation and bioresorption of calcium phos-

phate ceramics. Clin Mater 1993;14:65}88.

[5] Wang S, Lace"eld WR, Lemons JE. Interfacial shear strength and

histology of plasma sprayed and sintered hydroxyapatite im-

plants in vivo. Biomaterials 1996;17:1965}70.

[6] van Dijk K, Schaeken HG, Wolke JGC, Jansen JA. In#uence of

annealing temperature on r.f. magnetron sputtered calcium phos-

phate coatings. Biomaterials 1996;17:405}10.

[7] Ong JL, Lucas LC, Lace"eld WR, Rigney ED. Structure, solubil-

ity and bond strength of thin calcium phosphate coatings produ-

ced by ion beam sputter deposition. Biomaterials 1992;13:249}54.

[8] Chen TS, Lace"eld WR. Crystallization of ion beam deposited

calcium phosphate. J Mater Res 1994;9:1284}90.

[9] Yoshinari M, Ohtsuka Y, Derand T. Thin hydroxyapatite coating

produced by the ion beam dynamic mixing method. Biomaterials

1994;15:529}35.

[10] Choi JM, Kong YM, Kin S, Kim HE, Hwang CS, Lee IS. Forma-

tion and characterization of hydroxyapatite coating layer on

Ti-based metal implant by electron beam deposition. J Mater Res

Soc 1999;14:2980}5.

[11] Singh RK, Qian F, Nagabushnam V, Damodaran R, Moudgil

BM. Excimer laser deposition of hydroxyapatite thin "lms. Bio-

materials 1994;15:522}8.

[12] Cotell CM, Chrisey DB, Grabowski KS, Spregue JA. Pulsed laser

deposition of hydroxyapatite thin "lms on Ti}6Al}4V. J Appl

Biomater 1992;8:87}93.

[13] Ducheyne P, Raemdonck WV, Heughebaert JC, Heughebaert M.

Sturctural analysis of hydroxyapatite coating on titanium. Bio-

materials 1986;7:97}103.

[14] Tsui YC, Doyle C, Clyne TW. Plasma sprayed hydroxyapatite

coating on titanium substrates. Part 1: mechanical properties and

residual stress levels. Biomaterials 1998;17:2015}29.

[15] Zyman Z, Weng J, Liu X, Zhang X, Ma Z. Amorphous phase and

morphological structure of hydroxyapatite plasma coatings. Bio-

materials 1993;14:225}8.

[16] Ji H, Marquis PM. E!ect of heat treatment on the microstructure

of plasma-sprayed hydroxyapatite coating. Biomaterials 1933;

14:64}8.

[17] Chen J, Wolke JGC, de Groot K. Microstructure and crystallinity

in hydroxyapatite coatings. Biomaterials 1994;15:396}9.

[18] Brossa F, Cigada A, Chiesa R, Paracchini L, Consonni C. Post-

deposition treatment e!ects on hydroxyapatite vacuum plasma

spray coatings. J Mater Sci Mater Med 1994;5:855}7.

[19] Chen J, Tong W, Coa Y, Feng J, Zhang X. E!ect of atmosphere

on phase transformation in plasma sprayed hydroxyapatite coat-

ings during heat treatment. J Biomed Mater Res 1997;34:15}20.

[20] Gross KA, Gross V, Berndt CC. Thermal analysis of amorphous

phases in hydroxyapatite coatings. J Am Ceram Soc 1998;

81:106}12.

[21] Cui FZ, Luo ZS, Feng QL. Highly adhesive hydroxyapatite

coatings on titanium alloy formed by ion beam assisted depos-

ition. J Mater Sci Mater Med 1997;8:403}5.

[22] Choi JW, Kong YM, Kim HE, Lee IS. Reinforcement of hy-

droxyapatite bioceramic by addition of Ni3Al and Al2O3. J Am

Ceram Soc 1998;81:1743}8.

[23] Hamagami JI, Kokubu D, Umegaki T, Yamashita K. Target-

composition e!ect on the hydroxyapatite thin "lms coated on

titanium by r.f. sputtering. Presented on the Third International

Meeting of Paci"c Rim Ceramic Societies 1998; paper

d 13-O-12,

Kyongju, Korea.

J.-M. Choi et al. / Biomaterials 21 (2000) 469 }473

473

Wyszukiwarka

Podobne podstrony:

14 2002 Mayer Ion beam analysis roughness

Floor beam ver 1 Student id 178 Nieznany

Platon z Aten Ion

02 Projekt BLUE BEAM dokladna informacja

68 979 990 Increasing of Lifetime of Aluminium and Magnesium Pressure Die Casting Moulds by Arc Ion

ion sputtering

Butterworth Finite element analysis of Structural Steelwork Beam to Column Bolted Connections (2)

blue beam

7 Modal Analysis of a Cantilever Beam

Beam Finishing PL

15m beam

8 Harmonic Analysis of a Cantilever Beam

Źródła prawa, zrodla 2, Mutuum & Depositum Irregulare

1 Effect of Self Weight on a Cantilever Beam

5 lect6 beam students

Projekt BLUE BEAM

9 Transient Analysis of a Cantilever Beam

więcej podobnych podstron