2a

CONSTRUCTION

Introduction

The most important factor in assembling your FM Wireless Microphone is good soldering techniques. Using the proper soldering iron is of prime importance. A smali pencil type soldering iron of 25 - 40 watts is recommended. The tip of the iron must be kept clean at all times and well tinned.

Safety Procedures

• Wear eye protection when soldering.

• Locate soldering iron in an area where you do not have to go around it or reach over it.

• Do not hołd solder in your mouth. Solder contains lead and is a toxlc substance. Wash your hands thoroughly after handling solder.

• Be surę that there is adeąuate ventilation present.

Assemble Components

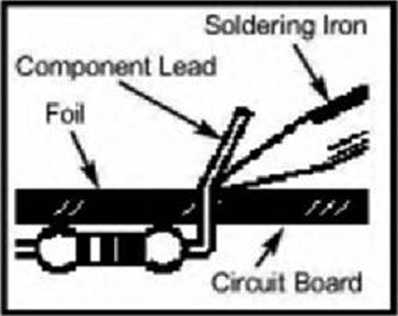

In all of the following assembly steps, the components must be installed on the top side of the PC board unless otherwise indicated. The top legend shows where each component goes. The leads pass through the corresponding holes in the board and are soldered on the foil side.

Use only rosin core solder of 63/37 alloy.

DO NOT USE ACID CORE SOLDER!

Types of Poor Soldering Connections

What Good Soldering Looks Like

A good solder connection should be bright, shiny, smooth. and uniformly flowed over all surfaces.

1.

2

3.

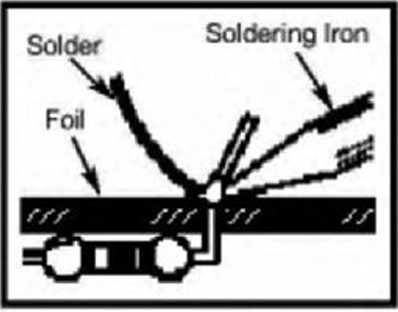

Appty a smali amount of solder to the iron tip. This allows the heat to leave the iron and onto the foil. Immediately apply solder to the opposito side of the connection. away from the iron. Allow the heated component and the Circuit foil to melt the solder.

Allow the solder to flow around the connection. Then. remove tho solder and the iron and let the connection cool. The solder should have flowed smoothly and not lump around the wire lead.

Hero is what a good solder connection looks like.

Solder all components from the coppor foil sido only. Push the soldering iron tip against both the lead and the Circuit board foil.

|

I | ||

1. Insufficicnt heat - the

solder will not flow onto tho lead as shown.

Rosin

Soldering iron positoned mcorrectly

Insufficicnt solder - let the solder flow over the

connection until it is covered. Use just enough solder to cover tho

connection.

Excessive solder • could mąko connections that you did not mtend to between adjacent foil areas or termmals.

Solder bridges - occur when solder runs betwoen Circuit paths and creates a short Circuit. This is usually caused by using too much soldor. To correct this, simply drag your soldering iron across the solder bridge as shown.

-5-

4.

Wyszukiwarka

Podobne podstrony:

egz1 History of English - FINAŁ EXAM YEAR III The most important force in shaping

3. INSTITUTIONAL FRAMEWORK National and local authorities in developed countries play the most impor

276 2. Economic Comparison of drilling systems One of the most important stages in sublevel stoping

12 7 It May happen d u ring negotiation that from your point ofview, the most important factor is th

Materiał Testirig Lab Materiał Testing Lab is one of the most important labs in the field of civil e

KWASY ŻÓŁCIOWE W CHEMII SUPRAMOLEKULARNEJ 1095 ABSTRACT One of the most important fields in modem sy

2 A. DĄBROWSKA, W. WICZK, L. ŁANKIEWICZ ABSTRACT a-Amino acids are among the most important compound

image031 Throughout a century RadogoSć was the most important sanctuary in Polabia. According to Thi

Gramatyka kontrastywna. Chapter 2. 3. Case 24.03.2012 Case is the most import ant In Polish. marking

9 7 How to make a good first impression ? One of the most important factors of the argumentation. Ou

IMGR53 THE CENTRES OF PRODUCTION LOW COUNTRIES The most important ccntrct of gile Icathcr productśon

Introduction INTRODUCTION The Basilica of St. Peter is one of the most important eccle-siastical bui

htdctmw 118 As you can imagine, the cover is probably the single most important page in any comicboo

GSM Architecture Some of the most important BSS tasks are listed in the following: Radio path contro

więcej podobnych podstron