Biomaterials 23 (2002) 349–356

Mechanical and in vitro testing of aerosol–gel deposited titania

coatings for biocompatible applications

Miguel Manso

a,1,

*,Samuel Ogueta

b,1

,Predestinaci

!oon Garc!ııa

b

,Jos

!ee P!eerez-Rigueiro

c

,

Carmen Jim

!eenez

d

,J.M. Mart

!ıınez-Duart

a

,Michel Langlet

d

a

Departamento de F

!ıısica Aplicada, Universidad Aut !oonoma de Madrid, 28049 Madrid, Spain

b

Departamento de Biolog

!ııa Molecular, Universidad Aut !oonoma de Madrid, 28049 Madrid, Spain

c

Departamento de Ciencia de Materiales, ETSICaminos, Canales y Puertos, Universidad Polit

!eecnica de Madrid, 28040 Madrid, Spain

d

Laboratoire des Mat

!eeriaux et du G!eenie Physique, Rue de la Houille Blanche-BP 46, 38402 Saint Martin d’H"eeres, France

Received 4 September 2000; accepted 7 March 2001

Abstract

The biocompatible properties of sol–gel titania have increased the interest in the mechanical properties of this material in the form

of functional coatings for prosthetic applications. In the present work,titania coatings with thicknesses of 1 mm have been prepared

using the aerosol–gel process. The main objective has been to evaluate the mechanical properties of the coatings and to prove their

in-vitro biocompatibility. For this purpose,the hardness and Young’s modulus of the coatings were measured by nanoindentation

with loads in the 6–30 mn range. A continuous increase of these magnitudes was observed for the coatings treated at increasing

sintering temperatures (150–8001C). The hardness and the Young’s modulus ranged between 15.8–19.5 GPa and 142–186 GPa,

respectively. This behaviour has been confirmed by measurements of the plastic energy of deformation in 10 mn full loading–

unloading tests and by determination of the mean indentation creep under 30 mn loads. The films were additionally characterised by

XRD,FTIR and ellipsometry to study the chemical and structural changes produced by sintering. Biocompatibility tests are very

conclusive. Cells seeded on aerosol–gel titania coatings grow while adhered onto the surface. These coatings are thus of potential

interest for the enhancement of the properties of prosthetic TiAlV alloys. r 2001 Elsevier Science Ltd. All rights reserved.

Keywords:

Aerosol–gel; Titania; Coatings; Biocompatibility; Mechanical properties; Ultra-microindentation

1. Introduction

Titania films prepared by diverse methods present

promising biocompatible properties. Electrochemically

prepared TiO

2

coatings have proved to be highly stable

in surgical practice [1]. In addition,sol–gel derived

titania coatings have been described to be apatite

nucleation inducers not only in vitro but also in vivo

[2]. It has been proposed that the nucleation of the

calcium phosphate is activated by the presence of

hydroxyl functional groups in the film [3]. Descriptions

concerning thickness and morphology effects on the

nucleation ability of these films have been reported [4].

The formation of TiO

2

coatings on TiAlV alloys was

thus proposed to ameliorate the biocompatibility of

load bearing prostheses. The titania coatings also

present a barrier function which would avoid the

negative effects of Al and V ions released by wear

processes over the TiAlV prostheses [5]. Furthermore,

in vivo studies of the performance of hydroxyapatite

coatings (HAP,Ca

10

(PO

4

)

6

(OH)

2

),a material that

provides faster fixation with bone tissue [6],have

shown that failures of these coatings are mainly

produced at the interface with the metallic substrate

[7]. It has been shown that calcium and phosphate

ions diffuse through the metallic substrate during

sintering treatments applied to enhance the crystal-

linity of the coatings [8]. A preferential diffusion

can dangerously modify the Ca=P ratio at the inter-

face,leading thus to a coating failure [9]. Titania

coatings can play the role of a protective barrier

avoiding the diffusion of these ions into the implant.

Both effects,i.e. apatite nucleation induction and

*Corresponding author. Tel.: +34-913-974-919; fax: +34-913-973-

969.

E-mail address:

miguel.manso@uam.es (M. Manso).

1

Authors with equal contributions.

0142-9612/02/$ - see front matter r 2001 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 0 1 ) 0 0 1 1 2 - 0

diffusion

barrier

properties,permit

to

envisage

applications for the improvement of metallic load

bearing prostheses,even more when a high bonding

strength to the commonly used TiAlV alloy is ensured.

In any case,the mechanical properties of titania

coatings remain crucial for any biological application

envisaged.

The sol–gel method has been explored for the

preparation of titania coatings. Its principal advant-

ages are the control of surface morphology and

composition and the possibility of low temperature

processing which allows the use of thermally fragile

substrates [10]. The aerosol–gel method,used in this

work,is based on the ultrasonic nebulisation of an

aerosol from a reactive sol–gel solution. The aerosol,

constituted of microdroplets,is driven onto the

substrate where the droplets spread and coalesce,

leading to a liquid film. After deposition,drying and

sol–gel polymerisation take place,forming a xerogel

film that can then be heat-treated. The method

introduces some extra advantages over the conven-

tional

methods

of

spin-

and

dip-coating.

The

thickness

can

be

precisely

tailored

by

selecting

different deposition times (aerosol flowing) and the

system lends itself to the deposition on large and

three-dimensional substrates [11]. These conditions

are essential for the processing of plates,screws

and elements of complex design such as hip-joint

prostheses. Previous works on aerosol–gel titania

coatings include the study of the changes produced

by doping coatings [12] and the preparation of

high refractive index coatings at low temperature [13].

Studies related with the precursor solution prepara-

tion,condensation and densification have also been

published [14,15].

The aim of this work is to demonstrate the

biocompatibility of aerosol–gel derived titania films

and to describe their mechanical behaviour taking

account of their physico-chemical properties. For

that purpose,we have not only studied the changes of

the Young’s modulus and hardness for increasing

sintering temperatures,but also the singular differences

in the plastic energy of deformation (PED) and the

behaviour under constant loads reflected in the mean

indentation creep (MIC). To achieve these characterisa-

tions,we used the nanoindentation technique. This

technique is a powerful tool that has already been used

by several groups to establish the mechanical differences

between bulk materials and their corresponding thin

film structures. It has also proved to be useful to

evidence different orientations of single-crystals and to

measure the stresses in thin films grown by different

techniques or over different substrates [16]. In addition,

it has been successfully applied to biological systems to

characterise human cortical and trabecular lamellar

bone [17].

2. Experimental procedure

2.1. Sample preparation

Silicon wafers (1 0 0) were used as substrates for the

deposition of titania coatings. TiAlV plates were used

for biocompatibility tests. Before deposition,the Si

wafers were treated in air at 5001C for 2 h to eliminate

adsorbed impurities and to form a thermally stable SiO

2

surface film.

The precursor solution was optimised considering

that highly viscous solutions (for instance,due to a high

precursor concentration or reactivity) are not easily

transformed into an aerosol. Therefore,a 0.4 m tetra-

isopropyl-orthotitanate (TIPT,Fluka chemicals) solu-

tion diluted in ethanol with a TIPT/water ratio

r

w

¼ 0:82 and a pH ¼ 1:27 was prepared as described

previously [14]. This solution exhibited a moderate

reactivity and low viscosity (2 cP). The ultrasonically

nebulised aerosol was conducted during 20 s by an

ethanol saturated air flux into the thermally regulated

deposition chamber (201C). The derived liquid films

were then allowed to dry and to polymerise in air. The

so-formed xerogel films were sintered in air at 1501C,

3001C,5001C,and 8001C for 10 min in a conventional

furnace. In order to prepare thicker TiO

2

films,a

multilayer deposition procedure was followed,i.e. the

deposition/heat-treatment cycle was repeated ten times.

The final coating was then sintered for 1 h at the

temperature used for the intermediate treatment. In

these pages,the film nomenclature refers to the sintering

temperature (i.e. TiO150,TiO300,TiO500 and TiO800).

2.2. Physico-chemical characterisation

The coatings characterisation was carried out by the

use of the following techniques. X-ray diffraction

(XRD) was performed in a y=2y Siemens diffractometer

using a 0.041 scanstep and 6 s integration time. Fourier

transform infrared (FTIR) spectra were recorded in

transmission using a Bio-Rad FTS165 spectrometer (100

scans at 20 Hz,4 cm

@1

resolution). The Si substrate

contribution was subtracted from the spectra for the

analysis of the different coatings. The thickness and

refractive index of the coatings were measured by

ellipsometry (Gaertner L116B) with a 632.8 nm wave-

length and 701 beam incidence. The values of thickness

and refractive index of transparent coatings grown on Si

can be obtained in these conditions from the values of

the phase ellipsometric parameter D,and the amplitude

parameter c.

2.3. Mechanical characterisation

The Young’s modulus and hardness have been

obtained using the nanoindentation technique. In the

M. Manso et al. / Biomaterials 23 (2002) 349–356

350

present work,the mechanical model described by Pharr

and Oliver has been followed in order to determine the

values of hardness and Young’s modulus [18]. The basis

of this method is the introduction of geometrical and

experimental corrections to the analytic expression used

for the calculation of the projected area of contact,

which is obtained from the estimation of the depth of

contact.

Indentation tests were performed in a Shimadzu

DUH-200 dynamic ultra microhardness tester with

resolutions of 0.02 mn in load and 0.005 mm in depth.

Six full loading–unloading tests (10 mn maximal load)

were applied to each sample to obtain the PED values.

The coatings behaviour under constant load was

analysed by measuring the MIC values. Each sample

was probed 10 times at 30 mn during 60 s. For the

hardness and Young’s modulus calculation,maximal

loads of 6,10,18 and 30 mn were applied. For a statistic

purpose,the samples surface was probed at six different

places with a Berkowich diamond tip indentor. Five

loading cycles were monitored,allowing a 50% unload

after 1 s. The tip area had been previously calibrated

using quartz and aluminium references.

2.4. Biocompatibility tests

Human chondrosarcome cells were used to test the

biocompatibility of TiO

2

coatings in comparison with

the TiAlV alloy surface. The experimental procedure

followed for the observation of the cell on opaque

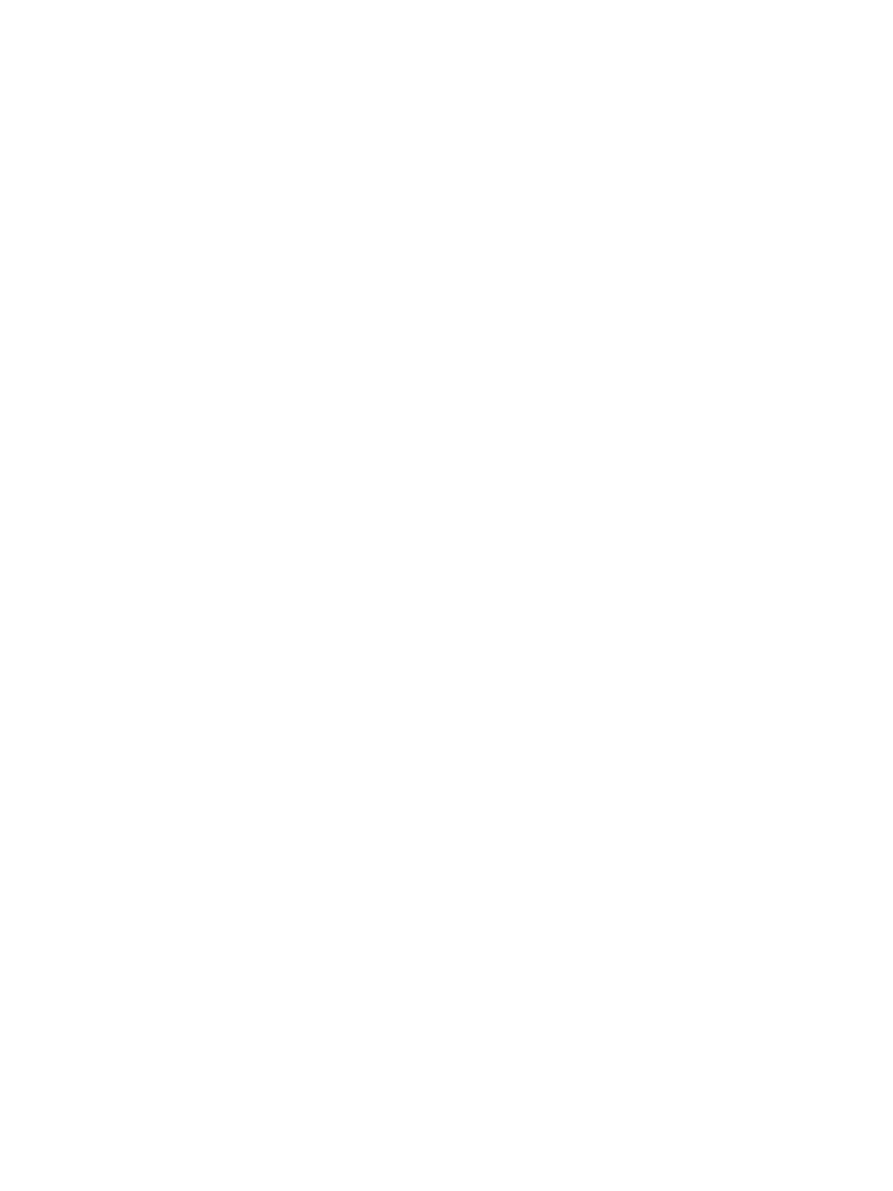

substrates is described in Fig. 1. The cells were cultured

and harvested as described previously [19] prior to

seeding onto TiO

2

surfaces. To perform the cell culture

onto the samples,one square cm of a titania coating

(TiO500) and a bare TiAlV substrate were washed with

PBS (phosphate buffer saline),placed individually on

tissue culture dishes and sterilised by over-night

exposure to UV in a tissue culture cabin. 200,000 cells

were seeded on each surface and incubated during 48 h

at 371C in an O

2

/CO

2

(96/4 v/v) atmosphere. Then,the

cells were washed with PBS,fixed with methanol and

kept in PBS at 41C until observation.

In order to visualise the cells on the samples,we

developed an easy immune technique overcoming the

material opacity. The above mentioned cultured sur-

faces were blocked with 5% milk protein in TBST

(10 mm Tris–HCl pH 7.5,150 mm NaCl and 0.05 Tween

20) during 2 h. The surfaces were washed three times

with 1 ml of 1% milk proteins in TBST and incubated

for 2 h at room temperature with 200 ml of sera from

transgenic mice at 1/400 dilution in TBST. These mice

develop an auto-immune disease and present antibodies

against nuclear and cytoskeleton proteins [19]. These

antibodies recognise human homologous proteins. After

incubation period,surfaces were washed three times

with 1% milk protein in TBST and incubated in dark

conditions for 30 min with a secondary antibody. An

anti-mouse labelled with fluorescein (Santa Cruz,CA) at

1/4000 dilution was used. After incubation,the surfaces

were washed and the cells were visualised by illumina-

tion at 495 nm in a fluorescence microscope (Axiovert

35). Three different experiments were carried out with

triplicate samples from TiO500 and TiAlV.

3. Results

3.1. Structure and composition

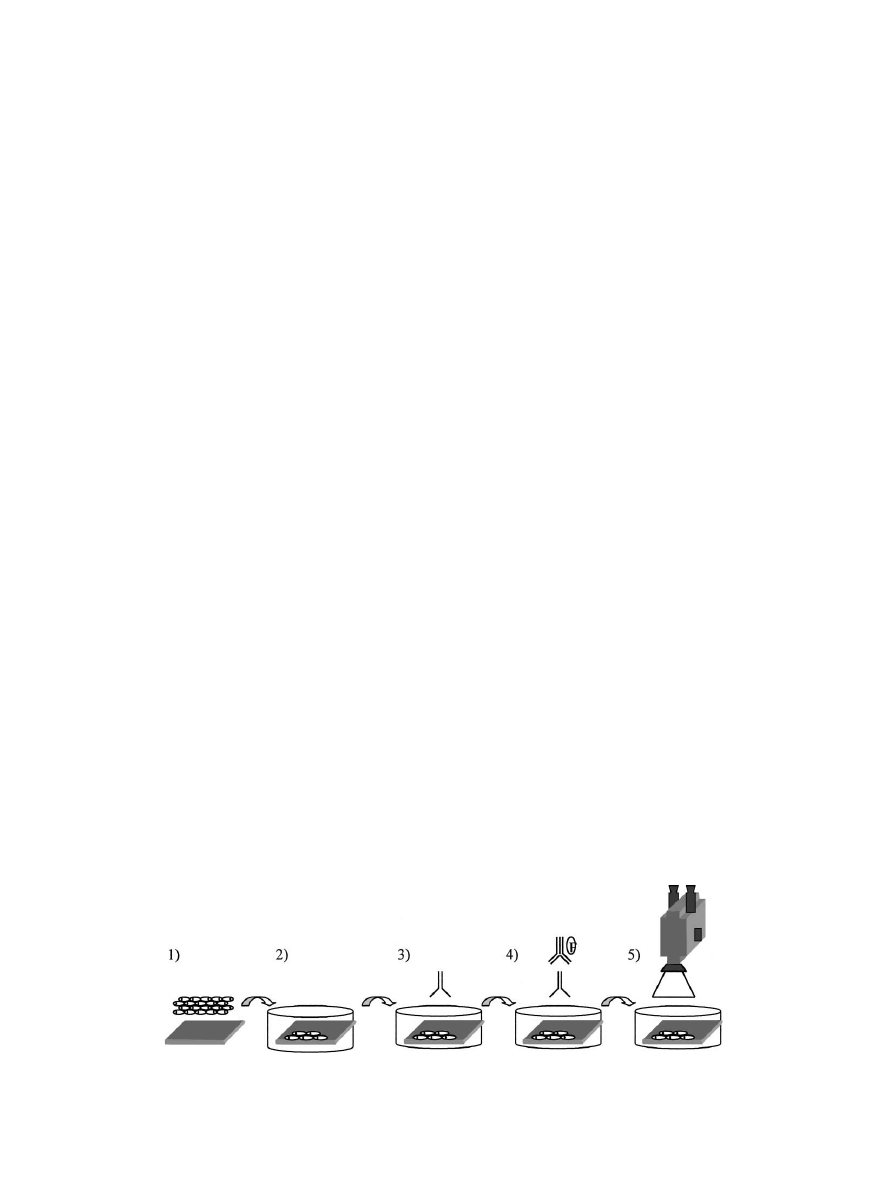

The XRD diagrams corresponding to TiO150 and

TiO300 samples (Fig. 2a and b) present no peaks arising

from the coating indicating that the phase formed is

amorphous. Sintering at higher temperatures drastically

activated the film crystallisation. Multiple peaks appear

in the XRD diagrams (Fig. 2c and d) proving that a

polycrystalline coating formed the TiO500 and TiO800

samples. The position of the peaks is in agreement with

the formation of a pure anatase phase corresponding to

the marked Miller indexes (JCPDS 84-1286). Two

residual peaks,issued from the Si substrate,are also

present in the diagrams. Sintering at 8001C led to

Fig. 1. General procedure followed to observe the cells overcoming substrate opacity. (1) Substrate pretreatment and cell culture. (2) Cell incubation

48 h. Methanol fixation. Albumin blockage. (3) Auto-immune serum incubation 1 h. (4) Secondary antibody reaction. 30 min. (5) Observation.

495 nm.

M. Manso et al. / Biomaterials 23 (2002) 349–356

351

narrower and more intense peaks that prove an increase

in the crystallite size of the titania coating. The relative

intensities of the diffraction peaks are in agreement with

those obtained from anatase standards showing that the

substrate induces no preferential growth directions in

the films.

FTIR spectra are presented in Fig. 3. Several bands

associated with Ti-alkoxi bonds [15] are detected at 930,

1040,1070,1125 and 1375 cm

@1

in the TiO150

coatings. Their intensity is drastically reduced or they

even disappear after sintering at 3001C. An interesting

feature concerning the Ti–O–Ti bonds is the related

band shift from 450 cm

@1

for the TiO150 coating to

435 cm

@1

for the coatings sintered at higher tempera-

tures (inset of Fig. 3). This evolution is in agreement

with structural and chemical changes of the titanium

environment,from the nonhydrolysed alkoxide to the

solid oxide obtained after hydrolysis/polyconensation.

Sintering at 5001C causes a notable intensity increase of

the Ti–O–Ti band that is produced by the amorphous to

crystalline transition already depicted by XRD. An

extra band appears at 1070 cm

@1

in the spectra of the

TiO800 coating due to the increasing absorption from

the SiO

2

film growing on the nonpolished backside of

the substrate. The band at 1625 cm

@1

associated with

molecular water is also discerned with decreasing

intensity for the samples prepared with increasing

sintering temperature. The wide band observed at

3600–3100 cm

@1

is assigned to hydroxyl groups which

are gradually eliminated for increasing sintering tem-

peratures.

The ellipsometric measurements performed on films

fired at 5001C showed that the thickness of a single layer

was 0.1 mm and that the film thickness increased linearly

with the number of deposition/heat-treatment cycles.

The thickness of the final coating after 10 cycles was

thus estimated to be 1 mm. Such a thickness was

necessary to perform nanoindentation measurements

reasonably insensitive to the substrate response. The

surface homogeneity was proved by the low dispersion

(

70.5%) in the values of the refractive index measured

throughout the film surface. For films fired at 5001C,the

averaged value of the refractive index was 2.22.

Ellipsometric measurements carried out on the rest of

the coatings showed an increase of the refractive index

for an increasing annealing temperature. Values of 1.93

and 2.34 were obtained for TiO150 and TiO800 coat-

ings,respectively. The refractive index increase with

increasing temperature reflects a thermally activated

densification mechanism.

3.2. Mechanical properties

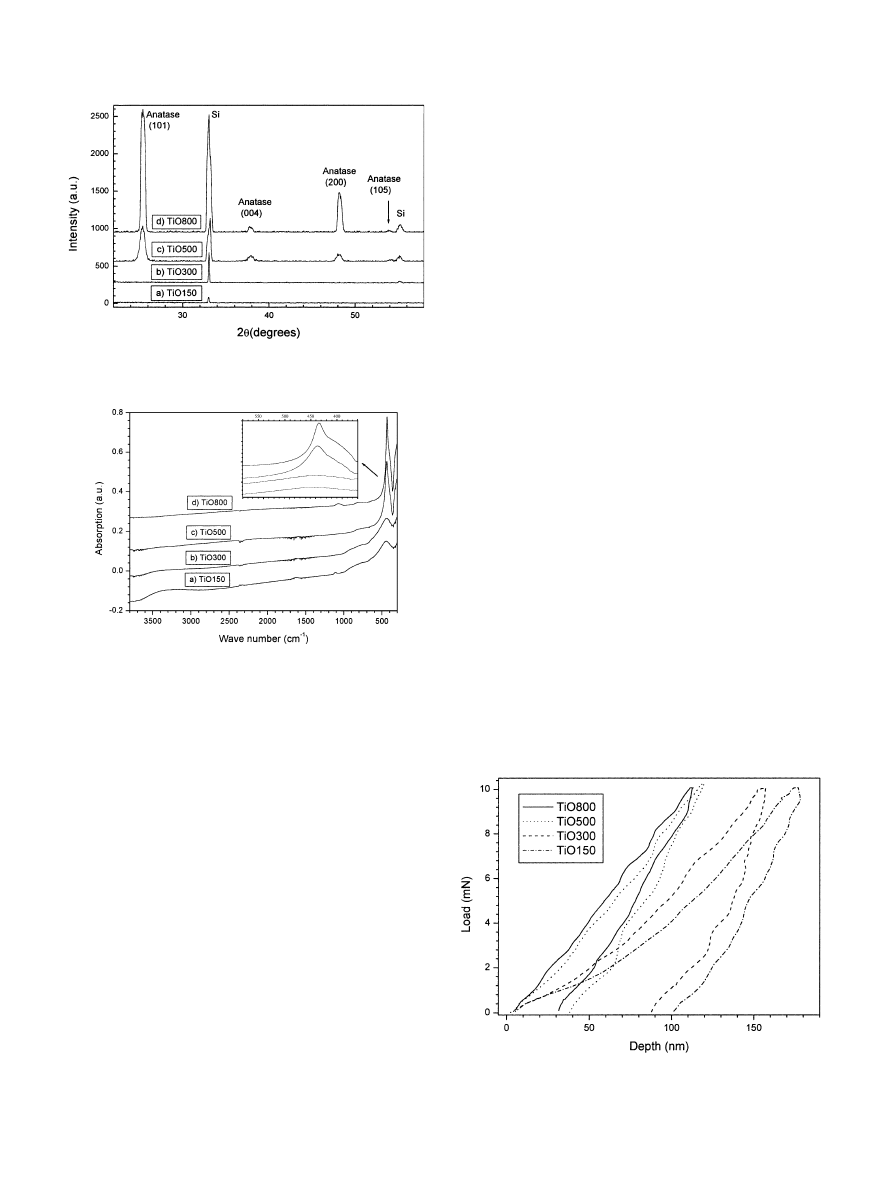

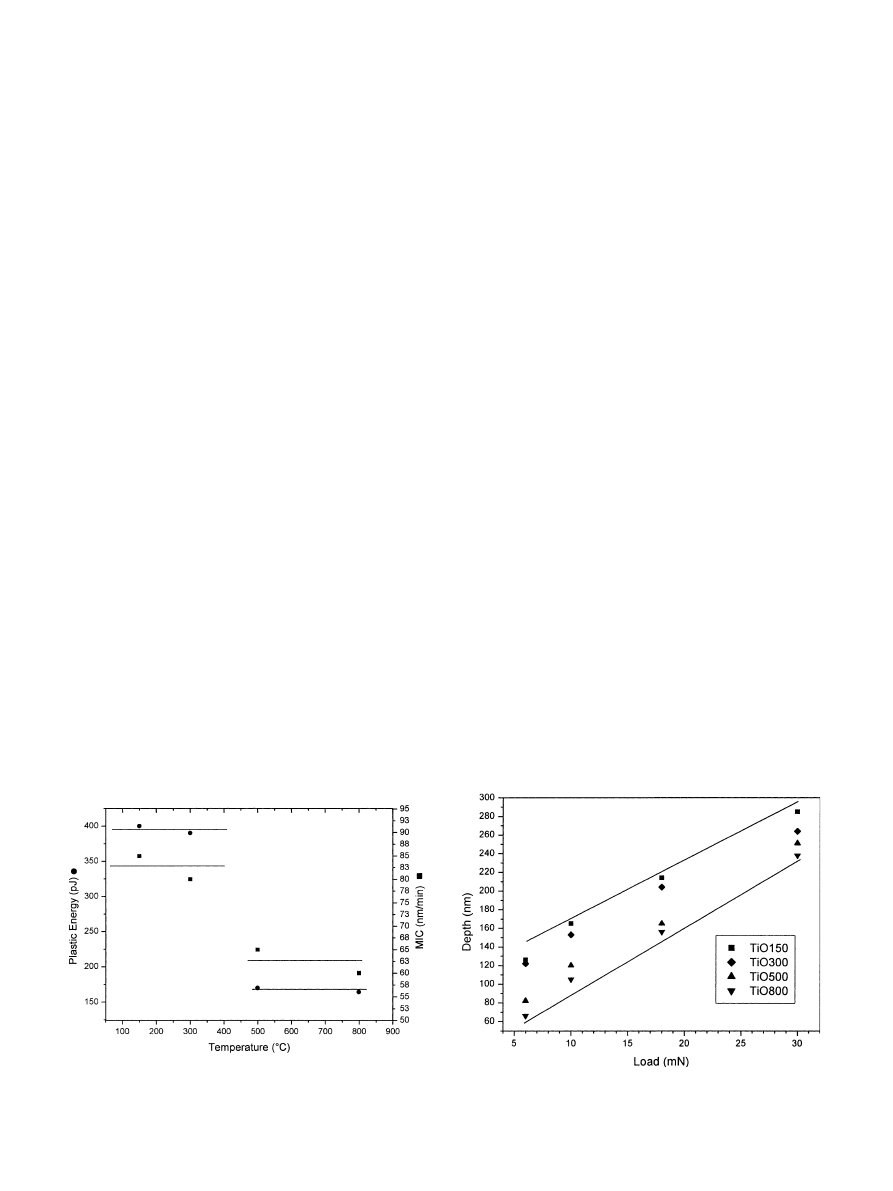

Typical 10 mn loading–unloading versus displacement

curves are presented in Fig. 4 for the different coatings.

All the parameters presented in this work are derived

from the differences existing between these curves after

Fig. 2. XRD diagrams of a TiO150 (a),a TiO300 (b),a TiO500 (c) and

a TiO800 (d) coating.

Fig. 3. FTIR spectra of a TiO150 (a),a TiO300 (b),a TiO500 (c) and a

TiO800 (d) coating.

Fig. 4. Full loading–unloading versus depth curves in 10 mn tests for a

TiO150 (dash–dot),a TiO300 (dash),a TiO500 (dots) and a TiO800

(straight) coating.

M. Manso et al. / Biomaterials 23 (2002) 349–356

352

an averaging process. The subtraction of the area

enclosed by the unloading curve from that defined by

the loading curve determines that coatings sintered at

1501C and 3001C suffered from considerably higher

plastic deformation than the coatings prepared with

5001C and 8001C sintering treatments (Fig. 5,left axis).

This difference is linked to the structural evolutions

depicted by FTIR,XRD and ellipsometry. The MIC

values measured at 30 mn (Fig. 5,right axis) are also

correlated with the structural evolution of the coatings.

Polycrystalline TiO500 and TiO800 coatings present

lower deformations with a significant gap compared to

TiO150 and TiO300 coatings. The mechanical differ-

ences are also evidenced by the values of maximal

indentation depth and by the unloading slope. The

maximal indentation depths,obtained from the root

mean square of six measurements after five loading–

unloading cycles,are presented in Fig. 6. It is clearly

seen that the coatings sintered at lower temperatures

generate a weaker opposite force to the loads and suffer

from deeper indentations. On the plot of Fig. 6,two

groups of samples can be distinguished in terms of

resistance to the indentation load (TiO150 and TiO300

vs the stiffer TiO500 and TiO800). These results are still

correlated with XRD,FTIR and ellipsometry data.

However,both groups could no longer be distinguished

for the highest load,presumably due to an increasing

interaction with the substrate. Thus,the overall results

confirmed that the condensation,crystallisation and

densification degrees reached after sintering at 5001C

drastically influence the film mechanical behaviour. The

values of hardness are presented in Table 1 with the

references of the load and the maximal depth reached

for every coating. The Young’s moduli were 142

77,

150

79,170720,190720 GPa for coatings sintered at

1501C,3001C,5001C and 8001C,respectively. Both

hardness values and Young’s moduli confirm that a

clear correlation exist between sintering temperature

and the mechanical properties.

3.3. Biocompatibility tests

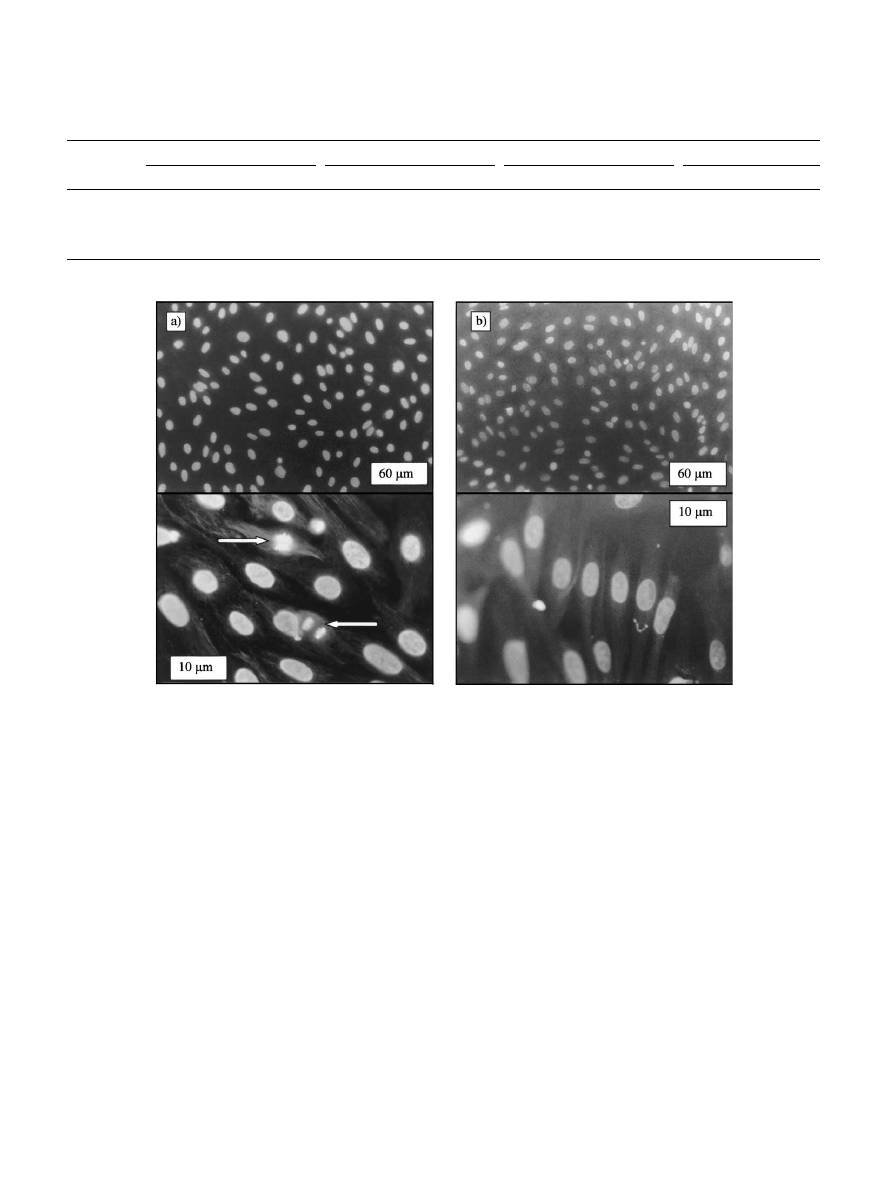

To determine whether aerosol–gel deposited titania

coatings could present a suitable biocompatibility,

we compared the adherence and growth of human

cells on our films with the behaviour on bare TiAlV

surfaces. The immuno assay performed to visualise

adhered

cells

on

opaque

surfaces

was

achieved

through a two step process. In the first immune reac-

tion,nuclear and cytoskeleton proteins were recogn-

ised by an auto-immune serum from mouse. Secondly,

the immune complexes formed were reacted with

an anti-mouse antibody labelled with fluorescein,

which

excites

the

fluorescence

reactions

in

cell

nuclei and cytoskeleton (Fig. 7). It was stated that

80% of seeded cells were adhered to both material

surfaces. However,some differences were observed.

For the titania surface (Fig. 7a),the distance between

cells was larger than that observed for the bare TiAlV

surface (Fig. 7b). This can be interpreted as a conse-

quence

of

an

increase

in

extra

cellular

matrix

components of cells adhered to titania. At higher

magnification,cytoskeleton of cells on titania showed

a polygonal array,while cells on TiAlV presented a

more

parallel

appearance.

In

addition,cells

on

titania surface showed growth signals since cells

were detected at different stages of the cellular cycle.

The arrows of Fig. 7 show these evolving nuclei,

which were not observed on TiAlV substrates. These

results support the notion of improved biocompatible

properties of aerosol–gel deposited titania in compar-

ison with the TiAlV surface.

Fig. 5. Values of the plastic energy of deformation (PED, K left axis)

and mean indentation creep (MIC, ’ right axis) versus the sintering

temperature applied to the titania coating.

Fig. 6. Maximal depth versus maximal load curves for a TiO150 ’, a

TiO300 ~,a TiO500 m and a TiO800 . coating.

M. Manso et al. / Biomaterials 23 (2002) 349–356

353

4. Discussion

The structure of titania coatings deposited by the

aerosol–gel process has been found to depend closely on

the applied sintering temperature. FTIR and XRD

analysis help to understand the sequence of processes

taking place during sintering. It was shown that an

important activation of the Ti–O–Ti network condensa-

tion and crystallisation is produced when a temperature

of 5001C is reached. Ellipsometric measurements of the

refractive index show that the processes are accompa-

nied by a significant film densification.

Indentation tests showed that physicochemical differ-

ences between the samples can be correlated with a

characteristic mechanical behaviour. It was stated that

the coatings can be classified into two groups. Coatings

sintered at 5001C or higher temperatures present lower

MIC and suffer from lower plastic deformations. This

behaviour can be related with the main mechanism

governing the indentation process,which is charac-

terised by the plastic deformation suffered for a fixed

applied load. Coatings sintered at 1501C and 3001C

suffer a dominant cutting mechanism (higher plastic

deformations),while coatings sintered at 5001C and

8001C undergo a compression strain mechanism (lower

plastic deformations) [20]. FTIR,ellipsometry and XRD

measurements show that this feature is closely related to

the Ti–O–Ti network polycondensation,densification

and crystallisation. Coatings sintered at higher tempera-

tures are also harder and present higher Young’s

moduli. It must be stated at this point that,taking into

account the properties of the TiO150 and TiO300

samples,these coatings are more prone to suffer from

substrate influence during indentation. Furthermore,

these coatings suffer from higher plastic deformations so

that,the measurement at the same time is actuating as a

driving force for the condensation and strengthening of

the coating. These two factors may explain the high

Table 1

Hardness values (H,

71 GPa) and maximal depth (h

max

,

75 nm) vs load (L) for the different coatings

L

(mn)

TiO150

TiO300

TiO500

TiO800

h

max

(nm)

H

(GPa)

h

max

(nm)

H

(GPa)

h

max

(nm)

H

(GPa)

h

max

(nm)

H

(GPa)

6

125

9

120

9

80

16

65

18

10

155

11

155

12

120

19

105

19

18

200

15

195

18

165

19

160

20

30

285

16

265

18

250

19

240

20

Fig. 7. Fluorescence micrograph showing the evolution of human chondrocite cells seeded on a TiO500 coating (a) and on the surface of TiAlV

alloy (b).

M. Manso et al. / Biomaterials 23 (2002) 349–356

354

values of Young’s moduli obtained for the not

completely densified TiO150 and TiO300 films.

A comparison of these coatings with other titania

films produced by alternative methods reveal interesting

features. The hardness and Young’s modulus values of

ion bombarded spin-coated films measured by ultra-

microindentation are considerably lower than the values

obtained for any of our coatings [21]. The results for arc

deposited titania coatings are nearer to the values

obtained in our study [22]. When amorphous arc

coatings

are

produced,the

Young’s

modulus

(140 GPa) is quite close to the value of our TiO150

coatings (142 GPa). When rutile crystalline coatings are

produced,the Young’s modulus (180 GPa) shows a

good level of coincidence with the value of our TiO800

coating (190 GPa). However,it should be mentioned

that the hardness values of aerosol–gel titania coatings

are higher than those obtained for arc TiO

2

coatings. In

any case,our hardness values appeared systematically

lower than the values measured for r.f. sputtered titania

films (23 GPa) [23].

Comparing titania coatings prepared by the afore-

mentioned techniques,it is worth mentioning that the

aerosol–gel titania coatings introduce a noticeable

advantage from the point of view of their mechanical

properties. Depending on the sintering temperature,

they present a range of mechanical properties that

makes it possible to tailor their response under stress.

Consequently,a multilayer deposition procedure can

produce coatings with gradual mechanical properties.

This configuration is considered of primary interest

since it has been shown that the drastic differences in

Young’s modulus between bone (30 GPa) and the

prostheses alloy (up to 200 GPa) can produce severe

damage. This effect is dramatic in the case of femur

heads sustaining hip-joint prostheses [5].

The development of an immune process has allowed

the in-situ observation of human cells seeded on titania

coatings. The adherence,growth and proliferation of the

cells prove that aerosol–gel titania coatings present

improved biocompatible properties with respect to the

traditional TiAlV alloys. This improved biocompatibil-

ity demonstrates that our coatings can be safely used for

prosthetic applications.

5. Conclusion

The aerosol–gel process has demonstrated to be a

suitable tool for the deposition of titania coatings

with tailored properties. The coatings mechanical

properties have been studied with respect to the sintering

temperature. The mechanical properties appear to be

strongly correlated to the polycondensation,densifica-

tion and crystallisation behaviour. The combination

of mechanical results,which prove the possibility to

tailor the mechanical properties of aerosol–gel derived

titania coatings,and of biological results,which show

enhanced biocompatibility of these coatings when

compared with a TiAlV alloy surface,are considered

of primary interest since they open the view to new

generation implants with a more suitable bone-implant

mechanical matching.

Acknowledgements

M. Manso thanks the Regional Government of

Madrid for his Research Grant and the financial

support during the stay at the ‘‘Laboratoire des

Mat

!eeriaux et du G!eenie Physique’’ in Grenoble.

References

[1] Szabo G,Kovacs L,Vargha K,Barabas J,Nemeth Z. A new

advanced surface modification technique- titanium oxide ceramic

surface implants: the background and long term results. J Long

Term Effects Med Impl 1999;3:247–59.

[2] Li P,Kangasniemi I,De Groot K. In vitro and in vivo evaluation

of bioactivity of gel titania. Bioceramics 1993;6:41–5.

[3] Haddow DB,James PF,Van Noort R. Characterisation of

sol–gel surfaces for biomedical applications. J Mater Sci: Mater

Med 1996;7:255–60.

[4] Haddow DB,Kothari S,James PF,Short RD,Hatton PV,Van

Noort R. Synthetic implant surfaces. 1. The formation and

characterisation of sol–gel titania films. Biomaterials 1996;17:

501–7.

[5] Long M,Rack HJ. Titanium alloys in total joint replacement

F

a materials science perspective. Biomaterials 1998;19:1621–39.

[6] Moroni A,Caja VL,Egger EL,Trinchese L,Chao EYS.

Histomorphometry of hydroxyapatite coated and uncoated

porous titanium bone implants. Biomaterials 1994;15:926–30.

[7] Hayashi K,Inadome T,Tsumura H,Nakashima Y,Sugioka Y.

Effect of surface roughness of hydroxyapatite coated titanium on

the

bone

implant

interface

shear

strength.

Biomaterials

1994;15:1187–91.

[8] Ducheyne P,Van Raemdonck W,Heughbaert KC,Heughbaert

JC. Structural analysis of hydroxyapatite coatings on titanium.

Biomaterials 1986;7:97–103.

[9] Ramselaar MMA,Driessens FCM,Kalk W,De Wijn JR.

Biodegradation of four calcium phosphate ceramics; in vivo

rates and tissue interactions. J Mater Sci: Mater Med 1991;2:

63–70.

[10] Scherrer GW,Brinker CJ. Sol–Gel Science: The Physics and

Chemistry of Sol–Gel. Boston MA: Academic Press,1990.

[11] Langlet M,Joubert JC. French Patent 9014312,1990; European

Patent 0486393 A1,1991.

[12] Viitala RI,Langlet M,Simola J,Lind

!een M,Rosenholm JB.

Aerosol–gel deposition of doped titania thin films. Thin Solid

Films 2000;368:35–40.

[13] Langlet M,Burgos M,Langlet L,Jimenez C,Morant C,Manso

M. Low temperature preparation of high-refractive index

and mechanically resistant sol–gel TiO

2

layers for multi-

player antireflective coating applications. J Sol Gel Sci Technol,

in press.

[14] Burgos M,Langlet M. Condensation and densification mechan-

ism of sol gel TiO

2

layers at low temperature. J Sol–Gel Sci

Technol 1999;17:267–76.

M. Manso et al. / Biomaterials 23 (2002) 349–356

355

[15] Burgos M,Langlet M. The sol gel transformation of TIPT

coatings: a FTIR study. Thin Solid Films 1999;349:19–23.

[16] Mante FK,Baran GR,Lucas B. Nanoindentation study of

titanium single crystals. Biomaterials 1999;20:1051–5.

[17] Jae-Young Rho,Tsui TY,George M. Pharr. Elastic properties of

human cortical and trabecular lamellar bone measured by

nanoindentation. Biomaterials 1997;18:1325–1330.

[18] Oliver WC,Pharr GM. An improved technique for determining

hardness and elastic modulus using load and displacement sensing

indentation experiments. J Mater Res 1992;7:1564–83.

[19] Ogueta S,Olaizabal I,Santos I,Delgado-Baeza E,Garc

!ııa

Ruiz JP. Transgenic mice expressing bovine GH develop arthritic

disorder and self-antibodies. J Endocrinology 2000;165: 329–36.

[20] Samuels LE. Microindentations in Metals. In: Microindentation

techniques in materials science and engineering. American Society

for testing materials,Philadelphia,1986;5–25.

[21] Jamting AK,Bell JM,Swain MV,Wielunski LS,Clissold R.

Measurement of the micromechanical properties of sol–gel TiO

2

films. Thin Solid Films 1998;332:189–94.

[22] Bendavid A,Martin PJ,Takikawa H. Deposition and modifica-

tion of titanium dioxide thin films by filtered arc deposition. Thin

Solid Films 2000;360:241–9.

[23] Bally AR,Hones P,Sanjines R,Schmid PE,Levy F. Mechanical

and electrical properties of fcc TiO

1+x

thin films prepared by r.f.

reactive sputtering. Surf Coat Technol 1998;1–3:166–70.

M. Manso et al. / Biomaterials 23 (2002) 349–356

356

Wyszukiwarka

Podobne podstrony:

Chemical Composition and in Vitro Antifungal Activity Screening

Apoptosis Induction, Cell Cycle Arrest and in Vitro Anticancer Activity

2001 In vitro fermentation characteristics of native and processed cereal grains and potato

Wheat bread enriched with green coffee – In vitro bioaccessibility and

The pathogenesis of Sh flexneri infection lessons from in vitro and in vivo studies

2000 Glucose Based Oligosaccharides Exhibit Different In Vitro Fermentation Patterns and Affect In V

in vitro, studia rolnictwo, rok IV

Kultury in vitro roslin rozmnazanie klonalne

In vitro antitumor actions of extracts

In vitro truskawka id 212540 Nieznany

1 1 Podstawowe definicje; główne kierunki przemian rozwojowych roślinnych tkanek in vitro(1)

53 755 765 Effect of Microstructural Homogenity on Mechanical and Thermal Fatique

Życie ludzkie świętość czy zabawka nt in vitro

Functional improvements desired by patients before and in the first year after total hip arthroplast

Screw mechanisms and joints

In vitro, Sem 1, TMR3

6 Hodowle komórek skóry w warunkach in vitro

więcej podobnych podstron