Assessing the treatment costs and the fertilizing value

of the output products in digestate treatment systems

K. Golkowska, I. Vázquez-Rowe, V. Lebuf, F. Accoe and D. Koster

ABSTRACT

The objective of this paper was to advance towards

finding sustainable solutions to deal with biogas

digestate and contribute to faster development of the market for digestate treatment products. The

study compares digestate treatment costs through four different treatment plants, estimates the

potential fertilizing and humus value (PFHV) of the derived products and allocates the cash

flows to

show the possible regional bene

fits. The treatment costs for the pre-dried solid fraction of digestate

ranged from

€19 to €23/tonne output. These costs may be covered by vending treatment products at

a price reaching at least 34

–41% of their PFHV (ca €55/tonne). Treatment of raw digestate generates

high operating costs (

€216–247/tonne output), much higher than the PFHV of the products (ca €35–

51/tonne). For such systems either the treatment has to be

financially subsidized by the authorities

or

€13–32/tonne input should be covered by the substrate deliverers as a disposal fee. Nevertheless,

a well-prepared investment concept in this

field may allow the local binding of up to 80% of total cash

flows. Finally, the current difficult market situation of the treatment products can be primarily

improved by clearing their legal status at European level.

K. Golkowska (corresponding author)

I. Vázquez-Rowe

D. Koster

Resource Centre for Environmental Technologies,

CRP Henri Tudor,

6A, Av. des Hauts-Fourneaux,

L-4362 Esch-sur-Alzette,

Luxembourg

E-mail: katarzyna.golkowska@tudor.lu

V. Lebuf

F. Accoe

Flemish Coordination Centre for Manure

Processing,

Abdijbekestraat 9,

8200 Brugge,

Belgium

Key words

|

digestate treatment, market value, mineral fertilizer, nutrient recovery, regional cash

flow, treatment costs

INTRODUCTION

Treatment of biogas digestate is currently an important issue

for several areas with high livestock density in Europe, such

as Belgium, the Netherlands, as well as for certain regions in

Italy or Germany (

). These regions suffer

from the surplus of nutrients in soils, due to intensive live-

stock farming causing diffuse emissions that have led to

important environmental burdens (

). In

this context, treatment allows reducing emissions related

to the spreading of untreated digestate (

), but also produces easily

exportable products with reduced water content and

volume.

Digestate treatment processes, depending on the applied

technology, generate several different outputs, such as dried

solid fraction, ammonium sulfate solution or reverse osmo-

sis concentrate, with different characteristics and fertilizing

parameters. In the current market and legal situation these

separated streams are usually remixed after the treatment

and disposed of by the farmers as a single output product.

This application procedure, however, does not take

advantage of the fertilizing potential and easier applicability

of separated streams, but mainly leads to cheaper transport

of the nutrients captured in those products out of the region.

A more sophisticated use of treatment outputs (with separ-

ated nutrient streams) without mixing them could help to

close the natural nutrient cycle by substitution of commonly

used mineral fertilizers (

;

). This important issue gains importance due to

the continuous price increase of mineral fertilizers linked

to depleting phosphorus rock (

) and

unstable prices of fossil fuels. However, there are still several

constraints preventing development of the market trading

digestate treatment products. These include restrictions

and obstacles linked to the legal status (waste or fertilizing

product), lack of acceptance by farmers (end users) partially

due to a limited knowledge concerning the fertilizing effects

of the treatment products, little information regarding

output characteristics for different treatment technologies

and, consequently, dif

ficulties in estimating fertilizing and

market value.

656

© CRP Henri Tudor 2014

Water Science & Technology

|

69.3

|

2014

doi: 10.2166/wst.2013.742

Therefore, the main objective of this paper is to help in

advancing towards

finding sustainable solutions to deal

with digestate from biogas plants. For this, a comparative

analysis of digestate treatment costs in four different treat-

ment plants is performed together with an attempt to

assess the potential fertilizing and humus value (PFHV)

of the output products. Finally, the results will allow assess-

ment of useful implications for the faster development of

this emerging market.

METHODS

Analyzed treatment systems

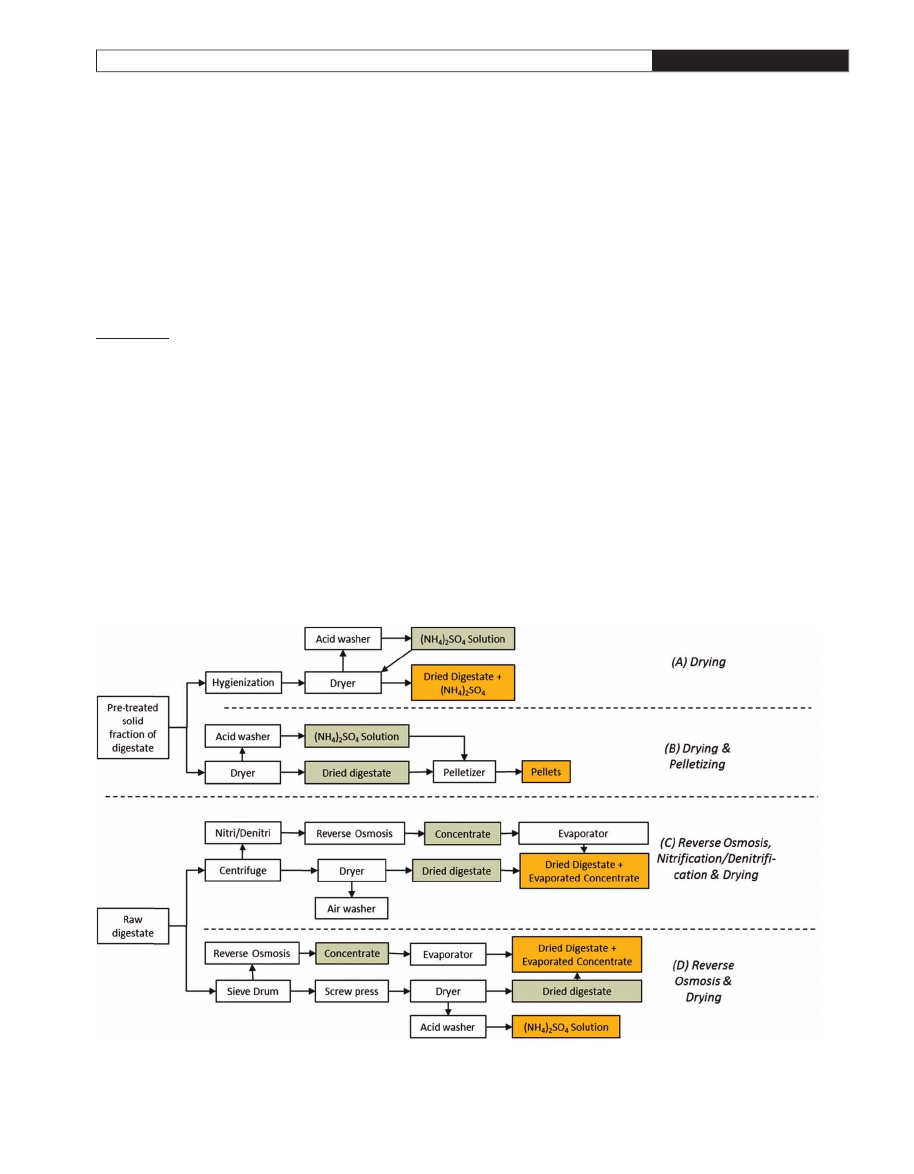

The current study compared four digestate treatment tech-

nologies: drying with

fixed bed dryer (A), drying with

fluidized bed dryer and pelletizing (B), biological treat-

ment, reverse osmosis and drying with

fluidized bed

dryer (C) and reverse osmosis and drying with double

boiler (D). The data for plants A

–C were delivered directly

by plant managers, while for plant D the information was

retrieved from

. Treatment

systems A and B deal with a pre-treated solid fraction of

digestate reaching a dry matter (DM) content of 56%.

Such input characteristics were obtained by mixing differ-

ent pre-dried streams or mixing untreated digestate with

completely processed dried digestate. Plants C and D pro-

cess raw digestate with DM content reaching ca 9% of

fresh matter (FM). In these plants digestate is separated

and, subsequently, both solid and liquid fractions are pro-

cessed in parallel. The simpli

fied chart flows of the

treatment plants are given in

. These schemes

do not include any by-products of the treatment. In

plants A, B and D the water vapor emissions from the

acid washer are exhausted into the air, while the permeate

is either directly discharged to a watercourse (plant C) or

sent to the lagoon for cooling, biological reactivation and

further water polishing, and subsequently discharged to

the surface water as well (plant D).

Based on the substrate description given by the plant

operators and the typical average characteristics of biogas

digestate from Flanders (VLACO (Vlaamse Compostorgani-

satie

vzw),

personal

communication),

the

nitrogen,

phosphorus and potassium composition of the input streams

was calculated for the different treatment technologies. The

Figure 1

|

Schematic chart

flows of the analyzed treatment systems. Light gray boxes indicate currently intermediate products that are potentially valuable for agricultural purposes, while

dark gray boxes show current

final products.

657

K. Golkowska et al.

|

Assessing the costs and value of output products in digestate treatment systems

Water Science & Technology

|

69.3

|

2014

stackable input streams for plants A and B contained 14.9

–

15.8 kgN/t

FM

, 21.3

–22.6 kgP

2

O

5

/t

FM

and 14.2

–16.2 kgK

2

O/

t

FM

. For plants C and D the calculated characteristics of the

input were the following: 4.3

–4.6 kgN/t

FM

, 3.8

–3.9 kgP

2

O

5

/

t

FM

, 3.5

–3.7 kgK

2

O/t

FM

. The nutrient fractions assigned to

intermediate and

final digestate streams, e.g. solid or liquid

fractions, were either calculated based on

for plants A

–C or extracted from

for plant D. More detailed characteristics on

the output streams are given in

Calculation of PFHV

The PFHV for the treatment products was calculated based

on the content of accountable P

2

O

5

, K

2

O, N and humus-C,

as well as the current market price for these nutrients. A

similar method has been applied by

to calculate

PFHV of digestate. This approach allows an easier assess-

ment of PFHV than comparison with different mineral

fertilizers existing on the market and containing prede

fined

mixes of different P, K and N compounds. Uptake ef

fi-

ciency of total P

2

O

5

, K

2

O and N is presented in

Solid dried digestate was the dominating fraction in all

the mixed outputs obtained in the different treatment

plants. Therefore, 30% of total N was assumed as contribut-

ing to the fertilizing value. For the second product obtained

in plant D (ammonium sulfate), 90% uptake of N was con-

sidered. Current prices for P

2

O

5

, K

2

O and N were retrieved

from

. Following the case studies presented by

, the humus C content was

assumed to be 60

–70 kg/tonne for the mixed products (cal-

culated humus-C content was assumed as ca 18% of

organic matter (OM), while OM was assumed as ca 40%

of DM). For ammonium sulfate no humus-C content was

taken into consideration, since the information about the

possible content was not available.

Calculation of treatment costs

Treatment costs were computed for the different treatment

processes existing in plants A

–D. All the costs linked to

the substrate transport to the plant, product transport out

of the plant as well as spreading were excluded from the

system boundaries of the assessment. For plants A and B

the pre-treatment steps (and, consequently, their costs),

which took place before substrate delivery to the plants,

were not included in this evaluation. No subsidies or any

form of

financial support were considered. Finally, the cal-

culations

do

not

include

VAT

(value

added

tax)

computation.

The treatment systems were assumed to be operational

during a 20 year period. Treatment costs were grouped in

three categories: (1) total investment costs, i.e. buildings,

installations, infrastructure, machines, land acquisition;

(2) operational costs, i.e. power and heat supply, materials,

chemicals, internal transport, machine operating costs;

and (3) manpower costs linked to the plant workers. All

the investment costs of (1), except for the machines,

were assumed to be

financed with a 20-year-loan credit

with the base rate of 6%. For the internal transporting

vehicles different loan times of 2

–20 years were considered

depending on their lifetime. Due to the con

fidential char-

acter of the information required, data were not retrieved

directly from plant operators. Consequently, most of the

financial data were obtained from literature, adjusting the

data to the speci

fic operating parameters delivered by

the plant operators. In addition, calculations included an

in

flation rate of 3%. A discount rate of 4% was used to cal-

culate back the future expenditures to the present net

value.

The treatment plants presented different heat and power

demands and developed very speci

fic supply mechanisms

based on biogas, natural gas, mixed scenarios, etc. To

Table 1

|

Characteristics of the currently received output products for treatment systems A

–D

Plant A

Plant B

Plant C

Plant D

Product

Dried digestate

þ

(NH

4

)

2

SO

4

Pellets

Dried digestate

þ reverse

osmosis concentrate

Dried digestate

þ reverse

osmosis concentrate

(NH

4

)

2

SO

4

DM

%FM

90

90

85.6

86.7

–

Total N

kg/t

FM

22.8

21.6

22.0

23.7

35

P

2

O

5

kg/t

FM

24.4

32.3

33.8

22.5

–

K

2

O

kg/t

FM

31.9

18.0

15.9

7.0

–

DM: dry matter; FM: fresh matter.

658

K. Golkowska et al.

|

Assessing the costs and value of output products in digestate treatment systems

Water Science & Technology

|

69.3

|

2014

achieve higher transparency and comparability of the treat-

ment costs the following heat and power

financing

scenario has been developed: treatment plants acquire natu-

ral gas from the grid and generate the necessary heat in their

own combined heat and power units. Produced electricity is

used to cover the energy demand of the plants, while the

surplus is sold on the market. The costs of natural gas,

reduced because of the revenues arriving from the electricity

sold, constitute the energy and heat supply costs of the treat-

ment plants.

RESULTS AND DISCUSSION

The obtained annual net treatment costs are shown in

, together with the speci

fic treatment costs in relation

to 1 tonne of incoming product. The speci

fic treatment costs

based on the output volume are much lower for plants A and

B. This is mainly due to the previous pre-treatment steps that

the incoming products underwent before entering the plants

(the costs and energy input of the pre-treatment are

unknown and not included in this study). Plants A and B

deal with stackable inputs with high DM content. Conse-

quently, the volume reduction during the treatment, as

well as the difference in treatment costs based on the

input and output volume are considerably lower than for

those plants that are directly treating raw digestate (i.e. C

and D). For the latter, the important volume reductions

that are achieved during the treatment process result in

increased speci

fic investment (since more treatment steps

and installations are necessary), as well as higher chemical

and material costs (

). In contrast, the

speci

fic costs linked to internal transport and maintenance

are much higher in plants A and B. This is a consequence

of dealing with stackable substrate, which requires the use

of transporting machines (lift trucks), while in plants C

and D the input and its larger part after separation have

liquid form and can be easily forwarded with the pumping

systems. The speci

fic annual net costs of manpower increase

in plants C and D due to higher complexity of these systems.

In general, the highest speci

fic costs were calculated for

plant D, which runs in pilot scale and treats much less

input than the other plants. Moreover, besides the

Table 2

|

Nutrient uptake ef

ficiency for different digestate related products

Type of product

Nutrient

Uptake ef

ficiency (%)

All types of digestate

a,b

P

2

O

5

100

All types of digestate

a,b

K

2

O

100

Untreated digestate

þ liquid fraction

of digestate

a,b

N

60

Solid fraction of digestate

þ

compost

a,b

N

30

Dried digestate

a,b

N

30

Ef

fluent after biological treatment

a,b

N

100

Mineral fertilizer

a,b

N

100

(NH

4

)

2

SO

4

– solution from air

scrubber

a,c

N

90

–100

Mineral concentrate from reverse

osmosis

d

N

70

–100

a

b

.

c

J. De Vries, personal communication.

d

.

Table 3

|

Calculated annual treatment costs for the digestate treatment systems A

–D together with the calculated PFHV

Parameter

Unit

Plant A

Plant B

Plant C

Plant D

Input volume

t/a

60,000

108,000

55,000

11,400

Output volume

t/a

37,500

79,000

3550

2000

Annual treatment costs

€/a

838,000

1,510,000

877,000

431,000

Input annual speci

fic treatment costs

€/t input

14.0

14.0

15.9

37.8

Power and heat

€/t input

6.04

4.30

5.95

14.20

Investment

€/t input

2.35

2.89

4.15

7.14

Chemicals and materials

€/t input

0.11

0.42

0.79

9.52

Internal transport and maintenance

€/t input

2.16

2.70

0.24

1.15

Manpower

€/t input

3.31

3.68

4.82

5.81

Output annual speci

fic treatment costs

€/t output

22.3

19.1

246.9

215.7

PFHV

€/t output

54.9

56.5

51.4

34.7

PFHV: Potential fertilizing and humus value.

659

K. Golkowska et al.

|

Assessing the costs and value of output products in digestate treatment systems

Water Science & Technology

|

69.3

|

2014

dimensions of this plant, dif

ficulties in estimating the tech-

nological costs (due to application of non-standard

technologies) were also an important source of uncertainty,

which may have led to the overestimation of the investment

costs (

).

The calculated PFHV for the treatment products are

compared in

with the annual speci

fic treatment

costs calculated on the product basis. This comparison

suggests that if the treatment products for plant A and B,

dealing with stackable digestate, were to be sold at

€25/

tonne (which constitutes only 34

–41% of their PFHV), the

treatment costs would be completely covered by sale reven-

ues. However, it is important to understand the very speci

fic

financial situation of plants treating stackable digestate.

Depending on the local market conditions, characteristics

and origin of the incoming digestate streams, plants might

be either paid for

‘disposing of’ such type of digestate or

forced to acquire their substrate from the digestate

producers.

In plants C and D, even if the products were to achieve

their PFHV, there would still be costs of

€13–32/tonne input

that would need to be covered either by the digestate deli-

verers or some form of

financial subsidy. Should the

product be delivered for free, then the complete input

based treatment costs would have to be covered from the

aforementioned

financing sources. For all four scenarios

the evaluation does not include any transport costs, which

need to be either additionally paid by the product end

users or included in the treatment costs, which in the case

of plants treating raw digestate would either lead to

increased substrate

‘disposing’ prices or would have to be

compensated for by higher subsidies for the treatment

installations.

Considering current legislation and the market situation

for digestate treatment products in Europe, the PFHV may

be considered highly theoretical estimations with important

underlying sources of uncertainty (

). In practice,

the price of digestate treatment products does not only

depend on their quality, but also on the application sector

(e.g. agriculture, horticulture, landscaping or hobby garden-

ing), volume produced or geographical location (

;

). In fact, many treatment plants are forced

to give their products away for free, others manage to sell at

prices ranging from

€2 to €10/tonne, while other plants

export over longer distances and sell their products for

nearly

€30/tonne (including current transporting costs of

ca

€8.50/tonne and 100 km).

All discussed treatment costs, which arise during the

whole operating period of the treatment plant, can be

divided into costs contributing to the development of the

regional or global market players. To estimate added

value of the treatment installations for the regional

market, the calculated cash

flows were divided into those

transferred out of the region (partial investment costs

including machines, fuel, materials and chemicals and

not-locally sourced energy) or those that remained in the

region (partial investment costs, internal transport exclud-

ing

fuel,

manpower,

locally

sourced

energy).

The

calculated cash

flows assigned to the region are presented

in

. The largest part of the cash

flow in each invest-

ment is always linked to energy supply costs. In plants A, C

and D the energy is partially or completely generated from

biogas. This strongly increases the regional cash

flow as

compared to plant B. Substituting the use of fossil fuel

based energy with locally produced renewable energy

would enhance the regional cash

flows for plants A and

B, allowing local binding of 62

–78% of the total investment

costs. In contrast, if for analogue plants the entire required

energy were to be sourced from the fossil fuels only 24

–

41% of the invested money would stay in the region.

This is important information to be analyzed by potential

investors, which can take decisions helping to create

additional local advantages for the treatment systems

through local binding of capital and generating safe jobs

in the

field of green energy (

;

).

CONCLUSIONS

Treated products cause less environmental emissions, and

are cheaper and easier to transport, but may also help

close the natural nutrient cycle by substituting mineral ferti-

lizers (

;

).

Low demand for products derived from digestate treatment

and their extremely low market price are not in accordance

Table 4

|

Regional cash

flows valid for the current energy supply system and renewable

or fossil fuel based energy supplies

Regional cash

flow

Plant A

Plant B

Plant C

Plant D

Current energetic scenario

70%

42%

78%

62%

Complete change to locally

sourced energy

þ8%

þ22% –

–

Complete change to the fossil

fuel based energy

35%

–

37%

38%

660

K. Golkowska et al.

|

Assessing the costs and value of output products in digestate treatment systems

Water Science & Technology

|

69.3

|

2014

with their real fertilizing and humus value. In the current

market

situation,

the

treatment

costs

for

stackable

pre-dried digestate could be covered by selling treatment

products even if

<50% of the fertilizing value were to be

returned. Dealing with raw digestate constitutes a much

more complex endeavor. Such treatment is more expensive

and cannot be

financed only by selling the treatment pro-

ducts even if the PFHV would be reached. For this reason

possible

financial support schemes, such as subsidies or

digestate disposal fees have to be proposed on the national

or European level to improve the market situation for the

output products and to assure the existence basis for the

treatment plants (

). Furthermore, strategic

planning of the treatment plant may lead to the regional

binding of up to 80% of the whole invested capital, contri-

buting to the development of the region by creating safe

green jobs in the agricultural sector.

Further development of the digestate product market

can be triggered by creating clear and supportive legis-

lation at European level, i.e. regulation of the outputs

status (product or waste). Marketing campaigns would

help to inform target groups regarding the fertilizing poten-

tial of digestate treatment products, while an initial

support system for the farmers substituting industrially pro-

duced mineral fertilizers with digestate treatment products

may increase their willingness to use these fertilizing

agents.

ACKNOWLEDGEMENTS

This study has been developed within the frame of the

ARBOR project with

financial support from the European

Union (EU) INTERREG IVb programme. The authors

would like to thank Evi Michels, Céline Vaneeckhaute

and Erik Meers (Gent University), Vincent Hallau (Störk

GmbH) and Aksel Meier (Amandus Kahl GmbH & Co.

KG) for their help regarding data collection, as well as

Jerke de Vries and Paul Hoeksma (Wageningen University)

and Torsten Rehl and Joachim Müller (University of Hohen-

heim) for valuable scienti

fic exchange.

REFERENCES

Bakx, T., Membrez, Y., Mottet, A., Joss, A. & Boehler, M.

État de l

’art des méthodes (rentables) pour l’élimination, la

concentration ou la transformation de l

’azote pour les

installations de biogaz agricoles de taille petite/moyenne

(State of the art methods (cost) for the elimination,

concentration or transformation of nitrogen produced in

average/small sized agricultural biogas plant)

. Federal

Department for the Environment, Transports, Energy and

Communication (DETEC), Bern, Switzerland.

Barth, J.

Quality and markets for compost and digestion

residues in Europe. The 1st Baltic Biowaste Conference,

Tallinn, Estonia.

http://www.recestonia.ee/ecn/presentations/

(accessed 3 June 2012).

Brouwer, F., Hellegers, P., Hoogeveen, M. & Luesink, H.

Managing nitrogen pollution from intensive livestock

production in the EU. Report 2.99.04, Agricultural Economics

Research Institute (LEI), The Hague, The Netherlands.

Döhler, H. & Wulf, S.

Technical Digestate Treatment –

Advantages, Limitations, Costs

. KTBL, Biogas Europe 25-2

October 2011, Nantes, France.

(accessed 18 June 2013).

Fixen, P. E. & Johnston, A. M.

reserves: a view to the future

. Journal of the Science of Food

and Agriculture

92 (5), 1001–1005.

FMD (Flemish Manure Decree)

Decreet van 6 mei 2011

houdende wijziging van het Mestdecreet van 22 december

2006 (Decree of 6 May 2011 amending the Manure Decree of

December 22, 2006).

http://www.vcm-mestverwerking.be/

information/index_en.phtml?informationtreeid=26

(accessed 30 May 2013).

Goldstein, N.

Organic recycling trends in the European

Union. BioCycle

52 (3), 32–34.

Golkowska, K., Vázquez-Rowe, I., Benetto, E. & Koster, D.

Life cycle assessment of ammonia stripping treatment of

biogas digestate. Proceedings of the Fourth International

Symposium on Energy from Biogas and Waste

, Venice, Italy.

Holm-Nielsen, J. B., Al Seadi, T. & Oleskowicz-Popiel, P.

future of anaerobic digestion and biogas utilization

Bioresource Technology

100 (22), 5478–5484.

Kellner, U., Delzeit, R. & Thiering, J.

Digestate treatment: The

in

fluence of the location and size of the plant on the cost.

Berichte über Landwirtschaft

89 (1), 38–55.

Lebuf, V., Accoe, F., Vaneeckhaute, C., Meers, E., Michels, E. &

Ghekiere, G.

Nutrient recovery from digestates:

techniques and end-product. Proceedings of the Fourth

International Symposium on Energy from Biogas and Waste

,

Venice, Italy.

Leifert, I. & Oechtering, A.

Germany – Marketing concept for

quality products from organic resources, RETERRA,

European Compost Network Workshop, 13 June 2012.

(accessed 3 June 2013).

Mouat, A., Barclay, A., Mistry, P. & Webb, J.

Digestate

Market Development in Scotland. Report OPR080

– 801,

Zero Waste Scotland, Stirling, United Kingdom.

files/wrap/Zero%20Waste%20Scotland%

20-%20Digestate%20Market%20Development.pdf

(accessed

5 June 2013).

RAL, Deutsches Institut für Gütesicherung und Kennzeichnung e.V.

RAL-Gütesicherung Kompost Chargenuntersuchung,

661

K. Golkowska et al.

|

Assessing the costs and value of output products in digestate treatment systems

Water Science & Technology

|

69.3

|

2014

Prüfzeugnis PZ-Nr.: 9999-1301-014 Gärprodukt

flüssig (RAL

Quality Assurance Compost batch analysis, Certi

ficate No.:

9999-1301-014 Liquid digestate).

docs/guetesicherung/Pruefzeugnis_Gaerprodukt_

(accessed 6 June 2013).

Rehl, T. & Müller, J.

Life cycle assessment of biogas digestate

. Resources Conservation and

Recycling

56 (1), 92–104.

Vaneeckhaute, C., Meers, E., Michels, E., Christiaens, P. & Tack,

F. M. G.

Fate of macronutrients in water treatment of

digestate using vibrating reversed osmosis

. Water, Air & Soil

Pollution

223 (4), 1593–1603.

Vaneeckhaute, C., Meers, E., Ghekiere, G., Accoe, F. & Tack,

F. M. G.

a

Closing the nutrient cycle by using bio-

digestion waste derivatives as synthetic fertilizer

substitutes: a

. Biomass and Bioenergy

55,

175

–189.

Vaneeckhaute, C., Meers, E., Michels, E., Buysse, J. & Tack,

F. M. G.

b

application of bio-based mineral fertilizers in modern

agriculture

. Biomass and Bioenergy

49, 239–248.

Vázquez-Rowe, I., Golkowska, K., Lebuf, V., Accoe, A., Benetto,

E. & Koster, D.

To treat or not to treat? Environmental

assessment of digestate drying technologies using LCA

methodology. 13th World Congress on Anaerobic Digestion.

Recovering (bio)Resources for the World

, Santiago de

Compostela, Spain.

Velthof, G. L.

Synthesis of the research within the framework

of the Mineral Concentrates Pilot. Alterra Report 2224,

Wageningen University & Research Centre, Wageningen,

The Netherlands.

VHE, Verbände der Humus- und Erdenwirtschaft (Associations of

Humus and Soil Management)

Entwicklung des

Reinnährstoffpreise von 5/2007

–5/2013 (Evolution of the

nutrient prices from 5/2007 to 5/2013).

anwendung/kompost-in-der-landwirtschaft/wertigkeit

(accessed 3 June 2013).

VLACO (Vlaamse Compostorganisatie vzw)

Ecologische en

economische voordelen digestaat (Ecological and economic

bene

fits of digestate).

http://www.vlaco.be/professionele-

verwerking/eindproducten/eampe-digestaat

(accessed

30 May 2013).

First received 11 July 2013; accepted in revised form 31 October 2013. Available online 25 November 2013

662

K. Golkowska et al.

|

Assessing the costs and value of output products in digestate treatment systems

Water Science & Technology

|

69.3

|

2014

Copyright of Water Science & Technology is the property of IWA Publishing and its content

may not be copied or emailed to multiple sites or posted to a listserv without the copyright

holder's express written permission. However, users may print, download, or email articles for

individual use.

Wyszukiwarka

Podobne podstrony:

Wartość nawozowa pofermentu i gnojowicy Włochy 2016

referat koszty wytworzenia Word 97 gotowe, Rachunkowosc zarzadcza

wyniki wartości odżywczej owoców różnych odmian porzeczki czarnej(1), Technologia żywnosci i Żywieni

9 Wartość nawozowa

Pomiot ptasi i słoma właściwości, sposoby stosowania,wartość nawozowa

RACHUNKOWOŚĆ-de vilk, koszty[2], Koszty - wyrażone wartościowo zużycie środków pracy (śr

referat koszty wytworzenia Word 97 gotowe, Rachunkowosc zarzadcza

Potencjał nawozowy pofermentu z pozostałości z farmy i przemysłu agro Hiszpania 2012

Instalacja SW 2014

Maszorek Szymala, Anna; Janiak, Martyna Uzależnienia wśród uczniów różnych poziomów kształcenia (20

Właściwości nawozowe i skład chemiczny różnych rodzajów pofermentu i kompostu Włochy 2010

Państwo jako najwyższa wartość narodowa w widzeniu bohaterów literackich różnych epok, prezentacje

Koszty w mikroekonomii (9 stron), Koszty ekonomiczne to wartość wszystkich zasobów (czynników) użyty

Opracowania różnych tematów, Praca jaka najważniejsza wartość człowieka, PRACA JAKO NAJWAŻNIEJSZA WA

WA RADEK, 1 ) Charakterystyki mechaniczne n = f ( M ) dla = /2 oraz dwóch różnych wart

Państwo jako najwyższa wartość narodowa w widzeniu bohaterów literackich różnych epok, SZKOŁA, język

koszty (z różnych stron internetowych), Administracja UKSW Ist, Administracja UKSW IIst, fundusze U

więcej podobnych podstron