00307 q1a6d5c65627818bee9c68afd4f7ed9

310

Peterson & Parvey

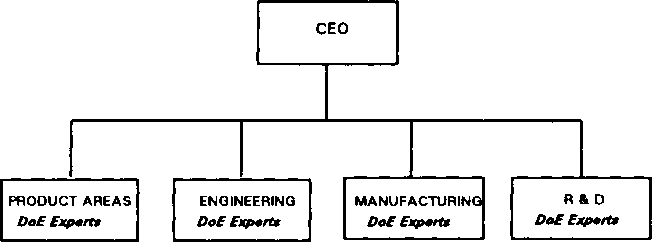

Figurę 3. Altemative C - Diyisional Taguchi Eiperts.

One corporate focal point for Taguchi methods resides within the R&D branch of the company and acts as a consultant for the entire organization. He is the author of a text on the subject of robust design and is nationally recognized as an expert on Taguchi methods. This person is not a full-time trainer, but is responsible for project support and development of new software applications using Taguchi methodologies. His work focuses entirely on DoE/Taguchi methods and he is not directly involved in other TQM training or activities. This company is ahead of most on the technical research and theoretic work with DoE/Taguchi techniques. They have a relatively long history of experience with the methods because they were one of the first companies to work directly with Dr. Taguchi in the early 1980 s.

Alternative D - Quality and Reliability Expertise

This large multi-divisional company has been extremely successful in applying DoE/Taguchi methods without specifically identifying intemal DoE experts. They have highly trained Quality and Reliability people (experts in Quality Function Deployment (QFD), Taguchi methods, and DoE) who are available to support projects and conduct any training that is needed, (see Figurę 4). Although they have been successful in pushing the use of the tools in manufacturing, they admit that this isn't the most effective way to integrate the concepts upstream in the development process.

The Quality and Reliability engineers are also considered to be the in-house statistical experts. Some employees have attended seminars at the American Supplier Institute, and extemal consultants have been contracted to

Wyszukiwarka

Podobne podstrony:

00303 S6f5ec79c7f009f5b2911cd990f7402 306 Peterson & Parvey of four large U.S. corporations wer

00497 ?58a15ec3b8d75f1fba24c3170d867c 504 Parvey Figurę 6. World Class Manufacturing at Honeywell I

00356 ?268bb4fa217b68c5b6c8bf725af104 360 Prairie & Zimmer Sample Ratę Figurę 7. Contours of Co

Document 2 (11) Figurę 2.13: Pronounced gynecomastia in a man with ReifensteirTs syndrome. For cosme

Figurę 2.73: Pronounced gynecomastid in a man with Reifensteir» s syndrome. For cosmetic reasons,

FIGURĘ A Berry Bead Ornaments Berry Bead Ornaments Basic Supplies (for Five Ornaments): Nylon

Figurę 2 Composite Assembly of Round Rods 4) The assembly shown in Figurę 2 consists of 2 round rods

10 36 Figurę 10-36 Compression of quadratus plantae trigger point

Figurę 2-2 RESTful Web services request to server 2.1.2 Resource Modelling for REST The advantages o

CISLAM, UNE RELIGION DASCENDANCE ABRAHAMIQUE? 285 4. La figurę desertiąue de la religion musulmane S

Droga od DNA do białka Figurę 3. From DNA to proteins. one of life s core processes. mRNA leaves sma

00142 4a32d94087a89c1d3df436ea34de80 143Optimization and Sensitiyity Analysis $311.96 $310.88 $310

00308 ?2bf35d8cf600ddab580cd8e4907d9a Altemative Approaches to Implement a DoE Program 311 Figurę 4

00493 /cd01bc74789856c919fee15819db05 500 Parvey pursuit of manufacturing excellence. He proposes a

skanuj0009 (310) , ? W socjalizacji wtórnej coraz mniej ważne cua Kolejności uczenia się są ogranicz

skanuj0011 (310) &nQOy /TTYLFns cdT-no^&tUi -^-cienóUiY *00^ iptfty VEA^‘~ 7r,Jy Ucm./"

skanuj0012 (310) Są 4c c&Mcu&y Idi a u&foMŁ — ^^łft/wcxe^ -OBU X ztmijeSA. f£% L knnUce

więcej podobnych podstron