057RT–01

05–700

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

865

Author:

Date:

2004 COROLLA (RM1037U)

TOYOTA VEHICLE INTRUSION PROTECTION SYSTEM

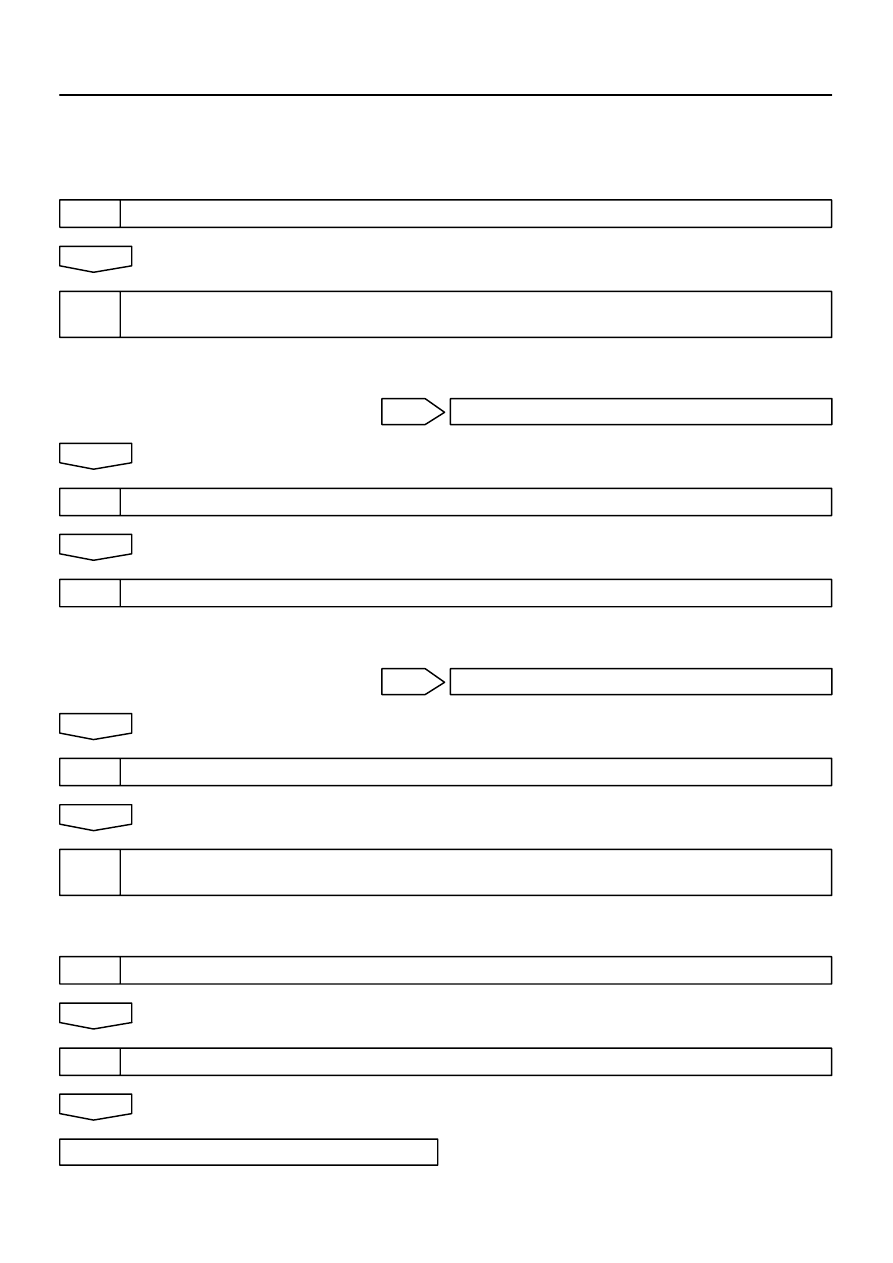

HOW TO PROCEED WITH TROUBLESHOOTING

Troubleshoot in accordance with the procedure on the following pages.

1

VEHICLE BROUGHT TO WORKSHOP

2

CUSTOMER PROBLEM ANALYSIS CHECK AND SYMPTOM CHECK

(See page

05–701

)

(a)

Without applicable symptoms, proceed to ”A”.

(b)

With applicable symptoms, proceed to ”B”.

B

Go to step 4

A

3

SYMPTOM SIMULATION

4

PROBLEM SYMPTOMS TABLE (See page

05–707

)

(a)

Without applicable symptoms, proceed to ”A”.

(b)

With applicable symptoms, proceed to ”B”.

B

Go to step 5

A

5

CIRCUIT INSPECTION AND PART INSPECTION (See page

05–707

)

6

PERFORM TROUBLESHOOTING IN THE FOLLOWING METHOD, DEPENDING ON

MALFUNCTION SYMPTOM

(a)

Terminals of ECU (Seepage

05–703

)

(b)

On–vehicle inspection (Seepage

73–14

)

7

ADJUSTMENT, REPAIR OR REPLACEMENT

8

CONFIRMATION TEST

END

057RU–01

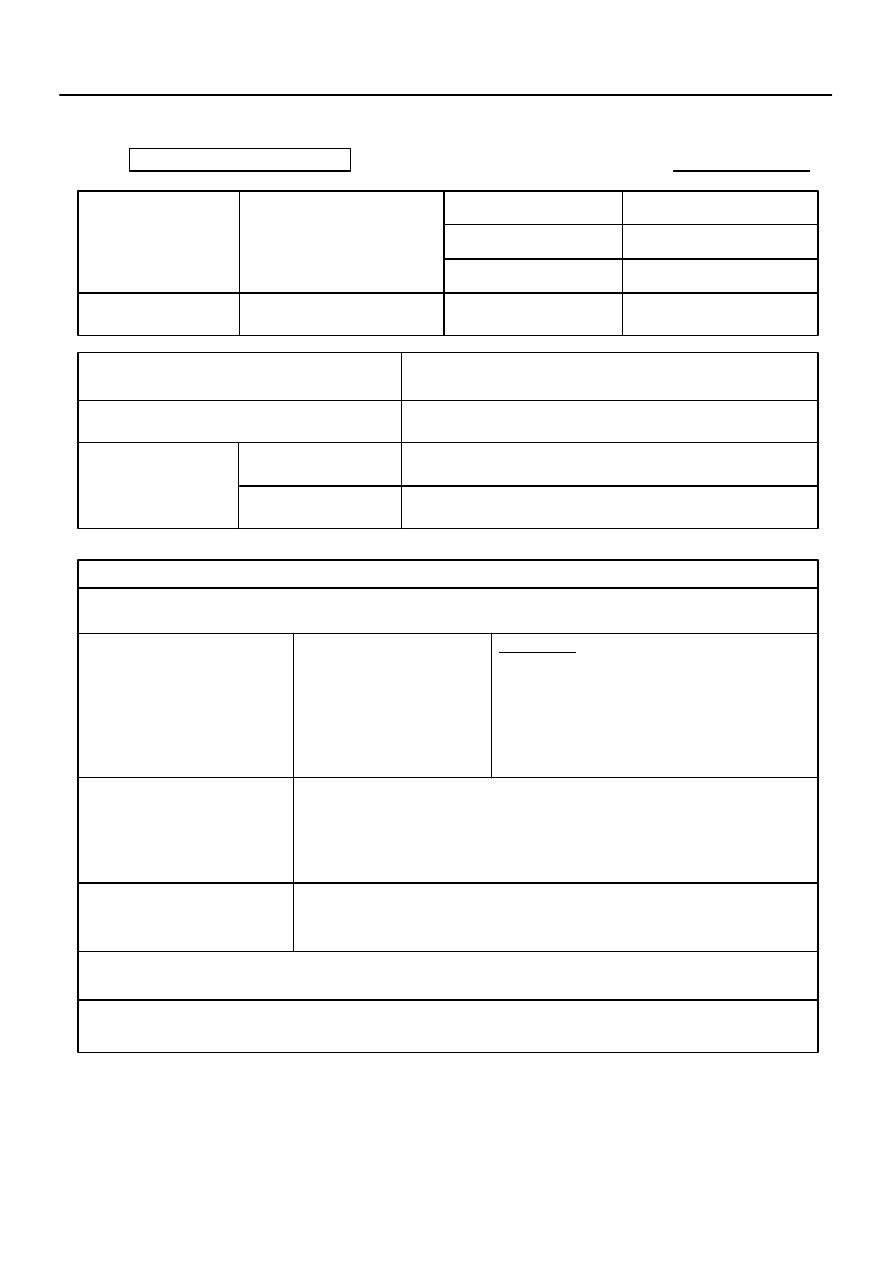

TVIP SYSTEM Check Sheet

Inspector’s name:

Customer’s Name

Date Vehicle

Registration No.

Registration Year

Frame No.

Odometer Reading

/ /

km

Mile

Weather Conditions

When Problem

Occurred

Frequency Problem Occurs

Weather

Outdoor temperature

/ /

Constant

Sometimes ( Times per day, month)

Once only

Brought in

TVIP system cannot be set.

Indicator light does not flash when the TVIP system is set.

(It stays on or does not light at all.)

TVIP system

does not operate.

When unlocked using the

front door lock knob.

When the doors or

luggage is opened.

System cannot be

canceled, once set.

When door is unlocked using key or wireless door lock control system.

When the key is inserted in the ignition key cylinder and turned to ACC or ON

position.

(However, only when the system has never operated)

System cannot be

canceled during warning

operation.

When door is unlocked using key or wireless door lock control system.

When the key is inserted in the ignition key cylinder and turned to ON

position.

Warning operation starts when the system is set and the door is opened with the key.

Others.

Date Problem First Occurred

Fine

Cloudy

Rainy

Snowy

Various/Others

Hot

Warm

Cool

Cold (Approx.

°

F (

°

C))

Problem Symptom

Malfunction

Horn only

Headlights only

Hazard lights only

Room light only

Forced door lock operation only

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–701

866

Author:

Date:

2004 COROLLA (RM1037U)

CUSTOMER PROBLEM ANALYSIS CHECK

057RV–01

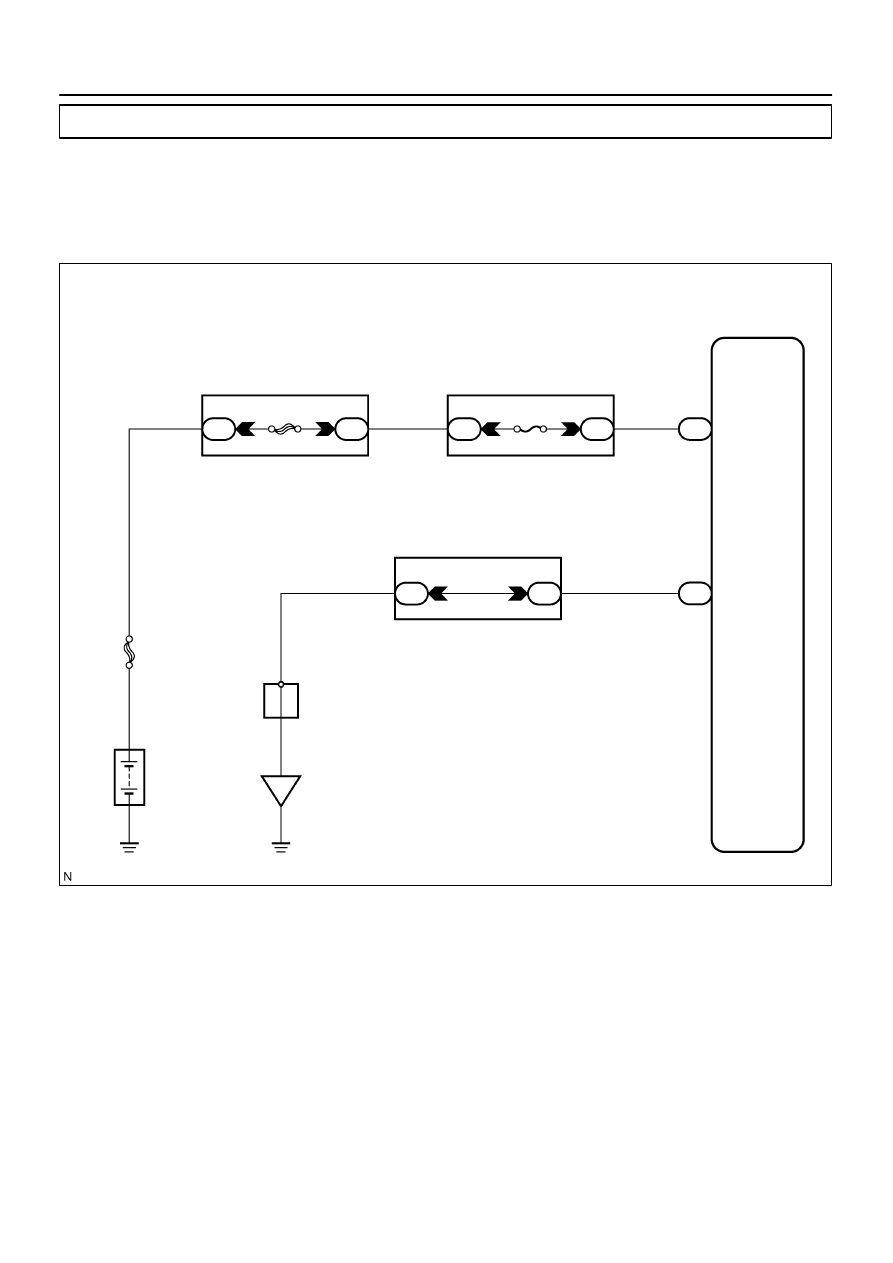

B58634

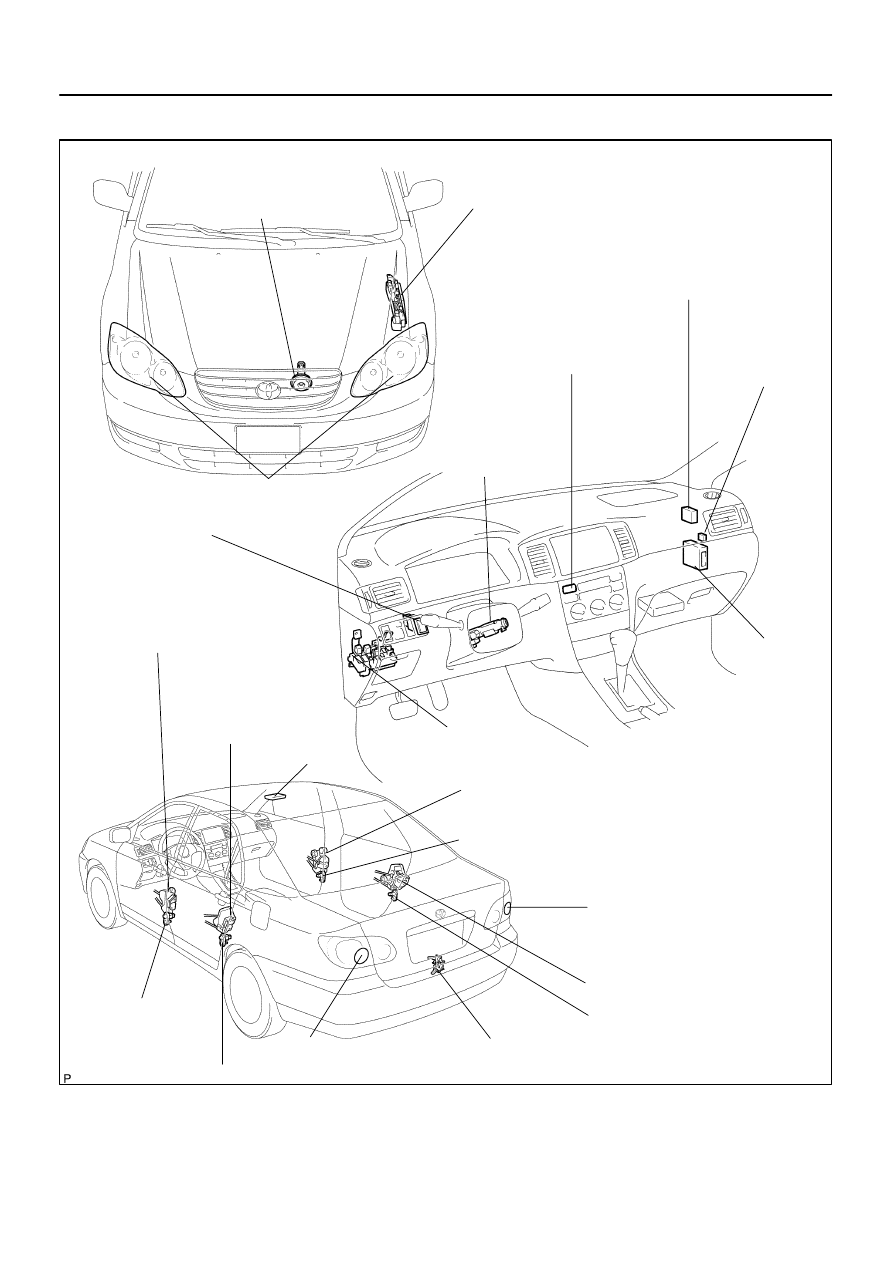

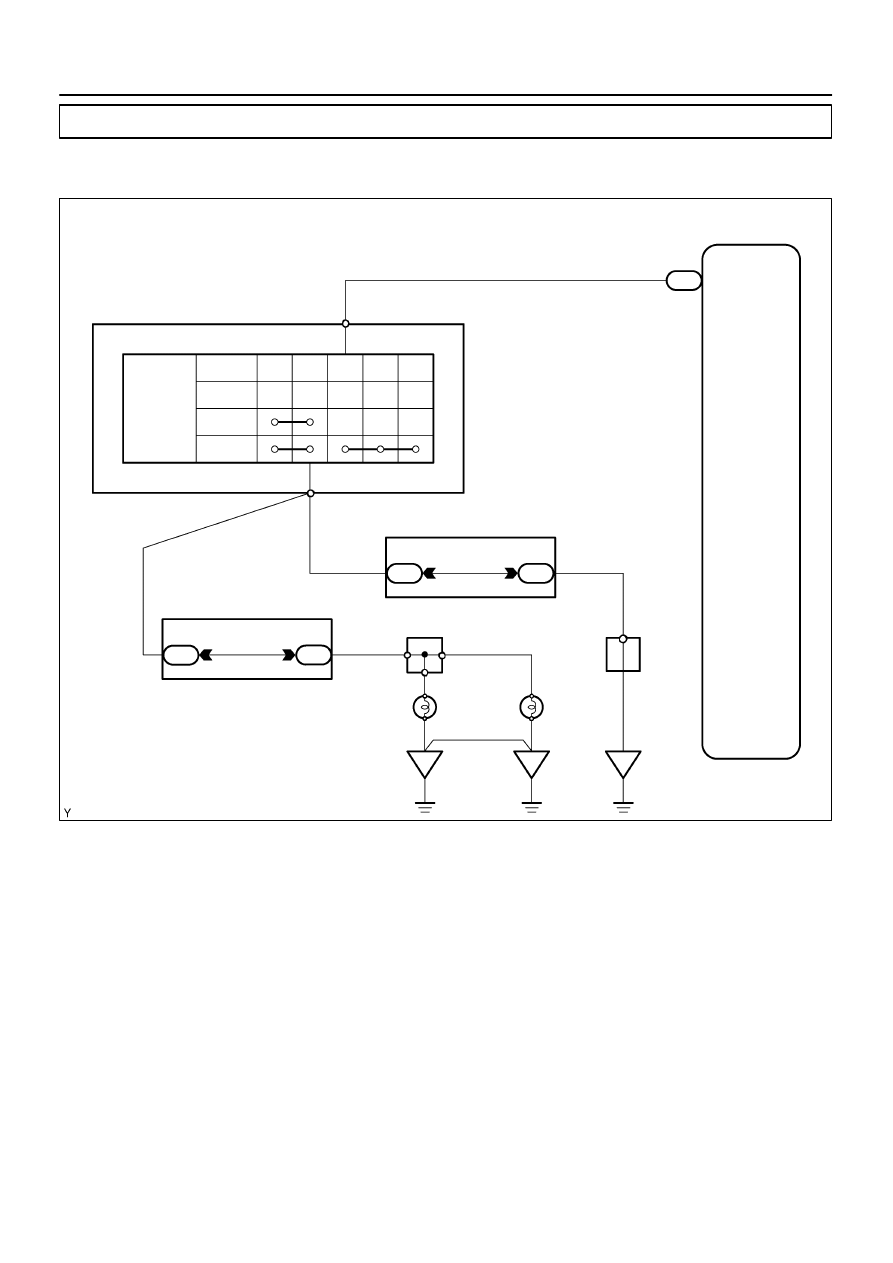

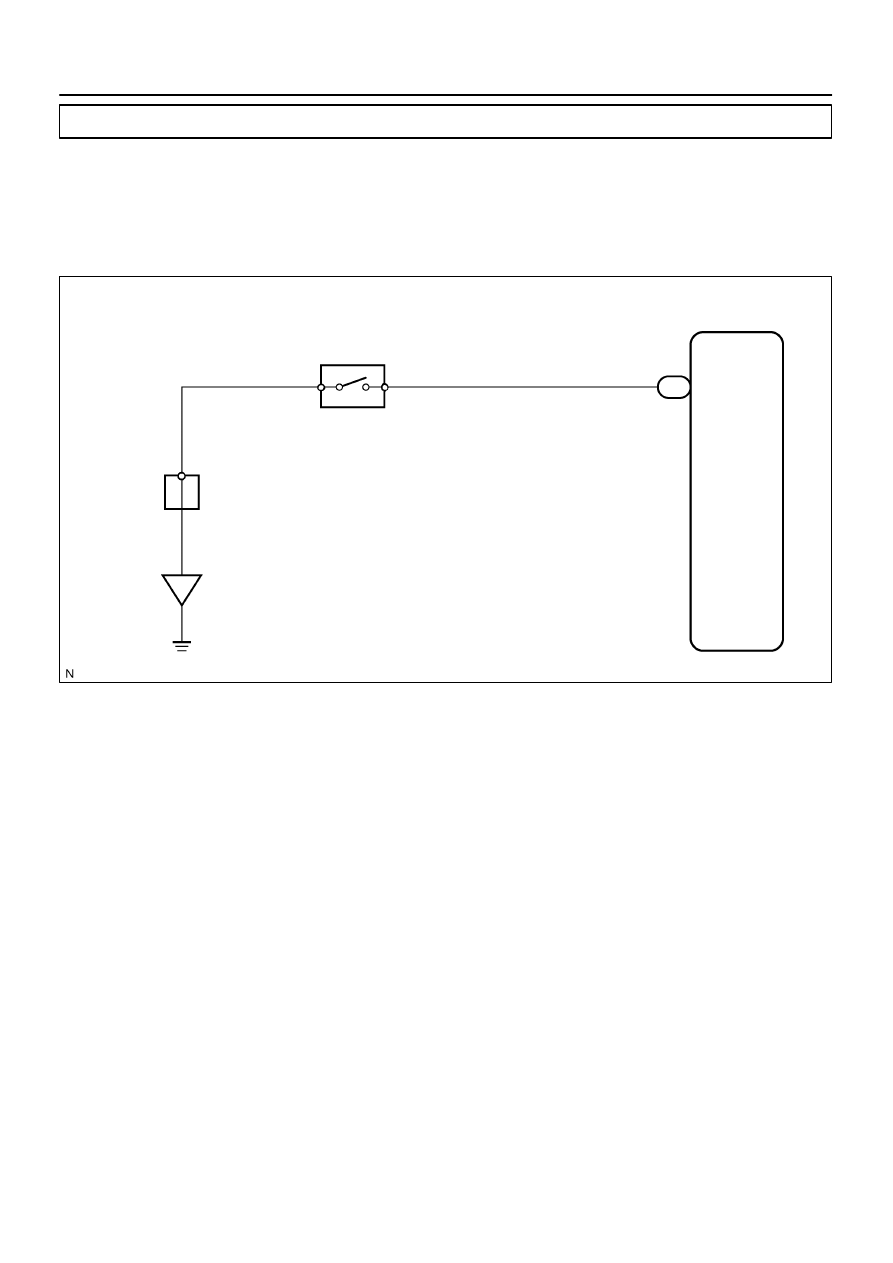

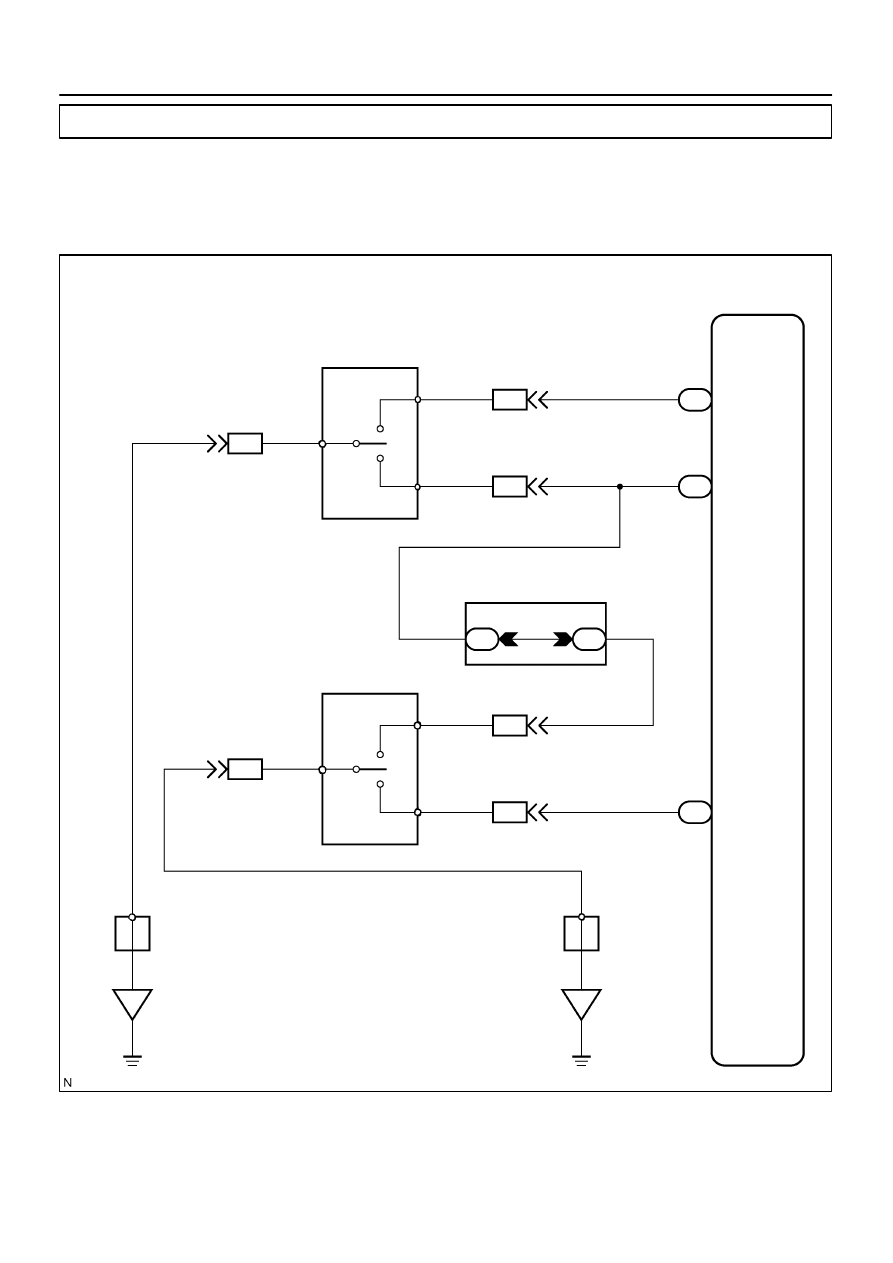

Horn Low Pitched Horn Assy (Horn)

Engine Room J/B

HORN Fuse

HORN Relay

Headlight Control Relay

Headlight

TVIP ECU

Ignition Switch

Key Unlock

Warning Switch

Security Indicator

(w/ Glass Breakage Sensor)

Starter Cut Relay

Glass Breakage Sensor ECU

Instrument Panel J/B

(Integration Relay)

Front Door w/ Motor Lock Assy LH

(Door Unlock Detection Switch)

Luggage Door Lock Assy

(Luggage Compartment Light Switch)

Hazard Warning Light

Room Light

Courtesy Lamp Switch

Assy Front LH

Front Door w/ Motor Lock Assy RH

(Door Unlock Detection Switch)

Rear Door w/ Motor

Lock Assy RH

Courtesy Lamp Switch Assy Front RH

Courtesy Lamp Switch Assy Rear LH

Hazard Warning Signal Switch

Courtesy Lamp Switch Assy Rear RH

Hazard Warning Light

Rear Door w/ Motor

Lock Assy LH

05–702

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

867

Author:

Date:

2004 COROLLA (RM1037U)

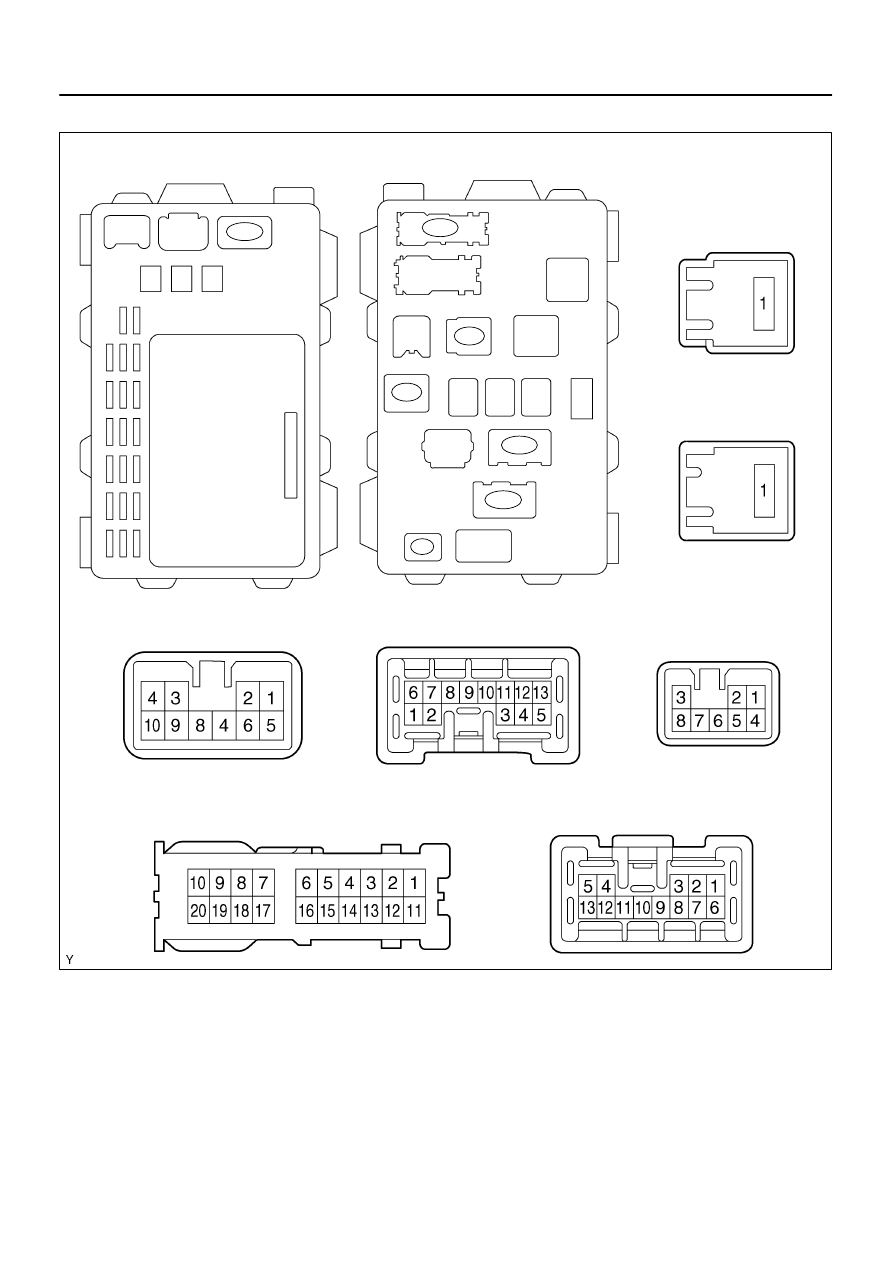

LOCATION

057RW–01

B50657

T3

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–703

868

Author:

Date:

2004 COROLLA (RM1037U)

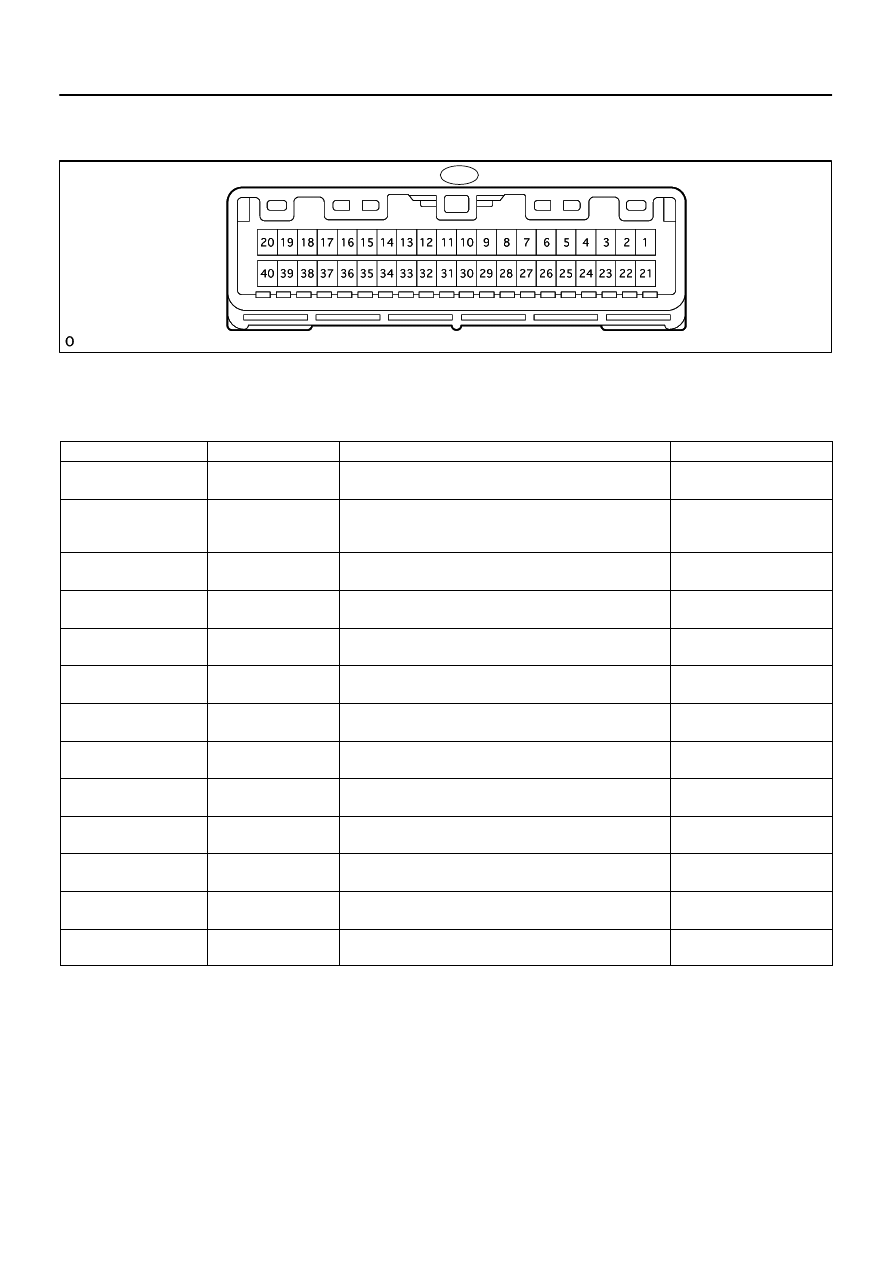

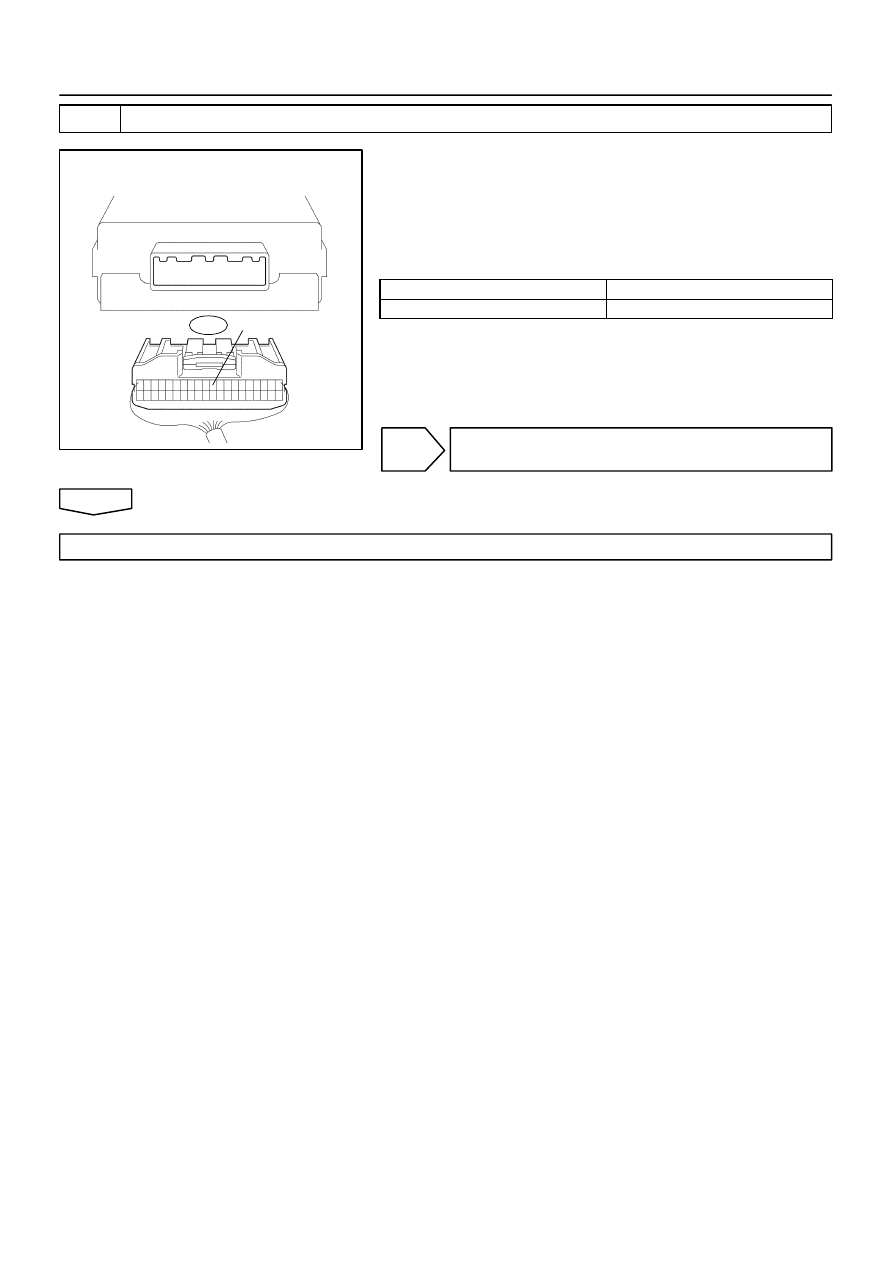

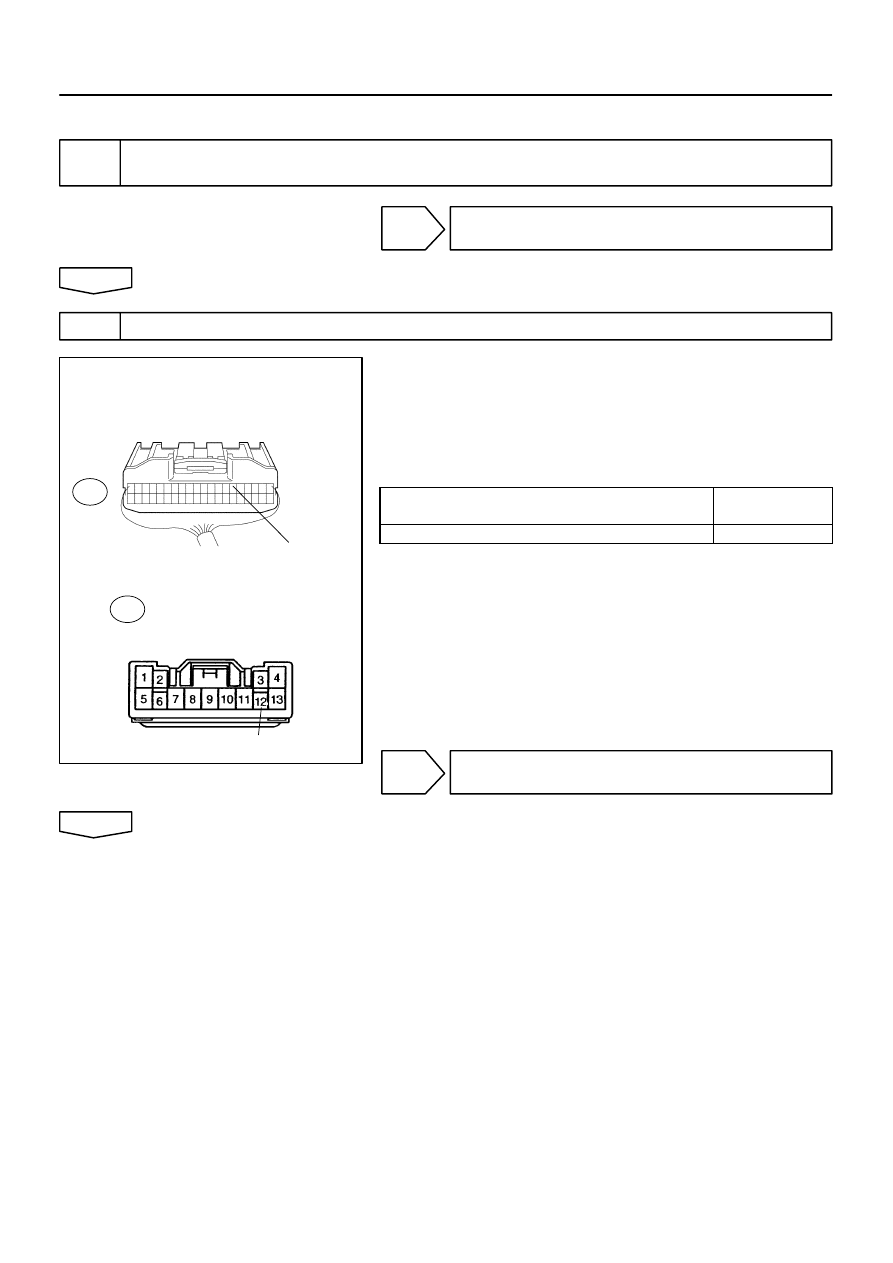

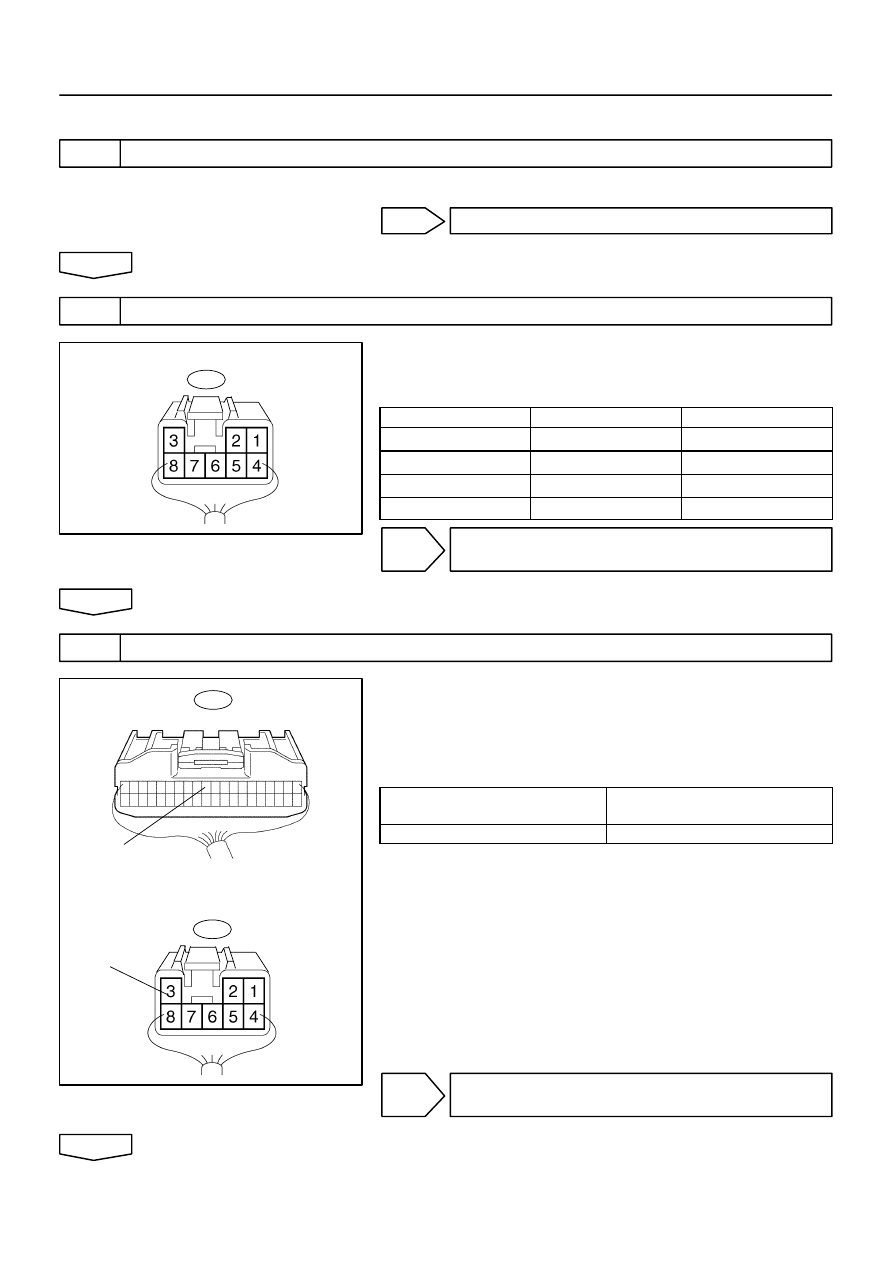

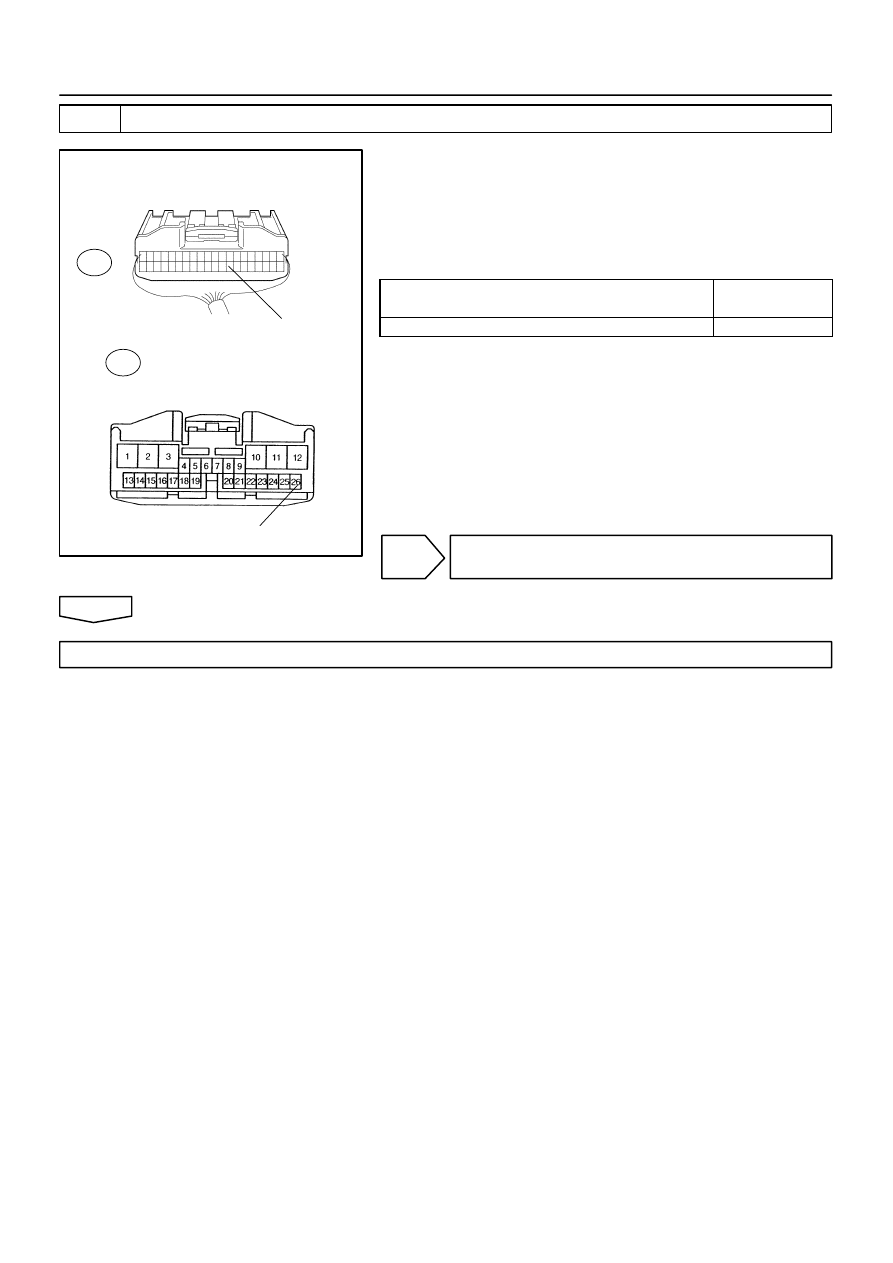

TERMINALS OF ECU

1.

INSPECT TVIP ECU

(a)

Inspect the ECU–B, DOME and ECU–IG fuses.

(b)

Disconnect the TVIP ECU connector, and the continuity and voltage of check each terminal of the dis-

connected connector.

Standard:

Symbols (Terminal No.)

Wiring Color

Condition

Specified Condition

+B1 (T3–2)

⇔

E (T3–29)

R–B

⇔

W–B

Constant

10 – 14 V

CTY (T3–19)

⇔

E (T3–29)

R

⇔

W–B

Passenger’s door fully closed

→

Opened

Rear right door fully closed

→

Opened

Rear left door fully closed

→

Opened

No continuity

→

Continuity

DSWD (T3–40)

⇔

E (T3–29)

R–W

⇔

W–B

Driver’s door fully closed

→

Opened

No continuity

→

Continuity

DSWL (T3–35)

⇔

E (T3–29)

R–W

⇔

W–B

Luggage’s door fully closed

→

Opened

No continuity

→

Continuity

KSW (T3–12)

⇔

E (T3–29)

L–B

⇔

W–B

No key in ignition switch lock cylinder

→

Key inserted

0 V

→

10 – 14 V

L2 (T3–16)

⇔

E (T3–29)

G

⇔

W–B

Driver’s door lock UNLOCK

→

LOCK

0 V

→

10 – 14 V

→

1 V or less

UL3 (T3–17)

⇔

E (T3–29)

L–Y

⇔

W–B

Driver’s door lock LOCK

→

UNLOCK

0 V

→

10 – 14 V

→

1 V or less

UL2 (T3–18)

⇔

E (T3–29)

L–B

⇔

W–B

Passenger’s door lock LOCK

→

UNLOCK

0 V

→

10 – 14 V

→

1 V or less

IRSG (T3–28)

⇔

E (T3–29)

W

⇔

W–B

Driver’s door lock LOCK

→

UNLOCK

Pulse generation

IG (T3–10)

⇔

E (T3–29)

B–W

⇔

W–B

Ignition switch OFF

→

ON

0 V

→

10 – 14 V

SRLY (T3–21)

⇔

E (T3–29)

B–R

⇔

W–B

Ignition switch OFF

→

ON

0 V

→

10 – 14 V

LSWD (T3–37)

⇔

E (T3–29)

W

⇔

W–B

Driver’s door lock UNLOCK

→

LOCK

0 V

→

10 – 14 V

LSWP (T3–38)

⇔

E (T3–29)

W–R

⇔

W–B

Passenger’s door lock UNLOCK

→

LOCK

0 V

→

10 – 14 V

If the result is not as specified, the vehicle’s side may malfunction.

B57790

Integration Relay Connector

(Wire Harness Side)

I11

05–704

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

869

Author:

Date:

2004 COROLLA (RM1037U)

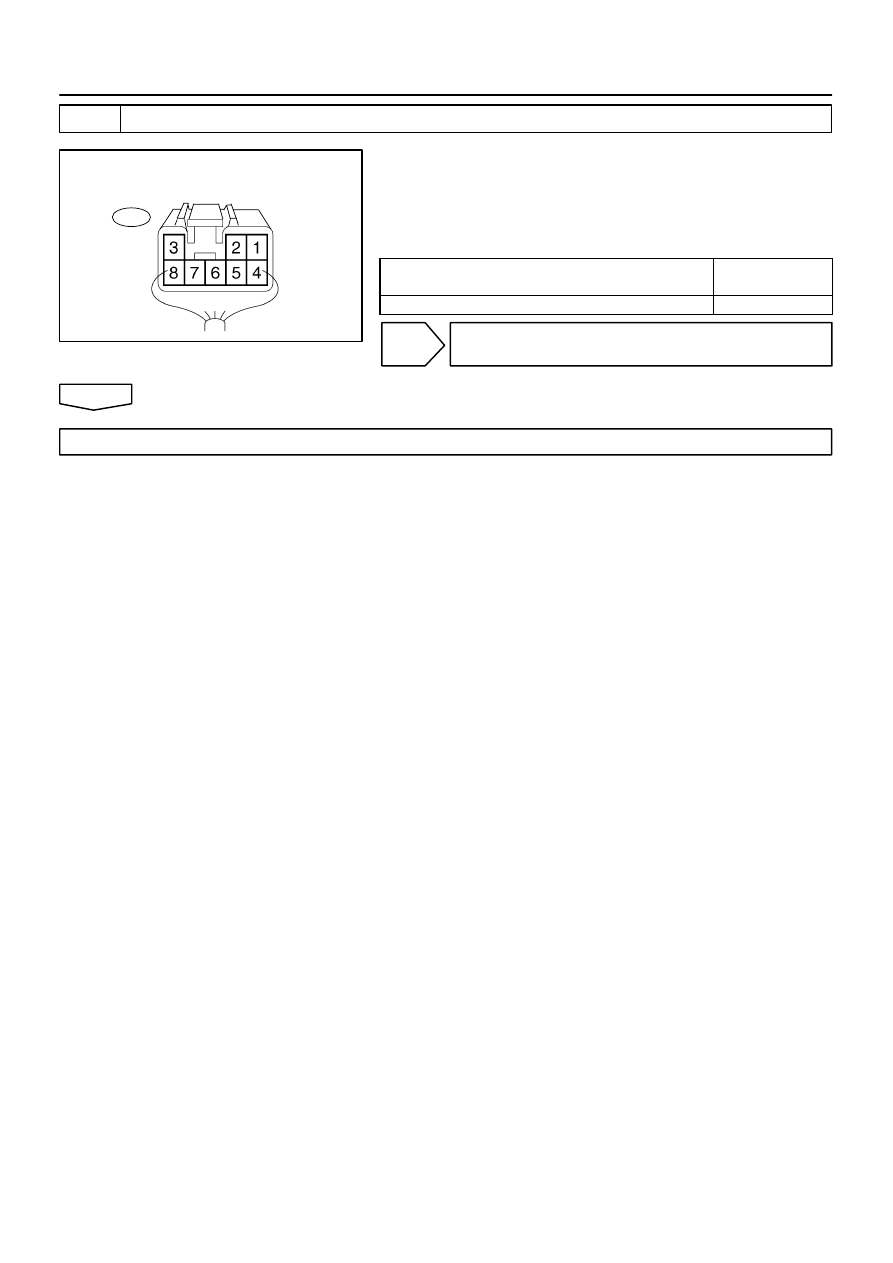

(c)

Reconnect the TVIP ECU connector, and the continuity and voltage of check each terminal of the dis-

connected connector.

Standard:

Symbols (Terminal No.)

Wiring Color

Condition

Specified Condition

DMLP (T3–9)

⇔

E (T3–29)

R–W

⇔

W–B

Armed state

→

Alarm sounding state

Pulse generation

HEAD (T3–6)

⇔

E (T3–29)

R

⇔

W–B

Light control switch position HEAD

→

OFF or TAIL

1 V or less

→

10 – 14 V

HAZD (T3–8)

⇔

E (T3–29)

Y–B

⇔

W–B

Armed state

→

Alarm sounding state

Pulse generation

IND (T3–25)

⇔

E (T3–29)

R–W

⇔

W–B

Security indicator light lights up.

(It lights up only for 30 sec.)

10 – 14 V

IOUT (T3–11)

⇔

E (T3–29)

L

⇔

W–B

Armed state

→

Alarm sounding state (on grass breakage detection)

Pulse generation

HORN (T3–5)

⇔

E (T3–29)

G–Y

⇔

W–B

Armed state

→

Alarm sounding state

Pulse generation

E (T3–29)

⇔

Body ground

W–B

⇔

Body ground

Constant

Continuity

If the result is not as specified, the TVIP ECU may malfunction.

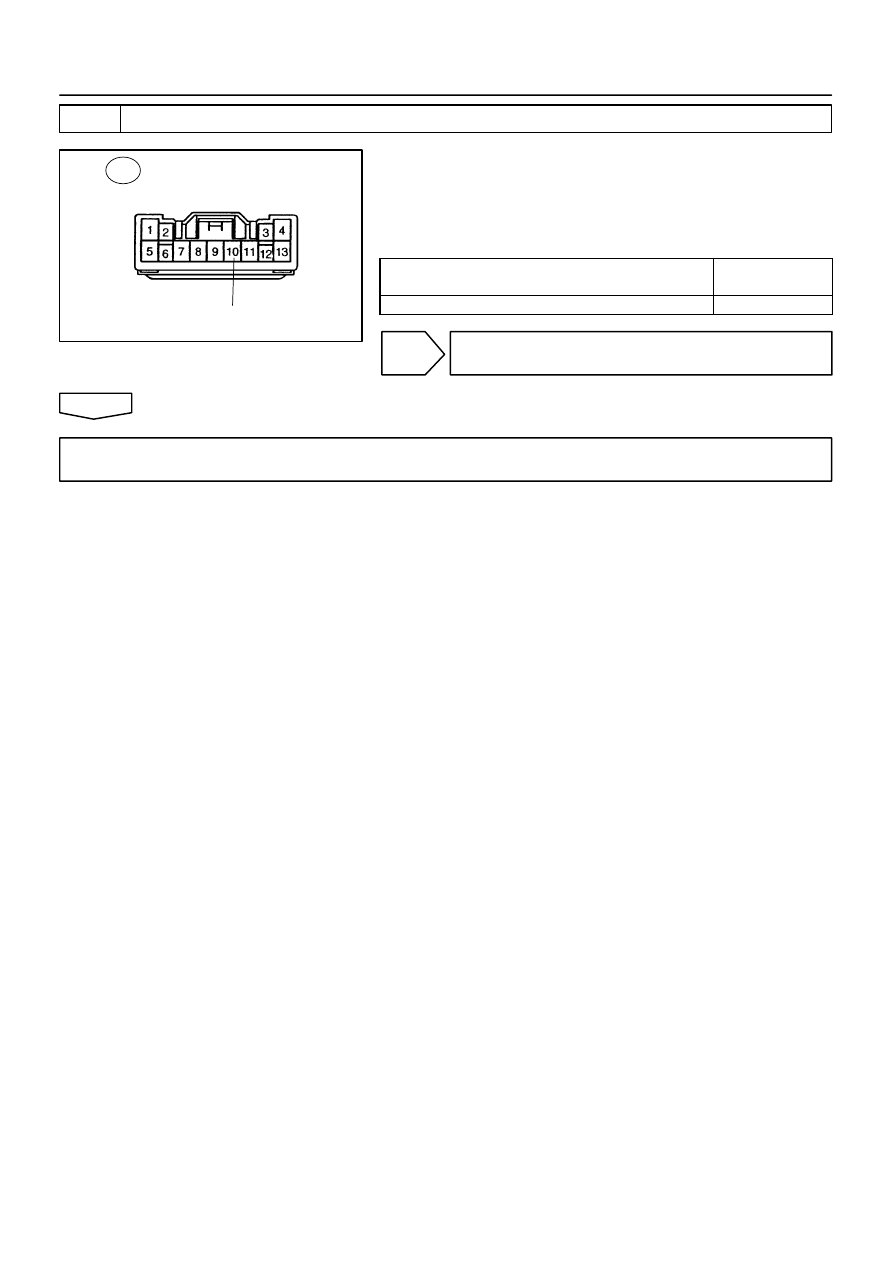

2.

INSPECT INTEGRATION RELAY

(a)

Disconnect the connector and check the continuity of each terminal of the disconnected connector.

Symbols (Terminal No.)

Wiring color

Condition

Specified Condition

PCTY (I11–13)

⇔

Body ground

R–W

⇔

Body ground

Passenger’s door fully closed

→

Opened

No continuity

→

Continuity

If the result is not as specified, the vehicle’s side may malfunction.

B59376

B59378

B59532

Instrument Panel J/B Side

IF

Instrument Panel J/B (Integration Relay)

ID

IH

IJ

Instrument Panel J/B Side

Instrument Panel J/B Side

Instrument Panel J/B Side

Connector IF

Connector ID

Connector IH

Connector IJ

IK

Instrument Panel J/B Side

Connector IK

Instrument Panel J/B Side

Connector IA

IA

IB

Instrument Panel J/B Side

Connector IB

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–705

870

Author:

Date:

2004 COROLLA (RM1037U)

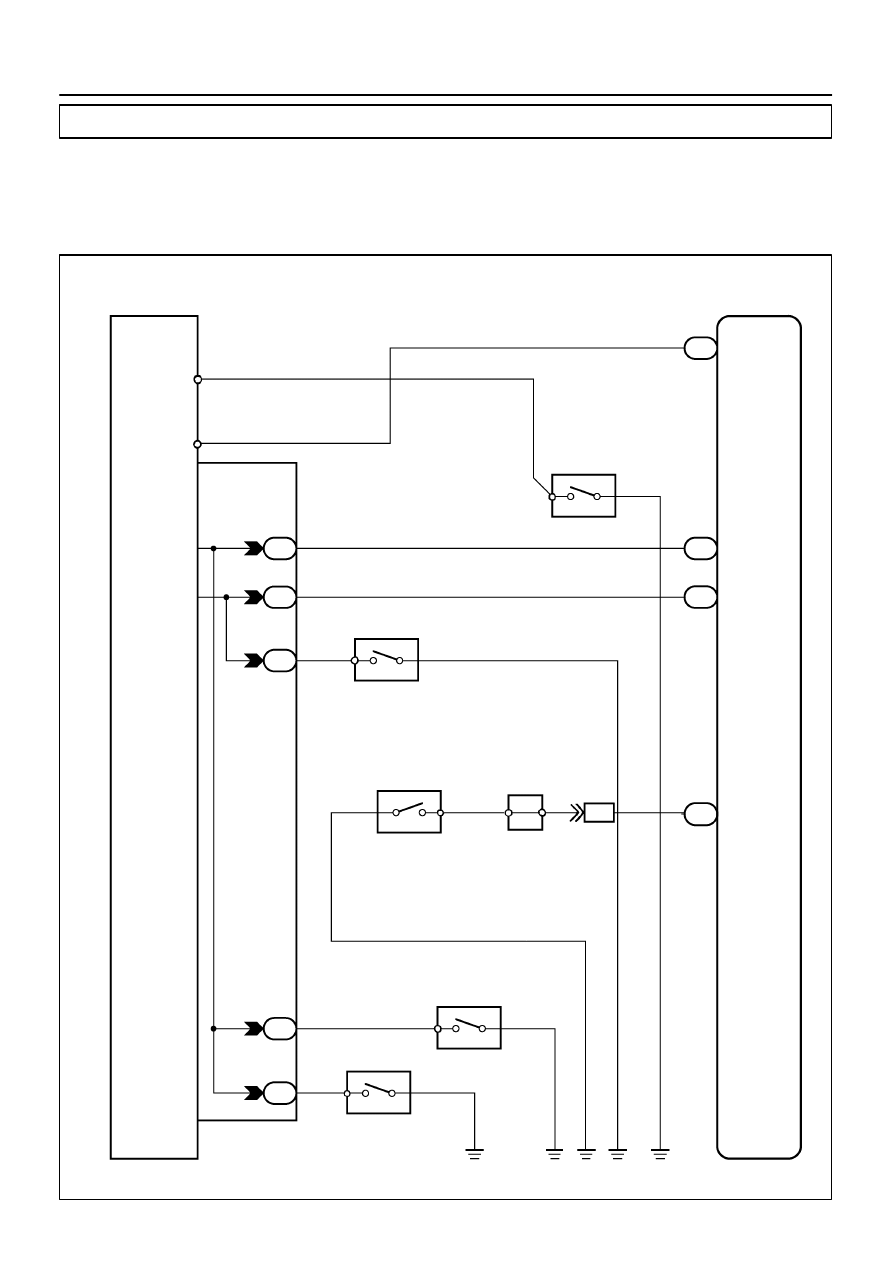

3.

INSPECT INSTRUMENT PANEL J/B (INTEGRATION RELAY)

05–706

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

871

Author:

Date:

2004 COROLLA (RM1037U)

(a)

Inspect the DOOR fuse.

(b)

Disconnect the ID connector of the instrument panel J/B, and check the continuity of each terminal of

the disconnected connectors.

Standard:

Symbols (Terminal No.)

Wiring color

Condition

Specified Condition

DCTY (ID–1)

⇔

Body ground

R–W

⇔

Body ground

Driver’s door fully closed

→

Opened

PRCTY (ID–14)

⇔

Body ground

R–B

⇔

Body ground

Rear LH door fully closed

→

Opened

No continuity

→

Continuity

PRCTY (ID–15)

⇔

Body ground

R–Y

⇔

Body ground

Rear RH door fully closed

→

Opened

If the result is not as specified, the vehicle’s side may malfunction.

057RX–01

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–707

872

Author:

Date:

2004 COROLLA (RM1037U)

PROBLEM SYMPTOMS TABLE

Proceed to the reference page shown in the table below for each malfunction symptom and troubleshoot

each circuit.

HINT:

Troubleshooting of the TVIP system is based on the premise that the door lock control system and wireless

door lock control system is operating normally. Accordingly, before troubleshooting the TVIP system, first

make certain that the door lock control system and wireless door lock control system is operating normally.

Symptom

Suspected Area

See page

TVIP system cannot be set

1. Indicator light circuit

2. ECU power source circuit

3. Key unlock warning switch circuit

4. Door key lock and unlock switch circuit

5. Door unlock detection switch circuit

6. Door courtesy switch circuit

7. TVIP ECU communication circuit

05–708

05–710

05–727

05–738

05–736

05–733

05–740

Indicator light does not blink when TVIP system is set.

1. Indicator light circuit

05–708

TVIP system does not operate when front door is unlocked (when

TVIP system is set).

1. Door unlock detection switch circuit

05–736

TVIP system is not canceled when ignition key is turned to ON

position (when TVIP system is set).

1. Ignition switch circuit

2. Key unlock warning switch circuit

05–713

05–727

TVIP system still operates when door is opened with key (when

TVIP system is set).

1. Door key lock and unlock switch circuit

2. Door unlock detection switch circuit

05–738

05–736

Horns do not sound while TVIP system is in warning operation.

1. Horn relay circuit

05–716

Headlights do not flash while TVIP system is in warning

operation.

1. Light control switch circuit

05–719

Hazard warning do not flash while TVIP system is in warning

operation.

1. Hazard warning switch circuit

05–722

Door is not locked while TVIP system is in warning operation.

1. Door unlock detection switch circuit

05–736

TVIP system is still set even when rear door is open

1. Door courtesy switch circuit

05–733

Horns sound even when TVIP system is not set.

1. Horn relay circuit

05–716

Headlights stay on even when TVIP system is not set.

1. Light control switch circuit

05–719

Hazard warning stays on even when TVIP system is not set.

1. Hazard warning switch circuit

05–722

B59175

TVIP ECU

IND

25

3A

W–B

T3

IND

GND

R–W

J7

J/C

RH J/B

19

11

A

IG

2

1

S4

Security Indicator

W–B

3A

B59187

Security Indicator

05–708

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

873

Author:

Date:

2004 COROLLA (RM1037U)

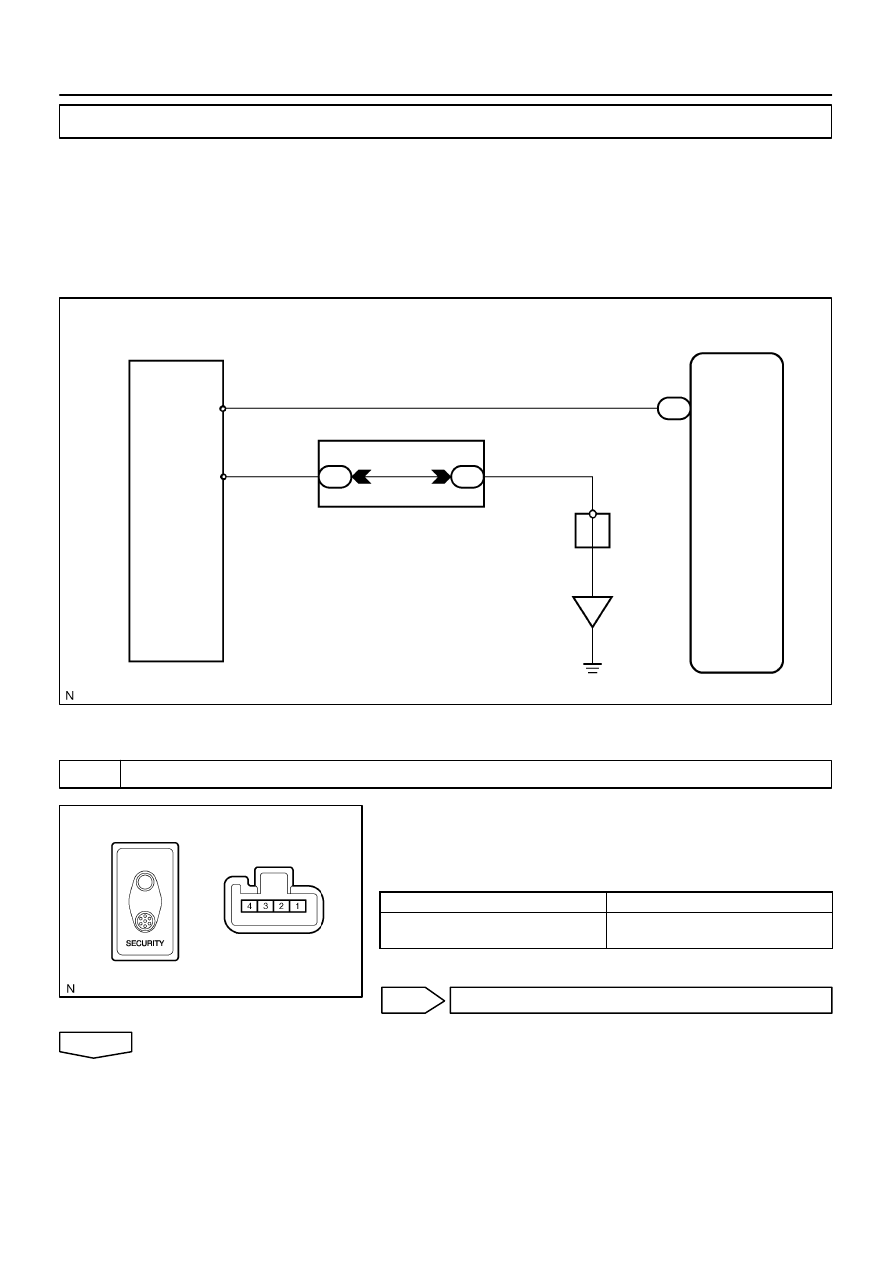

INDICATOR LIGHT CIRCUIT

CIRCUIT DESCRIPTION

When the TVIP system is preparing to be set, this circuit lights up the indicator light. When the system has

been set, it continually turns the indicator light on for 0.2 seconds and turns it off for 1.8 seconds, thus the

indicator light blinks.

WIRING DIAGRAM

INSPECTION PROCEDURE

1

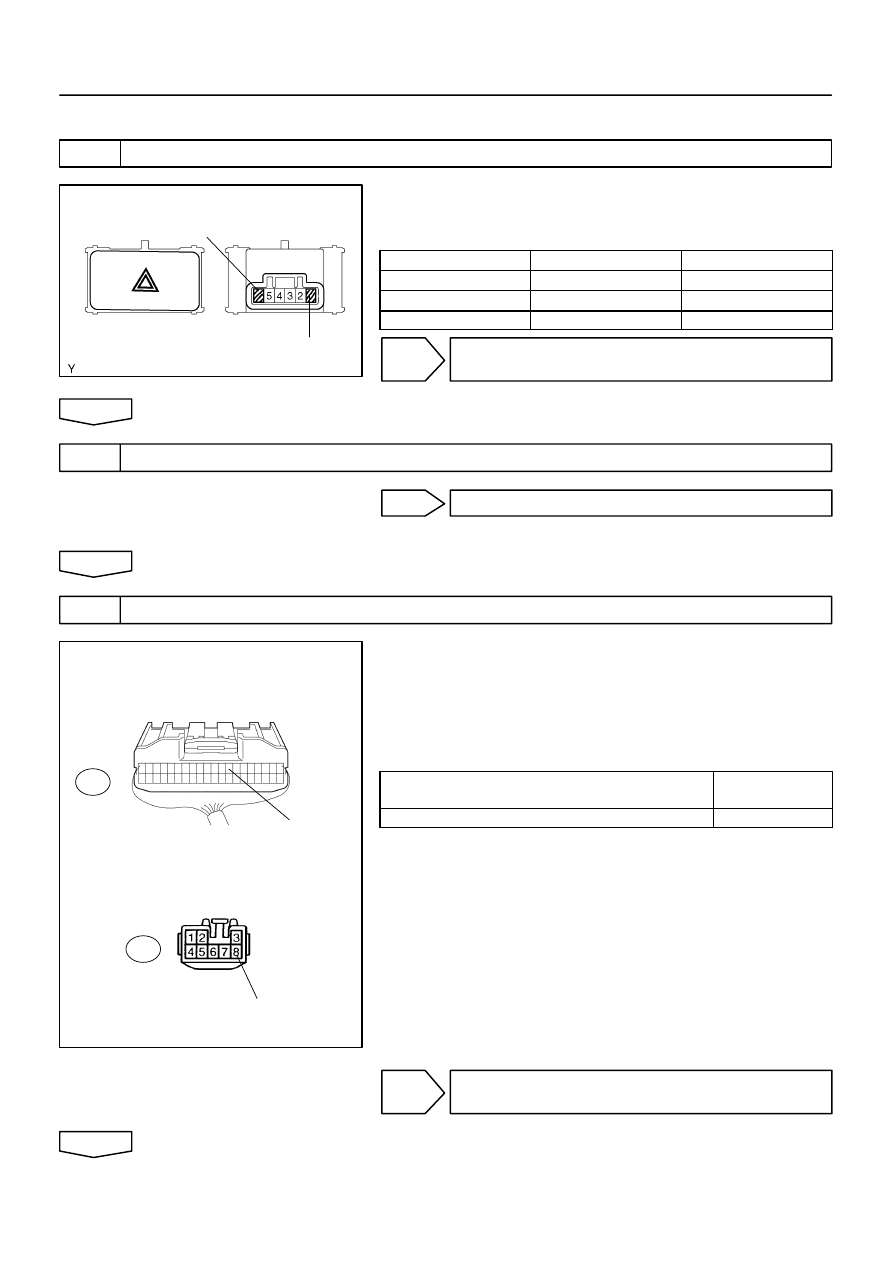

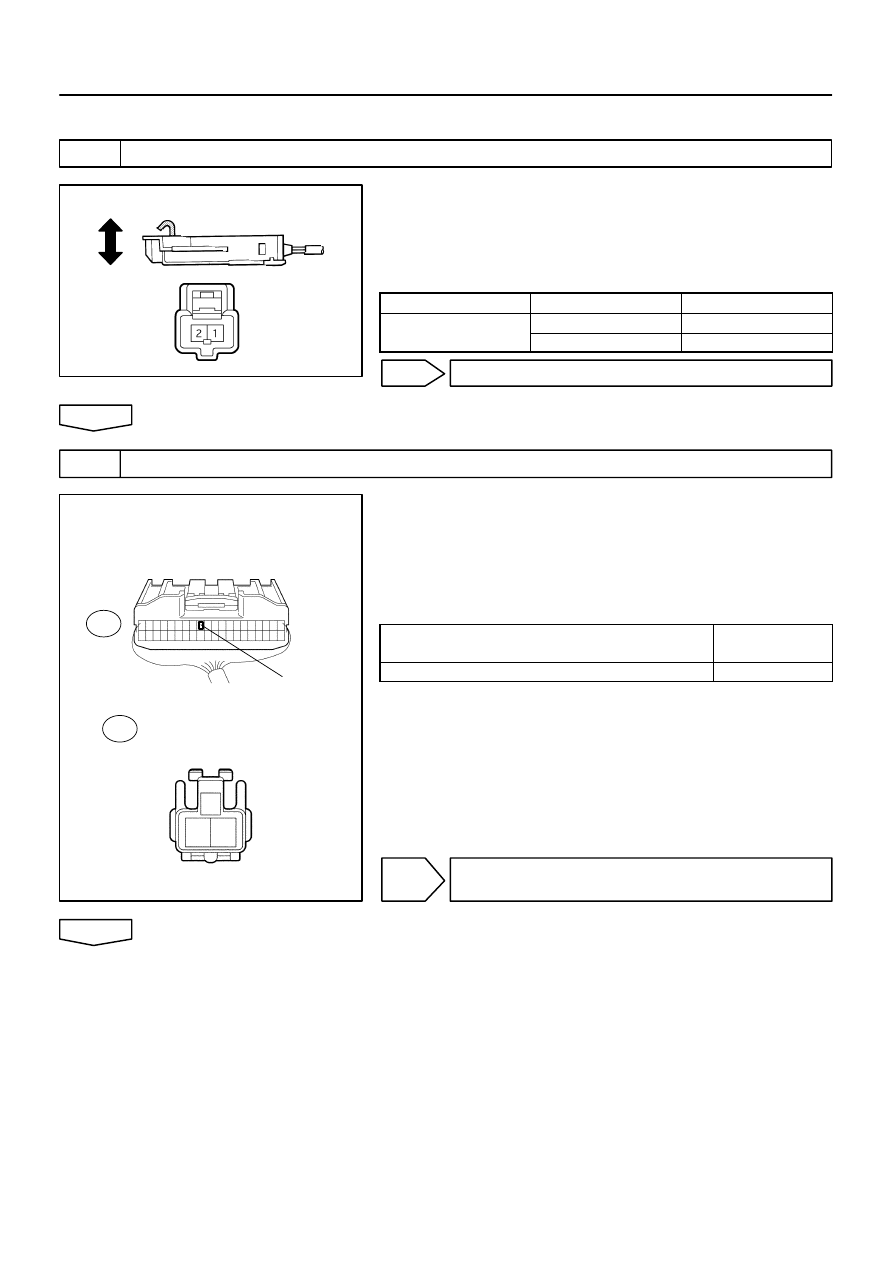

CHECK SECURITY INDICATOR LIGHT

(a)

Remove the security indicator.

(b)

Check the indicator light, as shown in the illustration and

table.

Standard:

Measuring condition

Operation

Battery positive (+)

⇔

Terminal 2

Battery negative (–)

⇔

Terminal 1

Indicator light comes on

NG

REPLACE SECURITY INDICATOR LIGHT

OK

057RY–01

B52239

B59192

B59594

Security Indicator

TVIP ECU

(Wire Harness Side)

T3

S4

(Wire Harness Side)

IND

IND (T3–25)

B59192

Security Indicator

S4

(Wire Harness Side)

GND

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–709

874

Author:

Date:

2004 COROLLA (RM1037U)

2

CHECK WIRE HARNESS (TVIP ECU

⇔

SECURITY INDICATOR)

(a)

Disconnect the TVIP ECU and security indicator connec-

tors.

(b)

Check the continuity between the terminals of the TVIP

ECU connector and security indicator connector, as

shown in the illustration and table.

Standard:

Symbols (Terminal No.)

(TVIP ECU

⇔

Security indicator)

Specified condition

IND (T3–25)

⇔

IND (S4–2)

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

3

CHECK WIRE HARNESS (SECURITY INDICATOR

⇔

BODY GROUND)

(a)

Disconnect the security indicator connector.

(b)

Check the continuity between the terminal of the security

indicator connector and body ground, as shown in the il-

lustration and table.

Standard:

Symbol (Terminal No.)

(Security indicator

⇔

Body ground)

Specified condition

GND (S4–1)

⇔

Body ground

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

CHECK AND REPLACE TVIP ECU (See page

01–30

)

I24315

B59176

TVIP ECU

+B1

E

FL MAIN

Battery

2

29

W

Engine Room J/B

RH J/B

W–B

B

1

1A

1

1C

ALT

1

2

1

IB

1

IH

ECU–B

Instrument Panel J/B

R–B

T3

T3

11

3A

19

3A

W–B

A

IG

J7

J/C

05–710

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

875

Author:

Date:

2004 COROLLA (RM1037U)

ECU POWER SOURCE CIRCUIT

CIRCUIT DESCRIPTION

This circuit provides power to operate the TVIP ECU.

WIRING DIAGRAM

057RZ–02

I24329

ECU–B Fuse

Instrument Panel J/B

B52239

+B1 (2)

T3

E (29)

TVIP ECU

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–711

876

Author:

Date:

2004 COROLLA (RM1037U)

INSPECTION PROCEDURE

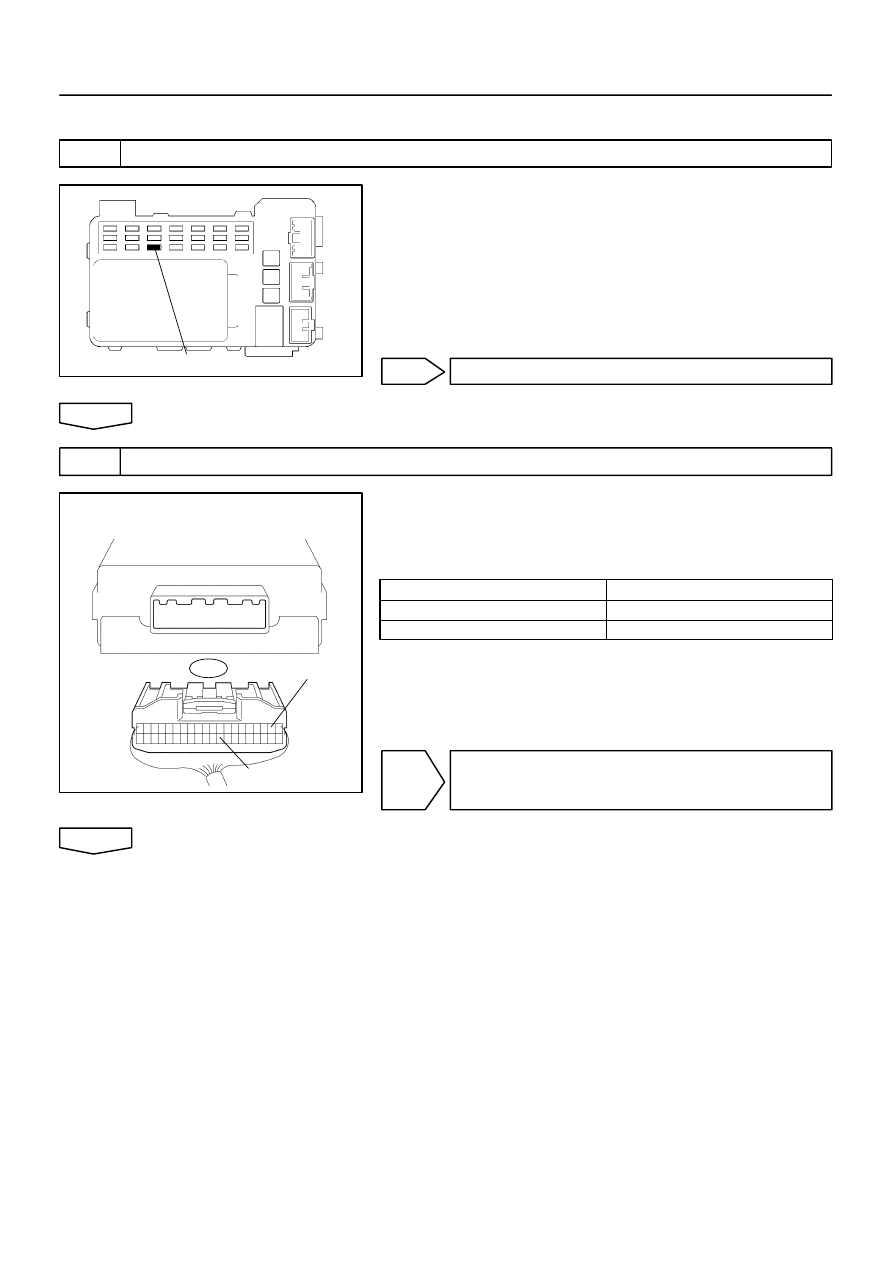

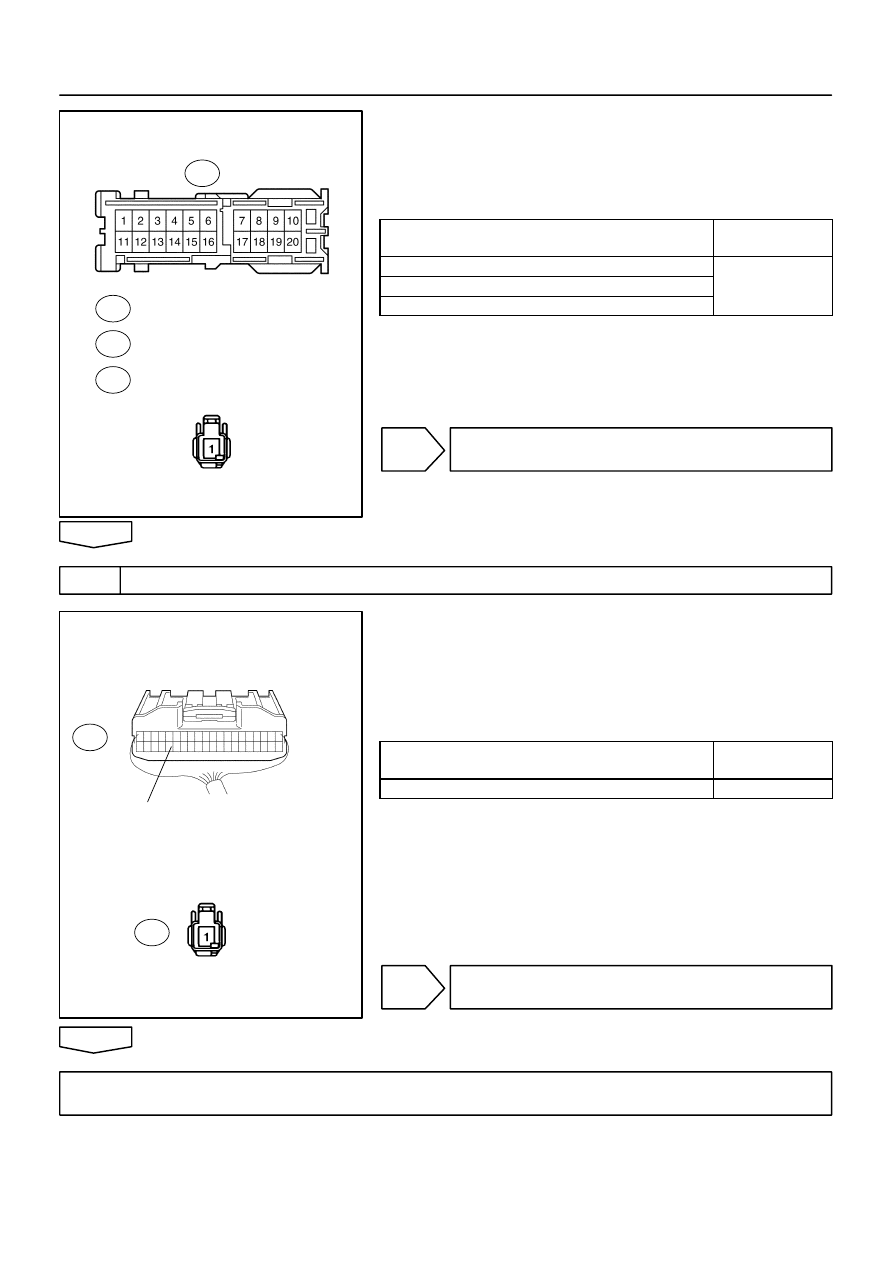

1

CHECK FUSE (ECU–B)

(a)

Remove the fuse from the instrument panel J/B.

(b)

Check the continuity of the fuse.

Standard: Continuity

NG

REPLACE FUSE

OK

2

CHECK TVIP ECU

(a)

Disconnect the TVIP ECU connector.

(b)

Measure the voltage between the terminals of the ECU

connector, as shown in the illustration and table.

Standard:

Symbols (Terminal No.)

Specified condition

+B1 (T3–2)

⇔

E (T3–29)

10 – 14 V

E (T3–29)

⇔

Body ground

0 V

NG

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN ON PROBLEM SYMPTOMS TABLE

(See page

05–707

)

OK

B52239

T3

E (29)

TVIP ECU

05–712

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

877

Author:

Date:

2004 COROLLA (RM1037U)

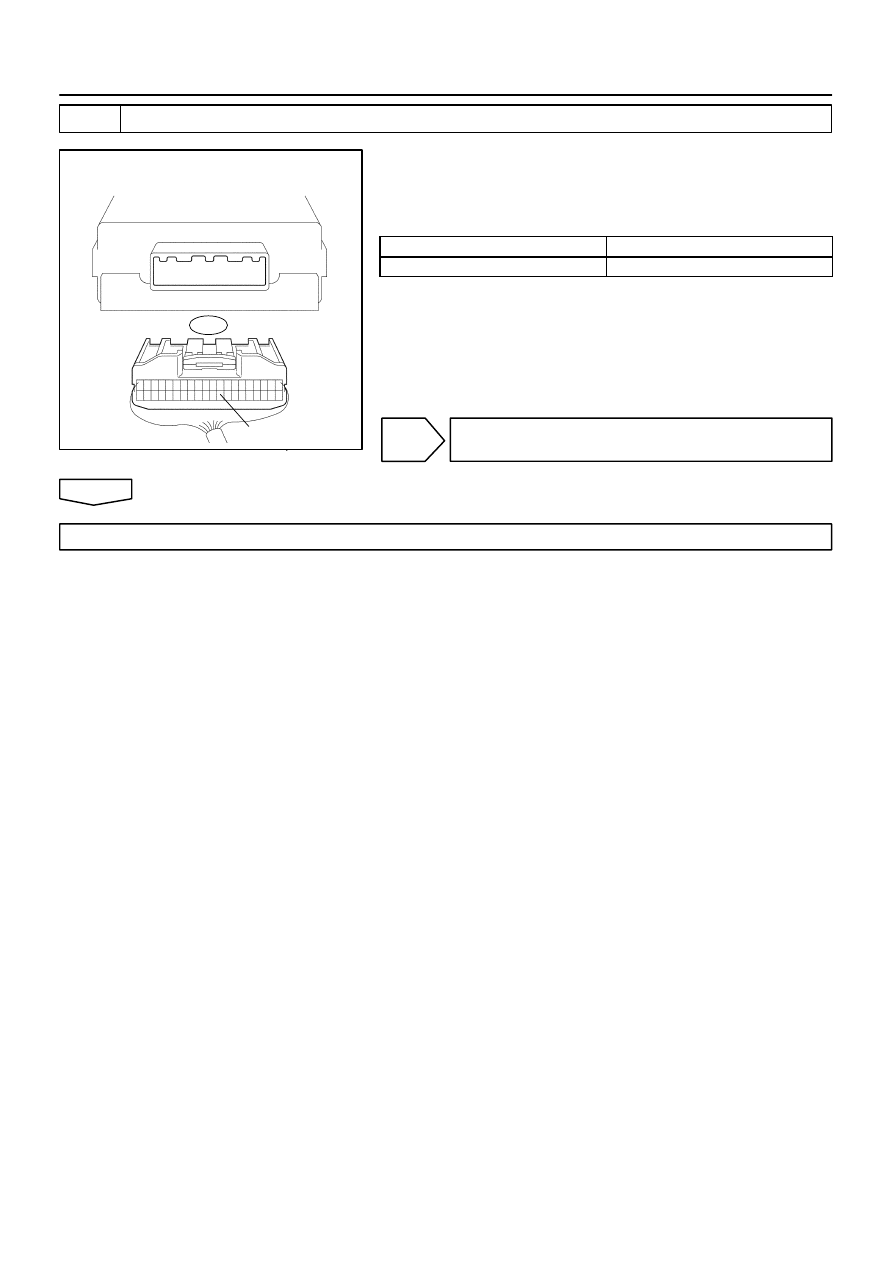

3

CHECK WIRE HARNESS (TVIP ECU

⇔

BODY GROUND)

(a)

Disconnect the TVIP ECU connector.

(b)

Check the connector on the harness side, as shown in the

illustration and table.

Standard:

Symbols (Terminal No.)

Specified condition

E (T3–29)

⇔

Body ground

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

CHECK AND REPLACE TVIP ECU (See page

01–30

)

B59177

10

IG

FL MAIN

Battery

Instrument Panel J/B

IG1 Relay

ECU–IG

9

IF

B–W

W–B

W

B–Y

AM1

IG1

I10

Ignition SW

ALT

Engine Room J/B

1

1C

J6

J/C

A

IE

1

2

W

1

1D

J7

J/C

A

IG

1

2

1

1A

B

T3

10

IH

4

IF

1

IB

3

5

1

2

1

2

IF

12

IF

AM1

W

W–B

IA

TVIP ECU

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–713

878

Author:

Date:

2004 COROLLA (RM1037U)

IGNITION SWITCH CIRCUIT

CIRCUIT DESCRIPTION

If the ignition switch is turned to the ON position, battery positive voltage is applied to the switches, such as

terminal IG of the ECU.

WIRING DIAGRAM

057S0–01

B51200

I24329

ECU–B Fuse

Instrument Panel J/B

B16200

05–714

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

879

Author:

Date:

2004 COROLLA (RM1037U)

INSPECTION PROCEDURE

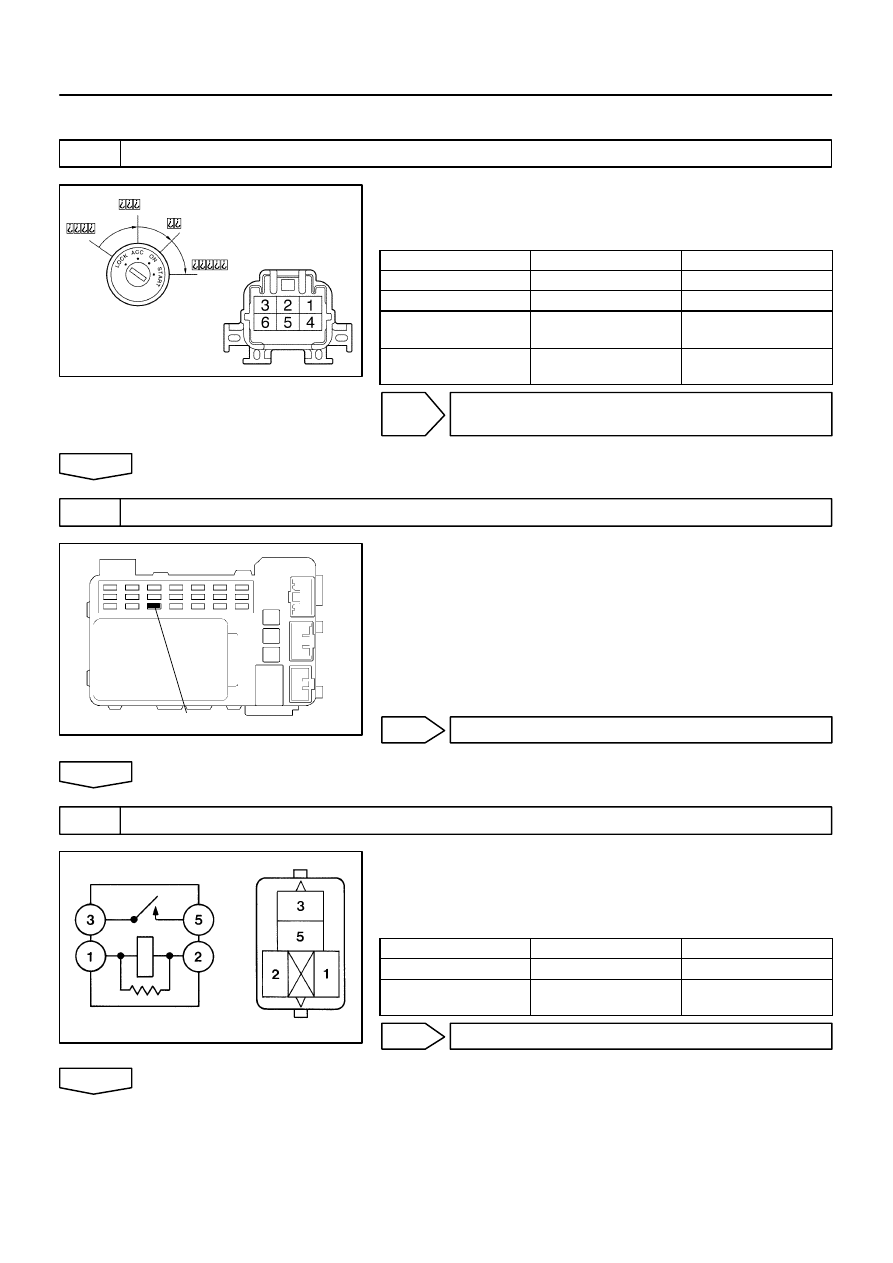

1

CHECK IGNITION OR STARTER SWITCH ASSY

(a)

Check the ignition switch, as shown in the illustration and

table.

Standard:

Terminal No.

Switch position

Specified condition

–

LOCK

–

1

⇔

3

ACC

Continuity

1

⇔

2

⇔

3

ON

Continuity

1

⇔

2

⇔

3

5

⇔

6

ON

Continuity

1

⇔

2

START

Continuity

1

⇔

2

4

⇔

5

⇔

6

START

Continuity

NG

REPAIR OR REPLACE IGNITION OR STARTER

SWITCH ASSY

OK

2

CHECK FUSE (ECU–B)

(a)

Remove the fuse from the instrument panel J/B.

(b)

Check the continuity of the fuse.

Standard: Continuity

NG

REPLACE FUSE

OK

3

CHECK RELAY (Marking: IG1)

(a)

Remove the relay from the instrument J/B.

(b)

Inspect the relay continuity, as shown in the illustration

and table.

Standard:

Terminal No.

Condition

Specified condition

1

⇔

2

Constant

Continuity

3

⇔

5

Apply B+ between

terminals 1 and 2

Continuity

NG

REPLACE RELAY

OK

B52239

T3

IG (10)

TVIP ECU

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–715

880

Author:

Date:

2004 COROLLA (RM1037U)

4

CHECK TVIP ECU

(a)

Disconnect the TVIP ECU connector.

(b)

Turn the ignition switch ON.

(c)

Measure the voltage between the terminal of the ECU

connector and the body ground, as shown in the illustra-

tion and table.

Standard:

Symbols (Terminal No.)

Specified condition

IG (T3–10)

⇔

Body ground

10 – 14 V

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

CHECK AND REPLACE TVIP ECU (See page

01–30

)

B59178

TVIP ECU

C10

Combination

SW

Engine Room J/B and R/B

HORN

5

T3

G–Y

18

IA5

B

Horn

Battery

FL MAIN

B

HORN Relay

B–W

1

3

5

1

2

HORN

G–Y

1

B–W

1

1

2

1

1A

1

1

1

1

G–Y

G–Y

G–Y

Center J/B

4A

12

4A

13

H6

Horn Low Pitched

Horn Assy (Horn)

05–716

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

881

Author:

Date:

2004 COROLLA (RM1037U)

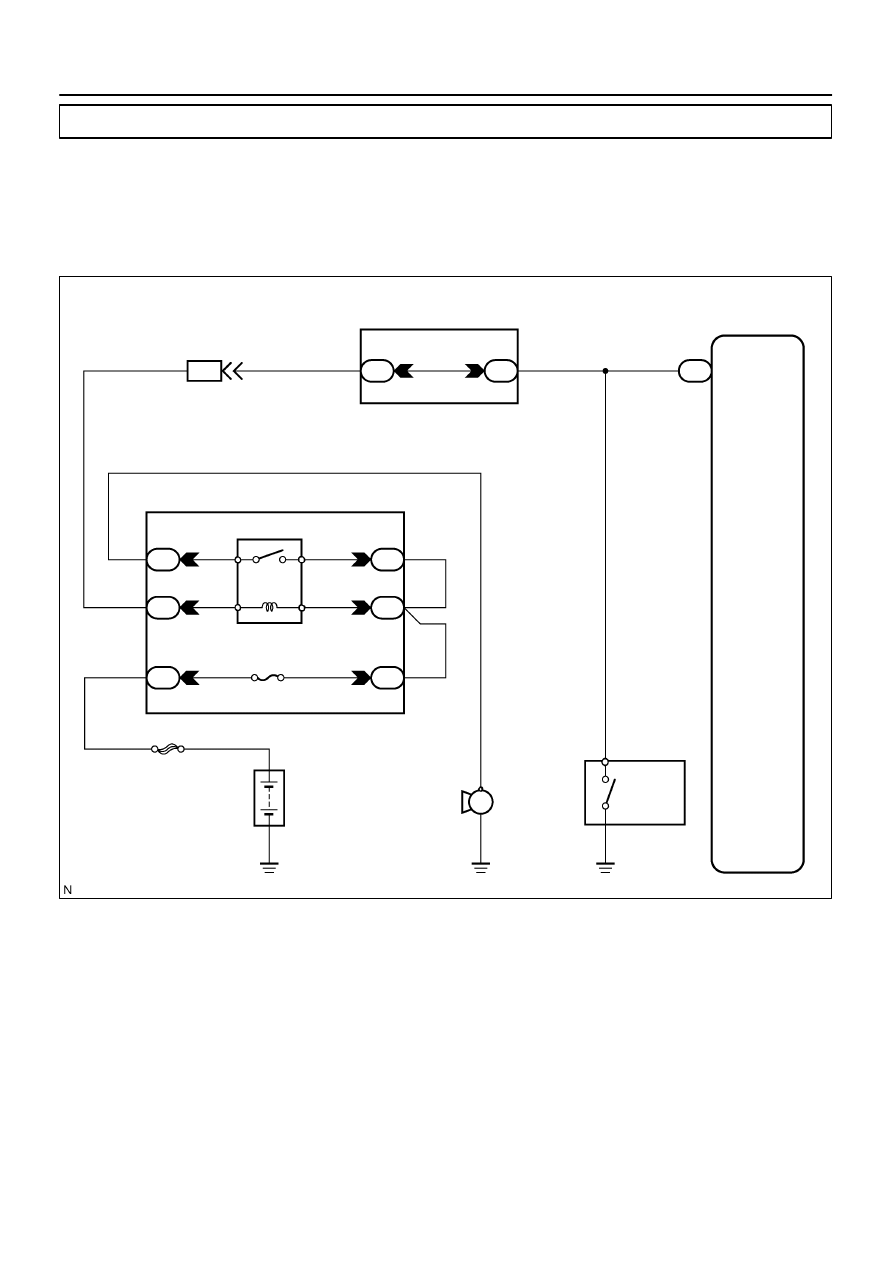

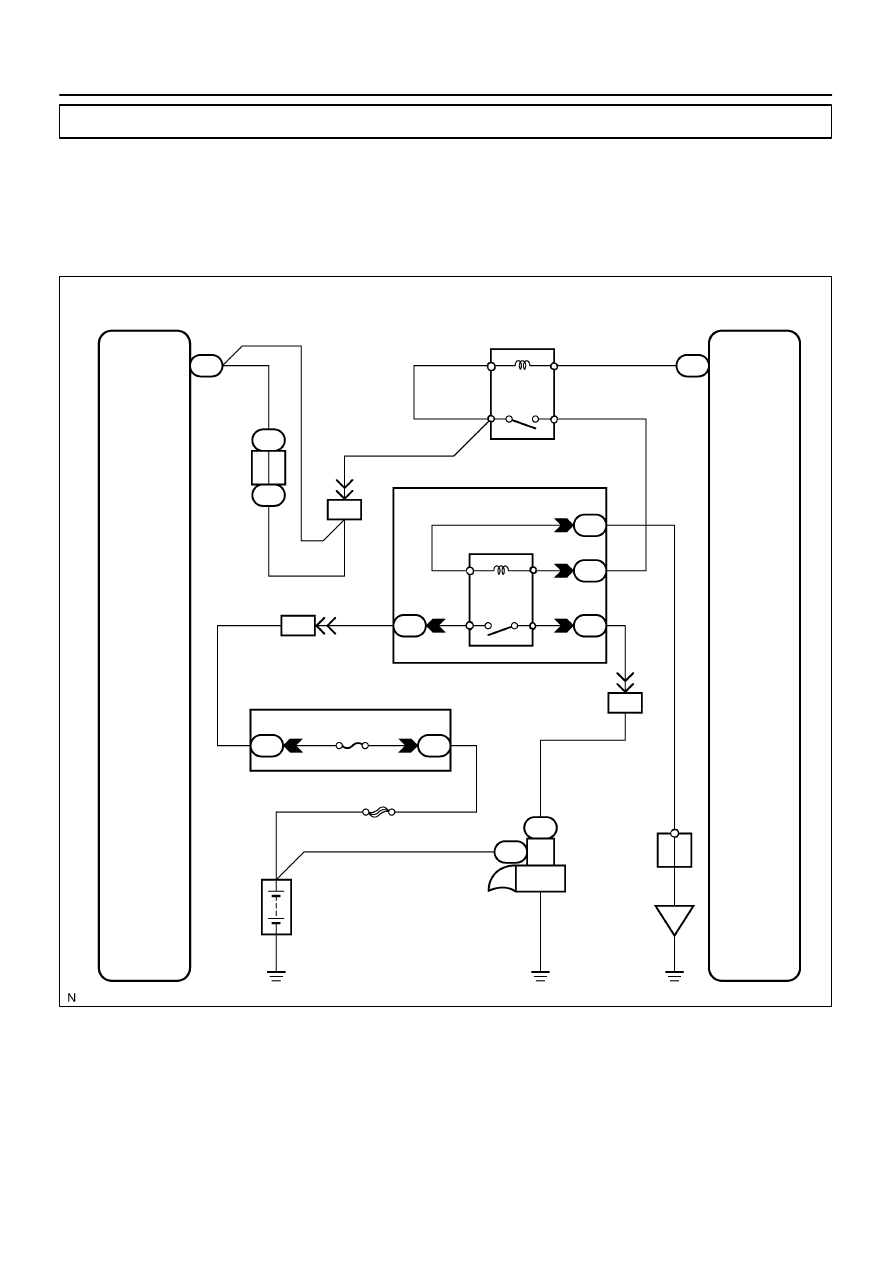

HORN RELAY CIRCUIT

CIRCUIT DESCRIPTION

When the TVIP system is transferred from the armed state to the alarm sounding state, the TVIP ECU

switches on the HORN relay so that it can sound the horns. The horn sounds in 0.4 seconds interval.

WIRING DIAGRAM

057S1–01

I11656

B16200

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–717

882

Author:

Date:

2004 COROLLA (RM1037U)

INSPECTION PROCEDURE

1

CHECK LOW PITCHED HORN ASSY

(a)

Connect the positive (+) lead from the battery to the termi-

nal and negative (–) lead to the horn body, and check that

the horn blows.

NG

REPAIR OR REPLACE LOW PITCHED HORN

ASSY

OK

2

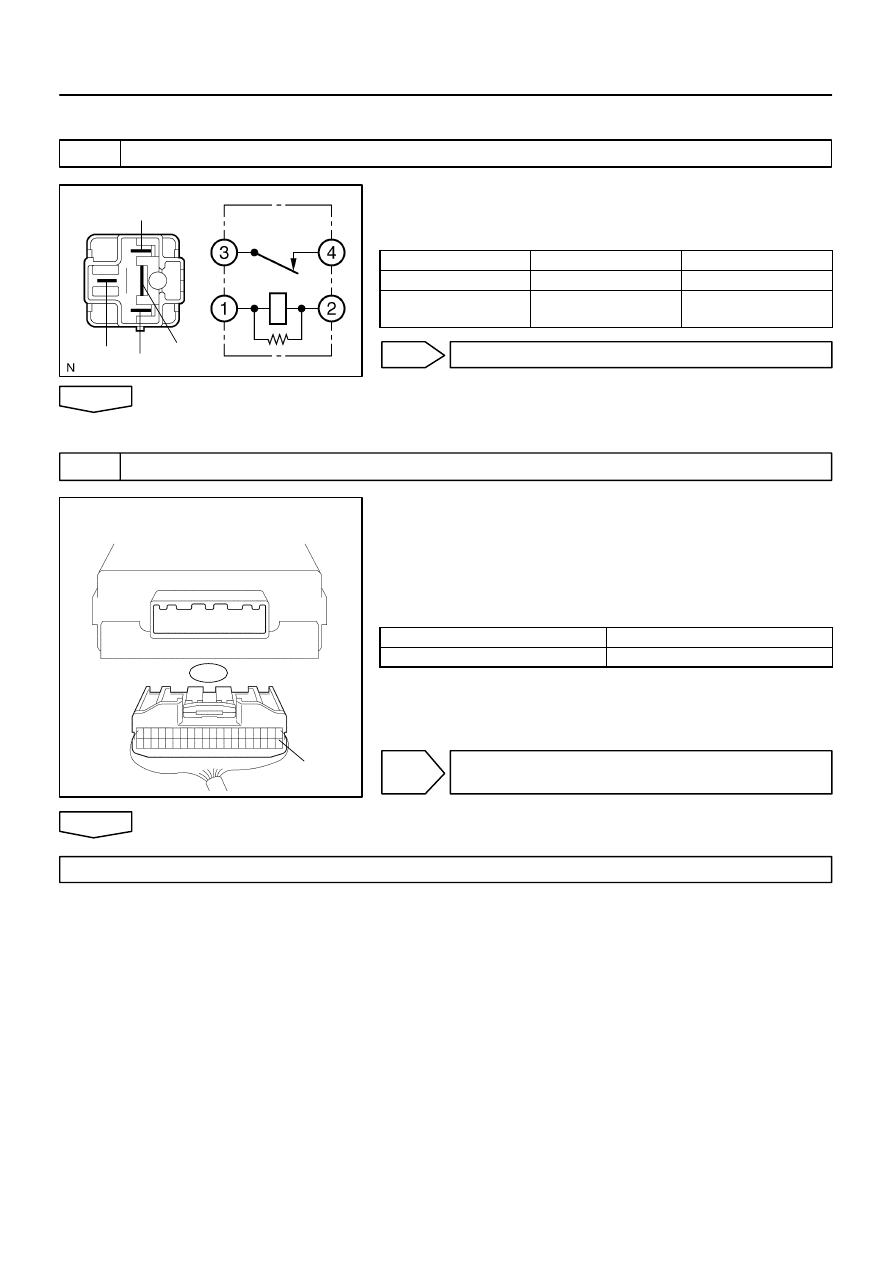

CHECK RELAY (Marking: HORN)

(a)

Remove the relay from the engine room J/B.

(b)

Check the horn relay continuity, as shown in the illustra-

tion and table.

Standard:

Terminal No.

Condition

Specified condition

1

⇔

2

Constant

Continuity

3

⇔

5

Apply B+ between

terminals 1 and 2

Continuity

NG

REPLACE RELAY

OK

B59602

B52239

B59603

TVIP ECU

(Wire Harness Side)

T3

Horn (5)

Engine Room J/B

1

2

3

5

Horn Relay

B59193

B59602

B59595

Horn

H6

(Wire Harness Side)

Engine Room J/B

1

2

3

5

HORN Relay

05–718

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

883

Author:

Date:

2004 COROLLA (RM1037U)

3

CHECK WIRE HARNESS (TVIP ECU

⇔

ENGINE ROOM J/B)

(a)

Remove the horn relay from the engine room J/B.

(b)

Check the continuity between the terminals of the TVIP

ECU and engine room J/B connectors, as shown in the il-

lustration and table.

Standard:

Symbols (Terminal No.)

(TVIP ECU

⇔

Engine room J/B)

Specified condition

HORN (T3–5)

⇔

2*

Continuity

*: Horn relay terminal.

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

4

CHECK WIRE HARNESS (ENGINE ROOM J/B

⇔

HORN)

(a)

Check the continuity between the terminals of the engine

room J/B and horn connectors, as shown in the illustration

and table.

Standard:

Symbols (Terminal No.)

(Engine room J/B

⇔

Horn)

Specified condition

3*

⇔

Horn (H6–1)

Continuity

*: Horn relay terminal.

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

CHECK AND REPLACE TVIP ECU (See page

01–30

)

B59179

TVIP ECU

C12

Combination SW

(Light Control Switch)

HEAD

6

T3

IE

A

J6

J/C

W–B*

1

10

21

4B

R

12

Light

Control

SW

OFF

Tail

Head

+B

T

RF

H

EL

Center J/B

G*

2

11

4B

2

IC

Instrument Panel J/B

2

IL

W–B*

1

J1

J/C

G*

2

G*

2

W–B

F4

Front

Parking

Light RH

F3

Front

Parking

Light LH

ED

EA

*

1

: USA

*

2

: Canada

G

A

A

1

2

1

2

A

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–719

884

Author:

Date:

2004 COROLLA (RM1037U)

LIGHT CONTROL SWITCH CIRCUIT

WIRING DIAGRAM

057S2–03

B59189

B52239

B59592

Light Control Switch

TVIP ECU

(Wire Harness Side)

T3

C12

(Wire Harness Side)

HEAD (6)

RF (12)

05–720

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

885

Author:

Date:

2004 COROLLA (RM1037U)

INSPECTION PROCEDURE

1

CHECK HEADLAMP DIMMER SWITCH ASSY (LIGHT CONTROL SWITCH)

(See page

65–7

)

NG

REPLACE HEADLAMP DIMMER SWITCH ASSY

(LIGHT CONTROL SWITCH)

OK

2

CHECK WIRE HARNESS (TVIP ECU

⇔

LIGHT CONTROL SWITCH)

(a)

Disconnect the TVIP ECU and light control switch con-

nectors.

(b)

Check the continuity between the terminals of the TVIP

ECU and light control switch connectors, as shown in the

illustration and table.

Standard:

Symbols (Terminal No.)

(TVIP ECU

⇔

Light control switch)

Specified condition

HEAD (T3–6)

⇔

RF (C12–12)

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

B59189

Light Control Switch

C12

(Wire Harness Side)

T (10)

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–721

886

Author:

Date:

2004 COROLLA (RM1037U)

3

CHECK WIRE HARNESS (LIGHT CONTROL SWITCH

⇔

BODY GROUND)

(a)

Disconnect the light control switch connector.

(b)

Check the continuity between the terminal of the light con-

trol switch connector and the body ground, as shown in

the illustration and table.

Standard:

Symbols (Terminal No.)

(Light control switch

⇔

Body ground)

Specified condition

T (C12–10)

⇔

Body ground

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS TABLE

(See page

05–707

)

B59180

TVIP ECU

*

1

: w/ Wireless Door Lock

*

2

: w/o Wireless Door Lock

HAZD

8

T3

T2

Turn Signal Flasher Relay

H7

Hazard Warning Signal

Switch Assy (Hazard SW)

RH J/B

Y–B*

1

2

3C

2

3

A

IG

J7

J/C

HAZ

8

Y–B

Y–B*

1

W–B

W–B*

1

3

3C

21

3A

11

3A

Y–B*

1

Y–B*

2

05–722

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

887

Author:

Date:

2004 COROLLA (RM1037U)

HAZARD WARNING SWITCH CIRCUIT

CIRCUIT DESCRIPTION

When the TVIP system is transferred to the alarm sounding state from the armed state, the signal flasher

assembly (relay for hazard warning lights) will be switched ON and the hazard warning lights will start blink-

ing.

WIRING DIAGRAM

057S3–03

B59609

No Pin (6)

No Pin (1)

B59600

B52239

B59593

Turn Signal Flasher Relay

(Wire Harness Side)

T2

TVIP ECU

(Wire Harness Side)

T3

HAZD (8)

HAZ (8)

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–723

888

Author:

Date:

2004 COROLLA (RM1037U)

INSPECTION PROCEDURE

1

CHECK HAZARD WARNING SIGNAL SWITCH ASSY

(a)

Check the hazard warning switch continuity, as shown in

the illustration and table.

Standard:

Terminal No.

Switch position

Specified condition

–

Switch OFF

Continuity

2

⇔

3

Switch ON

Continuity

4

⇔

5

Illumination circuit

Continuity

4

⇔

5

Illumination circuit

Continuity

NG

REPLACE HAZARD WARNING SIGNAL SWITCH

ASSY

OK

2

CHECK TURN SIGNAL FLASHER ASSY (See page

65–4

)

NG

REPLACE TURN SIGNAL FLASHER ASSY

OK

3

CHECK WIRE HARNESS (TVIP ECU

⇔

TURN SIGNAL FLASHER)

(a)

Disconnect the TVIP ECU and turn signal flasher connec-

tors.

(b)

Check the continuity between the terminals of the TVIP

ECU and turn signal flasher connectors, as shown in the

illustration and table.

Standard:

Symbols (Terminal No.)

(TVIP ECU

⇔

Turn Signal Flasher)

Specified condition

HAZD (T3–8)

⇔

HAZ (T2–8)

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

B31237

Hazard Warning Switch

(Wire Harness Side)

H7

05–724

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

889

Author:

Date:

2004 COROLLA (RM1037U)

4

CHECK WIRE HARNESS (HAZARD WARNING SWITCH

⇔

BODY GROUND)

(a)

Disconnect the hazard warning switch connector.

(b)

Check the continuity between the terminal of the hazard

warning switch connector and the body ground, as shown

in the illustration and table.

Standard:

Symbols (Terminal No.)

(Hazard warning SW

⇔

Body ground)

Specified condition

H7–2

⇔

Body ground

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

CHECK AND REPLACE TVIP ECU (See page

01–30

)

I24321

B59181

TVIP ECU

Engine Room J/B and R/B

SRLY

21

T3

Battery

FL MAIN

S8

Starter Cut Relay

Instrument Panel J/B

ECM

Starter

STA

9

E4

B (M/T)

B (A/T)

B–R

B–W

B

2

1

3

4

W–B

4

IF

II1

7

A

IE

J6

J/C

1

S3

1

S2

B–R

B–R

2

IA4

MAIN

2

1

B–R

J2

G

J/C

II2

11

B (A/T)

B

B

B

1

1

1A

B

11

IL

1

IM

2

1

5

3

ST Relay

3

IM

J2

G

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–725

890

Author:

Date:

2004 COROLLA (RM1037U)

STARTER CUT RELAY CIRCUIT

CIRCUIT DESCRIPTION

When the TVIP system operates, the TVIP ECU controls the starter cut relay so that the relay should not

be turned on and consequently the starter can not crank the engine.

WIRING DIAGRAM

057S4–01

I24337

1

4

3

2

B52239

T3

SRLY (21)

TVIP ECU

05–726

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

891

Author:

Date:

2004 COROLLA (RM1037U)

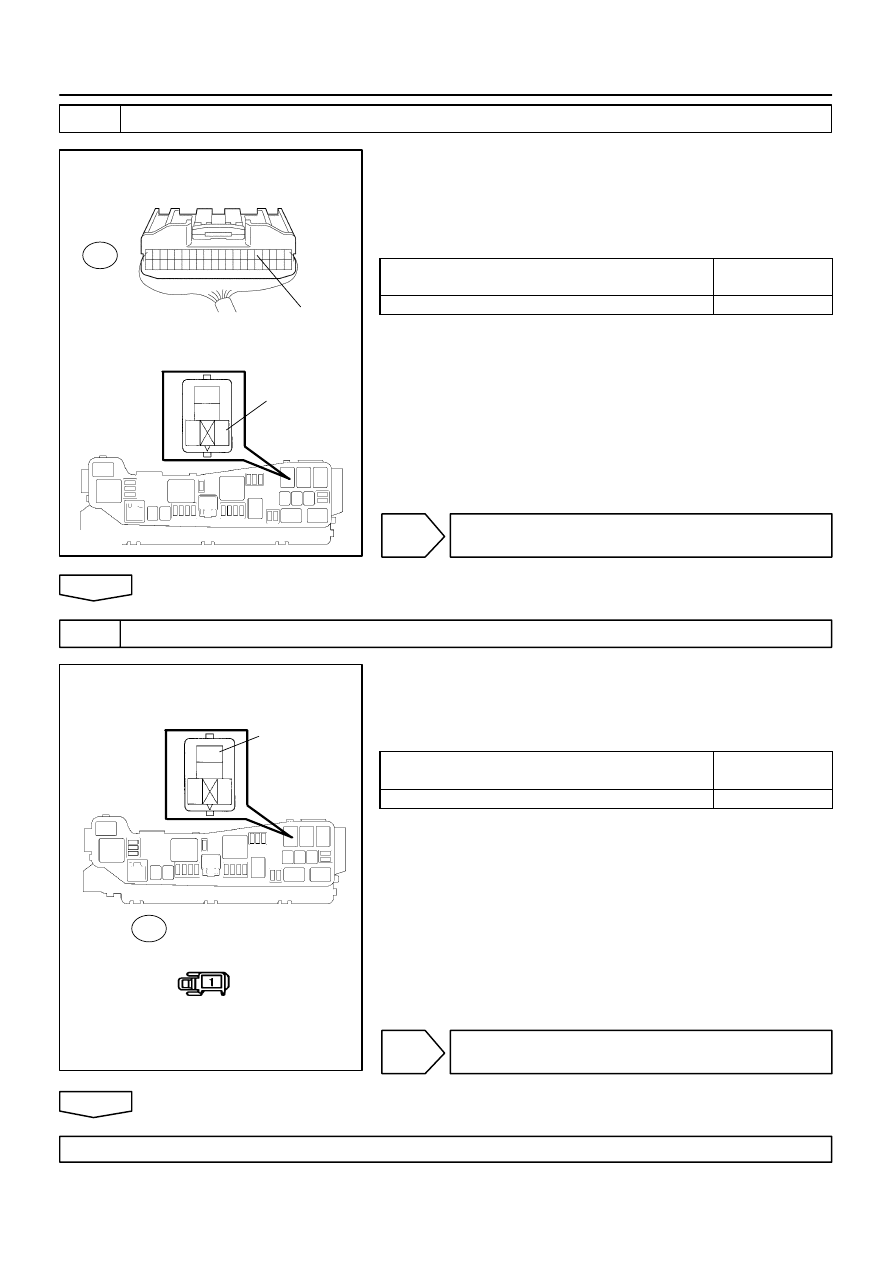

INSPECTION PROCEDURE

1

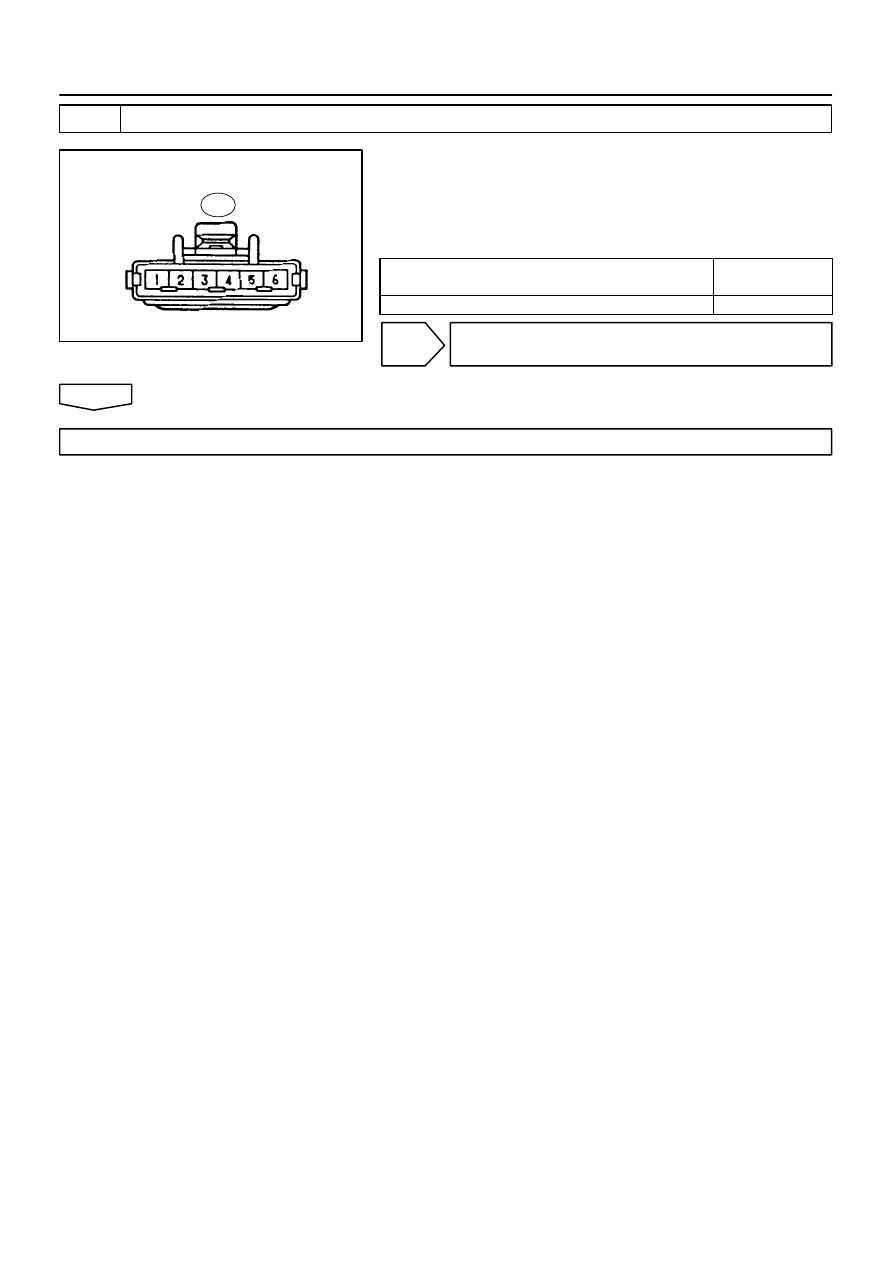

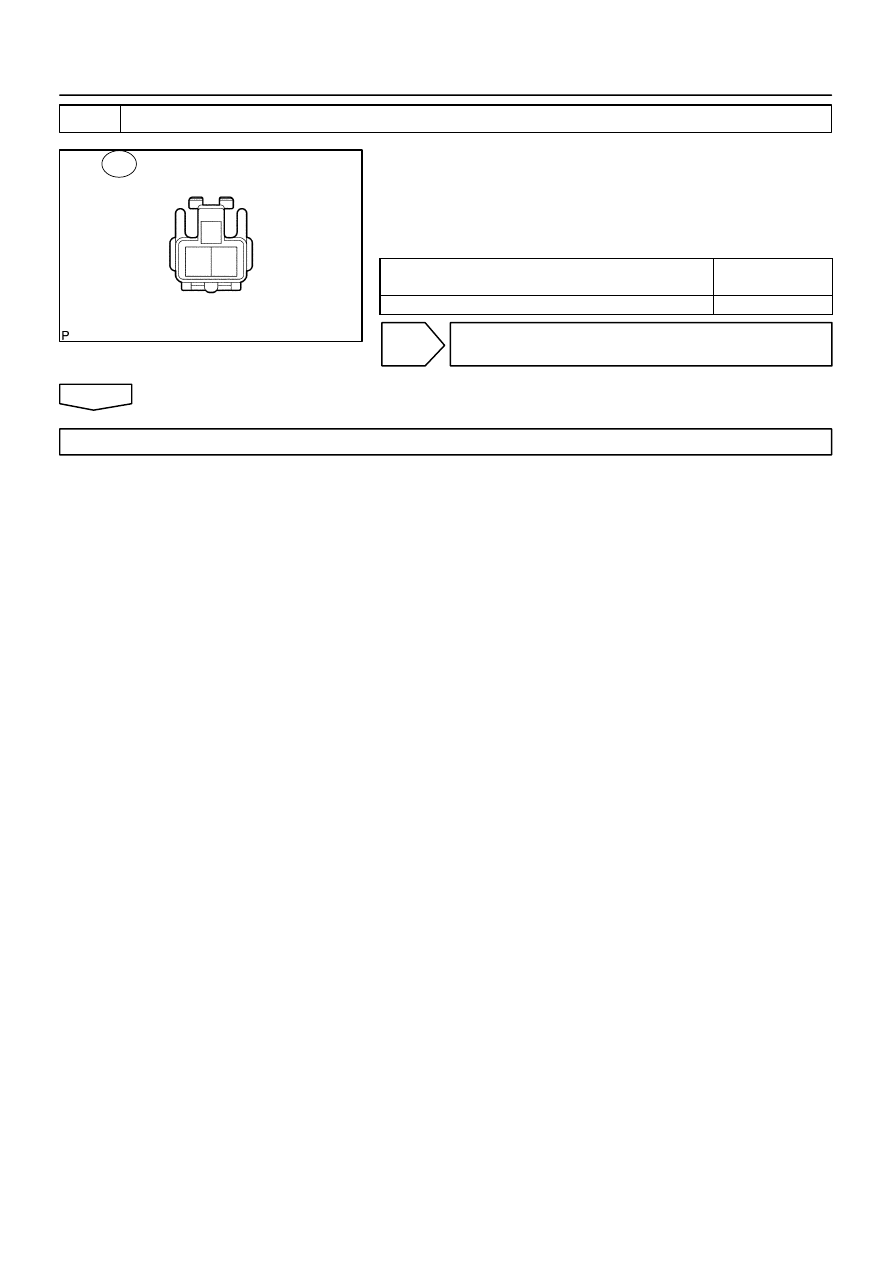

CHECK RELAY (Marking: STARTER CUT)

(a)

Inspect the relay continuity, as shown in the illustration

and table.

Standard:

Terminal No.

Condition

Specified condition

1

⇔

2

Constant

Continuity

3

⇔

4

Apply B+ between

terminals 1 and 2

Continuity

NG

REPLACE RELAY

OK

2

CHECK TVIP ECU

(a)

Disconnect the TVIP ECU connector.

(b)

Turn the ignition switch position to the START.

(c)

Measure the voltage between the terminal of the ECU

connector and the body ground, as shown in the illustra-

tion and table.

Standard:

Symbols (Terminal No.)

Specified condition

SRLY (T3–21)

⇔

Body ground

10 – 14 V

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

CHECK AND REPLACE TVIP ECU (See page

01–30

)

I24320

B59182

TVIP ECU

KSW

1

2

12

U1

Unlock

Warning SW

J6

J/C

A

IE

W–B

L–B

T3

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–727

892

Author:

Date:

2004 COROLLA (RM1037U)

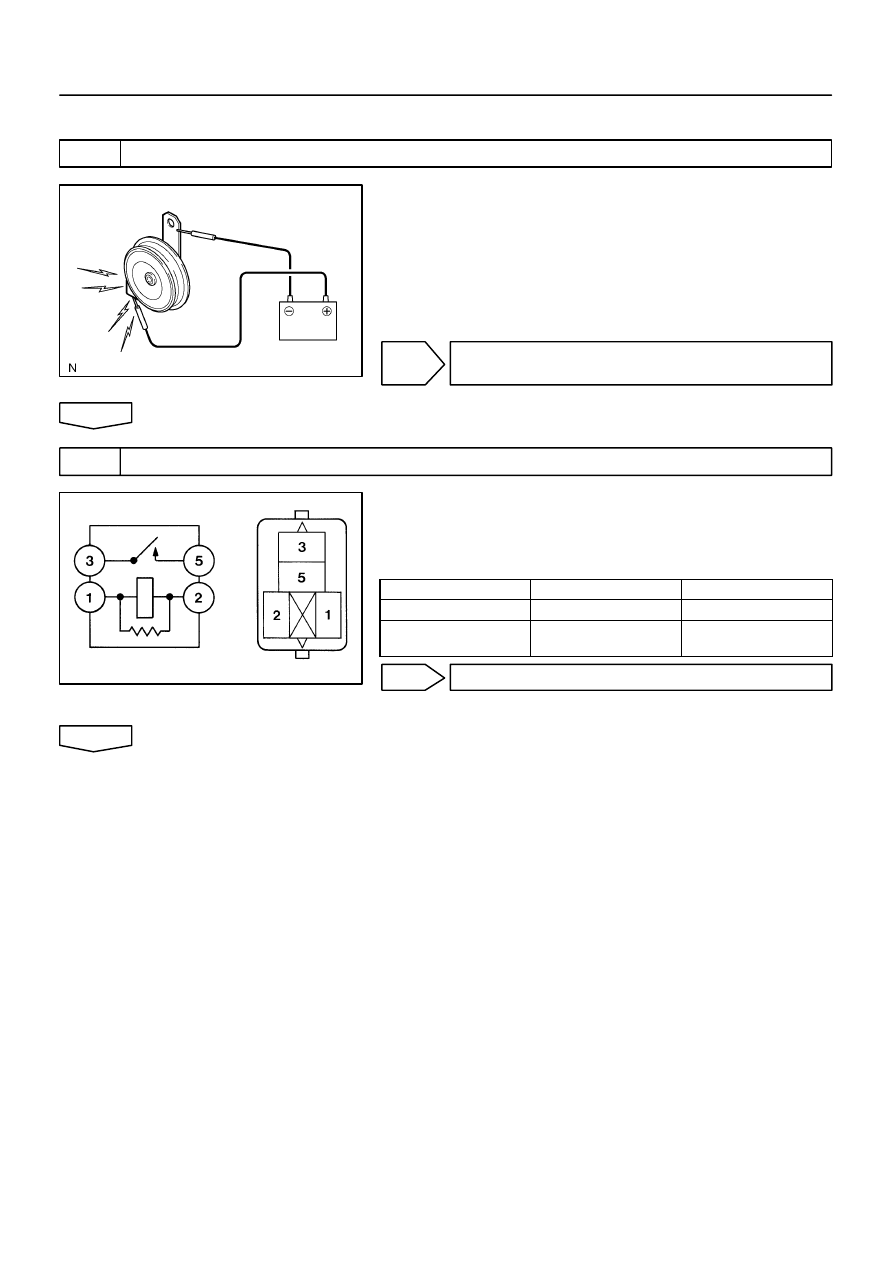

KEY UNLOCK WARNING SWITCH CIRCUIT

CIRCUIT DESCRIPTION

The key unlock warning switch comes on when the ignition key is inserted in the key cylinder and goes off

when the ignition key is removed.

WIRING DIAGRAM

057S5–01

B51903

Push

Free

Unlock Warning Switch

Unlock Warning Switch

B59296

B52239

B59596

Unlock Warning Switch

TVIP ECU

(Wire Harness Side)

T3

U1

(Wire Harness Side)

1

2

KSW (12)

05–728

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

893

Author:

Date:

2004 COROLLA (RM1037U)

INSPECTION PROCEDURE

1

CHECK UN–LOCK WARNING SWITCH ASSY

(a)

Disconnect the key unlock warning switch connector.

(b)

Check the continuity between the terminals of the key un-

lock warning switch connector, as shown in the illustration

and table.

Standard:

Terminal No.

Switch position

Specified condition

1

⇔

2

Push (Key inserted)

Continuity

1

⇔

2

Free (Key removed)

No continuity

NG

REPLACE UN–LOCK WARNING SWITCH ASSY

OK

2

CHECK WIRE HARNESS (TVIP ECU

⇔

UNLOCK WARNING SWITCH)

(a)

Disconnect the TVIP ECU and key unlock warning switch

connectors.

(b)

Check the continuity between the terminals of the TVIP

ECU connectors and unlock warning switch connector, as

shown in the illustration and table.

Standard:

Symbols (Terminal No.)

(TVIP ECU

⇔

Unlock warning switch)

Specified condition

KSW (T3–12)

⇔

U1–2

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

B59296

Unlock Warning Switch

U1

(Wire Harness Side)

1

2

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–729

894

Author:

Date:

2004 COROLLA (RM1037U)

3

CHECK WIRE HARNESS (KEY UNLOCK WARNING SWITCH

⇔

BODY GROUND)

(a)

Disconnect the key unlock warning switch connector.

(b)

Check the continuity between the terminal of the key un-

lock warning switch connector and the body ground, as

shown in the illustration and table.

Standard:

Terminal No.

(Key unlock warning SW

⇔

Body ground)

Specified condition

U1–1

⇔

Body ground

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

CHECK AND REPLACE TVIP ECU (See page

01–30

)

I24322

B59183

TVIP ECU

S4

Security Indicator

(Glass Breakage Sensor)

G3

Glass Breakage Sensor ECU

Instrument Panel J/B

Engine Room J/B

I10 Ignition SW

Battery

FL MAIN

ALT

AM1

IG1

AM1

ECU–B

R–B

IG1 Relay

ECU–IG

1

IA

W

(Shielded)

SMIC

SMCE

3

4

IOUT

11

T3

L

B–W

MIC

IOUT

GMIC

GND

S+B

TRIG

1

1D

1C

J6

J/C

A

IE

1

1A

2

IF

12

IF

1

IH

9

IF

4

IF

1

IB

1

2

B–Y

W

W

W

W–B

B–W

5

1

2

3

4

5

1

3

6

8

W

R–B

B

1

1

2

W–B

W–B

J7

J/C

A

IG

19

11 3A

3A

RH J/B

Microphone

W–B

W

05–730

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

895

Author:

Date:

2004 COROLLA (RM1037U)

GLASS BREAKAGE SENSOR CIRCUIT

CIRCUIT DESCRIPTION

The microphone of the grass breakage sensor is built in the security indicator. When this microphone senses

breakage of grass, the grass breakage sensor ECU sends the signal of this breakage to the TVIP ECU.

WIRING DIAGRAM

057S6–01

I24334

Connector connected

G3

B59576

TVIP ECU

(Wire Harness Side)

Glass Breakage Sensor ECU

(Wire Harness Side)

IOUT (3)

T3

G3

IOUT (11)

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–731

896

Author:

Date:

2004 COROLLA (RM1037U)

INSPECTION PROCEDURE

1

CHECK SECURITY INDICATOR LIGHT

(a)

Set the system in 30 seconds after filliping the security indicator to check if the alarm is triggered.

OK

NO PROBLEM

NG

2

CHECK GLASS BREAKAGE SENSOR ECU (GLASS BREAKAGE SENSOR)

(a)

Check the continuity and voltage of the glass breakage

sensor

ECU

, as shown in the illustration and table.

Standard:

Terminal No.

Condition

Specified condition

G3–1

⇔

Body ground

Constant

Battery voltage

G3–3

⇔

Body ground

Constant

Pulse generation

G3–5

⇔

Body ground

Constant

Continuity

G3–8

⇔

Body ground

Ignition switch ON

Battery voltage

NG

CHECK AND REPLACE GLASS BREAKAGE

SENSOR ECU (See page

01–30

)

OK

3

CHECK WIRE HARNESS (TVIP ECU

⇔

GLASS BREAKAGE SENSOR ECU)

(a)

Disconnect the TVIP ECU and glass breakage sensor

ECU connectors.

(b)

Check the continuity and between the connectors on the

harness side, as shown in the illustration and table.

Standard:

Symbols (Terminal No.)

(TVIP ECU

⇔

Sensor ECU)

Specified condition

IOUT (T3–11)

⇔

IOUT (G3–3)

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

I24334

G3

Glass Breakage Sensor ECU

(Wire Harness Side)

05–732

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

897

Author:

Date:

2004 COROLLA (RM1037U)

4

CHECK WIRE HARNESS (GLASS BREAKAGE SENSOR ECU

⇔

BODY GROUND)

(a)

Disconnect the glass breakage sensor ECU connector.

(b)

Check the continuity between the terminal of the glass

breakage sensor ECU connector and the body ground, as

shown in the illustration and table.

Standard:

Symbols (Terminal No.)

(Glass breakage sensor

⇔

Body ground)

Specified condition

GND (G3–6)

⇔

Body ground

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

CHECK AND REPLACE TVIP ECU (See page

01–30

)

B59184

I11

Integration Relay

TVIP ECU

D5

Door Courtesy SW

Front RH

D4

Door Courtesy SW Front LH

L4

Luggage Compartment

Light SW

D7

Door Courtesy SW

Rear RH

D6

Door Courtesy SW Rear LH

DMLP

9

T3

R–W

PCTY

LP

PRCTY

DCTY

13

3

6

5

R–W

R–W

1

4

IK

3

IL

1

ID

R

R–W

R–W

1

R–W

J10

J/C

A

A

R–Y

1

1

R–B

15

ID

14

ID

CTY

19

T3

DSWD

40

T3

R–W

1

DSWL

35

T3

R–W

ID2

R–W

11

Instrument Panel J/B

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–733

898

Author:

Date:

2004 COROLLA (RM1037U)

DOOR COURTESY SWITCH CIRCUIT

CIRCUIT DESCRIPTION

The door courtesy switch turns ON when the door is opened and OFF when the door is closed.

WIRING DIAGRAM

057S7–01

B59818

Push

Free

B59191

B60033

B59599

(Wire Harness Side)

Integration Relay

(Wire Harness Side)

I11

D5

Door Courtesy SW Front RH

05–734

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

899

Author:

Date:

2004 COROLLA (RM1037U)

INSPECTION PROCEDURE

1

CHECK COURTESY LAMP SWITCH

(a)

Check the courtesy switch, as shown in the illustration

and table.

Standard:

Terminal No.

Switch position

Specified condition

1

⇔

Body ground

Push

Continuity

1

⇔

Body ground

Free

No continuity

NG

REPLACE COURTESY LAMP SWITCH

OK

2

CHECK WIRE HARNESS (INTEGRATION RELAY

⇔

DOOR COURTESY SW)

(a)

Disconnect the integration relay and door courtesy con-

nectors.

(b)

Check the continuity between the terminals of the integra-

tion relay and door courtesy switch connectors, as shown

in the illustration and table.

Standard:

Terminal No.

(Integration relay

⇔

Door courtesy SW)

Specified condition

I11–13

⇔

D5–1

Continuity

B59191

B59527

B59598

(Wire Harness Side)

Integration Relay (Instrument Panel J/B)

(Wire Harness Side)

ID

D6

Door Courtesy SW Front LH

Door Courtesy SW Rear RH

Door Courtesy SW Rear LH

D4

D7

B59191

B52239

B59597

TVIP ECU

(Wire Harness Side)

T3

L4

(Wire Harness Side)

Luggage Compartment Light SW

DSWL (35)

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–735

900

Author:

Date:

2004 COROLLA (RM1037U)

(c)

Disconnect the each door courtesy switch connectors.

(d)

Check the continuity between the terminals of the integra-

tion relay and door courtesy switch connectors, as shown

in the illustration and table.

Standard:

Terminal No.

(Integration relay

⇔

Door courtesy SW)

Specified condition

ID–1

⇔

D4–1

ID–15

⇔

D7–1

Continuity

ID–14

⇔

D6–1

y

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

3

CHECK WIRE HARNESS (TVIP ECU

⇔

LUGGAGE COMPARTMENT LIGHT SW)

(a)

Disconnect the TVIP ECU and luggage comportment

light switch connectors.

(b)

Check the continuity between the terminals of the TVIP

ECU and luggage compartment light switch connectors,

as shown in the illustration and table.

Standard:

Symbols (Terminal No.)

(TVIP ECU

⇔

Luggage compartment light SW)

Specified condition

DSWL (T3–35)

⇔

L4–1

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS TABLE

(See page

01–30

)

I24325

B59186

D8

Door Key Lock and Unlock SW Front LH

Door Lock Motor Front LH

Door Unlock Detection SW Front LH

D9

Door Key Lock and Unlock SW Front RH

Door Lock Motor Front RH

Door Unlock Detection SW Front RH

UL3

17

T3

L2

W–B

W–B

16

T3

6

IC1

J6

J/C

W–B

J7

J/C

A

IE

IG

A

TVIP ECU

Unlock

Lock

L–Y

Center J/B

G

2

4A

UL2

1

4A

18

T3

G

L–Y

10

IC1

11

IC1

G

G

G

G

G

7

9

10

L–B

11

IJ2

10

IJ2

L–B

6

5

Unlock

Lock

8

1

IJ2

W–B

05–738

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

903

Author:

Date:

2004 COROLLA (RM1037U)

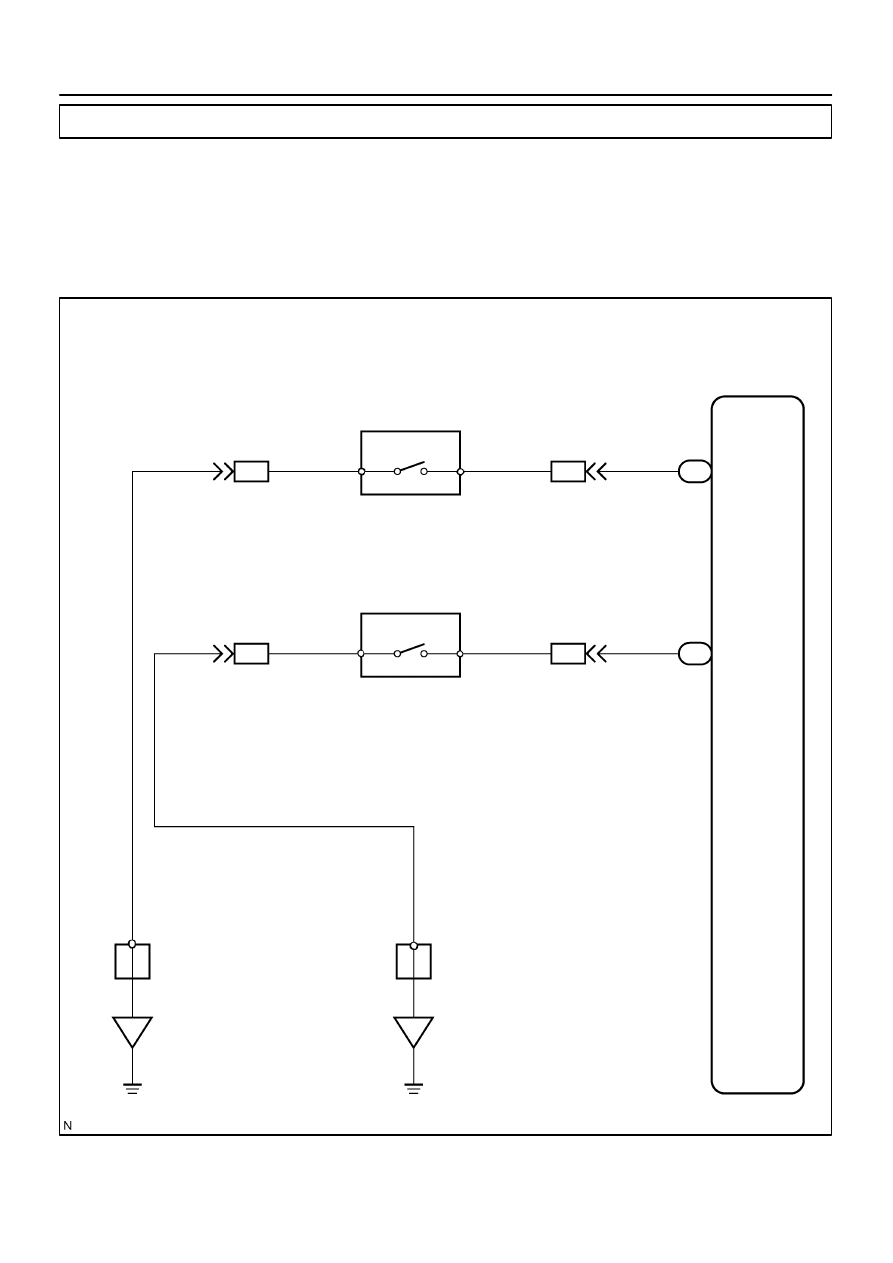

DOOR KEY LOCK AND UNLOCK SWITCH CIRCUIT

CIRCUIT DESCRIPTION

The door key lock and unlock switch is built in the door lock motor.

WIRING DIAGRAM

057S9–01

4

3

1

2

6

5

8

7

9 10

B58512

B52239

B59591

Passenger’s Door Lock

TVIP ECU

(Wire Harness Side)

T3

D8

D9

(Wire Harness Side)

Driver’s Door Lock

L2 (16)

UL3 (17)

UL2 (18)

4

3

1

2

6

5

8

7

9 10

B58512

B59773

Passenger’s Door Lock

D8

D9

(Wire Harness

Side)

Driver’s Door Lock

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–739

904

Author:

Date:

2004 COROLLA (RM1037U)

INSPECTION PROCEDURE

1

CHECK DOOR LOCK (See page

73–3

)

NG

REPLACE DOOR LOCK

OK

2

CHECK WIRE HARNESS (TVIP ECU

⇔

DOOR LOCK)

(a)

Disconnect the TVIP ECU and door lock connectors.

(b)

Check the continuity between the terminals of the TVIP

ECU and door lock connectors, as shown in the illustra-

tion and table.

Standard:

Symbols (Terminal No.)

(TVIP ECU

⇔

Door lock)

Specified condition

UL3 (T3–17)

⇔

D8–10

L2 (T3–16)

⇔

D8–9

Continuity

L2 (T3–16)

⇔

D9–6

Continuity

UL2 (T3–18)

⇔

D9–5

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

3

CHECK WIRE HARNESS (DOOR LOCK

⇔

BODY GROUND)

(a)

Disconnect the door lock connector.

(b)

Check the continuity between the terminal of the door lock

connector and the body ground, as shown in the illustra-

tion and table.

Standard:

Symbols (Terminal No.)

(Door lock

⇔

Body ground)

Specified condition

D9–8

⇔

Body ground

Continuity

D8–7

⇔

Body ground

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS TABLE

(See page

05–707

)

I24324

B59185

TVIP ECU

D9

Door Key Lock and Unlock SW Front RH

Door Lock Motor Front RH

Door Unlock Detection SW Front RH

D8

Door Key Lock and Unlock SW Front LH

Door Lock Motor Front LH

Door Unlock Detection SW Front LH

Detection

Detection

LSWP

38

T3

W–R

3

IJ2

7

8

LSWD

1

IJ2

W–B

W–B

37

T3

W

3

IC1

6

IC1

W–B

J6

J/C

W–B

8

7

J7

J/C

A

IE

IG

A

W–R

W

05–736

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

901

Author:

Date:

2004 COROLLA (RM1037U)

DOOR UNLOCK DETECTION SWITCH CIRCUIT

CIRCUIT DESCRIPTION

The door unlock detection switch is built in the door lock motor assembly. This switch is ON when the door

lock knob is in the unlock position and OFF when the knob is in the lock position. The ECU detects the door

lock knob conditions in this circuit.

WIRING DIAGRAM

057S8–01

4

3

1

2

6

5

8

7

9 10

B58512

B52239

B59591

Passenger’s Door Lock

TVIP ECU

(Wire Harness Side)

T3

D8

D9

(Wire Harness Side)

Driver’s Door Lock

LSWP (38)

LSWD (37)

4

3

1

2

6

5

8

7

9 10

B58512

B59773

Passenger’s Door Lock

D8

D9

(Wire Harness

Side)

Driver’s Door Lock

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–737

902

Author:

Date:

2004 COROLLA (RM1037U)

INSPECTION PROCEDURE

1

CHECK DOOR LOCK (See page

73–3

)

NG

REPLACE DOOR LOCK

OK

2

CHECK WIRE HARNESS (TVIP ECU

⇔

DOOR LOCK)

(a)

Disconnect the TVIP ECU and door lock connectors.

(b)

Check the continuity between the terminals of the TVIP

ECU and door lock connectors, as shown in the illustra-

tion and table.

Standard:

Symbols (Terminal No.)

(TVIP ECU

⇔

Door lock)

Specified condition

LSWD (T3–37)

⇔

D8–8

Continuity

LSWP (T3–38)

⇔

D9–7

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

3

CHECK WIRE HARNESS (DOOR LOCK

⇔

BODY GROUND)

(a)

Disconnect the door lock connector.

(b)

Check the continuity between the terminal of the door lock

connector and the body ground, as shown in the illustra-

tion and table.

Standard:

Terminal No.

(Door lock

⇔

Body ground)

Specified condition

D9–8

⇔

Body ground

Continuity

D8–7

⇔

Body ground

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS TABLE

(See page

05–707

)

I24326

B59563

TVIP ECU

I11

Integration Relay

TVSS

26

W

28

T3 IRSG

05–740

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

905

Author:

Date:

2004 COROLLA (RM1037U)

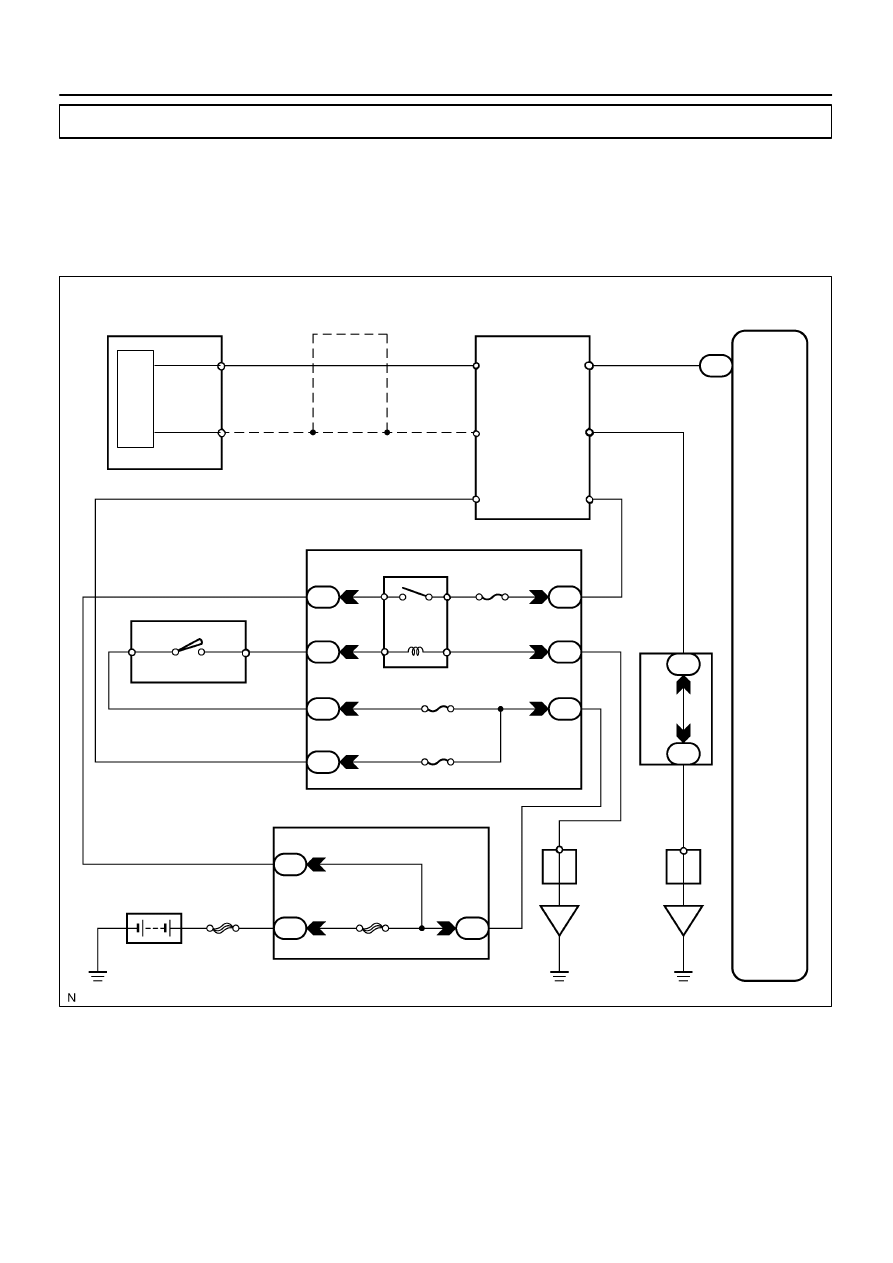

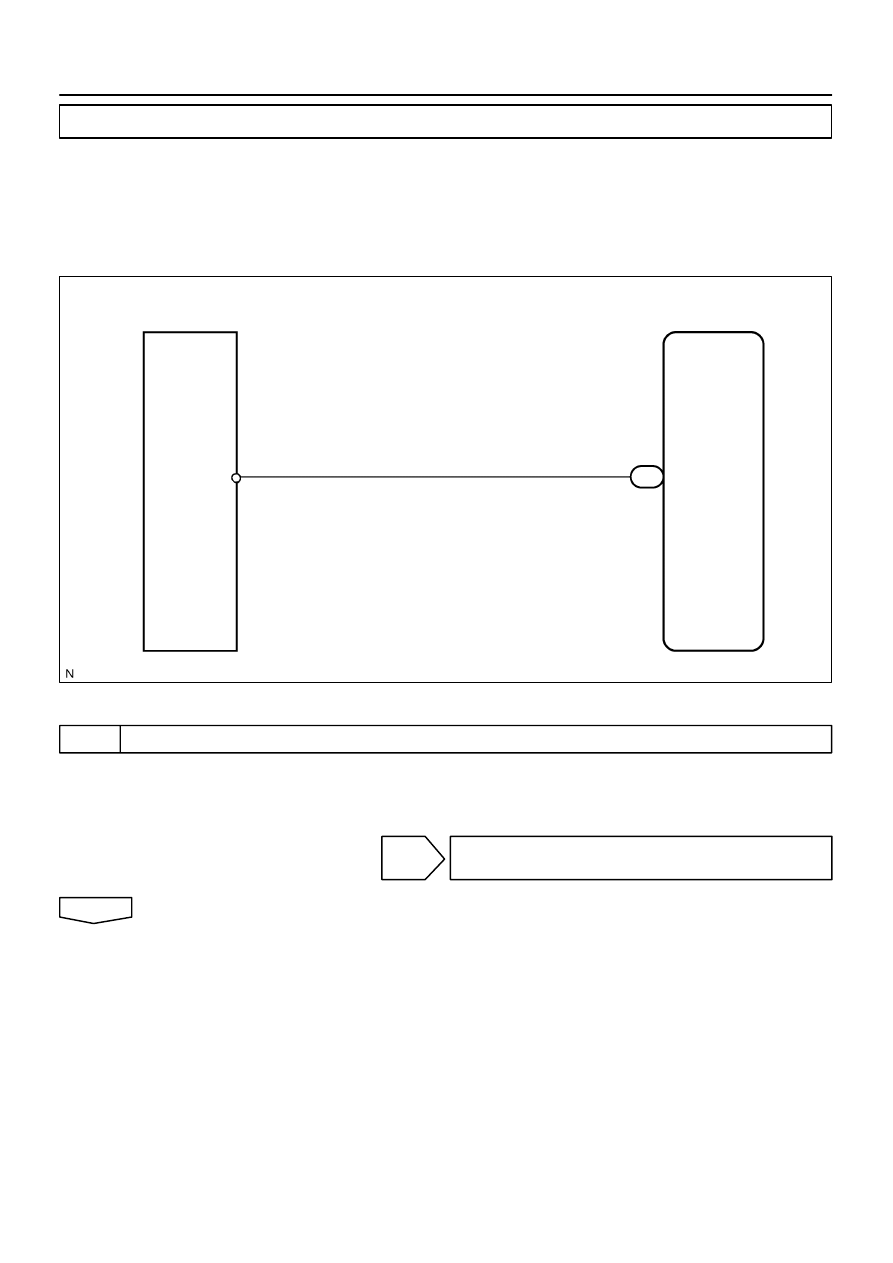

TVIP ECU COMMUNICATION CIRCUIT

CIRCUIT DESCRIPTION

The wireless receiver receives a SET/UNSET signal for the TVIP system and sends the signal to the TVIP

ECU via the integration relay.

WIRING DIAGRAM

INSPECTION PROCEDURE

1

CHECK TVIP ECU

(a)

Check that the operation of the TVIP function is normal.

HINT:

With this inspection, the TVIP ECU CPU can be diagnosed if it works normally or not.

NG

CHECK AND REPLACE TVIP ECU

(See page

01–30

)

OK

057SA–01

B59601

Integration Relay

TVIP ECU

(Wire Harness Side)

T3

I11

(Wire Harness Side)

IRSG (28)

TVSS (26)

–

DIAGNOSTICS

TOYOTA VEHICLE INTRUSION PROTECTION

SYSTEM

05–741

906

Author:

Date:

2004 COROLLA (RM1037U)

2

CHECK WIRE HARNESS (TVIP ECU

⇔

INTEGRATION RELAY)

(a)

Disconnect the TVIP ECU and integration relay connec-

tors.

(b)

Check the continuity between the terminal of the TVIP

ECU connector and integration relay connectors, as

shown in the illustration and table.

Standard:

Symbols (Terminal No.)

(TVIP ECU

⇔

Integration relay)

Specified condition

IRSG (T3–28)

⇔

TVSS (I11–26)

Continuity

NG

REPAIR OR REPLACE WIRE HARNESS AND

CONNECTOR

OK

CHECK AND REPLACE TVIP ECU (See page

01–30

)

Wyszukiwarka

Podobne podstrony:

diagnostics Anti Theft

Anti theft Immobilizer On Board Diagnostic (OBD) inst vw

M39t1 Remote Keyless Entry and Anti theft System

M39t2 Remote Keyless Entry and Anti theft System

M39t3 Imobiliser Anti theft System

73 Anti Theft and Door Locks

REMOTE ENTRY & KEYLESS ANTI THEFT SYSTEM 9T 12

05 6 F01 Anti theft System

BMW E38 schematic Anti theft

73 Anti Theft and Door Locks

20 E65 Anti Theft Alarm System

05c3 E70 Anti Theft Alarm System

diagnostyka

T 3[1] METODY DIAGNOZOWANIA I ROZWIAZYWANIA PROBLEMOW

Przedmiot PRI i jego diagnoza przegląd koncepcji temperamentu

DIAGNOSTYKA FIZJOLOGICZNA I 1

więcej podobnych podstron