23-1

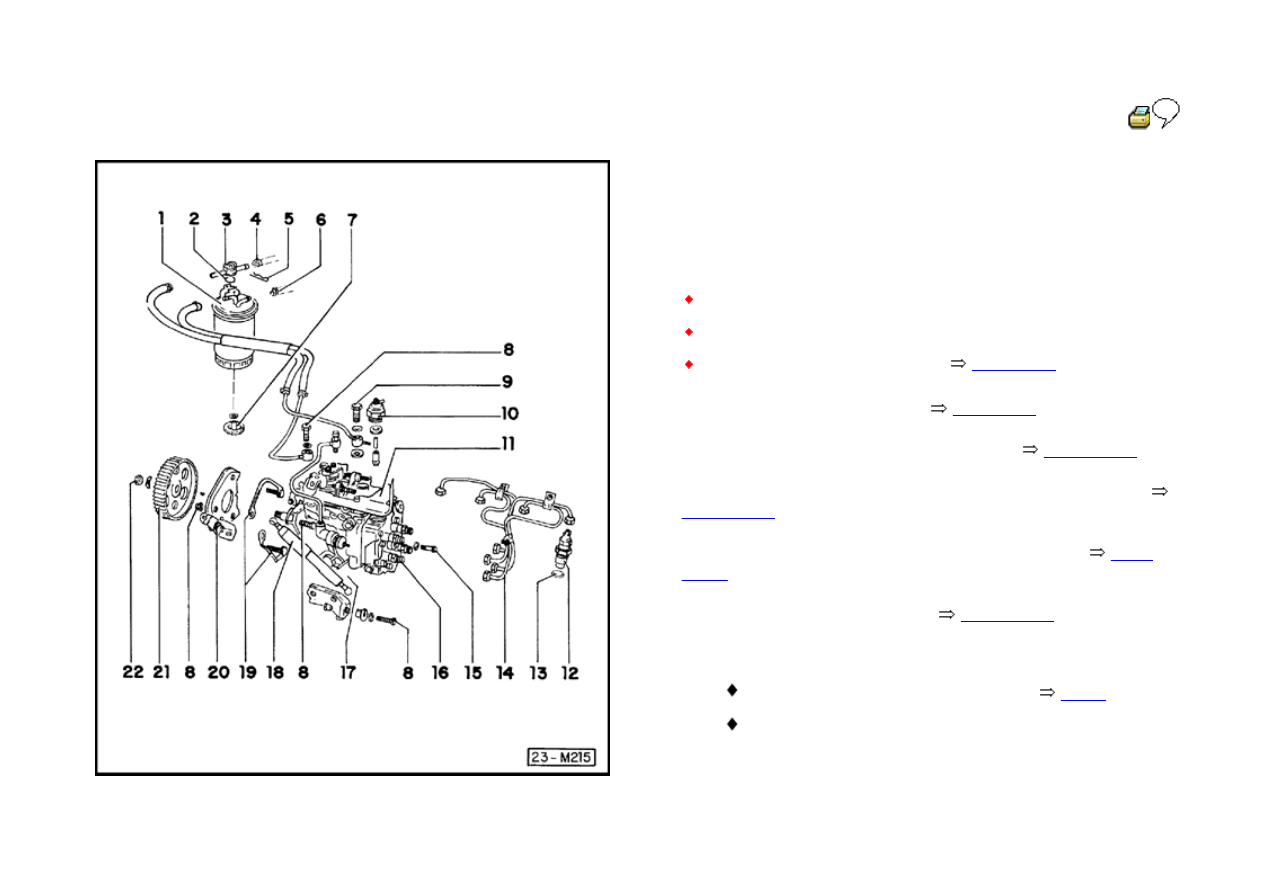

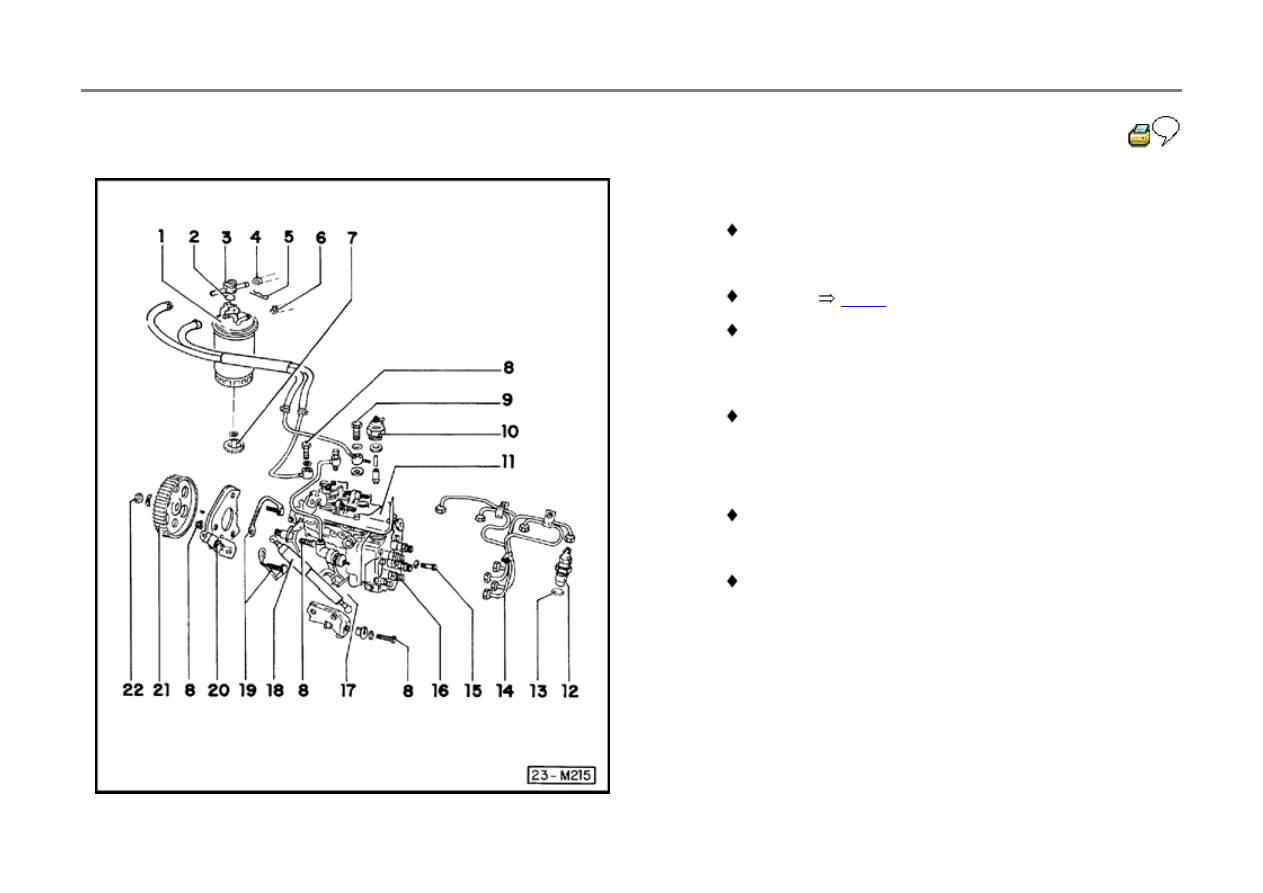

Diesel fuel injection system,

component layout

CAUTION!

Checking fuel system for leaks

Page 23-6

Diesel injection pump, general information

Page 23-12

Diesel injection pump static timing, checking and adjusting

Page 23-14

Max. engine speed (RPM), checking and adjusting

Page

23-20

Diesel injection pump, servicing

Page 23-29

Secure all fuel hoses with hose clips.

Always replace seals and gaskets.

Observe rules of cleanliness

Page 23-7

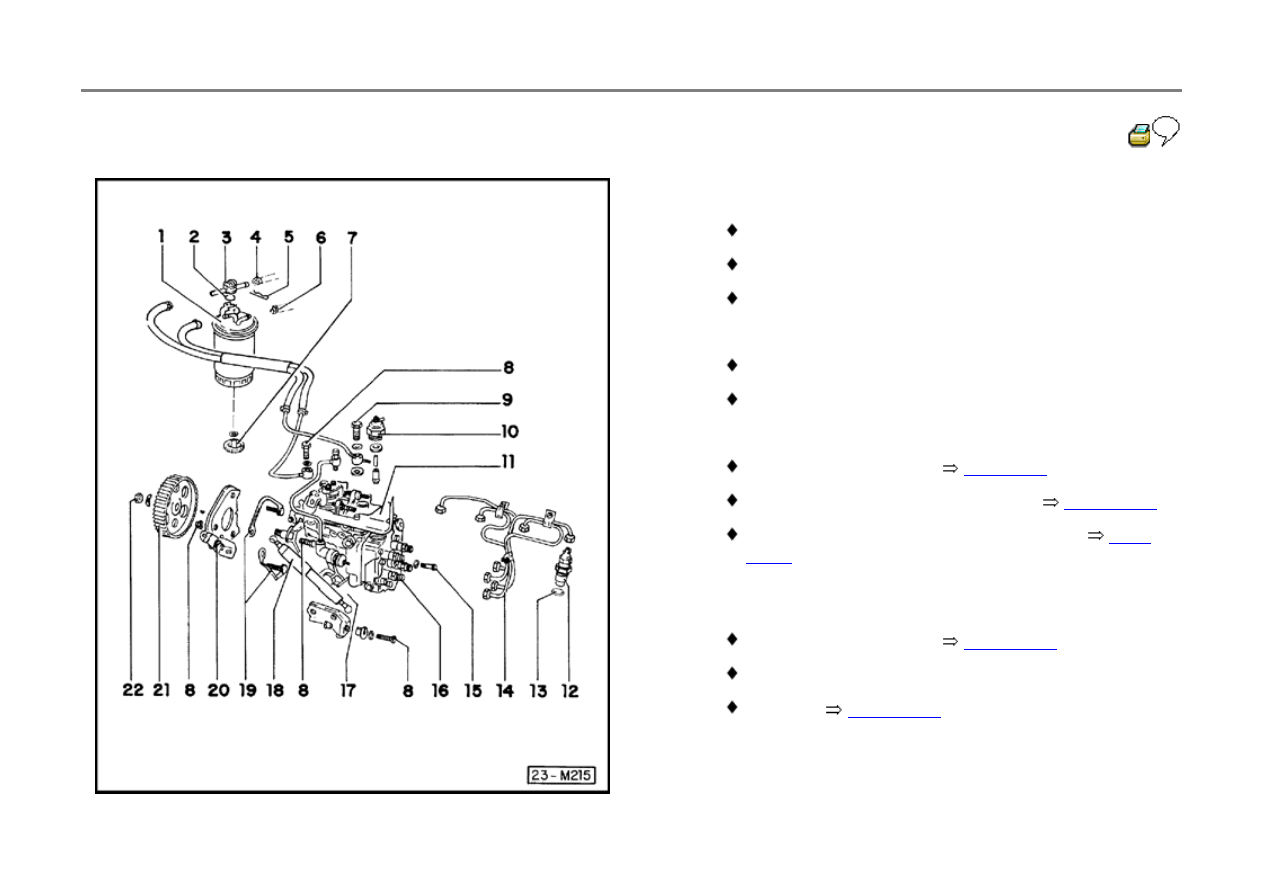

1 - Fuel filter

Direction of flow indicated by arrows

Fig. 1

Do not interchange connections

23-2

2 - O-ring

Always replace

3 - Control valve

Location

Fig. 1

When replacing filter, release spring clip and remove

control valve with fuel lines connected

4 - Fuel return line

To fuel tank

5 - Retaining clip

6 - Fuel supply line

From fuel tank

7 - Drain plug

To bleed:

- Remove retaining clip for control valve.

- Remove control valve with fuel lines connected.

- Loosen plug and let 100 cc (3.4 oz.) of fuel run

out.

- Re-install plug and control valve.

8 - 25 Nm (18 ft lb)

23-3

9 - Banjo bolt

For fuel return line

Is marked with "OUT"

Tightening torque: 25 Nm (18 ft lb)

10 - Fuel Cut-Off Valve -N109-

Must click when ignition is switched on and off

Tightening torque: 40 Nm (30 ft lb)

11 - Diesel injection pump

Removing and installing

Page 23-8

Static timing, checking and adjusting

Page 23-14

With the exception of repairs described on

Page

23-29

, an injector pump test bench is required for

pump repairs; a faulty pump must be replaced

12 - Fuel Injector

Removing and installing

Page 23-25

Tightening torque: 70 Nm (52 ft lb)

Checking

Page 23-27

23-4

13 - Heat shield

Always replace

Installation position

Page 23-25

14 - Fuel Injector lines

Tightening torque: 25 Nm (18 ft lb)

Remove with tool 3035

Always remove complete set of lines

Do not alter shape

15 - 15 Nm (11 ft lb)

May be tightened to max. 25 Nm (18 ft lb) to stop

leaks

16 - Connector

Removing, installing and stopping leaks

Page 23-

19

17 - Securing clip

18 - Shock absorber

19 - Fixture

20 - Mounting bracket

21 - Injection pump sprocket

Removing: first remove injection pump

Page 23-8

22 - 45 Nm (33 ft lb)

23-5

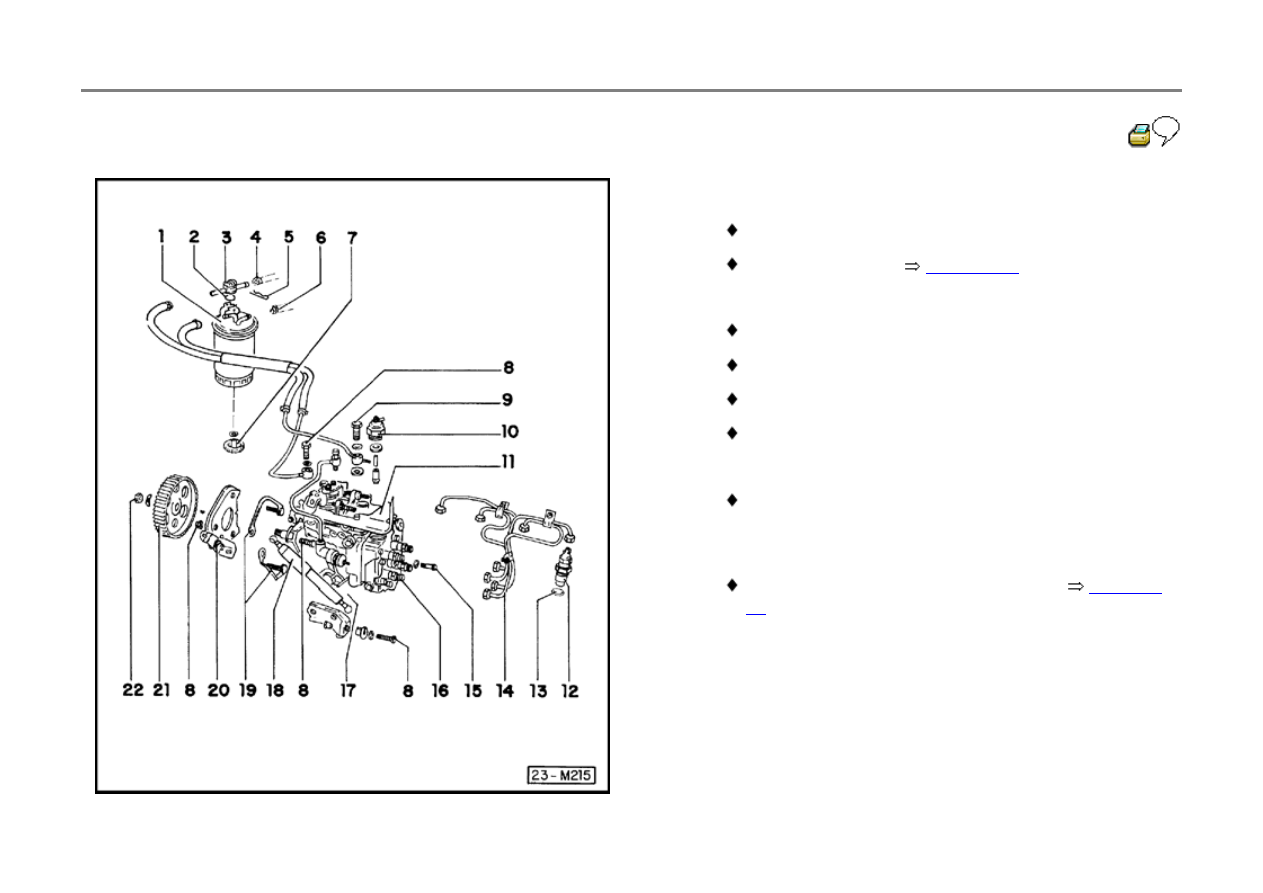

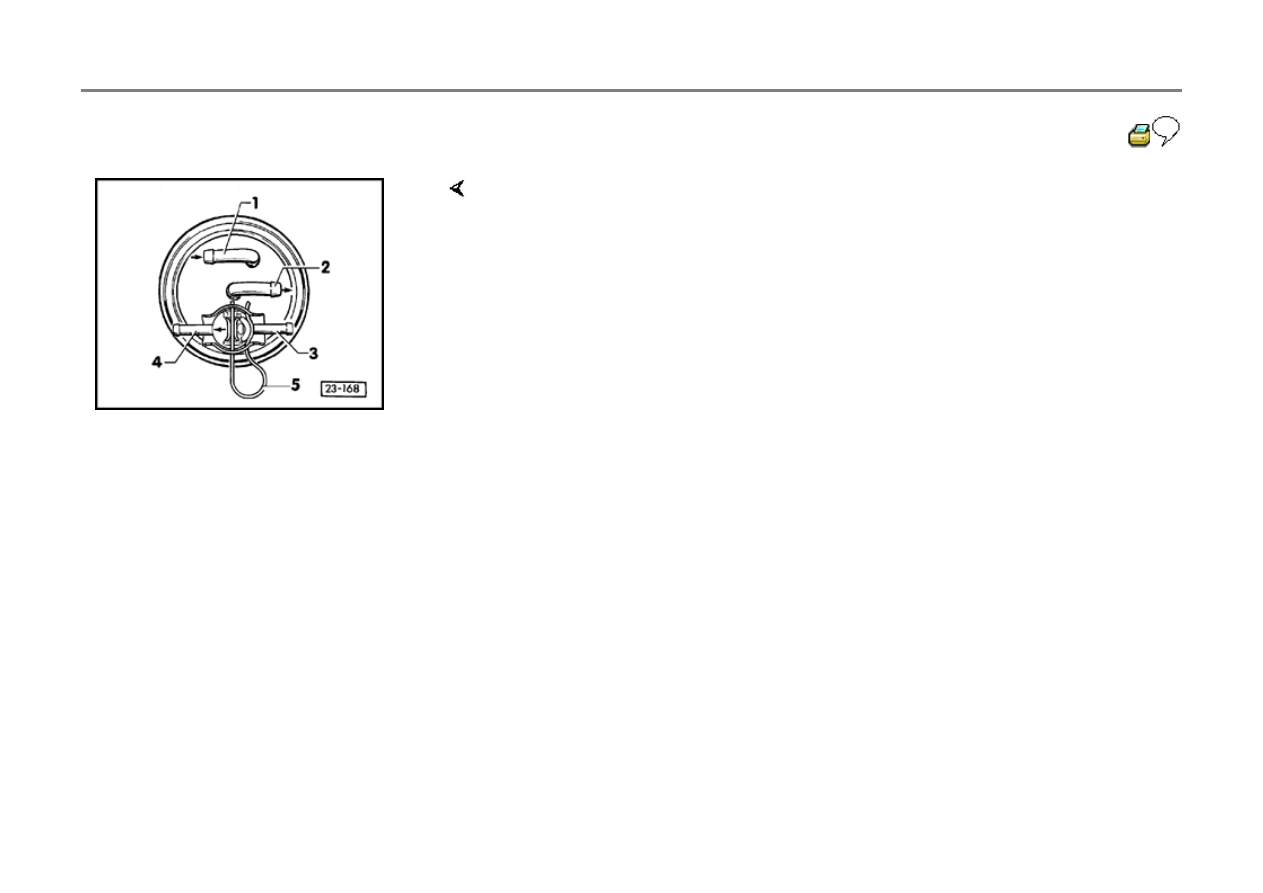

1 - Supply from fuel tank

2 - Supply to injection pump

3 - Return from injection pump

4 - Return to fuel tank (marked with arrow)

5 - Retaining clip

Fig. 1

Fuel filter and control valve connections

Wyszukiwarka

Podobne podstrony:

aaz 1z ahu turbocharger syst

Proj syst log wykl 6

syst tr 1 (2)TM 01 03)13

Program Progr Syst i Wspolb2011

pomoc SYST[1].INF, Szkoła

Cechy org jako syst społ

biogas as vehicle fuel id 87120 Nieznany

4 Fuel and Lubrication System

08 fuel system

05 Fuel System

Bosch Motorsport com HDP 5 Fuel Pump

Leki inj - Prostavasin 20, 000-Nasze Zdrowko, Leki i Witaminy

#10 MAR FUEL HANDLING AND PRETREATMENT

There are people who see the rising corporate average fuel?onomy

Instrukcja drgania 1, Automatyka i robotyka air pwr, VI SEMESTR, Syst. monit. i diagn. w przem, Mate

(15)Syst.rz-d. Cz. II, Prawne podstawy bezpieczeństwa państwa

analogowe sprawko cw B, Automatyka i robotyka air pwr, VI SEMESTR, Analogowe i cyfr. syst. pom

więcej podobnych podstron