66638 Suzuki RM250P

CYLINDER. CYLINDER HEAD AND PISTON 4-5

CYLINDER. CYLINDER HEAD AND PISTON 4-5

DATA

Basa

INSPECTION

CYLINDER HEAD

♦ Remove carbon deposits from the cylinder head.

♦ Inspect the cylinder head for cracks around the spark pług hole.

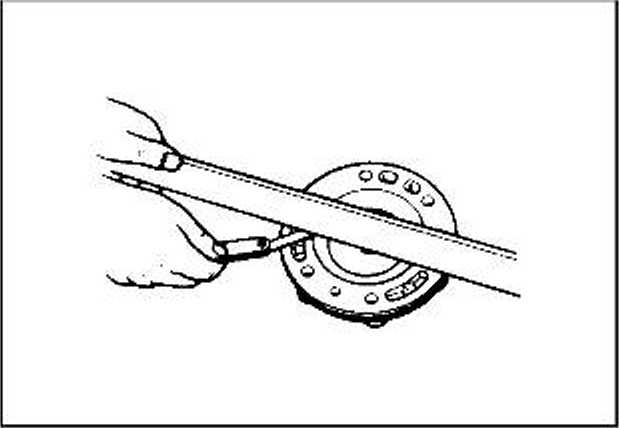

♦ Inspect for cylinder head distortion with the thickness gauge.

Cylinder head distortion Service limit: 0.05 mm (0.002 in)

09900-20803: Thickness gauge

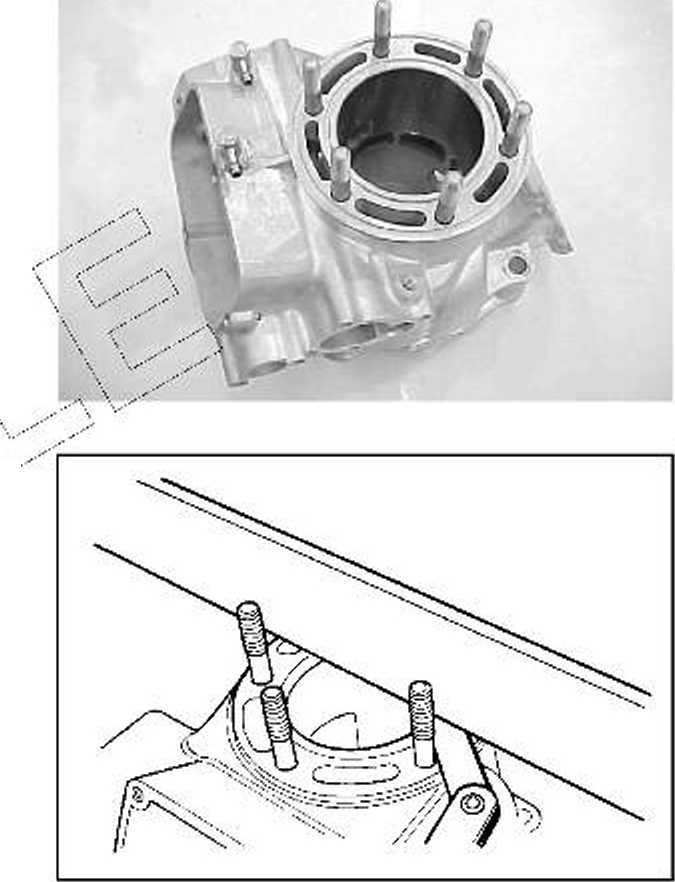

CYLINDER

♦ Remove the exhaust valve assembly. (C7M1 -3)

♦ Remove carbon deposits from the exhaust port.

♦ Inspect the cylinder for cracks and replace the cylinder if nec-essary.

♦ Inspect the cylinder borę for wear and scratches.

NOTĘ:

Chrome-plated cylinder borę can not be modified such as boting and honing. . \ \ \

w

Inspect for cylinder distortion with the thickness gauge.

\ \ \ \ \ \

Cylinder distortion: Service limit: 0.05 mm (0 002 in) 09900-20803: Thickness gauge ^

W

//—■

V-

V-

0353

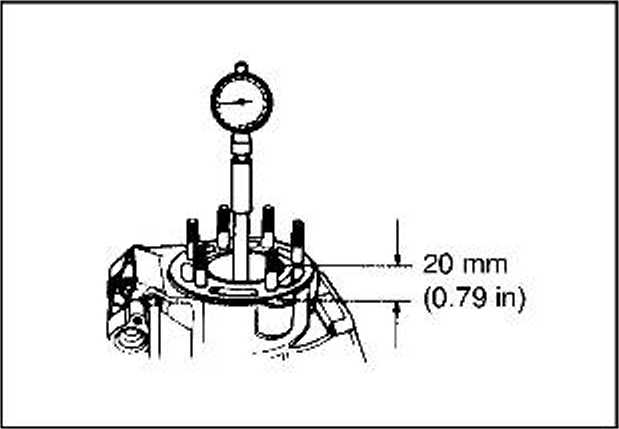

* Measure the cylinder borę for wear with the cylinder gauge at 20 mm (0.79 in) from the top surface.

NOTĘ:

The cylinder borę must be measured perpendicular to the crank-shaft axis direction.

H Cylinder borę

Standard: 66.400 - 66.415 mm (2.6142 - 2.6148 in)

09900-20508: Cylinder gauge set (40 - 80 mm)

PISTON TO CYLINDER CLEARANCE

H Piston to cylinder clearance:

Standard: 0.045 - 0.055 mm (0.0018 - 0.0022 in) Service limit: 0.120 mm (0.0047 in)

Wyszukiwarka

Podobne podstrony:

78685 Suzuki RM250T CYLINDER. CYLINDER HEAD AND PISTON 4-9 ♦ Install new O-rings @

78157 Suzuki RM250F CYLINDER, CYLINDER HEAD AND PISTON 4-1CYLINDER, CYLINDER HEAD AND PISTON CONTENT

82673 Suzuki RM125v CYLINDER. PISTON AND EXHAU$T VALVE 6-3ENGINE TOP SIDECYLINDER HEAD REMOVAL ♦ &nb

48636 Suzuki RM250H CYLINDER. CYLINDER HEAD AND PISTON 4-3REMOVALCYLINDER HEAD • D

Suzuki RM125y 6-6 CYLINDER, PISTON AND EXHAU$T VALVECYLINDER HEAD INSPECTION • Rem

Suzuki RM250Q 4-6 CYLINDER. CYLINDER HEAD AND PISTON 4-6 CYLINDER. CYLINDER HEAD AND

Suzuki RM250R CYLINDER, CYLINDER HEAD AND PISTON 4-7 CYLINDER, CYLINDER HEAD AND PISTON 4-7 KQ3 • Me

36954 Suzuki RM250S 4-8 CYLINDER. CYLINDER HEAD AND PISTON • Face the embossed mar

84546 Suzuki RM250G 4-2 CYLINDER, CYLINDER HEAD AND PISTONCONSTRUCTION H 25 N-m (2.5 kgf-m, 18.0 Ib-

więcej podobnych podstron