AGH UNIVERSITY OF SCIENCE AND TECHNOLOGY

IN CRACOW

FACULTY OF MINING AND TECHNOLOGY

The project sheet from subject:

UNDERGROUND CONSTRUCTIONS

Theme:

EVALUATION OF THE QUALITY OF THE ROCK MASS

IN THE VICINITY OF THE TUNNEL (CHAMBER)

WITH THE INITIAL PROPOSAL FOR HOUSING

Prepared by:

Łukasz Ładak

Civil engineering

Year 3, Group 3

Project number: 108

- 2 -

TABLE OF CONTENTS

1.

Project data ........................................................................................................................... - 3 -

2.

Rock Quality Designation – RQD ............................................................................................. - 4 -

3.

Rock Mass Rating System Classification – RMR ....................................................................... - 5 -

3.1.

Basic RMR....................................................................................................................... - 5 -

3.2.

Modified RMR (MRMR) .................................................................................................. - 6 -

3.3.

Uniaxial compressive strength R

crm

................................................................................. - 7 -

3.3.1.

Hoek ....................................................................................................................... - 7 -

3.3.2.

Aydan & Kawamoto ................................................................................................ - 7 -

3.3.3.

Kalamaras & Bieniawski .......................................................................................... - 7 -

3.3.4.

Summary ................................................................................................................ - 8 -

3.4.

Young’s modulus ............................................................................................................ - 8 -

3.4.1.

Bieniawski & Serafim & Pereira ............................................................................... - 8 -

3.4.2.

Hoek & Brown......................................................................................................... - 8 -

3.4.3.

Summary ................................................................................................................ - 8 -

4.

Rock Tunneling Quality Index Q .............................................................................................. - 9 -

4.1.

Rock Tunneling Quality Index calculations ...................................................................... - 9 -

4.2.

Young’s modulus: ........................................................................................................... - 9 -

4.3.

Equiwalent dimention D

e

...............................................................................................- 10 -

4.4.

Support system..............................................................................................................- 10 -

4.4.1.

Preliminary support proposal based on the graph ..................................................- 10 -

4.4.2.

Bolt length .............................................................................................................- 11 -

5.

Correlation between RMR and Q Systems .............................................................................- 11 -

6.

Comments ............................................................................................................................- 12 -

- 3 -

1. Project data

The main aim of the project is to estimate of rock mass quality along with preliminary support

proposal.

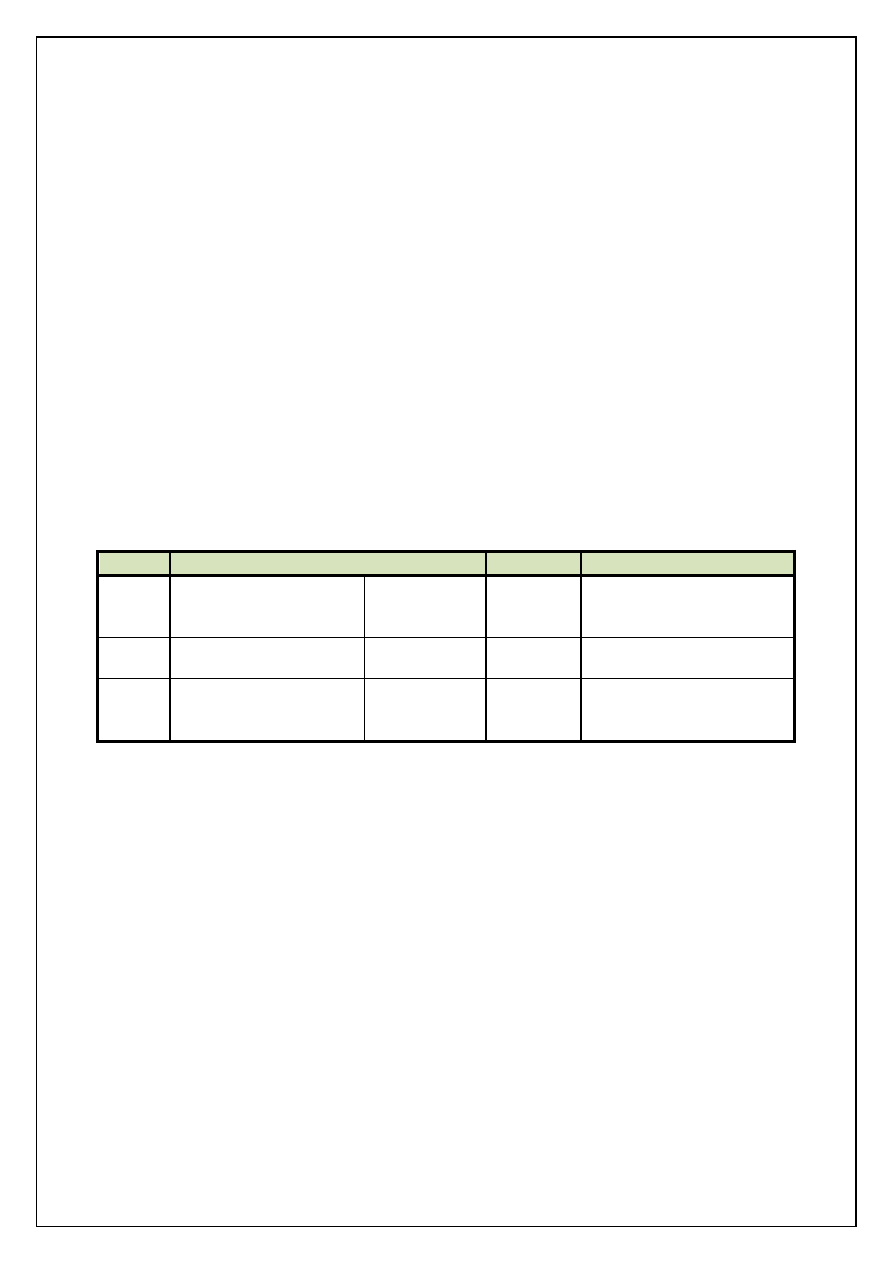

Table 1. Initial data

No.

Parameter

Value or description

1.

Shape, dimensions and destinations of tunnel

(chamber)

Underground parking chamber, crossing

rectangular, width 25 m, height 8 m

2.

Average depth, m

30

3.

General characteristic of rock mass in the

region of excavation

Concise, block

4.

Average compressive strength of rock

surrounding tunnel, MPa

70

5.

Average tension strength of rock surrounding

tunnel, MPa

3

6.

RQD, %, core diameter 55 mm

As in the picture

7.

Number and average spacing of discontinuities

sets

Two sets of discontinuities with average

spacing 1.0m

8.

Discontinuities characteristic

Stratas in contact, impermeable natural

filling

9.

Ground water

Driping

10.

Orientation of discontinuities sets to the dip

orientation of tunnel (chamber)

Strike perpendicular to longer chamber

axis; drive against dip, dip 25

o

11.

Way of excavating

Manual and mechanical excavating with

using blasting materials

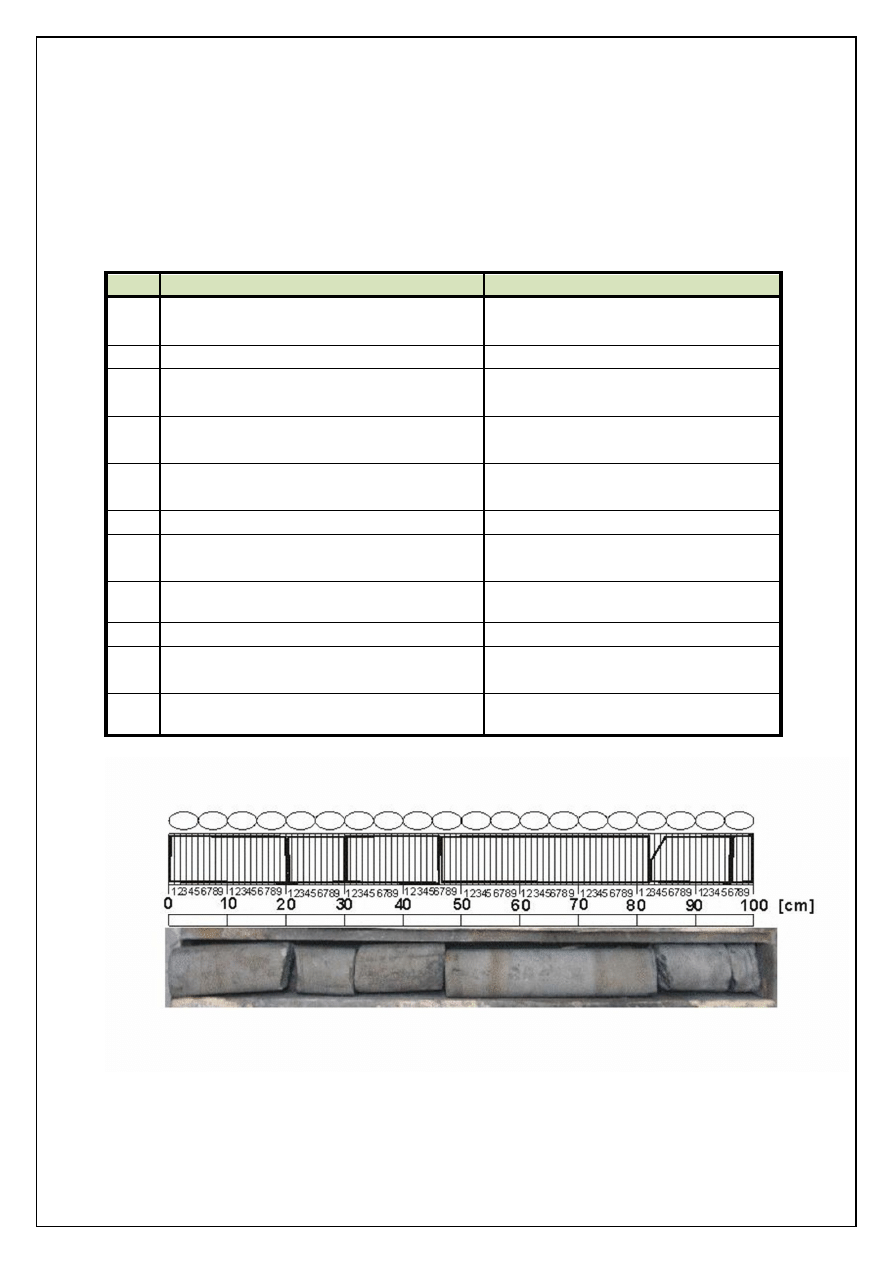

Figure 1. Drilling core

- 4 -

2. Rock Quality Designation – RQD

Rock Quality Designation index is the borehole core recovery percentage incorporating only

pieces of solid core that are longer than 100 mm in length measured along the centerline of the core.

In this respect pieces of core that are not hard and sound should not be counted though they are 100

mm in length. RQD has considerable value in estimating support of rock tunnels.

Rock Quality Designation index is most often calculated according to the following formula:

=

∑

· 100%

[1]

Where:

∑

–

sum of length of core sticks longer than 100 mm measured along the center line of the core

– total length of core, m.

Therefore there are 4 core piece that are longer than 100 mm and theirs lengths sum up to:

= (20 + 16 + 35 + 14) = 85[

]

As seen in the picture 1, total length of core amounts to:

= 100[

]

In this case the equation [1] for calculating the RQD index was as follows:

=

85

100

· 100% =

.

[%]

According to the estimated RQD value, examined rock mass was classified as good (range

between 75 and 90%).

- 5 -

3. Rock Mass Rating System Classification – RMR

Rock Mass Rating System is a geomechanical classification system for rocks, developed by

Z. T. Bieniawski between 1972 and 1973. The following six parameters are used to classify a rock

mass using the RMR system: uniaxial compressive strength of rock material, RQD, spacing of

discontinuities, condition of discontinuities, groundwater conditions and orientation of

discontinuities. Each of the six parameters is assigned a value corresponding to the characteristics of

the rock. These values are derived from field surveys. The sum of the six parameters is the "RMR

value", which lies between 0 and 100.

3.1. Basic RMR

Table 2. Rock Mass Rating System (after Bieniawski 1989)

No.

Parameter

Value

Rating

Comments

1

Strength of intact rock material

(uniaxial compressive strength)

70 MPa

9

Linear adjustment

2

Drill core quality (RQD)

85 %

16

Linear adjustment

3

Spacing of discontinuities

1.0 m

13

Linear adjustment

4

Condition of

discontinuities

Discontinuity

length

(persistence)

< 1 m

6

Envisaged value

Separation

(aperture)

< 0.1 mm

5

Envisaged value,

stratas in contact

Roughness

Very rough

6

Envisaged value

Infilling (gouge)

Hard filling < 5 mm

4

Envisaged value,

natural filling

Weathering

Unweathered

6

Envisaged value,

RQD=85%

5

Groundwater

Dripping

4

Lack of data about

inflow

6

Dip direction and orientation

Strike perpendicular to

longer chamber axis;

drive against dip with

25

o

dip

-10

Unfavorable

= 9 + 16 + 13 + 6 + 5 + 6 + 4 + 6 + 4 − 10 =

According to the estimated RMR value, examined rock mass was classified as fair

(class III, range between 41 and 60 points).

- 6 -

3.2. Modified RMR (MRMR)

Calculation of Modified Rock Mass Rating in the present project is not necessary. The MRMR

describes decrease of rock mass strength and other parameters under influence of specified factors.

However, these differences are related only to the rock mass in close neighborhood of excavation

area. In present project, the whole surrounding rock mass is being investigated and this is why there

is no need to calculate MRMR.

Nevertheless, for educational and comparative reasons, the MRMR will be calculated.

Modified Rock Mass Rating index is calculated according to the following formula:

=

·

· S ·

[2]

Each parameter was explained in table 3 below.

Table 3. Adjusted Rock Mass Rating System

No.

Parameter

Value

Comments

1

Blasting damage

adjustment

A

B

0,8

Manual and mechanical

excavating with using

blasting materials

2

In-situ stress and change

of stress adjustment

A

S

1

Average value of parameter

3

Major faults and fractures

S

1

Two sets of discontinuities

with average spacing

1.0 m

In this case the equation [2] for calculating the modified RMR index was as follows:

= 59 · 1 · 1 · 0.8 =

According to the estimated RMR value, examined rock mass was classified as fair

(class III, range between 41 and 60 points).

- 7 -

3.3. Uniaxial compressive strength R

crm

3.3.1. Hoek

= √ ·

,

[3]

Where:

– material constant,

– average compressive strength of rock surrounding tunnel, MPa.

Tunnel width was estimated from the following equation:

=

[4]

Therefore:

=

= 0.01051

According to equation [3] uniaxial compressive strength amounts to:

,

= √0.01051 · 70 = .

[

]

3.3.2. Aydan & Kawamoto

= 0.0016 ·

.

,

[5]

Therefore:

,

= 0.0016 · 59

.

=

,

[

]

3.3.3. Kalamaras & Bieniawski

=

·

,

[6]

Therefor:

,

=

70

2

·

59 − 15

85

=

.

[

]

- 8 -

3.3.4. Summary

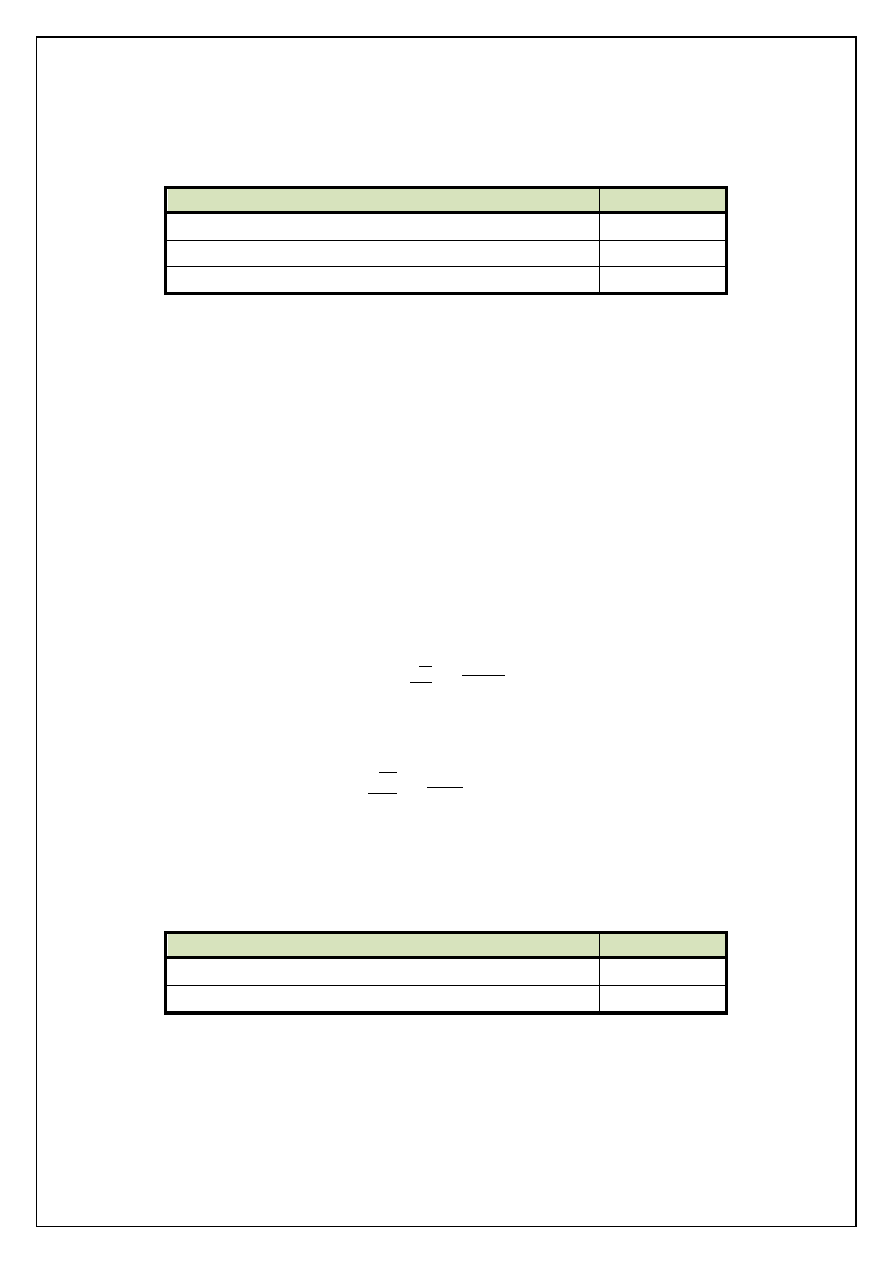

Table 4. Uniaxial compressive strength of rock mass values

Uniaxial compressive strenght of rock mass

Value

Hoek

7.18 MPa

Aydan & Kawamoto

24.78 MPa

Kalamaras & Bieniawski

18.12 MPa

3.4. Young’s modulus

3.4.1. Bieniawski & Serafim & Pereira

For

> 50 Young’s modulus is calculated from the equation below:

= 2 ·

− 100,

[7]

Therefore:

,

= 2 · 59 − 100 =

.

[

]

3.4.2. Hoek & Brown

=

· 10

,

[8]

Therefore:

,

=

√70

10

· 10

=

.

[

]

3.4.3. Summary

Table 5. Young’s module values

Young’s module

Value

Bieniawski & Serafim & Pereira

18.00 GPa

Hoek & Brown

14.05 GPa

- 9 -

4. Rock Tunneling Quality Index Q

4.1. Rock Tunneling Quality Index calculations

Rock Tunneling Quality Index ‘Q’ was estimated from the equation below:

=

·

·

[9]

Where:

– Rock Quality Designation,

– joint set number,

– joint roughness number,

– joint alternation number,

– joint water reduction factor,

– stress reduction factor.

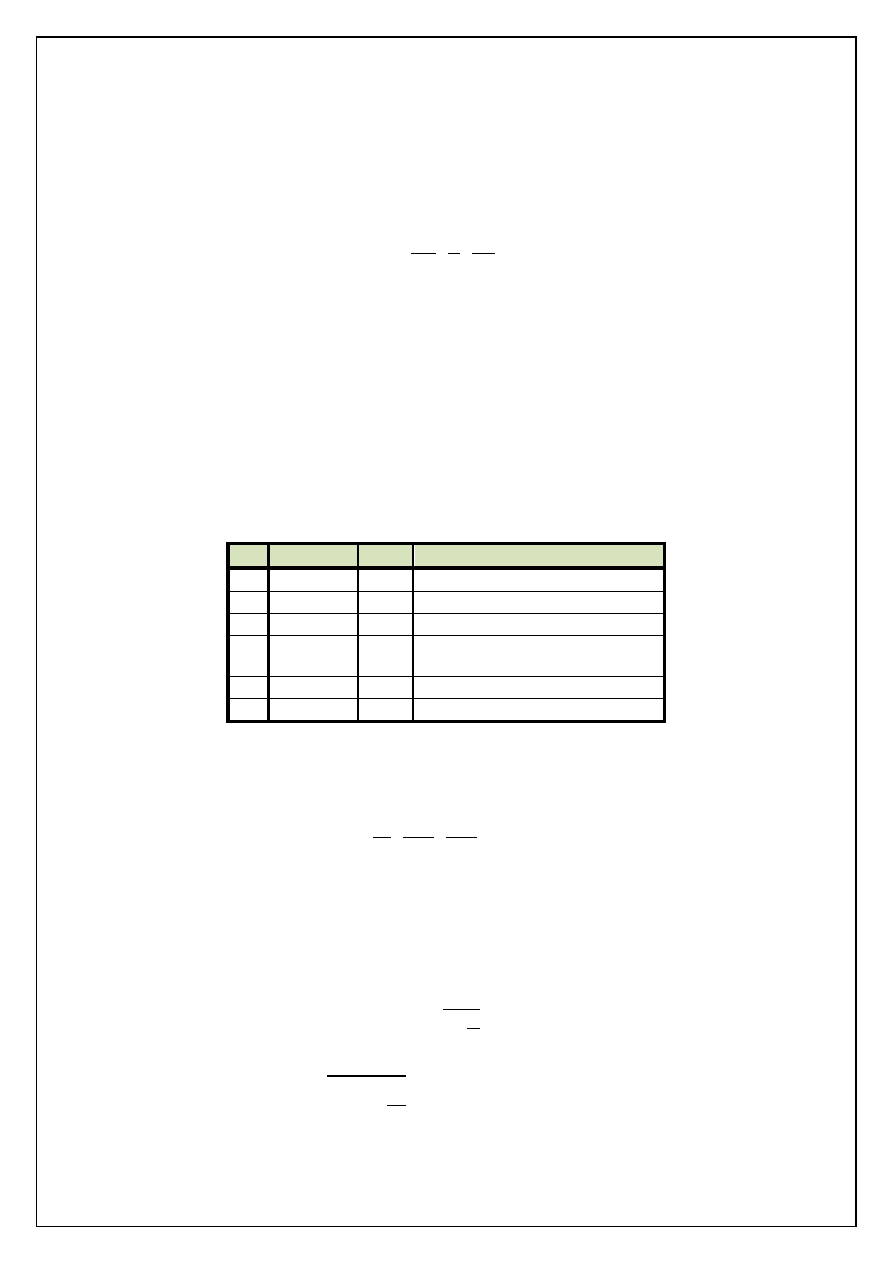

Table 6. Statement of Tunneling Quality Index ‘Q’ parameters

No. Parameter Value

Comments

1

RQD

85

-

2

J

n

4

Two discountinuity sets

3

J

r

1,5

Rough or irregular, planar

4

J

a

0.75

Tightly healed, hard, non-softening

impermeable filling

5

J

w

0.33

Large inflow or high pressure

6

SRF

1

Medium stress

In this case the equation [8] for calculating the Rock Tuneling Quality Index ‘Q’ was as follows:

=

85

4

·

1.5

0.75

·

0.33

1

=

.

According to the estimated Rock Tuneling Quality Index ‘Q’ value, examined rock mass was

classified as good (range between 10 and 40 points).

4.2. Young’s modulus:

= 10 ·

·

,

[10]

Therefore:

= 10 ·

14.025 ·

70

3

=

. [

] = .

[

]

- 10 -

4.3. Equiwalent dimention D

e

=

,

[11]

Where:

– excavation diameter, m,

– Excavation Support Ratio (for underground parking assumed

= 1.2).

=

25

1.2

=

[ ]

4.4. Support system

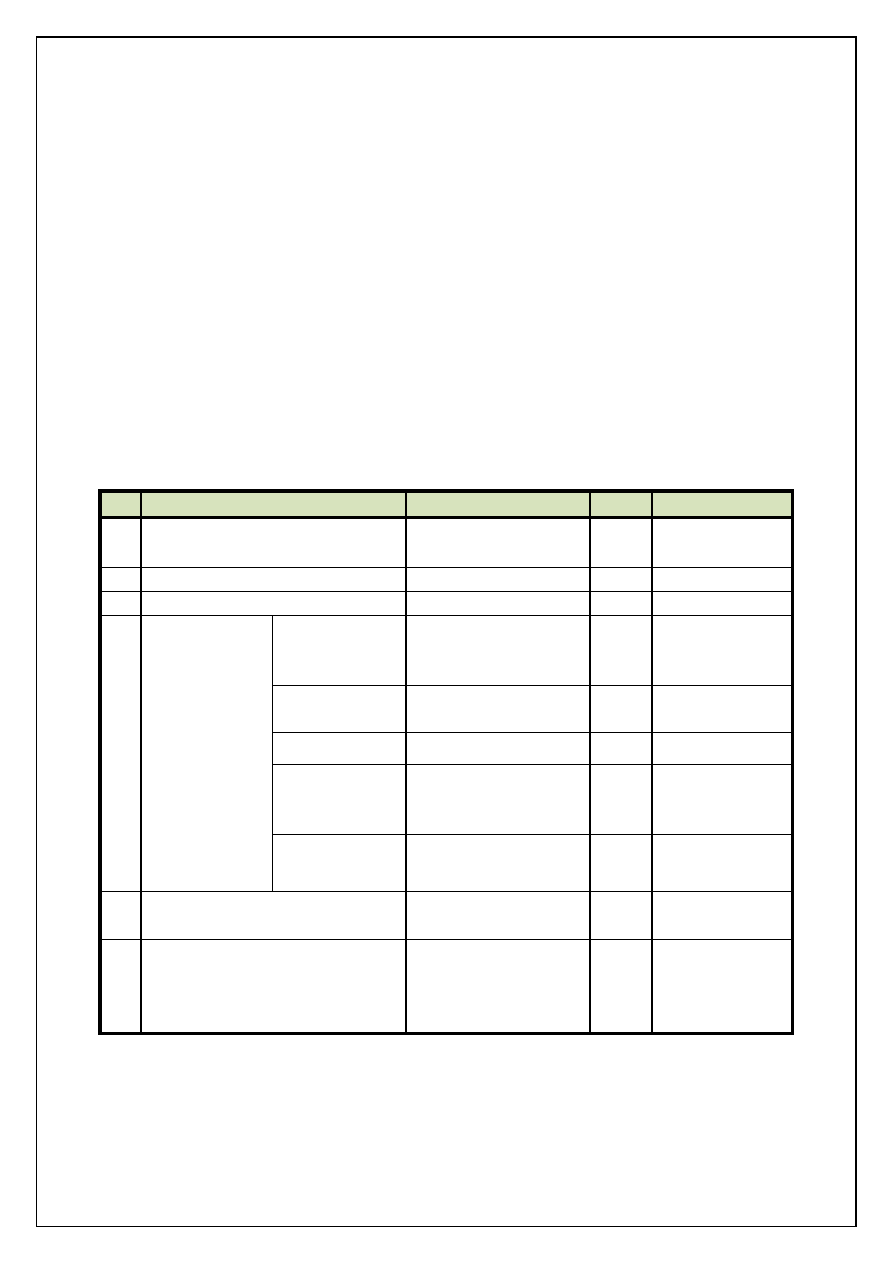

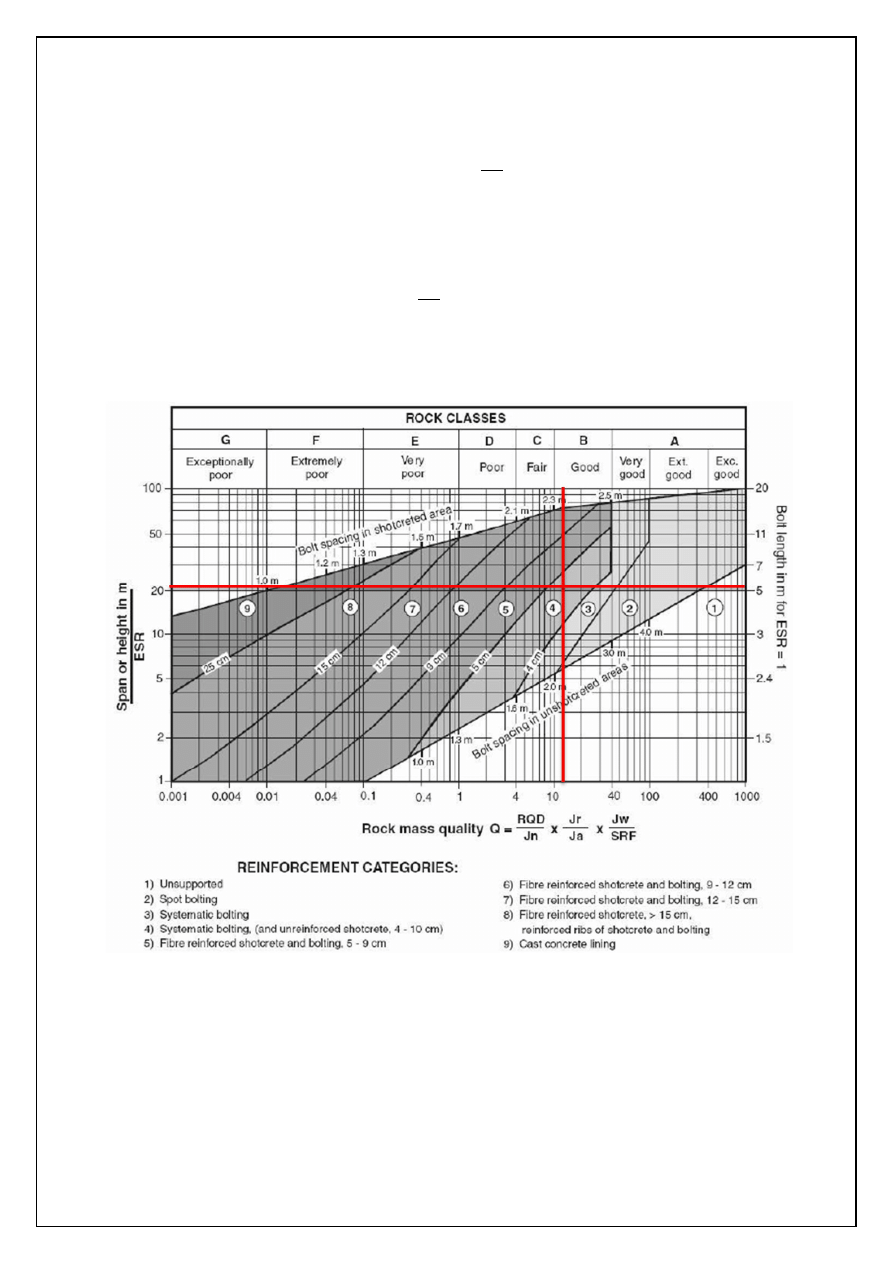

Figure 2. Estimated support categories based on the Tunneling Quality Index ‘Q’

4.4.1. Preliminary support proposal based on the graph

According to the graph, chamber in examined rock mass belongs to the 4

rd

reinforcement

category.

- 11 -

Proposed support solution for examined conditions is systematic bolting and unreinforced

shotcrete with following parameters:

Bolt spacing (in unshotcreted area) – 2.1 ÷ 2.2 m

Bolt length (only predicted value) – value close to 5.0 m

Shotcrete thickness – 4 ÷ 10 cm

4.4.2. Bolt length

It is possible to estimate bolts length from the graph above but only for ESR value equal 1.

Although, there is analytical way to calculate needed length of bolts. The equations that were used

are represented below:

=

.

·

,

[12]

Therefore:

=

2 + 0.15 · 25

1.2

= . [ ]

5. Correlation between RMR and Q Systems

Table 7. Correlation between RMR and Q Systems under Different Conditions

Correlation

Source of case

studies

Source of case studies,

Comments

RMR value

RMR = 13,5·log(Q) +43

New Zealand

Civil engineering tunnels

58.483

RMR = 9·ln(Q) +44

Diverse origin

Civil engineering tunnels

65.127

RMR = 12.5·log(Q) +55.2

Spain

Civil engineering tunnels

69.536

RMR = 5·ln(Q) +60.8

South Africa

Civil engineering tunnels

74.004

RMR = 43.89 - 9.19·ln(Q)

Spain

Mining tunnels, soft rock

19.621

RMR = 10.5·ln(Q) +41.8

Spain

Mining tunnels, soft rock

69.699

RMR = 12.11·log(Q) +50.81

Canada

Mining tunnels, soft rock

64.699

RMR = 8.7·ln(Q) +38

Canada

Civil engineering tunnels,

sedimentary rocks

60.975

RMR = 10·ln(Q) +39

Canada

Mining tunnels, hard rocks

65.408

According to the results, the closest value to the basic RMR is the one from correlation

= 13.5 · log( ) + 43, therefore supposed localization of the underground parking is

New Zeland.

- 12 -

6. Comments

Using RMR index the rock mass was classified as class III – fair rock. However, established

RMR value (59 points) is very close to the brackets’ border, which is 60-61 points. According to the

Rock Tunneling Quality index ‘Q’ value (14 points) rock mass taken under consideration is good but

here the ‘Q’ index value is close to fair rock bracket (4-10 points). In summary, these two methods

gave us similar results. It can be said, that the rock mass examined in this project may be recognized

as a rock between fair and good.

Some different results were obtained using RMR modified index (MRMR). That method also

ranked rock mass into class III – fair rock but with lower score - 47 points. The main reason of that

assignment is using A

B

factor value equal 0.8, which is caused by using blasting materials in

excavating process. However, as it was said above, that value reflects the rock mass strength only in

close neighborhood of the excavation area.

There are sizable discrepancies in Young’s modulus and the Uniaxial compressive strenght of

rock mass values. Quite big differences shows up comparing Young’s modulus calculated for RMR

and ‘Q’ index. Values obtained from formulas for RMR (14 GPa and 18 GPa) are very higher than

value calculated for ‘Q’ index (6.89 GPa). Uniaxial compressive strenght of rock mass was calculated

using formulas for RMR and here were also some diffrent values obtained, depenging on which

formula was used. The maximum difference is noticed between Hoek’s method (7.18 MPa) and

Aydan’s & Kawamoto‘s method (24.78 MPa).

In both classifications there are some factors that have the major influence at final result.

They are RQD value, ground water conditions, spacing and conditions of discontinuities.

In my opinion RMR method is more precise. It contains more parameters obtained in

research than ‘Q’ index. On the other hand we have not got any information about some of them and

we have to estimate or predict them basing on our subjective opinion, so it could reduce precision of

RMR.

Score of ‘Q’ index imposes preliminary support which contains systematic bolting with bolt

spacing between 2.1 ÷ 2.2 m. According to figure 2, unreinforced shotcreted support 4 ÷ 10 cm thick

is also needed. Bolts’ length red from the figure 2 amounts about 5 m but that is the value for

= 1. The precise bolts’ length for

= 1.2 were calculated from analytical formula and gave

us the value equal 4.8 m.

Correlation between RMR and Q-system pointed out supposed localization of civil

engineering tunnel – New Zeland.

Wyszukiwarka

Podobne podstrony:

Projekt Łukasz Ładak BAD

projekt luk, zut, projekt łukasz 1 i 2

mój projekt Łukasz Zaskórski docx

projekt lukasz doc

Projekt oczyszczalni sciekow Lukasz Jankowsk-Kate made, Technologia Wody i Ścieków

projektZAP dokumentacja koncowa Łukasz Kinel gr17 , Student:

Dane techniczne projektu lotu, studia, rok III, fotogrametria, od Łukasza

Projekt-wytrzymałość Omieciuch Łukasz, Przodki IL PW Inżynieria Lądowa budownictwo Politechnika Wars

Lukasz Przejczowski geomechanika projekt 1, AGH, GiG, AGH, geomechanika

Lukasz projekt obudowa, AGH, GiG, AGH, geomechanika

Projekt sprawozdanie Śledzik Łukasz(1)

ŁUKASZ projekt 1

wenio Łukasz grunty projekt

więcej podobnych podstron