Chapter 11

Heat balance of the mining faces of a copper mine

J. Wacławik |

W. Turkiewicz |

University of Mining and Metallurgy Kraków |

Copper Research and Design Centre „Cuprum” Ltd. Wrocław |

ABSTRACT

Rock-mass and technical conditions in the G-11 mining panel of the „Rudna” mine are characterised. Using the basic heat balance equation and results of the measurements of air parameters in the panel, the analysis of the each factor which influences shaping the climate condition was made. The air heat content increase in the mining field was calculated as well as the size of the air temperature and humidity rise. The necessary cooling power as a function of the air temperature on the inlet to the panel was established. The basic rules describing the type of activities necessary to limit a value of air temperature increase in the panel were formulated.

KEYWORDS

Air conditioning, heat transfer in mining

Introduction

The copper ore deposit in the Legnica - Głogów Copper District mainly occurs at a depth from between 550 and 1200 meters. The total thickness of the mineralised strata is uneven and varies between about 3 to 20 meters. The deposit inclination is from 3 to 6o. Due to the unfavourable geothermal temperature gradient the primary temperature of the rocks at the depth below 900 meters is one of the fundamental causes of the difficult climate conditions. This part of deposit is exploited now by three mines i.e. „Lubin”, „Polkowice-Sieroszowice” and „Rudna”.

The copper ore deposit is currently mined within three mining areas which are divisions of the KGHM Polska Miedź SA. The „Rudna” mine currently is accessed by ten shafts, and seven of them are downcast ones. In the near future a new shaft, 1200 m. deep, will be sunk. At the current extent of mining operations a total of 3000 m3/s of air is drawn into the mine. The average ratio of the air quantity at the inlet to the mine is 4.5 m3/min per tonne of daily output. However the average ratio at the inlet into mining panels is from 2.75 m3/min to 3.85 m3/min, and for the roadway work regions more than 6.0 m3/min per tone of the day output. The „Rudna” mine has ventilation connection with the „Polkowice-Sieroszowice” mine.

The „Polkowice-Sieroszowice” has two mining areas - „Sieroszowice” and „Polkowice” (previously separate mines). The „Sieroszowice” is a perspective mining region which is currently opened out by four shafts, two of them are downcast ones. At the one of those shafts one of three fans of the main underground ventilation station was commissioned in 1998.

The „Lubin” mine has seven shafts. Three operate as downcast shafts. In order to enable the proper ventilation of mining operations in the first quarter of 1999, in the “Małomice” area at the level of 650 m., the supportive fan with the capacity of 500 m3/s and total head of about 3000 Pa was started. Using this fan allowed to resign the construction of additional station of the main ventilation fans at one of the shafts, which now has a function of the downcast shaft.

The geothermal gradient of rocks in the zone of deposit occurrence changes from 20.9 to 38.1 m/K. The average value of the geothermal gradient in the south-east part of the district is 27.4 m/K and in the north-west part 30.2 m/K [2]. The values of geothermal gradient in the north-west part are the crucial factor which will form the unfavourable temperature of the mine air during the mining operations.

The past thirty five years mining in the copper mines was concentrated in the south-west part of the LGOM area i.e. in the region where the geothermal parameters of rocks were more favourable. Problems with maintaining climatic conditions which were in accordance with mining regulations were most difficult to achieve in works in the long-drift roadways. At the mining faces, the temperature hazard escalated at a depth greater than 1000 meters in the north-west part of the copper deposit. The climate factor for this region is from 1.48 at the depth of 1000 meters to 1.95 at the depth of 1200 m. Difficult geothermal conditions, as well as the long distances between shafts and operational mining areas mean that at the many faces, especially those situated below 1000 meters, there are problems in maintaining proper climatic conditions using normal ventilation methods.

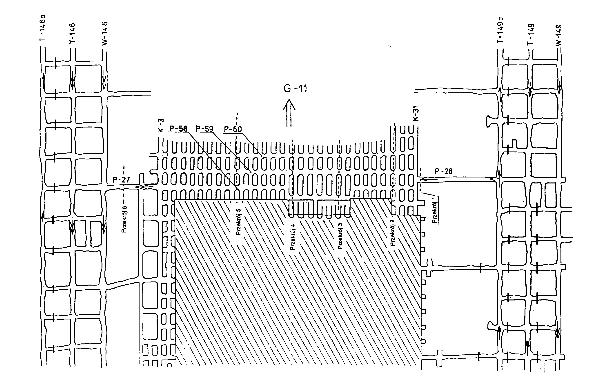

Figure 1. Draft of workings in the mining panel

Table 1. Air parameters at the inlet and outlet from the mine workings

Date of measurements |

Air inlet |

Air outlet |

||

|

T |

Tm |

T |

Tm |

22 June |

29.8 31.2 |

23.8 25.2 |

35.2 |

29.2 |

29 June |

29.6 30.6 |

25.6 26.0 |

33.0 34.8 |

27.8 30.2 |

30 July |

30.2 28.6 |

24.0 25.2 |

34.2 35.0 |

29.4 31.2 |

20 August |

31.4 28.2 |

25.8 23.2 |

33.4 36.0 34.0 35.4 |

28.2 30.4 29.6 30.0 |

23 September |

31.4 28.2 |

27.8 25.2 |

34.8 34.8 |

31.6 31.2 |

7 October |

32.6 28.2 |

23.2 22.8 |

34.8 |

31.6 |

27 October |

32.0 27.4 |

26.2 24.8 |

34.8 |

30.2 |

10 November |

25.8 |

20.4 |

35.2 |

28.6 |

Average |

29.68 |

24.61 |

34.67 |

29.94 |

Tables 2. Results of measurements in the mining field made on June 22nd 1999

Table 2 a. Air inlet

T,oC |

Tm,oC |

|

|

es, Pa |

e, Pa |

x, kg/kg |

|

29.8 |

23.8 |

4 300 |

89.87 |

2947.32 |

2522.28 |

0.0145971 |

1.254 |

H = 2.7652 + 3,1896 ≅ 6.0 MW |

|||||||

Table 2 b. Air inlet

T,oC |

Tm,oC |

|

|

es, Pa |

e, Pa |

x, kg/kg |

|

31.2 |

25.2 |

1100 |

22.864 |

3204.66 |

277.62 |

0.0161249 |

1.247 |

H = 0,7376 + 0,8952 ≅ 1,6 MW |

|||||||

Table 2 c. Air outlet

T,oC |

Tm,oC |

|

|

es, Pa |

e, Pa |

x, kg/kg |

|

35.2 |

29.2 |

5800 |

118.64 |

4050.88 |

3625.84 |

0.0212013 |

1.227 |

H = 4,3638 + 6,0834 ≅ 10,45 MW |

|||||||

Due to the changeable thickness of strata and complex geo-mechanical conditions, the deposit is mined using different types of the room-and-pillar method. From the ventilation point of view this method needs great amounts of air. The big rock areas, having a contact with flowing air, cause a substantial increase of temperature as well as a build-up of air humidity. Fig. 1 shows a draft of the mining field where some measurements aimed to determine the amount of the heat inflow from the different sources were made.

The basic criterion for the selection of the quantity of air to be supplied to the mining sectors by ventilation is the output (minerals extracted) from the sectors. The amount of the air delivered to the sectors/faces is also determined by the depth of mining and the distance of the air flow from the downcast shaft to the mining operation area.

Air parameters in the mine working

In order to establish the intensity of the heat sources, measurements of the air parameters were made in one of the mining faces of „Rudna” mine located at the depth of 1100 m. The initial rock temperature is ![]()

= 42oC, the air temperature at the inlet into the mine workings changes from 27.5oC to 31oC. The mining field takes

a shape of the rectangle 360 m long and 70 m. wide. In the direction of air flow for the 1 meter of the working falls about 140 m2 of the uncovered un-mined rocks. In the eight runs of measurements which were made in 1999 the average air flow was 95,5 m3/s. The flow velocity in the workings between the belts is about

1,9 m/s. The temperatures as per dry-bulb (T) and wet-bulb (Tm) thermometers in the inlet and outlet sections of the mining filed are presented in Table 1.

The average value of the temperature on the dry-bulb thermometer is T = 32.26oC, and on the wet-bulb thermometer is Tm = 27.21oC. The difference of the water vapour on the surface of vet rocks and in the turbulent air stream, calculated for those temperatures, is about Δe = 1500 Pa.

The heat sources cause an increase in the air's enthalpy. The open heat exchange contributes to the temperature increase, latent heat exchange causes the growth of air humidity. The measurements allowed the determination of the enthalpy increase in the mining field area. In

Table 2 sample values of the air enthalpy increase in the workings of the mining field, calculated on the basis of physical measurements are presented. The enthalpy of the air stream is given in the form of sums, where the first element gives the direct part calculated on the basis of temperature change, and the second, latent one is connected with the change of humidity.

The enthalpy brought by the inlet air equals the sum of the respective values given in 2 a and 2 b Tables: Hin = 3.5038 + 4.0848 ≅ 7,6 MW. The enthalpy at the outlet presented in Table 2 c, equals: Hout = 4.3638

+ 6.0834 ≅ 10.45 MW. The air enthalpy increase on the area of the mining field is the same as the difference between enthalpy at the inlet and outlet ![]()

Hout - Hin = 0.8600 + 2.0 = 2.86 MW.

Influence of the heat sources on the climate conditions

The measurement of the mine air temperature and humidity as well as the air output enables one to determine the total effect of all heat sources. Attributing a part of the temperature or humidity increase to a specific heat source requires special measurements, usually impossible to make during mining operations, or calculations based on theories or resulting from experiments. Some standards can be found in the papers and articles, especially [3], [6], [9], [10], [11], [12], [13] and [14]. It is necessary to determine the heat emitted by rocks, heat from detritus, heat emitted by devices driven by internal combustion engines and separately by the equipment using electric motors as well as energy changes connected with the evaporation of water. In the mining field the part of the roof is wet and is some cases there is free water falling to the floor of the excavation. Moreover, evaporation of water from the mined rock takes place. In our case the surface film conductivity is about α = 4 W/(m2K), the latent heat of evaporation

rw = 2.4255×106 J/kg, and humidity transfer factor

h = 2.72×10-8 kg/(m2Pa s).

Heat from rocks

At an average speed of advance of about 0.8 m/day the heat exchange with rocks, calculated using the heat equation and the air energy equation [14], [9], [1], [8] and [4], is about 1450 W/m. The open stream of enthalpy flowing form the rock-mass in the mining field equals 0.52 MW and causes a temperature increase of 4.6oC.

Heat exchanged with rock detritus

The air temperature and humidity increase in the mining field takes place due to the contribution of heat from mined rocks. Approximately 1/3 of the output is mined from the heading face whilst that from the redundant pillars comprises about 2/3 of the output, which during one shift, amounts to about 1 000 tones. Exploitation and detritus haulage during one shift last about 4 hours. The reduction of the temperature of the detritus within the mining field was estimated as about ![]()

3oC. The flow of this stream is ![]()

106/(4×3600) = 69.4 kg/s, the specific heat of rocks is cu = 1000 J/(kgK). The heat stream transferred from the extracted material to the air equals:

![]()

= ![]()

MW (1)

According to J. Vo* [13] only about 70% of the heat calculated using the formula (4) is transferred to the air, and 15 % passes openly but 85% by the evaporation of water. Therefore:

![]()

oC, ![]()

kg/kg (2)

Heat from machines and equipment

In the example adduced, mining work is conducted by many machines driven by diesel engines. The monthly consumption of the diesel oil, of calorific value of 34 000 kJ/l is about 54 000 l. Almost all of this fuel is used in the workings of the mining face. Only haulage cars and loaders during the short time of crossing from the parking and maintenance areas are external to the mining area. During peak load of ICEs machines, the hourly consumption of diesel oil is 192.9 l. The fuel consumption in the diesel engines is about. 0.254 kg per hour of operation and per 1 kW of power. It means that for 1 kW of engine power, 3.21 kW of calorific value is used. This amount of energy is turned into heat. Less than one third of the heat is emitted from the engine itself, a considerable part flows out as an integral part of the exhaust gas, partly in the form of water vapour. As a result of combustion of 1 litre of the diesel oil, about 1.1 of water vapour is emitted into the air. Useful energy changes into heat due to friction.

J. Vo* [13] suggests that approximately 30% of the heat emitted as a result of the machines' operation is associated with the working together with hauled detritus (coal). The rest is transferred to the air - 10÷25 % openly and 90÷75% as latent energy way.

In the mining field of one face many machines are powered by diesel engines: haulage cars, ŁK- Toro loaders, ŁK-2 loaders, roof-bolting machines, scaling device, bulldozer, SWS blasting and SWT transport cars. The heat coming from the diesel oil equals:

![]()

= 1.82 MW (3)

The air temperature and humidity rise due to the heat flow from the diesel engines and machines which are driven by them, is ΔTs = 1.6oC, ![]()

0.00374 kg/kg.

In the working area of the mine field and on the haulage roads for extracted material, machines driven by electric motors are in operation, mainly fans and belt-conveyors. The average power of the electrically driven machines is 800 kW, calculated as a uniform load per shift or 1600 kW over a period of four hours of work. The electric motors and the machines which are driven by them cause the following changes:

ΔTs = 0.7002 oC, ![]()

0.001644 kg/kg.

Heat exchanged due to humidity evaporation form the walls of workings

The quantity flow of evaporating moisture was determined assuming a humidity of 20% in the roof, floor and side walls of a total area of about Fm =

4000 m2. The mass-rate of moisture ![]()

evaporating from the part of roof and floor surface equals to:

![]()

= hFmΔe = 2.72×10-8×4 000× 1500 = 0.1632 kg/s.

(4)

The enthalpy necessary to evaporate such amount of water is:

![]()

0,1632×2,4262×106 = 0,3960 MW. (5)

During this process the increase of the specific humidity of the air will take place:

![]()

(6)

It is estimated that the enthalpy of the moisture evaporation from the roof and floor is at ![]()

covered by the heat from the rock-mass and at ![]()

from the air. Such assumption results from the similar temperature values of the fluid moisture and the flowing air. Therefore as an effect the air temperature is lower - T=-2.5°C the results of calculations for the state without air-conditioning, for the inlet temperature of 30 oC are presented in the Table 3.

Table 3. Calculation results for the inlet air of temperature 30oC.

Heat source |

Power, MW |

Apparent increase in temperature, oC |

Air temperature increase, oC |

Air humidity increase, kg/kg |

Unmined rock-mass |

0.52 |

4.624 |

4.6 |

----- |

Humidity from roof and floor |

-0.396 |

-3.300 |

-2.5 |

0.001367 |

Muck |

0.208 |

1.249 |

0.18 |

0.00043 |

Diesel engines |

1.82 |

15.186 |

1.6 |

0.00374 |

Electric equipment |

0.800 |

7.076 |

0.700 |

0.001644 |

Total |

2.95 |

-------- |

4.58 |

0.00718 |

Table 4. Necessary cooling power as a function of inlet temperature

Inlet temperature, oC |

Water vapour pressure, Pa |

Air humidity, kg/kg |

Power of temperature reduction, kW |

Power of humidity outdropping, kW |

Cooling power, kW |

26 |

2228.1 |

0.012859 |

437.4 |

65.7 |

503.1 |

28 |

2505.5 |

0.014498 |

557.0 |

310.0 |

867.0 |

30 |

2812.5 |

0.016321 |

679.0 |

581.6 |

1261.0 |

32 |

3151.7 |

0.018347 |

796.0 |

883.2 |

1679.2 |

34 |

3525.8 |

0.020597 |

915.5 |

1217.9 |

2133.4 |

Obtaining the necessary heat work conditions needs the air-conditioning. Due to the existing technical conditions it was decided that the half of the air output would be cooled. In the case of the air stream of ![]()

m3/s, temperatures T = 30oC, Tm = 25oC at the inlet to the mining field, air temperature should be reduced to 18.68oC. In front of coolers the air has the following parameters: T = 30oC, Tm = 25oC, e =

2812.54 Pa, x = 0.0163209, and behind the cooler: T = 18.68oC, Tm = 18.68oC, e = 2153.20 Pa, x = 0.01241845. It was assumed that ![]()

kg/m3.

The difference of enthalpy equals:

47.75×1.25{1,005(30-18.68)+(0.0163209-0.01241845)[1.884×(30-18.68)+(2502.5-2.386×

(30-18.68))]}=679.041+581.577=1, 260.62 kW=1.261 MW

In order to determine the influence of the inlet temperature on the necessary cooling power the adequate calculations were made. It was assumed that the relative humidity was the same as in the above described case and amounted to ![]()

. The results are presented in Table 4.

In the case of transporting the air along two belts (instead by three) and reduction of the air output by approximately 30 % the necessary cooling power will be lower by about 20 %. When the air is cooled at its inlet and at the half of distance inside the mining field the necessary cooling power is similarly smaller.

Possibilities of the reduction of heat emitted to the air and choice of the advantageous method of workings ventilation

The calculations showed that in mining panels of KGHM Polska Miedź SA copper mines, the climate conditions depend mainly from the described below factors, which can be changed using new modifications of the room-and-pillar mining method as well as new systems of the output haulage. Moreover some suggestions about the trends of studies aiming at developing the proper mining method for the copper deposit occurring in the difficult rock-mass conditions are presented.

The biggest influence on the climate conditions in the horizontal mine working has the heat from rocks and the local heat sources:

winning and haulage equipment especially self-propelled, driven by combustion engines as well as fans, pumps and lighting,

rocks already mined and hauled along the roadways,

humidity evaporating in the workings.

Due to the heat exchanged between the rock and passing by air, if is favourable to keep the small area of contact between air and rocks. The fresh air flows along the smallest possible number of roadways in the multi-strips galleries, small lengths and widths of the mining field, “straighten mining face” in the mining panel are conducive to this aim. The dimensions of those workings should, however, guarantee the proper level of production.

The calorific value of the fuel in the combustion engines is about three times bigger than their effective power. The diesel engine uses about 0.254 kg of fuel per working hour and per 1 kW of power and the calorific value of the diesel oil is 45.6 MJ/kg or 34.0 MJ/l. It means that for 1 kW of the engine power the energy of 3.21 kW is used. This energy stream in the form of heat and the reaction product, including water vapour, transfers into the environment. Effective energy passes into the heat during the friction processes. Therefore the combustion drive emits into the environment about three times more heat that electric drive with the same effective power. It means that it is necessary to reduce usage of the combustion engines in the difficult climate conditions and use electric driven engines instead. Therefore we should undertake studies to check the possibility of at least partial exchange of the combustion engines driven equipment into electric ones. The other positive effect of the combustion drive reduction will be decrease in the nitrogen oxides and other hazardous exhaust gases emission into the mine air.

The power of the electric driven equipment should be also reduced. It is connected, among other things, with the reduction of free fans and location of conveyors and other machines out of tracks of air inflow into the exploitation workings.

One of the problems is the relationship between the air stream and the necessary cooling power. It is usually assumed that the air temperature at the end of mine workings will not exceed the value regarded as acceptable. Due to the Polish climate conditions and with the moderate depth of the KGHM mines, this problem has not the clear-cut solution. Since it can happen that the temperature of air flowing into the air-conditioned space is lower than the allowable temperature. In such case the increase in the air amount will reduce the demand for the cooling power. Because in the inlet stream of air there is a certain shortage of the air enthalpy comparing with the enthalpy of the allowable temperature. The biggest is this reserve of enthalpy, the greater is the air output. The opposite situation is for the inlet temperature substantially exceeding the allowable temperature. Then the smallest output is more favourable, because it is necessary to take from the inlet air, the surplus of the enthalpy. When the difference between inlet and allowable temperature is small, the problem is in the nature of heat exchange, especially it depends on the air humidity and its changes within the air-conditioned working..

The more precise values of the air temperature and humidity at the outlet from coolers can be obtained after determining the type and technical and heat parameters of the cooler. Since it is known that depending on cooled air parameters and coefficients characterising open and hidden heat exchange, the cooling power can undergo the same, usually small, change.

References

Carslaw H.S., Jaeger J.C.: Conduction of heat in solids, Oxford University Press, 1959

Downorowicz S.: Geotermika złoża rudy miedzi Monokliny Przedsudeckiej, cz.VI, Prace Instytutu Geologicznego, Warszawa 1983

Duckworth I., Mousset-Jones P.F., Danko G., Marks J.: A heat study for cut-and-fill stope, Fifth International Mine Ventilation Congress, Johannesburg 1992, p. 123-129

Gupta M.L., Panigrahi D.C., Banerjee S.P.: Simulation of unsteady and quasi-steady heat transfer in mine airways, Fourth International Mine Ventilation Congress, Johannesburg 1992, p. 119-122

Hartman H.L., Mutmansky J.M., Ramani R.V., Wang Y.J.: Mine Ventilation and Air Conditioning, John Wiley & Sons, New York 1997

Howes M.J.: Heat and moisture exchange in mine airways, Fourth International Mine Ventilation Congress, Brisbane, Queensland July 1988 p. 257-272

Madeja-Strumińska B., Nędza Z., Strumiński A., Turkiewicz W.: Wentylacja i klimatyzacja kopalń LGOM, Pr. Naukowe Inst. Górn. Pol. Wr. 66, mon. 31, Wrocław 1992

Marais D.: Development of a model for the prediction of the overall heat load on a Southern African colliery, Fifth International Mine Ventilation Congress, Johannesburg 1992, str. 131-138

McPherson M.J.: Subsurface ventilation and environmental engineering, Chapman & Hall, London 1992

Nixon C.A., Gillies A.D.S., Howes M.J.: Analysis of heat sources in a large mechanised development end at Mount Isa Mine, Fifth International Mine Ventilation Congress, Johannesburg 1992, str.109-118

Starfield A.M., Dickson A.J.: A study of heat transfer and moisture pick-up in mine airways, J. S. Afr. Inst. Min. Met. t. 68, 1966, str. 211-234

Vost K.R.: The prediction of air temperatures in intake haulage in mines, J. S. Afr. Inst. Min. Met., t. 82, 1982, str. 316-328

Vo* J.: Grubenklima, Verlag Gl*ckauf, t. 27, Essen 1981

Wacławik J., Cygankiewicz J., Knechtel J.: Warunki klimatyczne w głębokich kopalniach, Bibl. Szk. Eks. Podz. nr 4, wyd. drugie, Kraków 1998

2

I SZKOŁA AEROLOGII GÓRNICZEJ 1999

5

74

PROCEEDINGS OF THE 7TH INTERNATIONAL MINE VENTILATION CONGRESS

73

Heat balance of the mining faces of a copper mine

Wyszukiwarka

Podobne podstrony:

8304

8304

8304

8304

8304

8304

8304

8304

8304

więcej podobnych podstron