Chapter 13

Supplement: Revisions and information on later models

Contents

Introduction

1. Specifications

2. Fuel, emission control and exhaust systems. Checking and adjusting throttle switch (turbo

models)

3. Ignition and starting systems

Ignition system — overview

TCI-H ignition system

Ignition coil — checking

Hall control unit — checking

Hall transmitter — checking

EIS control unit — checking

Flywheel sensor (Digital Ignition Timing Control system) — checking

Flywheel sensor (Digital Ignition Timing Control system — removal and

installation

Distributor — removal and installation

Ignition retard — checking

Timing control unit — removal and installation

4. Transmission and transaxle

Shift linkage — adjusting

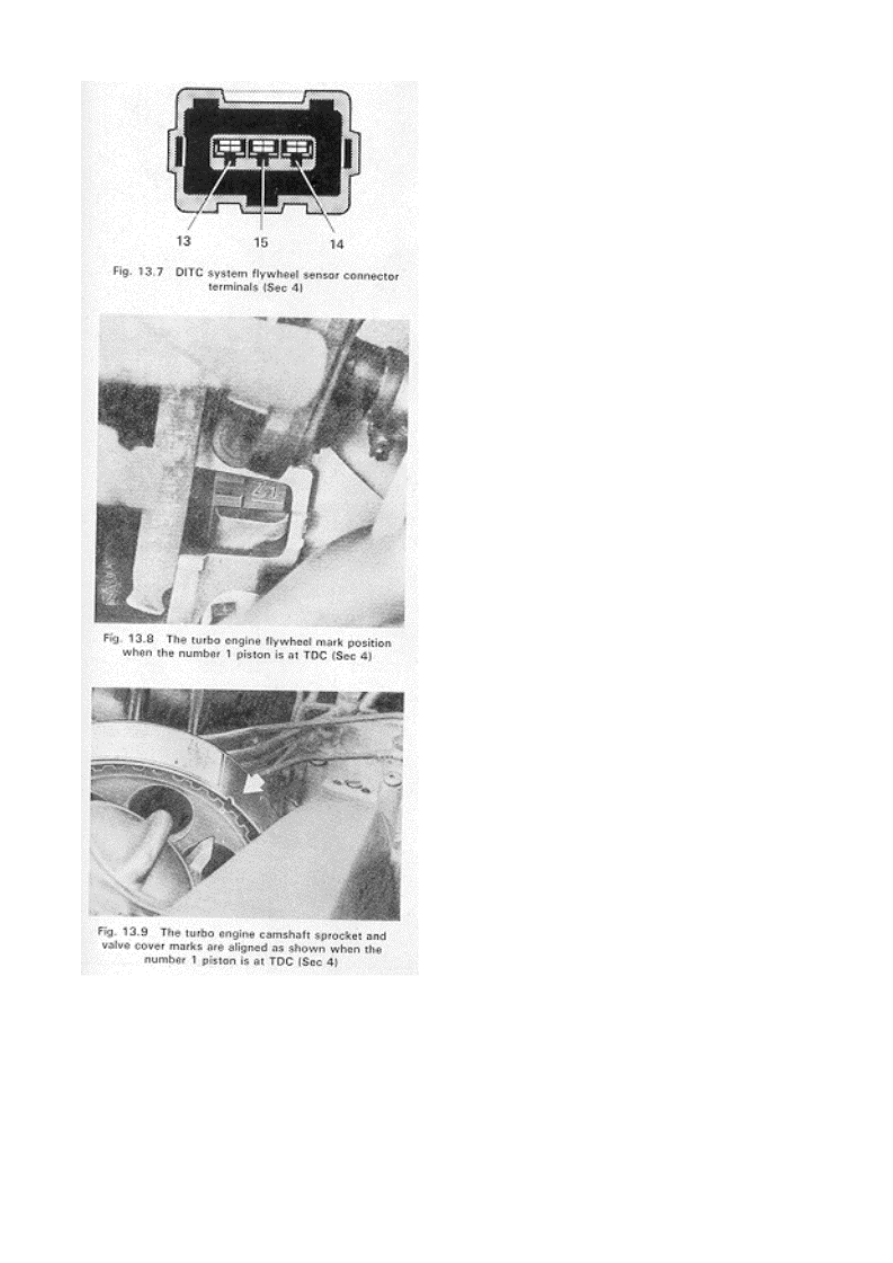

Introduction

This Supplement contains specifications and service procedure changes that apply to Porsche 924

models produced for the 1981 and 1982 model years. Also included is information related to

previous models that was not available at the time of the original publication of this manual. Where

no differences (or very minor differences) exist between the 1981 and 1982 models and previous

models, no information is given. in such instances, the original material included in Chapters 1

through 12 should be used.

1 Specifications

Note: The specifications listed here include only those items which differ from those listed in

Chapters 1 through 12. For information not specifically listed here, refer to the appropriate Chapter.

Fuel. emission control and exhaust systems

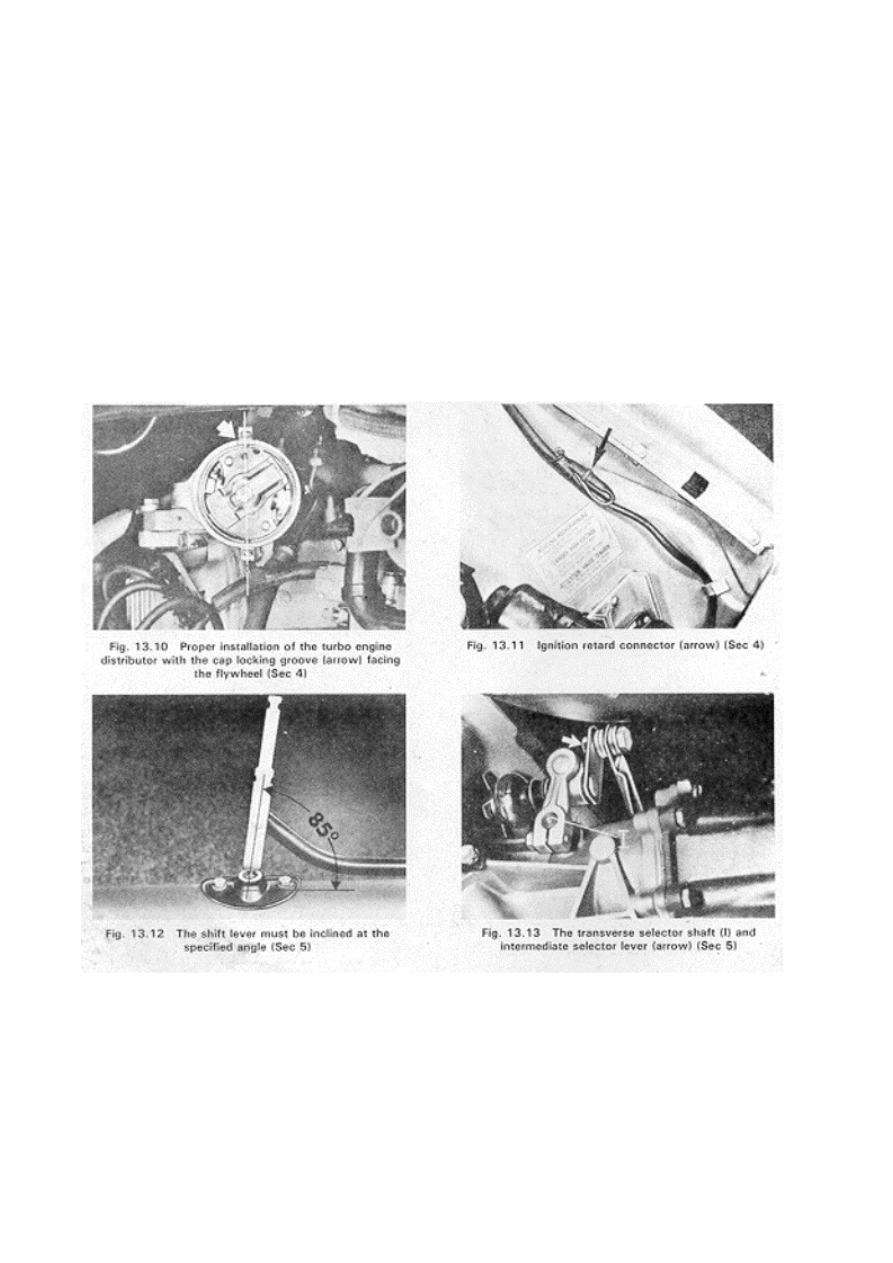

Idling speed

Manual transmission

750 to 800 rpm

Automatic transmission

1000± 50 rpm

Leak test

Minimum pressure after 10 minutes

2.0 bar

Minimum pressure after 20 minutes

1.7 bar

Fuel pump delivery rate

750 cc per 30 seconds

Spark plug type

2 Fuel, emission control and exhaust systems Checking and adjusting throttle switch (turbo

models)

Checking

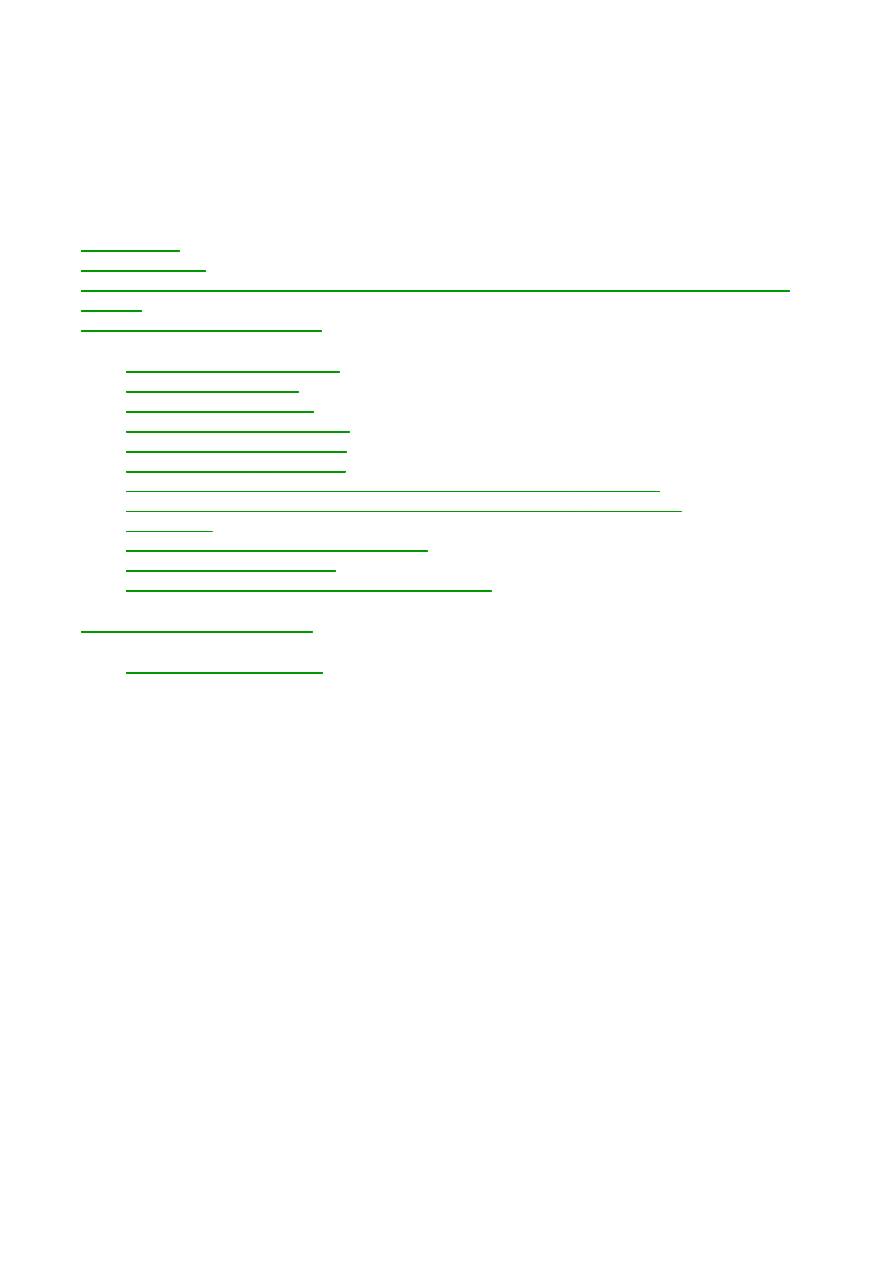

1 Connect a test lamp between the battery and the white/blue wire on the multiple pin plug as shown

in the accompanying illustration.

2 The lamp should light. Move the throttle slowly by hand and make sure the lamp goes out at about

1 °. This can be checked with a 0.2 to 0.5 mm feeler gauge at the stop screw as shown in the

illustration.

Adjusting

3 Remove the throttle housing and loosen the mounting screw on the switch.

4 Insert a 0.3 mm feeler gauge between the stop screw and throttle stop and connect a test lamp

between terminals 2 and 18. 5 Turn the switch until it just opens and the test lamp goes out. Tighten

the screw.

6 Repeat the test and install the throttle housing.

'Warm' control pressure

3.4 to 5.2 bar

'Cold' control pressure

2.2 ± 0.20 bar at 68°F (20°C)

Injection vaive opening pressure

2.5 to 3.6 bar

System pressure (test value)

4.5 to 5.2 bar

Ignition and starting systems

Ignition timing

Non-turbo

0° ± 1 ° at 650 to 800 rpm

Turbo

6° to 10° BTDC at 900 rpm

Non-turbo

Bosch

WR 6 DS

Beru

RS 37

Turbo

Bosch

WR 6 DS

Champion

N 7 GY

Spark plug gap

Non-turbo

0.028 in (0.7 mm)

Turbo

Bosch

0.028 in(0.7 mm)

Champion

0.024 in (0.6 mm)

Ignition coil type

Non-turbo

Bosch 211 905 115B without

resistor wire

Turbo

Bosch 211 905 115B

Non-turbo Electronic Ignition

Stabilization (EISI unit)

Bosch 211 .905 351

Distributor type Non-turbo

Bosch 477 905 203

Turbo

Bosch 931 602 141 00

Non-turbo idle stabilization control unit Bosch 477 906 083

Turbo control unit

Bosch 931 602 073 00

3 Ignition and starting systems

Ignition system — overview

1 These models are equipped with a different type of ignition system. While the distributor and some

components differ from earlier models, many checking and adjustment procedures are unchanged.

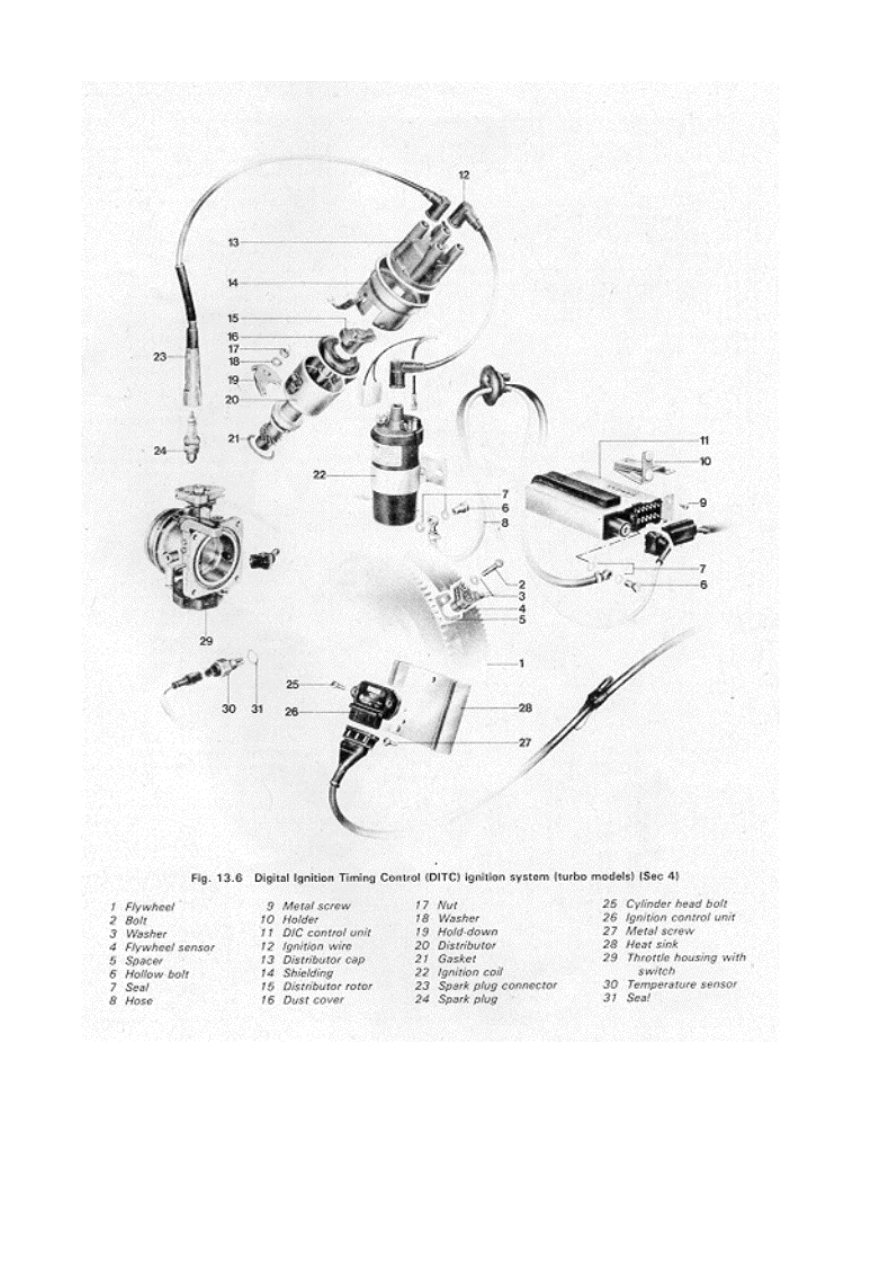

2 Non-turbo engines are equipped with a TCI-H ignition system, while turbo engines are equipped

with a Digital Ignition Timing Control System (DITC)

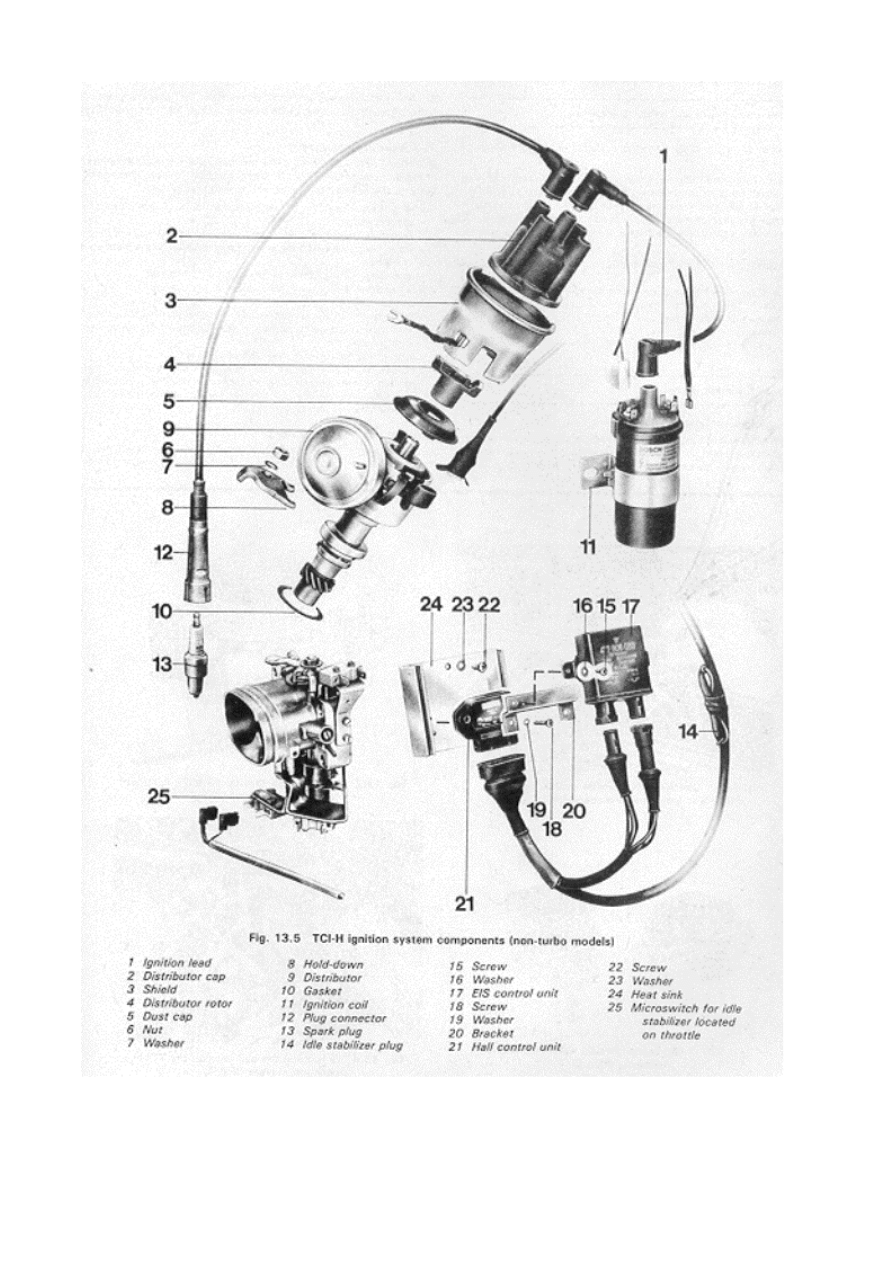

TCI-H ignition system

3 The TCI-H system uses a Hall transmitter and idle stabilizer in place of the induction transmitter

on earlier models. To avoid damage to the system, the following precautions must be observed: The

ignition should be Off when testers or leads are connected or disconnected. The distributor cap and

dust cap spring retainers must not be allow-ed to hang down into the sensor system when the engine

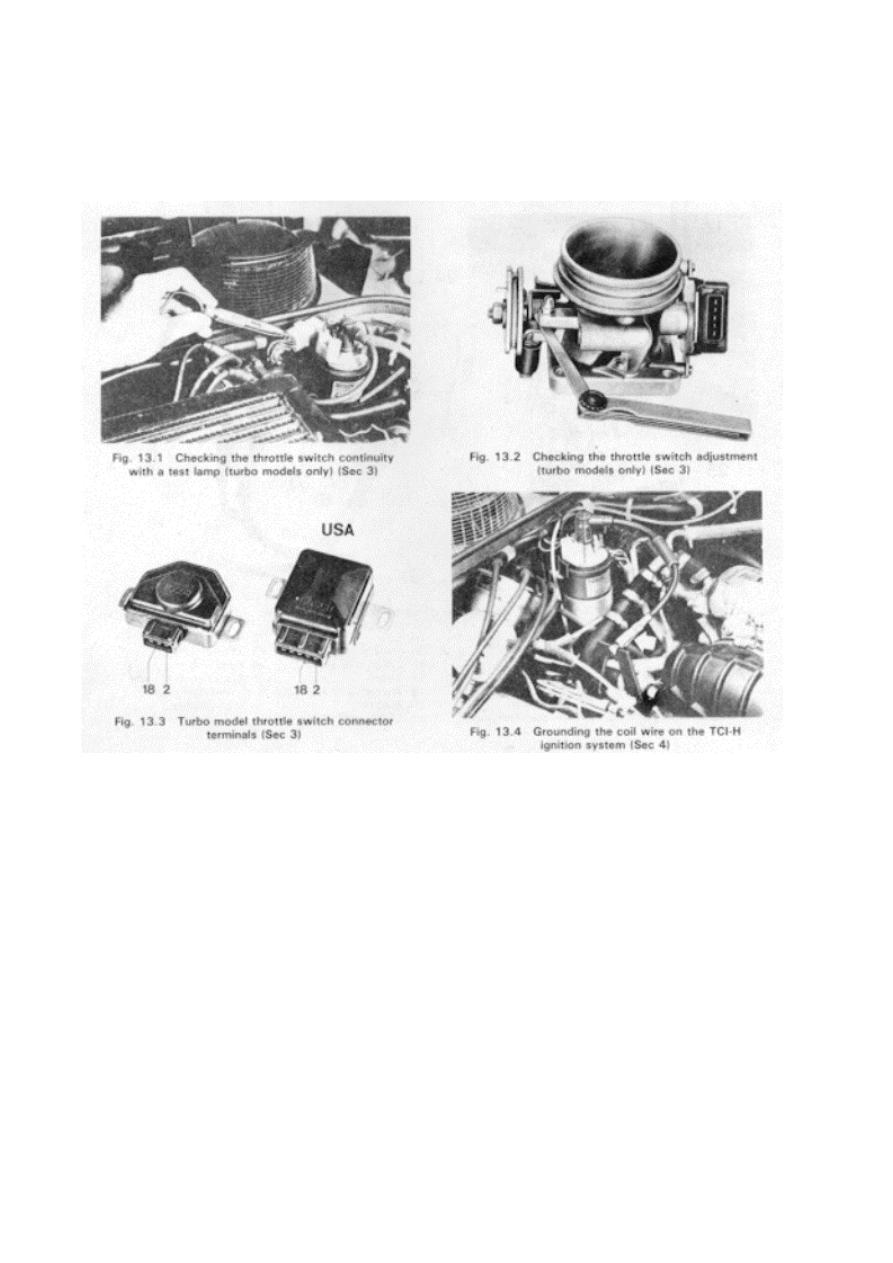

is being cranked. A capacitor should never be connected to the coil. The ignition coil must, be

replaced with a coil of the same specification. Whenever the engine is cranked over without starting

it, connect the coil wire to ground as shown in the illustration or unplug the Hall control unit.

Starting voltage should never exceed 16 volts. Because the EIS control unit Will affect idle speed,

the unit must be disconnected during testing and adjustments. This is accomplished by detaching the

plug located on the left wheel well housing in the engine compartment.

Ignition coil — checking

4 Disconnect the coil wires and remove the cap. Inspect the top of the coil to make sure the plug is

secure and that no sealing compound is leaking. Replace the coil with a new one if the plug is

damaged or missing

5 Measure the resistance between terminal 1 and terminal 15. The resistance should be 0.52 to 0.76

ohms

6 Measure the resistance between terminal 1 and terminal 4. The resistance should be 2.4 to 3.5 K-

ohms.

7 Replace the ignition coil with a new one if the resistance is not within the specifications.

Hall control unit — checking

8 Disconnect the idle stabilizer plug.

9 Ground the ignition coit as described in the precautions in Paragraph 3.

10 Unplug the Hall transmitter at the distributor.

11 Connect a voltmeter to ignition coil terminals 15 and 1 and turn the ignition on. The voltmeter

should indicate between 5 and 6 volts, then after about 1 second, it should drop to 0.

12 With the voltmeter connected as described in Paragraph 11, momen- tarily connect a wire

between the green (center) terminal of the Hall transitter plug and a good ground. The voltage should

rise and then drop to 0.

13 Measure the voltage between the outside terminals of the plug with the ignition on and make sure

the reading is at least 10 volts.

14 Replace the control unit with a new one if it fails any of the tests.

Hall transmitter — Checking

15 With the ignition coil grounded, connect a test lamp between terminals 1 and 15.

16 When the starter is operated, the test lamp should flicker. If it does not, the Hall transmitter is

defective and must be replaced with a new one.

EIS control unit — checking

17 Inspect the control unit and plugs for proper connection, corrosion, bent connectors and damaged

O-rings.

18 With the engine at normal operating temperature, disconnect the idle stabilizer plug.

19 Set the idle speed at approximately 700 rpm and then plug in the idle stabilizer. The engine speed

should rise to around 800 rpm, indicating that the EIS has moved the ignition timing control in the

advance direction [which means it is operating properly).

20 Disconnect the stabilizer plug and adjust the idle speed to between 750 and 800 rpm. Connect the

stabilizer plug.

21 Replace the EIS control unit if it fails the test.

Flywheel sensor (Digital Ignition Timing Control system) — checking

22 Unplug the flywheel sensor plug at the control unit.

23 Use a test lamp to check for continuity between terminals 13 and 15, followed by terminals 14

and 15 of the sensor plug.

24 Replace the sensor with a new one if it fails either continuity test.

Flywheel sensor (Digital Ignition Timing Control system) — removal and instaifation

Removal

25 Remove the ignition mark cover.

26 Remove the flywheel sensor mounting bolt and pull out the sensor and spacers (if equipped).

27 Remove the hollow bolts on the intake air distributor and timing control unit and disconnect the

flywheel sensor plug.

28 Remove the sensor, grommet and hose. Remove the clamp to separate the hose from the

grommet.

Installation

29 Push the hose into the grommet and secure it with a new clamp.

30 Push the lines into the passenger compartment and install the grom met, making sure it fits

tightly. It may be necessary to use body sealant.

31 Install the flywheel sensor and spacers (if equipped), tightening the bolt to 6 ft-lb (8 Nm).

32 Connect the hose to the air distributor and timing control unit, making sure the seals are not

damaged. Route the hose in such a way that there are no sharp bends and tighten the hollow bolt to 7

Ft-lb (9 Nm).

Distributor — removal and instaifation

33 Position the number 1 piston at TDC with the mark on the flywheel aligned with the edge of the

bellhousing and the marks on the cam shaft sprocket and valve cover aligned as shown in the

illustrations.

34 Remove the distributor cap and disconnect the ground wire at the shielding.

35 Remove the hold-down nut and withdraw the distributor from the engine.

36 Install the gasket on the distributor flange.

37 Insert the distributor carefully into the engine so that the cap locking groove is facing the flywheel

and the mounting clips face the vehicle longitudinal axis and install the rotor as shown in the

illustration.

38 Install the distributor cap.

39 Install the hold-down nut and tighten it securely.

Ignition retard — checking

40 Connect a timing tight to the engine. 4T. Start the engine, rev it up to approximately 1500 rpm

and note the ignition liming. Shut the engine off.

42 Unplug the ignition retard connector shown in the accompanying illustration.

43 Start the engine and check that the timing is now retarded by about 7°.

44 If the ignition timing is not retarded the specified amount there is a fault in the wiring or timing

control unit.

Timing control unit — removal and installation Removal

45 Unplug the multiple pin connector on the timing control unit and remove the hollow bolt from the

hose.

46 Remove the bolts on the holder and withdraw the control unit toward the footwell. Installation

47 Push the timing control unit into place and tighten the bolts securely.

48 Carefully plug in the connector and install the hollow bolt. Tighten the bolt to 7 Ft-lb (9 mm).

4 Transmission and transaxle

Shift linkage — adjusting

1 With the transmission in Neutral, the intermediate selector lever can only be installed with one

inclination as it is the only way it will fit on the shaft due to the changed design.

2 Move the base of the selector lever to adjust it to an angle of 85° as shown in the illustration.

3 With the selector lever in Neutral, the transverse selector shaft I shown in the illustration will be

held in the middle (3rd and 4th gear) by spring pressure. When correctly adjusted, the shift lever

should not lean to the side. Adjustment is made at the intermediate selector lever.

Wyszukiwarka

Podobne podstrony:

Frysztacki, konspekt z rozdziałów 13 16

15. Rozdzial 13

Rozdział 13, Dni Mroku 1 - Nocny wędrowiec

16 10 13 Psychologia

Badanie płytą 16 05 13 MC 20 ( rondo 1 w wa)

16 rozdzial 15 EJCDLTJY3F3I2FKL Nieznany (2)

14 rozdzial 13 w2pa42u4da5r3dcm Nieznany (2)

16 rozdzial 15 zpgg3d2etikxyjv3 Nieznany

16(2), Rozdzial drugi

16(3), ROZDZIA˙ SZESNASTY

18. Rozdzial 16, Rozdział XVI

007, p2, ROZDZIAŁ 13 : POD ZNAKIEM BOGÓW

Teoria egzamin 16.09, 13-16, Zadanie 13

Rozdział-13-Motoszybowce, Szkolenie Szybowcowe, Procedury operacyjne

13 rozdzial 13 NSBB2L5SXN4GTHOI Nieznany (2)

rozdzial 13, Zimbardo ksiazka i streszcznie

Lauferowie rozdziały 9 13

więcej podobnych podstron