17

Mask Processing

Syed A. Rizvi

CONTENTS

17.1 Mask Processing: Introduction

17.2 Resists and Developers

17.3 Pattern Transfer: Etching of Chrome

17.3.1 Wet Etching of Chrome

17.3.2 Dry Etching of Chrome (or Other Underlying Material)

Plasma Applications and Processes

17.4 Resist Stripping and Cleaning

17.4.1 Wet and Dry Cleaning Processes

Cleaning with Semidry Processes

17.4.2 Cleaning of Embedded Attenuated Phase Shift Masks

17.1

Mask Processing: Introduction

The term ‘‘mask processing’’ relates to all steps starting from resist development down to

the final cleanup, until the pellicles are mounted on the mask.

For the conventional chrome-on-glass (CoG) structure, the mask processing involves

the following basic steps:

1. Developing the mask after exposure to laser or e-beam

2. Pattern transfer: etching the chrome that is now exposed after resist is developed out

3. Stripping the resist

4. Final cleanup

The CoG masks are also referred as binary masks or simply BIMs. In many cases, steps

(3) and (4) are carried out in one single operation.

Depending on the type of resists, some bake operations may be required during the

processing. Deviation from the above process can occur for masks with more complex

structures.

Typically, the CoG mask blanks are coated with chrome and resist film at the supplier’s

site before they are delivered to the mask shop. At the mask shop the blanks are exposed

Rizvi / Handbook of Photomask Manufacturing Technology DK2192_c017 Final Proof page 367 7.3.2005 6:27pm

© 2005 by Taylor & Francis Group.

on laser or e-beam writers and then run through the appropriate developer resulting in

the emergence of resist patterns on the plate.

Although the subject of resists and developers has been addressed in

for

the sake of continuity a very short review of the topic will be given here.

17.2

Resists and Developers

One of the criteria of resist classification is whether the resist is positive or negative.

Positive resist is the one where its exposed portion is developed out leaving behind the

unexposed resist. This step results in the emergence of a pattern of unexposed resist and

chrome film that is no longer covered by the resist. In case of a negative resist it is the

unexposed portion that is developed out leaving behind the exposed resist. Here also, a

pattern of resist and chrome emerges.

While specifics may differ, there is a set of specs that the resist is expected to meet as

shown in Tables 17.1 and

[1,2]. The values in these tables are for generic resist and

may vary from the norm as required by individual cases.

Although most mask blanks are received already coated from the supplier, there are

times when some of the resist coatings are to be done at the mask shop facility. The

procedure is called ‘‘spin-coat,’’ where the resist is delivered onto the surface of mask

mounted on a chuck that is then spun at a speed of a few thousand revolutions per

minute. The chuck when spun at a prescribed speed causes the resist to spread with the

formation of a uniform film thickness across the mask surface. A typical spec on resist

thickness is 300–450 nm with a uniformity of + 3 nm.

Before exposure the masks need to be baked to remove the solvents from the resist.

There are two techniques commonly employed for developing masks after exposure.

One technique is the immersion method where the mask is dipped into a tank of

developer where the chemical reaction takes place. An advantage of this method is that

it can readily be adapted to batch processing where several plates can simultaneously be

TABLE 17.1

Resist Material Properties Requirements [2] (Courtesy of John G. Skinner & Associates.)

Material Property

Requirements

Resist solution shelf life

>

6 months

Batch to batch reproducibility

<5% in composition and molecular weight

Resist film coating shelf life

>

3 months

Resist thermal properties

Glass transition temperature

a

Tg > 808C; decomposition

temperature Td >1208C

Wet etch Cr chemistry

No degradation or adhesion failure

Dry etch Cr chemistry

Minimum 1:1 selectivity in Cl

2

O

2

-based plasma

b

Solubility

Environmentally safe spin coating solvents and aqueous base

developers

Strippability

Removal in commercial amine-based stripping solutions or O

2

,

halogen-based plasma

a

Tg is the glass transition temperature. It is the temperature at which the resist changes from a glassy

amorphous state to rubbery state.

b

The plasma, used for ‘‘dry-etching’’ the chromium film, may change according to the chromium film

composition.

Rizvi / Handbook of Photomask Manufacturing Technology DK2192_c017 Final Proof page 368 7.3.2005 6:27pm

© 2005 by Taylor & Francis Group.

processed. This method, however, has a drawback of contaminating the mask that later

requires additional clean up actions.

The other more commonly practiced technique is ‘‘spin-develop’’ with mechanism

similar to ‘‘spin-coat’’ mentioned earlier. Here the plate is always immersed in fresh

developer at the beginning of each cycle and hence is less prone to contamination.

The uniformity of development across the plate can have an effect on CD uniformity;

and hence due to the nature of spin-develop a degree of radial CD variation on the plate is

possible.

A number of modifications in spin-develop have been introduced to improve the CD

uniformity. Some of such methods employ single spray nozzle, multi-spray nozzle, and

puddle development techniques. In the puddle development technique, the plate is

slowly spun, while the developer is sprayed from the nozzle (or nozzles).

In all cases the developer is spray-rinsed and spin-dried. Table 17.3 [2,3] shows the

effects of various techniques on CD uniformity.

17.3

Pattern Transfer: Etching of Chrome

After the resist has been developed, the next step is to transfer the resist pattern on to the

underlying chrome film that now becomes uncovered by the removal of resist. This is

done by the etching of the exposed chrome. However, at this point it is important to

examine the plate to make sure that the resist is completely developed out. With certain

types of resists, an iterative process of CD-measurement and redevelopment may be

necessary until the required CD is achieved.

In some cases, traces of resist known as ‘‘scum’’ are left behind in the open windows

that can interfere with the etching of chrome. These scums can be removed by a quick

exposure to oxygen plasmas. The process is called ‘‘descum.’’

TABLE 17.2

Resist Lithographic Properties Requirements [2] (Cour-

tesy of John G. Skinner & Associates.)

Lithographic Property

Requirements

Sensitivity

E-beam

2.0 mC/cm

2

at the rate of 10 keV

Laser

100 mJ/cm

2

at wavelength 365 nm

Contrast (g)

>

4 for 858 feature wall slope

Resolution

<0.3 mm (for OPC features)

TABLE 17.3

CD Uniformity over 6-in. Mask [2,3]

Dev. Method

3 Sigma (nm)

Radial Error (nm)

Side Error (nm)

Single Spray Nozzle

32

23

12

Dual Spray Nozzle

16

18

10

Puddle

11

7

4

Dip

19

11

8

© 2005 by Taylor & Francis Group.

The etching of chrome has historically been carried out with wet chemicals that are

regarded as a part of wet processing. In recent years, due to increased demands on the

tolerance of shrinking features, many plasma etch processes known as dry etch processes

are introduced onto the manufacturing lines for photomasks.

17.3.1 Wet Etching of Chrome

The processing stations for wet etch can be similar to those of develop stations, namely,

immersion tanks or spin stations.

The chemicals commonly used for chrome etch are cerric ammonium nitrate and

certain acids that include perchloric acid, acetic acid, nitric acid, and hydrochloric acid [2].

Due to the liquid nature of the chemicals, the wet process tends to be isotropic and

causes certain degree of under-cuts. These under-cuts, however, turn out to be helpful in

minimizing the effect of slope that the resist profile exhibits towards its edges.

17.3.2 Dry Etching of Chrome (or Other Underlying Material)

As the feature sizes are getting smaller and the tolerance of their size are getting more

stringent, the industry is moving towards dry etch, which is more or less of an anisotropic

process and requires very little or zero bias in the transferring image form resist to chrome

film. Dry etch can also meet the stringent tolerance required by the state-of-the-art

designs.

Considering a 100-nm technology node it would seem that the mask feature would be

400 nm. However, when OPCs are involved, the 4:1 rules breakdown, and in such cases

mask feature needs to be significantly below 200 nm. At present, 100-nm or even smaller

features (on mask) are pursued.

Dry etching involves use of plasma (a mixture of electrons, ions, and various neutral

species). In today’s vocabulary, dry etch has become synonymous with plasma etch.

17.3.2.1 Plasma Reactors

There are various types of reactors for the creation and application of plasma that are used

for the etching of chrome or whatever underlying material is there to be etched. Some of

such examples of the etching systems are given in the following:

Ion milling: Here ions are accelerated towards the target, where it is the mechanical

impact of the ions rather than any sort of chemical reaction that does the etching of the

chrome film.

Reactive ion etching (RIE) and magnetic enhanced RIE (MERIE): In this case a reactive

species in the plasma chemically reacts with the target to increase etching rate. The

composition of chrome etching is CH

2

Cl

2

þ O

2

[2].

Inductive coupled plasma (ICP): This is a low-pressure high-density plasma. It improves

CD control and uniformity. ICP is also good for low defect counts.

17.3.2.2 Plasma Applications and Processes

In the case of CoG or binary masks only the chrome film needs to be etched, but with the

emergence of phase shift masks new processes are fashioned that can etch other materials

also, such as molybdenum silicon (MoSiON). There are also chromeless masks, where

features are etched into quartz, which is now being done with plasmas.

In one example of MERIE, the etch parameters for Cr and MoSiON have been cited as

the Cl

2

/O

2

with gas-assisted etching (GAE).

© 2005 by Taylor & Francis Group.

For Cr the composition involved is Cl

2

/O

2

with GAE, and for MoSiON the composition

is CF

4

/O

2

. The GAE increases the etch selectivity 1.8 times higher than without GAE [4].

There are a number of factors that affect the plasma etching and need to be addressed.

An important factor is chrome loading, that is, the amount of chrome on the mask,

it affects several plasma etch responses, e.g., resist selectivity, Cr etch rate, overall CD

uniformity, and uniformity within mask [5].

During the dry etch of chrome a certain amount of resist is lost and appears as

redeposited polymers and debris on mask surface adding to increased defect counts.

The resist lost can also affect the CD uniformity and etch bias. The phenomena of resist

loss are related to poor selectivity. The objective is then to minimize this resist loss by

improving the selectivity.

The CD control in uniformity and etch bias show opposite trend lines with standard

chemistry of He/Cl

2

/O

2

. Increasing the oxygen flow can improve the uniformity, but it

also decreases the selectivity.

In order to overcome the limitations of the two opposite trends, what is needed is to

develop a process with improved selectivity to photoresist and with reduced dependence

on O

2

flow. There have been chemistries proposed that could provide this benefit.

Hydrogen and carbon containing gases are considered as the promising alternatives.

Several gases proposed are H

2

, HCl, and NH

3

, and carbon containing gases to promote

selectivity are C

2

F

6

, CCl

4

, C

3

F

8

, CHF

3

, CH

4

, and CF

4

–H

2

, etc. [6].

Another work, also on chrome etch, reports on achieving 90-nm features on masks

using ICP reactor. Features of this small require a number of process optimization other

than just plasma, such as the type of resist, processing, and the writing scheme [7].

Unaxis, another major supplier of plasma etch systems, has its Generation-4 ICP

introduced into the market in 2004 that will be addressing the 65-nm technology node [8].

As mentioned earlier, there are phase shift masks that require etching of the quartz to

the right depth. Here, after the opening of chrome windows, it is the glass (quartz) that is

to be etched. In the case of quartz etching, there is no under-layer that can be used as etch

stop. In such cases, the technique is to etch for a predetermined time that can be

guaranteed for the desired depth.

The work referred here utilized ICP source with gas composition as CHF

3

/CF

4

[9].

17.4

Resist Stripping and Cleaning

Cleaning of photomask starts from the stripping operation where the unwanted resist

after chrome etch is to be removed.

However, simply stripping of the resist does not result in perfectly clean mask. There

can be defects arising from various sources where some may be as common as water

marks whereas others may be subtler and extremely small in size. These defects and other

contaminants can adhere to mask surface by either van der Waals force or electrostatic

force and can be detected only by sophisticated techniques.

17.4.1 Wet and Dry Cleaning Processes

In general, the cleaning operations fall under the class of wet processes where masks are

cleaned with a specific type of solution; or it can fall under the dry process where the

mask is exposed to a plasma environment or subjected to high-energy photons for its

© 2005 by Taylor & Francis Group.

cleaning. At present, most operations are carried out using wet processes although dry

processes are beginning to emerge at many facilities.

17.4.1.1 Cleaning with Wet Processes

The wet process where the mask is subjected to some form of liquid treatment can be

further classified as mechanical or purely chemical by its nature.

Example of mechanical treatment is the scrubbing of masks with specially designed

brush or sponge, whereas in the other case the mask is immersed into a tank of chemicals

where the reactions between the contaminants and chemicals clean the mask.

There are also techniques that employ high-pressure spray cleanup that can be used to

take the advantage of mechanical impact of the spray, as well as reactions with the

chemicals, to dislodge the contaminants from the mask surfaces.

17.4.1.1.1

Chemistry of Wet Process

Most of the wet processes involve a mixture of H

2

SO

4

and H

2

O

2

in the ratio of 4:1 used at

908C, commonly know as Piranha Clean, and is primarily used for removing the resist

and heavy organic material. It works as an oxidant and attacks the hydrocarbons [1].

Also, another material used for mask cleaning is a mixture of H

2

O, H

2

O

2

, and NH

4

OH

in the ratio of 5:1:1 used at room temperature, known as RCA Standard Clean-1 or simply

SC-1. This chemistry was designed for removing traces of organic impurities from the

mask surface by (1) solvating action of NH

4

OH and the oxidation capability of the H

2

O

2

.

The NH

4

OH also serves as a complexant for many metallic contaminants. In this case the

peroxide in the solution oxidizes the surface, and then the ammonium hydroxide dis-

solves this oxide. Although this sequential growth and etching of the surface help in the

removal of particles, it also results in the undesired micro-roughening of substrate. Recent

research has shown that lowering the NH

4

OH concentration ratio to 0.01–0.25 greatly

reduces the micro-roughening while retaining the particle removal efficiency of the

SC-1 [1].

17.4.1.1.2

Application of the Wet Chemistry

Two common practices for the application of chemicals to the mask are:

(a) Immersing the mask into a tank of chemicals

(b) Spraying chemicals on mask while it is spun on a chuck

The use of immersion tanks allows batch processing of masks and has been in practice

since the early days of mask making. The spinning processes because of their superior

cleaning results are more frequently employed, although this is a single mask processing

technique and could result in a lower throughput compared to batch processing.

After wet cleaning, the plates need to be run through final rinse and dried.

Newer techniques like ultrasonic cleaning and megasonic cleaning are becoming quite

prevalent. Also, technique of scrubbing the masks with brushes or sponges using ‘‘tank’’

or ‘‘spinners’’ are commonly employed.

Two major issues with chemical cleaning are disposition of used chemicals and rede-

position of particles especially in case of immersion cleaning.

17.4.1.2 Cleaning with Dry Processes

Dry cleaning is mainly associated with use of plasma that reacts with the contamination

resulting in a by-product, which is then flushed out by the flowing gas. There is also

Rizvi / Handbook of Photomask Manufacturing Technology DK2192_c017 Final Proof page 372 7.3.2005 6:28pm

© 2005 by Taylor & Francis Group.

another area of dry processing known as laser-assisted-cleaning, developed by Radiance

Services Company [10,11], which uses high-energy photons that can break bonds that

hold particles to surface without affecting the surface. Another dry cleaning system

utilizes flowing gas that sweeps the particles away from the mask area. Since the process

is dry and uses no water or toxic chemicals, the benefits of this technique may include a

reduced need for deionized water, chemical handlers, and waste treatment systems in

semiconductor facilities.

The gas flow characteristics must be optimized to avoid turbulence otherwise redeposi-

tion of particles could occur.

The use of UV radiation has also been known to help strip resist from mask by

weakening the bonds of remaining particles after the first strip process.

There is also an on-line in-situ dry cleaning process known as plasma mechanical

activation and extraction of particle contamination (PLASMAX). This system, jointly

developed by Beta Squared and Los Alamos National Labs (LANL), employs resonant

spherical harmonic vibration to lift particles from surface, which then suspends, traps,

and channels these particles down the vacuum port, thus preventing the particle

deposition on the mask surface. The technique is capable of cleaning a mask substrate

within 25 s.

This dry cleaning technology can be directly integrated into the exposure system, which

can serve as an in-situ mask cleaning process, very effective for NGL masks where pellicle

cannot be employed.

17.4.1.3 Cleaning with Semi-dry Processes

In addition to the wet and dry cleaning processes there are processes that can be classified

as semi-dry process.

In one case, by employing vapor of some liquid (water, isopropanol, and ethanol),

a layer of water is deposited on the mask, after which the particle is ‘‘hit’’ with a laser

beam. The heated water turns into steam and lifts the particle off the mask surface, and

the particle then carried away by a stream of gas flow across the mask surface [12].

17.4.2 Cleaning of Embedded Attenuated Phase Shift Masks

The above paragraphs mainly dealt with the conventional CoG masks, but the structure of

some of the advanced masks may differ from the conventional masks and new methods

for their cleanup are constantly being developed and implemented. One such example is

the case of embedded attenuated phase shift masks (EAPSM), which are MoSiON-based

masks. The structure of EAPSM is considerably different from that of the CoG masks.

MoSiON can react differently with some of the chemicals used in CoG cleaning. Dry

process is more commonly used for MoSiON-based masks because of the ease of plasma

etching, but the process also leaves the surface with polymer residues and plasma debris,

the removal of which requires due care not to alter the phase and transmitivity of the

MoSiON film.

Traditionally, H

2

SO

4

–H

2

O

2

mixture (SPM) followed by NH

4

OH–H

2

O

2

mixture

(APM) has been used for removing photoresists and organic residues from previous

processes.

SPM has been seen to cause variations in phase and transmittance compared to other

oxidizing chemistries. Hence, ozone-involved chemistries, namely, H

2

SO

4

–O

3

mixture

(SOM) and Ozonated DI Water (DIO3

1

) from Akrion are introduced to replace SPM

[12].

Rizvi / Handbook of Photomask Manufacturing Technology DK2192_c017 Final Proof page 373 7.3.2005 6:28pm

© 2005 by Taylor & Francis Group.

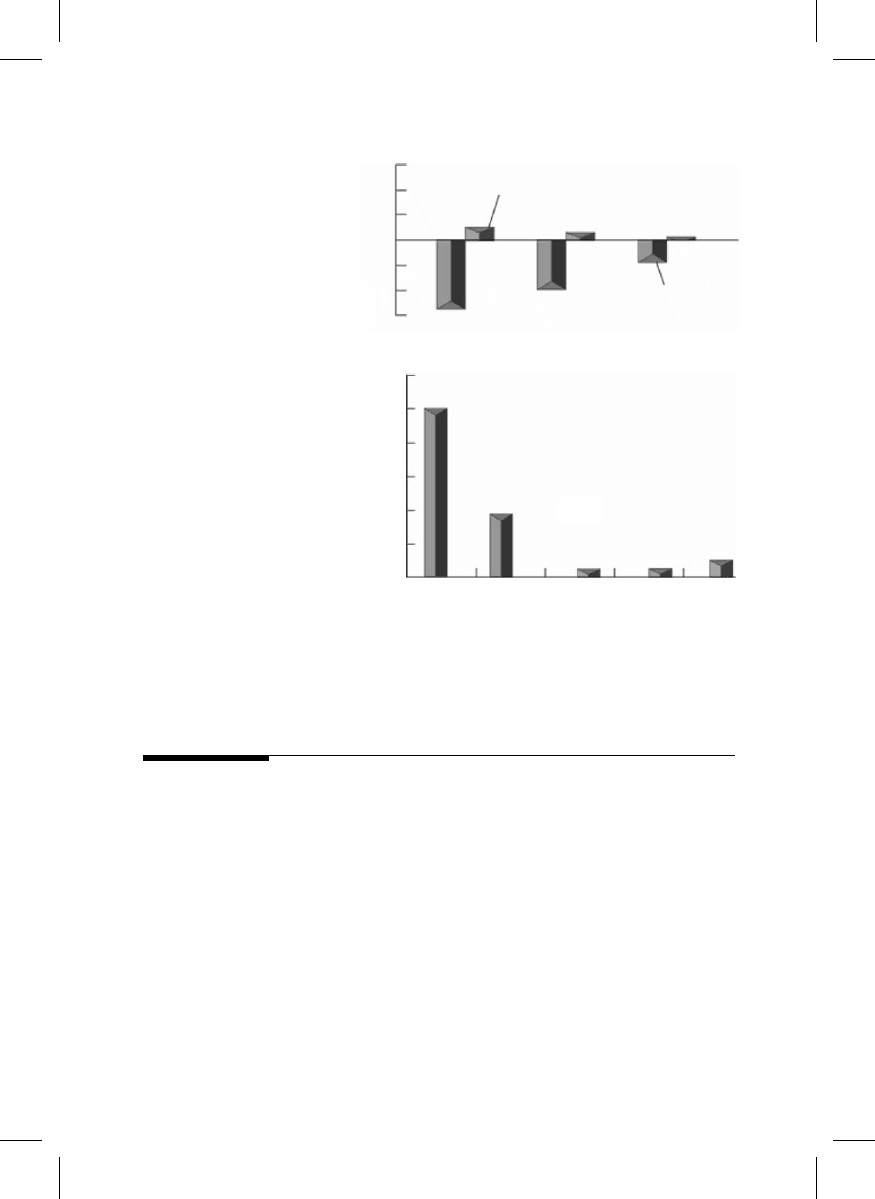

The efficiencies of SOM and DIO3 for heavy polymer removal, such as stripping

photoresists, can be limited. However, by incorporating megasonic technology resist

removal has been enhanced as shown in Figure 17.2 [12].

References

1. P. Rai Choudhury, Handbook of Microlithography, Micromachining and Microfabrication, vol. 1, SPIE

Optical Engineering Press, 1997, pp. 377–474. Bellingham, WA, USA.

2. John G. Skinner, Photomask Fabrication for Today and Tomorrow, SPIE Short Course, SC122, 2001,

pp. 104–105.

3. Seong-Yong Moon, Won-Tai Ki, Byung-Cheol Cha, Seong-Woon Choi, Hee-Sun Yoon, and Jung-

Min Sohn, 19th Annual Symposium on Photomask Technology, vol. 3873, 1999, pp. 573–576.

4. H. Handa, S. Yamauchi, K. Hosono, and Y. Miyahara, Dry etching technology of Cr films to

produce fine pattern reticles under 720 nm with ZEP-7000, in: 19th Annual Symposium of Photo-

mask Technology, vol. 3873, 1999, pp. 98–106.

5. C. Constantine, R. Westremann, and J. Plumhoff, Plasma etch of binary Cr mask, in: 19th Annual

Symposium of Photomask Technology, vol. 3873, 1999, pp. 93–97.

6. M.J. Buie, B. Stoehr, and Y.C. Huang, Chrome etch for <0.13 micron, in: 21st Annual BACUS

Symposium of Photomask Technology, vol. 4562, 2001, pp. 633–640.

7. M. Mueller, S. Komarov, and K.H. Baik, Dry etching of chrome for photomasks for 100 nm

technology using CAR, Photomask Japan, 350–360 (2002).

8. Unaxis Website: http://semiconductors.unaxis.com/en/download/65%20nm%20Dry%20Etch.pdf.

FIGURE 17.1

The effect of different cleaning chem-

istries on phase and transmittance of

EAPSM [11]. (Courtesy of Akrion.)

Delta trans

SPM + APM

SOM + APM

DIO3 + APM

Delta phase

2

0

Arbitrary unit

−

4

FIGURE 17.2

The effect of megasonic on photo-

resist removal efficiency of SOM

chemistry [11]. (Courtesy of Akrion.)

0.37

SOM w/o

Meg

Relative particle count @ >0.2

µ

m

SOM w/o

Meg

SOM w/

Meg

SOM w/

Meg

SOM w/

Meg

0.05

0.05

0.1

Five Cr blanks

coated with photoresist

were stripped with

SOM at 80

⬚

C in 3 min.

1

1

0.8

0.6

0.4

0.2

1.2

0

Rizvi / Handbook of Photomask Manufacturing Technology DK2192_c017 Final Proof page 374 7.3.2005 6:28pm

© 2005 by Taylor & Francis Group.

9. S.A. Anderson, R.B. Anderson, M.J. Buie, M. Chnadrachood, J.S. Clevenger, Y. Lee, N. Sandlin,

and J. Ding, Optimization of a 65 nm alternating phase shift quartz etch process, in: 23rd Annual

BACUS Symposium on Photomask Technology, 5256, 66–75 (2003).

10. Semiconductor

International

Website:

http://www.reed-electronics.com/semiconductor/article/

CA163977.

11. Radiance Services Website:

http://www.radianceprocess.com/rad.html.

12. R. Novak, I. Kashkoush, and G.S. Chen, Today’s binary and EAPSMs need advanced mask

cleaning methods, Solid State Technol., February, 45–46 (2004).

© 2005 by Taylor & Francis Group.

Document Outline

- Contents

- Section V Mask Processing, Materials, and Pellicles

Wyszukiwarka

Podobne podstrony:

Ch17 Screw Connections

CH17

ch17

ch17

BW ch17

Genomes3e ppt ch17

Ch17 Screws

Ch17 Combine Parts

Ch17 Screw Connections

Essentials of Biology mad86161 ch17

DK2192 CH9

Ch17 Screws

From NY 3 16 05 Sauter Ch17 18 MBW

DK2192 CH28

DK2192 CH20

DK2192 CH1

DK2192 CH13

DK2192 CH7

DK2192 CH26

więcej podobnych podstron