13

Mask for Proximity X-Ray Lithography

Masatoshi Oda and Hideo Yoshihara

CONTENTS

13.1 PXL System

13.2 X-Ray Mask Structure

13.2.1 Membrane

13.2.2 Absorber

13.3.1 Mask Processes

13.3.2 EB Writing

13.3.3 Dry Etching

13.3.4 Frame Bonding

13.4 Defect Inspection and Repair

13.5 X-Ray Masks for LSI Fabrication

13.6 Summary

References

Proximity x-ray lithography (PXL) was proposed 30 years ago as a technology to perfectly

replicate mask patterns to a wafer using soft x-rays [1]. Although the PXL was confirmed

to have sufficient resolution to form patterns below 100 nm soon after its proposal [2], it

could not be used in industry for a long time because x-ray sources were too weak and

mask fabrication was too difficult. The development of a compact synchrotron radiation

(SR) ring [3] gave the industry an x-ray source that could produce x-rays at an intensity

strong enough for practical use. The SR ring together with improved mask technology has

made PXL the most promising technology for making sub-100-nm patterns. Here, x-ray

mask technology is introduced.

13.1

PXL System

A PXL system consists of an x-ray source, a mask, and a stepper, and uses soft x-rays with

wavelengths between 0.5 and 1.5 nm. x-rays with shorter wavelengths are not suitable

because their higher transparency makes both resist sensitivity and mask contrast too

low. On the other hand, x-rays at longer wavelength degrade pattern resolution due to the

large diffraction.

Rizvi / Handbook of Photomask Manufacturing Technology DK2192_c013 Final Proof page 305 7.3.2005 6:25pm

© 2005 by Taylor & Francis Group.

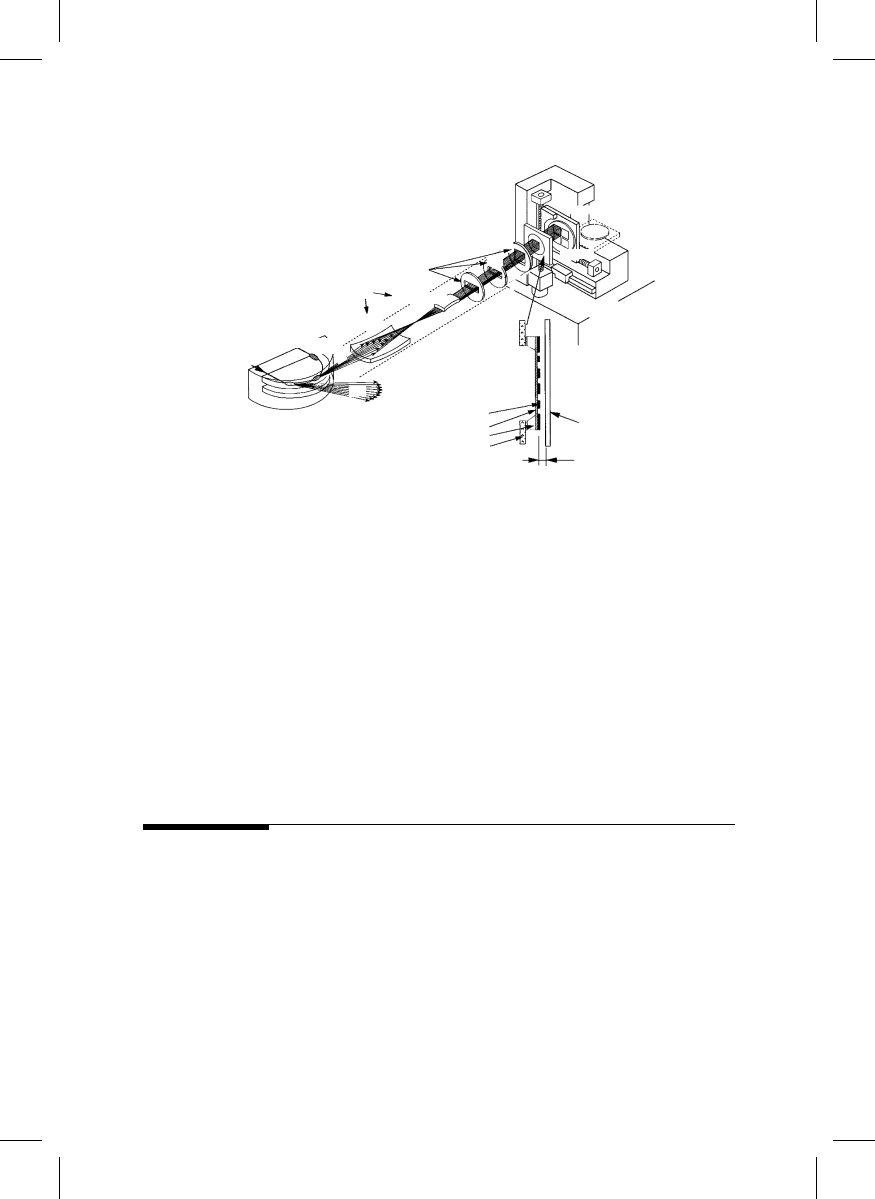

Figure 13.1 shows a PXL system using an SR ring. In this SR lithography system, x-rays

from the SR ring are directed to the mask through a beam line. A wafer coated with resist

is set behind the mask leaving a small proximity gap of the order of a few ten microm-

eters. The stepper aligns the wafer.

In PXL, the objective is to replicate to the wafer patterns that are of the same size as the

mask patterns. Thus, the mask patterns must be of the right size and all features must be

at right locations according to the design layout.

Furthermore, the substrate must be thin enough to allow maximum transmission of the

soft x-rays. On the other hand, the absorbers have to be thick enough to stop the x-rays

from reaching the wafer. The biggest issue is how to produce absorber patterns with high

accuracy on such a thin membrane.

13.2

X-Ray Mask Structure

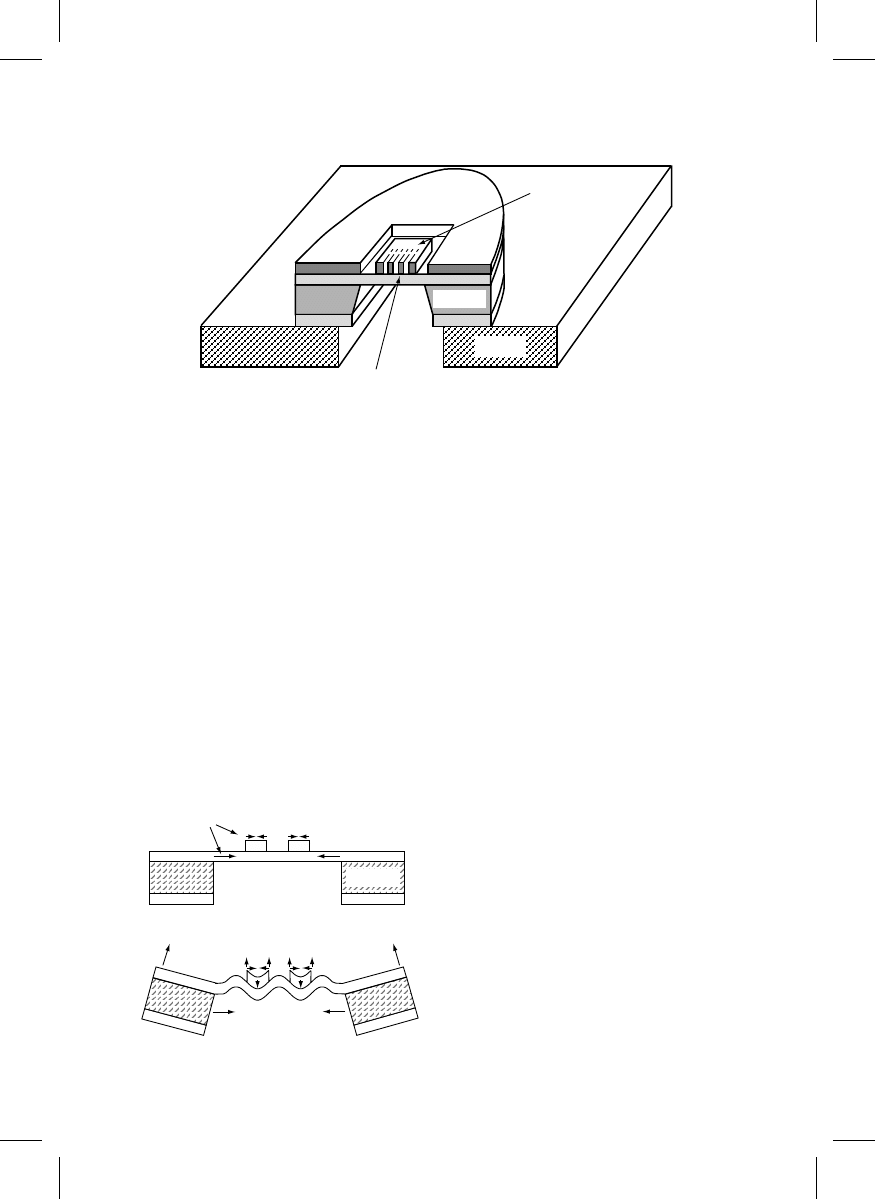

X-ray masks differ significantly in construction from the photomasks. An x-ray mask

consists of absorber patterns on a membrane held by a Si wafer, as shown in

where the Si wafer is mounted on a frame. The membrane corresponds to the glass

substrate of a photomask. The frame is made of materials having high rigidity, such as

Pyrex glass or SiC, which is needed so that the masks can be easily and safely handled.

For the membrane to stay flat, it must have tensile stress. The absorber patterns also

have stresses, though they are produced unintentionally. These stresses tend to deform

the mask as shown in

The deformation must be very small so that it does not

affect the accuracy of the x-ray masks. To keep the Si wafer from being deformed by

membrane stress, Si wafers as thick as 2 mm are used. Absorber stress must also be kept

small so as not to deform the membrane.

X-ray extraction window

X-ray mirror

Beam

convergence

High

vacuum

SiN

He

Vertical

x

−

y

stage

Ultra-high vacuum

Beamline

X-ray stepper

X-ray mask

X-ray source

(SR ring)

Wafer

10

−

30

µ

m

Absorber

Membrane

Si wafer

Frame

Scanning

SR

Electron

SR

Be

Wafer

FIGURE 13.1

Schematic of the SR lithography system.

© 2005 by Taylor & Francis Group.

13.2.1 Membrane

The essential membrane requirements are as follows: (a) high transparency to soft x-rays,

(b) good smoothness, (c) good flatness, (d) high dimensional stability, (e) high mechanical

strength, (f) high chemical durability, (g) high optical transparency, and (h) ease of

fabrication. To achieve high x-ray transparency, the membrane material must be made

of light elements with small x-ray absorption coefficients. Recently used membrane

materials are Si, SiN, SiC, and diamond (

In addition to these materials,

organic films, such as Mylar, have also been studied. Organic films, however, suffer

from dimensional and thermal stability problems.

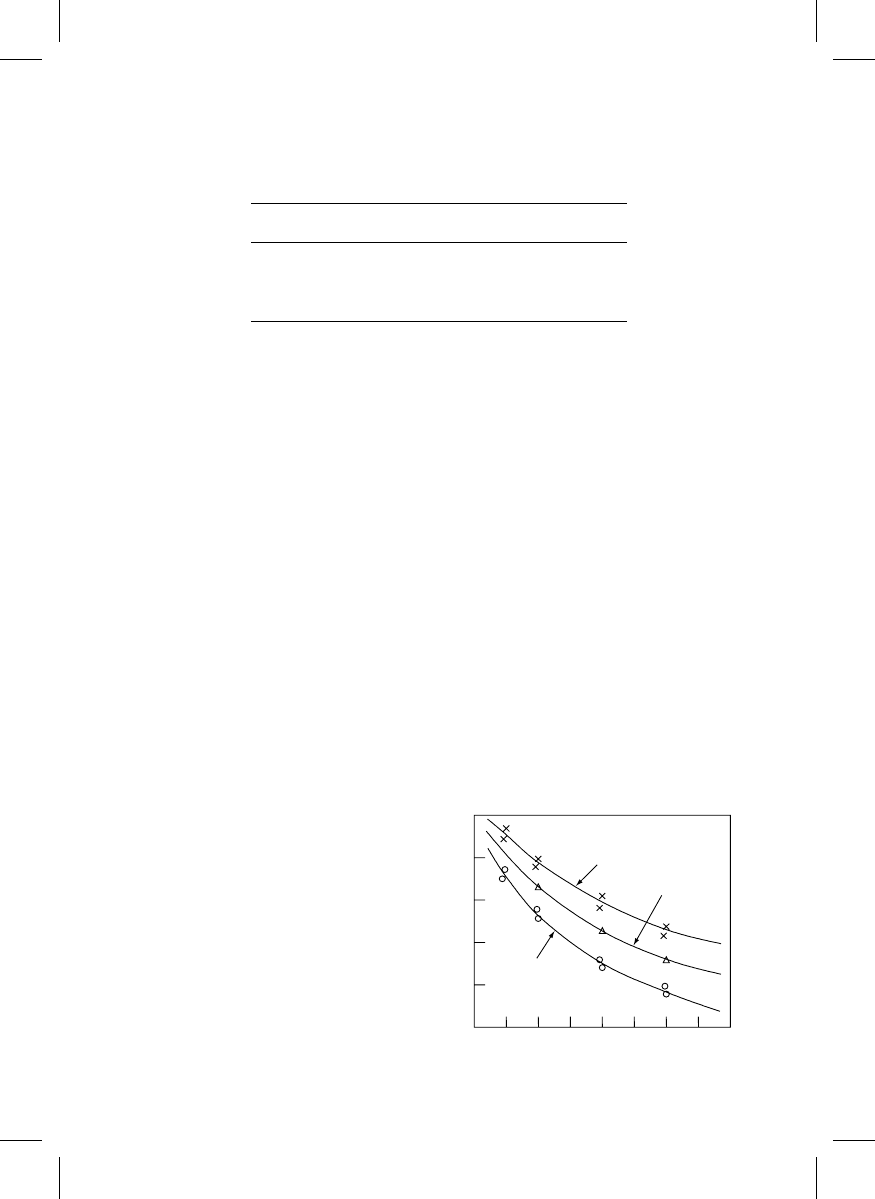

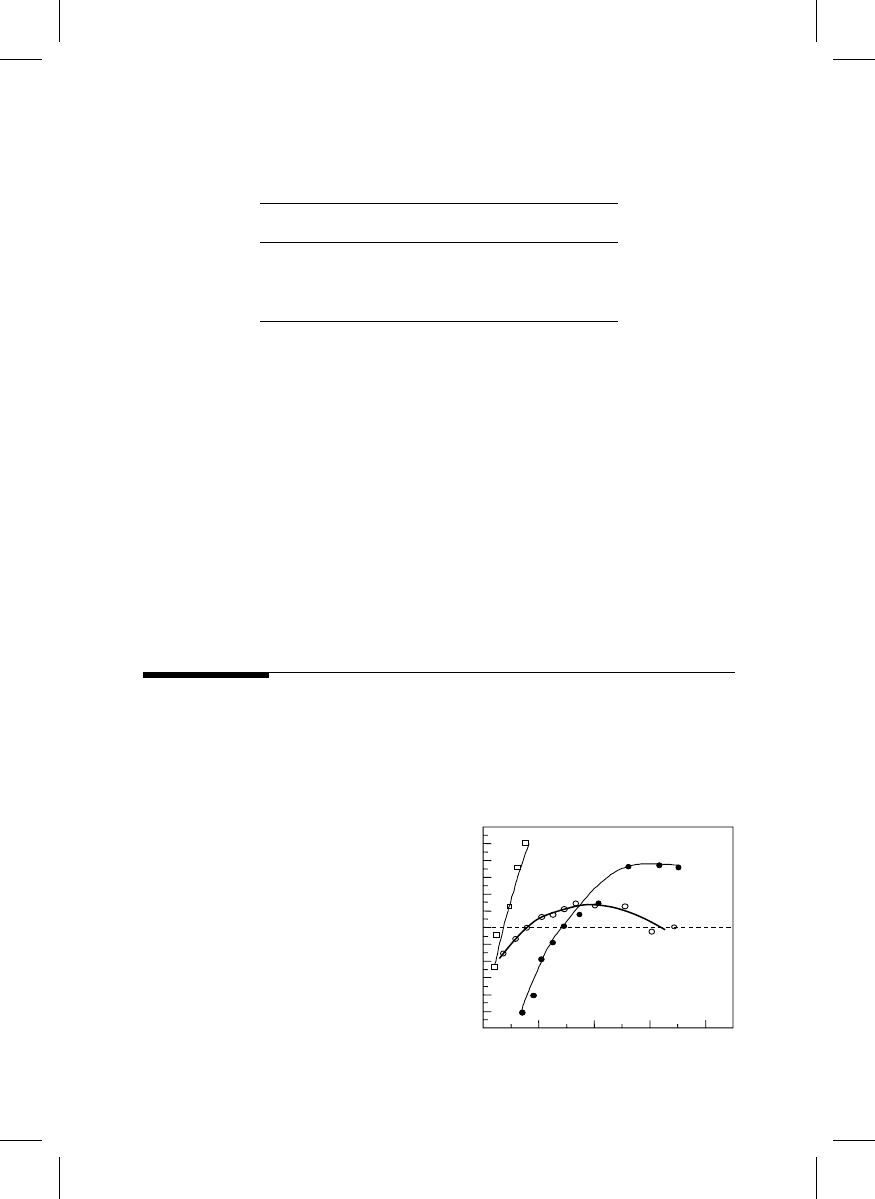

The deposition of SiN [4] and SiC [5] is carried out by low-pressure (LP) CVD, whereas

the deposition of diamond is typically done by microwave plasma CVD [6]. The stress of a

SiN film can be easily controlled by adjusting the temperature and gas flow ratio during

low-pressure CVD as shown in

[4]. Films with low tensile stress are deposited

at high temperatures or at a large NH

3

flow rate. The stresses of SiC and diamond can also

be controlled by adjusting deposition conditions. SiN is amorphous, so the film surface is

smooth after deposition. On the other hand, SiC [7] and diamond [6] are poly-crystals, so

Absorber patterns

Frame

Membrane

Si wafer

FIGURE 13.2

Schematic of an x-ray mask.

Si frame

Membrane

Absorber

Stress

(a) Stress

(b) Deformation

FIGURE 13.3

Membrane and absorber stress, and mask deformation

caused by the stress.

© 2005 by Taylor & Francis Group.

the surfaces are rough due to crystal grains. The roughness is removed by mechanical

polishing after deposition.

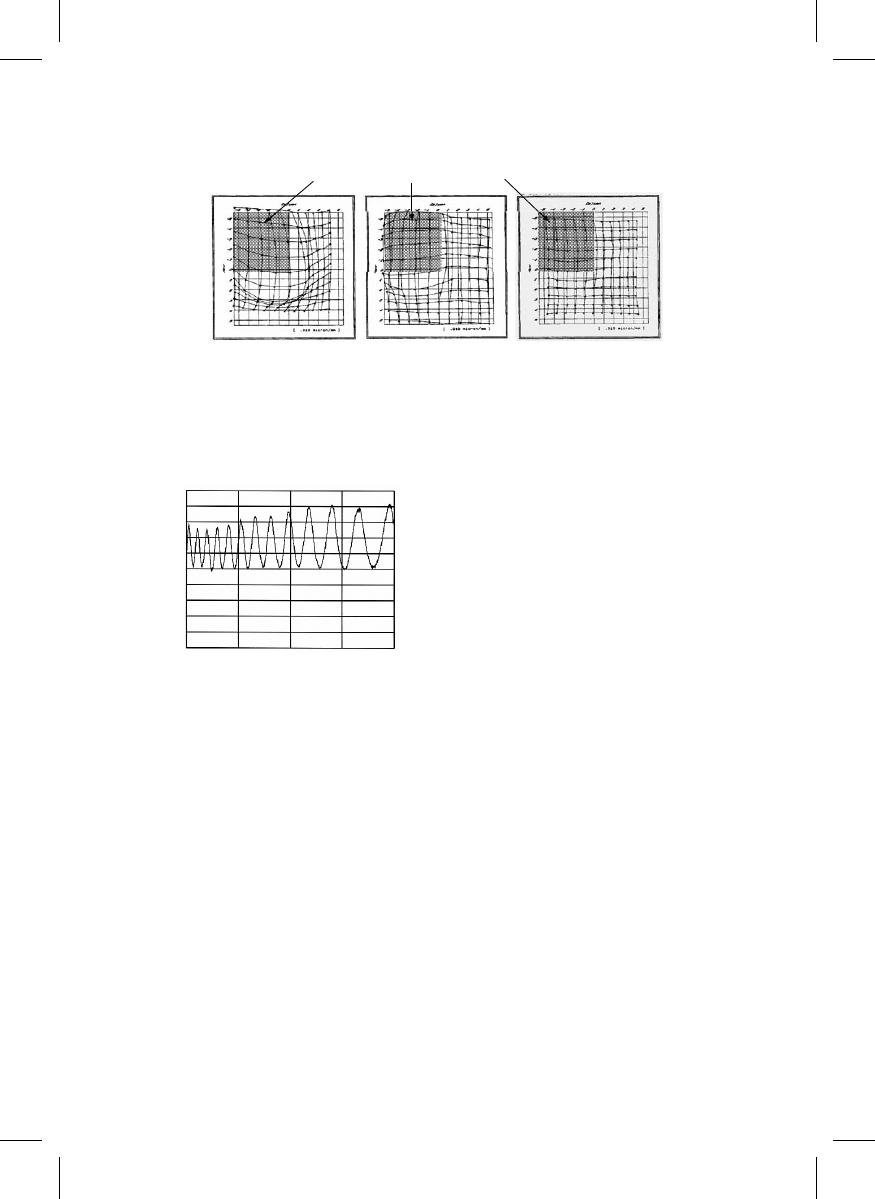

shows deformation of SiN, SiC, and diamond membranes caused by Ta

absorber stress. As the absorber patterns having compressive stress of about 30 MPa at the

upper left spread, the membranes deform. The deformation decreases as the membrane’s

Young’s modulus increases, and the smallest deformation is in the diamond membrane.

Young’s modulus is thus a very important factor for highly accurate masks.

For highly accurate optical alignment, highly optical transparency is needed. Figure

13.6 shows the transparency of diamond membrane for wavelengths ranging from 400 to

800 nm. The transparency varies periodically with wavelength, which results from inter-

ference from light reflected at the surfaces. The transparency can be improved to over 80%

at every wavelength between 500 and 800 nm by depositing antireflection material, such

as SiO

2

, on both sides of the membrane.

The membrane must have enough durability for x-rays. When the membrane contains

hydrogen atoms from the deposition source gasses, the stress and transparency are varied

by x-ray exposure [8]. It has been reported that SiC and diamond with good film quality

have good x-ray durability.

Unlike the Si-based materials in Table 13.1, the diamond does not have an x-ray

absorption edge near 0.7 nm because it has no Si element. Thus, x-rays having wave-

lengths shorter than 0.7 nm can be used.

Recently, it was reported that such short-wavelength x-rays make it possible to repli-

cate patterns smaller than a nanometer. The PXLs with short-wavelength x-rays are

referred as second-generation PXL [9].

TABLE 13.1

Properties of Membrane Materials

Young’s

Modulus (GPa)

Thermal Expansion

Coefficient (deg

1

)

Density

(g/cm

3

)

Si

160

3.7 10

6

2.33

SiN

160

2.1 10

6

3.18

SiC

460

4.6 10

6

3.21

Diamond

1050

3.5 10

6

3.52

FIGURE 13.4

SiN stress and deposition condition of low-pres-

sure CVD.

850

⬚

C

750

⬚

C

800

⬚

C

−

200

0

200

400

600

800

Stress (MPa)

(Tensile)

0

1

2

3

4

5

6

7

8

Gas flow ratio (SiH

2

Cl

2

/NH

3

)

Rizvi / Handbook of Photomask Manufacturing Technology DK2192_c013 Final Proof page 308 7.3.2005 6:25pm

© 2005 by Taylor & Francis Group.

13.2.2 Absorber

The required absorber properties are as follows: (a) a high absorption coefficient, (b) high

stress controllability, (c) capability of patterning below 100 nm, (d) high chemical and

radiation durability, and (e) the ease of fabrication. The high absorption coefficient

requirement is met by using high-density heavy metals as absorber. Au has been used

as an absorber material since the beginning of x-ray mask development [10] because it has

a large x-ray absorption coefficient, and fine patterns can easily be formed. Recently, Ta

[11], W [12], and their compounds [13,14] have been used as absorber materials, which

can be patterned by dry etching [11–14]. These materials have approximately the same

absorption coefficient as gold at x-ray wavelengths ranging from 0.5 to 1.5 nm. Physical

properties of absorber materials are summarized in

Absorber stress must be small so that it does not cause membrane distortion (

Generally, in films deposited by sputtering, the stress can be controlled by the

pressure during deposition.

shows the dependence of films’ (Ta, W, and Re)

stress on pressure. For each material, the stress changes from compressive to tensile, as

the pressure increases. For Ta, the tensile stress reduces again with pressure and is zero at

around 8.5 Pa. The stress of W and Re also comes close to zero when in the high-pressure

region. However, stress-free Ta film deposited at high pressure has smaller density than

30-MPa compressive absorber area

SiN (Max: 239 nm)

SiC (Max: 112 nm)

Diamond (Max: 56 nm)

FIGURE 13.5

Membrane material and its deformation caused by absorber stress.

400

500

600

700

800

0

50

100

Wavelength ( nm)

Transmittance (%)

FIGURE 13.6

Optical transmittance of diamond membrane.

© 2005 by Taylor & Francis Group.

that deposited at low pressure. Thus, the low-pressure region is used for depositing Ta

absorber films. In Figure 13.7, the gradient of the stress–pressure curve near the stress-free

point is smaller for Ta than for Re or W, indicating the stress in Ta film can be controlled

more precisely.

To control the stress even more precisely, annealing is performed after deposition. The

stress in Ta film shifts to compressive side by annealing as shown in

Ta films

deposited by sputtering have columnar grains. Oxygen diffuses along the grain bound-

aries from the film surface and causes oxidation in Ta films, making the stress compres-

sive. Stress-free Ta films can be obtained by depositing tensile films after annealing for an

appropriate time.

The stress in Ta or W compounds having an amorphous structure is more stable. These

films can also be deposited by sputtering, and stress control can be done in the same way

as for Ta film. However, contrary to Ta, the stress changes from compressive to tensile by

annealing [13].

13.3

Fabrication

The key areas in the fabrication of x-ray masks are: (1) processing (2) e-beam writing,

(3) dry etching, and (4) frame bonding, discussed in the following.

TABLE 13.2

Properties of Absorber Materials

Young’s

Modulus (GPa)

Thermal Expansion

Coefficient (deg

1

)

Density

(g/cm

3

)

Au

88

1.5 10

5

19.3

Ta

190

6.5 10

6

16.7

W

410

4.6 10

6

19.3

WTi, TaBN

—

—

15–16

FIGURE 13.7

Film stress and gas pressure during sputtering.

10

8

6

4

2

Re

Ta

W

Pressure (Pa)

Compressive

Stress (MPa)

0

200

400

600

800

1000

1200

−

400

−

600

−

800

−

1000

−

1200

−

200

Tensile

© 2005 by Taylor & Francis Group.

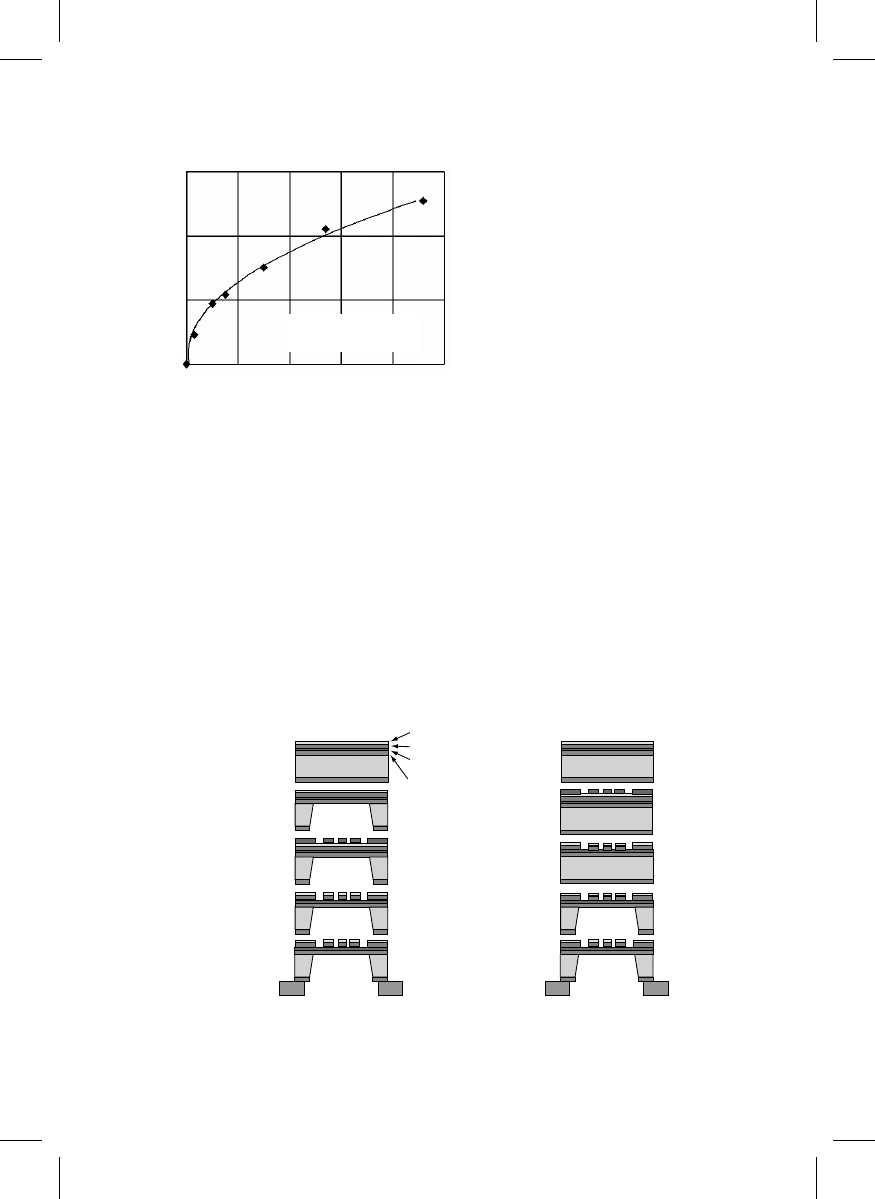

13.3.1 Mask Processes

There are two processes for making x-ray masks. One is a membrane process, in which

absorber patterning is carried out after back-etching [Figure 13.9(a)]. The other is a wafer

process, in which absorber patterning is done before back-etching [Figure 13.9(b)]. In the

wafer process, no membrane breakage occurs. However, improving the pattern place-

ment accuracy is difficult because large pattern shifts occurs during back-etching. In the

membrane process, masks with high pattern-placement accuracy can be produced, al-

though the apparatus must have special functions for handling wafers with a membrane.

In recent days, the membrane process has been mostly favored because the process leads

to highly accurate masks.

As shown in Figure 13.9(a), a 2-mm-thick SiC or diamond film is deposited on a 4-in. Si

wafer. A Ru film is deposited on the membrane to a thickness of 20 nm by sputtering.

Then Ta film is deposited on Ru by ECR-sputtering. Following this, SiO

2

is then deposited

on Ta by using ECR-plasma CVD technique. The Ru film stabilizes Ta stress [15], and the

0

20

40

60

80

100

0

50

100

150

Annealing time (min)

Stress change (MPa)

Ta thickness: 0.55

µ

m

Temperature: 250

⬚

C

FIGURE 13.8

Stress change of Ta film caused by annealing in

air.

ECR-Ta

Ru

SiC or

diamond

SiO

2

(a) Membrane process

(b) Wafer process

Deposition

Back-etching

EB writing

Etching

Frame bonding

Deposition

Back-etching

EB writing

Etching

Frame bonding

FIGURE 13.9

X-ray mask fabrication process.

© 2005 by Taylor & Francis Group.

SiO

2

is used as a mask for Ta etching. After the deposition of these films, back-etching is

carried out using KOH solution. Resist patterns are formed on the membrane with an

electron beam (EB) writer and the SiO

2

film is etched by reactive ion etching. Next, the Ta

film is etched using the SiO

2

as a mask. Finally, the Si wafer is bonded to a glass frame. In

the wafer process in

x-ray masks are produced using similar deposition

and patterning techniques.

To produce highly accurate x-ray masks, one can correct pattern position shifts by a

method known as previous analysis of distortion and transformation (PAT) of coordin-

ates [16] or product-specific emulation (PSE) [17]. In this method, first, send-ahead masks

are made to obtain information about pattern position shifts. Next, working masks are

produced by an EB writing process, in which patterns are delineated so as to compensate

for the pattern position shifts. If the pattern position shifts are sufficiently reproducible,

very highly accurate masks can be made. Nippon Telegraph and Telephone Corporation

(NTT) has produced x-ray masks with feature-placement accuracy below 25 nm by using

this method [18].

The membrane process has three key operations: EB writing to form resist patterns on

the thin membrane with high accuracy, etching of absorber film on the membrane, and

the frame bonding.

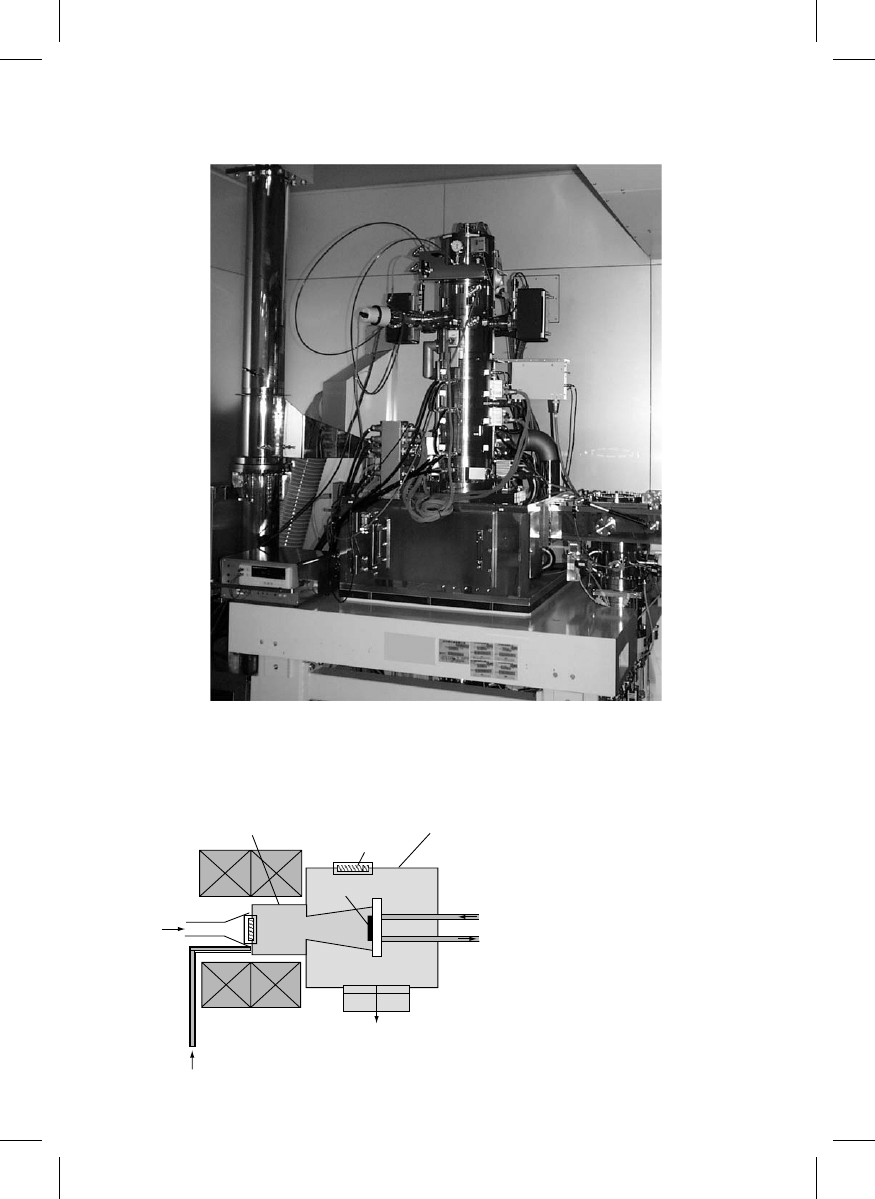

13.3.2 EB Writing

EB writing must be performed on a thin membrane supporting a heavy metal absorber.

Electrons scattering from the absorber strongly affect the formation of resist patterns.

Therefore, an EB writer with acceleration voltage of 100 keV was developed, which is

significantly higher than the conventional 30 keV systems (

[19]. This EB

writer can form resist patterns with a width of 50 nm. The high resolution comes from the

excellent beam sharpness and small forward-scattering in the resist film. Due to the high

acceleration voltage, most of the electrons pass through the membrane. The small num-

bers of electrons that scatter backward in the absorber disperse widely. Therefore, the

proximity effect is very small. Using this writer, even complex fine patterns, such as LSI

patterns (more complex than 4-Gbits DRAMs), can be formed with a large margin [14].

The mask holder for the EB writer must be designed carefully. The surface of the holder

has to be such that electrons passing through the membrane do not scatter backward [20].

13.3.3 Dry Etching

In an x-ray mask, pattern width precision must be as good as pattern placement accuracy.

Since the absorber patterns are thicker than 0.3 mm, the etching system must be able to

form precise patterns having an aspect ratio larger than 5. There are some dry etching

systems for metal etching. Here, electron cyclotron resonance (ECR) ion stream etching

[21] is introduced (

In this system, etching gases are effectively decomposed

in the low-pressure chamber by ECR discharge, and ion energy incident on the etched

surface is controlled to be below 100 eV. Therefore, large selectivity can be expected. The

main etching gas is C

12

for Ta and Ta compounds, and SF

6

for W compounds.

Generally, metal etching depends strongly on the substrate temperature. Therefore,

temperature control of the membrane during absorber etching is very important. Helium

cooling is very helpful in these etching systems.

Furthermore, in etching such small patterns, we must take into account the micro-

loading effect that means decreased etching rate with decreased pattern widths.

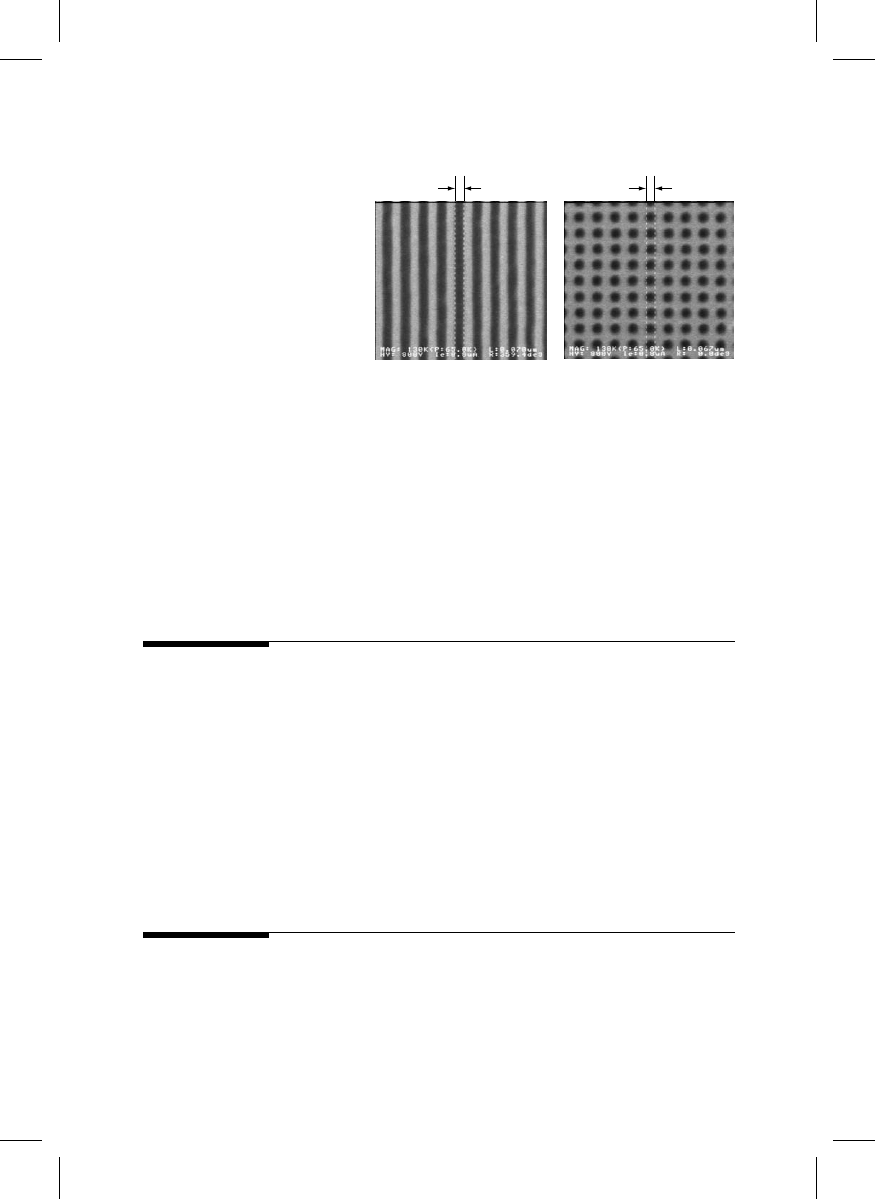

shows Ta patterns etched by ECR systems; 70-nm-wide patterns are clearly

formed.

© 2005 by Taylor & Francis Group.

FIGURE 13.10

50-nm-wide resist patterns delineated by an EB writer with an acceleration voltage of 100 kV.

Plasma chamber

Etching chamber

View port

Microwaves

Sample

Chiller

Vacuum system

Magnet coils

Gas

ECR

Plasma

Ion stream

FIGURE 13.11

Schematic of the ECR ion stream

etching system.

© 2005 by Taylor & Francis Group.

13.3.4 Frame Bonding

The membrane can suffer deformation from frame bonding. There are two ways to

resolve this problem. One is to use a bonding method that does not deform the wafer.

For this purpose, the one-point bonding method [22] was developed. In this method, a

very small area of a wafer is bonded to a frame, and only that area contacts the frame

surface. This is useful for mask processes, in which bonding is the final step. The other

way is a process in which the bonding is done before patterning the absorber. In this

process, bonding must be very hard so that the wafer does not peel off during the

patterning process. Anodic bonding was developed for this purpose [23].

13.4

Defect Inspection and Repair

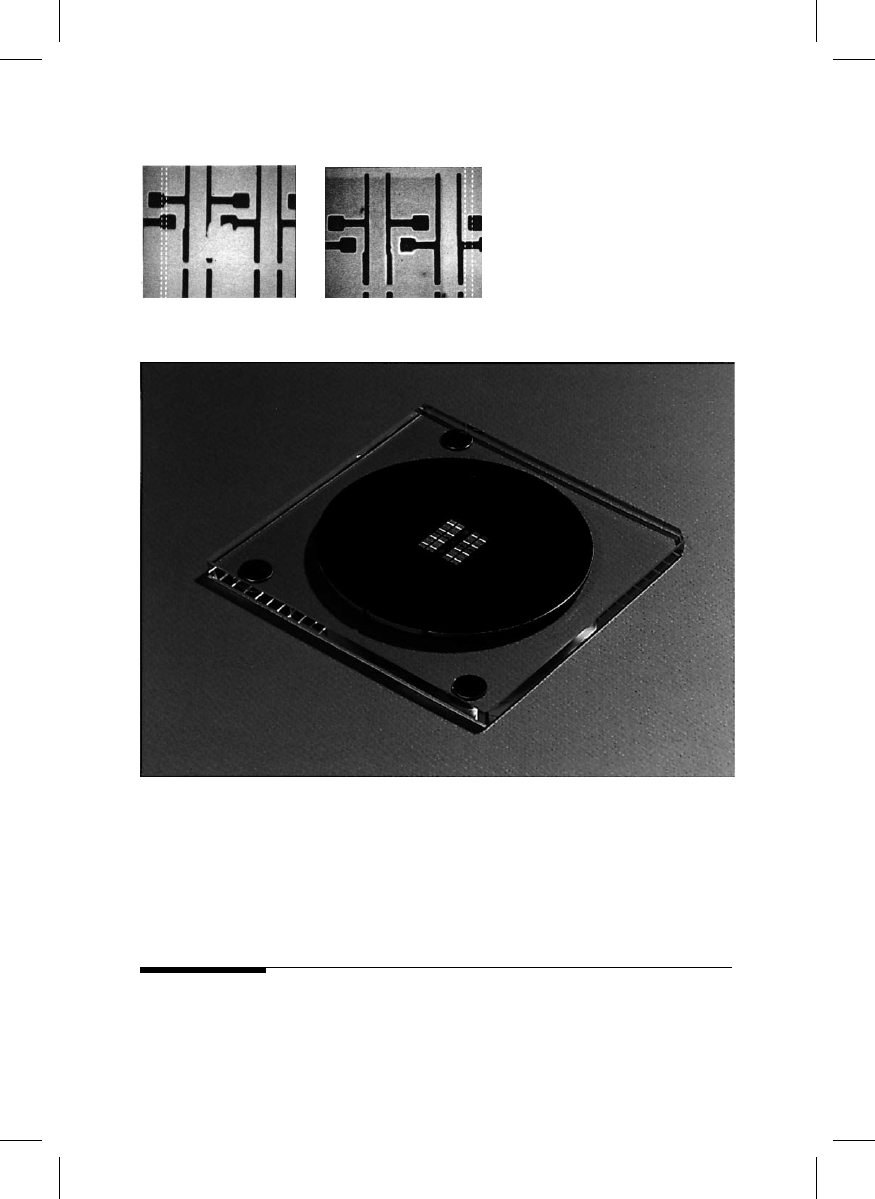

Defect inspection and repair are crucial to the production of x-ray masks for LSI processes.

A scanning electron beam system has been investigated for this purpose. For SiN or

diamond membrane, which is an insulator, it is difficult to inspect defects directly because

of the charge-up problem. Mask defects are therefore confirmed by inspecting wafers

having resist patterns replicating the mask patterns [24]. One can directly inspect defects

on SiC membrane because it has low conductivity. To repair defects in x-ray masks, a

focused-ion-beam repair system has been studied [25,26]. The system uses a Ga ion beam

focused to a spot less than 10 nm in diameter. Transparent defects are repaired by ion-

beam-induced deposition of Ta, and opaque defects are repaired by ion milling or gas-

assisted etching.

shows an example of a repair made to Ta absorber mask.

13.5

X-Ray Masks for LSI Fabrication

Many LSIs and devices have been produced using x-ray lithography. IBM developed x-

ray masks with 0.5-mm LSI patterns [27] and x-ray masks with 0.25-mm LSI patterns [28].

Mitsubishi Electric developed masks with 1-Gbit DRAM patterns in 1989 [29]. NEC

reported LSI masks in 1994 [30]. NTT developed x-ray masks with 200-nm [31] and 100-nm

[32] LSI patterns. NTT and Association of Super-Advanced Electronics Technologies

FIGURE 13.12

70-nm-wide Ta absorber patterns.

70 nm

67 nm

Lines and spaces

Holes

© 2005 by Taylor & Francis Group.

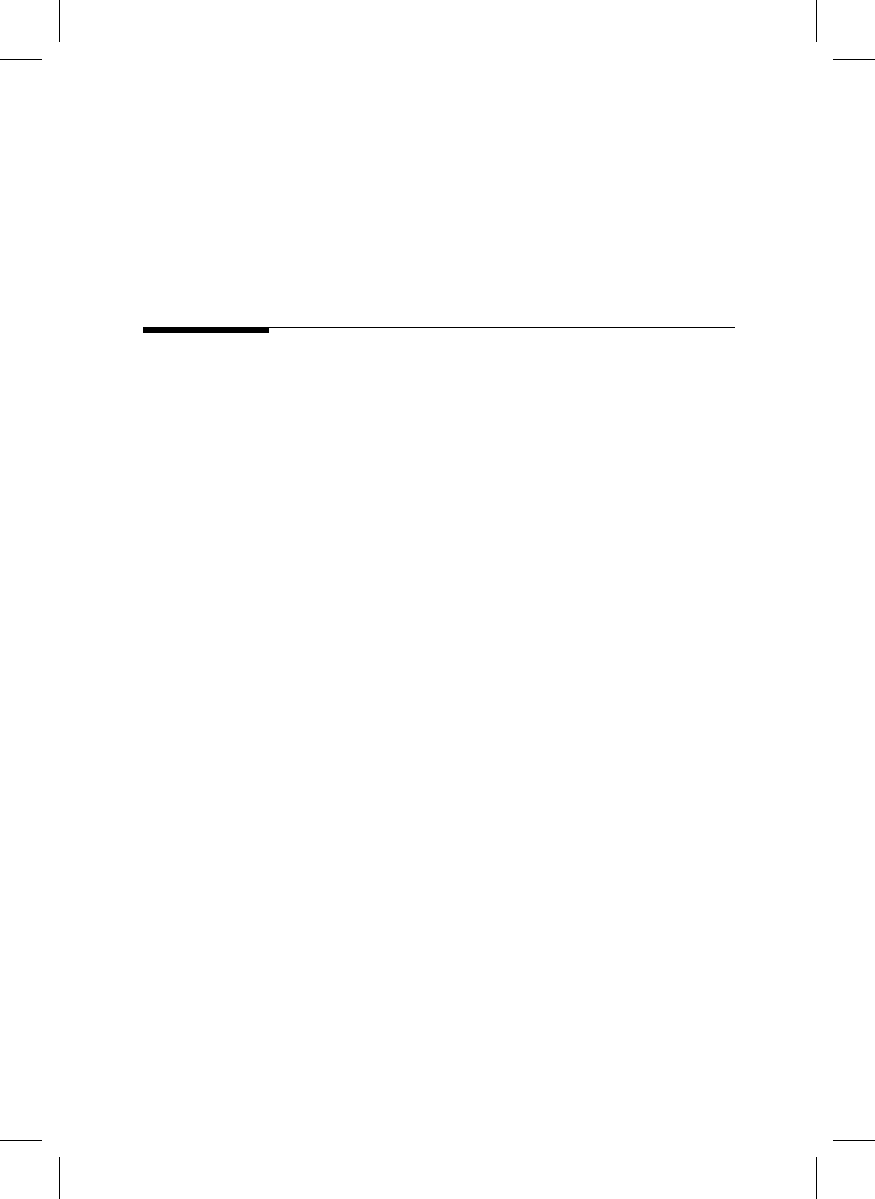

(ASET) developed masks with 100-nm LSI patterns with position accuracy of 25 nm in

1999 (Figure 13.14) [33]. The usefulness of x-ray lithography has been thoroughly proven

by these studies.

13.6

Summary

x-ray masks mainly consist of a thin membrane and absorber patterns. The membranes

are made of Si, SiN, SiC, or diamond film and Ta and W, or their compounds are used as

the absorbers. Stress control of these films is crucial in mask fabrication. An e-beam writer

(a) Before repair

(b) After repair

FIGURE 13.13

Ta absorber patterns repaired by a focused

ion-beam system.

FIGURE 13.14

X-ray mask.

Rizvi / Handbook of Photomask Manufacturing Technology DK2192_c013 Final Proof page 315 7.3.2005 6:25pm

© 2005 by Taylor & Francis Group.

with high acceleration voltage is necessary for pattern delineation on heavy metals.

Highly accurate masks can be fabricated by adopting a membrane process, in which

back-etching is carried out before the absorber film is patterned and then by correcting

any distortion. A scanning EB system and a focused-ion-beam system enable defect

inspection and repair. Highly accurate x-ray masks have been produced, and the useful-

ness of x-ray lithography has been proven.

References

1. D.L. Spears and H.I. Smith, High-resolution pattern replication using soft x-rays, Electron. Lett.,

8, 102–104 (1972).

2. R. Feder, E. Spiller, and J. Topalian, Replication of 0.1-mm geometries with x-ray lithography,

J. Vac. Sci. Technol., 12, 1332–1335 (1975).

3. T. Hosokawa, T. Kitayama, T. hayasaka, S. Ido, Y. Uno, A. Shibayama, J. Nakata, and

K. Nishimura, NTT superconducting storage ring—Super-ALIS, Rev. Sci. Instrum., 60, 1783–

1786 (1989).

4. M. Sekimoto, H. Yoshihara, and T. Ohkubo, Silicon nitride single-layer x-ray mask, J. Vac. Sci.

Technol., 21, 1017 (1982).

5. M. Yamada, M. Nakaishi, J. Kudou, T. Eshita, and Y. Furumura, An x-ray mask using Ta and

heteroepitaxially grown SiC, Microelectron. Eng., 88, 135–138 (1989).

6. H. Windischmann and G.F. Epps, Properties of diamond membranes for x-ray lithography,

J. Appl. Phys., 68, 5665–5673 (1990).

7. K. Yamashiro, M. Sugawara, H. Nagasawa, and Y. Yamaguchi, Smoothing roughness of SiC

membrane surface for x-ray masks, Jpn. J. Appl. Phys., 30, 3078–3082 (1991).

8. W.A. Johnson, R.A. Levy, D.J. Resnick, T.E. Saunders, A.W. Yanof, H. Betz, H. Huber, and

H. Oertel, Radiation damage effects in boron nitride mask membranes subjected to x-ray

exposures, J. Vac. Sci. Technol. B., 5, 257–261 (1987).

9. T. Kitayama, K. Itoga, Y. Watanabe, and S. Uzawa, Proposal for a 50 nm proximity x-ray

lithography system and extension to 35 nm by resist material selection, J. Vac. Sci. Technol. B.,

18, 2950–2954 (2000).

10. H.I. Smith, D.L. Spears, S.E. Bernacki, x-ray lithography: a complementary technique to electron

beam lithography, J. Vac. Sci. Technol., 10, 913–917 (1973).

11. H. Sekimoto, A. Ozawa, T. Ohkubo, and H. Yoshihara, A High Contrast Submicron x-ray Mask

with Ta Absorber Patterns, Extended Abstracts of the 16th (1984 International) Conference on

Solid State Devices and Materials, Kobe, 1984, pp. 23–26.

12. R.R. Kola, G.K. Celler, J. Frackoviak, C.W. Jurgensen, and L.E. Trimble, Stable low-stress

tungsten absorber technology for sub-half-micron x-ray lithography, J. Vac. Sci. Technol. B., 9,

3301–3304 (1991).

13. K. Marumoto, H. Yabe, S. Aya, K. Kise, and Y. Matsui, Total evaluation of W–Ti absorber for

X-ray mask, Proc. SPIE, 2194, 221–230 (1994).

14. S. Tsuboi, Y. Tanaka, T. Iwamoto, H. Sumitani, and Y. Nakayama, Recent progress in 1 x-ray

mask technology: feasibility study using ASET-NIST format TaXN x-ray masks with 100 nm

rule 4 Gbit dynamic random access memory test patterns, J. Vac. Sci. Technol. B., 19, 2416–2422

(2001).

15. M. Shimada, T. Tsuchizawa, S. Uchiyama, T. Ohkubo, S. Itabashi, I. Okada, T. Ono, and M. Oda,

Development of highly accurate x-ray mask with high-density patterns, Jpn. J. Appl. Phys., 38,

7071–7075 (1999).

16. S. Uchiyama, S. Ohki, A. Ozawa, M. Oda, T. Matsuda, and T. Morosawa, Improving x-ray mask

pattern placement accuracy by correcting process distortion in electron beam writing, Jpn.

J. Appl. Phys., 34, 6743–6747 (1995).

Rizvi / Handbook of Photomask Manufacturing Technology DK2192_c013 Final Proof page 316 7.3.2005 6:25pm

© 2005 by Taylor & Francis Group.

17. D. Pusito, M. Struns, and M. Lawliss, Overlay enhancement with product-specific emulation in

electron-beam lithography tools, J. Vac. Sci. Technol. B., 12, 3436–3439 (1994).

18. M. Oda, M. Shimada, T. Tsuchizawa, S. Uchiyama, I. Okada, and H. Yoshihara, Progress in

x-ray mask technology at NTT, J. Vac. Sci. Technol. B., 17, 3402–3406 (1999).

19. S. Ohki, T. Watanabe, Y. Takeda, T. Morosawa, K. Saito, T. Kunioka, J. Kato, A. Shimizu,

T. Matsuda, S. Tsuboi, H. Aoyama, H. Watanabe, and Y. Nakayama, Patterning performance

of EB-X3 x-ray mask writer, J. Vac. Sci. Technol. B., 18, 3084–3088 (2000).

20. K.K. Christenson, R.G. Viswanathan, and F.J. Hohn, x-ray mask fogging by electrons back-

scattered beneath the membrane, J. Vac. Sci. Technol. B., 8, 1618–1623 (1990).

21. T. Tsuchizawa, H. Iriguchi, C. Takahashi, M. Shimada, S. Uchiyama, and M. Oda, Electron

cyclotron resonance plasma etching of a-Ta for x-ray mask absorber using chlorine and fluoride

gas mixture, Jpn. J. Appl. Phys., 39, 6914–6918 (2000).

22. M. Oda, T. Ohkubo, and H. Yoshihara, One-point wafer bonding for highly accurate x-ray

masks, Proc. SPIE, 2512, 152–159 (1995).

23. J. Trube, J. Chlebek, J. Grimm, H.-L. Huber, B. Lochel, and H. Stauch, Investigation of process

latitude for quality improvement in x-ray lithography mask fabrication, J. Vac. Sci. Technol. B., 8,

1600–1603 (1990).

24. M. Sekimoto, H. Tsuyozaki, I. Okada, A. Shibayama, and T. Matsuda, x-ray mask inspection

using replicated resist patterns, Jpn. J. Appl. Phys., 33, 6913–6918 (1994).

25. I. Okada, Y. Saitoh, T. Ohkubo, M. Sekimoto, and T. Matsuda, Repairing x-ray masks with Ta

absorbers using focused ion beams, Proc. SPIE, 2512, 172–177 (1995).

26. A. Wangner, J.P. Levin, J.L. Maner, P.G. Blauner, S.J. Kirch, and P. Longo, x-ray mask repair

with focused ion beams, J. Vac. Sci. Technol. B., 8, 1557–1564 (1990).

27. R. Viswanathan, R.E. Acosta, D. Seeger, H. Voelker, A. Wilson, I. Babich, J. Maldonado,

J. Warlaumont, O. Vladimirsky, F. Hohn, D. Crockatt, and R. Fair, Fully scaled 0.5 mm metal–

oxide semiconductor circuits by synchrotron x-ray lithography: mask fabrication and charac-

terization, J. Vac. Sci. Technol. B., 6, 2196–2201 (1988).

28. R. Viswanathan, D. Seeger, A. Bright, T. Bucelot, A. Pomerene, K. Petrillo, P. Blauner, P. Agnello,

J. Warlaumont, J. Conway, and D. Patel, Fabrication of high performance 512Kb SRAMs in

0.25 mm CMOS technology using x-ray lithography, Microelectron. Eng., 23, 247–252 (1994).

29. N. Yoshioka, N. Ishio, N. Fujiwara, T. Eimori, Y. Watakabe, K. Kodama, T. Miyachi, and

H. Izawa, Fabrication of 1-Mbit DRAMs by using x-ray lithography, Proc. SPIE, 1089, 210–218

(1989).

30. K. Fujii, T. Yoshihara, Y. Tanaka, K. Suzuki, T. Nakajima, T. Miyatake, E. Orita, and K. Ito,

Applicability test for synchrotron radiation x-ray lithography in 64-Mb dynamic random access

memory fabrication processes, J. Vac. Sci. Technol. B., 12, 3949–3953 (1994).

31. K. Deguchi, K. Miyoshi, H. Ban, T. Matsuda, T. Ohno, and Y. Kado, Fabrication of 0.2 mm large

scale integrated circuits using synchrotron radiation x-ray lithography, J. Vac. Sci. Technol. B., 13,

3040–3045 (1995).

32. M. Oda, S. Uchiyama, T. Watanabe, K. Komatsu, and T. Matsuda, x-ray mask fabrication

technology for 0.1 mm very large scale integrated circuits, J. Vac. Sci. Technol. B., 14, 4366–4370

(1996).

33. H. Aoyama, T. Taguchi, Y. Matsui, M. Fukuda, K. Deguchi, H. Morita, M. Oda, T. Matsuda,

F. Kumasaka, Y. Iba, and K. Horiuchi, Overlay evaluation of proximity x-ray lithography in

100 nm device fabrication, J. Vac. Sci. Technol. B., 18, 2961–2965 (2000).

© 2005 by Taylor & Francis Group.

Document Outline

- Contents

- Section IV NGL Masks

Wyszukiwarka

Podobne podstrony:

CH13

Ch13 Q4

cisco2 ch13 concept DEPLAEMNY56CXKYBER7D5JJA4Y4E4WS45RAVJSI

Ch13 Drawing Views

Ch13 Q3

CH13 2

Ch13 Q1

Ch13

ch13

Ch13 Q2

Ch13 Shafts

Genomes3e ppt ch13

ch13

Ch13 PolutionAndItsControll

Ch13 rolling

Ch13 Pg441 484

CH13

Ch13 Q4

więcej podobnych podstron