The Phaeton

Auxiliary heater Thermo TOP C and

supplementary heater Thermo TOP Z

Design and function

Self-study programme 280

Service.

2

NEW Important

Note

This self-study programme explains the design and

function of new developments.

The contents will not be updated.

Please refer to the relevant service literature for

current inspection, adjustment and repair instructions.

The use of heater units that work

independently of the engine is continually rising.

They are offered as an accessory for retrofit or as

an optional extra by the manufacturer.

The petrol engine Phaeton features an auxiliary

heater as an optional extra that heats the interior

when the engine is not running.

For diesel engines, the Phaeton is fitted as

standard with a supplementary heater that

boosts coolant heating when the engine is

running.

In this way, the operating temperature of the

engine is reached faster and is maintained

throughout operation at an equal level.

This self-study programme provides you with an

overview of the auxiliary heater and the

supplementary heater installed in the Phaeton.

S280_053

3

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Coolant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operating stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Deactivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Functional diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Explanation of highlighted terms

Test yourself . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4

Introduction

The auxiliary heater

The auxiliary heater is a wise choice as an

accessory. The heater and ventilation function

provides a comfortable environment in the

interior, which is available as soon as you climb

into the vehicle.

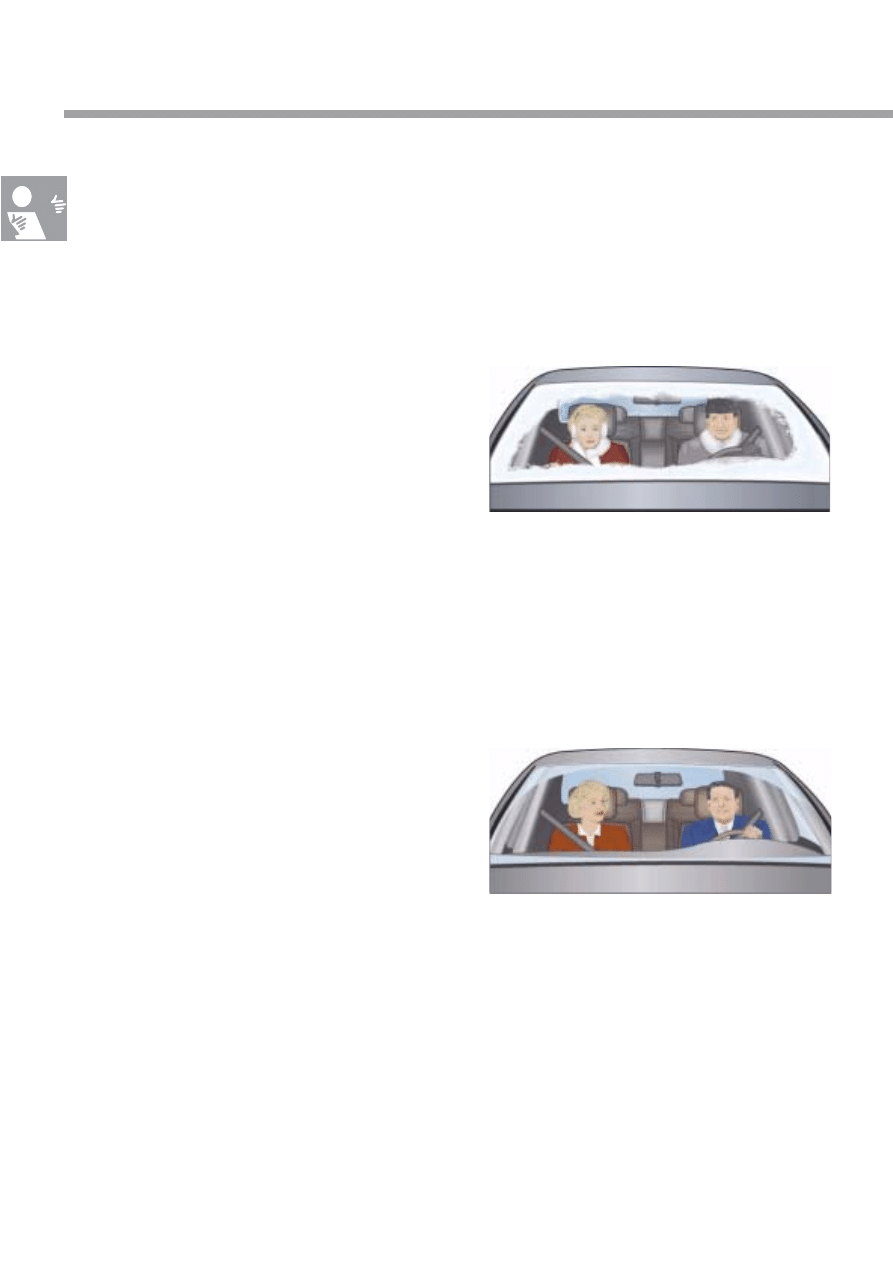

Frosted or steamed up windows inhibit all-round

view. Therefore, they are a considerable risk in

traffic situations.

Heavy winter clothing, when worn in the vehicle,

results in loose seat belts as they are no longer

comfortably taut against the body. The optimal

efficiency of the seat belt is markedly impaired.

A further disadvantage is that unsuitable

clothing restricts freedom and thereby also the

ability to react quickly to given situations.

By heating up the interior before the journey is

started, the windows are cleared.

Good all-round view is guaranteed.

Less restrictive clothing in a preheated vehicle

increases the efficiency of seat belt protection

and reaction time of the wearer.

Further, use of an auxiliary heater is financially

viable. In many regions, the temperature on

100 days of the year is less than +5 °C, which

equals a third of a year of operation.

S280_013

S280_012

5

The supplementary heater

The diesel engines in the Phaeton feature

a heater that works to boost heat.

When the engine is started, the coolant is heated

additionally by the supplementary heater.

This helps diesel engines to make use of their

good efficiency and reach their operating

temperature in a short space of time.

The heat generated from the combustion process

is an unavoidable side-effect. The energy stored

within is converted partly into heat instead of

power.

This has the effect of reducing the degree of

efficiency.

Direct injection diesel engines reach a high level

of efficiency thanks to their optimised combustion

process. The use of a supplementary heater

supports the high level of efficiency in the engine

by heating of the coolant. In addition,

the passenger compartment is heated

comfortably.

6

Activation

Operation

The auxiliary heater can be operated in a number of different ways:

●

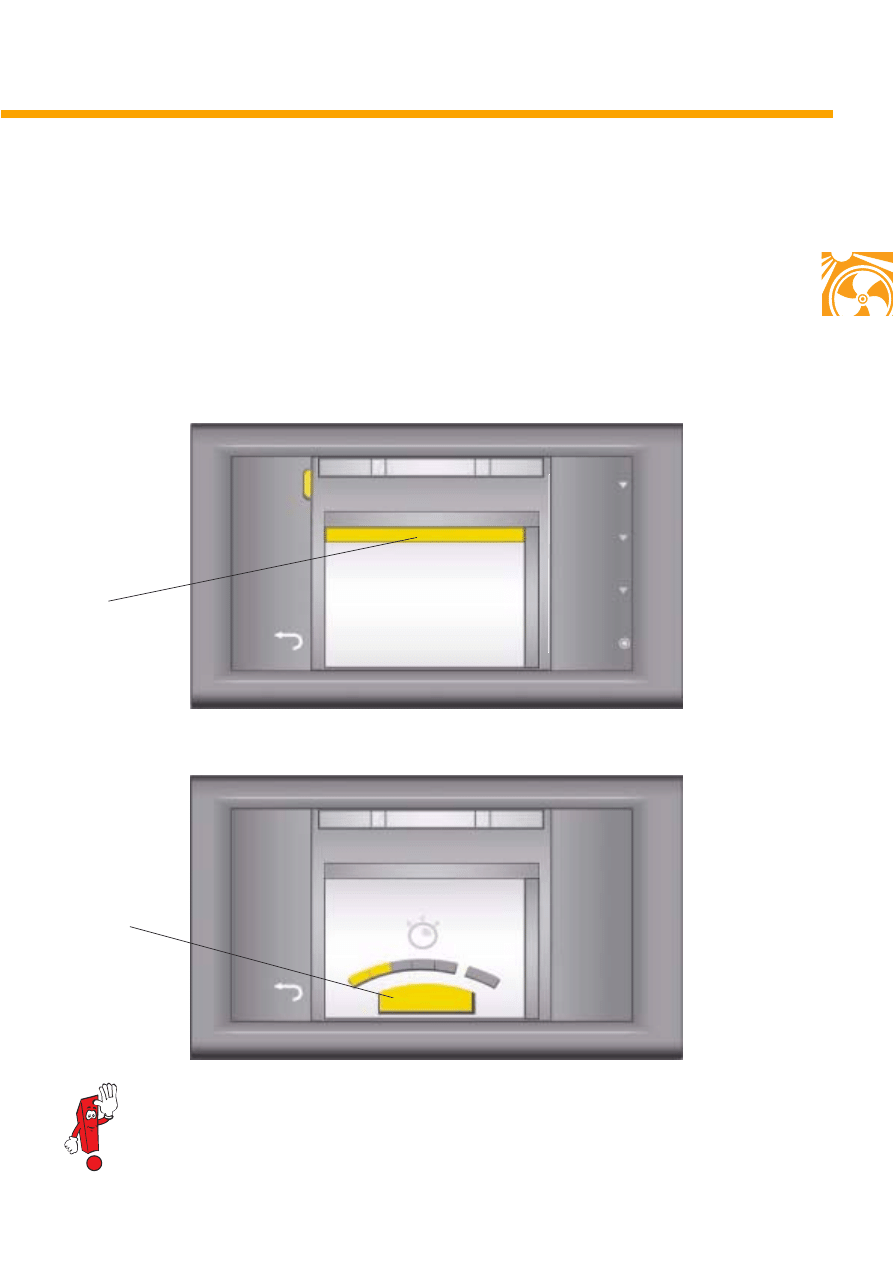

Immediate start is carried out via the front information display and operating unit, in the sub-menu of

the air conditioning system.

●

Programming a fixed start time is done via a timer in the same sub-menu.

●

Additionally, the auxiliary heater can be started using a remote control.

Immediate start

By pressing the auxiliary heater function button, the sub-menu can be accessed

for auxiliary heater control.

The heater button allows manual activation and deactivation of the auxiliary heater.

S280_008

Heater button for immediate start

22°C

22°C

92.8 MHz TP

A/C

Other functions/Auxiliary heater

Timer (duration:10 min)

Monday

06:20

Heater

Back

Duration

Day

Departure

time

Sel-

ection

Front information display and operating unit

7

S280_021

When the auxiliary heater is activated at temperatures above +22 °C, auxiliary ventilation is

activated automatically.

Display: Set duration

Timer preselection

The start time for the heater can be programmed in the sub-menu. To do this, the weekday,

the start time and the desired duration should be entered using the operating elements.

When the weekday and time have been reached, auxiliary heater operation will begin. In addition, the

weekday will jump automatically to the next day.

S280_061

Display:

Weekday,

time

22°C

22°C

92.8 MHz

A/C

Other functions/Auxiliary heater

Timer (duration:10 min)

Monday

06:20

Heater

Back

Duration

Day

Departure

time

Sel-

ection

Display: Timer preselection

TP

Tuesday

08:50

22°C

22°C

92.8 MHz

A/C

..../Auxiliary heater/Heating duration

Back

Confir-

mation

TP

15 min

Display:

Duration

8

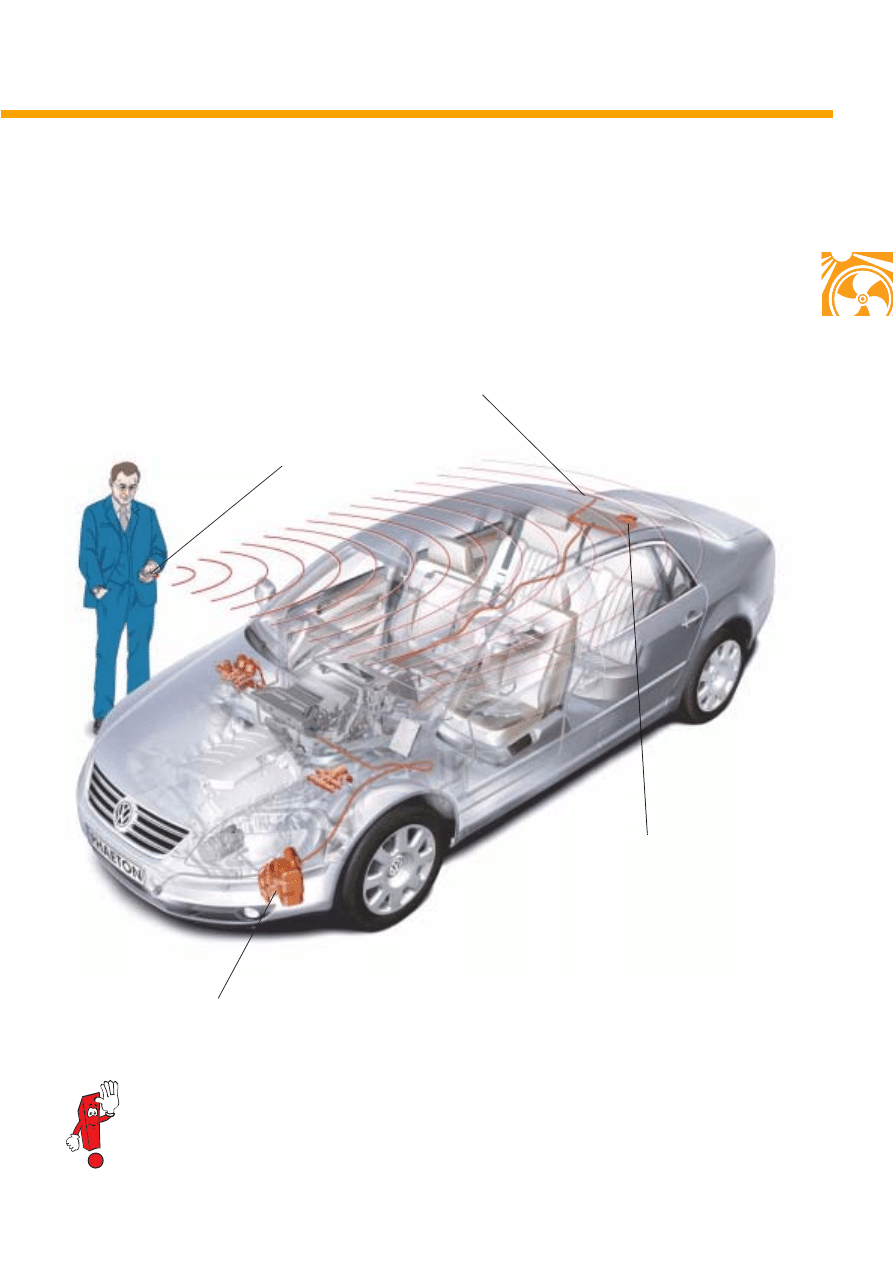

Remote start

The auxiliary heater features an additional

remote control, which is not integrated in the

vehicle key.

With this remote control, the auxiliary heater is

switched on and off remotely.

The on button serves to start the heater and the

off button is used to switch it off.

For power supply of the remote control, a battery

is necessary.

The range of the remote control in open areas is

approx. 600 m.

The control lamp of the remote control lights up

green when the auxiliary heater is switched on,

and red when it is switched off.

Operation

S280_023

On button

Off button

Remote control

Control lamp

S280_066

Opening for battery replacement

9

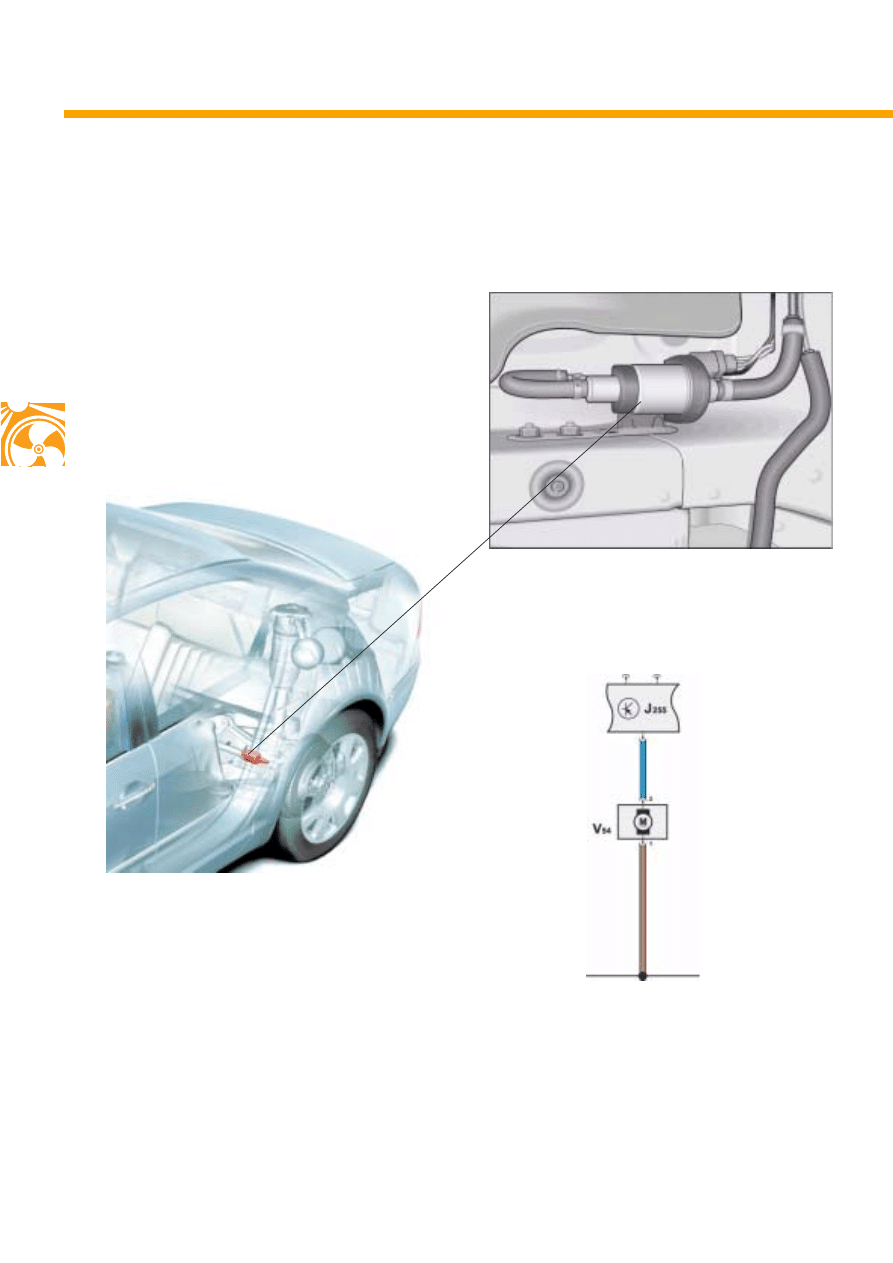

The signal is sent to the auxiliary heater control

unit (J255) by pulse width modulated

transmission along a special data lead.

The radio signal from the remote control is

pikked up by an aerial, which is installed in the

upper area of the rear window, and transmitted

to a receiver located beneath the rear shelf.

The remote control must be coded to the radio receiver. A maximum of two remote controls can

be coded. The work procedure necessary is described in the electronic service information

system (ELSA).

Remote control

Aerial

Radio receiver

Auxiliary heater control unit

S280_019

Overview of associated components

10

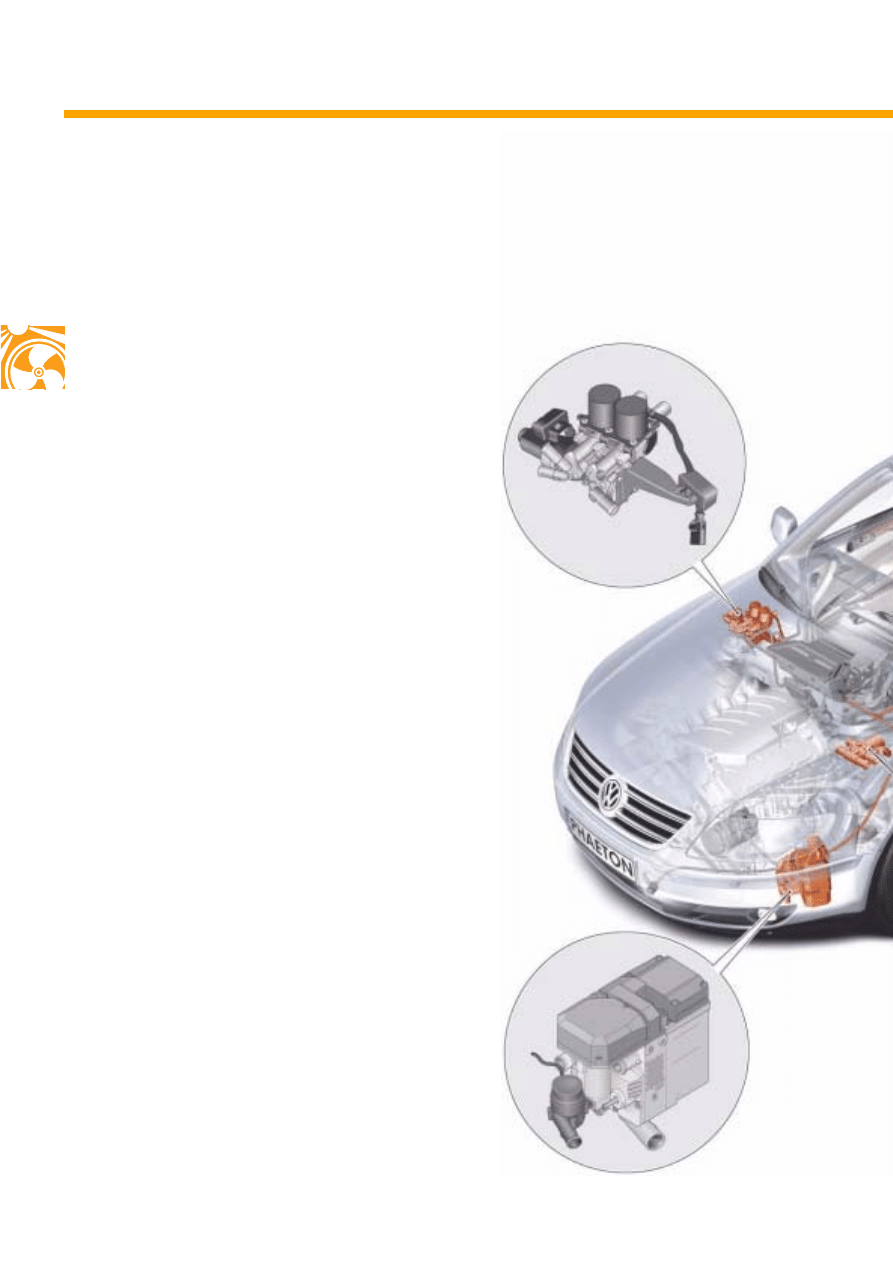

Fitting locations

The components necessary for operation of the

auxiliary heater or the supplementary heater are

installed in the vehicle decentrally.

Overview

Auxiliary/supplementary heater

with control unit,

front left beneath wing

Pump valve unit,

front right in vicinity of plenum

chamber

Overview of fitting locations

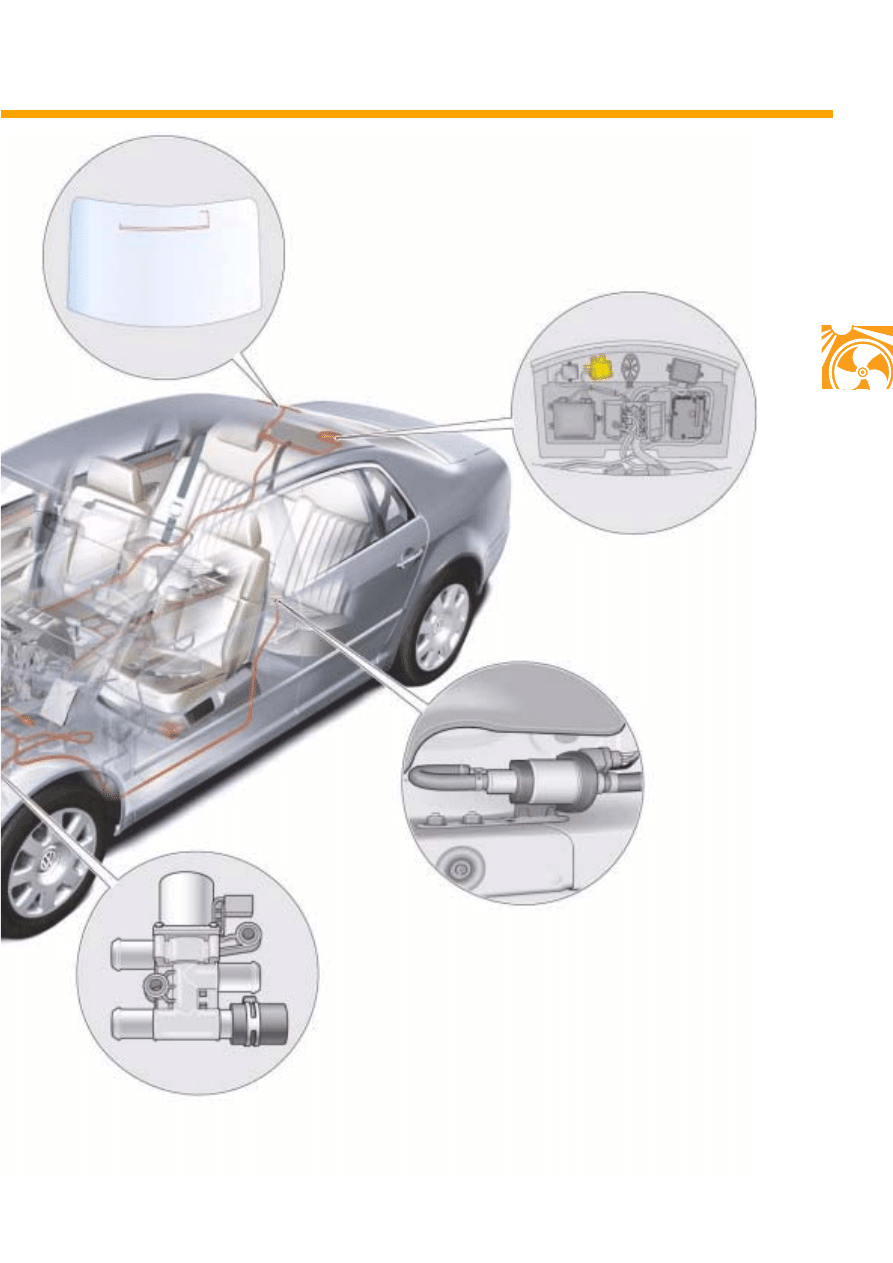

11

Metering pump,

above rear axle,

left of centre

Radio receiver,

beneath rear shelf

S280_017

Aerial for remote start,

beneath rear window upper

trim

Coolant shutoff valve,

on left in engine compartment

12

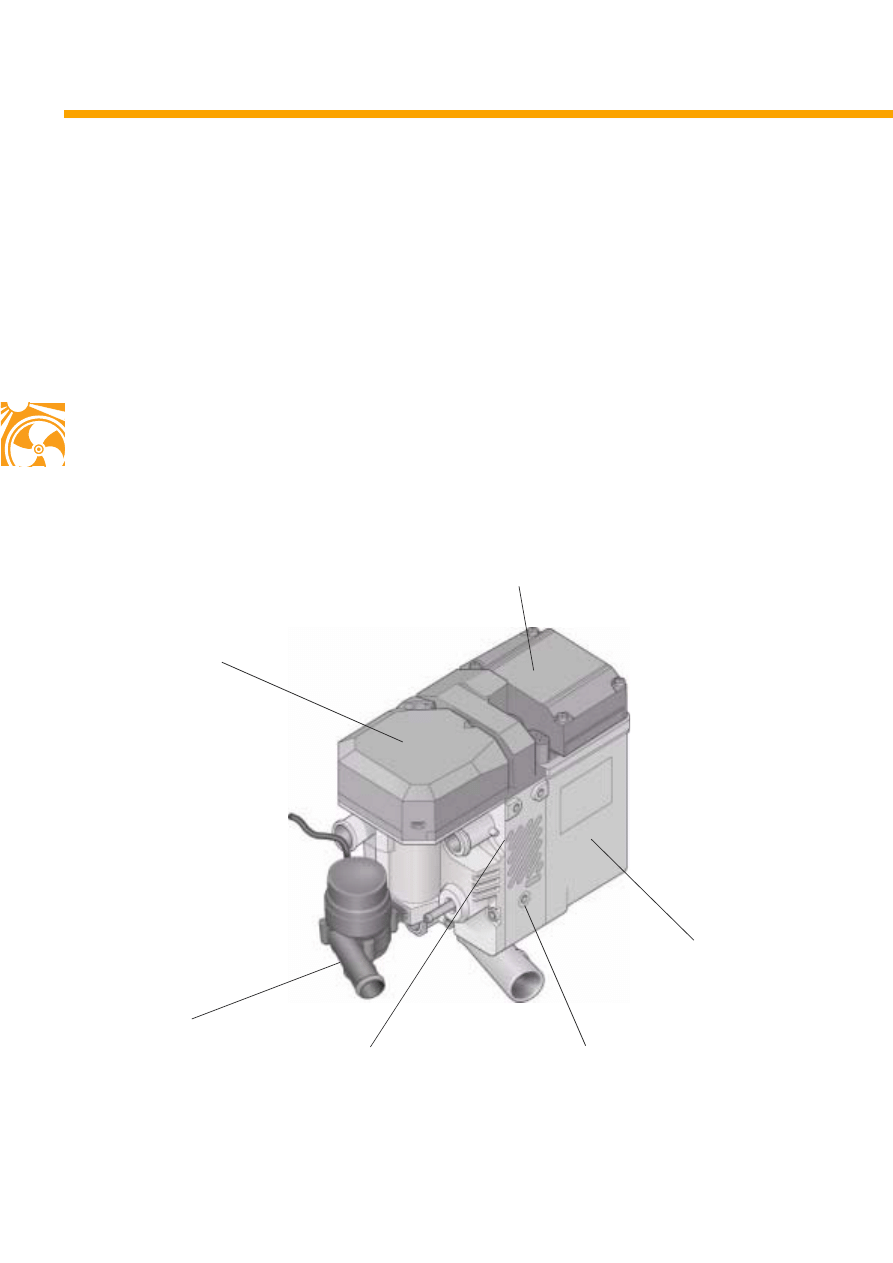

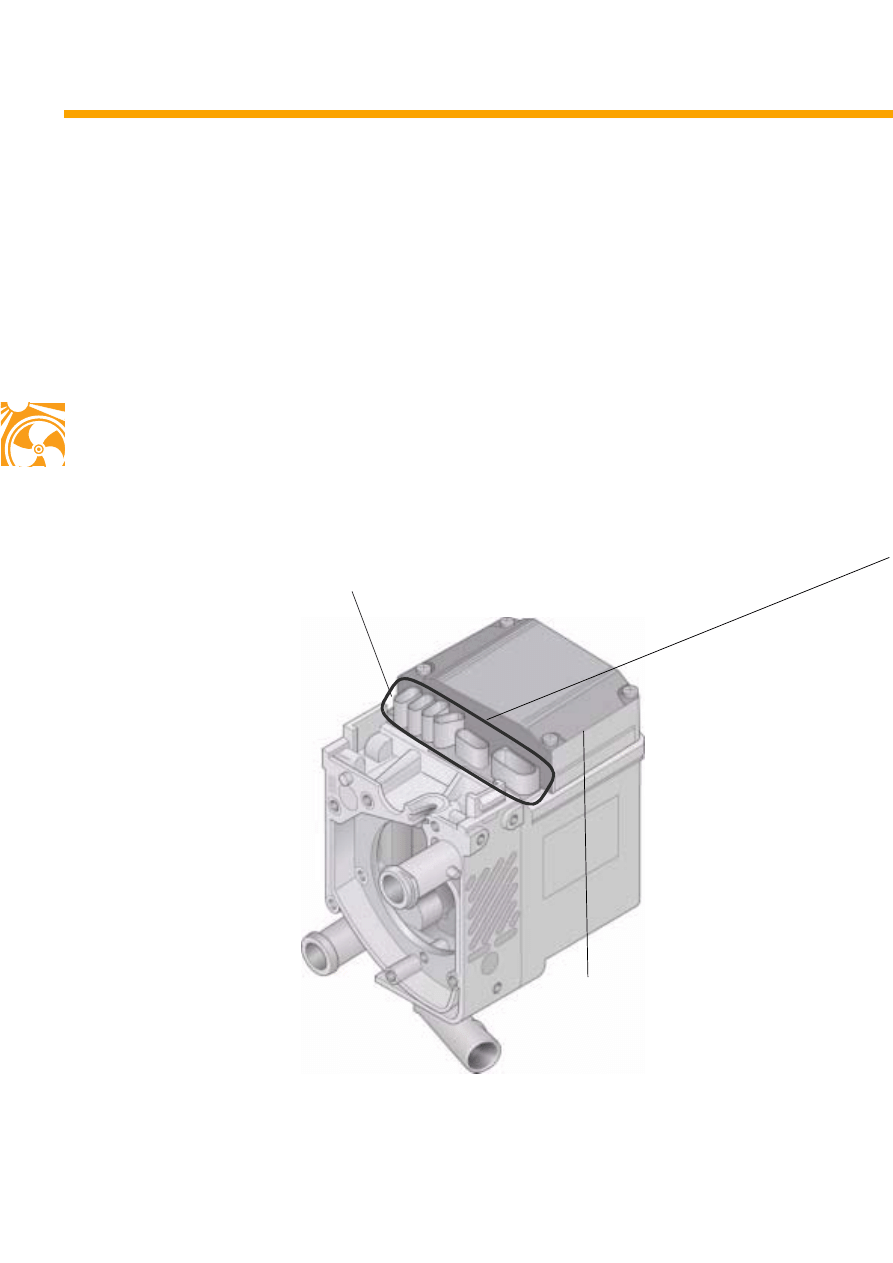

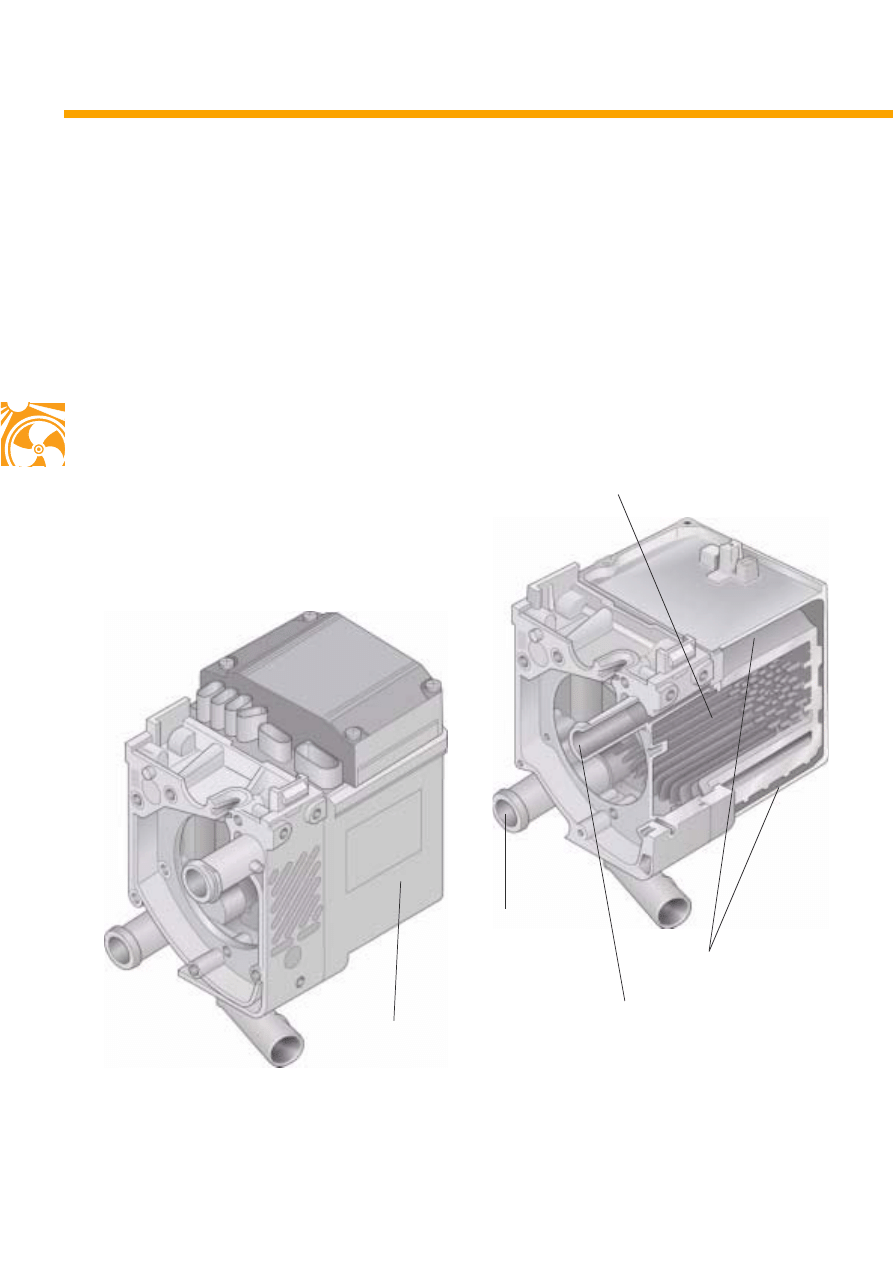

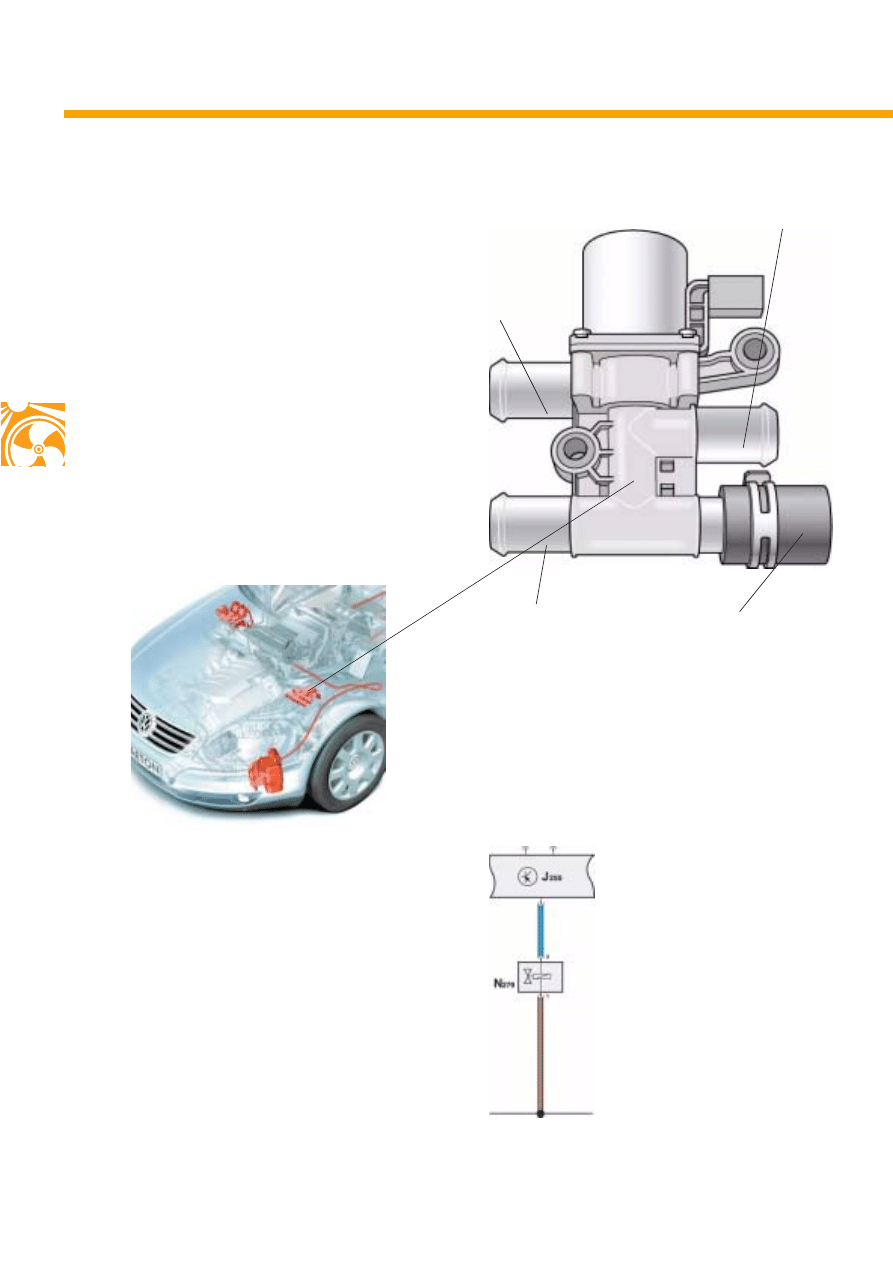

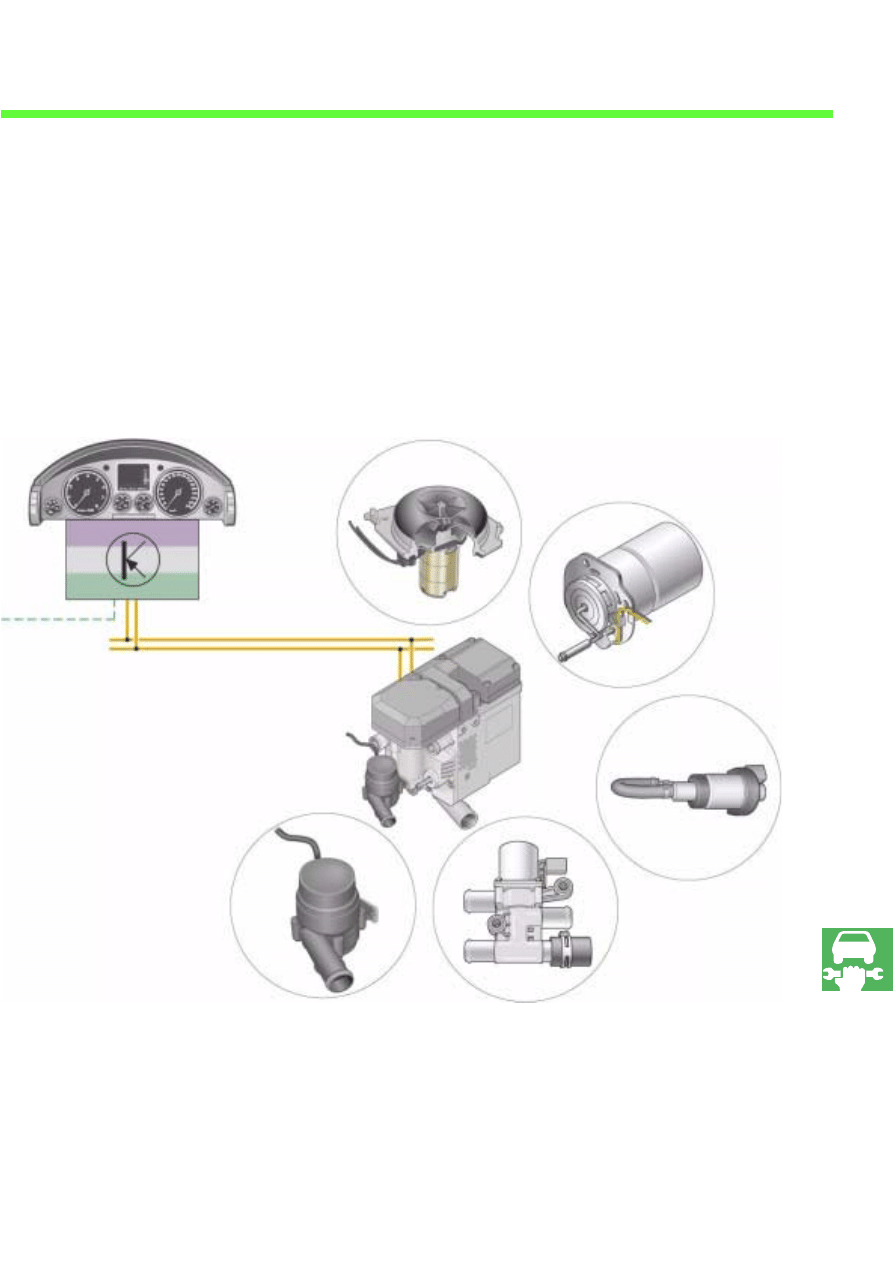

The components

The auxiliary heater and the supplementary

heater consist of:

- recirculating pump V55,

- combustion air blower V6,

- control unit J255,

- burner housing,

- combustion chamber with flame pipe and

glow plug Q9 (with flame monitor) in burner

housing,

- coolant jacket.

Additional components are:

- metering pump V54 and

- coolant shutoff valve N279.

Construction

S280_002

Recirculating pump

Burner housing

Coolant jacket

Combustion air blower V6

Combustion chamber in

burner housing

Thermo Top Z/C (heater)

Control unit

13

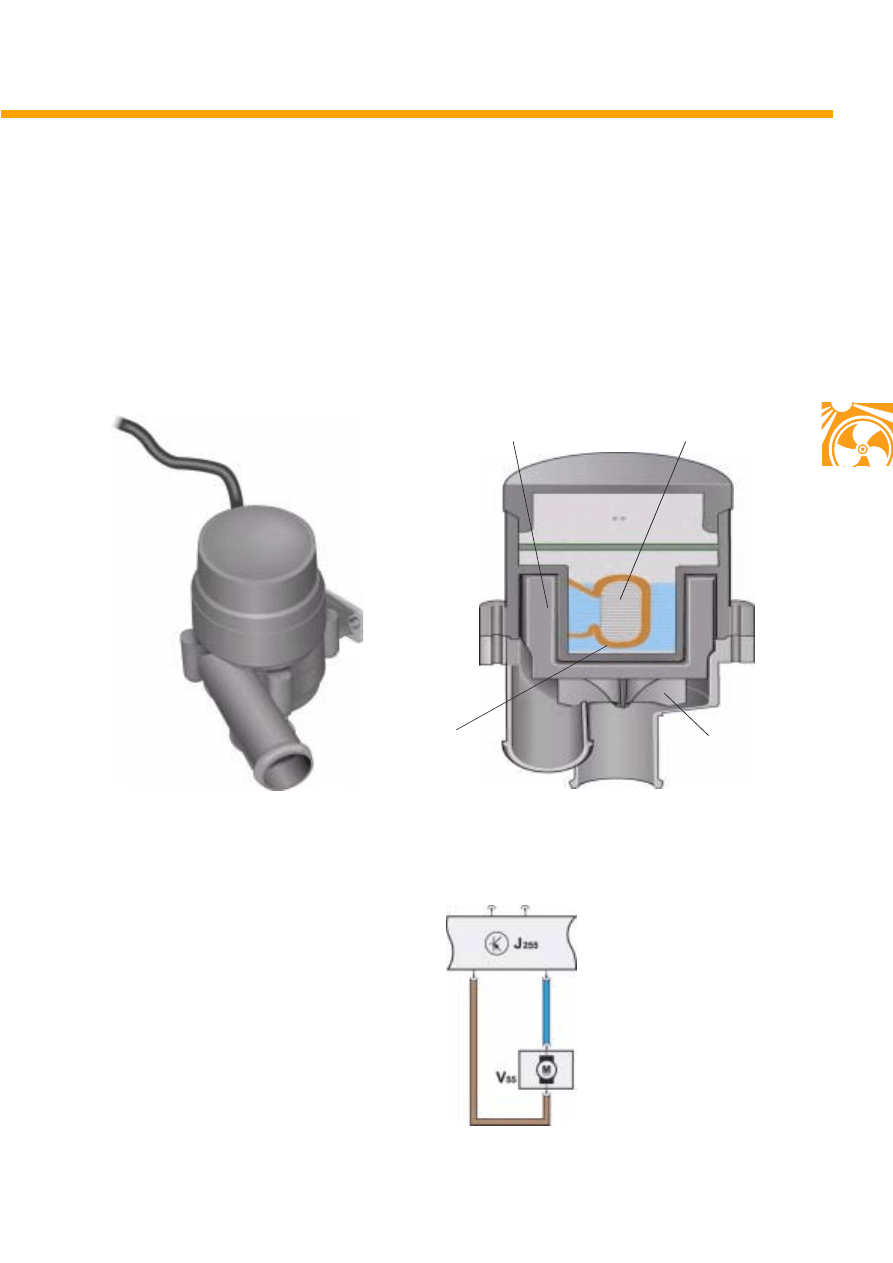

The recirculating pump V55

When the engine is switched off, coolant is

circulated by a recirculating pump. This is

actuated electrically by auxiliary heater control

unit J255.

Actuation

Actuation is by the auxiliary heater control unit.

S280_057

S280_044

S280_007

Recirculating pump

Cross section

Iron core

Permanent magnet

Coil

Pump rotor

14

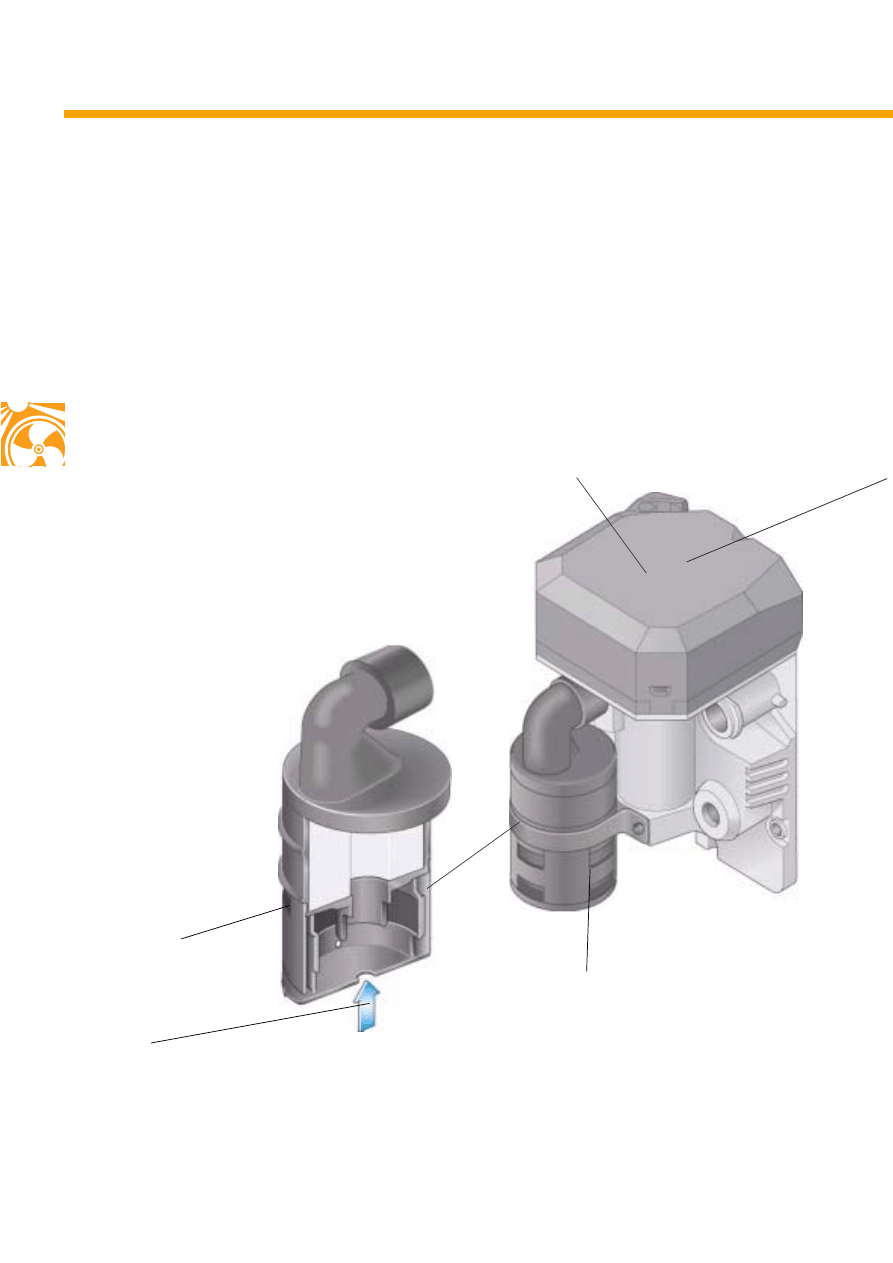

The combustion air blower V6

The air required for combustion is drawn in via

an air intake pipe with silencer by the

combustion air blower, then via the air channel

to the fuel evaporator (fleece) and further to the

combustion chamber.

Construction

S280_003

Silencer

Combustion air blower

Main view

Silencer and filter element

S280_058

Air intake

15

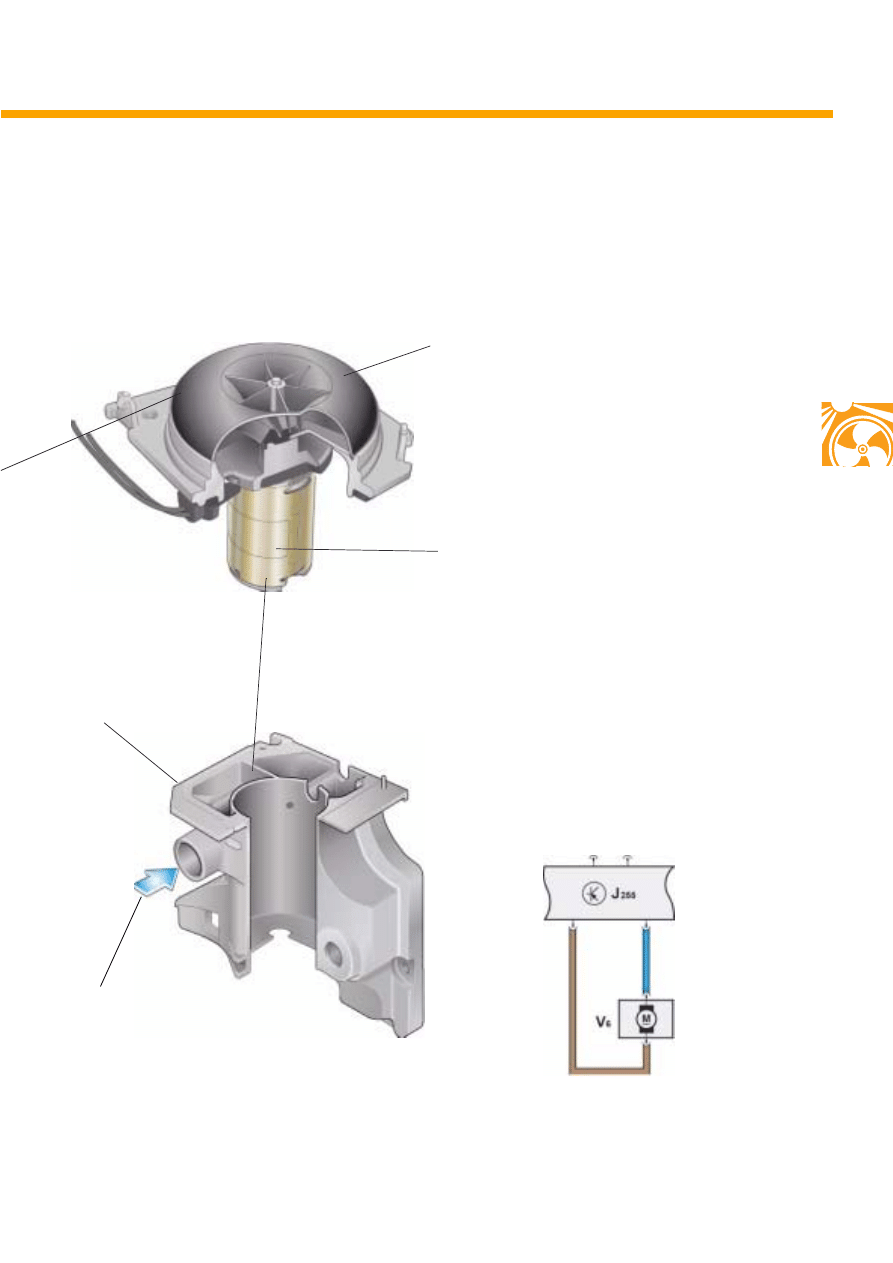

Actuation

The combustion air blower is supplied with

voltage direct from the control unit via a two pin

connector.

S280_047

Blower rotor with vanes

Blower motor

S280_059

S280_055

Housing

Air intake

16

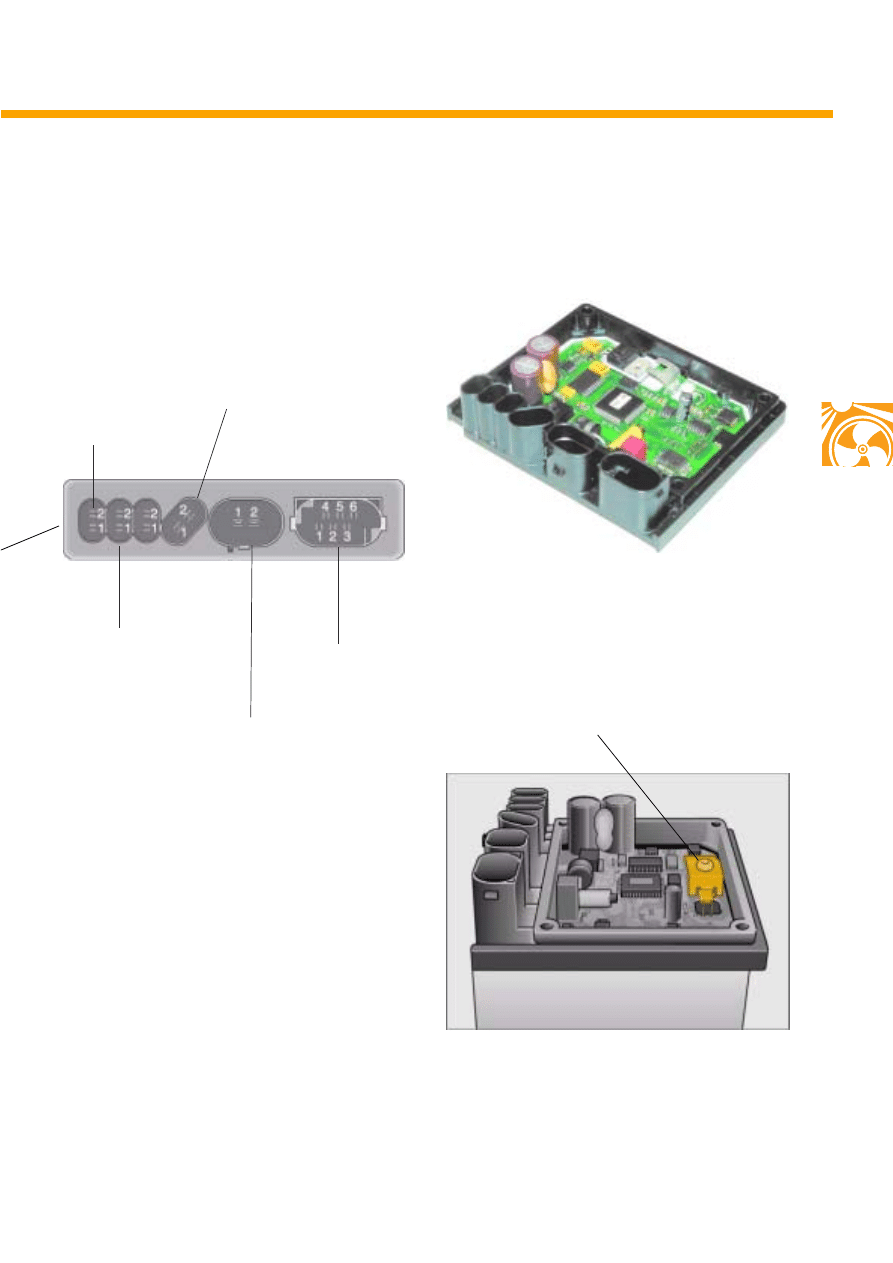

Construction

Control unit

S280_004

Connector strip

The auxiliary heater control unit J255

Main view

As primary control unit, the control unit guarantees the functional sequence and monitor heater

operation.

Connection to the vehicle onboard electrical system is via a connector strip.

The supplementary heater and the auxiliary heater differ in control unit codes and connection to the

coolant circuit. In addition, the auxiliary heater has a remote start function and a coolant shutoff valve.

17

Temperature monitoring

Coolant temperature is monitored in the heater

and heater operation is regulated via the

temperature sender G241. At coolant

temperatures above 125 °C, the heater is

shut off and locked.

To unlock, follow the instructions on the diagno-

sis, testing and information system VAS 5051 and

the electronic service information system (ELSA).

S280_054

Control unit opened

S280_065

Temperature sender

Glow plug with flame monitor Q9

Power supply

Combustion air blower V6

Recirculating pump V55

Connector to onboard

electrical system

S280_035

18

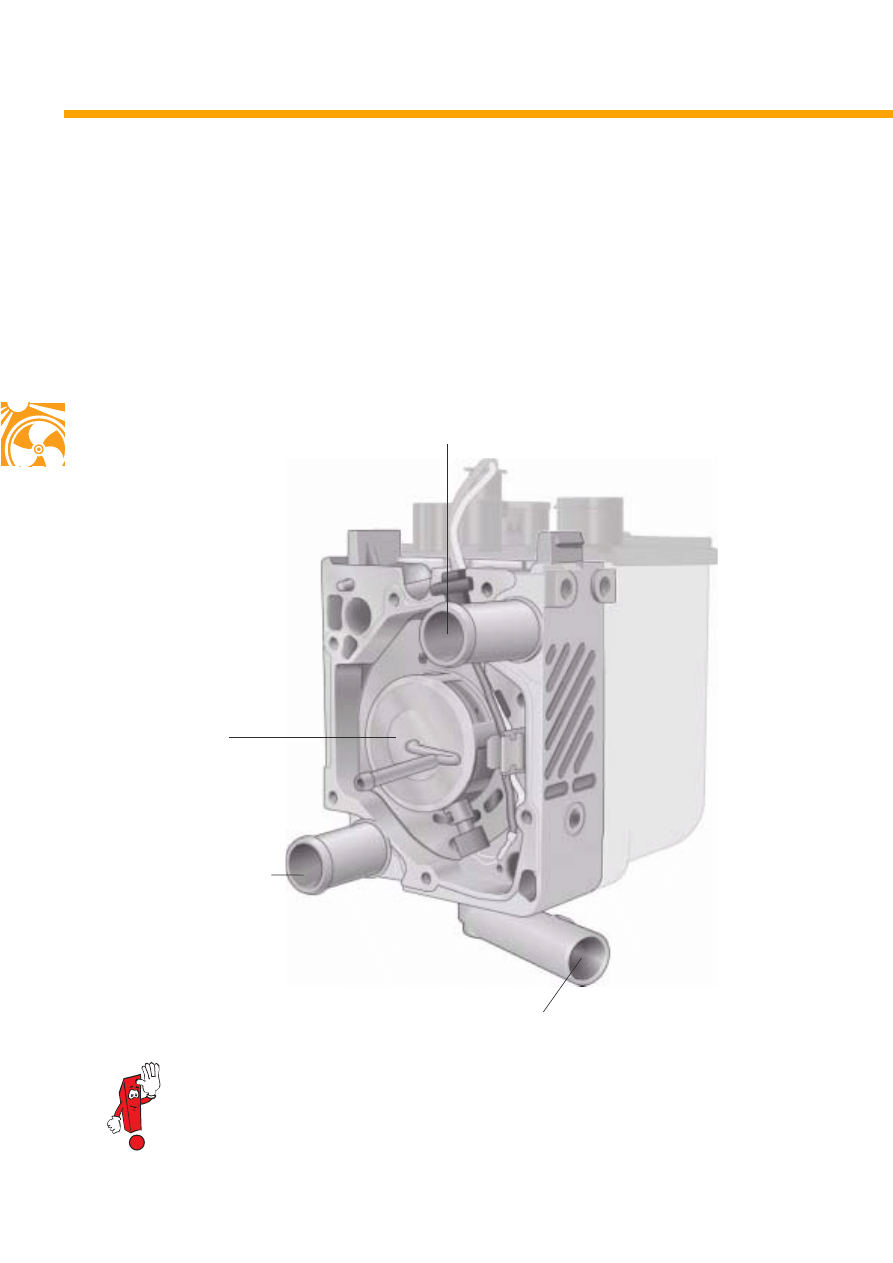

The burner housing

Located on the burner housing are:

- the coolant outlet,

- the exhaust pipe,

- the coolant inlet and

- the combustion chamber.

Construction

Coolant inlet

Coolant outlet

S280_027

Further, the burner housing houses the combustion chamber and forms a unit with the coolant

jacket and the control unit.

Combustion

chamber

Burner housing

Exhaust pipe

19

Formation of the fuel-air mixture takes place in

the combustion chamber. This mixture is then

burnt in the flame pipe.

The glow plug with flame monitor can be found

in the combustion chamber. This ignites the

fuel-air mixture initially. During the heating

stage, the glowing walls of the combustion

chamber ignite the fuel-air mixture.

The glow plug is designed as an electrical

resistor and features a flame monitor. It monitors

the temperature of the flame during the whole

phase of heating.

Glow plug with flame monitor

S280_005

Combustion air inlet

Combustion air inlet

into

fuel evaporator

Fuel intake

Flame pipe

The combustion chamber with flame

pipe and heater glow plug Q9 (with flame monitor)

Combustion air inlet

Flame pipe

Combustion chamber

Combustion chamber

Combustion chamber cross section

S280_056

20

The coolant jacket.

Construction

Coolant jacket

S280_004

Coolant inlet

Coolant outlet

Space for coolant

(transfer of heat)

Main view

Coolant jacket cross section

Space for combustion chamber

S280_060

The heat generated from combustion is conveyed to the coolant via the coolant jacket.

Coolant enters the housing via the coolant inlet of the coolant jacket (heat transmitter). The necessary

heat is then drawn for heating. Coolant leaves the housing via the coolant outlet.

21

The exhaust system

S280_025

Silencer

Exhaust pipe

The heater features its own exhaust system, which consists of an exhaust pipe and silencer. The exhaust

system channels the exhaust gas generated from heater combustion to the outside independently of the

vehicle exhaust system.

In order to guarantee safe operation of the heater, the prescribed length of the exhaust system should

not be altered.

The length is set to balance the combustion vibrations of the heater.

22

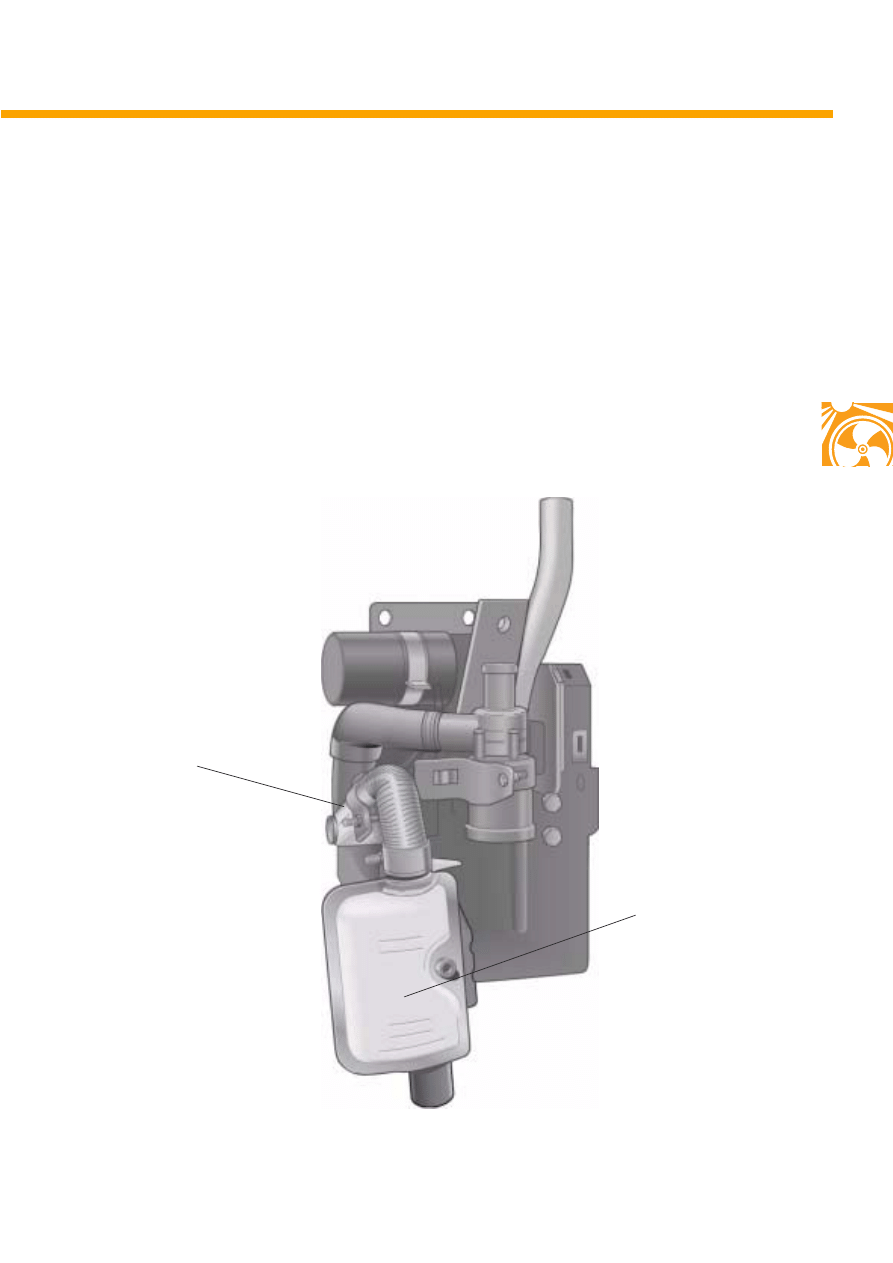

The metering pump V54

Supply of fuel from the fuel tank of the vehicle to

the heater is by metering pump. The pump is

designed as a combined supply, metering and

shutoff system. This means that fuel is metered

during operation and fuel supply is blocked

when the heater is switched off.

Fitting location

The metering pump can be found above the rear

axle. To remove the pump, the rear axle has to be

lowered. In order to ensure correct ventilation of

the pump, the prescribed fitting location must not

be changed.

Actuation

The metering pump is pulse-actuated via the

control unit based on the required heater output.

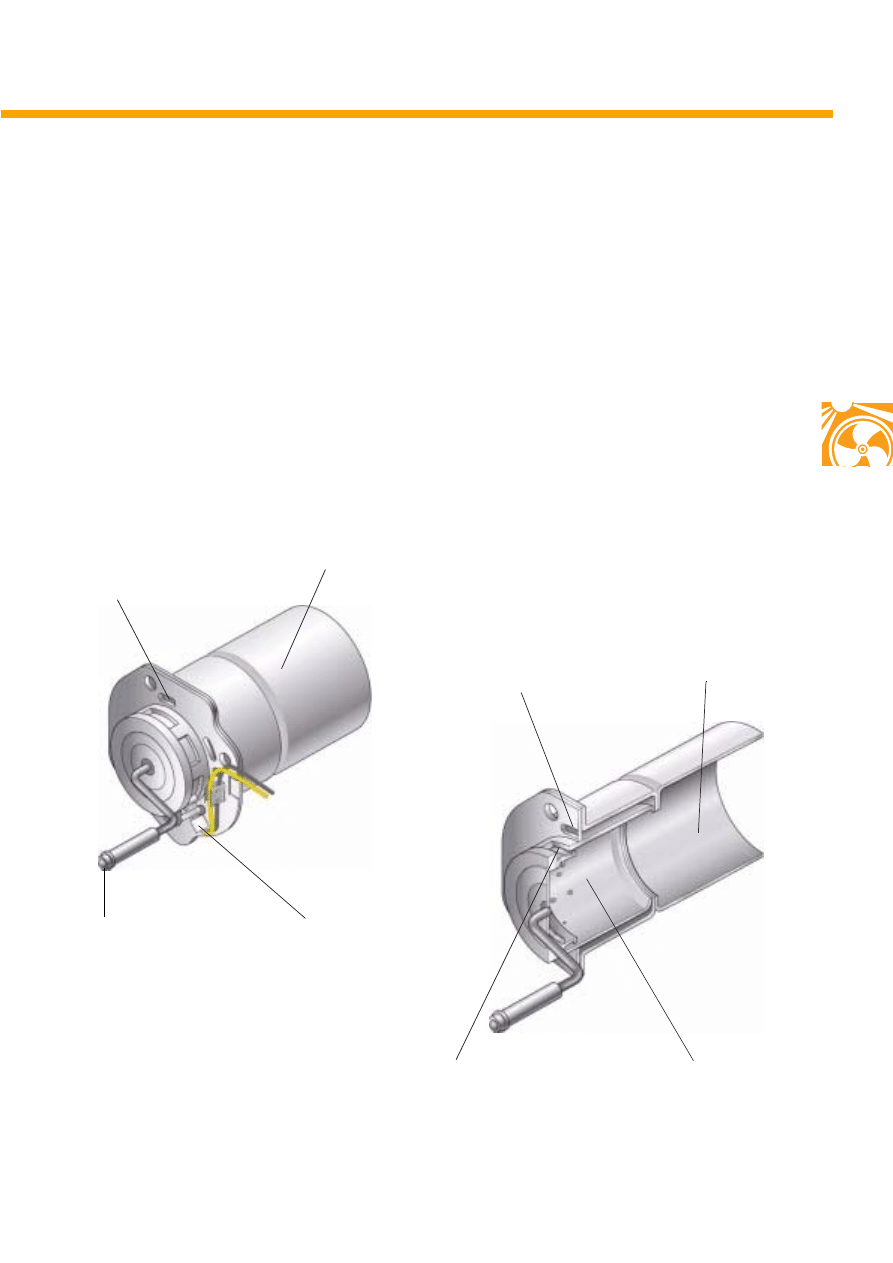

Construction

S280_014

S280_063

S280_046

23

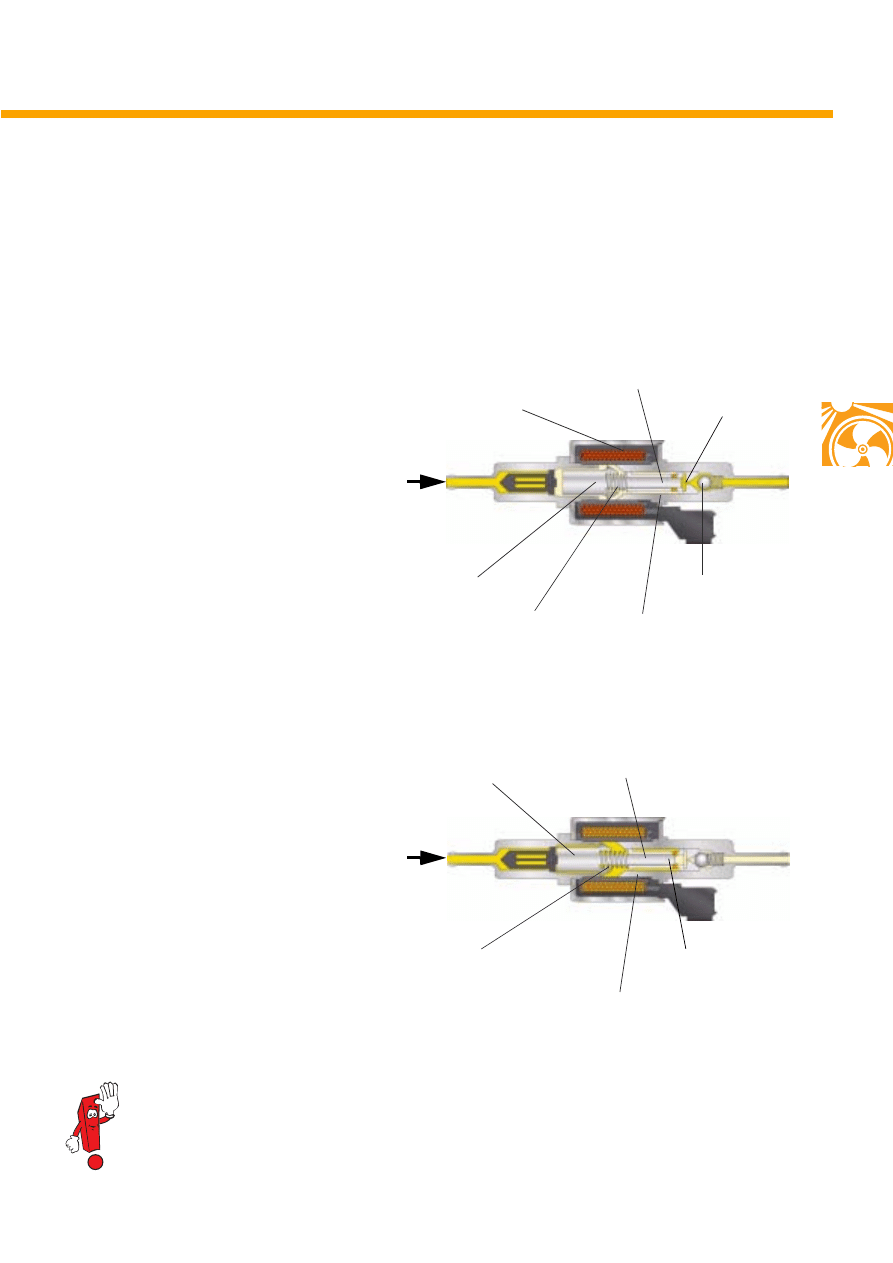

Functional description

The metering pump is of the plunger type, in

which the armature is attached permanently to

the pump plunger.

Supply of fuel

The metering pump is filled with fuel when there

is no voltage.

When the coil is energised, the armature pushes

the pump plunger against the spring.

The pump plunger lifts up the ball valve and

delivers fuel from the pump chamber. At the

same time, the supply hole to the pump chamber

is closed.

Fuel suction

During this period, fuel flows in the armature

chamber. When the coil is not energised, spring

pressure forces the armature and the pump

plunger back.

The resulting vacuum draws fuel into the pump

chamber via the opened inlet holes.

This kind of operation allows a high level of

metering accuracy, high durability and low noise

generation.

S280_067

Coil

Ball valve

Armature

Pump plunger

Spring

Inlet hole

Pump chamber

Armature

chamber

S280_062

Armature

Pump plunger

Pump chamber

Inlet hole

An animated view of the function can be found on the internet at

"www.thomas-magnete.com"

24

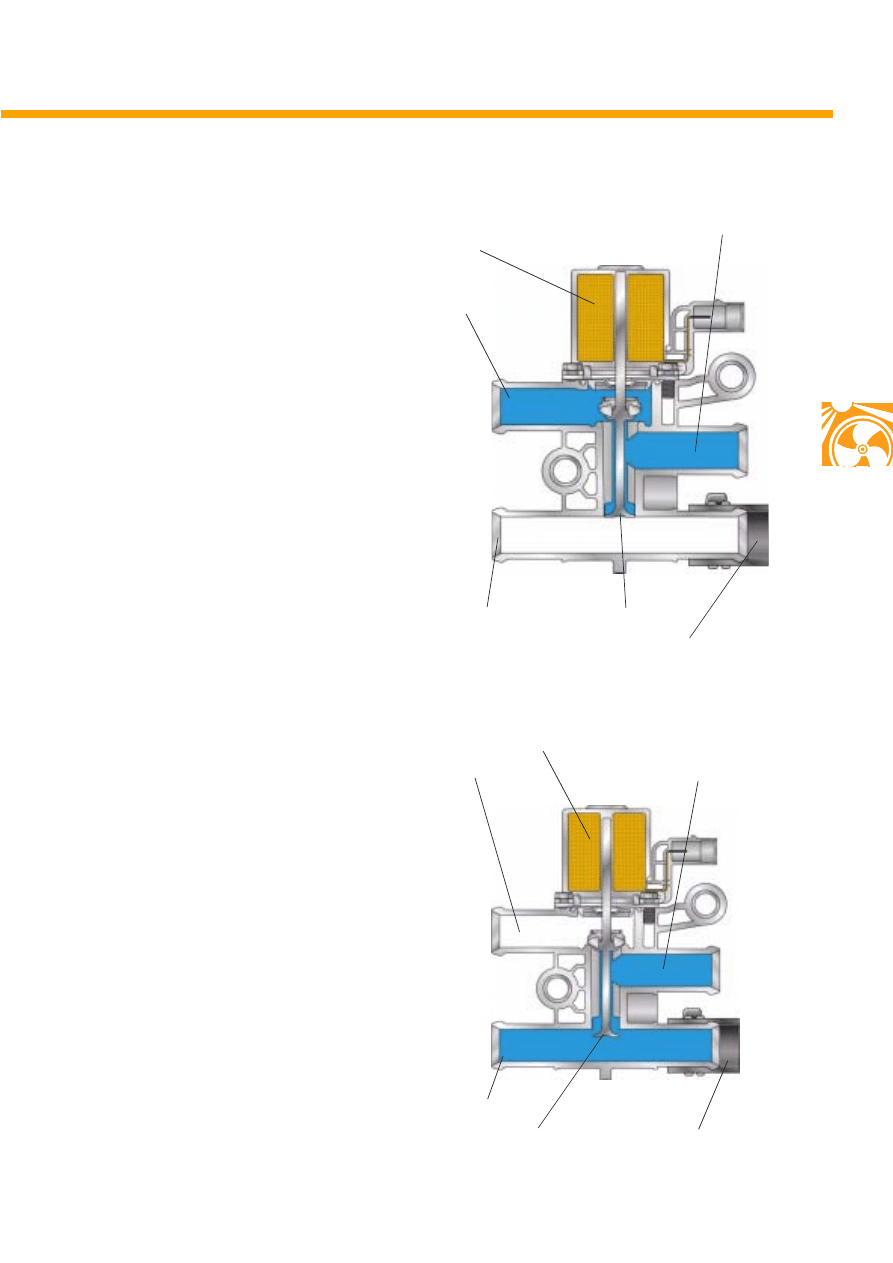

Only the auxiliary heater features a coolant

shutoff valve. When the auxiliary heater is in

operation, engine coolant circulation is

separated from the heat exchangers to the

interior.

Separation is via the coolant shutoff valve.

Fitting location

The coolant shutoff valve can be found on the

left in the engine compartment.

Actuation

The auxiliary heater control unit actuates the

valve directly.

Construction

To engine

From pump valve unit

To heater

S280_016

Plug

S280_064

Coolant shutoff valve N279

S280_048

25

Normal operation

When there is no power, the coolant shutoff

valve connects the coolant circuit between the

pump valve unit and engine circuit.

Heater operation

The shutoff valve is actuated and the pump valve

unit is connected with the auxiliary heater.

In this way, the interior of the vehicle is

preheated and not the engine.

To engine

From pump valve unit

Plug

Coil

Valve plunger

To engine

From pump valve unit

To heater

Plug

Coil

Valve plunger

S280_050

S280_051

To heater

26

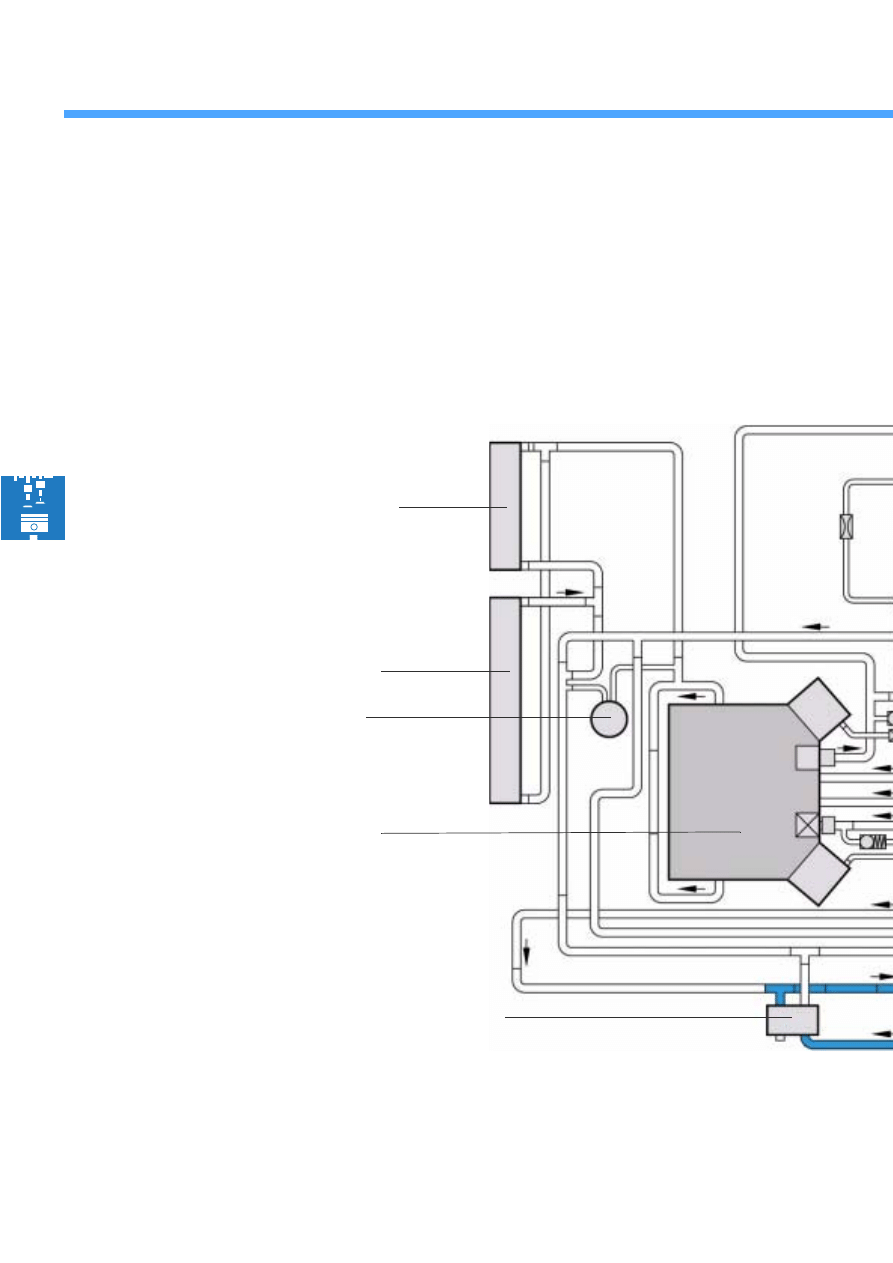

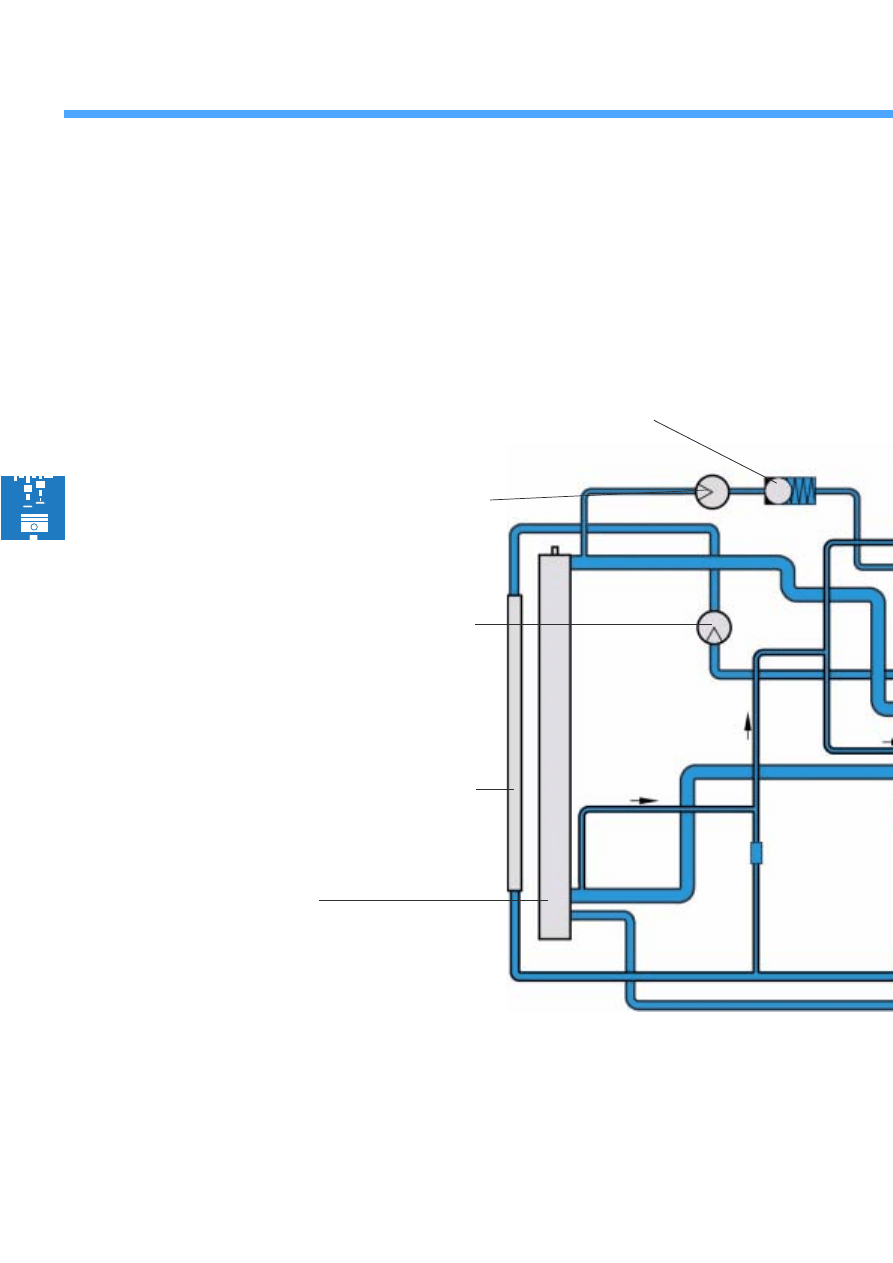

Coolant circuit

Connection of auxiliary heater in coolant circuit of W12 engine

If the auxiliary heater is started when the engine is switched off, the coolant shutoff valve closes.

The recirculating pump pumps coolant through the coolant jacket in the auxiliary heater to the pump

valve unit, then through the heat exchanger inside the vehicle and back to the auxiliary heater.

The vehicle interior is heated.

Gearbox oil cooler

Engine oil cooler

Alternator C

Cylinder block

Coolant circuit

Coolant shutoff valve N279

27

Function

When voltage is applied to the shutoff valve, coolant can flow from the pump valve unit to the heater.

When there is no voltage at the shutoff valve, coolant can flow from the pump valve unit to the engine.

Recirculating pump

V55

Auxiliary heater

Pump valve unit

Left heat exchanger

Right heat exchanger

Expansion tank

Air reservoir

Continued coolant circulation pump V51

Thermostat

Radiator

The pump valve unit is part of the

vehicle heater and is described in

SSP 271.

S280_015

28

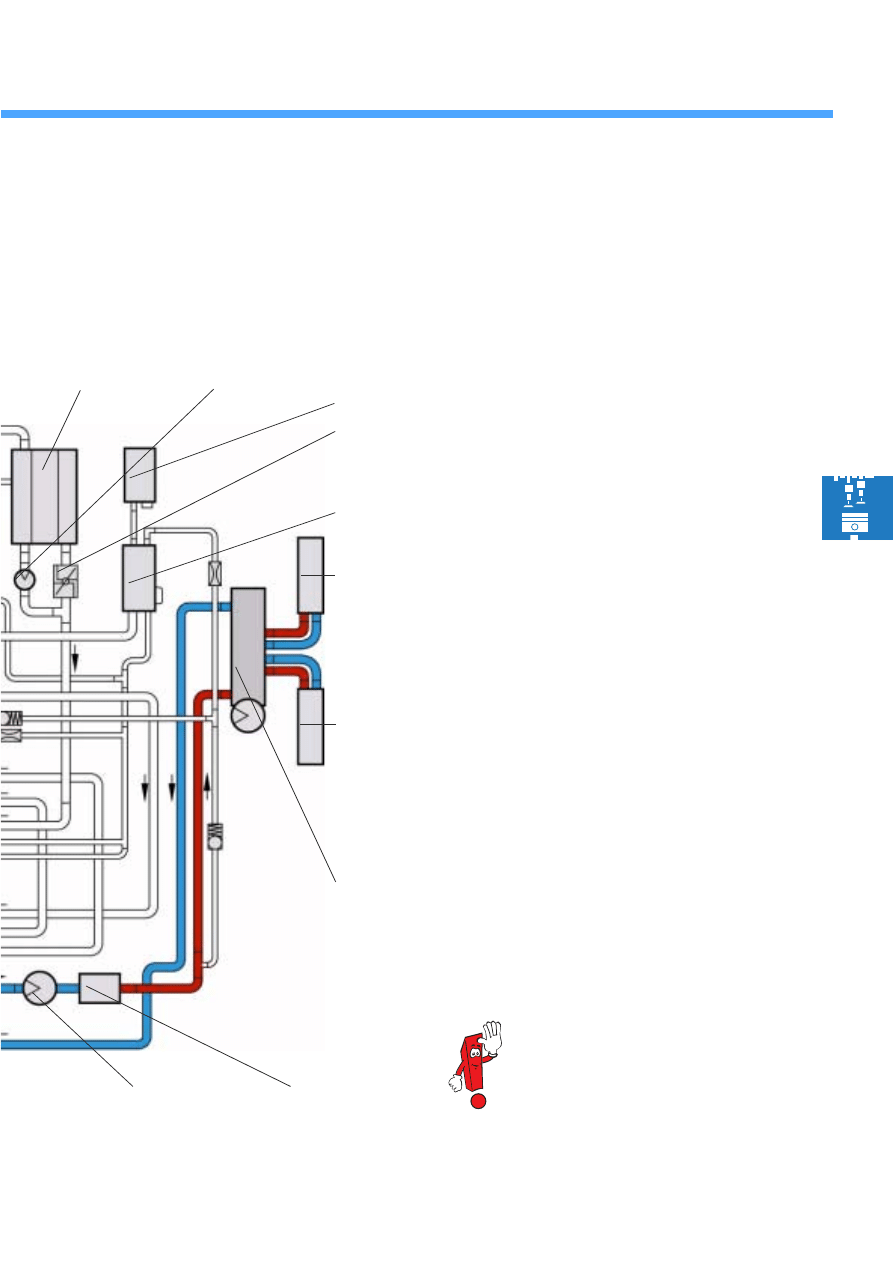

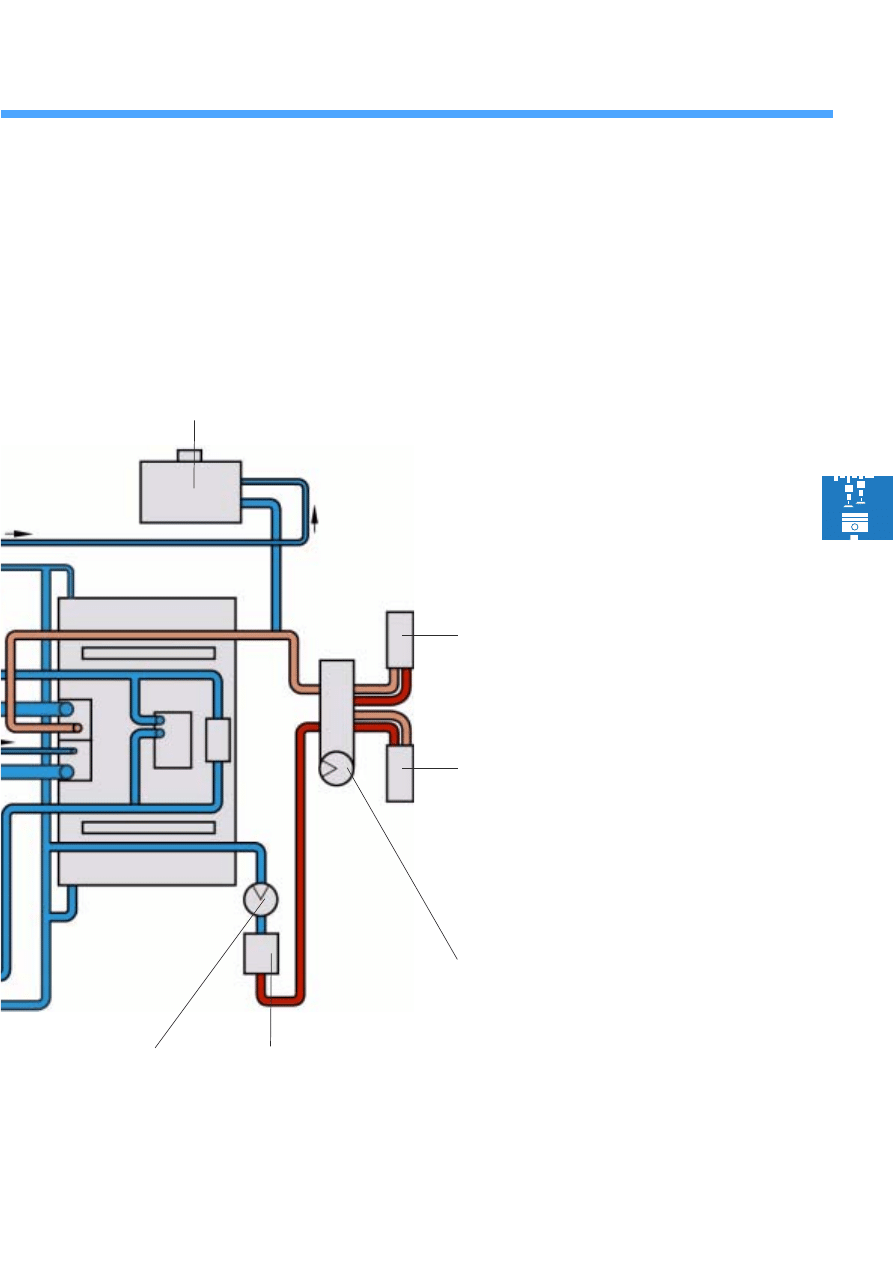

Coolant circuit

Connection of auxiliary heater in coolant circuit of V10 TDI engine

On the supplementary heater there is no coolant shutoff valve. The heater is permanently connected to

the engine coolant circuit.

Coolant circuit

Low temperature cooler for

alternator and fuel cooling

Radiator

Fuel cooling pump V166

Continued coolant circulation pump

V51

Check valve

29

Expansion tank

Right heat exchanger

Left heat exchanger

Pump valve unit

Supplementary heater

S280_052

Recirculating pump

V55

30

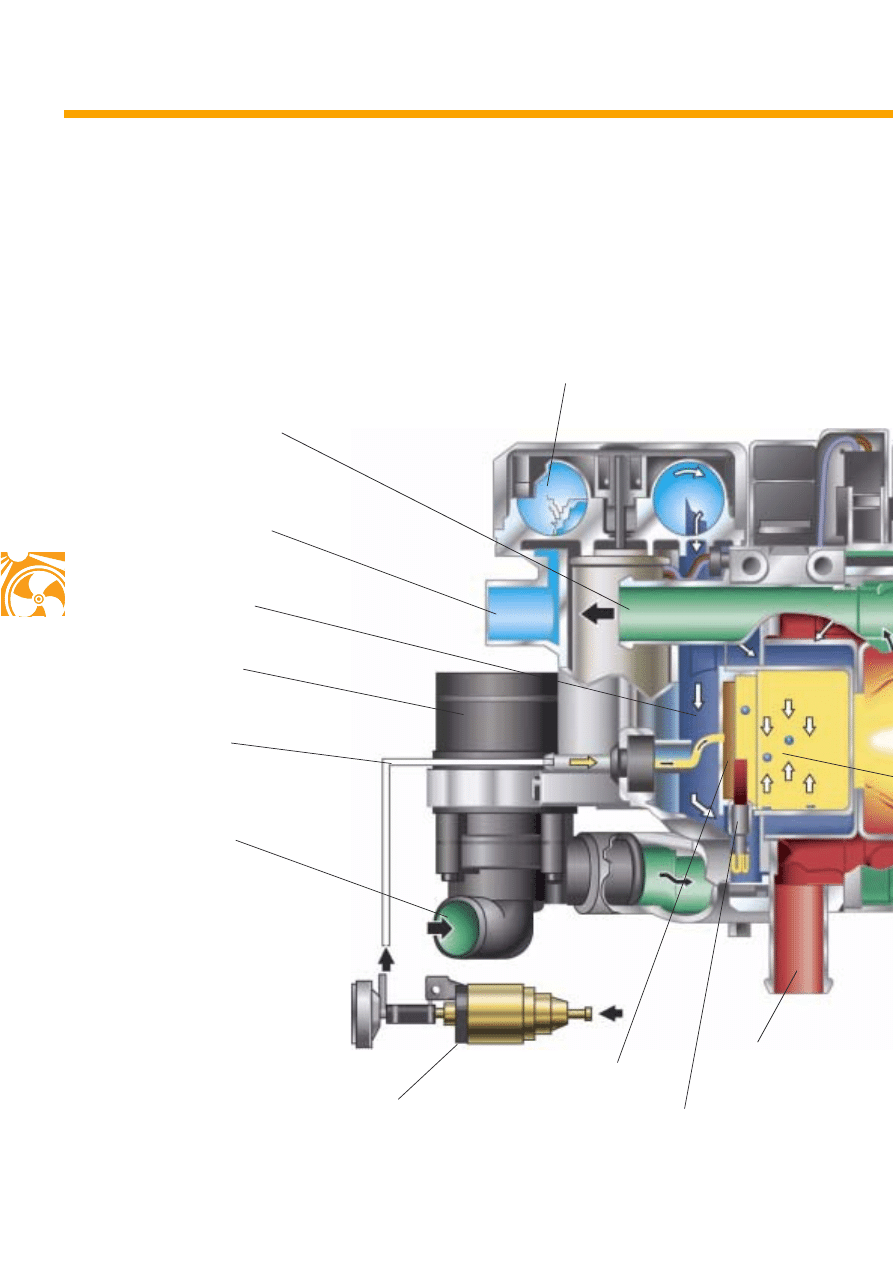

Air supply

The air required for combustion is drawn via the

combustion air intake from the combustion air

blower and passed through the combustion air

channel to the combustion chamber.

Function

Combustion air blower V6

Coolant outlet

Combustion air inlet

Fuel channel

Coolant inlet

Metering pump V54

Combustion air channel

Heater glow plug Q9

(with flame monitor)

Fuel evaporator

Exhaust pipe

Recirculating pump V55

31

The fuel supply

Fuel is supplied through the fuel channel. In the

fuel evaporator (fleece), fuel is mixed with the

combustion air, forming a combustible fuel-air

mixture.

The glow plug with flame monitor ignites the

mixture in the combustion chamber at the start.

Once operation has begun, ignition occurs at the

flame front in the flame pipe.

During operation of the heater, the glow plug Q9

is supplied with only a small amount of energy

from the control unit.

The electrical resistance of the glow plug can

thus be used as a flame monitor.

The coolant

Coolant enters through the coolant inlet in the

coolant jacket. Here, it is heated. The heated

coolant flows out the coolant outlet into the

coolant circuit.

S280_010

Coolant jacket

Flame pipe

Combustion chamber

in burner housing

32

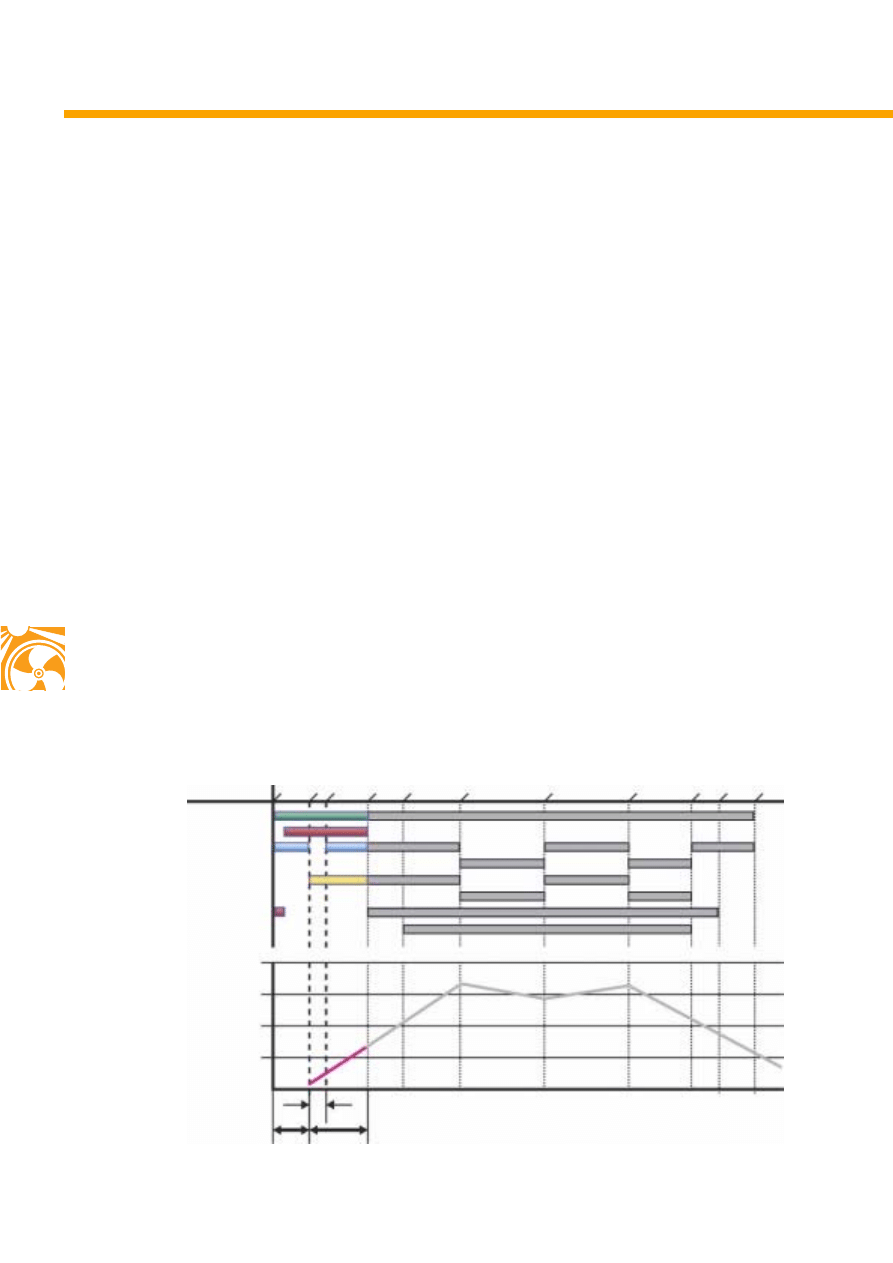

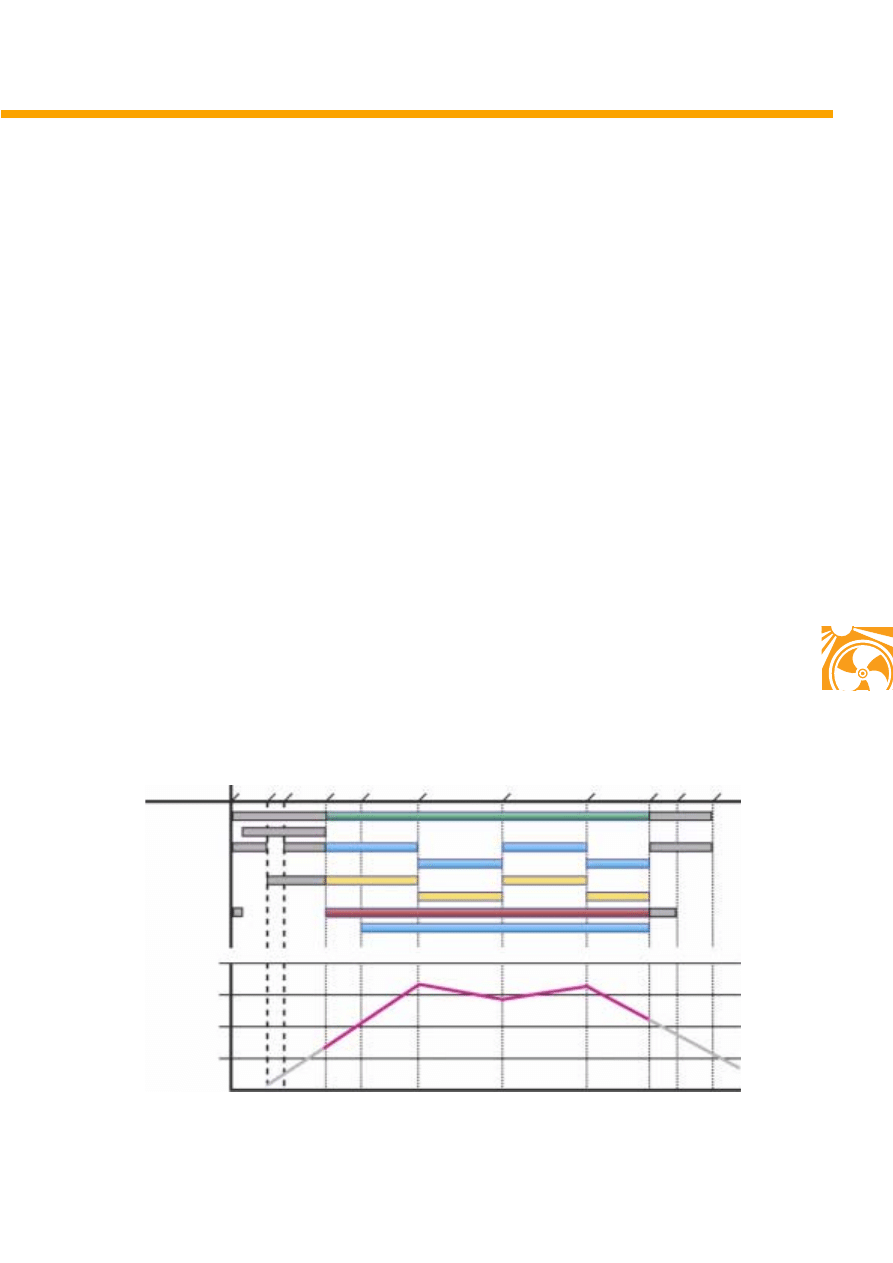

The auxiliary heater

Start phase

The auxiliary heater is started either:

- immediately,

- via the timer or

- using the remote control.

The combustion air blower and the recirculating

pump are actuated.

The glow plug starts to glow and the combustion

air blower pumps air into the burner insert.

After about 30 seconds, the metering pump

starts to deliver fuel and the combustion air

blower is switched off for about 5 seconds until

a rich mixture has built up.

The output of the combustion air blower is

increased in stages to full load and the fuel-air

mixture is delivered to the combustion chamber.

Combustion begins.

If no flame is formed or the flame dies, restart is

initiated automatically. After a total of

90 seconds of fuel delivery without flame

formation, the system is switched off until the

ignition is switched on again (terminal 15).

Metering pump TL

Operating stages

Glow plug

Recirculating pump

Combustion air blower TL

Combustion air blower VL

Fresh air blower

Metering pump VL

Flame monitor interrogation

Temperature in °C

90

85

80

75

70

5

30

90

Time in seconds

St

ar

t

Sta

rt

of

com

bu

stio

n

Ful

l l

oad oper

at

ion

Fre

sh

ai

r blower

Pa

rt

load

Ful

l load

Sh

ut

of

f

Pa

rt l

oa

d

Sta

rt o

f ru

n-

on

End

of

run-

on

S280_036

Pr

eg

low

33

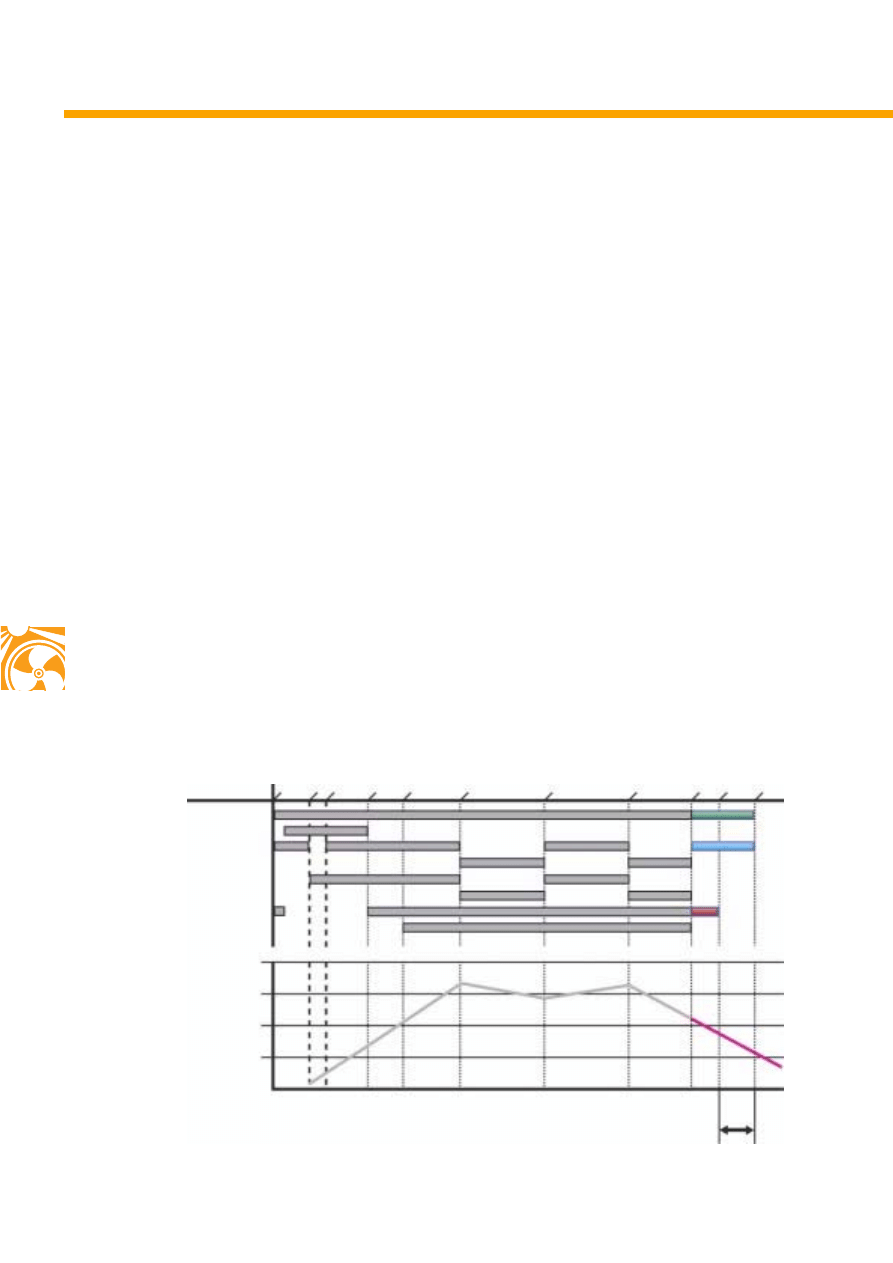

Heating phase/regulated phase

When the coolant reaches a temperature of

87 °C, the heater is switched from full load to

part load. This reduces the combustion air

blower output and the metering pump delivers

less fuel. If the coolant temperature drops to

approx. 83 °C, full load is activated again.

At a coolant temperature of approx. 89 °C,

heating is interrupted. When the coolant

temperature drops to approx. 85 °C, heating is

initiated once again.

Temperature in °C

90

85

80

75

70

S280_037

Sta

rt

St

ar

t o

f co

m

bu

stio

n

Fu

ll l

oad

oper

at

ion

Fr

es

h ai

r blow

er

Pa

rt

load

Ful

l l

oad

Sh

uto

ff

Pa

rt l

oa

d

St

ar

t o

f ru

n-

on

En

d of

ru

n-

on

Pr

eg

lo

w

Metering pump TL

Glow plug

Recirculating pump

Combustion air blower TL

Combustion air blower VL

Fresh air blower

Metering pump VL

Flame monitor interrogation

34

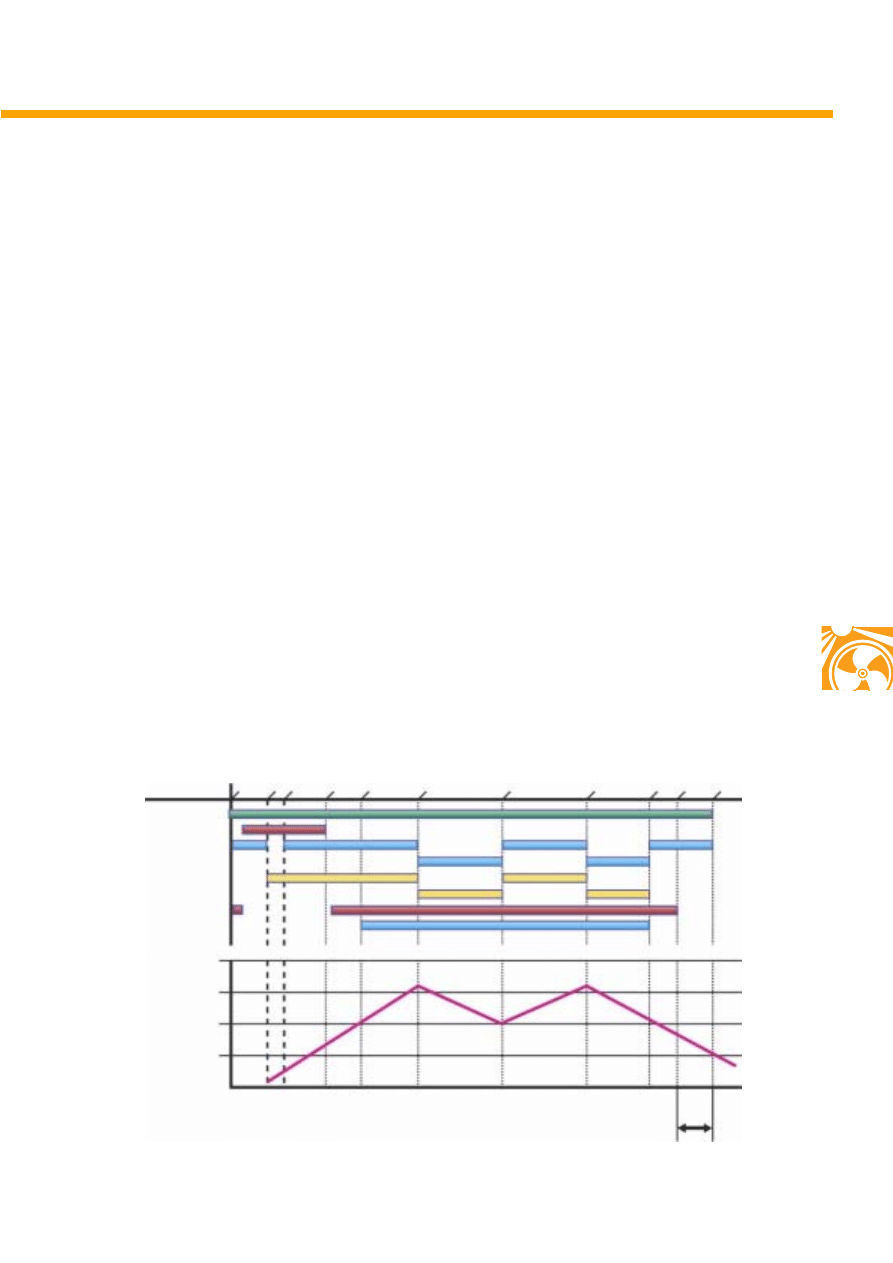

Run-on phase

The auxiliary heater is deactivated by:

- switching off the engine,

- switching off the auxiliary heater or

- expiration of the automatic heating duration

(max. 60 minutes).

The metering pump is switched off, combustion

stops, the combustion air blower and the

recirculating pump run-on to cool down and are

then switched off automatically.

Run-on time depends on the type of heater and

can be between 100 and 175 seconds.

The run-on time for petrol-driven heaters is:

●

168 seconds when switched off from full load

●

157 seconds when switched off from part load

The run-on time for diesel-driven heaters is:

●

175 seconds when switched off from full load

●

100 seconds when switched off from part load

There may be slight deviations in the given

figures depending on the development of the

software.

Operating phases

Temperature in °C

85

80

70

60

50

Time in seconds

100 - 175

S280_038

Metering pump TL

Glow plug

Recirculating pump

Combustion air blower TL

Combustion air blower VL

Fresh air blower

Metering pump VL

Flame monitor interrogation

St

ar

t

St

ar

t of

com

bu

sti

on

Fu

ll

load oper

at

io

n

Fre

sh

a

ir

bl

ow

er

Pa

rt l

oa

d

Ful

l l

oad

Sh

ut

of

f

Pa

rt

load

Sta

rt

of

ru

n-

on

End of

ru

n-

on

Pr

eg

lo

w

35

The supplementary heater

(diesel engines)

Start phase

When the engine is started, the heater is made

ready.

When the coolant temperature is below 60 °C,

ambient temperature is below + 5 °C and the

control unit has received an engine speed signal,

start is initiated.

Heating phase

If the coolant reaches 78 °C, operation is

interrupted. When the coolant temperature

reaches 76 °C, full load operation is switched to

part load. The transition from part load to full

load comes at 70 °C and to part load at 65 °C.

Run-on phase

When the engine is switched off, the

supplementary heater is stopped.

Combustion is stopped and run-on begins.

The supplementary heater run-on time is:

●

175 seconds when switched off from full-load

●

100 seconds when switched off from part-load

There may be slight deviations in the given

figures depending on the software version.

Temperature in °C

80

75

70

60

50

Time in seconds

S280_020

Sta

rt

St

ar

t o

f co

m

bu

stio

n

Fu

ll l

oad

oper

at

ion

Fr

es

h ai

r blow

er

Pa

rt

load

Ful

l l

oad

Shut

off

Pa

rt l

oa

d

St

ar

t of

ru

n-

on

En

d of

ru

n-

on

Pr

eg

lo

w

Metering pump TL

Glow plug

Recirculating pump

Combustion air blower TL

Combustion air blower VL

Fresh air blower

Metering pump VL

Flame monitor interrogation

100 - 175

36

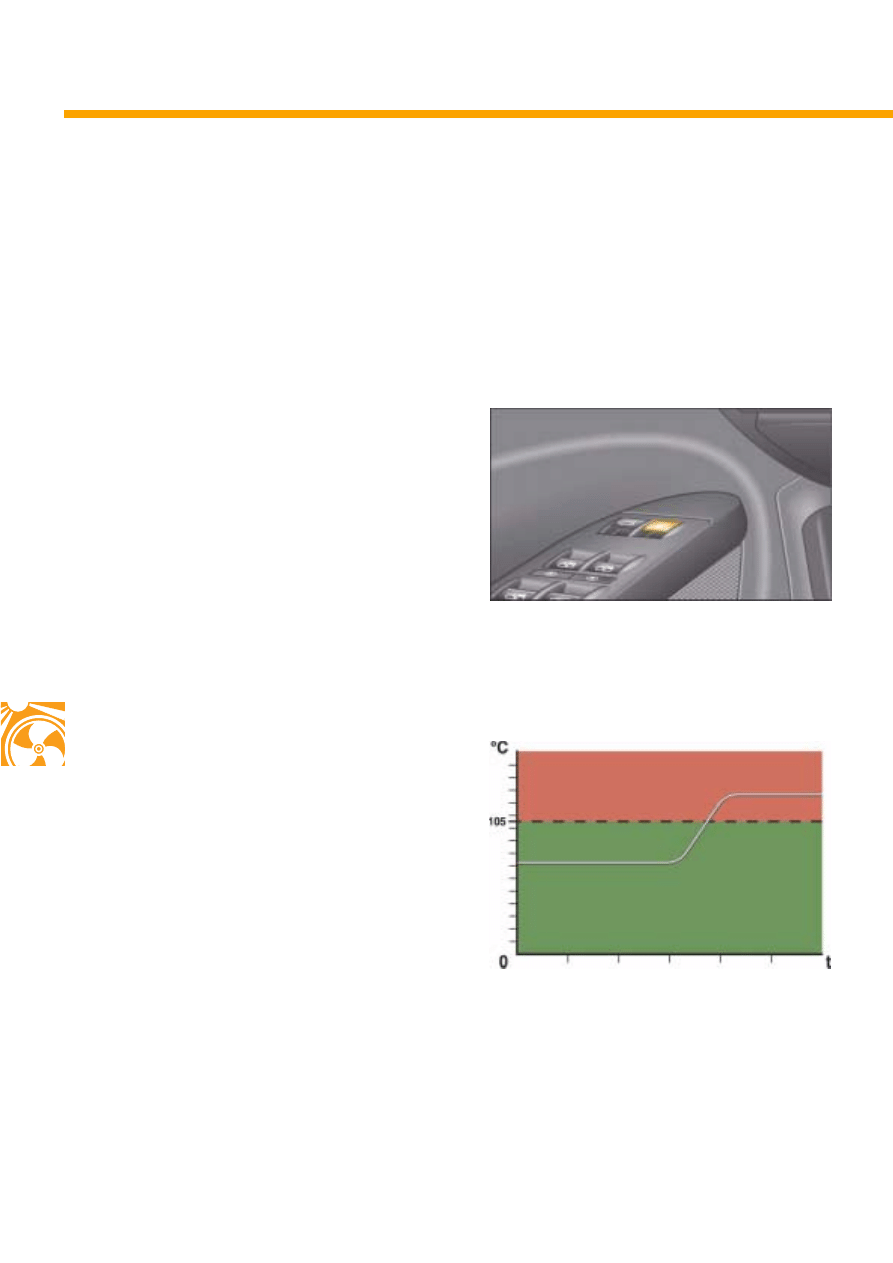

Deactivation

The auxiliary heater and the supplementary

heater are switched off for reasons of safety

under certain conditions.

Vehicle-specific deactivation

The auxiliary heater is switched off when:

- the tank flap is opened,

- the fuel level is low,

- the onboard electrical system is placed under

heavy load by the onboard electrical system

control unit,

- an airbag is triggered by an accident

- heater output is sufficient during normal

driving.

Temperature related deactivation

If the coolant temperature rises above 105 °C

during heater operation, fuel supply is

interrupted.

In this instance, the heater will run-on for

approx. 120 seconds. If there is a fault in the

combustion air blower, there will be no run-on.

S280_028

Deactivation conditions

S280_024

Heater operation

Deactivation

37

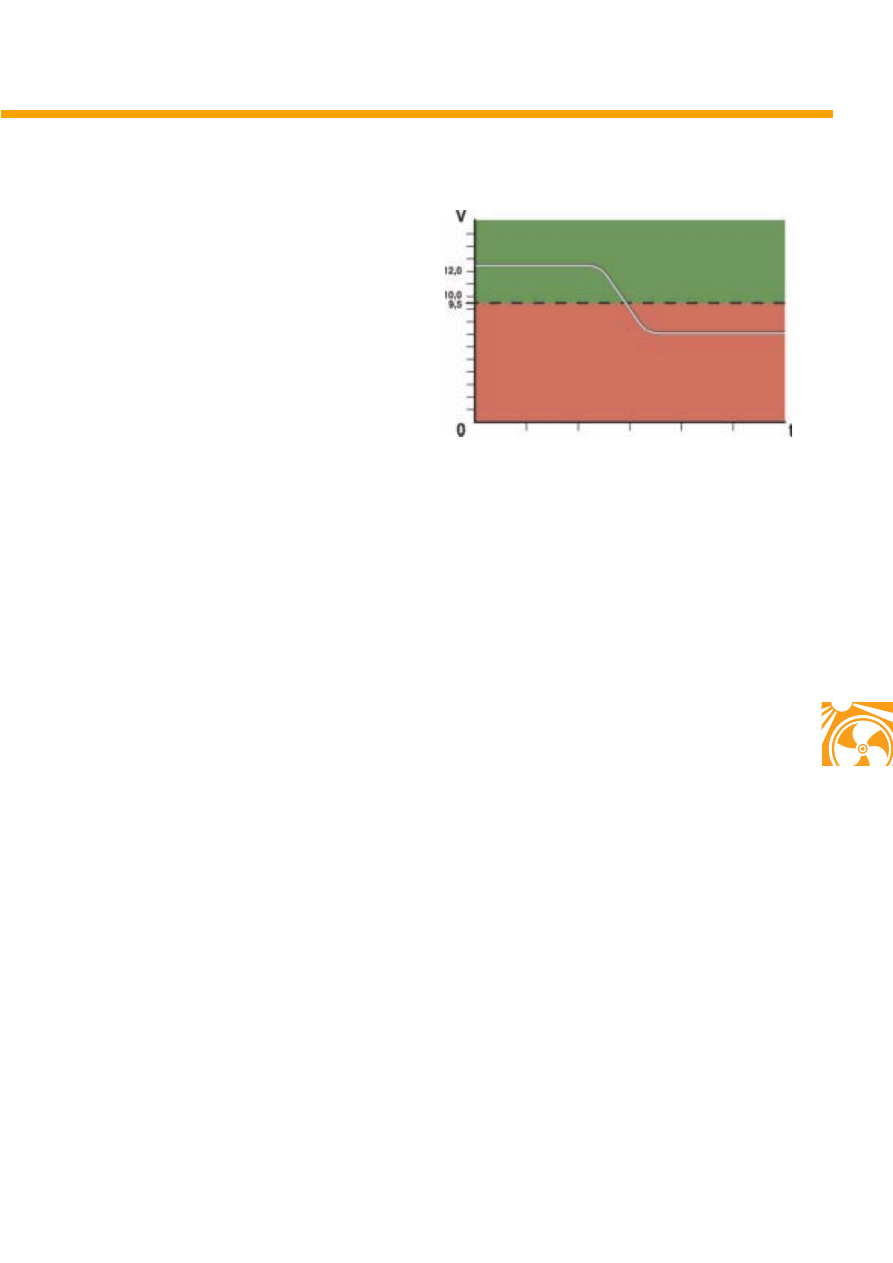

Deactivation due to excessive or insufficient

voltage

In addition to monitoring of the onboard

electrical system voltage by the onboard

electrical system control unit, the auxiliary heater

control unit also deactivates the heater if

excessive or insufficient voltage is detected.

Fixed deactivation due to insufficient voltage

If the battery voltage drops to below 9.5 volts for

longer than 6 seconds, the heater is deactivated

with a run-on time of 120 seconds.

Deactivation due to excessive voltage

If the battery voltage exceeds 15.5 volts for more

than 60 seconds, the auxiliary heater is

deactivated.

S280_029

Heater operation

Deactivation

38

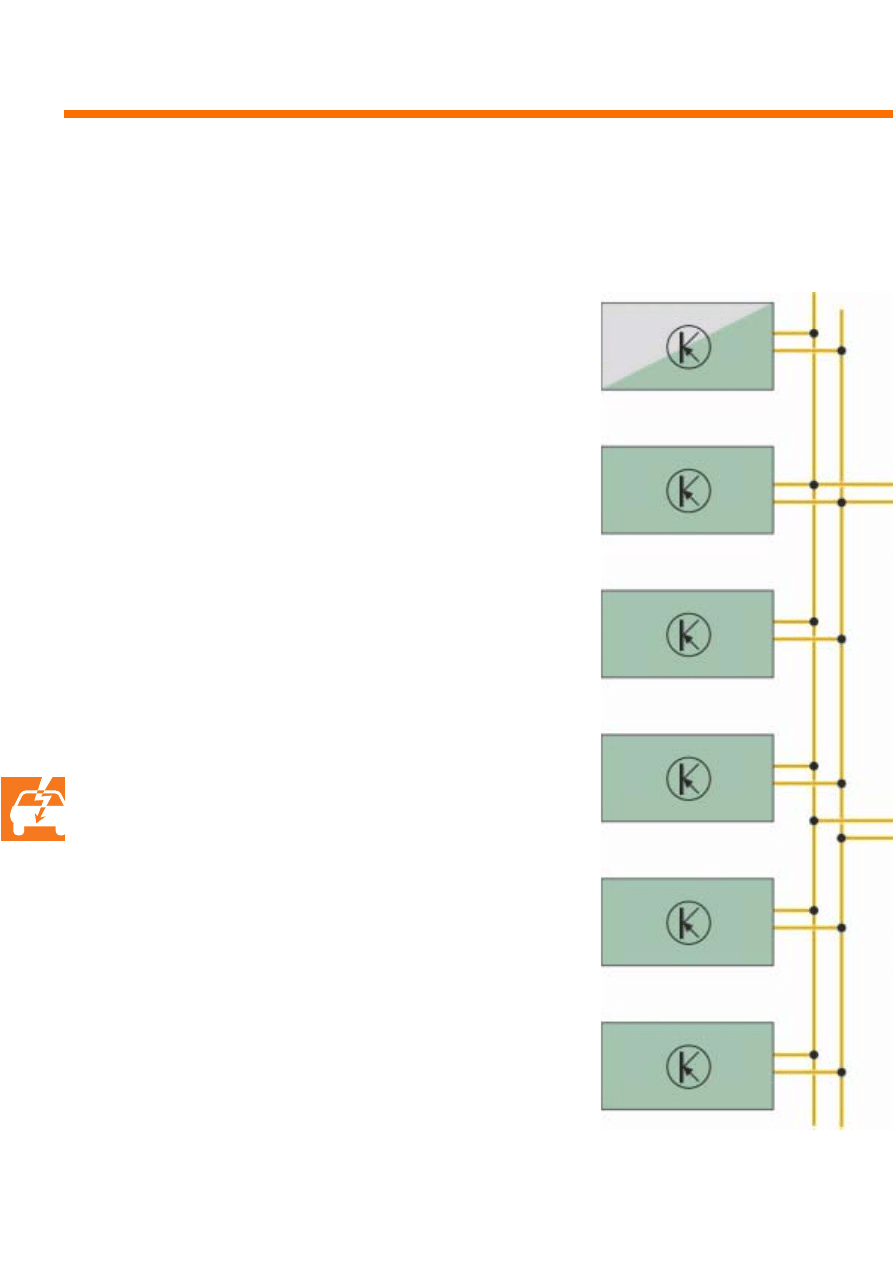

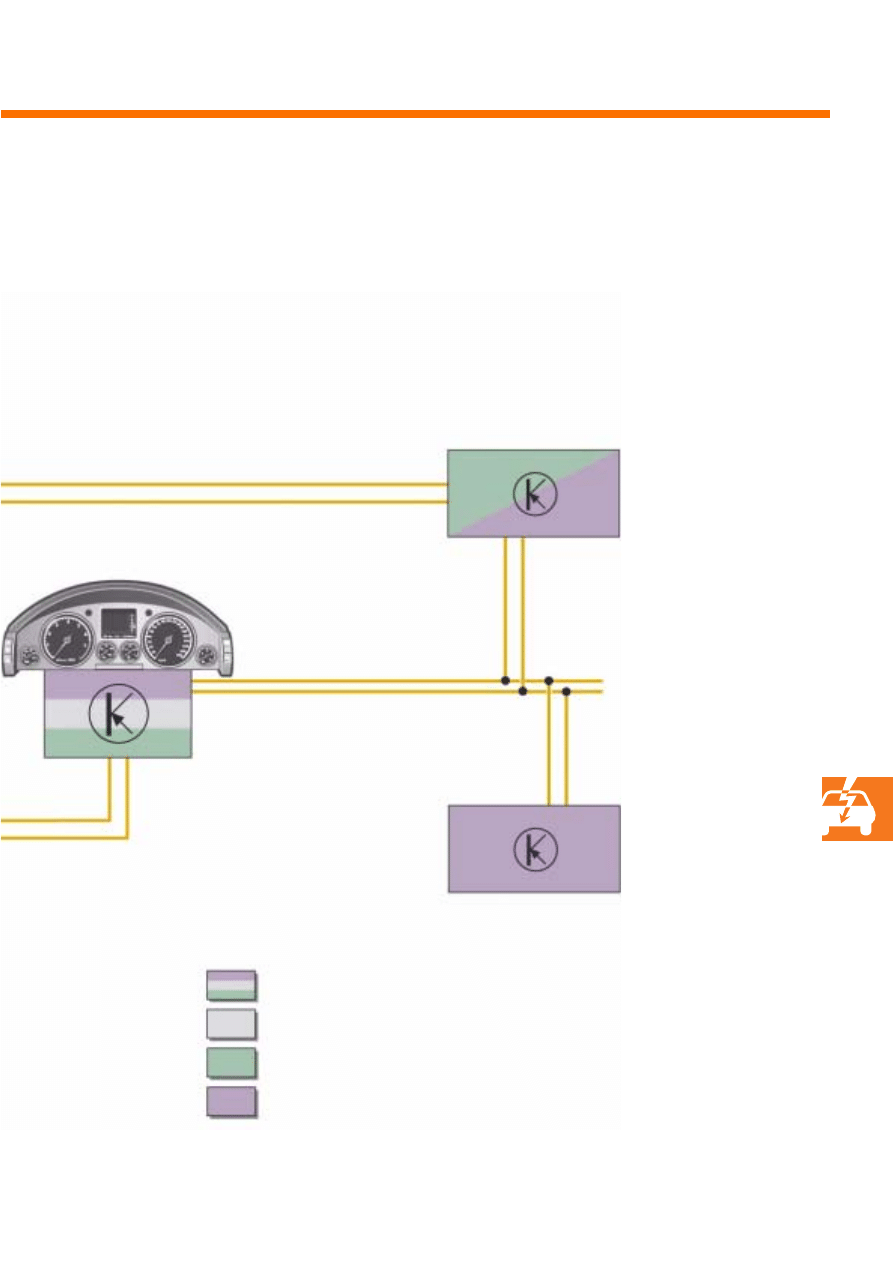

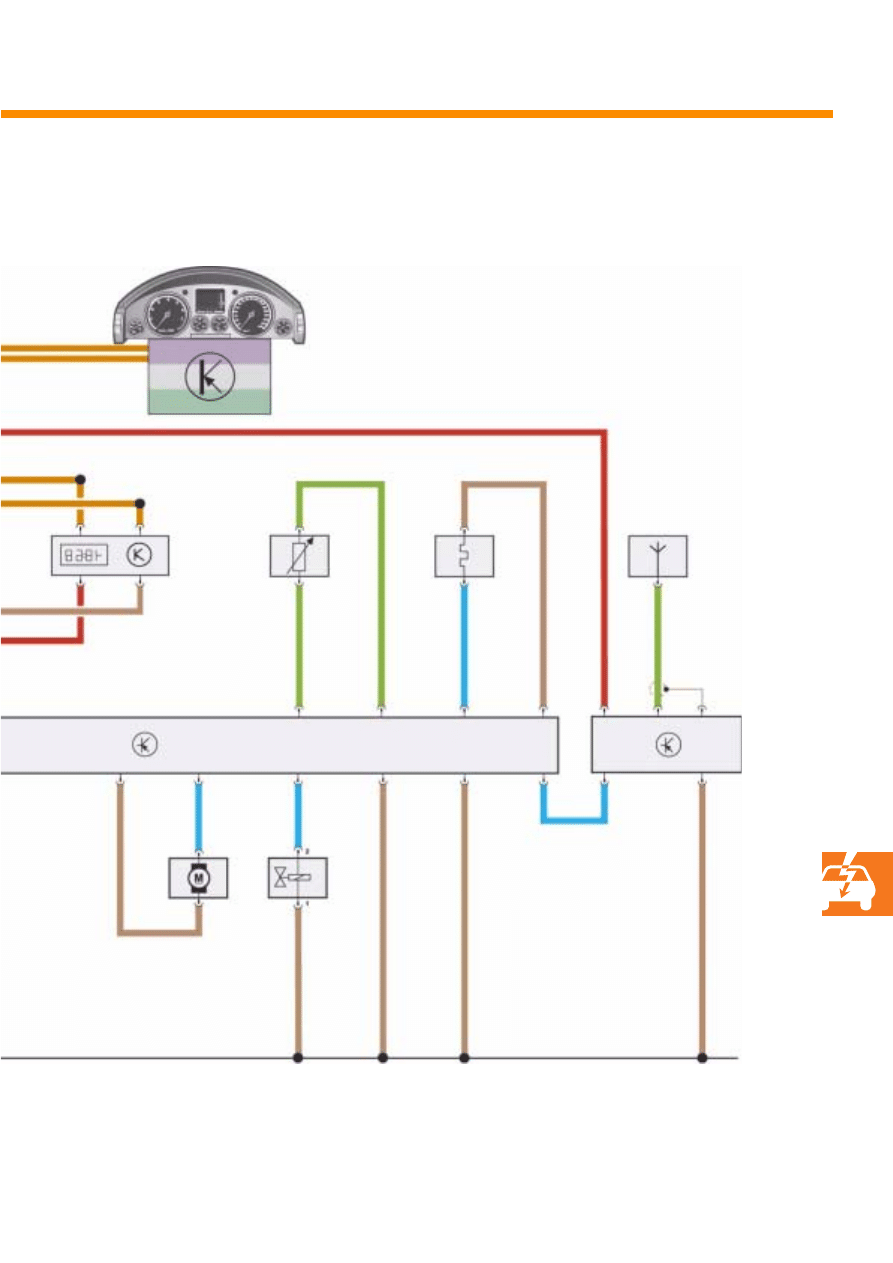

The auxiliary heater control unit is connected

with the other control units in the vehicle via the

infotainment CAN data bus and the diagnosis

data bus interface in the dash panel. All the

necessary information can be exchanged with

other control units via this data network.

Networking

Control unit for front informa-

tion display and operating

unit

Communication via CAN data bus

Roof electronics control unit

J528

Climatronic/air conditioning control unit

J301

Onboard electrical supply control unit J519

Entry and start authorisation control unit J518

Door control unit, driver side

J386

Climatronic operating and control unit

E265

39

Auxiliary heater control unit

J255

Drive train CAN data bus

Convenience CAN data bus

Infotainment CAN data bus

S280_034

Data bus diagnosis interface

Control unit for front information

display and control unit

J523

Data bus diagnosis interface

J533

in dash panel

40

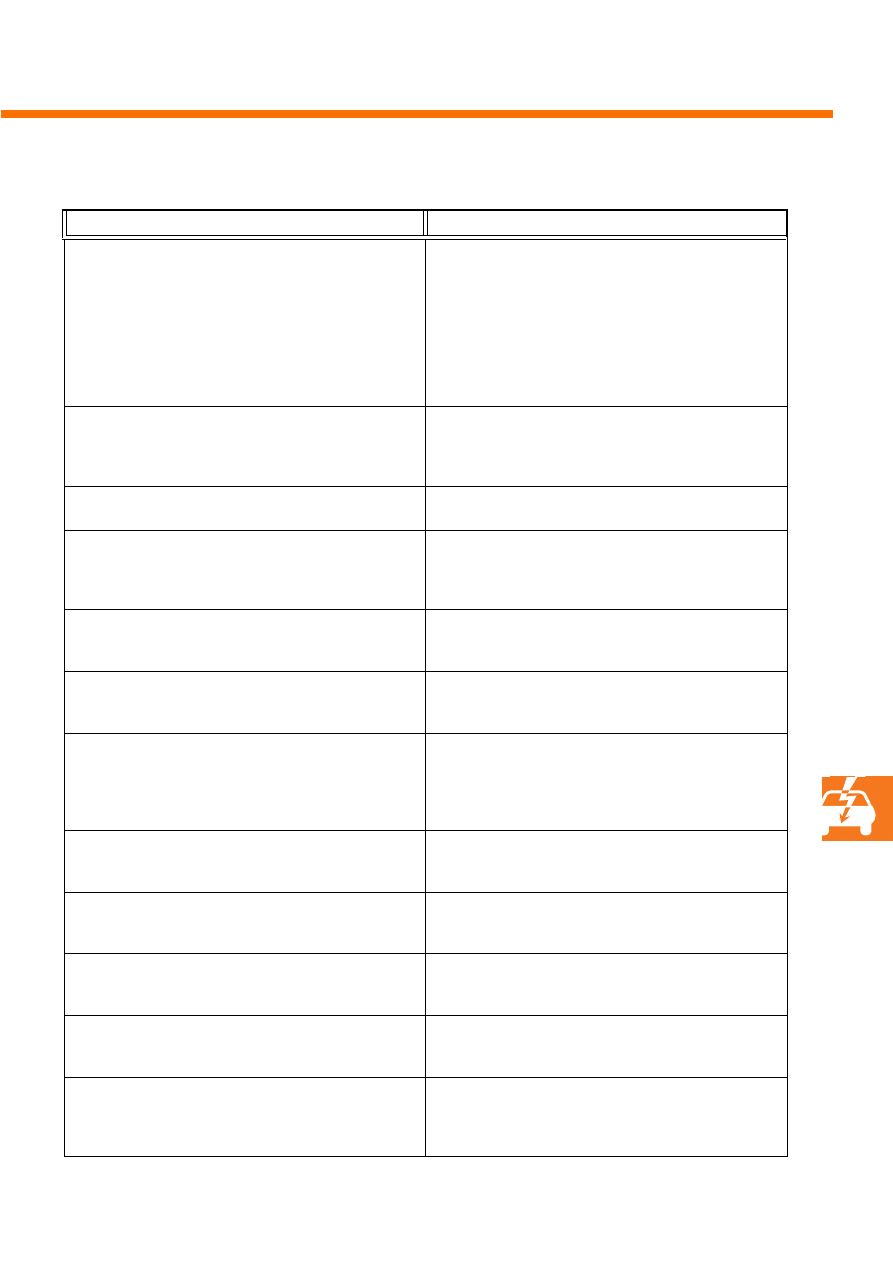

The data bus messages

A) Function

B) Message

Auxiliary heater messages received from remote

commands and from modes of operation

Activation via remote control

Activation of blower

Activation of control LED

Commands and information to auxiliary heater control

unit

Activation of auxiliary heater

Tank warning on

Convenience CAN data bus messages

Terminal information

Ignition on

Auxiliary heater operation

Operating commands

e.g. auxiliary ventilation

e.g. immediate start

Auxiliary heater operation

Auxiliary heater operating mode

Heating duration

Programming of auxiliary heater

Start time

Actuation of auxiliary heater

Auxiliary heater operating mode

Auxiliary heater duration information

Auxiliary heater duration

Heater deactivation

Tank flap opened

Heater deactivation

Onboard electrical system critical battery level

Heater deactivation

Crash impact signal

Status information

Engine speed

Ambient temperature

Engine type

Networking

41

C) Sender

D) Receiver

Auxiliary heater control unit

Control unit with display unit in dash panel insert

Climatronic/air conditioning control unit

Roof electronics control unit

Entry and start authorisation control unit

Onboard electrical supply control unit

Control unit for front information display and

operating unit

Climatronic/air conditioning

operating and display unit

Control unit with display unit in dash panel insert

Additional water heater control unit

Control unit with display unit in dash panel insert

Auxiliary coolant heater control unit

Control unit with display unit in dash panel insert

Auxiliary heater control unit

Climatronic/air conditioning control unit

Control unit for front information display and

operating unit

Control unit with display unit in dash panel insert

Control unit for front information display and

operating unit

Control unit with display unit in dash panel insert

Climatronic/air conditioning control unit

Climatronic/air conditioning

operating and display unit

Control unit with display unit in dash panel insert

Control unit for front information display and

operating unit

Control unit with display unit in dash panel insert

Climatronic/air conditioning control unit

Door control unit, driver side

Control unit with display unit in dash panel insert

Onboard electrical supply control unit

Control unit with display unit in dash panel insert

Control unit with display unit in dash panel insert on

receipt of message from airbag control unit

Auxiliary heater control unit

Control unit with display unit in dash panel insert

Additional coolant heater control unit

42

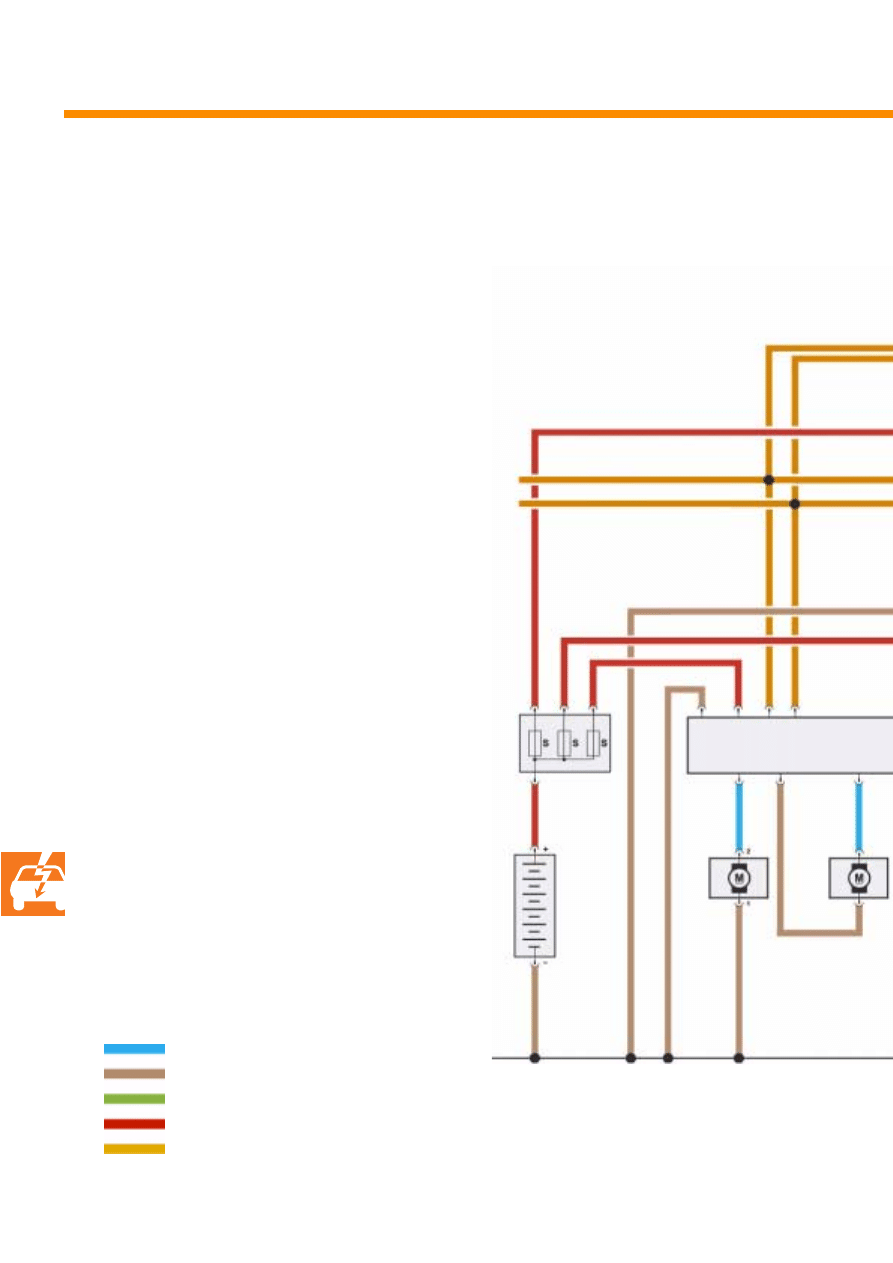

Functional diagram

Key

A

Battery

G241 Coolant temperature sender, heater

J255 Auxiliary heater control unit

on auxiliary heater

J285 Control unit with display unit in

dash panel insert

J533 Data bus diagnosis interface

N279 Coolant shutoff valve, heater

Q9

Heater glow plug Q9

(with flame monitor)

R11

Aerial

R149 Auxiliary heater remote receiver,

beneath rear shelf

S

Fuse

V6

Combustion air blower

V54 Metering pump

V55 Recirculating pump

Y

Analogue clock

Signal output

Earth

Signal output

Positive

Infotainment CAN data bus

A

V54

V55

43

S280_043

V6

N279

J255

R149

Y

G241

Q9

R11

J533

J285

44

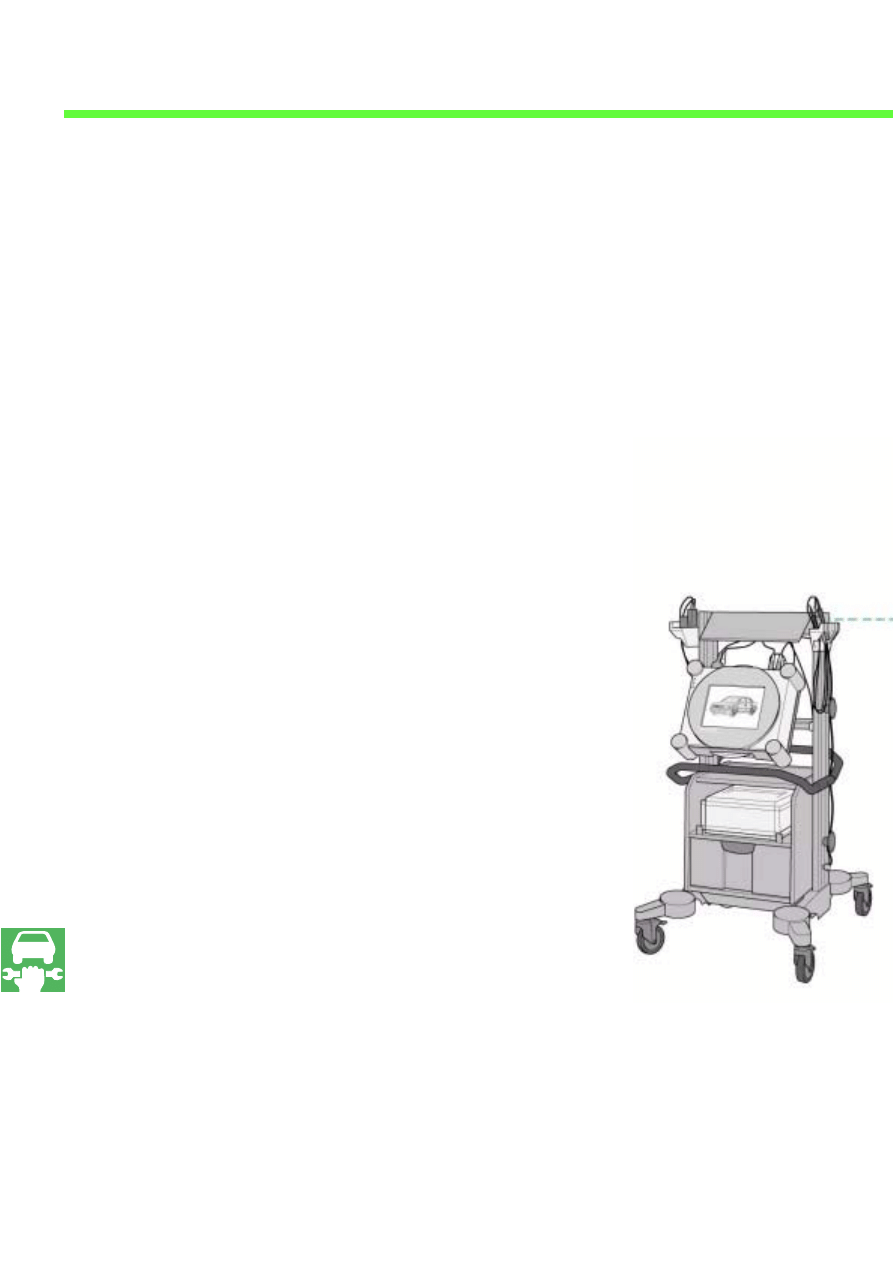

Diagnosis

Diagnosis can be carried out using the

testing and diagnosis system VAS 5051.

Communication is via the diagnosis interface.

The exchange of data between the diagnosis

system and the diagnosis interface in the dash

panel insert is via the COM lead.

Continued exchange of data is via the

infotainment CAN data bus.

If the data bus is defective or the data bus

diagnosis interface

is defective, diagnosis is not possible.

A description of the individual diagnosis

functions can be found in the guided fault

finding program on the testing and diagnosis

system VAS 5051. These are accessed

automatically.

The following components are monitored by the

diagnosis system:

●

Auxiliary heater control unit

●

Combustion air blower

●

Glow plug

●

Metering pump

●

Coolant shutoff valve

●

Recirculating pump

Additionally, the power supply and data bus

communication are checked and any faults are

stored in the fault memory.

Service

Testing and diagnosis system VAS 5051

45

S280_018

Combustion air blower

Glow plug

Metering pump

Shutoff valve

Recirculating pump

Data bus diagnosis interface

46

Diagnosis interface

The diagnosis interface is a virtual control unit in

the dash panel insert. It transmits CAN data bus

messages from one CAN data bus to the next

and also transmits data from the COM lead to

the CAN data bus lines

Loose belt

The distance between the seat belt and the upper

body (thorax).

The heavier the clothing, the greater the distance

between upper body and

seat belt. This distance has to be balanced by the

belt tensioner in a collision.

Degree of efficiency

The relationship between the energy supplied

and energy returned. The chemical energy

stored in the fuel is converted partly into

mechanical energy and thereby into kinetic

energy.

The remaining energy ends up as heat,

exhaust gas and radiant energy.

Glossary

47

48

1. The auxiliary heater is activated

a) automatically when the ignition is switched on.

b) by the on/off switch in the driver's door.

c) by the immediate start function in the information display and operating unit.

2. The fixed start time is programmed

a) by the timer preselection in the front information display and operating unit.

b) by the preselection clock in the driver's door.

c) by the analogue clock setting in the dash panel insert.

3. Remote start

a) is initiated by dialing telephone number 0800 89 73 74 23 and giving the start time to the

centre.

b) is initiated by pressing the start button on the remote control.

c) is initiated by pressing the open button on the ignition key.

4. When the engine is not running, the auxiliary heater heats

a) the engine.

b) the interior via the pump valve unit and the left and right heat exchangers.

c) the interior via the pump valve unit and the left and right heat exchangers,

the luggage compartment and the engine.

Test yourself

49

5. In the start phase of auxiliary heating

a) the combustion air blower is switched off for 5 seconds so that a rich mixture is

created.

b) the metering pump is increased to 150 % delivery so that a rich mixture is created.

c) the combustion air blower delivers more air to create a leaner mixture.

6. The auxiliary heater is switched off if

a) during the start phase there is no independent flame.

b) the coolant temperature rises above 105 °C.

c) the battery voltage is less than 9.5 volts for six seconds.

7. The auxiliary heater control unit

a) communicates with other control units in the vehicle via the drive train CAN data bus.

a) communicates with other control units in the vehicle via the convenience CAN data bus.

c) communicates with other control units in the vehicle via the infotainment CAN data bus and

data bus diagnosis interface in the dash panel insert.

Answ

ers

1c; 2a; 3

b; 4

b; 5

a;

6a

,b,c; 7

c;

50

Notes

51

For internal use only © VOLKSWAGEN AG, Wolfsburg

All rights and the right to make technical alterations reserved

240.2810.99.20 Technical status 02/03

❀

This paper was manufactured from pulp that

was bleached without the use of chlorine.

280

Wyszukiwarka

Podobne podstrony:

Self Study Programme 276 Phaeton automatic proximity control

Self Study Programme 365 4 2L V8 with common rail

Self Study Programme 388 4 2L V8 4V FSI engine

Self Study Programme 431 Audi RS 6

Self Study Programme 17 Octavia convenience electronic system

Self Study Programme 279 2 0L 110kw with petrol direct injection FSI

Self Study Programme 189 2 3L petrol engine in the LT 97

Self Study Programme 376 5 2 litre V10 FSI engine

Self Study Programme 396 Lane change assist

Self Study Programme 351 Common rail fuel injection system fitted in the 3 0l V6 TDI engine

Self Study Programme 288 Audi A8 03 distributed functions

Self Study Programme 398 Audi lane assist

Programmed repair Auxiliary heater Part C Models 124, 126 020 024 025

Programmed repair Auxiliary heater Part C Models 124, 126 020 024 025

0400 Function description B Operating principle with function diagram Auxiliary heater Models 124,

0402 Arrangement of components Auxiliary heater A Model 124

0400 Function description auxiliary heater A General Models 124, 126, 201

więcej podobnych podstron