* Corresponding author. Tel.: 0044 0151 706 5606; fax: 0044 151

706 5803.

Biomaterials 20 (1999) 631 — 637

The corrosion behaviour of Ti—6Al—4V, Ti—6Al—7Nb

and Ti—13Nb—13Zr in protein solutions

M.A. Khan, R.L. Williams*, D.F. Williams

Department of Clinical Engineering, University of Liverpool, Duncan Building, P.O. Box 147, Liverpool L69 3GA, UK

Received 6 March 1996; accepted 13 October 1998

Abstract

Ti alloys are used in orthopaedic applications owing to their appropriate mechanical properties and their excellent corrosion

resistance. The release of titanium and the other alloying elements into the surrounding tissue has been reported due either to passive

corrosion or accelerating processes such as wear. Since the passive layer can be broken down in certain circumstances by wear it is

important to study the ability of these alloys to repassivate in biological environments, in particular in the presence of proteins, and

evaluate how the repassivated surface may vary from the original surface. In this study we investigated the ability of Ti—6Al—4V,

Ti—6Al—7Nb and Ti—13Nb—13Zr to repassivate in phosphate buffered saline (PBS), bovine albumin solutions in PBS and 10% foetal

calf serum in PBS at different pH values and at different albumin concentrations. It was found that an increase in pH had a greater

effect on the corrosion behaviour of Ti—6Al—4V and Ti—6Al—7Nb than on Ti—13Nb—13Zr in PBS and that the addition of protein to

the PBS reduced the influence of pH on the corrosion behaviour of all the alloys. The effect of the corrosion and repassivation was

investigated by measuring changes in the surface hardness of the alloys and it was found that corrosion reduced the hardness of the

surface oxides of all the alloys. In PBS the reduction was smallest for Ti—6Al—4V and largest for Ti—13Nb—13Zr and that corrosion in

protein solutions further reduced the hardness of the surface oxides. This effect was greater for Ti—6Al—4V and Ti—6Al—7Nb than for

Ti—13Nb—13Zr. In conclusion, proteins in the environment appear to interact with the repassivation process at the surface of these

alloys and influence the resulting surface properties.

1999 Elsevier Science Ltd. All rights reserved

Keywords: Mechanical properties; Corrosion

1. Introduction

Ti—6Al—4V alloy has been used extensively for many

years as an implantable material mainly in the applica-

tion of orthopaedic prostheses. It has been shown on

numerous occasions that its corrosion resistance is far

superior to many of the alternatives presently available

such as stainless steel alloys and even better under most

circumstances than alloys based on cobalt-chromium

[1, 2]. Recently, however, much concern has developed

over the issue of biocompatibility with respect to the

dissolution of aluminium and vanadium ions and the

possibility of any toxic effects [3, 4]. Consequently, other

titanium alloys are currently being considered as alterna-

tives to the Ti—6Al—4V alloy. In the present study, two

such alloys (i.e. Ti—6Al—7Nb and Ti—13Nb—13Zr) have

been investigated in terms of their relative corrosion

resistance compared to that of the Ti—6Al—4V alloy.

The Ti—6Al—7Nb was developed using the alloying

element niobium to replace vanadium in the Ti—6Al—4V

alloy, since both vanadium and niobium are beta

amorphous (i.e. have similar phase relations) with body-

centred cubic (b.c.c.) titanium, and thus, can both act as

suitable beta phase stabilizers, suppressing the formation

of the alpha phase which is a close-packed hexagonal

(c.p.h.) structure [5]. Recent studies have also mentioned

the excellent short- and long-term biocompatibility of

niobium [6, 7]. The aluminium continues to fulfil its role

as a useful alpha phase stabilizer, and thus, maintain the

improved mechanical properties over pure titanium.

The other material being considered is Ti—13Nb—13Zr

which once again relies on niobium as a beta phase

stabilizer. The other alloying element, zirconium, is one

that is unique in that it is isomorphous with both the

alpha and beta phases of titanium [5]. A combination

0142-9612/99/$ — see front matter

1999 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 2 - 9 6 1 2 ( 9 8 ) 0 0 2 1 7 - 8

of these two alloying elements has made it possible to

develop a structure that is a ‘near’ beta phase supposedly

possessing a superior corrosion resistance over the

alpha—beta phase alloys mentioned earlier, but one that

still has enough alpha phase present in the final structure

to provide the necessary mechanical strength. It has been

proposed that Ti—13Nb—13Zr alloy is more favourable

for orthopaedic implants than Ti—6Al—4V alloy because

of its superior corrosion resistance and biocompatibility.

Reasons for this superiority have included the fact that

less metal ion release is likely to occur during sponta-

neous passivation of Ti—13Nb—13Zr alloy because the

corrosion products of the minor alloying elements,

niobium and zirconium, are less soluble than those of

aluminium and vanadium. Also, that the passive oxide

layer on the surface of the alloy is more inert consisting of

a dense rutile structure providing greater protection to

the underlying alloy [8, 9].

It is well known that proteins affect the corrosion

behaviour of some metals, and that their presence

can either inhibit or accelerate the corrosion phenomena.

They are known to behave differently with different

metals, since their role in a corrosive environment

is governed by many factors such as the surface chemistry

of the metal, protein adsorption characteristics, inter-

action of protein molecules with other ions present

in the electrolyte solution to produce organic com-

plexes, and the transport of anionic and cationic

charges around and away from the local environment

[10—12].

In this study we have assessed the corrosion resistance

of the alloys using cyclic anodic polarisation techniques

to break down the passive layer and then allow repas-

sivation to occur. The value of the breakdown potential

for Ti alloys is difficult to assess owing to the instability

of the aqueous electrolytes at the high potentials re-

quired. The ability of the surfaces to repassivate in the

environment, as measured by the hysteresis in the cyclic

polarisation curve, is a better measure of the corrosion

behaviour of these material. For these reasons we have

assessed the corrosion resistance of these alloys by re-

cording the difference between the breakdown potential

(E) and the repassivation potential (E). This study

shows that in different environments (i.e. at different pHs

or in the presence of proteins) the ability of the alloys to

repassivate is affected. We have used hardness measure-

ments to evaluate the surface oxide formed during repas-

sivation and to determine that it is different from the

original surface oxide.

2. Materials and methods

The titanium alloys were obtained from different

sources: The Ti—6Al—4V alloy from IMI Titanium Ltd.,

England, the Ti—6Al—7Nb alloy from Sulzer Medical

Technology Ltd., Switzerland and the Ti—13Nb—13Zr

alloy from Smith and Nephew Richards inc., USA.

All materials were received in the annealed condition

in the form of rods between 10 and 15 mm in diameter.

Disc specimens were cut from the rods with a thickness of

approximately 5 mm. A wire lead was attached to the

back of each disc using a small amount of conducting

paste. Each specimen was mounted into a thermosetting

resin mould to form a 30 mm diameter rod. Each speci-

men was polished down to 1200 grit specification and

then polished using 6, 1 and 0.25

lm diamond paste.

A portion of the surface around the margins between the

alloy and the resin was covered with an insulating laquer

leaving a specimen area of 5 mm

.

The electrolytes used included:

E Phosphate-buffered saline (PBS) solution at three pH

levels 5, 7.4 and 9.

E Phosphate-buffered saline (PBS) solution #1 mg/ml

bovine albumin (Sigma, UK) at three pH levels 5, 7.4

and 9.

E Phosphate-buffered saline (PBS) solution#albumin

at concentrations of 0.1, 1 and 10 mg/ml at pH 7.4.

E Phosphate-buffered saline (PBS) solution#10% foe-

tal calf serum at pH 7.4.

The electrolyte cell was maintained at 37°C through-

out the tests using a suitable water bath. All tests were

carried out under aerated conditions.

Cyclic polarisation data were obtained in the form of

potential vs. current density curves between a range of

0—5000 mV using an ‘AUTOSTAT’ computer controlled

potentiostat. The potential was increased at a rate of

200 mV/min, starting with the rest potential (E0). Tripli-

cate measurements were obtained in all cases. The elec-

trolyte cell was made of glass and had a capacity of

200 ml. The specimen acted as a ‘working’ electrode

(anode) and was placed in the cell facing a platinum

‘auxiliary’ electrode (cathode). A saturated calomel elec-

trode was used as the ‘reference’ electrode. The corrosion

resistance of the alloys was evaluated by measuring the

difference between the breakdown and repassivation po-

tentials, E and E, respectively. E was noted to be the

value at which the potential-current density plot was seen

to show a sudden increase in current density. E was

noted as the value of potential at which the current

density returned to the passive current density on the

reverse scan. Generally, smaller differences between these

two values indicated a better corrosion resistance. Fol-

lowing the corrosion tests the surfaces of the specimens

were examined under a microscope for evidence of pits.

Hardness

measurements

were

undertaken

using

a Vickers hardness indentation machine to obtain values

of the macrohardness of the surface of each alloy both

prior to and following corrosion. Measurements were

undertaken on three specimens in all cases to ensure

reproducibility and the average of four or five indents

was calculated for each surface.

632

M.A. Khan et al. / Biomaterials 20 (1999) 631—637

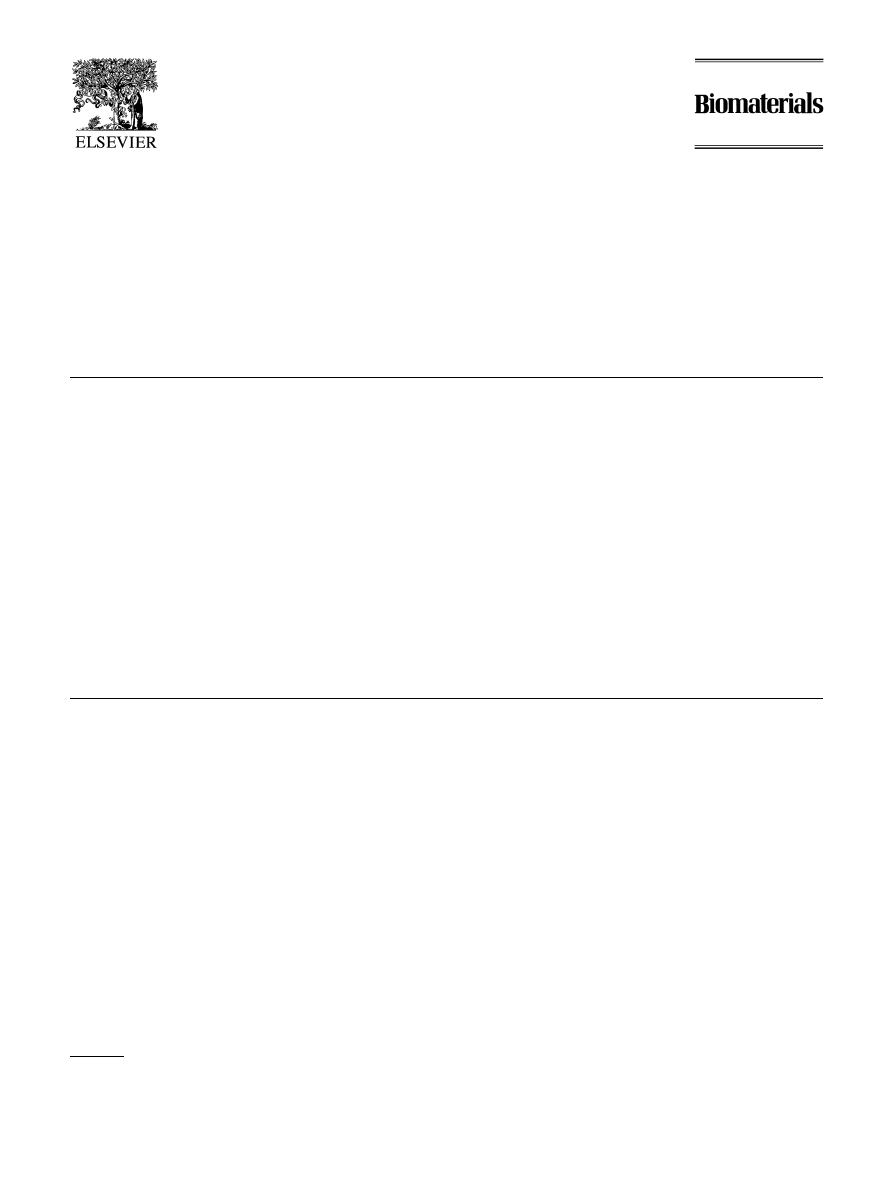

Fig. 1. E—E values for all three Ti alloys in PBS and 1 mg/ml bovine albumin solution at different pH values, presented as the mean and the range of

three measurements. Ti64"Ti—6Al—4V, Ti67"Ti—6Al—7Nb, Ti1313"Ti—13Nb— 13Zr, PBS"phosphate-buffered saline, Alb"bovine albumin,

the value in parenthesis is the pH of the electrolyte.

3. Results

Figures 1 and 2 present the corrosion resistance data

for the three alloys in different environments. From

Fig. 1 the corrosion resistance of the alloys (i.e. E—E

values) at three different pH levels (i.e. 5, 7.4 and 9) can be

evaluated. Generally, it was noticed that as the pH level

increased in PBS, the corrosion resistance of Ti—6Al—4V

and

Ti—6Al—7Nb

decreased,

whereas

that

of

Ti—13Nb—13Zr was seen to increase but only slightly.

When albumin, at a concentration of 1 mg/ml, was added

the effect of pH on the corrosion resistance of Ti—

6Al—4V and Ti—6Al—7Nb was reduced whereas for

Ti—13Nb—13Zr the addition of albumin caused a de-

crease in corrosion resistance as the pH increased,

although again the changes were small.

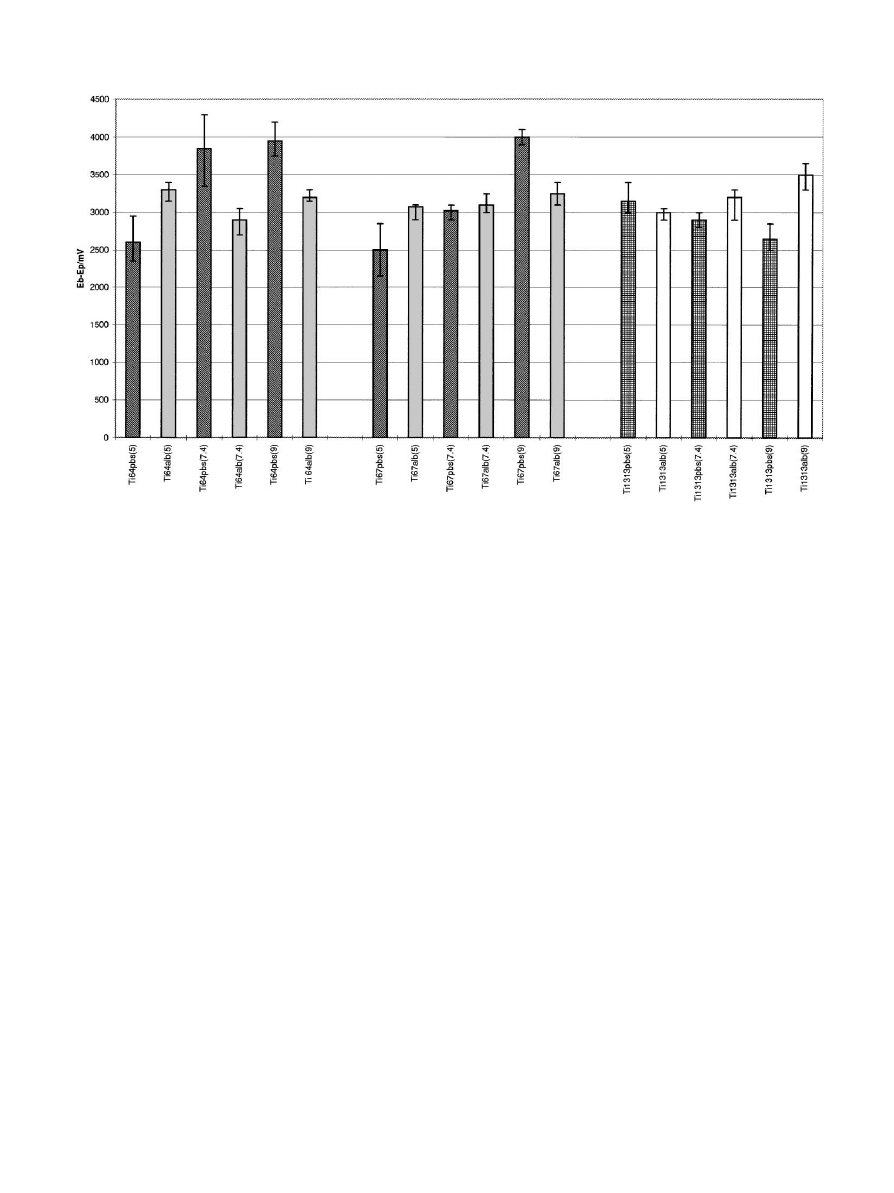

From Fig. 2 the corrosion resistance of the alloys,

in environments containing progressively increasing

concentrations of albumin, can be evaluated. It was ob-

served that by adding albumin (0.1 mg/ml) to PBS, the

corrosion resistance increased for Ti—6Al—4V. For

Ti—6Al—7Nb and Ti—13Nb—13Zr the changes in cor-

rosion resistance were smaller showing a slight increase

for Ti—6Al—7Nb and a slight decrease for Ti—13Nb—

13Zr. As the concentration of albumin increased

the corrosion resistance of Ti—13Nb—13Zr appeared

to remain at the same level, whereas, that for the other

two alloys tended to decrease. The Ti—6Al—4V alloy

was more corrosion resistant in all the albumin solu-

tions than in PBS, whereas the Ti—6Al—7Nb and

Ti—13Nb—13Zr alloys were generally less corrosion

resistant in protein solutions than in PBS. The addition

of foetal calf serum produced a similar effect with each

alloy as had the presence of higher concentrations of

albumin.

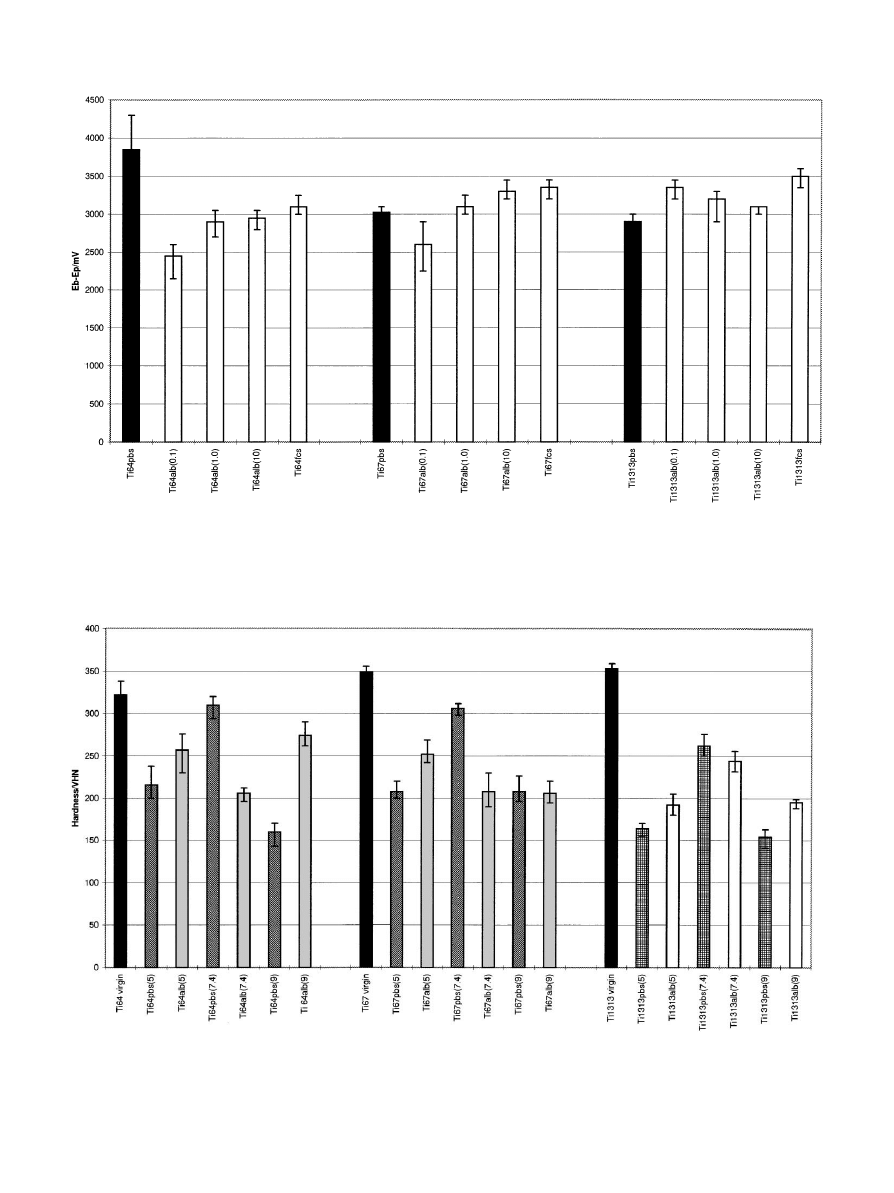

Figure 3 outlines the surface hardness of the three

alloys following corrosion in PBS with and without al-

bumin at varying pH levels and generally demonstrates

that corrosion of all the alloys in all the environments

reduced the surface hardness. For all three alloys the

surface hardness was least affected by corrosion in

PBS at pH 7.4. For Ti—6Al—4V the surface hardness was

only slightly reduced following corrosion in PBS at pH

7.4 but it was significantly reduced following corrosion

in PBS at pH 5 and more so at pH 9. For the other two

alloys the surface hardness was significantly reduced

following corrosion in PBS at pH 7.4 but also reduced

further following corrosion in PBS at both higher and

lower pH.

Following corrosion in albumin at pH 7.4 the surface

hardness of Ti—6Al—4V and Ti—6Al—7Nb was signifi-

cantly less than that following corrosion in PBS at pH

7.4, whereas, that for Ti—13Nb—13Zr was not signifi-

cantly affected by the addition of albumin at pH 7.4. At

M.A. Khan et al. / Biomaterials 20 (1999) 631—637

633

Fig. 2. E—E values for all three Ti alloys in PBS, bovine albumin at different concentrations and 10% foetal calf serum, presented as the mean and the

range of three measurements. Ti64"Ti—6Al—4V, Ti67"Ti— 6Al— 7Nb, Ti1313"Ti—13Nb—13Zr, PBS"phosphate-buffered saline, Alb"bovine

albumin, fcs"10% foetal calf serum and the value in parenthesis is the concentration of albumin in mg/ml.

Fig. 3. Vickers hardness values for all three Ti alloys before corrosion and following corrosion in PBS and 1 mg/ml bovine albumin solution at

different pH values, presented as the mean and standard deviation bars. Ti64"Ti— 6Al—4V, Ti67"Ti—6Al—7Nb, Ti1313"Ti —13Nb—

13Zr, PBS"phosphate-buffered saline, Alb"bovine albumin, the value in parenthesis is the pH of the electrolyte.

634

M.A. Khan et al. / Biomaterials 20 (1999) 631—637

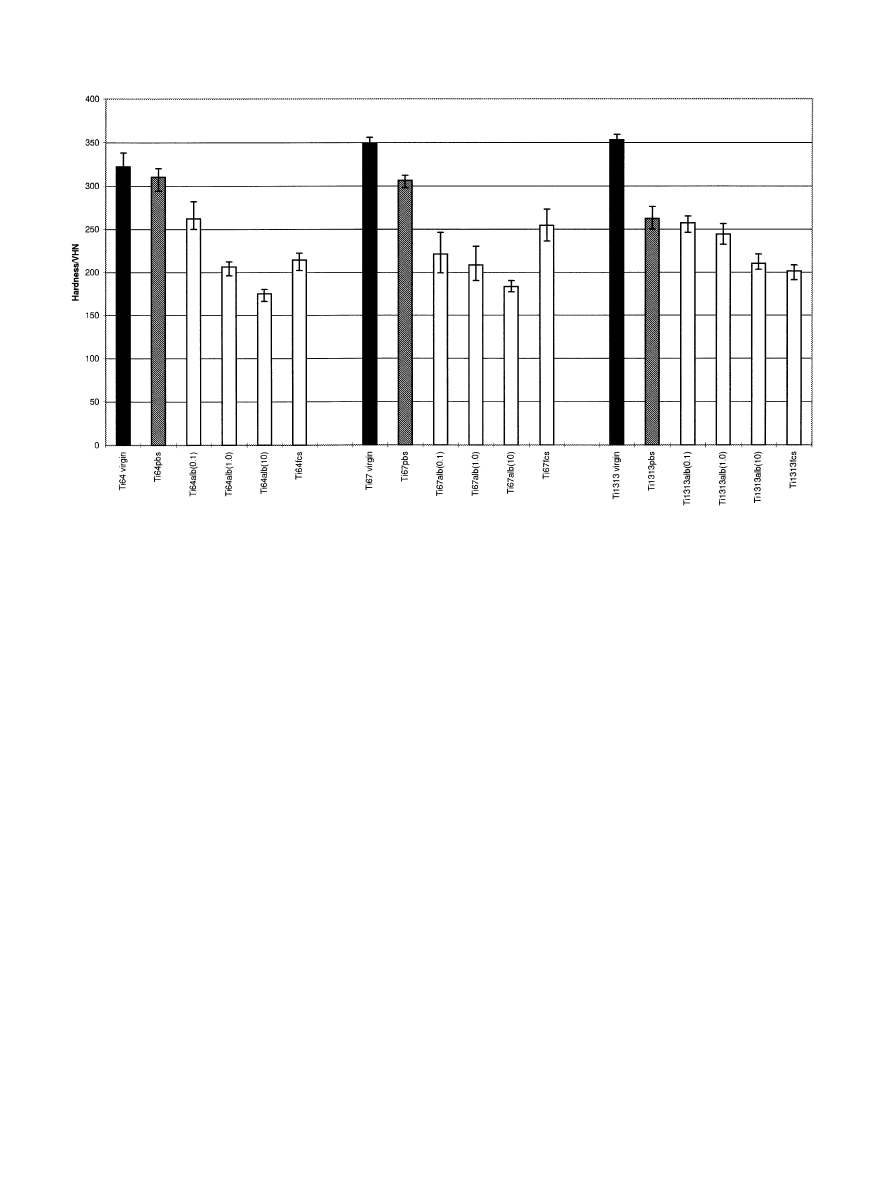

Fig. 4. Vickers hardness values for all three Ti alloys before corrosion and following corrosion in PBS, bovine albumin at different concentrations and

10% foetal calf serum, presented as the mean and standard deviation bars. Ti64"Ti —6Al—4V, Ti67"Ti—6Al—7Nb,

Ti1313"

Ti—13Nb—13Zr, PBS"phosphate-buffered saline, Alb"bovine albumin, fcs"10% foetal calf serum and the value in parenthesis is the concentra-

tion of albumin in mg/ml.

higher pH the surface hardness of Ti—6Al—7Nb was

unaffected by the presence of albumin and that of

Ti—13Nb—13Zr was only slightly increased. At low pH

the surface hardness of Ti—6Al—7Nb was influenced to

a greater extent by the presence of albumin than that of

Ti—13Nb—13Zr, resulting a slight increase in hardness.

At low pH the surface hardness of Ti—6Al—4V was not

significantly changed, however at high pH the presence of

albumin greatly increased the surface hardness following

corrosion.

Figure 4 shows the influence of protein concentration

on the hardness values following corrosion. It demon-

strates that the addition of protein reduces the hardness

of all surfaces following corrosion. Increasing the concen-

tration generally caused further reduction in the

hardness. The surface hardness of Ti—13Nb—13Zr was

reduced less than that of the other two alloys. When FCS

was added at a concentration of 10% the surface hard-

ness of Ti—6Al—4V and Ti—6Al—7Nb was not reduced as

much as in the albumin solutions whereas the result for

Ti—13Nb—13Zr was very similar to that for the surface

hardness of the repassivated surface following corrosion

in the albumin solutions.

Microscopic examination of all alloy surfaces showed

evidence of pits following cyclic polarisation.

4. Discussion

Titanium alloys are used in orthopaedic applications

and there is concern about the release and subsequent

build up of material in the tissues. It is unlikely that

the passive layers on these alloys will be broken

down electrochemically in the physiological environ-

ment. It is known, however, that the integrity of

the passive layer can be influence by wear. It is impor-

tant therefore to investigate the repassivation processes

of these alloys in a biological environment. In this

study we used electrochemical techniques to breakdown

the passive layer so that we could investigate the re-

passivation and the interaction of proteins with this

process.

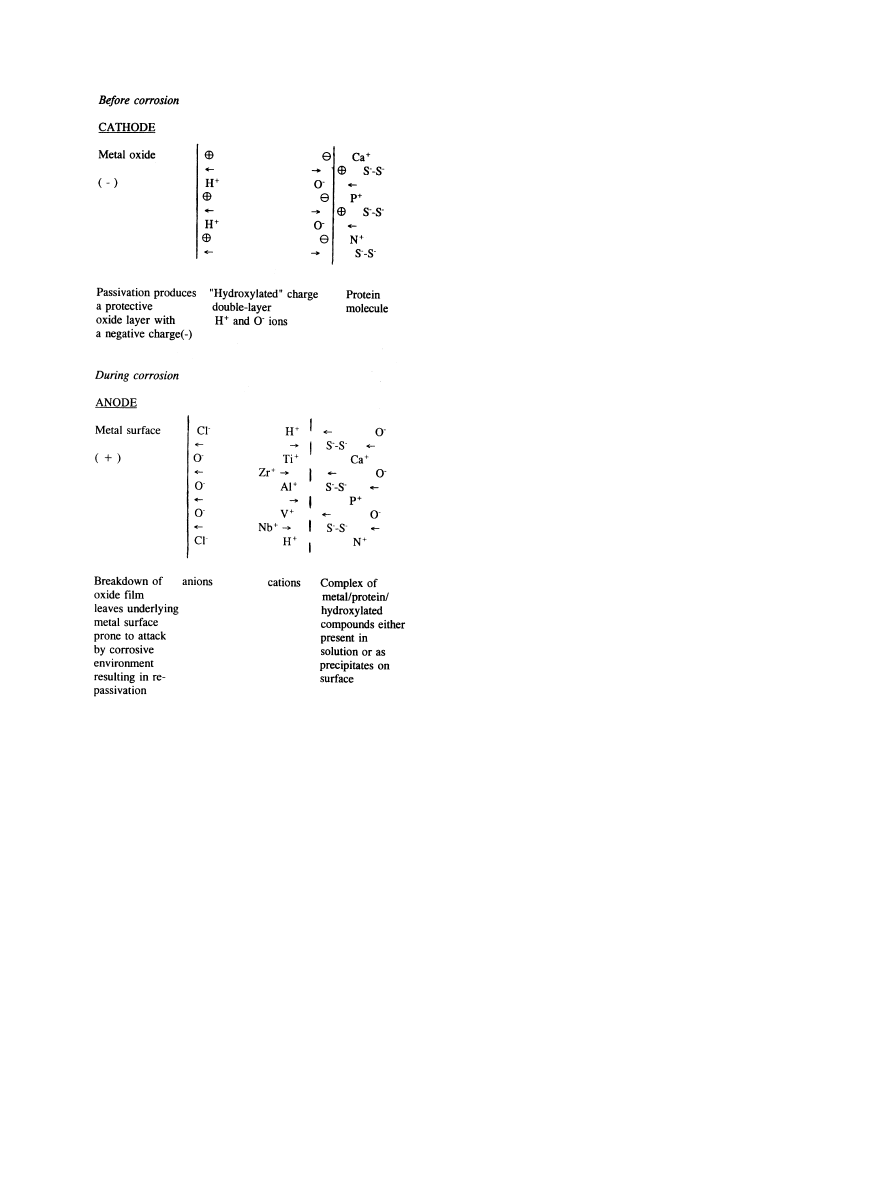

To understand comprehensively how corrosion takes

place in terms of charge transfer at the metal/electrolyte

interface, it is necessary to consider an accepted model

for the charge distribution in terms of a charge double-

layer structure (Fig. 5). In this case, a double-layer is

present due to hydroxylated ions at the metal surface and

charge transfer can occur within the layer depending on

whether the metal oxide is stable (i.e. acting as a cathode)

or whether it is passivating up to and beyond removal of

its protective oxide layer (i.e. as an anode).

M.A. Khan et al. / Biomaterials 20 (1999) 631—637

635

Fig. 5. Theoretical model of charged double layer showing the transfer

of charge at the metal/oxide/protein interfaces before and during the

corrosion process.

When the passive layer is broken the titanium alloy is

able to release ions into solution until the passive layer is

rebuilt. The action of rebuilding this layer results from

the chemical interaction of anions in the environment

reacting with the surface. It is hypothesised that any

anions in the environment may have a bearing on the

final composition of the repassivated layer and its ability

to form. It is this hypothesis that we have investigated in

this study. We have used cyclic polarisation studies to

assess the ability of the surface to repassivate and hard-

ness measurements to investigate the properties of the

repassivated surface.

Throughout this study we examined the surface under

a microscope following cyclic polarisation and found

evidence of pit formation. This evidence and the presence

of hysteresis during cyclic polarisation suggests that the

passive layer is being broken down and repassivated

under these experimental conditions. The difference be-

tween the breakdown potential and the repassivation

potential is related to the reactions that are taking place

at the surface of the material as repassivation occurs. In

this study we are using this measurement to elucidate

how proteins in the environment might be interacting

with the repassivating process and thus influencing the

properties of the passive layer. When the pH of the

environment changes the proteins will have a different

charge owing to their zwitterion character and therefore

it is reasonable to suspect that they may interact with the

repassivation process in a different way.

In an environment without the presence of proteins it

was observed that as the pH increased the corrosion

resistance of Ti—6Al—4V and Ti—6Al—7Nb was reduced.

In other words, the repassivation process became more

difficult and therefore there would be the possibility of

greater release of metal ions into solution. This could

occur with these two alloys owing to the solubility of Al

and V ions and their increased solubility in the presence

of increased hydroxyl concentration. It was observed

that, under the same conditions the corrosion resistance

of Ti—13Nb—13Zr increased slightly although the cha-

nges were very small. This could be explained by the

lower solubility of Zr and Nb ions, in comparison with Al

and V, thus repassivation occurs in preference to dissolu-

tion.

When albumin is added to the PBS at the three pH

levels it appears to reduce the effect of pH on the cor-

rosion resistance of Ti—6Al—4V and Ti—6Al—7Nb. Pro-

teins can interact with the corrosion reactions in several

ways and thus shift the position of equilibrium. For

example, proteins can bind to metal ions and transport

them away from the interface thus encouraging further

dissolution or proteins may adsorb onto the metal sur-

face thus restricting the diffusion of oxygen to the surface

thus make it harder for the surface to repassivate. Both

these mechanisms might be expected to decrease the

corrosion resistance of the alloy. Our data suggest that

the proteins are increasing the corrosion resistance of the

alloy, in particular, at the higher pH level. At these pH

levels albumin will have a negative charge since its iso-

electric point is 4.9. It may be possible that under these

conditions a metal/protein/hydroxide complex forms

and becomes adsorbed to the surface restricting metal

dissolution.

The properties of the repassivated surface may be

reflected in the hardness of that surface. For all the alloys

the virgin surface was the hardest and it is assumed that

this is a dense rutile Ti oxide surface following the polish-

ing and cleaning procedures. Following corrosion in PBS

at pH 7.4 the hardness of all the surfaces was reduced but

this reduction was small for Ti—6Al—4V and greatest for

Ti—13Nb—13Zr. As the pH of the PBS was increased or

decreased the hardness of the repassivated surface was

636

M.A. Khan et al. / Biomaterials 20 (1999) 631—637

significantly reduced for all the alloys suggesting that

the repassivated surface had a different character to

the original Ti oxide surface. When albumin was added

to the PBS at pH 7.4, following corrosion the hardness

of the

Ti—6Al—4V

and Ti—6Al—7Nb alloys

was

further reduced whereas that of the Ti—13Nb—13Zr

surface was only marginally reduced. This would

appear to suggest that at this pH the proteins were

interacting with the repassivation process to a greater

extent for Ti—6Al—4V and Ti—6Al—7Nb than for

Ti—13Nb—13Zr.

Increasing the protein concentration from 0.1 to

1 mg/ml was measured to have a small influence on the

corrosion resistance of the alloys. Further increases in

protein concentration did not appear to have a signifi-

cant effect. This can be explained from the knowledge

that such proteins are only sparingly soluble and that

once saturation has been reached in terms of corrosion,

there should be no further influence of additional protein

on corrosion [12].

The results showed that in the presence of whole serum

(10%) the corrosion resistance of Ti—6Al—4V improved

in comparison to that in PBS (in agreement with other

workers [1, 13]) and

the

corrosion resistance of

Ti—13Nb—13Zr and Ti—6Al—7Nb reduced. These results

are similar to those in albumin solutions which may

reflect the high proportion of albumin in whole serum.

The surface hardness of Ti—6Al—4V and Ti—6Al—7Nb

following corrosion in FCS, however, was higher

than those surfaces following corrosion in solutions

with higher concentrations of albumin. This result

is difficult to explain, but may reflect the complexity

of different protein interactions with the alloy sur-

faces.

It is difficult to relate the changes in hardness to the

corrosion resistance data except that changes in surface

hardness may relate to incorporation of species from

the electrolyte into the passive layer and the reactions

occurring to allow this incorporation may influence the

repassivation process and thus the position of the re-

passivation potential. The

hardness measurements

are useful in defining the extent to which the mechanical

integrity of the alloys has been affected following break-

down and repassivation. The reduction in hardness

of these alloy surface may be important in terms of

long-term wear resistance. The retention of the sur-

face hardness of Ti—13Nb—13Zr following repassiva-

tion in an environment containing proteins could point

to enhanced performance of this alloy, in comparison

with the other two, in situations where continual

removal of the passive layer and repassivation are occur-

ring.

5. Conclusion

(1) An increase in pH had a greater effect on the cor-

rosion behaviour of Ti—6Al—4V and Ti—6Al—7Nb

than on Ti—13Nb—13Zr.

(2) The addition of protein to the PBS reduced the influ-

ence of pH on the corrosion behaviour of all the

alloys.

(3) Corrosion reduced the hardness of the surface oxides

of all the alloys. In PBS the reduction was smallest of

Ti—6Al—4V and largest of Ti—13Nb—13Zr.

(4) Corrosion in protein solutions further reduced the

hardness of the surface oxides. This effect was greater

for Ti—6Al—4V and Ti—6Al—7Nb than for Ti—

13Nb—13Zr.

Acknowledgements

This work was supported by a postgraduate student-

ship from the University of Liverpool for M.A. Khan

which is gratefully acknowledged.

References

[1] Aragon PJ, Hulbert SF, Corrosion of Ti— 6Al—4V in simulated

body fluids and bovine plasma. J Biomed Mater Res 1972;

6:155—164.

[2] Mueller HJ, Greener EH, Polarization studies of surgical mate-

rials in Ringers solution. J Biomed Mater Res 1970;4:29— 41.

[3] Black J. Does corrosion matter? J Bone and Jt Surg 1988;

70B:517—20.

[4] Wapner KL. Implications of metallic corrosion in total knee

arthroplasty. Clin Orthop 1991;271:12—20.

[5] Donachie MJ, Titanium—a technical guide. OH, USA: ASM

International, 1988.

[6] Semlitsch MF, Weber H, Streicher RM, Schon R. Joint replace-

ment components made of hot-forged and surface-treated

Ti—6Al—7Nb alloy. Biomaterials 1992;13:781—8.

[7] Plenk H, Schider S. Tantalum and Niobium. In: Williams DF,

editor. Concise encylopedia of medical and dental materials. Ox-

ford: Pergamon Press, 1990:355—60.

[8] Kovacs P, Davidson JA. The electrochemical behaviour of a new

titanium alloy, Ti— 13Nb—13Zr. Presented at the 19th Annual

meeting of the Society for Biomaterials, 1993:88.

[9] Davidson JA, Mishra AK, Kovacs P, Poggie RA. New surface-

hardened, low modulus, corrosion resistant Ti—13Nb— 13Zr alloy

for total hip arthroplasty. Biomed Mater Eng 1994;4:231—43.

[10] Sousa SR, Barbosa MA. Corrosion resistance of titanium CP in

saline physiological solutions with calcium phosphate and pro-

teins. Clin Mater 1993;12:1—4.

[11] Pourbaix M. Electrochemical corrosion of metallic biomaterials.

Biomaterials 1984;5:122—34.

[12] Williams DF. Physiological and microbiological corrosion. Crit

Rev Biocompat 1985;1:1—24.

[13] Brown SA, Merritt K. Electrochemical corrosion in saline and

serum. J Biomed Mater Res 1980;14:173—5.

M.A. Khan et al. / Biomaterials 20 (1999) 631—637

637

Wyszukiwarka

Podobne podstrony:

The corrosion behaviour of Ti

51 721 736 Evaluation of the Cyclic Behaviour During High Temperature Fatique of Hot Works

40 549 563 On the Precipitation Behaviour in Maraging Steels

On the transformation behavior

[Elsevier] Corrosion Behaviuor Of Stressed Magnesium Alloys

Corrosion behaviour of commercially pure titanium shot blast

Corrosion behavior and surface characterization of titanium

Postmodernism In Sociology International Encyclopedia Of The Social & Behavioral Sciences

Report on the Sexual Behavior o Robert F Young(1)

The corrosion resistance of pure titanium

Burnat, Barbara; Blaszczyk, Tadeusz; Leniart, Andrzej Effects of serum proteins on corrosion behavi

Contacts and contracts dyadic embeddedness and the contractual behavior of firms

Corrosion behavior

Corrosion behavior of titanium nitride

A Behavioral Genetic Study of the Overlap Between Personality and Parenting

Post feeding larval behaviour in the blowfle Calliphora vicinaEffects on post mortem interval estima

DYNAMIC BEHAVIOUR OF THE SOUTH Nieznany

więcej podobnych podstron