Compression Systems and Carburetor Troubleshooting:

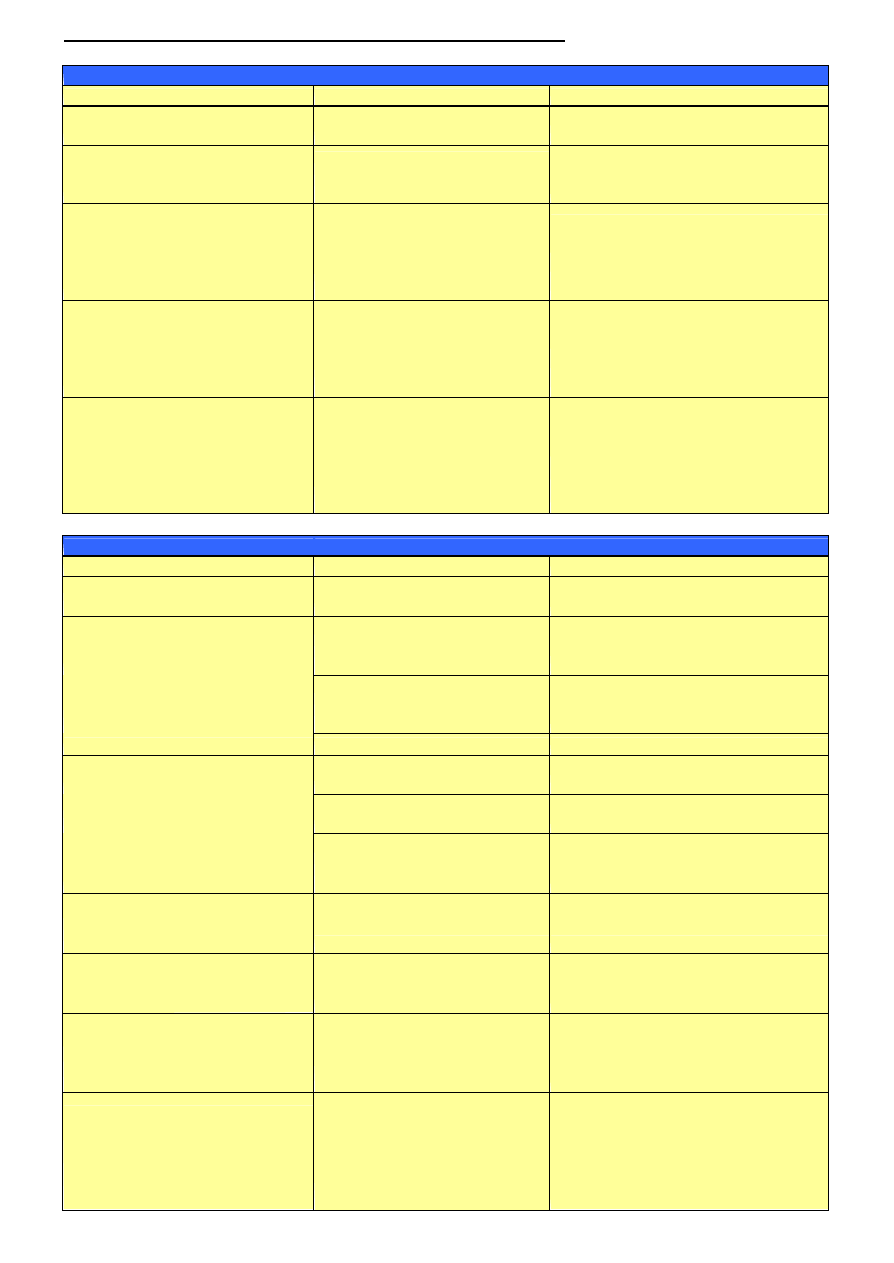

TROUBLESHOOTING COMPRESSION SYSTEMS

Problem prior to testing

Test Result

Solution

Lack of power or starting problem

Reading is green - minimal air flow

Investigate for other (non-compression)

problems

Lack of power or starting problem

Reading is green - minimal

(audible) air flow with small amount

coming through the head gasket

Replace head gasket

Lack of power or starting problem

Reading is green - all the air

escaping from one component

Check that the piston is at TDC on the

compression stroke, rotate 720°, lock the

crankshaft, and retest. If the reading is

correct, investigate the possible problem

with that component.

Lack of power or starting problem

Reading is red - all the air

escaping from one component

Check that the piston is at TDC on the

compression stroke, rotate 720°, lock the

crankshaft, and retest. If the reading is

correct, investigate the possible problem

with that component.

Lack of power or starting problem

Reading is red - the air escaping is

from several components

Check that the piston is at TDC on the

compression stroke, lock the crankshaft,

and retest. If the reading is correct,

investigate the possible problems starting

with the component that appeared to leak

the greatest volume of air.

CARBURETOR PROBLEM SOLVING CHART

Problem

Cause

Solution

Flo-Jet carburetor leaking after being

transported

Float bounce

Use the fuel shutoff valve

Fuel tank too far above carburetor

causing excessive pressure at the

needle valve

Lower the tank to a maximum of 45"

above the carburetor

Flo-Jet carburetor leaks during

operation

Loose, missing, incorrectly

assembled/adjusted, or damaged

parts

Correct parts problem

Contaminated fuel

Clean system/replace fuel

Long coast-down period

Lower engine speed to idle before

shutting down

Flo-Jet carburetor leaks shortly after

engine is shut OFF

Fuel leaking past main nozzle

Clean/replace emulsion tube/nozzle

Loose, missing, incorrectly

assembled/adjusted, or damaged

parts

Correct parts problem

Engine dies at idle, runs normal at

high speed-full load, but surges when

running at high speed-no load

Idle passage is blocked

Clean the passage

Engine runs normal at high speed

with or without load, but at idle it runs

rough with a rhythmic idle

Idle air bleed is blocked

Clean air bleed

Engine runs normal at high speed

and idle with no load, but at high

speed under load there is a severe

loss of power and the engine dies

High speed pick-up tube partially

blocked

Clean obstruction

At idle, engine is running slightly fast.

At high speed under load it is very

rich, blowing black smoke, and top

speed does not exceed 2200 rpm.

At top speed with no load it is also

slightly rich

High speed air bleed is partially

blocked

Clean obstruction

For Briggs & Stratton Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

Wyszukiwarka

Podobne podstrony:

Jvc Power Supply Description And Trouble Shooting Procedure

SHSBC024 RAW MEAT TROUBLE SHOOTING

Sevcon Powerpak trouble shooting guid 1

COMMON SPECIFICATIONS FOR BRIGGS & STRATTON ALL SINGLE CYLINDER OHV ENGINE MODELS EXCEPT INTEK MODEL

Storybook Reading Improving Vocabulary and Comprehension for English Language Learners

COMMON SPECIFICATIONS FOR BRIGGS & STRATTON VANGUARD OHV V TWIN CYLINDER ENGINE MODELS

Z1010 Trouble Shooting Guide

ignition wiring basic wiring diagram BRIGGS & STRATTON

COMMON SPECIFICATIONS FOR ALL BRIGGS & STRATTON TWIN CYLINDER ENGINE MODELS

trouble shooting

Q7T4 FP71G 99 L1C72 000 trouble shooting

RF Trouble Shooting V9vs V975 L3 1[1] 0 050427154852

46b D Jetronic Trouble Shooting

Motore Stirling Fabriquer un moteur Stirling à partir d un Briggs & Stratton

Dan Kennedy Advanced and Comprehensive Copywriting Bootcamp 2008 NOTES

COMMON SPECIFICATIONS FOR BRIGGS & STRATTON ALL SINGLE CYLINDER INTEK ENGINE MODELS

Check Chart common specs metric all BRIGGS & STRATTON engines

basic trouble shooting

więcej podobnych podstron