1

CHAPTER

SEVEN

QUALITY CHANGES DURING DRYING OF FOOD MATERIALS

Magdalini Krokida and Zacharias Maroulis

1. INTRODUCTION

The commonly examined properties of dried products may be classified into two

major categories: the engineering properties of the drying products and properties,

which are related to product quality.

The engineering properties of dried food systems are essential in the design of

food processes and processing equipment, and in the efficient operation and control of

processing plants. The engineering properties of the dried food involve effective

moisture diffusivity, effective thermal conductivity, specific heat, equilibrium

moisture content, and viscosity.

The comprehensive term “quality” comprises of a number of parameters of the

drying material, either in a mid-state (at intermediate stages of the drying process) or

after the completion of the drying. Although these properties are not necessary for

prediction of drying time and process modeling, they are important for

characterization and prediction of the quality of dried product. They are also very

important for the development of new industrial products with desired properties or

for quality improvement of already existing ones. The quality related properties could

be grouped into the following:

•

Structural properties (density, porosity, pore size, specific volume)

•

Optical properties (color, appearance)

•

Textural properties (compression test, stress relaxation test, tensile test)

•

Thermal properties (state of product: glassy, crystalline, rubbery)

•

Sensory properties (aroma, taste, flavor)

•

Nutritional characteristics (vitamins, proteins)

•

Rehydration properties (rehydration rate, rehydration capacity)

2

Structural, optical and textural properties of dehydrated products are examined in

this chapter. The following topics are discussed for each property:

•

Definition

•

Methods of experimental measurement

•

Data compilation

•

Effect of various factors

•

Mathematical modeling

The industrial product quality aspects are usually to control product moisture

content at the dryer outlet, to minimize chemical degradation reactions, maintain

product structure and texture, obtain desired color, control product density and

porosity, and develop a flexible drying process that can yield products of different

structures for various uses.

Drying method and physicochemical changes that occur during drying seem to

affect the quality properties of the dehydrated product. More specifically, drying

method and process conditions affect significantly the color, texture, density and

porosity, and sorption characteristics of materials. So, the same raw material may end

up as a completely different product, depending on the type of drying method and

conditions applied.

The increasing need for producing efficient high quality and convenient products

at a competitive cost has led to the employment of several drying methods in practice

(Saravacos, 1967; 1993). Each drying method has some characteristic drying

parameters, which can be regulated, changing in this way the moisture transport

mechanism and the drying rate. It has been proved that the moisture transport

mechanism and the drying rate at which the material is dried are related to the quality

properties of the dried product. The most commonly used drying methods and

conditions are the following:

•

Conventional air drying is one of the most frequently used operation for food

dehydration. The drying parameters that are usually examined for food quality are

the following:

air temperature (50 - 90

o

C for food materials)

air relative humidity (10 – 40% for food materials)

air velocity (1-4m/sec)

•

Microwave drying is an alternative drying method, which is recently used in the

food industry. Dielectric heating with microwaves (MW) has been proven to

greatly reduce the drying time of many agricultural products and it is usually used

as pretreatment before conventional drying. The drying parameters that are

usually examined for food quality maters are the follows:

Dielectric power

Exposure time to MW radiation

•

Vacuum drying is a drying method in which drying is performed using low

pressure. It makes use of the fact that the boiling point of water is reduced as the

3

pressure is reduced. The drying parameters that are usually examined for food

quality are the follows:

Pressure (30-600 mbar)

Air temperature (50-100

o

C)

•

Osmotic dehydration is a process resulting in products of intermediate moisture

content, due to water flow from the product to a concentrated solution and solute

transfer from the solution into the product. It is a pretreatment technique, which

claims to achieve simultaneously dewatering and direct formulation of the product

(through impregnation plus leaching). The main drying parameters that are usually

examined are the following:

Solute concentration

Process temperature

Sample size

Speed of agitation

Time of immersion

•

Freeze drying is one of the most sophisticated methods. It makes use of the fact

that when the system pressure is kept so low that the boiling point is below 0

o

C,

the water in the material remains frozen and it sublimes away from the dry solids.

The freeze drying method provides dried products of porous structure with

advantageous quality properties, which are weighted against its high treatment

cost. The main parameter of drying method is the applied pressure, which

corresponds to a specific temperature that ice sublimes.

Blanching is a pretreatment process used before drying of most vegetables, in

order to prevent the development of off flavor in subsequent storage; it involves heat

treatment for a short time, usually by steam or hot water. The objective of blanching

is to produce certain favorable effects on processed materials, such as the inactivation

of enzymes present, the expulsion of air trapped intercellularly, the reduction of

possible initial infection, and the removal of undesirable flavors and aromas.

Although food quality is of major importance during last years, limited

information is available in the literature on the quality properties of foods, especially

the solid and semi solid food materials.

The present review is an effort to describe the effect of drying method and

conditions on some quality related properties of foods.

4

2. STRUCTURAL PROPERTIES (Density and porosity)

2.1 Definitions

Structural properties are important for the characterization of the quality of a

dehydrated product. Food structure has a profound effect on the transport properties

of foods (e.g. diffusivity, permeability and thermal conductivity), it is therefore

important to know the physical structure of a food material. Food structure is of

fundamental importance in the developing field of Food Materials Science. The

structure of a food material may be characterized by its apparent density, solids

density, bulk porosity, pore size distribution, specific volume, etc.

•

Apparent density (

ρρρρ

b

) concerns powdered and porous materials and it is

determined by the mass of the sample and its apparent volume. The terms bulk

density and bulk volume are also used for granular materials.

•

True density (

ρρρρ

p

) is the density excluding all pores and it is determined by the

mass of sample and its true volume. The terms particle density and particle

volume are used for granular materials.

•

Porosity (

εεεε

) characterizes the overall open structure of a dehydrated material. It is

the fraction of the empty volume (void fraction) and it is usually estimated from

the apparent density and the true density of the material according to the following

equation:

ε

= 1-

ρ

b

/

ρ

p

(1)

•

Specific volume (

υυυυ

) is determined by the mass of the dry solids and its bulk

volume.

2.2 Experimental Measurement

The determination of structural properties of a material is based on the mass,

apparent volume and true volume determination. Mass is determined measuring

sample’s weight, while there are several methods for apparent volume and true

volume measurement.

•

Apparent volume Several methods have been used in order to determine the

apparent volume of a solid material. The most commonly used can be summarized

as follows:

- volumetric displacement methods: the apparent volume is determined by

placing the sample in a container of known liquid volume and measuring

the volume displacement (Krokida et al. 1997).

- dimension methods: the apparent volume is determined by averaging a

number of dimension measurements with micrometers, assuming spherical

or slab shapes (Lozano et al. 1983; Ratti 1993; Karathanos & Saravacos

1993).

- stereopycnometer methods: the sample is covered with silicone grease in

order to make it impervious to gases and its apparent volume is measured

by a stereopycnometer (Bonazzi et al. 1992).

•

True volume is usually measured by means of a gas (helium) stereopycnometer,

which measures the true volume, excluding the interparticle volume (Moshenin

1980; Donsi et al. 1996; Zogzas et al. 1994).

5

2.3 Experimental data

Porosity is the most commonly reported in the literature structural property.

Bulk porosity of agricultural products has been usually estimated during and after

drying with various drying methods. Table 1 gives some literature values of the bulk

porosity in food materials. The corresponding moisture content is also mentioned.

Porosity is strongly affected by material moisture content, drying method and

conditions. In, general, comparison among structural properties reported in the

literature is difficult because of the variation of drying methods and conditions used

from the various investigators.

In order to examine the effect of experimental factors on structural properties,

materials for which sufficient experimental data are available have been chosen to be

presented for the needs of the present chapter.

Table 1.

Porosity values of some foodstuffs

Material

Drying method/conditions

Moisture

content

(kg/kgdb)

Porosity

Reference

1. Amioca Starch

Air drying, 60

o

C 0.1

0.4-0.6

Marousis et al. 1989

Extrusion, 180

o

C 0.3

0.502

Karathanos & Saravacos 1993

Extrusion, 180

o

C 0.4

0.314

Karathanos & Saravacos 1993

Extrusion, 100

o

C 0.5

0.168

Karathanos & Saravacos 1993

Air drying, 60

o

C, RH:10%

0.2

0.45

Marousis & Saravacos 1990

2. Apple

Natural air drying, 50

o

C

Forced air dr 50

o

C, RH:15%

Vacuum drying, 50

o

C

Freeze drying

0.1

0.1

0.1

0.1

0.2

0.1

0.4

0.8

Donsi et al. 1996

Air drying, 50-60

o

C, 0.1-2m/s

0.1

0.5-0.3

Ratti 1994

Osmotic deh. (15-45% sugars)

(10-40

o

C)

3-5 0.2-0.4

Reppa et al. 1999

Osmotic deh. (50% sucroce 20

o

C) 3 0.35

Mavroudis et al. 1998

Air drying 70

o

C, RH:20-60%

0.1

0.65

Zogzas et al. 1994

Air drying, 70

o

C

Lozano et al. 1980

Vacuum drying, 80

o

C 0.1

0.5

Torreggiani et al. 1995

Air drying, 60

o

C 3m/sec RH: 10%

0.1

0.6

Sjoholm & Gekas 1995

Air drying, 70

o

C, 10%

Vacuum drying, 30-900mbar

Osmotic dehydration glucose

Microwave drying

Freeze drying

0.1 0.6

0.75-0.6

0.5

0.6

0.92-0.75

Krokida et al. 1997

Krokida & Maroulis 1997

Krokida et al. 1998c

3. Banana

Air drying, 70

o

C, 10%

Vacuum drying, 30-900mbar

Osmotic dehydration glucose

Microwave drying

Freeze drying

0.1 0.2

0.2-0.7

0.15

0.25

0.9-0.84

Krokida et al. 1997

Krokida & Maroulis 1997

Krokida et al. 1998c

6

4. Blueberries

Air dried , 50

o

C

Microwave oven dried

Vacuum-oven dried, 40

o

C

Freeze dried

0.1

0.1

0.1

0.1

0.15

0.21

0.45

0.70

Yang & Atallah, 1985

Air dried , 45

o

C

Microwave oven dried

0.1

0.1

0.2

0.21-0.2

Raghavan & Venkatachalapathy, 1999

5. Carrot

Air drying, 50-60

o

C, 0.1-2m/s

0.1

0.1-0.3

Ratti , 1994

Air drying 70

o

C, RH:20-60%

0.1

0.10

Zogzas et al. 1994

Air drying, 70

o

C, 10%

Vacuum drying, 30-900mbar

Microwave drying

Freeze drying

0.1 0.1

0.1-0.5

0.7

0.94-0.88

Krokida et al. 1997

Krokida & Maroulis 1997

Krokida et al. 1998c

Air drying, 40

o

C, RH:30%

0.1

0.1

Suzuki et al. 1976

6. Cornmeal

Extrusion, 140

o

C

0.16 0.951

Karathanos & Saravacos 1993

7. Garlic

Air drying, 50-60

o

C, 0.09-1.2m/s

0.1

0.7-0.8

Madamba et al. 1993

Air drying, 70

o

C, RH: 14.5%

0.05

0.13

Madamba et al. 1994

8. Grapes

Air drying, 40-80

o

C

Pretr. 2% CaCO

3

3% ethyl oleate

0.1 0.1-0.2

Gabas et al. 1999

9. Hulls

Air drying

0.05

0.55

Teotia & Ramakrishna, 1989

10. Hylon 7

Air drying, 60

o

C, RH:10%

0.2

0.46

Marousis & Saravacos 1990

11. Kernel

Air drying

0.08

0.076

Teotia & Ramakrishna, 1989

12. Onion

Air drying, 70

o

C, RH: 14%

0.05

0.1-0.2

Rapusas et al. 1995

13. Potato

Natural air drying, 50

o

C

Forced air dr 50

o

C, RH:15%

Vacuum drying, 50

o

C

Freeze drying

0.1

0.1

0.1

0.1

0.1

0.1

0.7

Donsi et al. 1996

Air drying, 50-60

o

C, 0.1-2m/s

0.1

0.1-0.2

Ratti , 1994

Air drying 70

o

C, RH:20-60%

0.1

0.05

Zogzas et al. 1994

Vacuum drying, 70

o

C 0.05

0.25

Suarez & Viollaz, 1991

Air drying, 70

o

C, 10%

Vacuum drying, 30-900mbar

Microwave drying

Freeze drying

0.1 0.2

0.1-0.2

0.7

0.87-0.78

Krokida et al. 1997

Krokida & Maroulis 1997

Krokida et al. 1998c

Air drying, 40

o

C, RH:30%

0.1

0.05

Suzuki et al. 1976

14. Radish

Air drying, 40

o

C, RH:30%

0.1

0.12

Suzuki et al. 1976

15. Raisins

Air drying, 39-51

o

C, RH: 14%

0.14-0.80 0.47-0.37

Vagenas et al. 1990

16. Seeds

Air drying

0.19

0.5

Teotia & Ramakrishna 1989

17. Squid flesh

Air drying, 70

o

C, RH:15%

0.02-0.8

0.12-0

Rahman & Potluri 1990

18. Sweat Potatoes

Air drying, 40

o

C, RH:30%

0.1

0.04

Suzuki et al. 1976

7

2.4 Factors affecting structural properties

During drying, significant changes in structural properties can be observed as

water is removed from the moist material. The main aspect, as far as structural

properties are concerned, is to control the product apparent density and porosity and

to yield products of different physical structures for various uses, choosing an

appropriate drying method and conditions.

As an explanation of the observed changes of structural properties during drying,

it could be presumed that in the early stages of drying, the cellular tissues are elastic

enough to shrink into the space left by the evaporated moisture. As the drying process

proceeds, structural changes in the cellular tissues result in a more rigid network, thus

favouring the development of porosity. This behaviour clearly depends on various

factors, which specify the structural properties of the dried material. These factors are

analytically examined in the following paragraphs:

•

moisture content

•

drying method

•

drying conditions

Considering that most of dehydrated products will be rehydrated, a basic aspect

seems to be that the structural behaviour of rehydrated products should be close to

that of fresh materials. The effect of drying method on structural properties of

rehydrated products is also examined in this chapter

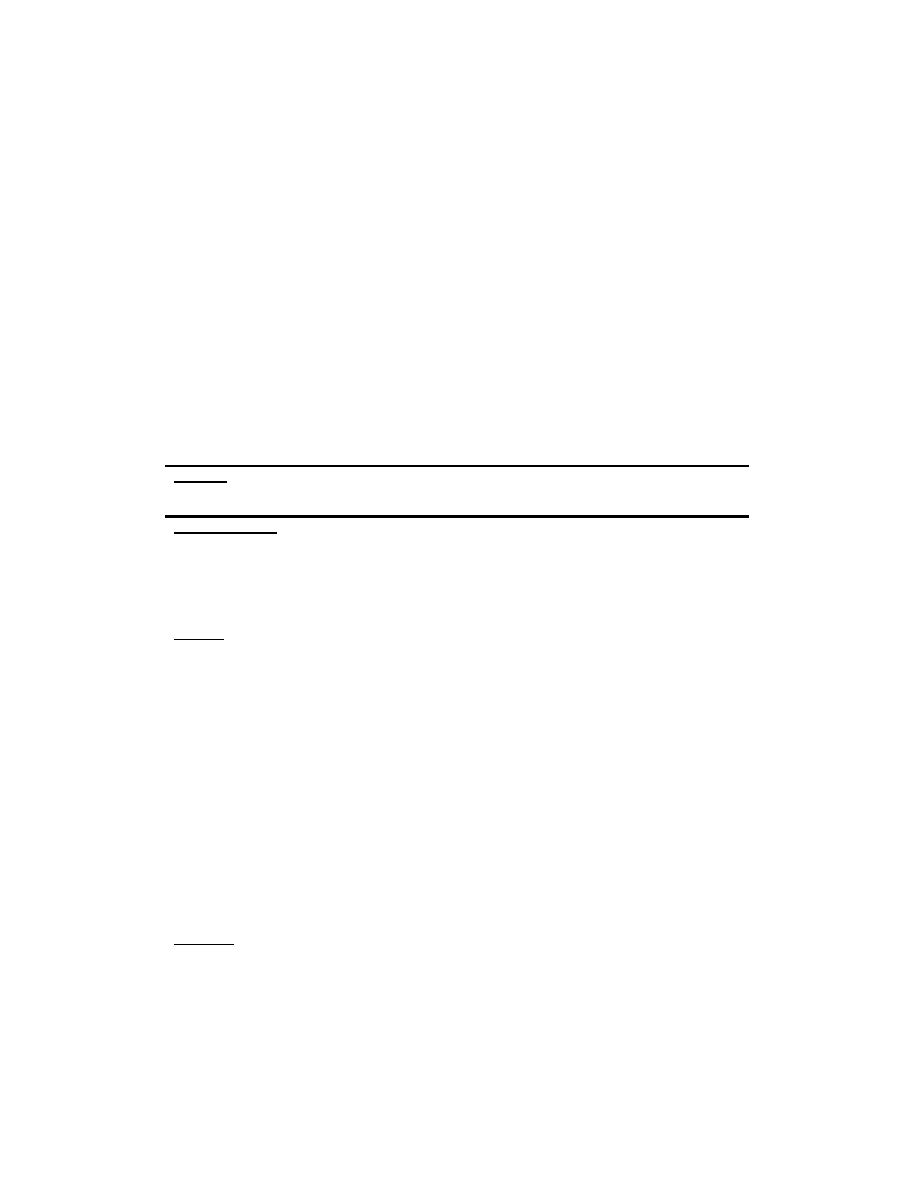

2.4.1 Effect of moisture content on structural properties

Structural properties of foods are strongly affected by material moisture content.

Diffusion of water molecules during drying forms cracks to the solid structure,

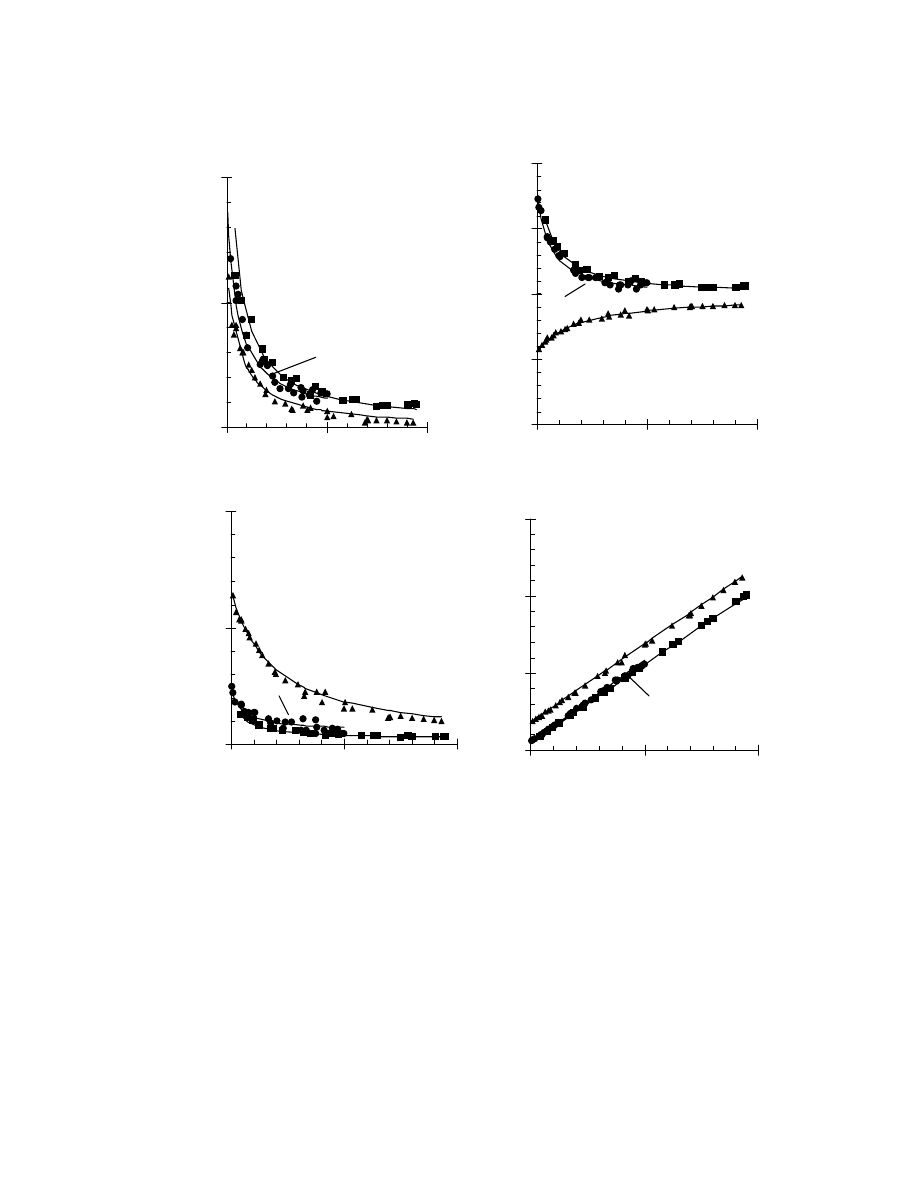

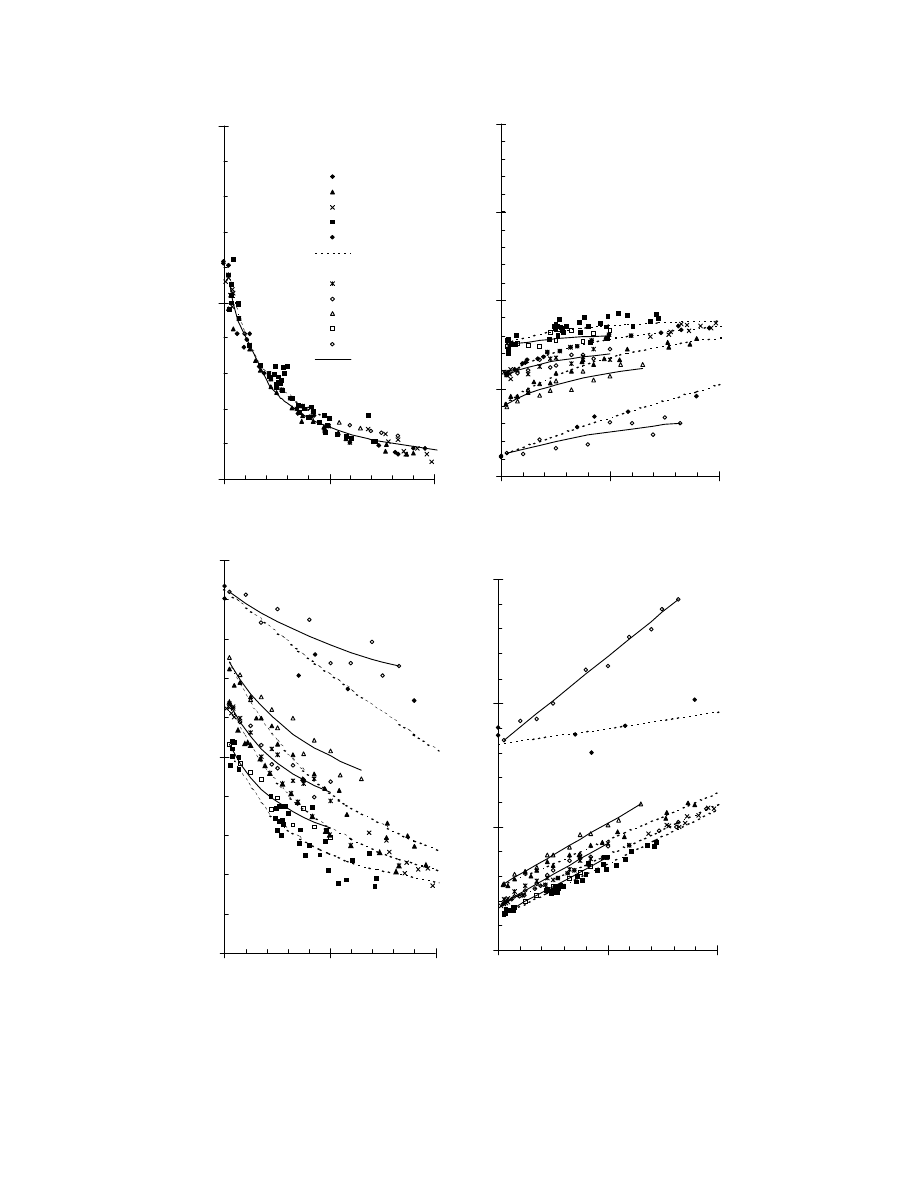

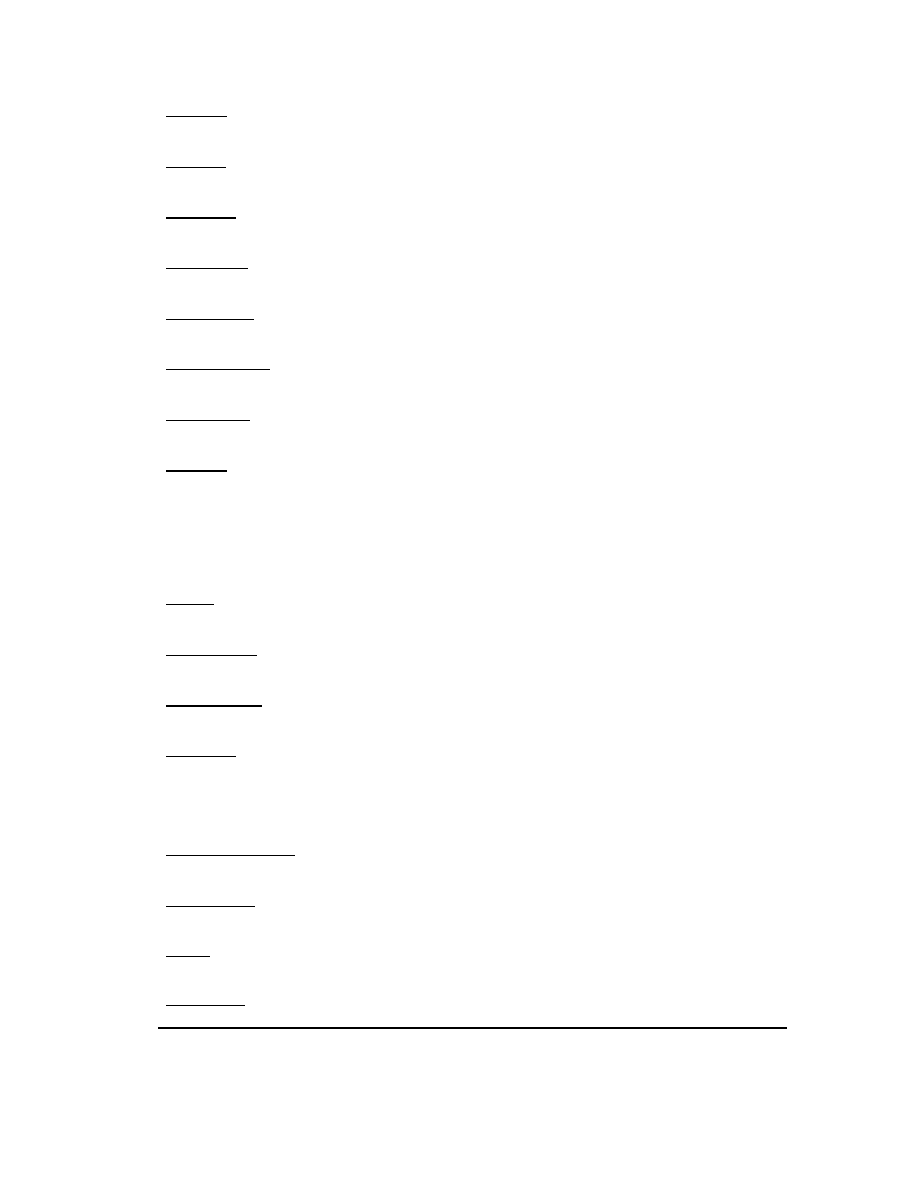

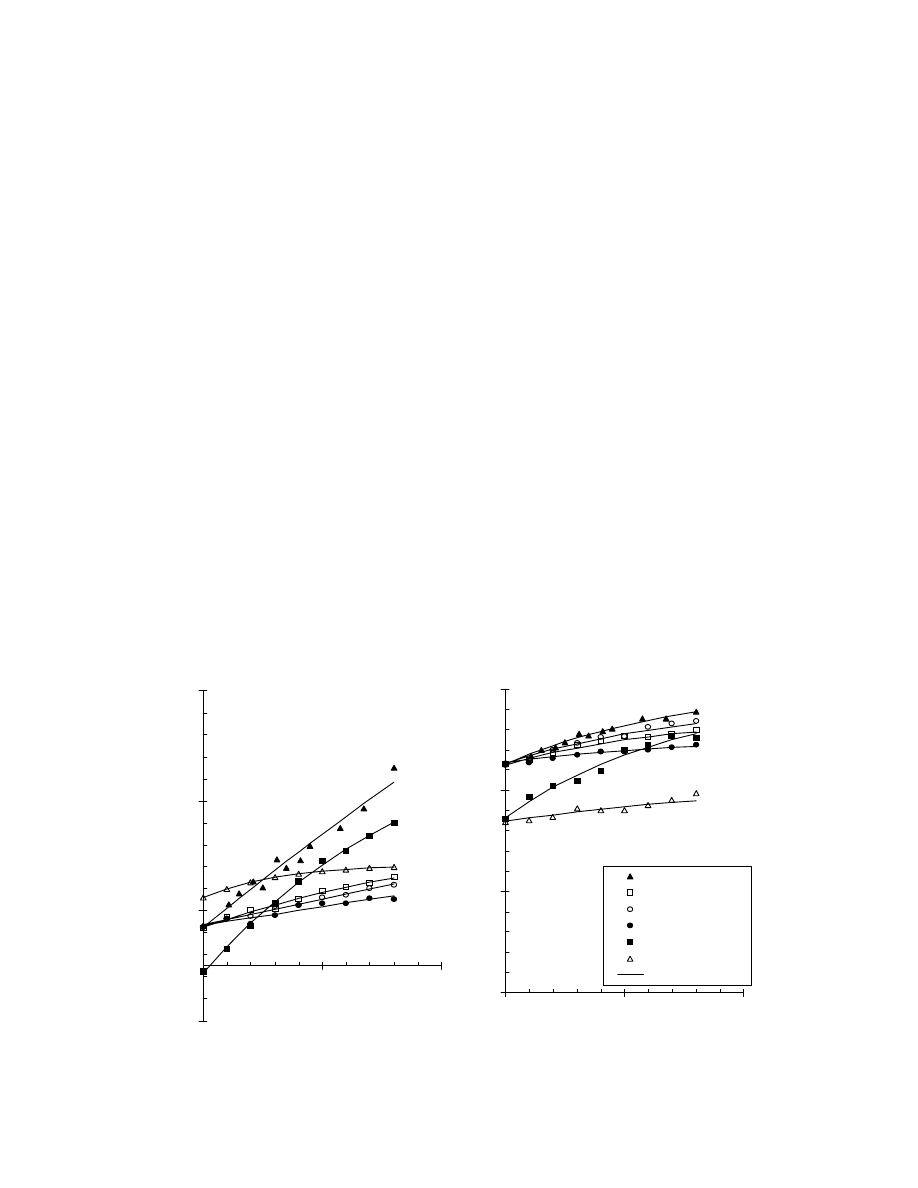

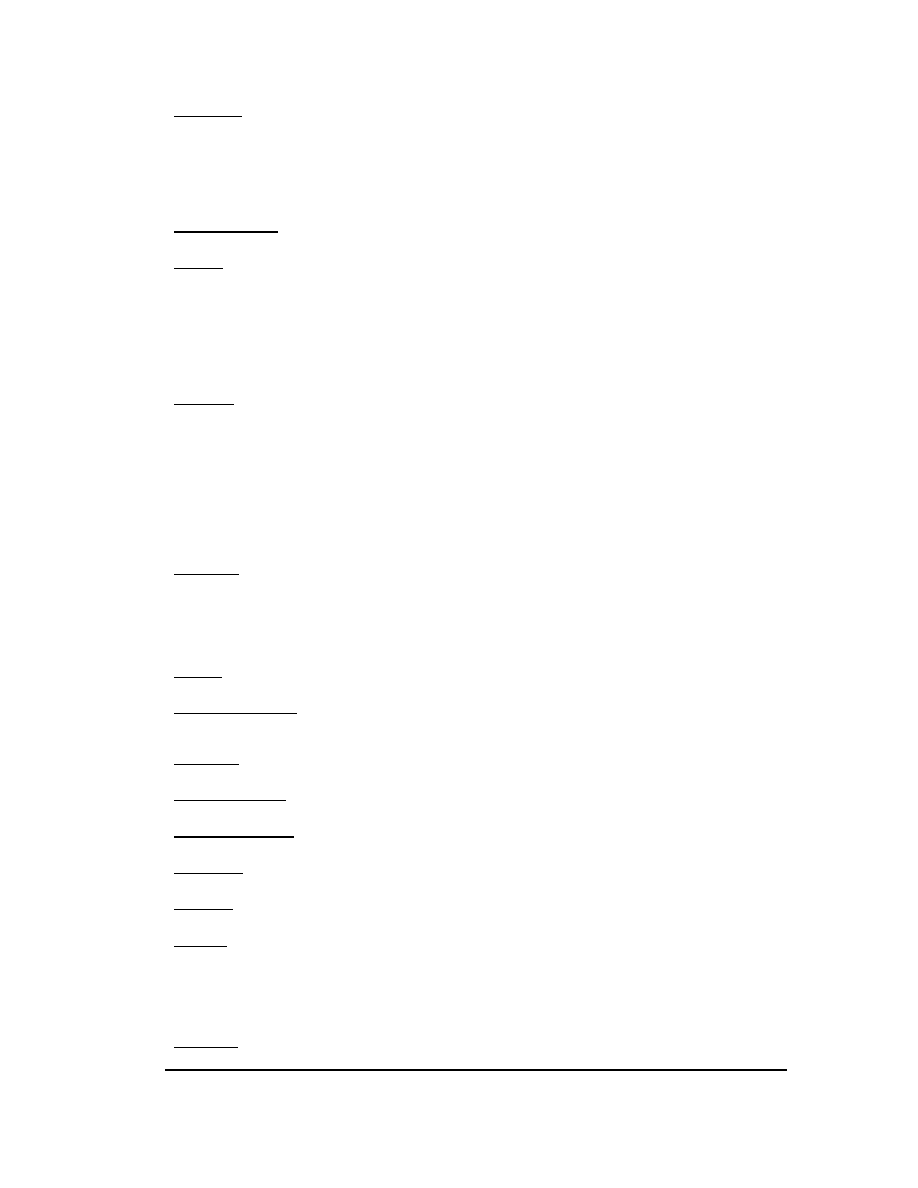

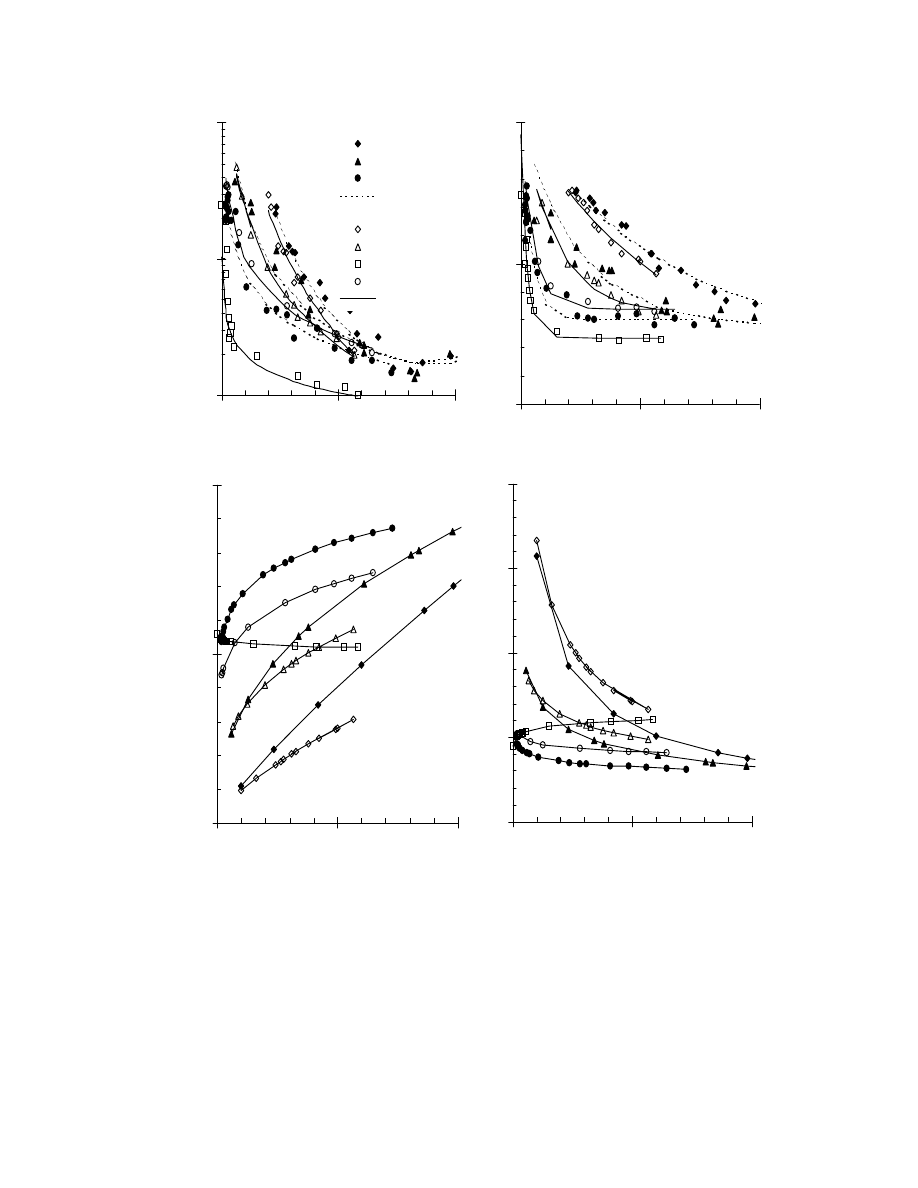

causing structural damage and significant changes to all structural properties. Figure 1

presents the variation of true density, apparent density, porosity and specific volume

for apple, banana and carrot during conventional drying (70

o

C, 15% relative

humidity).

True density increases as the water is removed, which should be expected since

true density ranges between the density of water and the dry solids density. Thus, as

the water is removed, the true density reaches the value of the material dry solid

density.

Apparent density ranges between the density of water and the density of the

completely dry material (

ρ

b0

). As a result, the value of apparent density at high

moisture content, approximates the density of water, while at low moisture content

values, it tends to the value of

ρ

b0

. Thus, apparent density of apples decreases with

moisture content, while it increases for carrot and banana, as water is removed during

conventional drying.

Porosity of food materials increases in general while moisture content is

decreased. The final porosity values of dehydrated products depend on the material

structure as well as the drying conditions. Dried apple (Fig. 1) develops the highest

porosity values, while the shrinkage phenomenon seems to be less intense. For the

specific drying conditions, banana and carrot seem to shrink intensely, developing

lower porosities.

8

Specific volume decreases linearly with moisture content during conventional

drying, showing similar values for all the materials.

Figure 1. Structural properties during conventional drying (70

o

C, 15% RH).

Apple

1.0

1.5

2.0

0

5

10

M ois ture conte nt (kg/kg db)

T

ru

e de

ns

it

y

(k

g/

lt

)

Banana

C arrot

0.0

0.5

1.0

1.5

2.0

0

5

10

M ois ture conte nt (kg/kg db)

A

p

pa

re

nt

de

ns

it

y

(

k

g/

lt

)

Apple

C arrot

Banana

0.0

0.5

1.0

0

5

10

M ois ture conte nt (kg/ kg db)

Po

ro

si

ty

Apple

Banana

C arrot

0

5

10

15

0

5

10

M ois ture conte nt (kg/kg db)

S

p

e

c.

V

o

lu

m

e

(l

t/k

g

d

b)

Apple

C arrot

Banana

9

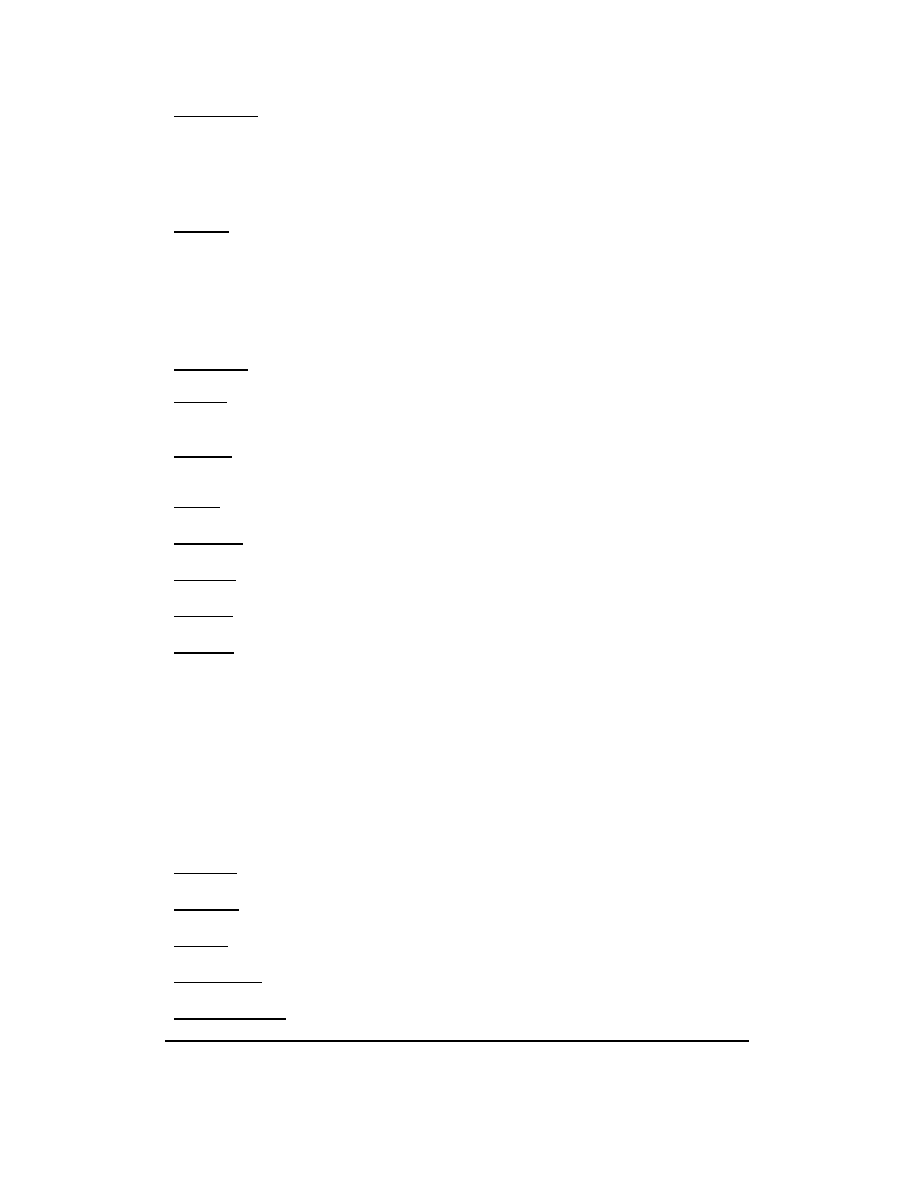

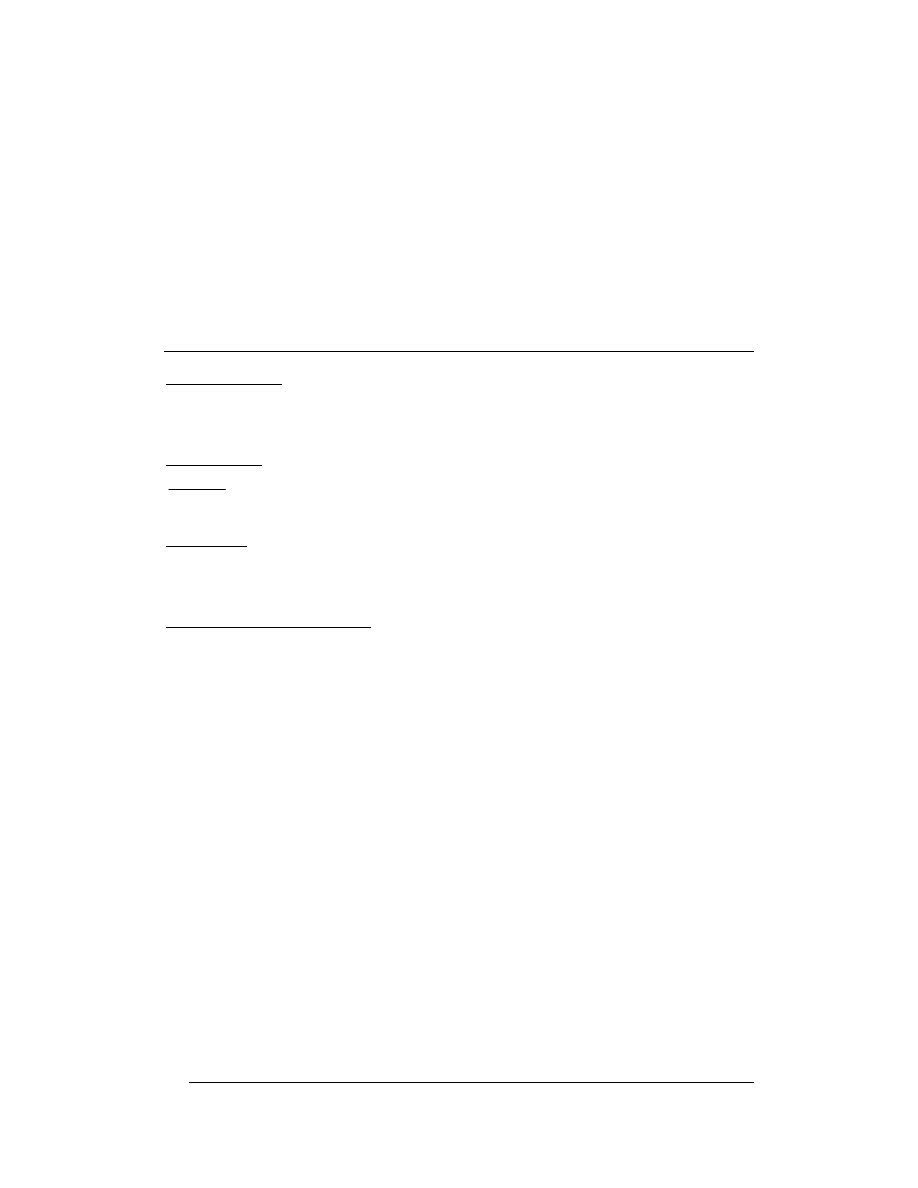

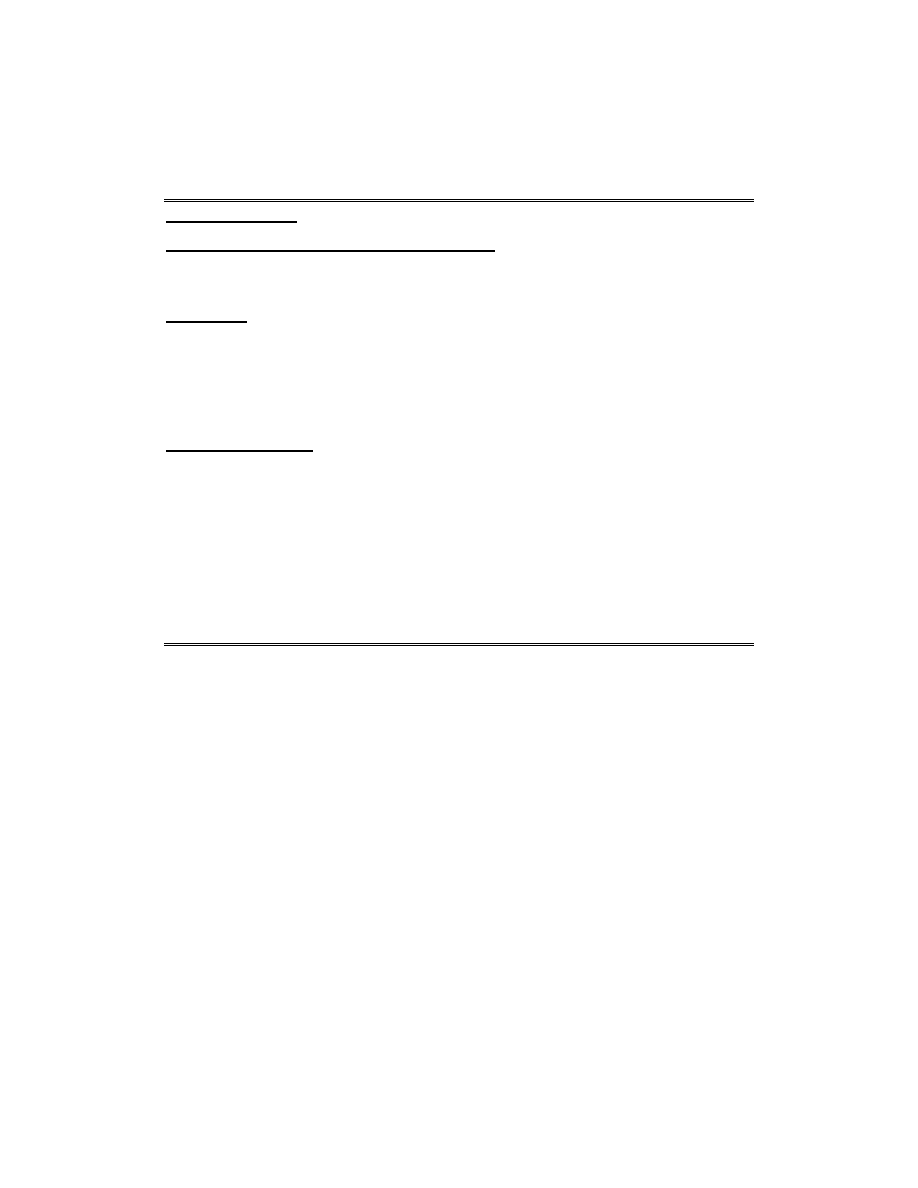

2.4.2 Effect of drying method on structural properties

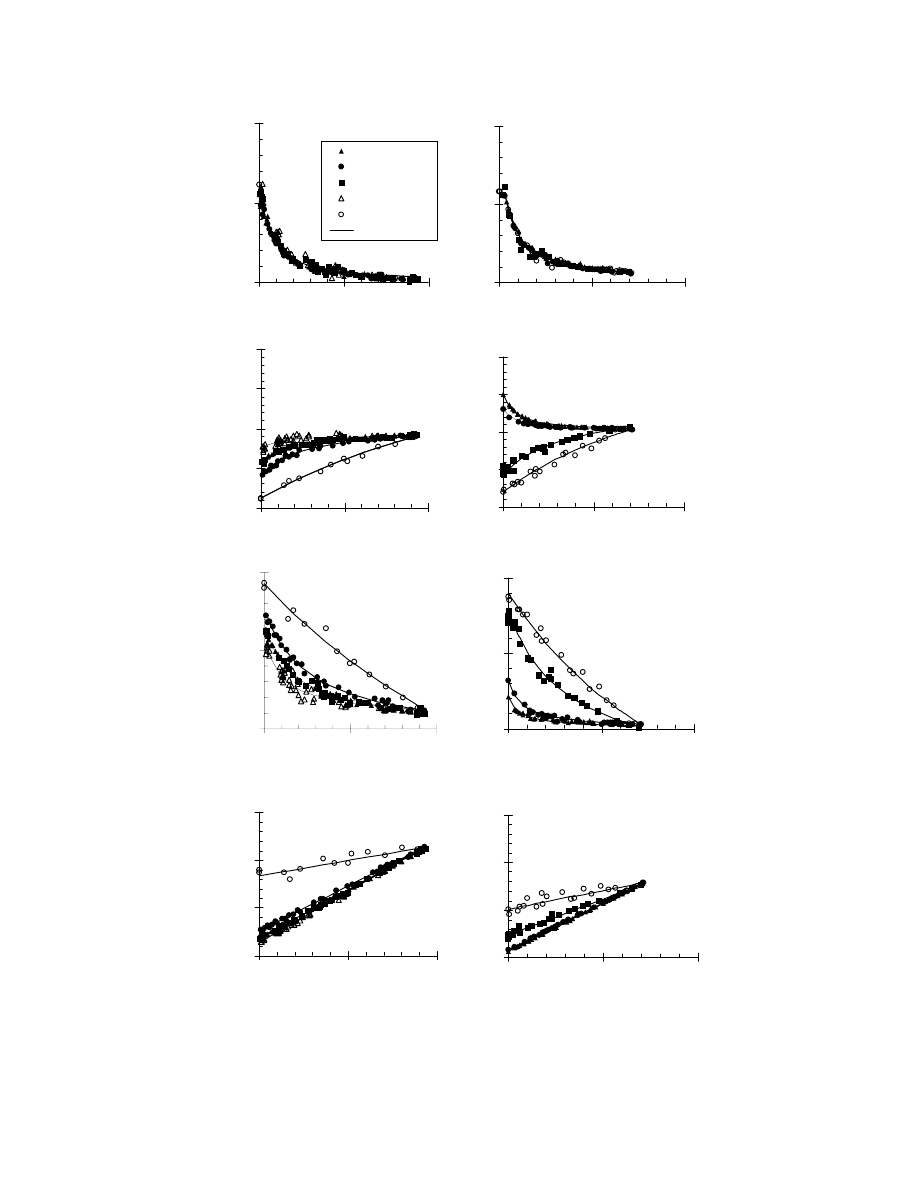

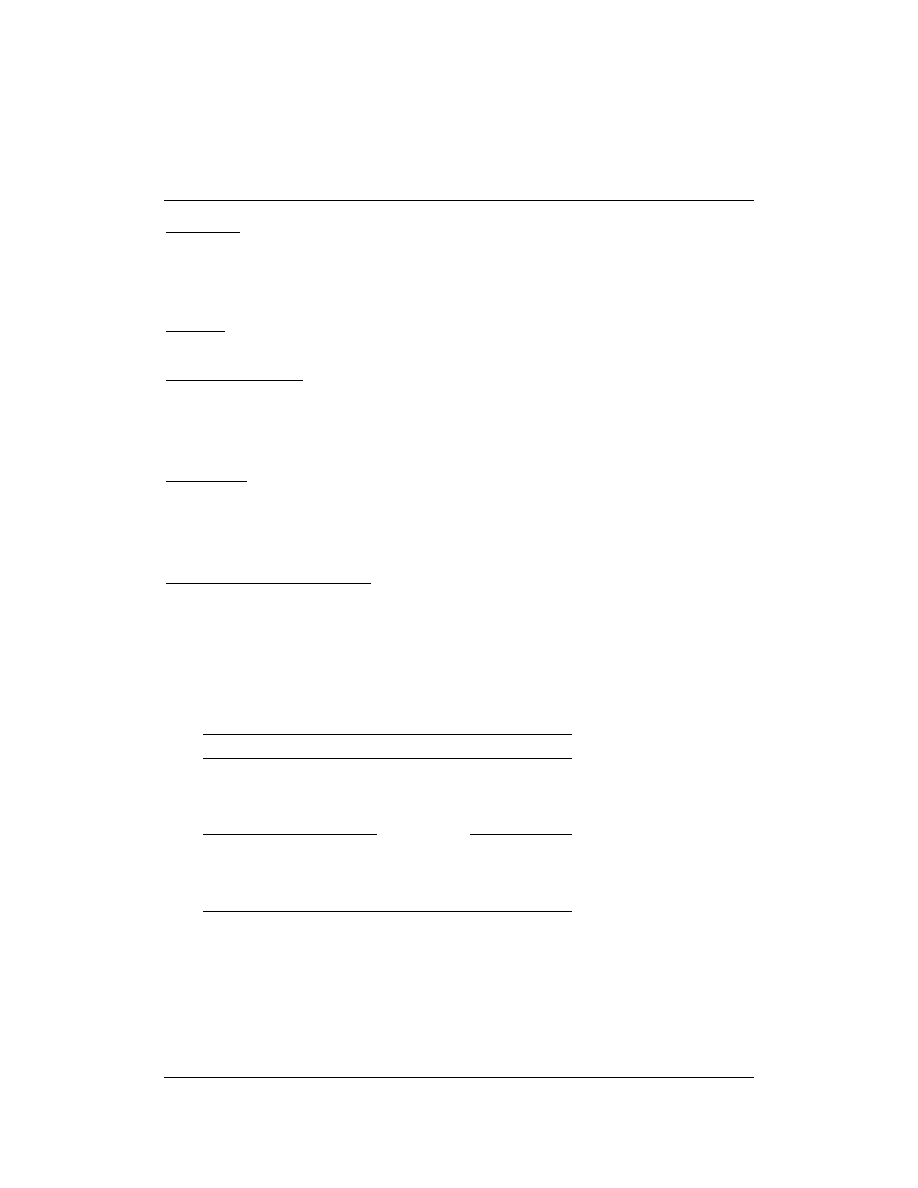

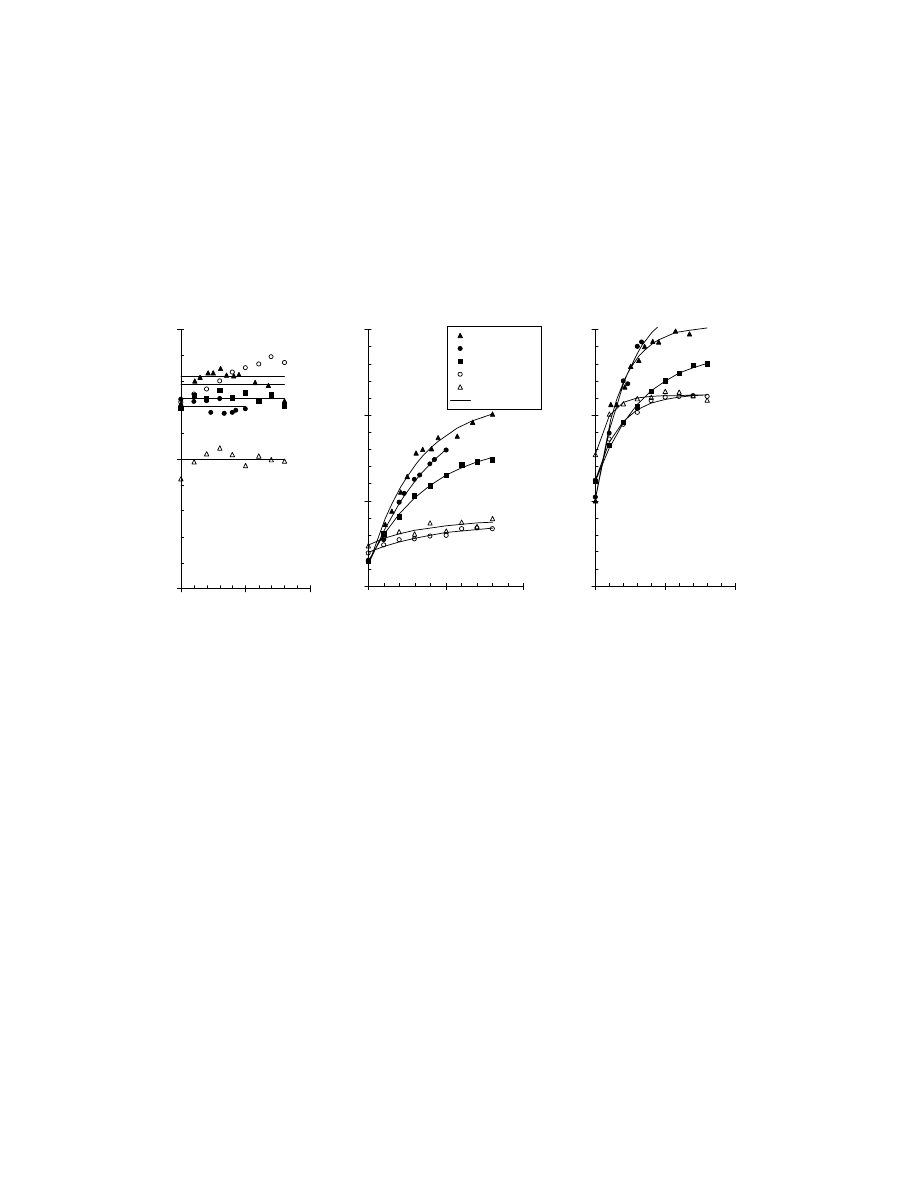

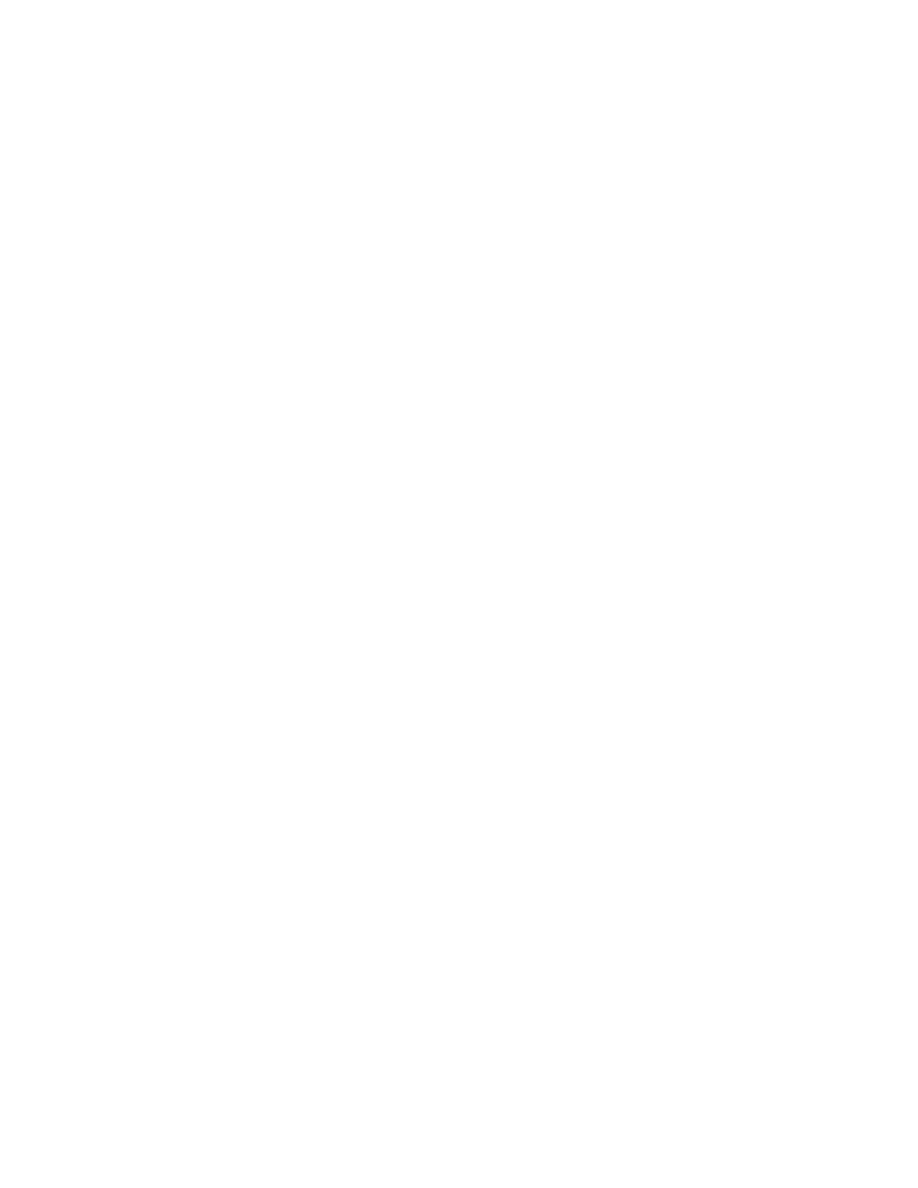

Structural properties are greatly affected by the drying method. Figure 2

presents the effect of drying method on the structural properties of two materials. It

was chosen to present one fruit and one vegetable, for which there are enough

experimental data.

True density is not affected by drying method. An exception seems to be the

case of osmotic dehydration. Osmotic dehydration influences true density values, as

mass transfer phenomena take place during osmotic treatment. Water loss and solids

gain of osmo-dehydrated fruits affect the dry solids density, which reaches the value

of sugar density. During all drying methods, true density increases as water is

removed. This should be expected, since true density ranges between the density of

water and the dry solids density. Thus, as water is removed, the true density reaches

the value of the dry solids density.

Apparent Density is strongly affected by dehydration process. More specifically,

the apparent density values during vacuum drying were significantly lower than those

of conventional drying for all materials. As far as freeze dried materials are

concerned, the values of apparent density are the lowest noticed. Also, the apparent

density of microwave - dried products seem to depend on the material structure.

Osmotic dehydration increases, in general, the apparent density of fruits. The apparent

density of apples decreases with moisture content for all dehydration methods. For

potato, the apparent density increases with moisture content for vacuum and

conventional drying, while it decreases during microwave and freeze drying.

Apparent density ranges between the density of water and the density of the

completely dry material (

ρ

b0

). As a result, the value of apparent density at high

moisture content, approximates the density of water, while at low moisture content

values, it tends to the value of ρ

b0

. Drying method conditions are expected to highly

affect ρ

b0

, which has also been noticed through the parameters estimation procedure.

Porosity of freeze dried materials is always higher in comparison to all other

dehydration processes (80-90%). Porosity of microwave dried potato follows (75%),

while microwave dried apple does not develop high porosity (25%). Vacuum dried

apple developed high porosity (70%), while for vacuum dried potato porosity values

were lower (25%).

Specific Volume reduction is almost absent in freeze dried materials. That

happens because a very limited shrinkage is detected in freeze dried samples, which

are characterised by a structure with minimum deformation in respect to fresh

samples. For all the other methods, specific volume does not vary significantly with

the drying method. So, for conventional and osmotically dehydrated materials, the

shrinkage phenomenon is very intensive, while this phenomenon is less intensive for

vacuum dried and microwave dried materials.

10

APPLE

0.0

0.5

1.0

1.5

2.0

0

5

10

M ois ture conte nt (kg/kg db)

A

ppa

re

nt

de

ns

it

y

(k

g/lt

)

APPLE

1.0

1.5

2.0

0

5

10

M ois ture conte nt (kg/kg db)

T

rue

de

n

sit

y (

k

g/

lt

)

conv. drying

vacuum drying

microwaves

osmotic deh.

freeze drying

Calculated

APPLE

0.0

0.5

1.0

0

5

10

M ois ture conte nt (kg/ kg db)

Po

ro

si

ty

APPLE

0

5

10

15

0

5

10

M ois ture conte nt (kg/kg db)

S

pe

c.

V

ol

um

e(l

t/

k

g d

b)

POTATO

1.0

1.5

2.0

0

5

10

M ois ture conte nt (kg/kg db)

T

rue

de

n

sit

y (

k

g/

lt

)

POTATO

0.0

0.5

1.0

1.5

2.0

0

5

10

M ois ture conte nt (kg/kg db)

A

ppa

re

nt

de

ns

it

y

(k

g/lt

)

POTATO

0.0

0.5

1.0

0

5

10

M ois ture conte nt (kg/ kg db)

Po

ro

si

ty

POTATO

0

5

10

15

0

5

10

M ois ture conte nt (kg/kg db)

S

pe

c.

V

ol

um

e(l

t/

k

g d

b)

Figure 2. Effect of drying method on structural properties of apple and potato.

11

2.4.2 Effect of drying conditions on structural properties

Drying conditions affect significantly the physical structure of a material. Thus,

the same raw material dried with the same drying method may end up to a completely

different material under different drying conditions. This suggests that the rate at

which the material is dried and its structural properties are interrelated. The effect of

some drying conditions, related to structural properties, which have been examined in

the literature, are presented in the next paragraphs. More specifically, the following

aspects are examined:

-

The effect of pressure during vacuum drying

-

The effect of temperature during freeze drying

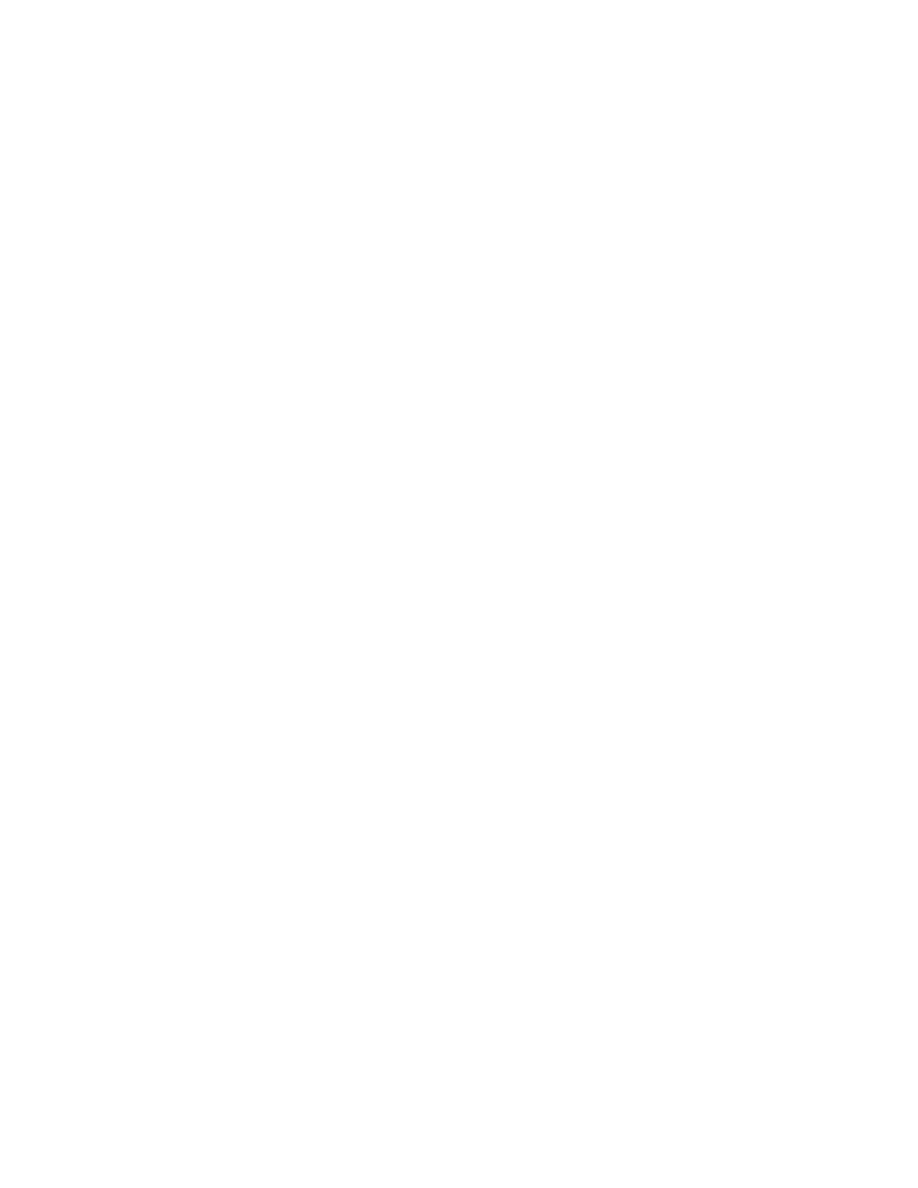

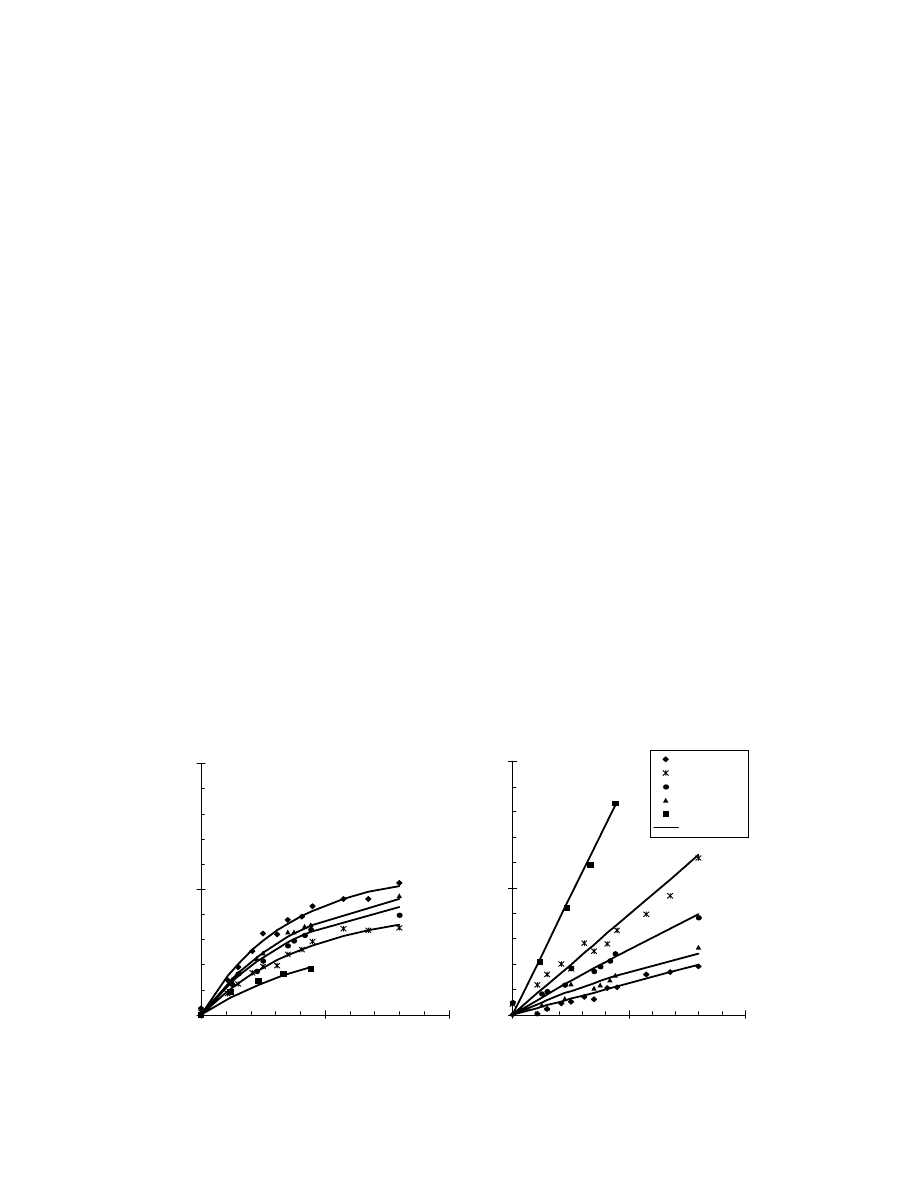

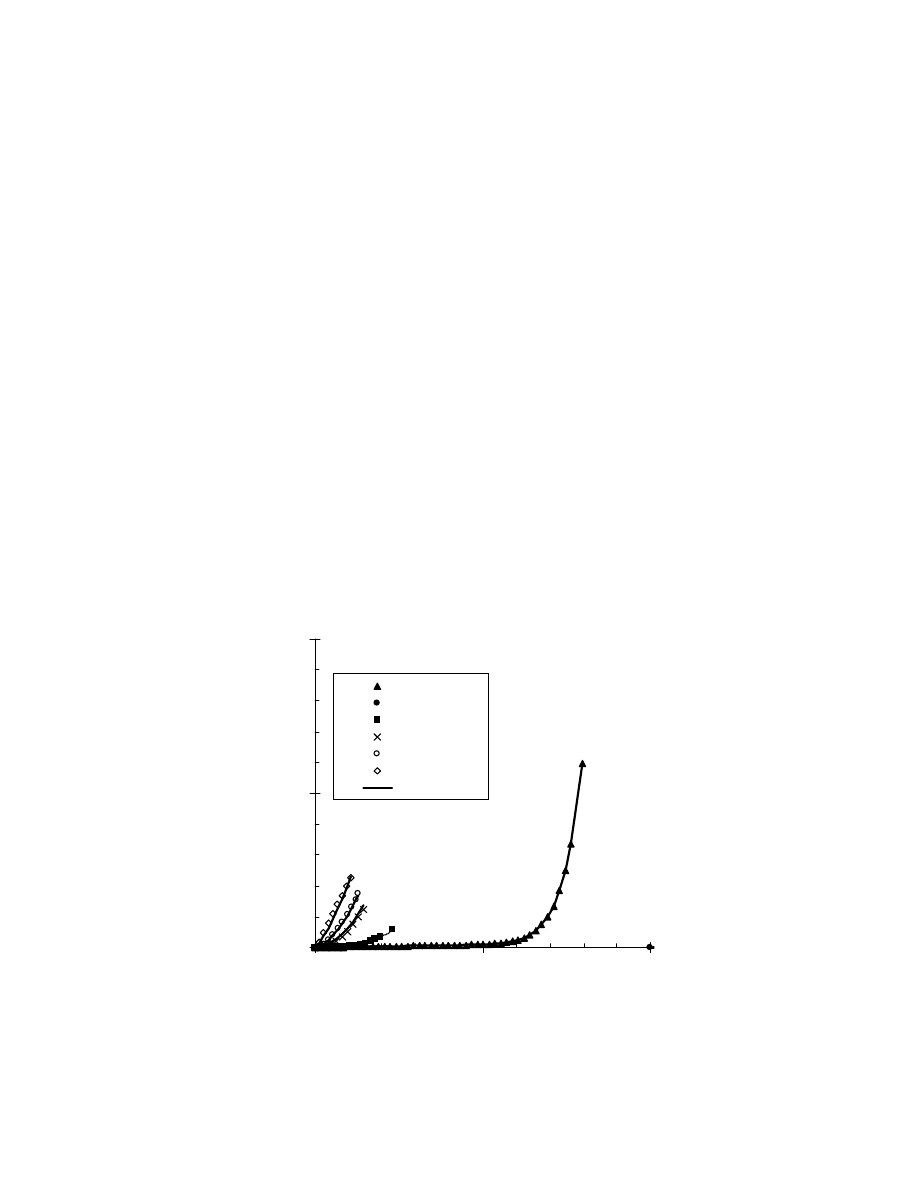

2.4.2.1 Effect of pressure during vacuum drying

The effect of pressure on structural properties of dehydrated products was

examined. Pressure affects significantly the percentage of air pores developed in the

final dry product. Consequently, only apparent density and porosity are expected to be

affected by pressure during vacuum dehydration (Figure 3).

Apparent density of dried materials decreases as vacuum pressure decreases,

which mean that lower pressure during vacuum dehydration prevents structural

collapse of foods. This phenomenon seems to be more intense for carrot and banana

than for apple and potato.

Porosity of dehydrated products increases as vacuum pressure decreases, which

means that shrinkage can be prevented by controlling pressure, allowing high porosity

values in the final products.

Figure 3. Effect of pressure on structural properties of vacuum dried materials.

Banana

Apple

C arrot

Potato

0.0

0.5

1.0

1.5

2.0

0

500

1000

Pre s s ure (mbar)

A

ppa

re

nt

de

ns

it

y o

f d

ry

s

ol

ids

(

k

g

/l)

Banana

Apple

C arrot

Potato

0

0.5

1

0

500

1000

Pre s s ure (mbar)

P

o

ro

si

ty

of

d

ry s

o

lid

s

12

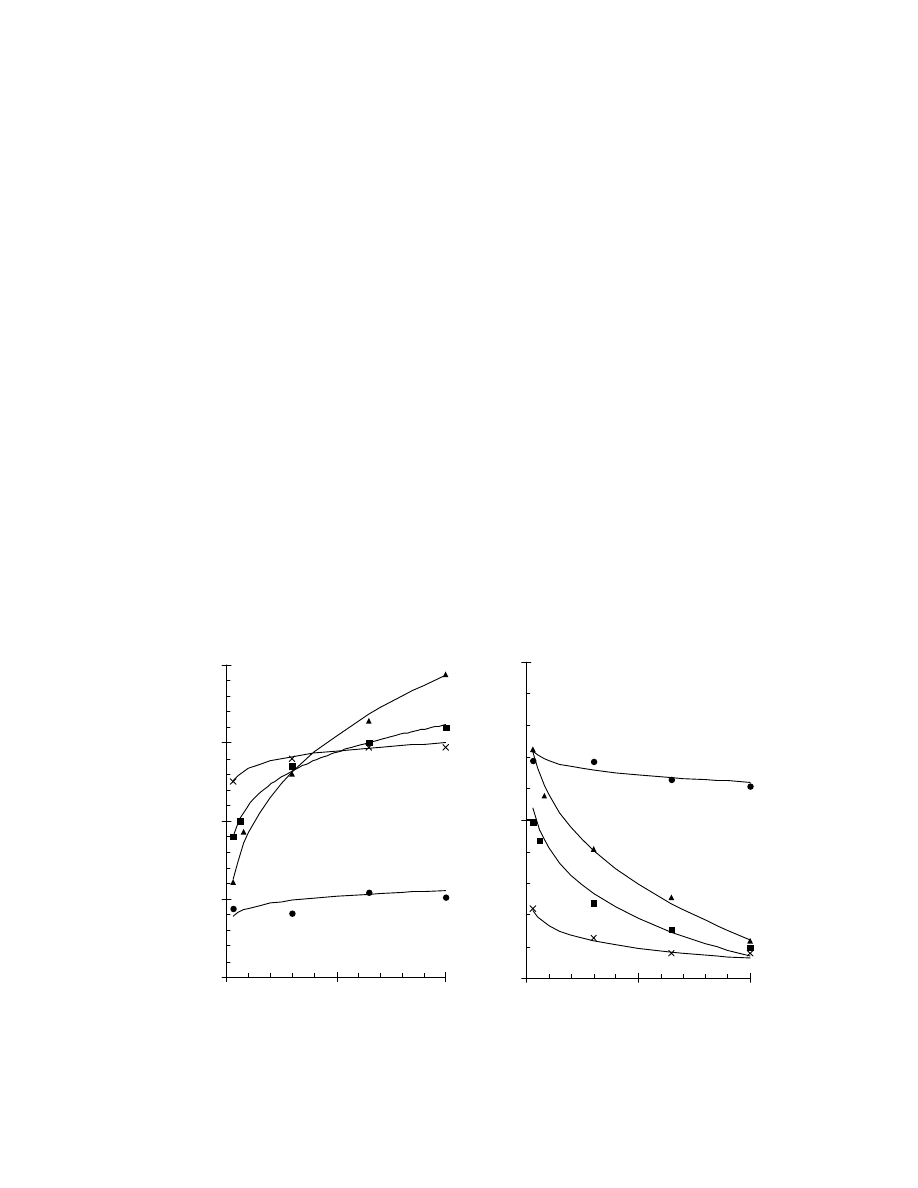

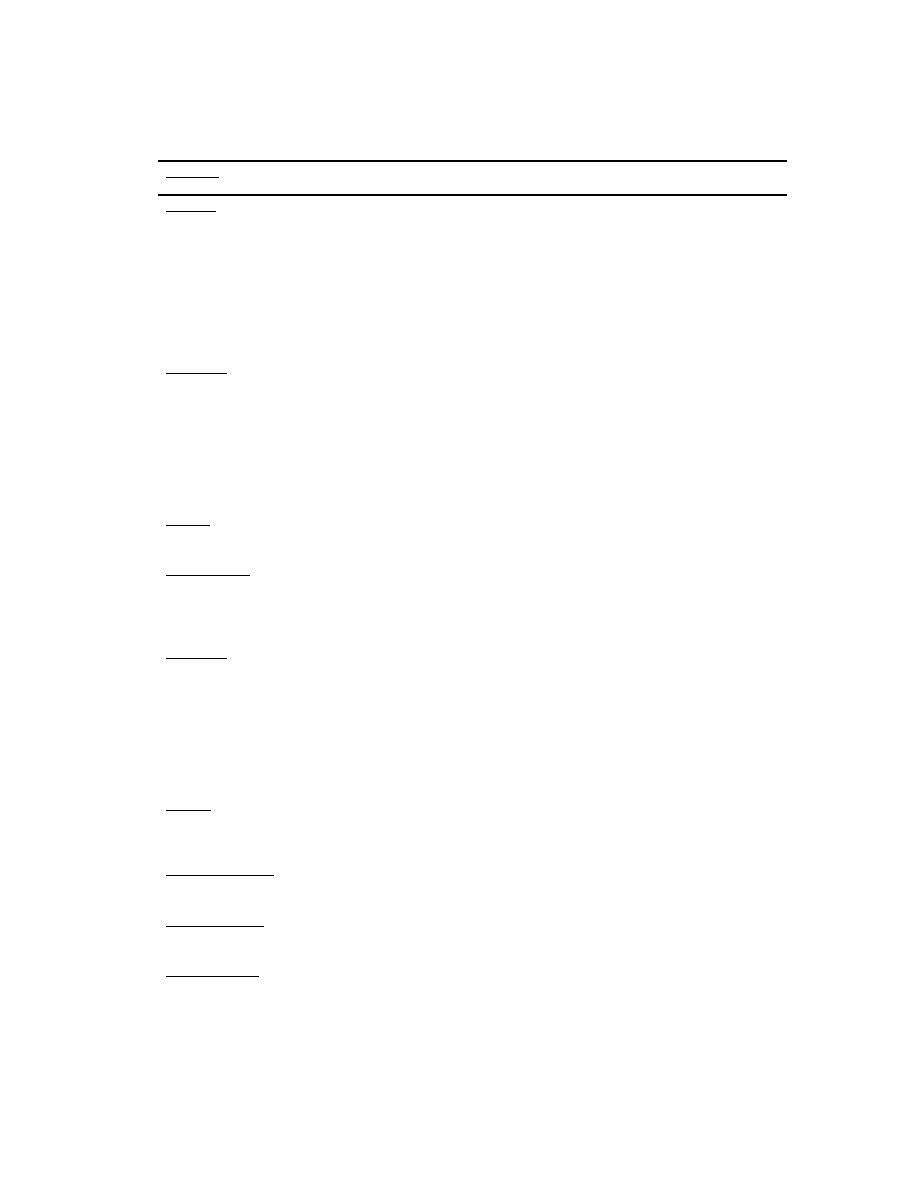

2.4.2.2 Effect of temperature during freeze drying

Freeze drying conditions affect significantly structural properties of dried

materials. Apparent density and porosity values of the final product depend on

whether on not the frozen product was kept below a critical temperature, the collapse

temperature during the sublimation of ice. The collapse temperature is related to the

glass transition temperature, which is the temperature above which the solute matrix

loses its shape. The effect of temperature on apparent density and porosity of freeze

dried materials is presented in Figure 4.

Apparent density of freeze dried plant materials, as determined experimentally,

was strongly affected by the freeze drying conditions (Fig. 4). More specifically, all

materials did not shrink significantly during freeze drying at low temperatures (lower

than the estimated glass transition temperature T

g

′

= - 45°C) and they resulted in low

apparent densities. The shrinkage was considerably more significant when freeze

drying occurred at reduced vacuums and, consequently, at higher temperatures. The

apparent density of freeze dried materials decreased as the temperature was increased

from (-50

°

C) to (-8

°

C). Apparent density of apple showed the greatest dependence on

temperature, the density of carrot followed, while banana and potato showed the

lowest dependence. Among the fresh samples, apple has the lowest bulk density,

which is due to its greater contained volume of air. Therefore, during sublimation of

the ice crystals, an additional volume (the empty pores) is available to shrink above

the shrinkage temperature.

Porosity of freeze dried materials is shown in Fig. 4. The porosity was greatly

affected by the freeze drying conditions. At low temperatures, the porosity for all

materials was the highest noticed (90%), while it decreased for drying at higher

temperatures. The reduction of the porosity varied from 30% for apple to 10% for the

other materials. During freeze drying, detrimental effects occurred due to the glass to

rubber transition of the CAS and the melting of ice which plasticized the matrix and

decreased the porosity, as the initial sample temperature was increased. Fresh apple

has the greatest porosity value, which means that the pore percentage is higher and

therefore a greater volume of pores is available to shrink.

Figure 4. Effect of temperature on structural properties of freeze dried materials.

0

0.1

0.2

0.3

0.4

0.5

220

240

260

280

Te mpe rature (K)

A

ppa

re

nt

D

e

ns

it

y

(

k

g

/lt)

0.7

0.8

0.9

1

220

240

260

280

Te mpe rature (K)

Po

ro

si

ty

Apple

Potato

C arrot

Banana

C alculated

13

2.4.2 Effect of drying method on structural properties of rehydrated products

Structural changes that take place during drying cannot be restored by a simple

addition of water. Examining structural properties of dehydrated products during

rehydration is a measure of the injury to the material caused by drying. The degree of

rehydration is depended also on the degree of structural disruption. The effect of

drying method on structural properties of apple is presented in figure 5.

True density is not affected by drying method and it is the same during

dehydration and rehydration for the same moisture content. That means that only

material and moisture content affect true density. Thus, as water is removed during

dehydration, true density reaches the value of the dry solid density, while as water is

gained during rehydration true density decreases again following the same route.

Apparent density during rehydration follows the same mode as during

dehydration, which means that apparent density of apple increases with moisture

content for the examined drying methods. It drops significantly during rehydration for

all the drying methods, having lower values than those during dehydration. That

means higher air pores proportion during rehydration, and that cellular and structural

disruption, which takes place during drying, results in reduced hydrophilic properties

and inability to imbibe sufficiently water, leaving pores uncovered. Moreover, the

inflation phenomenon, which takes place during rehydration, results in decrement of

apparent density during rehydration. As it may be seen, the hysteresis phenomenon

appears for apparent density during rehydration and the degree of that phenomenon

depends on the drying method.

Porosity of dehydrated products decreases during rehydration for all the

examined materials. The hysteresis phenomenon is noticed for all drying methods,

which appears as an increment of porosity values during rehydration in comparison to

those noticed during dehydration. The reduced hydrophilic properties and the inability

to imbibe sufficiently water, leaving pores uncovered, result in higher porosity values.

Shrinkage phenomena that take place during dehydration prevent rehydration and

develop products with higher porosity values. Freeze dried materials, seem to have the

highest rehydration ability, while air and microwave vacuum products show the

lowest noticed.

14

Figure 5 Effect of temperature on structural properties of freeze dried materials.

APPLE

0.0

0.5

1.0

1.5

2.0

0

2

4

M oisture conte nt (kg/kg db)

A

ppa

re

nt

de

ns

it

y

(k

g

/l

t)

APPLE

0.0

0.5

1.0

0

2

4

M oisture conte nt (kg/ kg db)

Po

ro

si

ty

APPLE

0

5

10

15

0

2

4

M oisture conte nt (kg/kg db)

S

p

e

c.

V

o

lu

m

e

(l

t/

k

g

d

b)

APPLE

1.0

1.5

2.0

0

2

4

M oisture conte nt (kg/kg db)

T

rue

de

n

si

ty

(

k

g

/l

t)

D e hydration

conv. drying

vacuum drying

microwaves

osmotic deh.

freeze drying

Calculated

R e hydration

microwaves

conv. Drying

vacuum drying

osmotic deh.

freeze drying

Calculated

15

2.5 Mathematical modeling

Many attempts have been made in the literature for the development of structural

models. The main purpose of a structural model is to describe the relation of porosity

development with moisture content. Most of these approaches require knowledge of

transport properties and are rather complicated.

Lozano et al. 1980 & 1983, developed a general model to correlate shrinkage

properties for fruits and vegetables. They suggested two alternative approaches; the

first considers porosity to depend on the shrinkage of the sample over all dimensions,

while the second takes into account the shrinkage of the cells of the cellular tissue of

the material. This approach requires knowledge of transport properties in general and

porosity in particular, which are not usually available.

Suzuki et al. 1976 developed three equations, which apply to three different

drying models: uniform drying, core drying and semicore drying. The first model

results in two alternative equations: one needs data for equilibrium moisture contents

and bulk density and the other requires the initial moisture content and bulk density of

the material. The second and the third model need the initial and equilibrium values

for moisture and bulk density.

A mathematical model, which predicts the porosity development during drying

and correlates it with the material moisture content, would be useful. It should be

simple, generalized and contain parameters with physical meaning.

A simple mathematical model is presented here to predict bulk density, particle

density, porosity and specific volume versus material moisture content ( Krokida et al.

1997, Zogzas et al. 1994). The proposed model is summarised in Table 2. It is a

simple model, generalized for all the materials.

This model involves four parameters with physical meaning: the density of

enclosed water

ρ

w

, the dry solids density

ρ

s

, the dry solids bulk density ρ

b0

and the

shrinkage coefficient

β

′

. Equation (1) is used for the determination of true density (

ρ

p

)

as function of moisture content (X), considering that particle density ranges between

the dry solid density (

ρ

s

) and the density of the water (

ρ

w

). It corresponds to a two-

phase serial mixing model. Similarly, in equation (2) bulk density ranges between the

bulk density of dry solids (

ρ

b0

) and the enclosed water density (

ρ

w

). Again, equation

(2) can be considered as a two-phase structural model. The total porosity is a function

of apparent density and particle density, equation (3). The definition of specific

volume involves three parameters: the bulk density of dry solids (

ρ

b0

), the enclosed

water density (

ρ

w

) and the shrinkage coefficient

β′

, equation (4).

The effect of factors such as material, drying method and drying conditions on

the examined structural properties is taken into account through their effect on the

four parameters incorporated in the structural model proposed (

ρ

s

,

ρ

w

,

β

′

,

ρ

b0

).

Five drying methods were examined: conventional (70

o

C, 15% RH), vacuum

(70

o

C, 30mbar), osmotic pre-treatment, microwave-conventional and freeze drying

.

The four parameters were estimated for each drying method during dehydration and

rehydration procedures and the results are presented in Table 2 for apple.

The effect of pressure on structural properties during vacuum drying, is expressed

through its effect on

ρ

b0

, using an exponential relation, while all other parameters

were not found to be affected by pressure changes. The estimated parameters are

presented in Table 2 again for apple.

The effect of temperature on structural properties during freeze drying, is

expressed through its effect on

ρ

b0

, using an exponential relation, while all other

16

parameters were not found to be affected by sublimation temperature during drying.

The estimated parameters are presented in Table 2, again for apple.

TABLE 2.

Mathematical Model

1. Properties

ρ

p

True density

(kg/m

3

)

ρ

b

Apparent density

(kg/m

3

)

ε

Porosity

(-)

υ

Specific volume

(m

3

/kg db)

2. Factors

Χ

Material moisture content

(kg/kg db)

3. Properties Equations

ρ

p

= (1+X)/(1/

ρ

s

+X/

ρ

w

)

(1)

ρ

b

= (1+X)/(1/

ρ

b0

+

β′⋅

X/

ρ

w

) (2)

ε

= 1 -

ρ

b

/

ρ

p

(3)

υ

= 1/

ρ

bo

+ β

′⋅

X /

ρ

w

(4)

4. Parameters

ρ

w

Enclosed water density

(kg/m

3

)

ρ

s

Dry solids density

(kg/m

3

)

ρ

b0

Dry solids bulk density

(kg/m

3

)

β′

volume-shrinkage

coefficient (-)

5. Factors affecting the parameters

•

Material

•

Drying method

Conventional (70

o

C, 15% RH)

Vacuum (70

o

C, 30mbar)

Osmotic pre-treatment

Microwave-conventional

Freeze

Application material: Apple

Material/Method

ρρρρ

s

ρρρρ

w

ββββ

΄

ρρρρ

bo

Convective

0,99

0,56

Vacuum

0,96

0,39

Microwave

1,01

0,56

Freeze

0,34

0,12

D

ryin

g

Osmotic

1,10

0,73

Convective

1,30

0,56

Vacuum

1,31

0,39

Microwave

1,30

0,56

Freeze

0,81

0,12

R

ehy

dra

t.

Osmotic

1,67

1,02

1,22

0,73

•

Drying conditions

- Effect of pressure during vacuum drying

ρ

b0

=

0.55

P

0.10

- Effect of temperature during freeze drying

ρ

b0

= 1.1

×

10

-6

exp(0.048 T)

17

3. OPTICAL PROPERTIES (Color)

3.1 Definition

Color is the sensation experienced by an individual when energy in the form of

radiation within the visible spectrum falls upon the retina of the eye. That color is a

sensation dependent upon what a person sees can not be overemphasized. Also there

are several factors, which influence the radiation and, subsequently, the exact color, or

sensation, which the individual perceives. These factors include:

1. The spectral energy distribution of the light

2. The conditions under which the color is being viewed

3. The spectral characteristics of the object, with respect to absorption, reflection

and transmission

4. The sensitivity of the eye

Thus, before measuring the color of any object, it is necessary to understand the

physical, physiological and psychological aspects of the stimulation, which ultimately

result in the visual perception of the color of an object.

For the determination of color solids the CIE system (International Commission

on Illumination) has been developed. The CIE has adopted methods for the

measurement and specification of color which include:

1. The use of standard light sources as prescribed by CIE definition

2. Exact conditions for the observation or measurement of sample color

3. The use of appropriate mathematical units in which to express the color of an

object

4. Definition of “standard observer” curves or tables relating objective

measurement to visual response, and thus, measuring what the eye sees.

The color of the material changes during dehydration not only due to evaporation

of the surface water but also due to certain reactions, such as enzymatic browning,

non-enzymatic browning and caramelization reactions (Kudra and Strumillo, 1998).

These reactions may be undesirable for many products, thus the regulation of color

during drying is the subject of various procedures, such as temperature deviation of

specified ranges, intermittent drying, use of color protective agents, (e.g. sulfur

dioxide) etc.

3.2 Experimental Measurement

There are certain methodologies for analyzing the color. The types of

colorimeters that have been employed widely in food applications in America, to date,

are the Hunterlab instruments, the Gardner series, the Color-Eye, the Colormaster and

the Tintometer.

The most common color measurement units are the RGB (Red, Green, Blue),

Lab (Lightness, Redness-greenness, Yellowness-blueness) and XYZ scales that

18

analyze the color into these parameters, so that each composite color can be easily

quantified by a set of three numbers.

Conversion of data from one type of instrument to another is usually via the CIE

XYZ system, and equations are provided with instructions from each manufacturer.

Clydesdale and Podlesny (1968) published a computer program for these

interconversions. The Agtron has also been used widely in food applications, but there

are no satisfactory methods to convert Agtron data to XYZ.

The measurement of color is done through colorimetric techniques by analysis

of the spectrum of light produced by an instrument and reflected on the product’s

surface. The color may be measured on line and lead to mechanical sorting of the

product, based on color evaluation. Other techniques involved in the browning of

foods make use of spectrophotometers to analyze the extend of browning. The

browning may be a very important qualitative parameter, since apart from the

desirable or undesirable appearance of food; it may also lead to significant nutrient

losses.

3.3 Experimental data

The color of foods is important to their acceptability. In a large-scale consumer

study product quality was related to color (Eagerman, 1978). Instrumental techniques

have been applied to obtain objective color evaluation.

The kinetics of browning has been studied by Bolin & Steele (1987) and Sapers

& Ziolkowski (1987). Bolin & Steele (1987) used low oxygen pressure or sulfur dioxide

processing to avoid the oxidative type of non enzymatic browning which, as they

showed, accounts for 60-70% of the total browning during storage. Sapers & Ziolkowski

(1967) added erythorbic or ascorbic acid to eliminate the enzymatic browning of cut

surfaces of fruits in order to eliminate the use of sulfur dioxide from treatment prior to

drying. Sulfur dioxide is a good color preservative of fresh fruits and vegetables, as it

retards both enzymatic and non-enzymatic browning reactions, but its extensive use in

foods has been questioned, as it might cause some health problems.

The color development has been studied by several researchers for a number of

products. The effect of various drying methods and conditions on color degradation

has been measured. Blanching is often used before drying of most vegetables, in order

to prevent the development of off flavours in subsequent storage. Many studies have

been conducted to determine whether steam or water blanching was the more efficient

when one considers the loss of nutrients as a result blanching (Voirol 1980). Steam

blanching is usually expected to conserve more soluble nutrients than water

blanching, but there is some indication that color of green vegetables is adversely

affected by steam (Odland & Eheart 1975).

Table 3 gives the most important references for color measurements of fruits

and vegetables. The values of color in Lab scale, as well as the method and conditions

are also reported.

19

Table 3

References of color measurements

Material

Drying method

Moisture

content

L a b

References

1. Apple

Air drying, 70

o

C, 10%

Vacuum drying, 30-900mbar

Osmotic dehydration glucose

Microwave drying

Freeze drying

0.1 64.8

50

35

55

76

6.69

7.73

1.12

4.73

0.97

20.2

22.1

16.2

18.7

12.8

Krokida et al. 1998b; 1999a

Heating 56-95

o

C

31

3

9.6

Lozano & Ibarz, 1997

Air drying 70

o

C, aw:0.5-0.7

0.1

50-70

0-10

0-4

Bolin & Steele, 1987

Air drying, 1-21

o

C 0.13-0.26

30-60

8-20

1-8

Sayaverda-Soto & Montgomery,

1988

2. Banana

Air drying, 90

o

C,

RH:25%

0.04-0.06 -10

-2 0.4-1 4-10

Chua et al., 1999

Osmotic deh 50-70

o

C sucrose

3

65

2

15

Waliszewski et al., 1999

Air drying, 70

o

C, 10%

Vacuum drying, 30-900mbar

Osmotic dehydration glucose

Microwave drying

Freeze drying

0.1 10

14

33

50

53

40.9

44.2

2.47

9.57

3.56

18.3

17.4

12.7

17.6

13.7

Krokida et al., 1998c; 1999b

3. Basil

Air drying 35-50

o

C

0.1 27-35

-1.5-5

10-16

Rocha et al., 1993

4. Blueberries

Air drying

Freeze drying

Osmo-convective 35-55

o

C

30

27.8

-2-3.5

1.43

1.95

27-32

-4.05

-3.31

1-3.9

Nsonzi & Ramaswamy, 1998

5. Carrots

Air drying, 70

o

C, 10%

Vacuum drying, 30-900mbar

Microwave drying

Freeze drying

0.1 45

43

76

30

15.7

20.2

19.8

13.8

22.0

20.1

21.7

18.9

Krokida et al., 1998c; 1999b

Water blanched

19-24

Eshtiaghi et al., 1994

Drying in batch tank (82

o

C) 0.1

42-50

-2

8

10-19

Howard et al., 1996

Air drying

33-37

32-24

16-19

Zhao & Chang, 1995

6. Corn

Fluidized bed drying,

150-170

o

C

0.19 40-50

8-10

18-23

Soponronnarit et al., 1999

7. Currant syrups

Drying, 100

o

C

56

50

39

Skrede, 1985

8. Green Alfalfa

Air drying 40-90

o

C

0.1

20-1

Sokhansanj & Patil, 1996

9. Green beams

Water blanching

Steam blanching

Microwave blanching

Convention oven blanching

51.2

51.6

55.2

52.6

-27.7

-29.4

-22.7

-23.6

22.6

21.3

22.2

21.2

Muftugil, 1986

Water blanched

2 36-42

Eshtiaghi et al., 1994

20

10. Guava

Air drying, 90

o

C, RH:25%

0.04-0.06 5-20 -1

1 5-20

Chua et al., 1999

11. Melon

Air drying, 90

o

C

0.9 55-44

10-12

19-22

Simandjuntak et al., 1996

12. Paprika

Natural drying

50

35

15

Guevara & Gonzalez, 1996

13. Pea Puree

Air drying, 110-125

o

C

0.1

23-51

Shin & Bhowmik, 1995

14. Peach pulp

Heating 56-95

o

C

29

8

14.9

Lozano & Ibarz, 1997

15. Pecan kernels

Steam treated 93

o

C

2.5 30-33

9-10

12-13

Senter et al., 1984

16. Plum pulp

Heating 56-95

o

C

25

4

8.8

Lozano & Ibarz, 1997

17. Potato

Air drying, 90

o

C, RH:25%

0.04-0.06

10-30

-0.1

8-18

Chua et al., 1999

Air drying, 70

o

C, 10%

Vacuum drying, 30-900mbar

Microwave drying

Freeze drying

0.1 45

46

40

40

29.9

35.3

35

5.07

16

13.1

15.1

12.8

Krokida et al., 1998c; 1999b

Water blanched

-2-4.5

Eshtiaghi et al., 1994

18. Rice

Extrusion

0.07 47-70

-0.9

4

8-13

Kapanidis & Lee, 1996

19. Rice brown

Air drying

0.06 78.9

0.4 12.3

Martinez-Bustos et al., 1996

20. Soy proteins

Heat treatment 25-55

o

C

0.8 70

-2 0.5

Dybowska & Fujio, 1998

21. Spinach

Freeze drying

Steam blanched

Water blanched

Microwave blanched

0.1 20

23.3

20.9

22.4

-4.2

-5.8

-7.1

-6.4

10.1

12.7

12.9

11.6

Quenzer & Burns, 1981

22. Strawberry suryp

Drying, 100

o

C

70

52

44

Skrede et al., 1992

23. Surimi gels

Air drying

0.7 0.8

78-80 -4 -3

7-4

Park, 1995

24. Tea

Air drying, 40

o

C

0.05 78 10 49

Toit & Joubert, 1998

25. Turmeric

Air drying 35-60

o

C 0.06

60

19

38

McGaw et al., 1998

21

3.4 Factors affecting optical properties

Colour changes, measured by tristimulus reflectance colorimetry, are related to

browning reactions that take place during drying of fruits and vegetables. As a result,

the kinetics of browning reactions defines color changes during drying. Color kinetics

are affected by many factors, the most important of which are analytically examined

at the following paragraphs.

•

drying method: the effect of five drying methods is examined (conventional,

vacuum, microwave, osmotic and freeze drying)

•

drying condition: the effect of some drying parameters that have been

experimentally proved that affect color kinetics is examined.

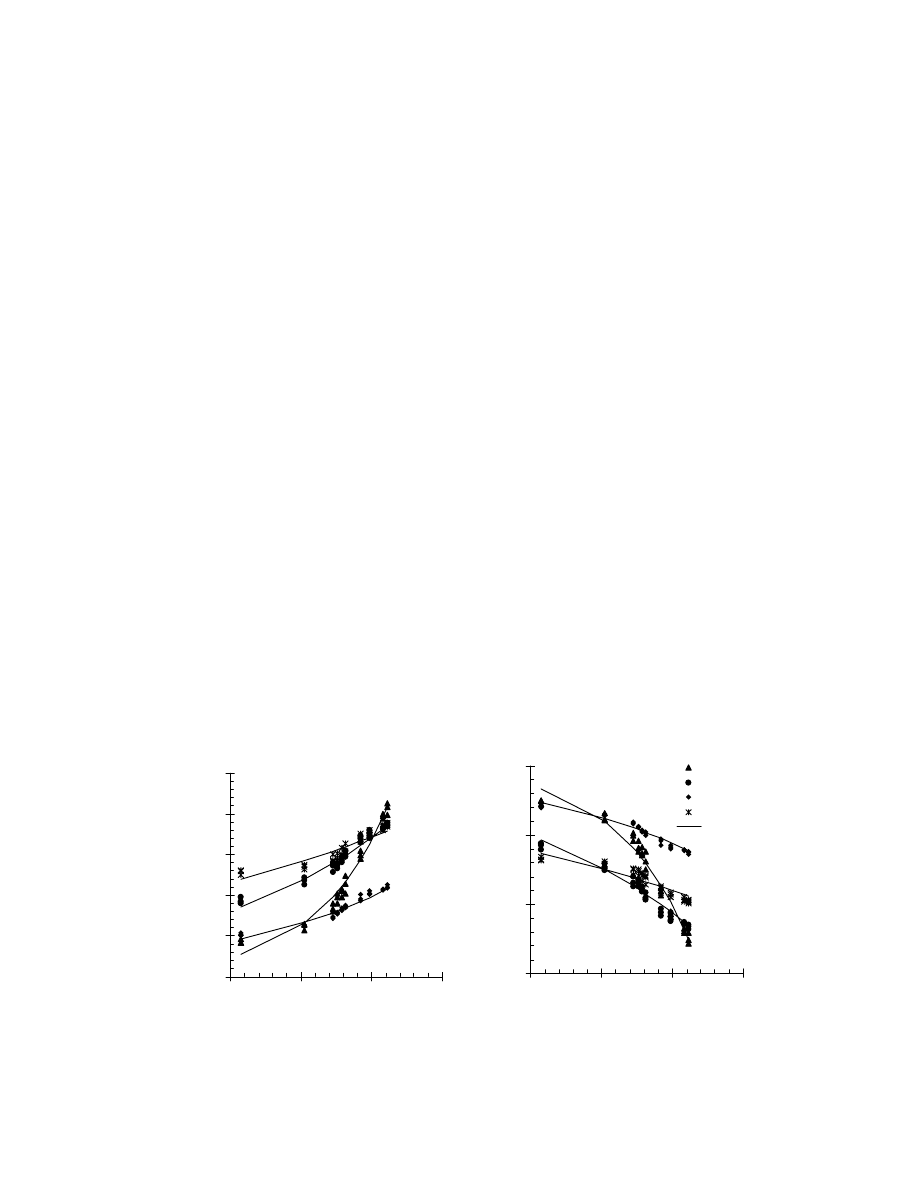

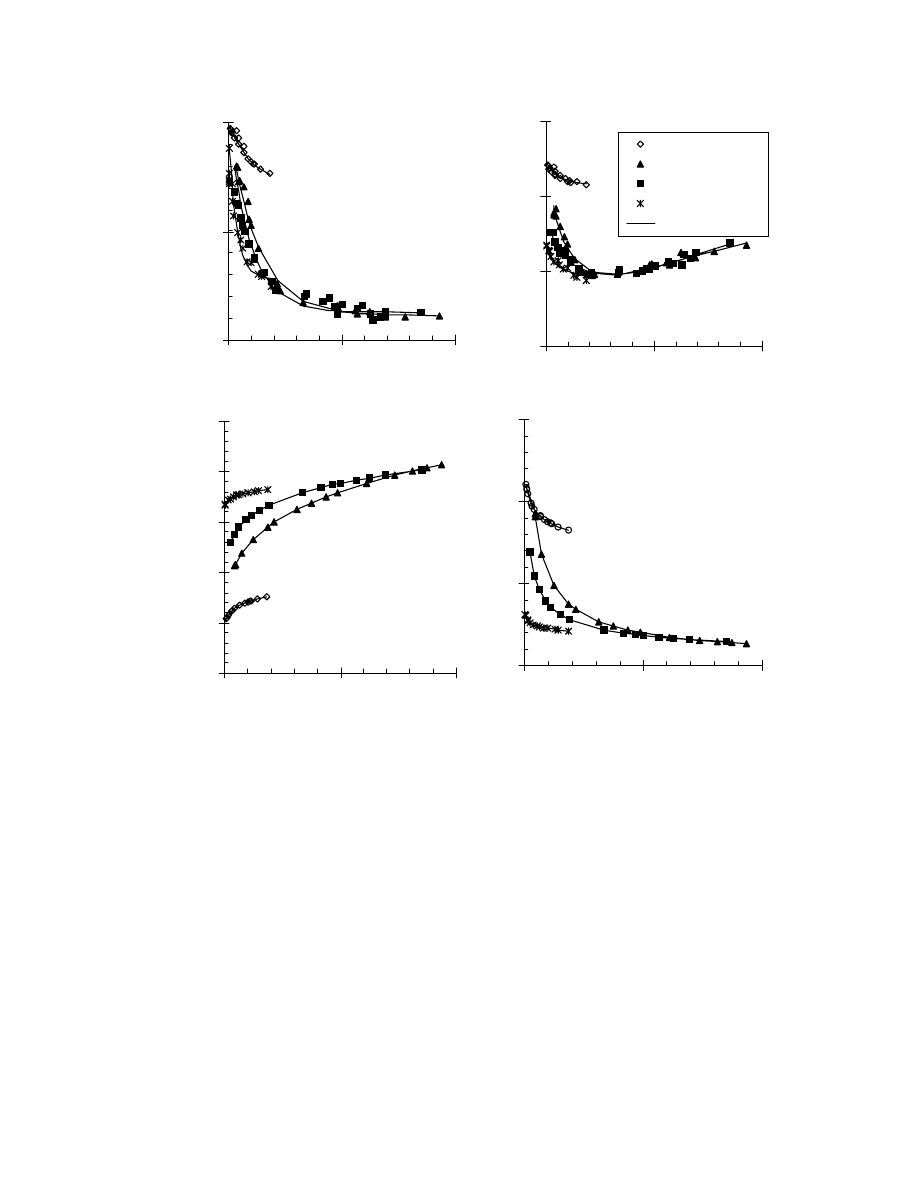

3.4.1 Effect of drying method on optical properties

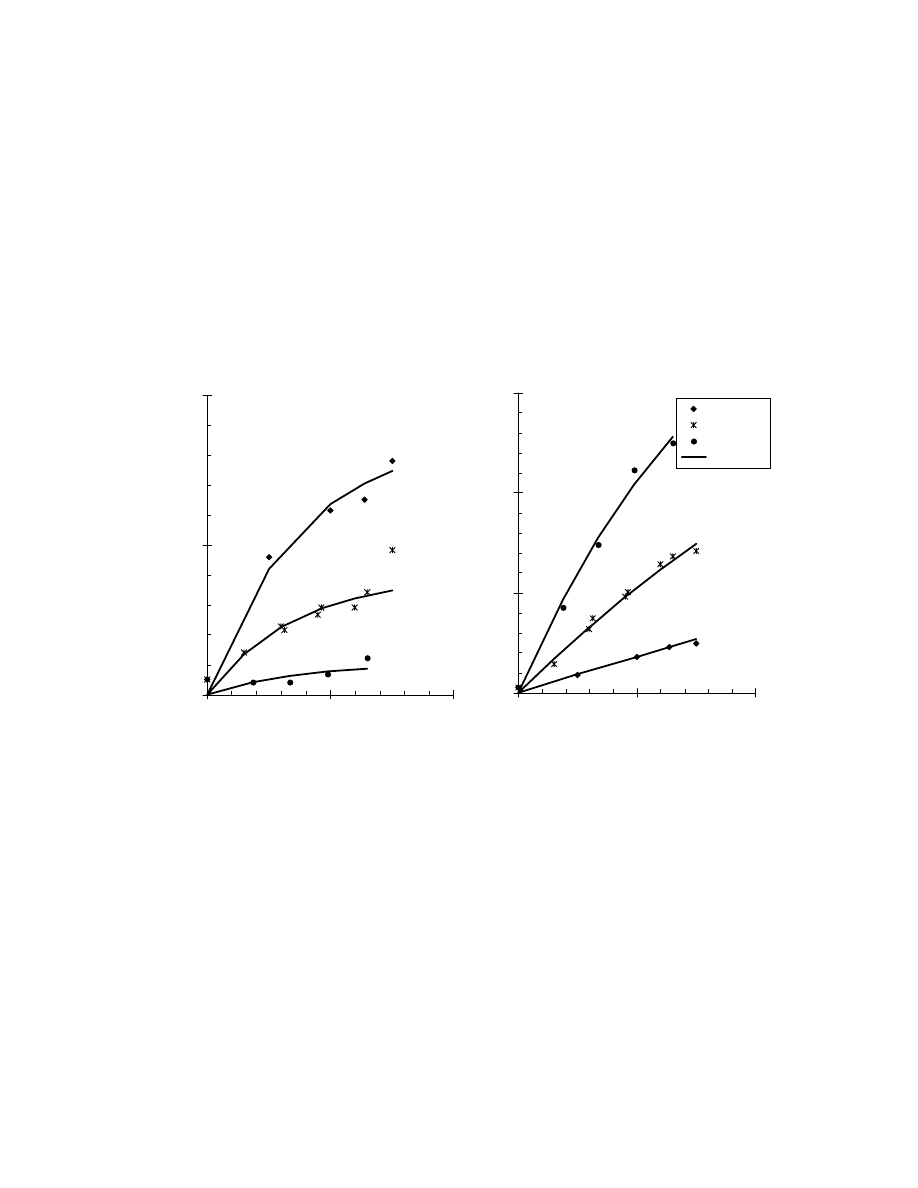

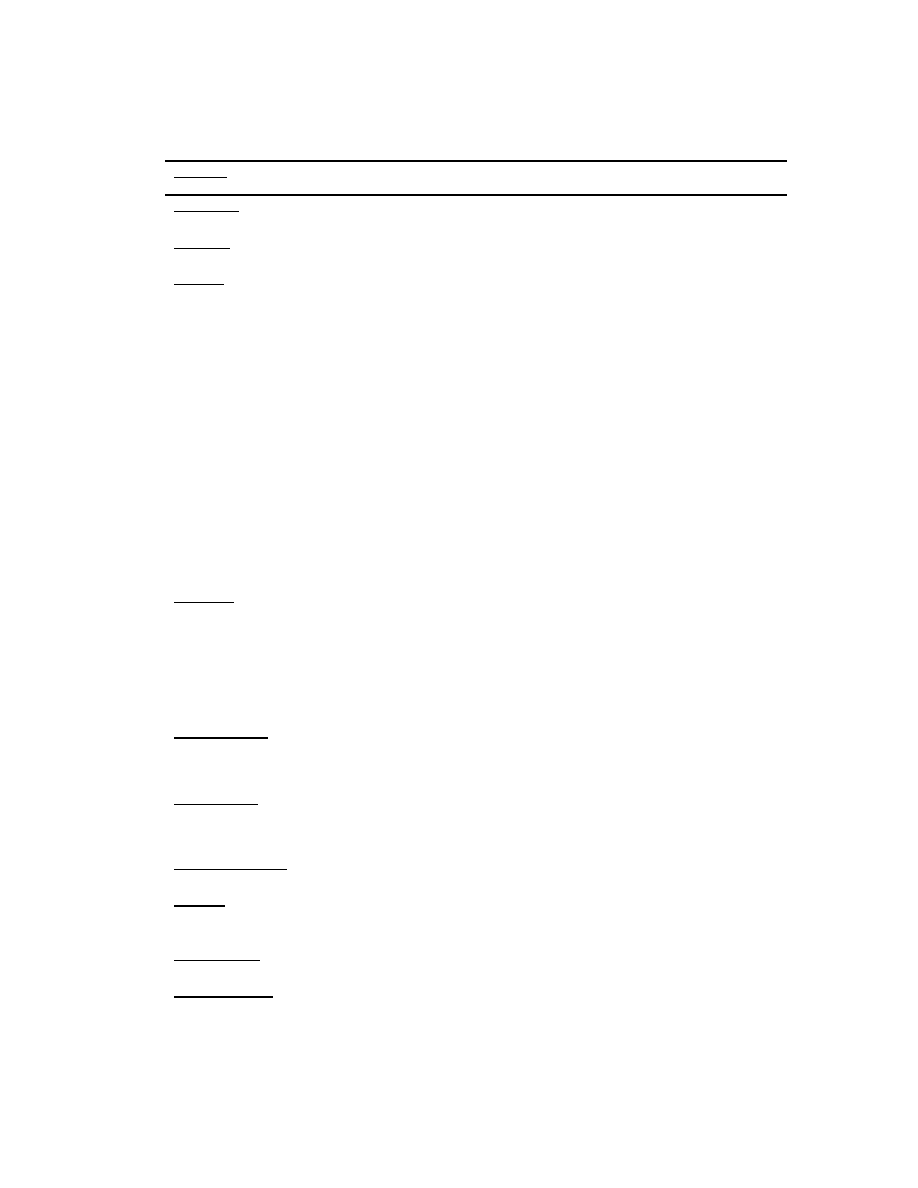

The drying method affects significantly the color of dehydrated products.

The experimental and calculated values of lightness (L), redness (a) and

yellowness (b) of apple during the five drying methods are shown in Fig. 5.

The tendency of lightness parameter (L) during drying is not quite clear, due to

significant experimental error. However, there are some conclusions that result from

these data. As shown in Fig. 5, the lightness parameter (L) decreased significantly during

air, vacuum and microwave drying. Although the lightness parameter of the osmotically

pretreated samples was lower than that of fresh ones, it showed a remarkable stability

over the whole duration of drying (Fig. 5). The lightness of freeze dried materials was

slightly increased during drying.

The browning of fruits and vegetables during drying is due to both enzymatic and

non-enzymatic browning reactions. The infusion of sugars in fruits causes a relative

stability of color parameters (L, a, b), especially in comparison to air dried samples,

which experienced an extensive browning. This is possibly due to the existence of

sugars, which cause the relative inactivation of enzymes, which are responsible for the

enzymatic browning. Freeze drying removes water by sublimation of ice and prevents

enzymatic browning reactions, resulting in relative stability of the color parameters (L, a,

b).

The (a) value of dried materials increased significantly during air drying. The

increase of a-value denotes a more red chroma, which is indicative of the browning

reaction. Microwave and vacuum drying caused a smaller increment of redness (a),

which means that the final products are less brown than air dried ones. Freeze dried

materials showed the smaller increment of redness (a) than all the others. Thus, freeze

drying prevents browning during drying. On the other hand, the osmotically treated

samples keep their a-value relatively constant. The initial value of a-value is larger for

the osmotically pretreated samples. The relative increase, however, of a-value for all

osmotically pretreated samples is very small compared to the significant increase for

untreated samples.

Similar to the behavior of chroma parameter (a) is the increase of value of chroma

parameter b (yellowness). This value increased fast for air dried samples, as air drying at

70

°

C proceeded, followed by a smaller increment of microwave and vacuum dried ones.

Osmotically and freeze dried samples showed the smaller increment of yellowness (b).

The different behavior of dried samples under various drying methods shows that

the drying method affects significantly browning reactions that occur during drying. The

22

osmotically treated and freeze dried samples keep their color intact upon subsequent air

drying. Thus, a method for color preservation is the immersion of fruits in sugar solution.

The color preservation may be seen by the relative constant lightness parameter L

(almost constant or an insignificant decrease) and chroma parameters (a, b), which

experience only a small increase. Thus, osmotic and freeze drying seem to prevent color

deterioration during drying, resulting in products with superior color compared to that of

dried with other methods.

Figure 5. Effect of drying method on color parameters of apple

Apple

-2

2

6

10

0

300

600

Time (min)

Red

n

es

s (

a)

C onv. drying

Vacuum drying

M icrowaves

Freeze drying

O smotic deh.

C alculated

5

10

15

20

0

300

600

Time (min)

Ye

llo

wn

e

ss

(

b

)

0

40

80

0

300

600

Time (min)

L

ig

h

tne

ss

(L

)

23

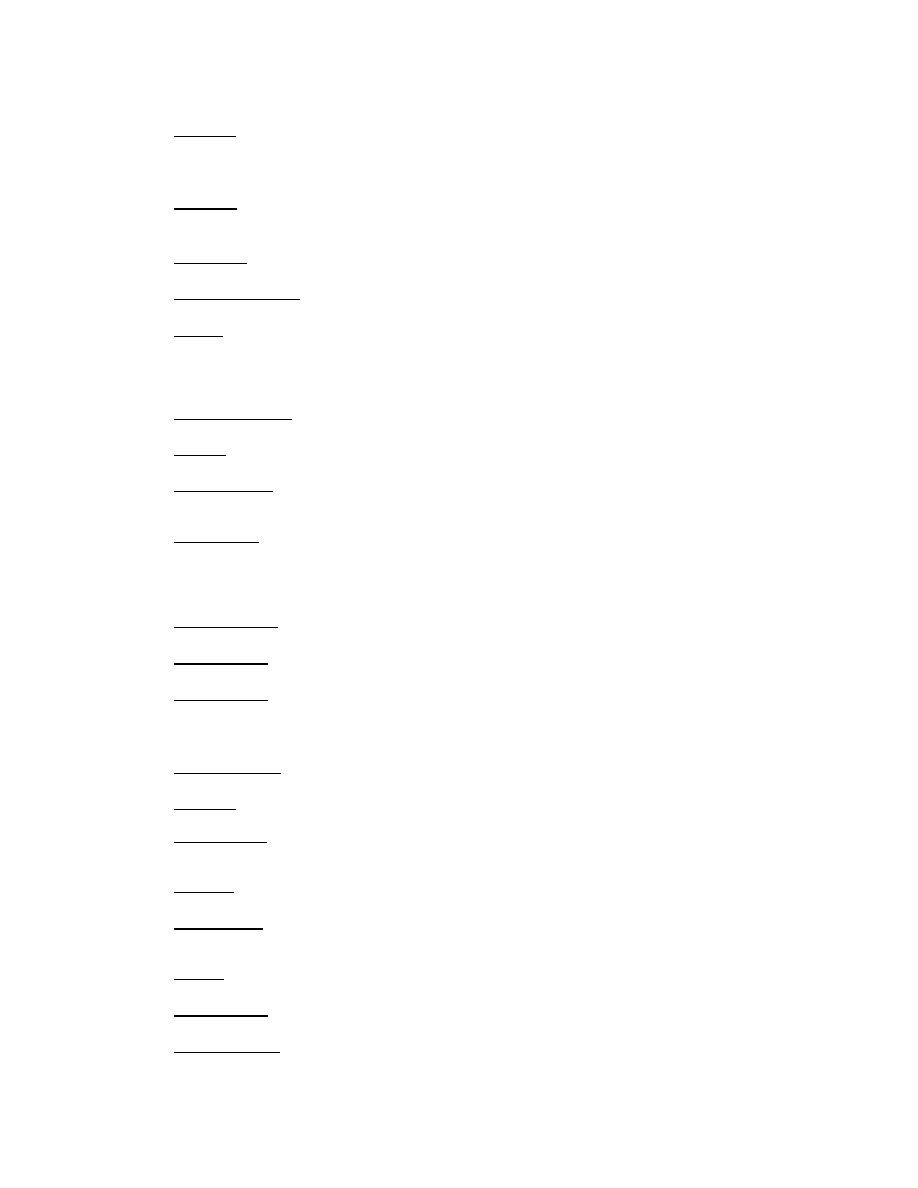

3.4.2 Effect of drying conditions on optical properties

Drying conditions affect significantly the kinetics of color degradation during

drying. Thus, the color of a dried product from rapid and slow drying techniques is

very different. The effects of some drying conditions on optical properties, which

have been examined in the literature, are presented in the next paragraphs. More

specifically it is examined:

•

The effect of temperature and air humidity during conventional drying

•

The effect of temperature during vacuum drying

•

The effect of method of pre-treatment

3.4.2.1 Effect of temperature and humidity during conventional drying

The lightness (L) of dehydrated materials is not affected by temperature and air

relative humidity for all the examined materials and drying methods.

Color difference Δa during conventional drying at various temperatures and air

humidities is presented in Figure 6. It is evident that redness (a) of dehydrated

materials is strongly affected by temperature and air relative humidity. Redness

increases during drying for all the examined materials and all conditions. Redness of

dehydrated products increases as drying temperature increases and relative humidity

decreases for all yellow materials. The effect of temperature on changes of redness

during conventional drying seems to be more intense than the effect of air relative

humidity for all materials. Color changes may be associated to Maillard reactions

(Hodge, 1953).

Color difference Δb during conventional drying at various temperatures and air

relative humidities is presented in Figure 6. It is evident that yellowness (b) of

dehydrated materials is strongly affected by temperature and air relative humidity.

Yellowness (b) is increased during drying for all the examined materials and all

conditions. Yellowness of dehydrated products is increased as drying temperature

decreases and relative humidity increases, for all yellow materials (apple, potato,

banana). The effect of temperature on changes of yellowness (b) seems to be more

intense than the effect of air relative humidity, for all cases.

Figure 6 Effect of drying conditions on color parameters of air dried banana.

B a na na

0

5

1 0

0

3 0 0

6 0 0

T im e (m in)

Δ

b

B a na na

0

5

1 0

0

3 0 0

6 0 0

T im e (m in)

Δ

a

5 0 C - 1 5 %

7 0 C - 1 5 %

7 0 C - 3 0 %

7 0 C - 4 0 %

9 0 C - 1 5 %

C a lc ulated

24

3.5.2.2 Effect of temperature during vacuum drying

Color difference Δa during vacuum drying at various temperatures is presented in

Figure 7. It is evident that redness (a) of dehydrated materials is strongly affected by

temperature. Redness of dehydrated products increases as drying temperature

increases.

Color difference Δb during vacuum drying at various temperatures is also

presented in Figure 7. It is evident that yellowness (b) of dehydrated materials is

strongly affected by temperature. Yellowness of dehydrated products is increased as

drying temperature decreases.

Figure 7. Effect of drying conditions on color parameters of vacuum dried banana.

3.4.2.3 Effect of pre-treatment on optical properties

The effect of pretreatment on color parameters of a fruit is shown in Figure 8.

Water and steam blanched materials as well as salt pretreated ones showed a

remarkable stability of lightness during drying, producing materials of high lightness

values.

Browning of fruits and vegetables during drying is typically related to both

enzymatic and non-enzymatic browning reactions. The infusion of sugars in fruits during

osmotic pretreatment causes a relative stability of color parameters (L, a, b), especially in

comparison to convective dried samples, that experienced extensive browning. This is

possibly due to the existence of sugars causing the relative inactivation of enzymes that

are responsible for the enzymatic browning. Salt, water and steam blanching also

B anana

0

4

8

12

0

200

400

Time (min)

Δ

a

50 C

70 C

90 C

C alculated

B anana

0

4

8

0

200

400

Time (min)

Δ

b

25

prevent enzymatic browning reactions, resulting in relative stability of the color

parameters (L, a, b).

The increase of "a" value denotes a deeper red chroma, which is indicative of the

browning reaction. An exception seems to be the one for carrot where redness is

relatively constant. Microwave pretreatment caused a smaller increase of "a" value,

which means that the final products are less brown than air dried ones. Salt pretreated

materials showed the smaller increase of "a" value than all others. Thus, salt

pretreatment prevents browning during drying. On the other hand, water and steam

blanched materials keep their a-value relatively constant. Steam blanching conserve

more soluble nutrients and keep the redness (a) more constant than that of water

blanching samples. Osmotic pretreatment also keep a-value relatively constant. The

initial value of "a" value is larger for the osmotically pretreated samples. The relative

increase, however, of "a" value for all osmotically pretreated samples is small indeed

compared to the significant increase for untreated samples.

Similar to the behavior of "a" value is the increase of value of chroma parameter

b value (yellowness). This value increased fast for air dried samples, as air drying at

70

°

C proceeded, followed by a smaller in of microwave dried ones. Osmotically and

water, steam, and finally salt - pretreated samples showed the smaller increment of

yellowness (b).

The different behavior of dried samples, under various types of pretreatment,

shows that the pretreatment procedure affects significantly browning reactions occurring

during drying. Osmotically treated and blanched samples keep their color intact upon

subsequent air drying. Thus, a method for color preservation is the immersion of fruits in

sugar solution or the blanching before drying. The color preservation may be seen by the

relative constant lightness parameter L (almost constant or an insignificant decrease) and

chroma parameters (a, b), experiencing only a small increase. Thus, osmotic, salt, water

and steam pretreatment seem to prevent color deterioration during drying, resulting in

products with superior color, compared to that of dried with no pretreatment.

Figure 8 Effect of pretreatment on color parameters of banana.

B a na na

- 2

2

6

1 0

0

3 0 0

6 0 0

T im e (m in)

R

e

dne

ss

(a

B a na na

0

6

1 2

1 8

0

3 0 0

6 0 0

T im e (m in)

Y

e

llo

w

n

e

ss

(

b

C o nv. d rying

W ate r b la nching

S te a m b la nching

S a lt b la nc hing

M ic ro w a ve s

O smo tic d eh.

C alc ula te d

26

2.5 Mathematical modeling

Color of dehydrated products is correlated with the drying time, considering that

color deterioration is caused by surface enzymatic reactions and is not related to the

material moisture content. In order to determine the rate of color changes during

drying, kinetics of the Hunter parameters, redness (a), yellowness (b) and lightness

(L) were investigated. It is assumed that each parameter follows first order kinetics.

The mathematical model is presented in Table 4.

Table 4

Color mathematical model

1. Color parameters

Lightness (L)

Red-Green (a)

Yellow-blue

(b)

2.Color kinetics.

t)

exp(-k

=

C

C

C

-

C

c

e

o

e

−

3. Parameters

C

o

initial

value

C

e

equilibrium

value

k

c

rate

constant

(min

-1

)

4. Factors affecting the parameters

•

Material

•

Drying method

Conventional (70

o

C, 15% RH)

Vacuum (70

o

C, 30mbar)

Osmotic pre-treatment

Microwave-conventional

Freeze

•

Drying conditions

- temperature (

o

C), air humidity (%) during conventional drying

H

T

n

n

eo

e

(H/30)

(T/70)

C

=

C

H

T

m

m

co

c

(H/30)

(T/70)

k

=

k

- temperature (

o

C) during vacuum drying

T

n

eo

e

(T/70)

C

=

C

T

m

co

c

(T/70)

k

=

k

•

Method of pre-treatment

- Water blanching

- Steam blanching

- Salt blanching

- Microwaves

- Osmotic dehydration

27

4. TEXTURAL PROPERTIES (Compression analysis)

4.1 Definition

Texture is one of the most important parameters connected to product quality.

Textural properties are usually related to mechanical tests, which examine the

viscoelastic behavior of the material.

Mechanical properties may be defined as those having to do with the behavior of

the material under applied forces. Following this broad definition, such properties as

stress - strain behavior of a material under static and dynamic loading as well as flow

characteristics of a material can be classified as mechanical properties.

The viscoelasticity is strongly related to complex quality characteristics

perceived by people as mouth feeling. Measurement techniques include the small

amplitude oscillatory compression tests, stress relaxation tests, creep tests and other

dynamic mechanical analysis tests.

A compression test is one of the most common techniques for the estimation of the

texture. The simplest approach is to measure the maximum applied force or stress at

fracture of the material. The quantification of difficult terms such as hardness and

chewiness, has been made by a methodology called Texture Profile Analysis.

The compression tests are performed applying constant deformation rate and

recording force and deformation. Stress-strain compression curves are constructed.

The compression test is usually continued until the fracture of specimens.

Textural behaviour is related to the structure of foods (Ramana & Taylor, 1994).

Textural characteristics depend on chemical and biophysical characteristics of the

products (Moshenin, 1986; Bourne, 1992; Thiagu et al., 1993). The rheological

behaviour of dehydrated products has been studied through both compression and

relaxation stresses (Bagley, 1987; Mohan Rao, 1984; Katz & Labuza, 1981). Both

tests examine the viscoelastic nature of the dehydrated materials, involving

parameters of elasticity such as the elastic modulus (E). Compression parameters,

such as maximum stress and corresponding strain, are usually investigated during

various drying methods by various researchers.

The references that are related to the textural properties of dehydrated fruits

and vegetables are presented in Table 6. The corresponding drying method and

textural parameters that each one measures is also mentioned.

28

Table 6.

References of textural properties

Material

Conditions

Textural Parameters

References

1. Agar gel

Fresh Stress

(kg/cm

2

):0.26-2.7 Peleg

1979

2. Alfalfa

Natural drying

Maximum stress (kPa): 1-7

Watts & Bilanski 1991

3. Apple

Fresh Stress

(kg/cm

2

): 0.8-2.2

Peleg 1979

Fresh

Failure force (N): 8

Peleg & Calzada 1976

Fresh

Fracturability (N): 30

Bourne & Comstock 1981

Air drying, 50

o

C

Maximum stress (kPa): 418-537

Al-Mashat & Zuritz 1993

Irradiation

Rupture force (N):230

Cathalin & McNulty 1996

Fresh

Failure stress (kPa): 360-480

Failure strain (%): 8-14

Failure energy (kPa): 17-31

Abbott & Lu 1996

Heat treated (40

o

C)

Firmness (N): 55

Strength (kPa):173

Brittleness:0.18

Stifness (kPa):1299

Lurie & Nussinovitch 1996

Fresh

Elastic modulus (MPa): 6.2-10

Intex of firmness (Hz

2

-g): 1.7-2.2 10

8

Internal fricton: 0.034-0.160

Absolute modulus (MPa): 6.7-12.6

Storage modulus (MPa): 11-16

Finney (1971; 1970)

Abbott et al. 1968

Morrow et al. 1971

Hamann & Diehl 1978

4. Banana

Air drying

Puncture force (N):0.3

Shear force (N): 1-0.3

Rupture force (N):1

Firmness (kN m-1):0.2-1

Elastic Modulus: 0.1

Ramaswamy & Tung 1989

Fresh

Stress at failure(kPa): 17

Kaletunc et al. 1991

Fresh

Elastic modulus (MPa): 0.85-2.72

Finney et al. 1967

5. Black pepper

Air drying

Failure force (N): 38-70

Failure strain (%): 16-29

Failure energy (J): 0.014-0.022

Murthy & Battacharya 1998

6. Blueberries

Osmoconv. drying

Freeze drying

Air drying

Hardness (N/mm

2

): 0.0034-0.0156

0.0013

0.0065

Nsonzi & Ramaswamy 1998

7. Bologna sausage

Fresh Stress

(kg/cm

2

): 1.9-4.6

Peleg 1979

8. Bread

Fresh

True strain: 0.94

Calzada & Peleg 1978

Fresh Stress

(kg/cm

2

): 0.3

Peleg 1979

9. Cake butter

Fresh

Shear stress (Dyne cm

-2

): ¼*10

3

Bourne

1992

10. Canola seeds

Air drying (25-55

o

C)

Total deformation (mm): 0.25-0.45

Modulus of elasticity (kPa): 5-12

Cenkowski et al. 1992

29

11. Carrot

Fresh

Fracturability (N): 200

Bourne & Comstock 1981

Irradiation

Rupture force (N): 140-180

Cathalin & McNulty 1996

Freeze drying

Maximum force (N): 4.6

Greaves et al. 1982

12. Cheese

Fresh

Stress at failure(kPa): 43

Kaletunc et al. 1991

Fresh

True strain: 0.40

Calzada & Peleg 1978

13. Cherries

Fresh

Maximum force (N): 6

Alonso et al. 1994

14. Chocolate spread

Fresh

Shear stress (Dyne cm

-2

): 1/3*10

3

Bourne

1992

15. Clay

Air drying

Maximum tensile stress (kPa): 600

Maximum comp. stress (kPa): 300

Itaya et al. 1999

Spray drying

Maximum tensile stress (kPa): 700

Maximum compres stress (kPa): 300

Gong & Mujumdar 1999

16. Condensed milk

Fresh

Shear stress (Dyne cm

-2

): 10

1

-10

4

Bourne

1992

17. Corn

Fresh

Absolute modulus (MPa): 213-675

Wen & Moshenin 1970

18. Corn kernels

Air drying (25-100

o

C)

Maximum stress (MPa):2-3

Relaxation modulus (MPa): 50-100

Waananen & Okos 1992

19. Corn meal

Extrusion

Fracture stress (kPa): 5.0-6.8

Barrett et al. 1994

Extrusion

Moisture cont: 3-31%

Compr.strength (N/mm2):5.2-15.8

Stiffness (N/mm

2

):15-257

Hakel et al. 1989

20. Cream cheese

Fresh

Fracturability (N): 0.5

Bourne & Comstock 1981

21. Cumin Seed

Air drying

Rupture force (N): 14.7

Singh & Goswami 1998

22. Frankfurter

Fresh

Stress at failure(kPa): 70

Kaletunc et al. 1991

Fresh

Fracturability (N): 10

Bourne & Comstock 1981

Fresh

Absolute modulus (MPa): 1.4-2.3

Webb et al. 1975

23. Glucose syrup

Fresh

Shear stress (Dyn cm-2):0.5*10

3

-10

5

Bourne

1992

24. Grains

Microwave drying

Max compr force (N): 60-100 N

Kudra et al. 1994

25. Grape skins

Air drying

Failure stress (MPa): 112-369

Strain energy (N cm): 0.16-0.66

Hankinson et al. 1977

26. Honey

Fresh

Shear stress (Dyne cm

-2

): 10

2

-10

4

Bourne

1992

27. Jelly candy

Fresh

Stress at failure(kPa): 190 Deform

at failure (%):50

Kaletunc et al. 1991

28. Kiwi

Osmotic dehydration

Compress force (kg): 1-10

Torreggiani et al. 1999

29. Lemon card

Fresh

Shear stress (Dyne cm

-2

): 10

2

-10

3

Bourne

1992

30. Marchmallow

Fresh

Stress at failure(kPa): 9

Kaletunc et al. 1991

30

31. Peaches

Fresh Firmness

(Hz

2

-g): 0.39-3.4x10

8

Stiffness coefficient: 0.54-1.6x10

5

Elastic modulus (MPa): 1.95-19.3

Internal friction: 0.090-0.143

Poisson’s ratio: 0.020-0.391

Absolute modulus (MPa): 4-10

Finney & Abbott 1972;

Shackford & Clark 1970;

Clark & Rao 1978

32. Peanut butter

Fresh

Shear stress (Dyn cm

-2

): 0.5*10

3

Bourne

1992

33. Pear

Fresh Stress

(kg/cm

2

): 2-3.3

Peleg 1979

Fresh

Failure force (N): 7

Peleg & Calzada 1976

Fresh

Stiffness coefficient: 9.0-10.7x106

Elastic modulus (MPa):12-29

Internal friction:0.072-0.099

Shear modulus (MPa): 4.6-5.8

Poissons ratio:0.252-0.354

Amen et al. 1972

Finney 1967

34. Potato

Fresh

Stress at failure(kPa): 970

Deform at failure (%):34

Kaletunc et al. 1991

Fresh

True strain: 0.25

Calzada & Peleg 1978

Fresh Stress

(kg/cm

2

): 1-1.8

Peleg 1979

Fresh

Failure force (N): 40

Peleg & Calzada 1976

Irradiation

Rupture force (N): 20

Cathalin & McNulty 1996

Fresh

Absolute modulus (MPa): 5.9-13

Internal friction: 0.082-0.118

Elastic modulus (MPa): 5.9

Finney & Norris 1967; 1968

35. Raisins

Solar drying,

Stress (MPa) 0.1-0.3

Work (mJ): 4-8

Lewicki & Wolf 1995

Natural drying

Max Force (N): 19-98%

Lewicki & Spiess 1995

Air drying

Relaxation time (sec): 140-935

Karathanos et al. 1994

36. Rice

Fresh

Absolute modulus (MPa): 840-4200

Chattopadhyay et al. 1978

37. Soybean Cotyled

Air drying (25-55

o

C)

Compressive strength (MPa): 5-25

Tensile strength (MPa): 1-8

Liu et al. 1990

38. Squash

Fresh

True strain: 0.26

Calzada & Peleg 1978

39. Tobacco leaves

Solar drying

Elastic modulus (N/mm): 0.5-8.8

Foutz et al. 1993

40. Tomato ketchup

Fresh

Shear stress (Dyne cm

-2

): 10

1

-10

2

Bourne

1992

41. Turnips

Fresh

Absolute modulus (MPa): 7.69

Harmann & Diehl 1978

42. Water

Fresh

Shear stress (Dyne cm

-2

): 10

1

-10

2

Bourne

1992

43. Weat

Fresh, triaxial tests

Maximum stress (Mpa): 90-120

Zhang et al. 1989

Air drying

Microwave drying

Damage index 7

3

Kudra et al. 1994

Microwave drying

Compress σ

max

(Mpa): 22-27

ε (%): 5.5-6.5

Wozniak & al. 1999

44. Yogurt

Fresh

Shear stress (Dyne cm

-2

): 10

2

-10

3

Bourne

1992

31